Patents

Literature

275results about How to "Improve thermo-oxidative stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

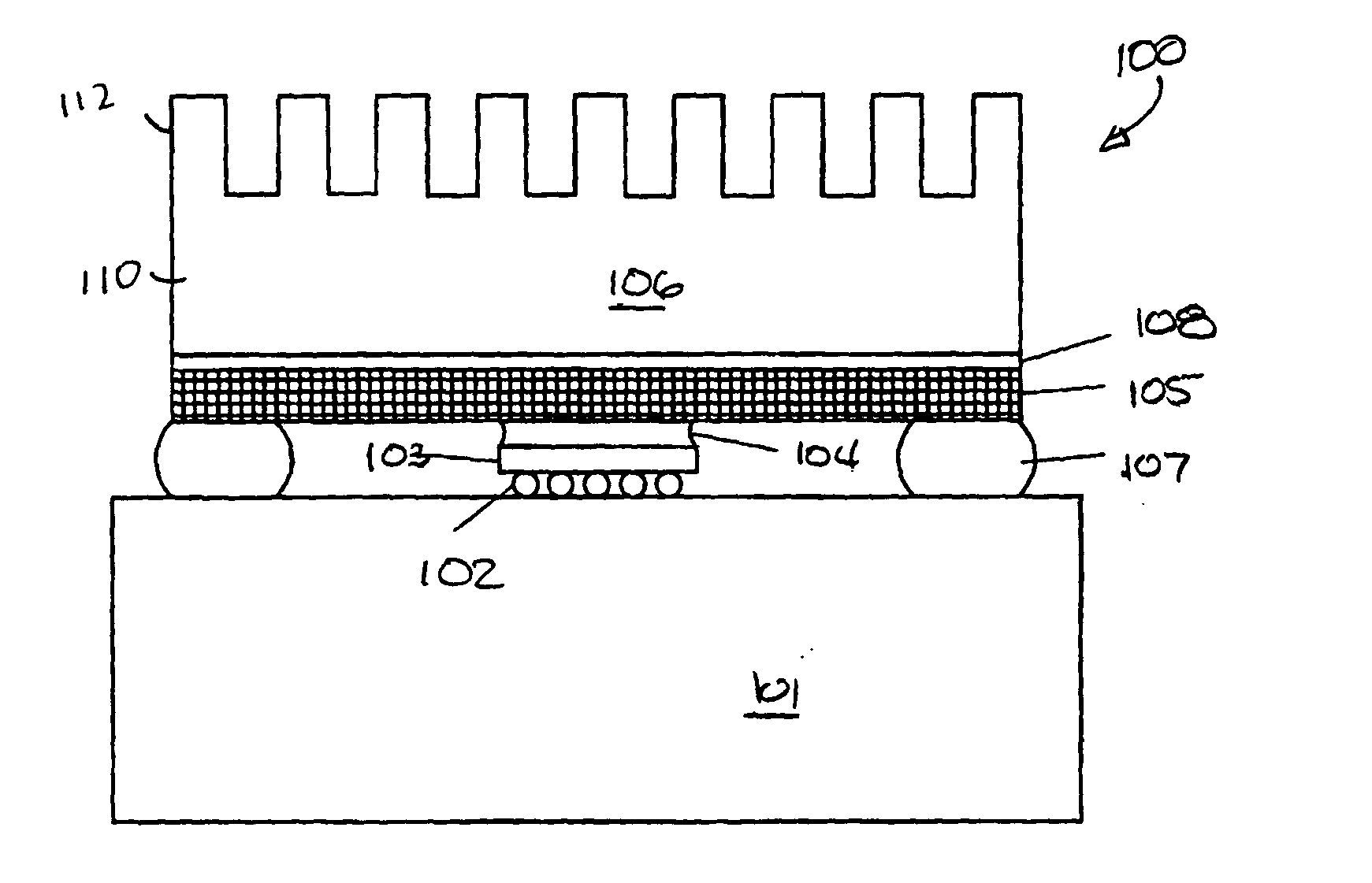

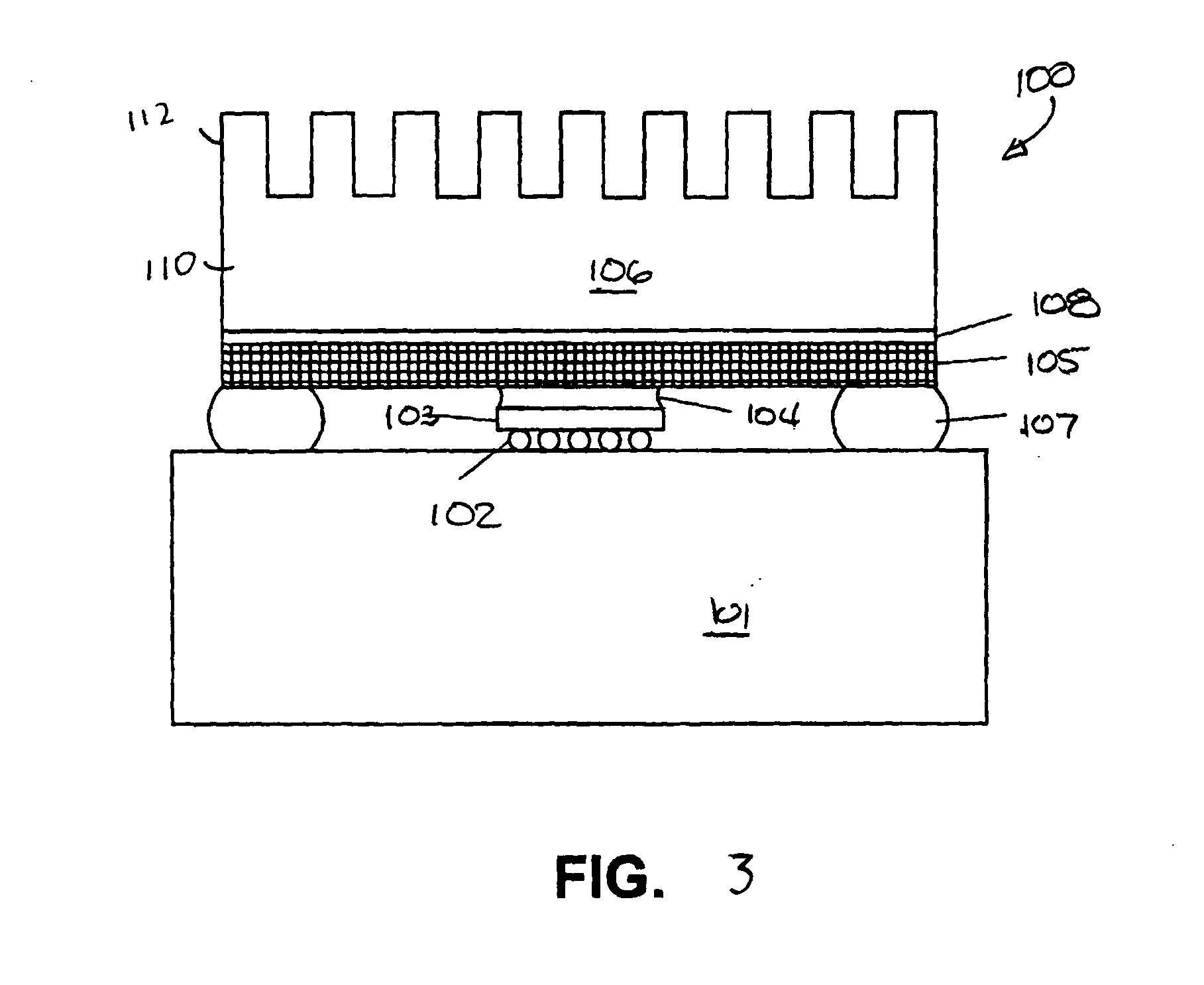

