Lignin-containing polyurethane sealant and preparation method thereof

A polyurethane sealant and lignin technology, which is applied in polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve the problems that polyurethane sealants are susceptible to ultraviolet light aging, and achieve improved thermal oxygen stability, Improves aging resistance and enhances the effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

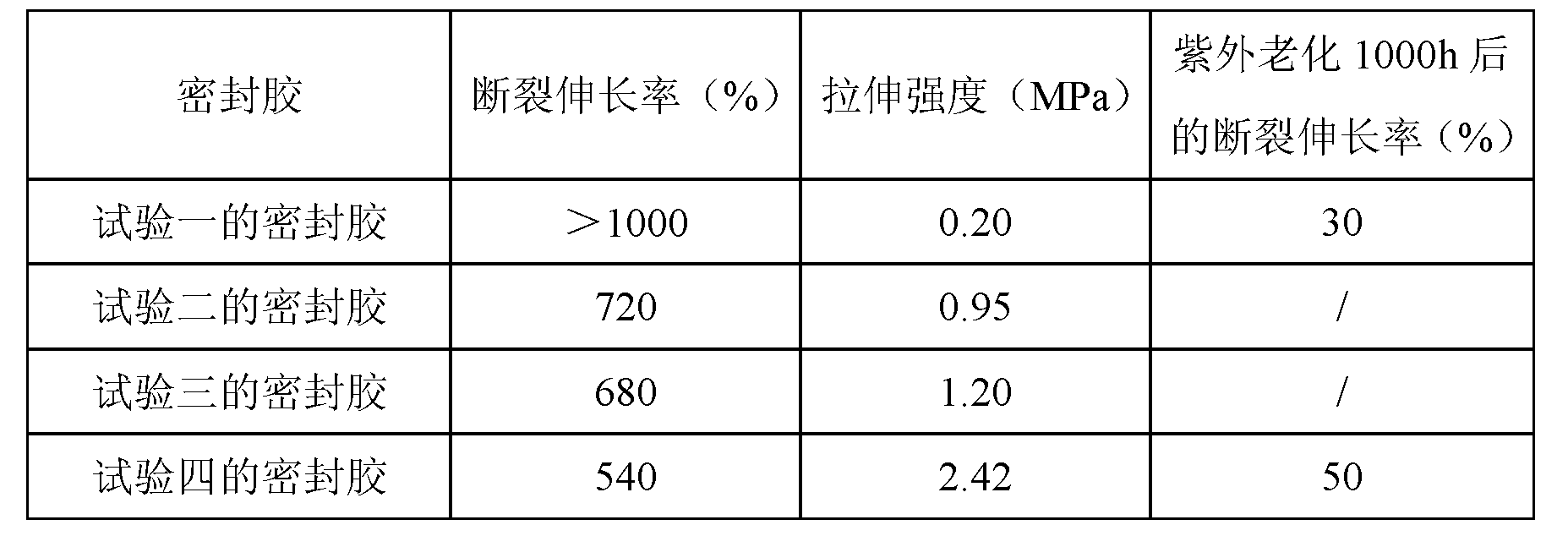

Examples

specific Embodiment approach 1

[0020] Specific Embodiment 1: In this embodiment, the lignin-containing polyurethane sealant consists of 90-100 parts by mass of lignin-containing prepolymer, 0.2-0.5 parts of catalyst, 1-5 parts of latent curing agent, 30-60 parts Made of plasticizer and 30-50 parts of filler;

[0021] The lignin-containing prepolymer is made of 90-100 parts of polyether glycol, 5-80 parts of lignin and 20-70 parts of isocyanate in parts by weight;

[0022] The polyether diol is polyoxypropylene diol with a molecular weight of 1000-2000;

[0023] The lignin is corn stalk lignin;

[0024] The isocyanate is one or more of 2,4-toluene diisocyanate, diphenylmethane diisocyanate, hydrogenated diphenylmethane diisocyanate, xylylene diisocyanate and isophorone diisocyanate combination.

specific Embodiment approach 2

[0025] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the catalyst is one or several of bismuth neododecanoate, zinc neododecanoate, dibutyltin dilaurate and stannous octoate combination. Others are the same as in the first embodiment.

[0026] When the catalyst described in this embodiment is a composition, the ratios between the respective components are arbitrary.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the latent curing agent is oxazolidine. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com