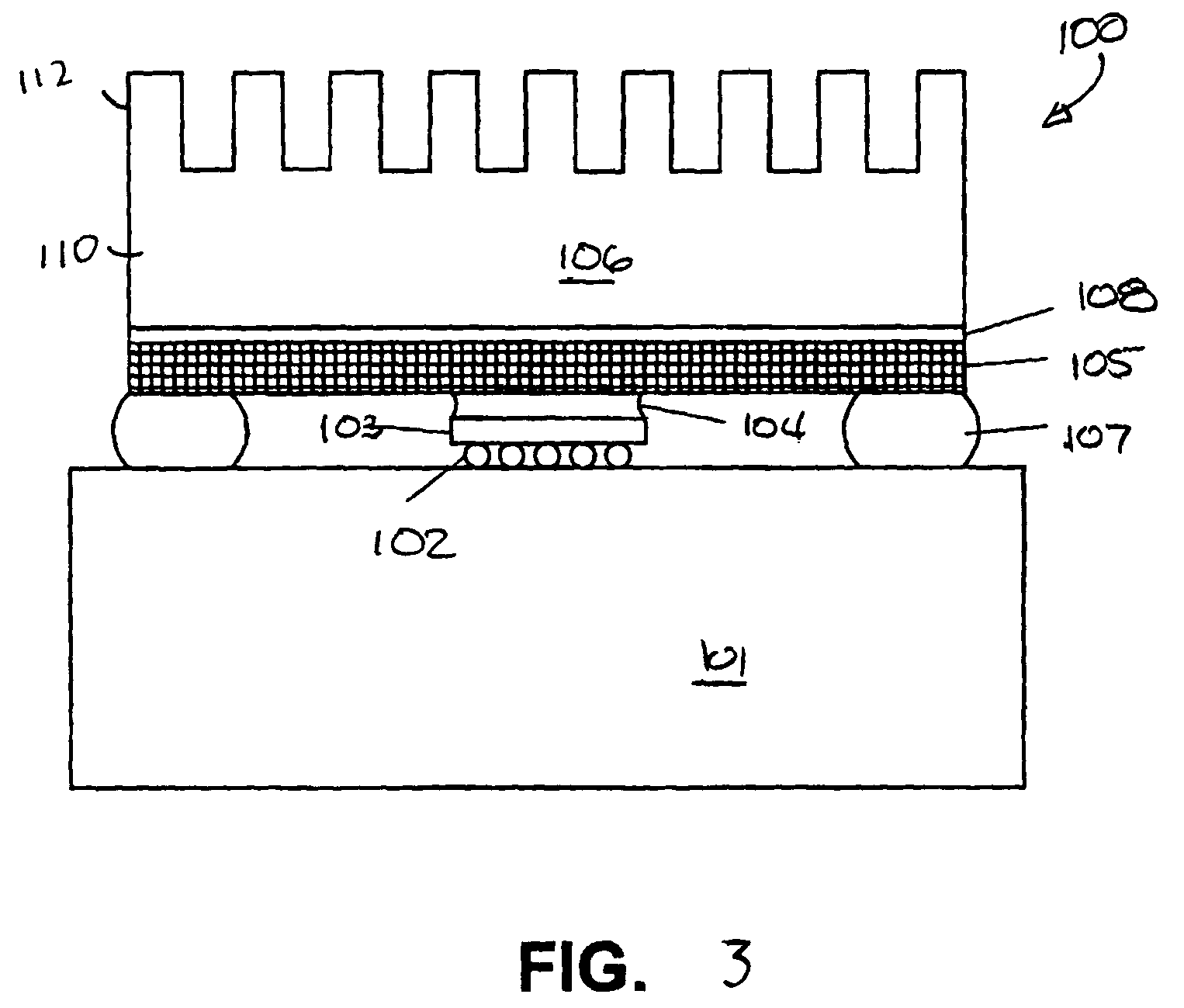

Phase change thermal interface materials including polyester resin

InactiveUS20050041406A1Improve thermo-oxidative stabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPolyolefinPolyester resin

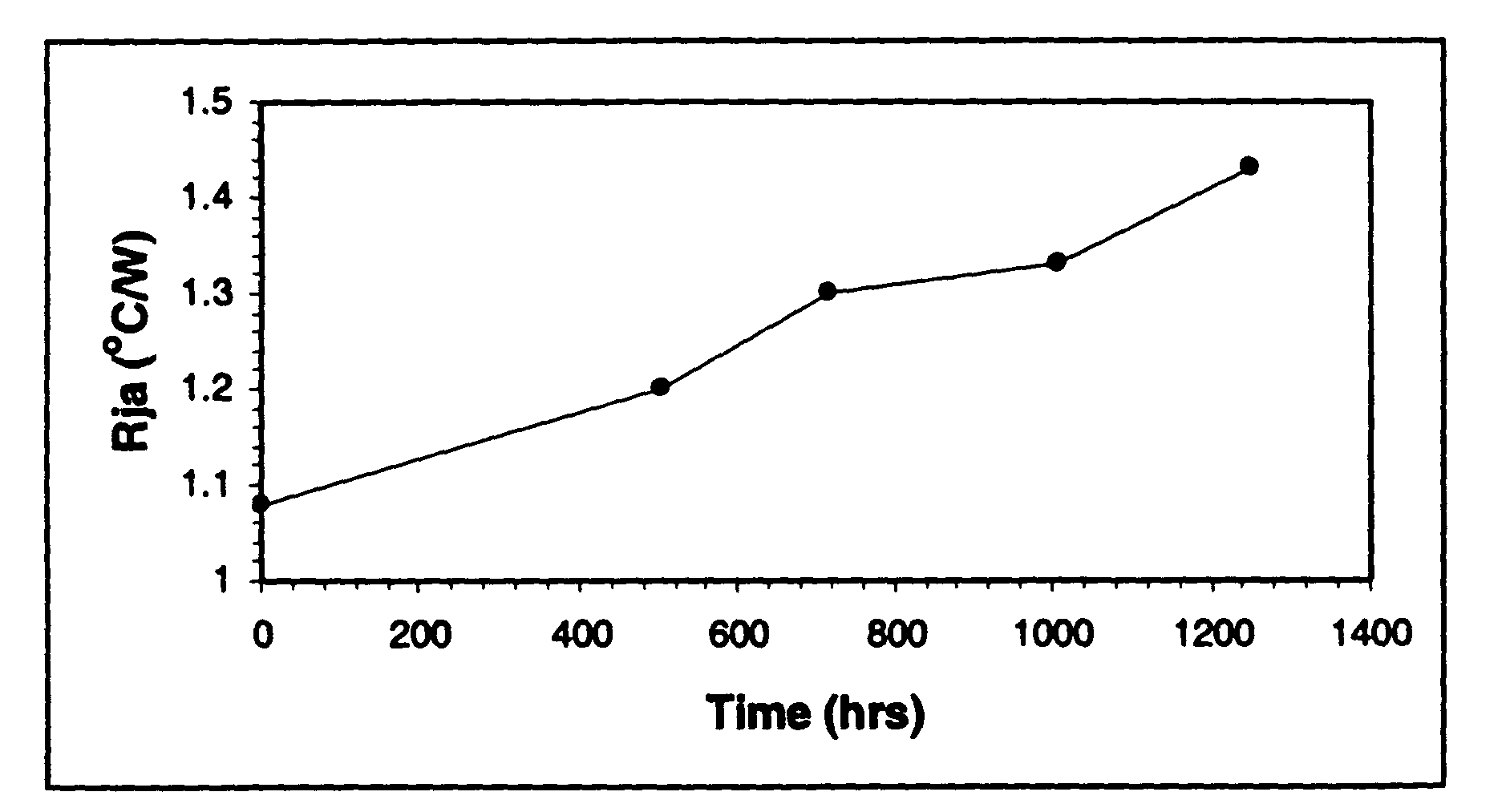

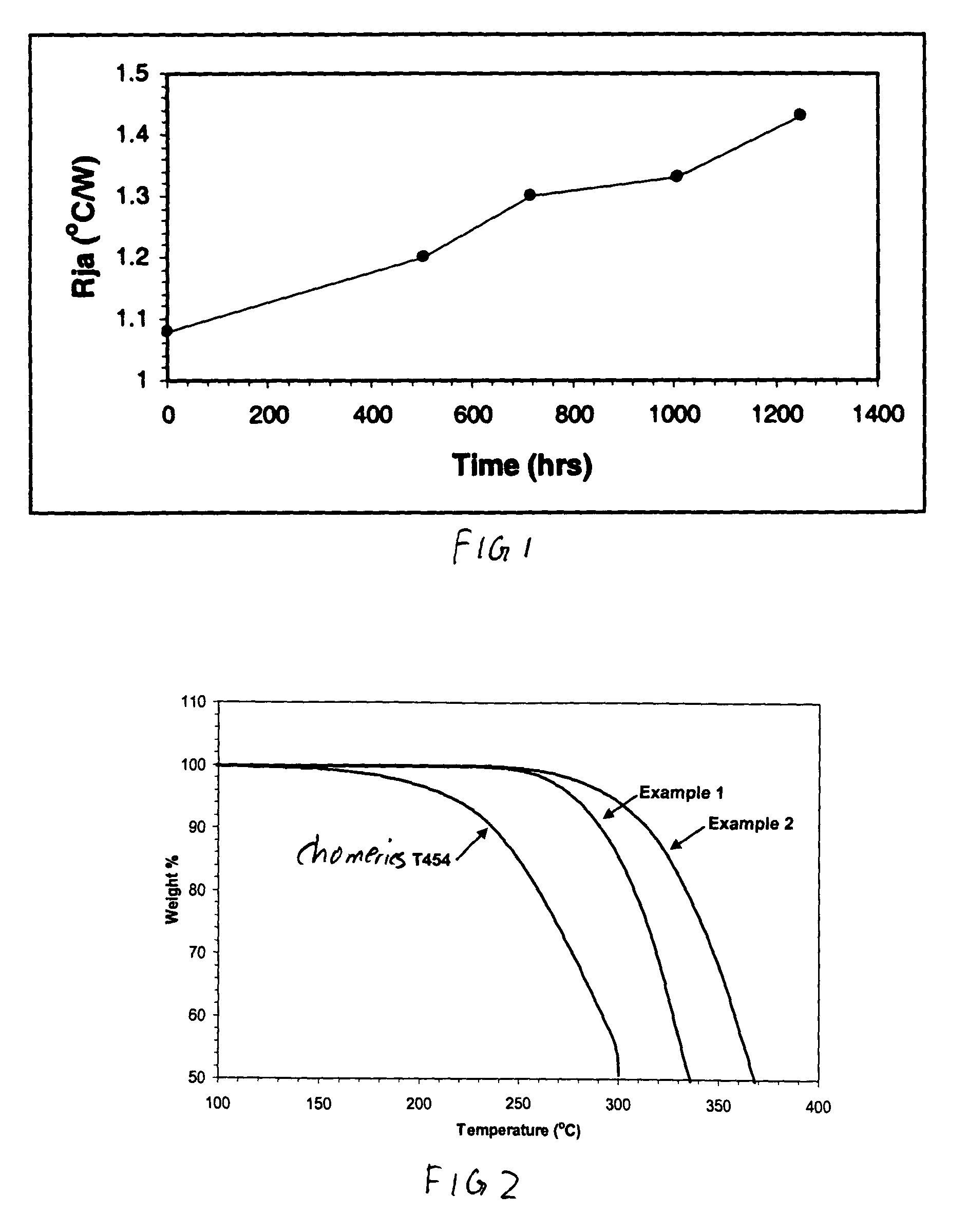

An embodiment of a phase change TIM of this invention comprises a polyester matrix with melting temperature near or below operating temperature (typically less than about 130° C.), thermally conductive filler with bulk thermal conductivity greater than about 50 W / mK, and optionally other additives. The polyester resin has improved thermo-oxidative stability compared to the polyolefin resins, thereby providing improved reliability performance during test.

Owner:INTEL CORP

High-temperature resistant flame-retardant epoxy glue and preparation method thereof

ActiveCN104726045AReduce usageHigh heat distortion temperatureNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyFire retardant

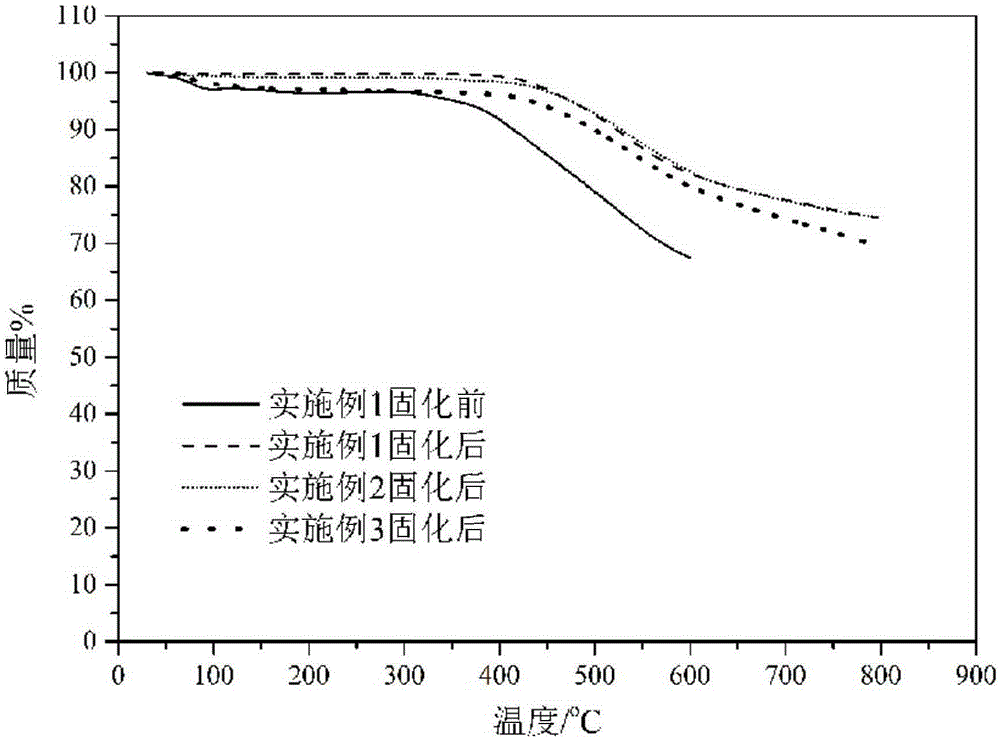

The invention relates to high-temperature resistant flame-retardant epoxy glue and a preparation method of the high-temperature resistant flame-retardant epoxy glue. The epoxy glue is a double-component epoxy glue; when the epoxy glue is used, a first component and a second component are mixed in a weight ratio of 4:(2-3); the first component is prepared from the following raw materials in parts by weight: 30-50 parts of polyfunctional epoxy resin, 5-15 parts of low-viscosity epoxy resin, 3-10 parts of an active toughening agent, 10-30 parts of temperature-resistant reinforcing fillers, 10-15 parts of flame retardant and 0.3-3 parts of antioxidant; the second component is prepared from the following raw materials in parts by weight: 70-95 parts of a temperature-resistant curing agent, 10-30 parts of temperature-resistant reinforcing fillers and 0.3-1 part of a coupling agent. Compared with the prior art, the high-temperature resistant flame-retardant epoxy glue has the advantages of high high-temperature toughness, high adhesion strength, high flame retardant performance and the like.

Owner:上海海鹰粘接科技有限公司

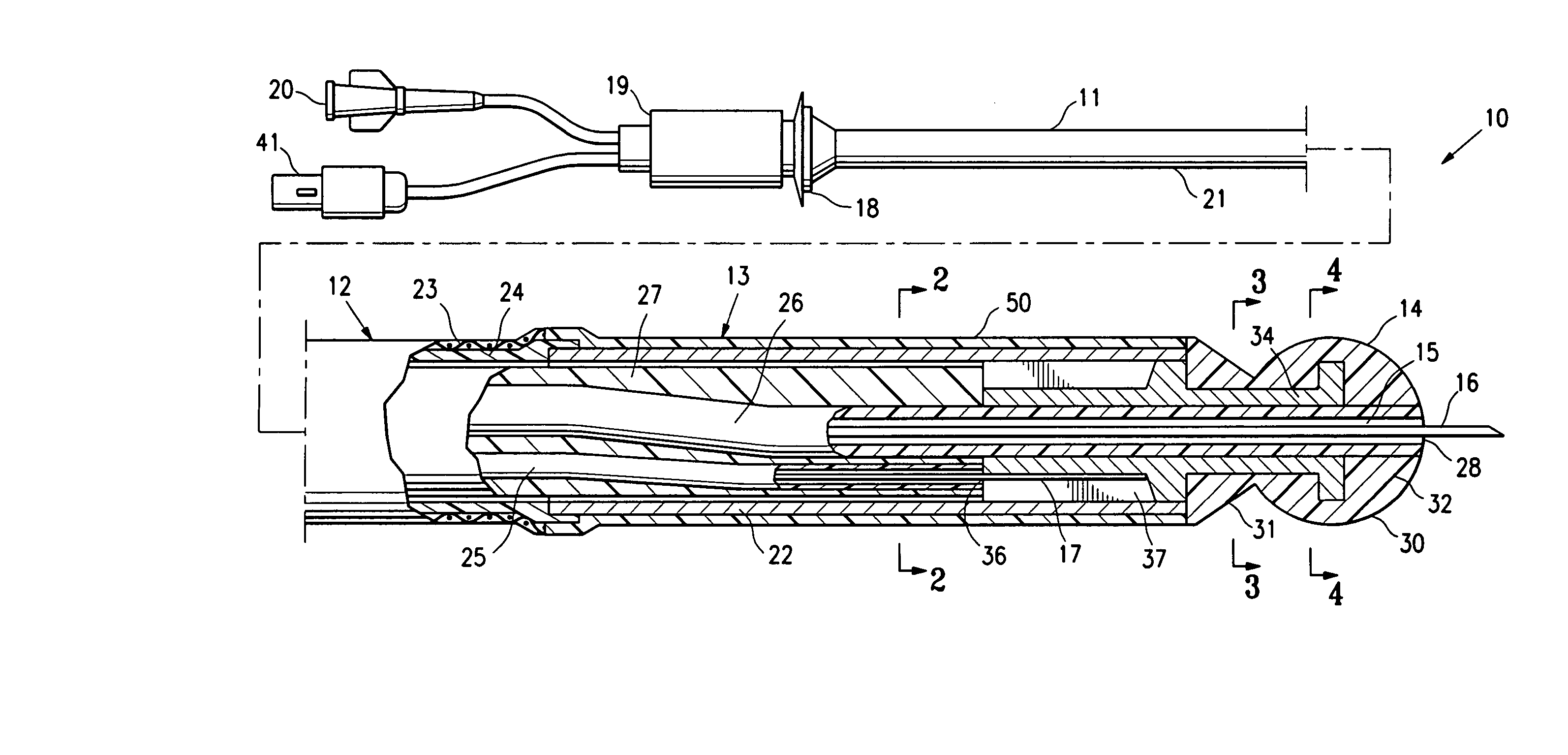

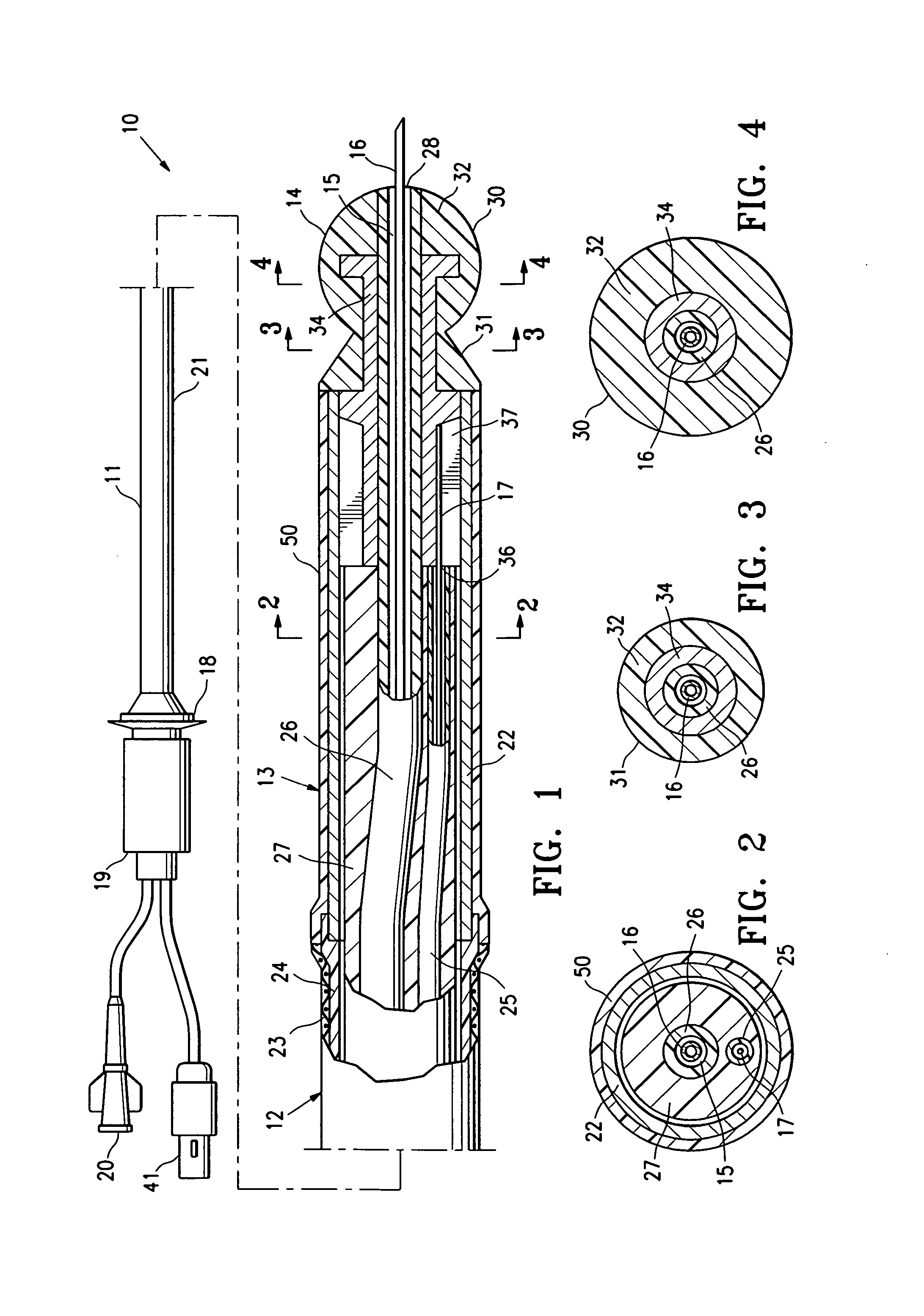

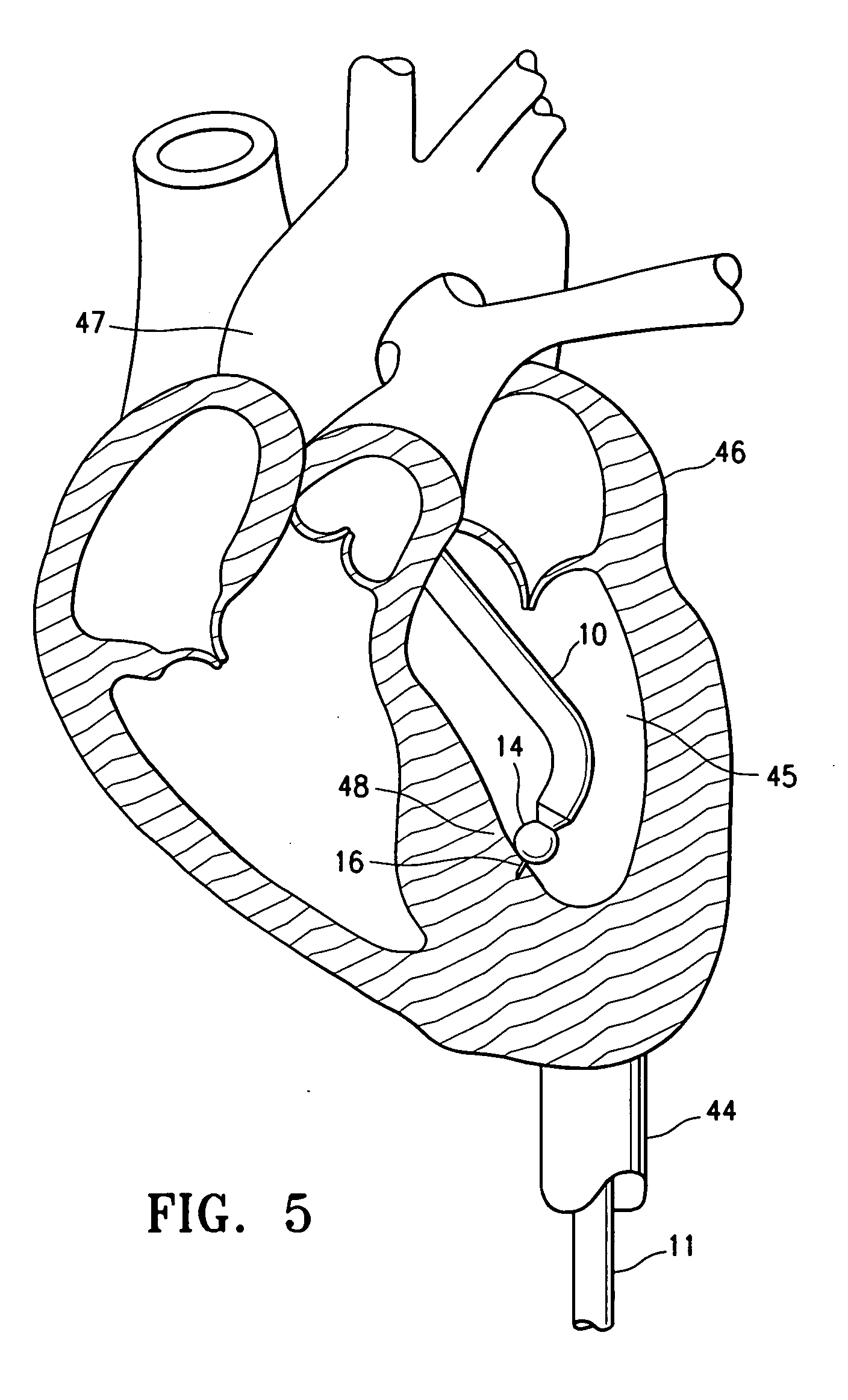

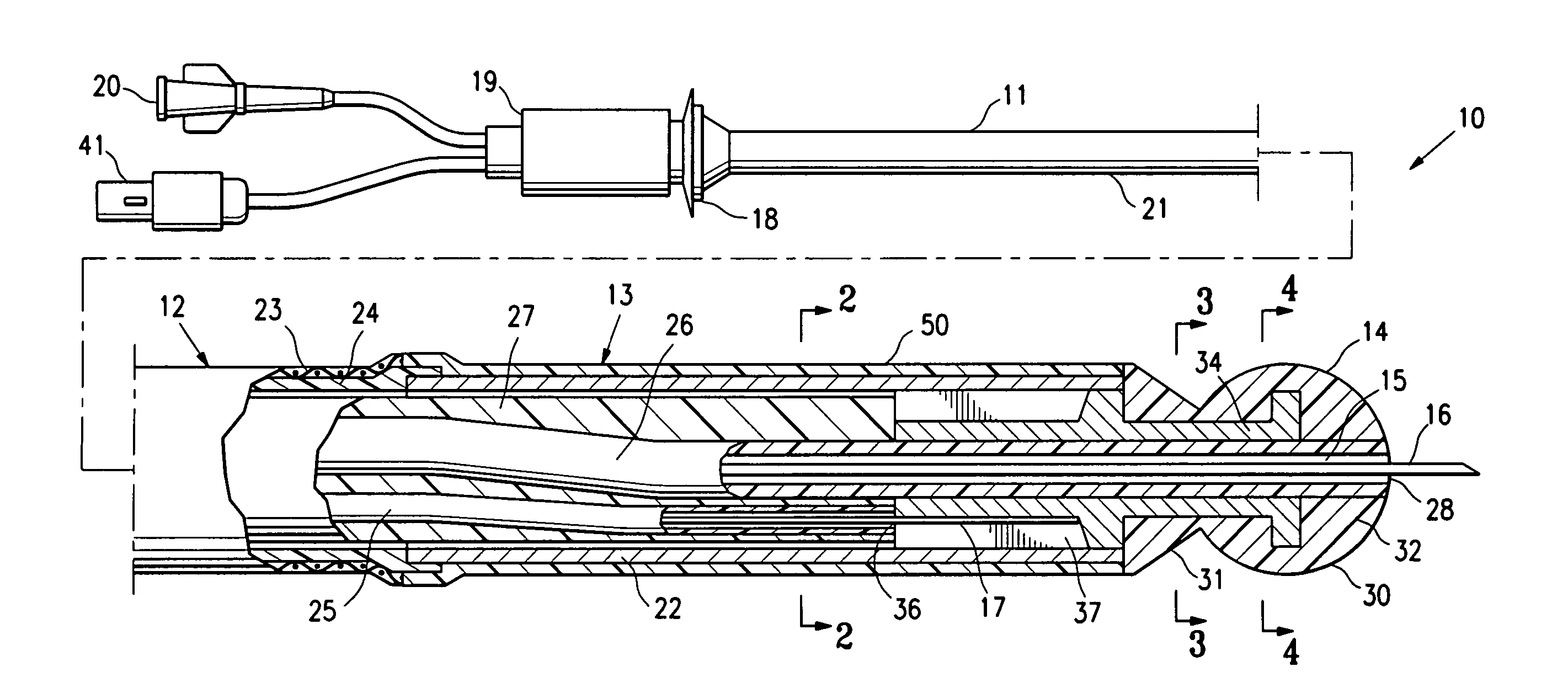

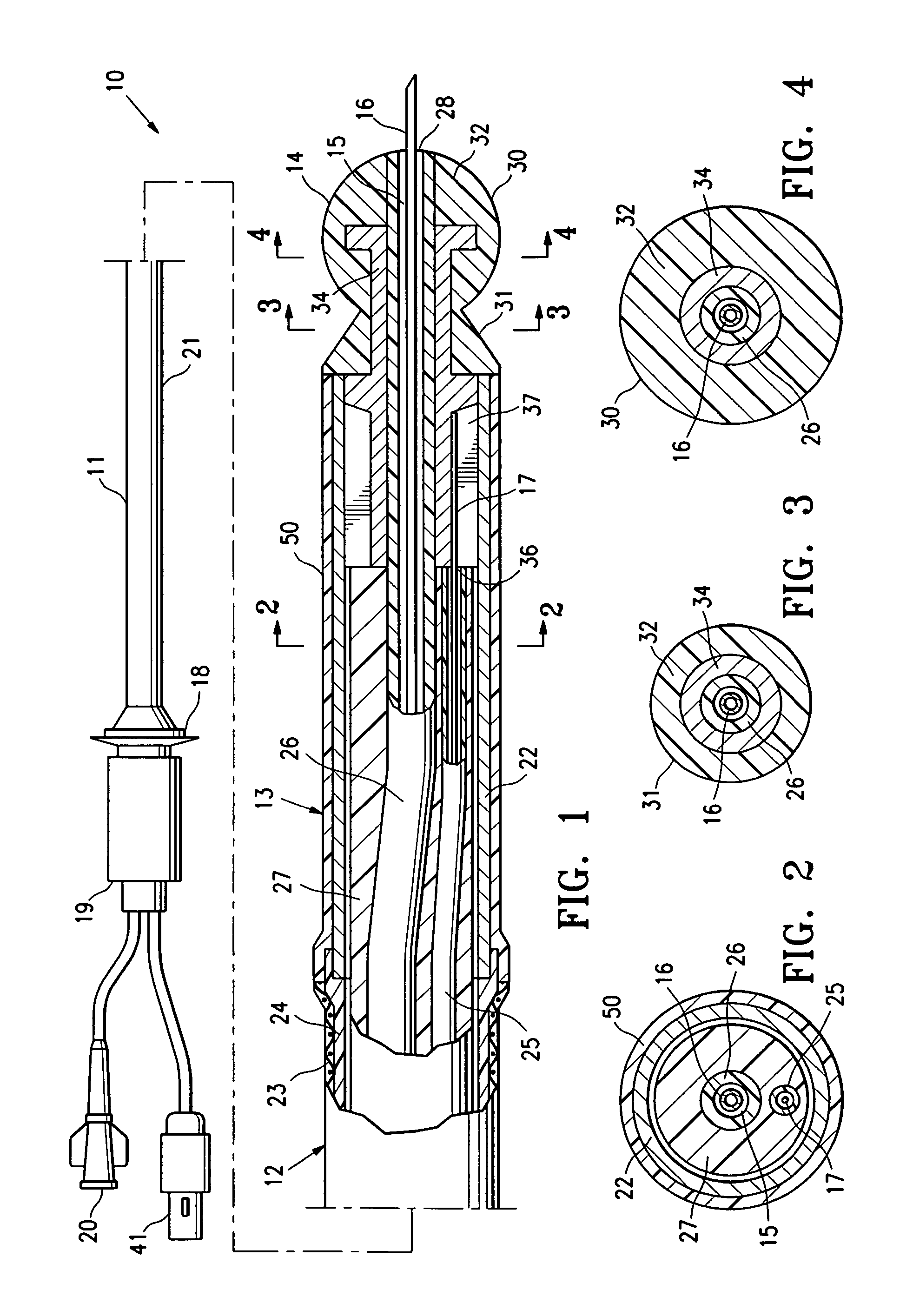

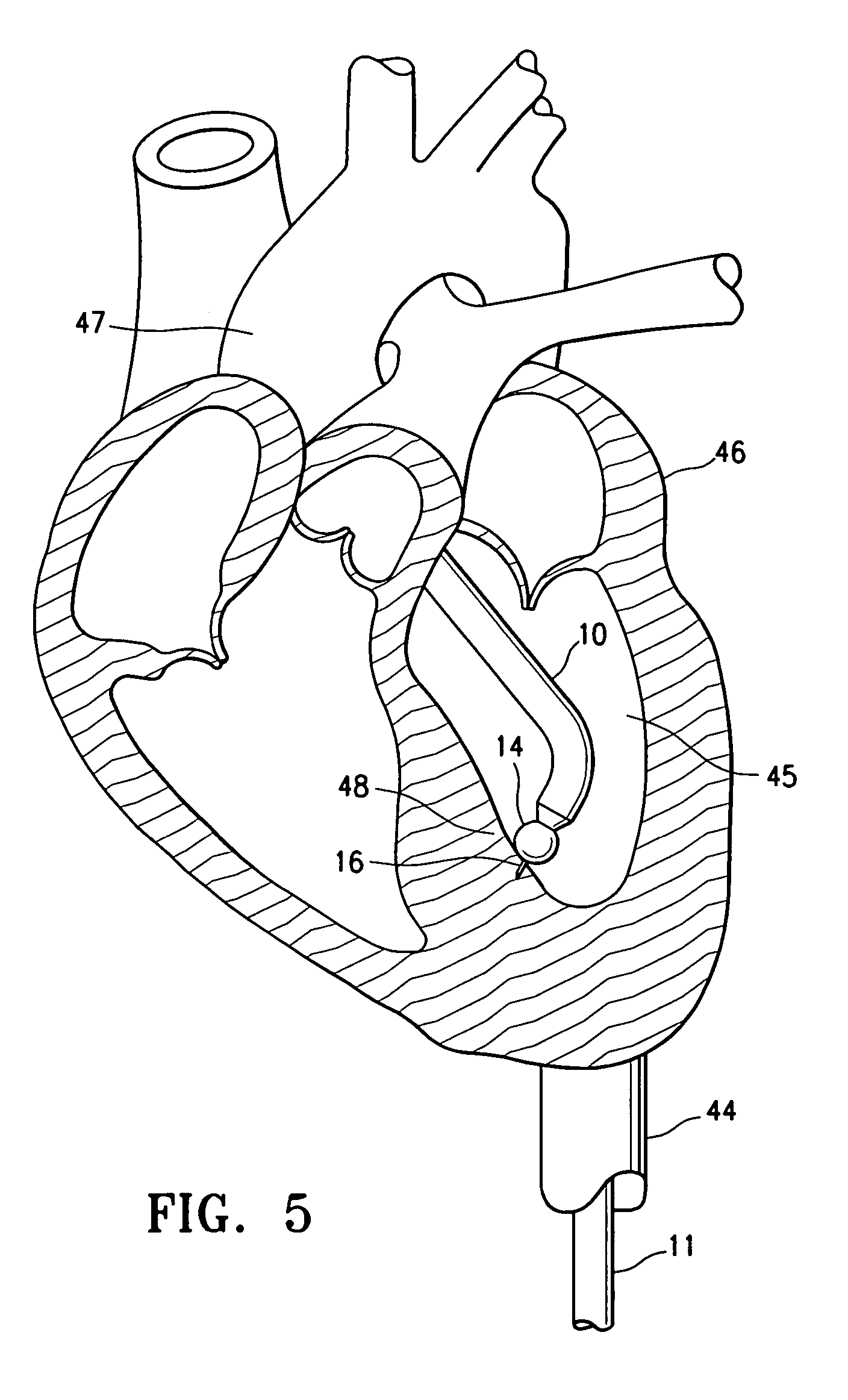

Echogenic needle catheter configured to produce an improved ultrasound image

InactiveUS20070265516A1Minimize amount of metalReduces and eliminates artifactElectrocardiographyBlood flow measurement devicesUltrasound imagingNeedle catheter

An echogenic catheter, such as a needle catheter, formed at least in part of an intrinsically conductive organic polymer for providing a highly conductive surface in combination with an improved ability to ultrasonically image the catheter, and a method of performing a medical procedure using a catheter of the invention.

Owner:ABBOTT CARDIOVASCULAR

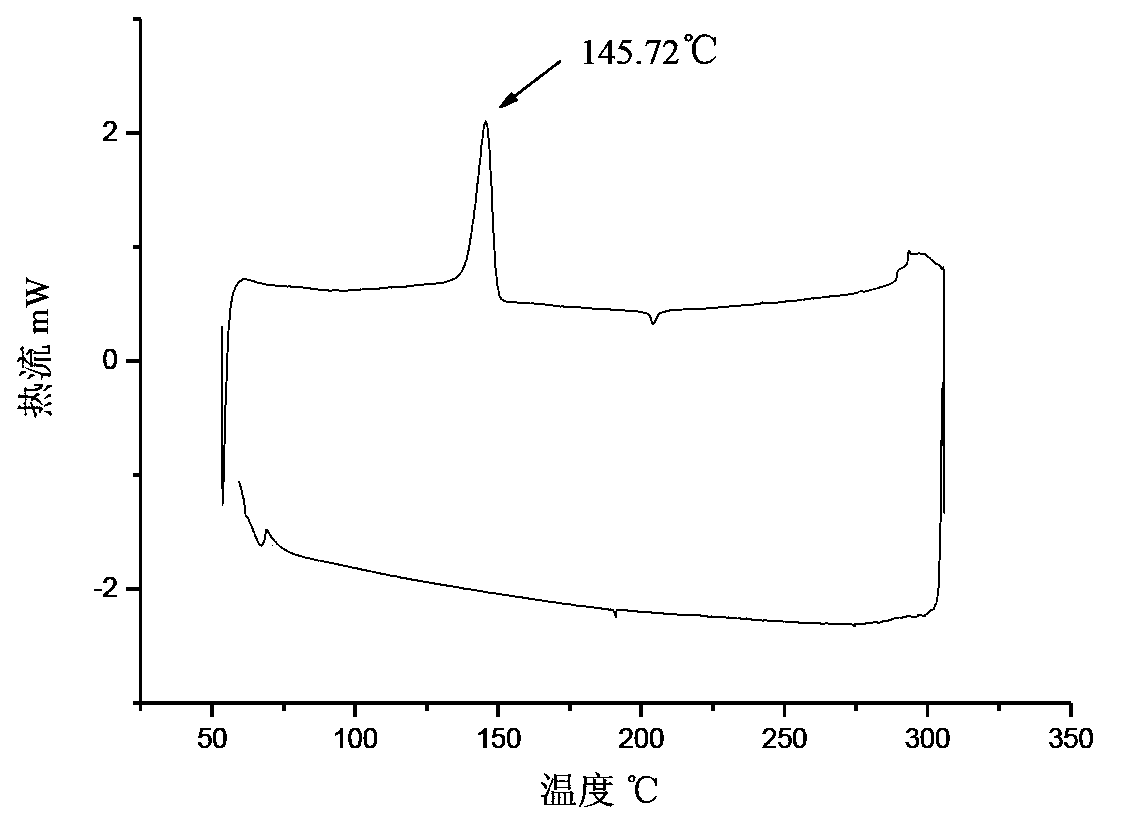

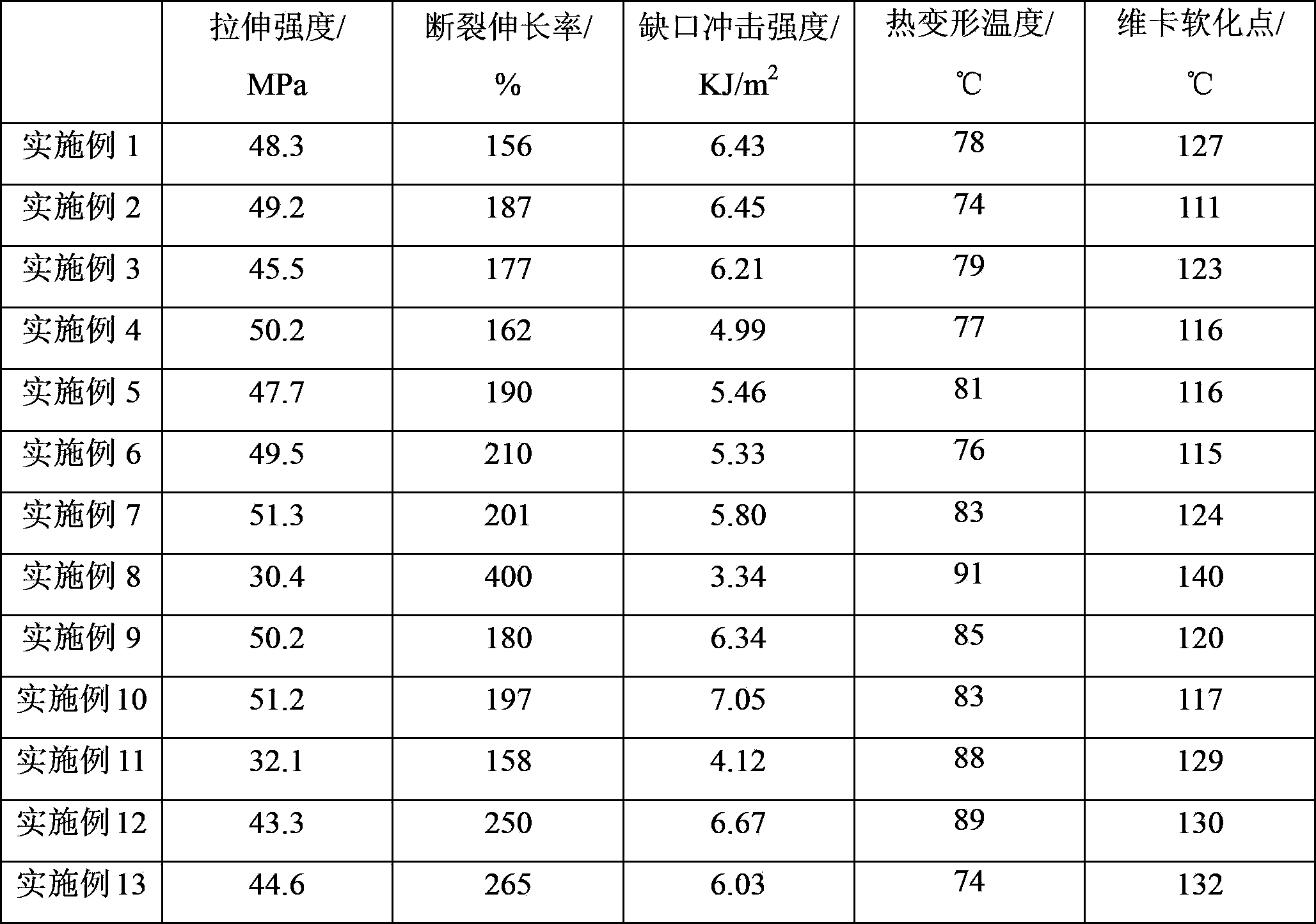

Novel heat-resistant high-toughness polylactic acid composite material and preparation method thereof

InactiveCN103819884AGuaranteed biodegradabilityExcellent mechanical properties and heat resistanceBiodegradable polyesterToughness

The invention belongs to the technical field of composite materials, and relates to a polylactic acid composite material and a preparation method thereof. The polylactic acid composite material is prepared from the following components in percentage by weight: 5 to 90 percent of polylactic acid, 5 to 80 percent of biodegradable polyester and 5 to 80 percent of heat-resistant master batch. The heat-resistant high-toughness polylactic acid composite material is obtained by continuous in-situ reaction extrusion. The composite material simultaneously has the characteristics of high toughness, high temperature resistance, low production cost, full biodegadability and the like.

Owner:SHANGHAI ZAIHE IND INVESTMENT CO LTD

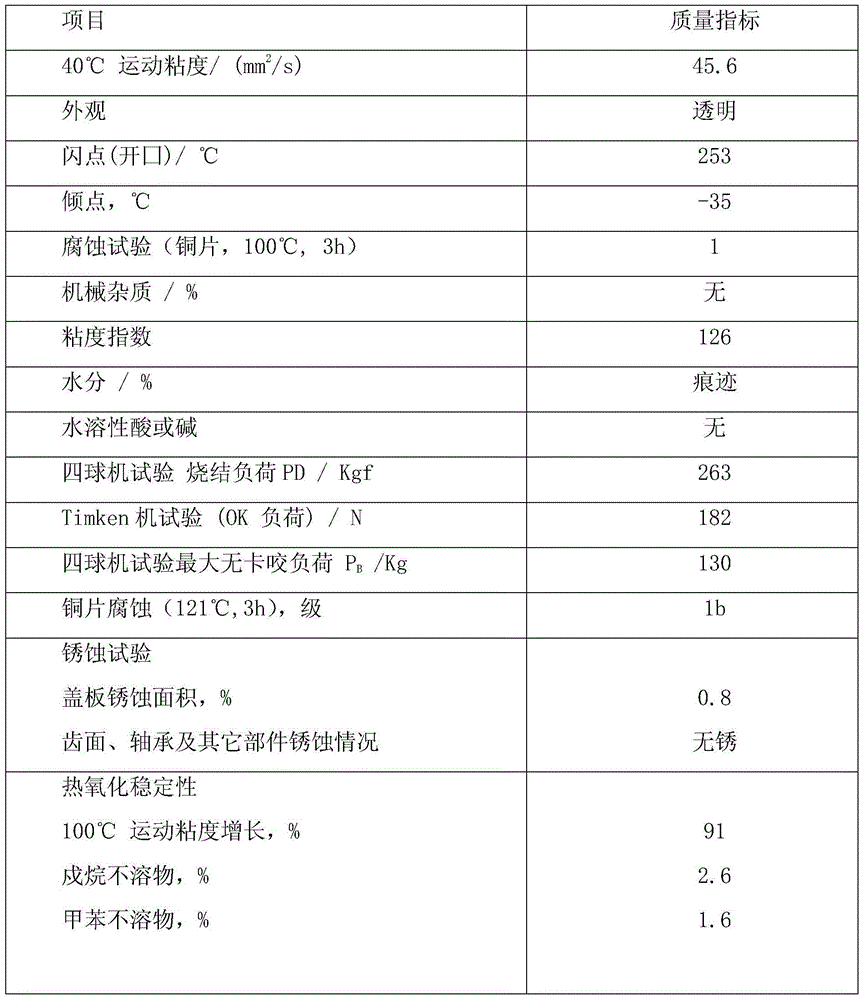

Sedan hand gearshift case gear lubricating oil composition

ActiveCN101298578AMeet lubricationMeet lubrication requirementsAdditivesBase-materialsGear wheelBench test

The invention provides a gear lubricant composite for manual transmissions of the light cars, comprising (A) at least one type of refining mineral oil with high viscosity index, or polyolefin synthesis oil, or ester lubricants, or a free composite of the above components, (B) at least one type of viscosity index improver, (C) at least one type of pour point depressant, (D) at least one type of extreme pressure additive with sulfurs, (E) at least one type of anti-wear additive with phosphorus, (F) at least one type of wear, oxygen, and corrosion-preventing multifunctional additive with phosphorus, (G) at least one type of anti-rusting additive, and (H) at least one type of friction modifier. The lubricant composite has excellent performance of high and low temperature, which can meet the requirements of gear oil with a viscosity grade of 75W / 90. Moreover, passing the full-size gear bench tests as CRCL-42, L-37, L-33, L-60, and L-60-1 as well as cycle bench tests for the manual transmissions of the light cars, the gear lubricant composite can meet lubrication requirements of the manual transmissions of the light top-grade cars.

Owner:PETROCHINA CO LTD

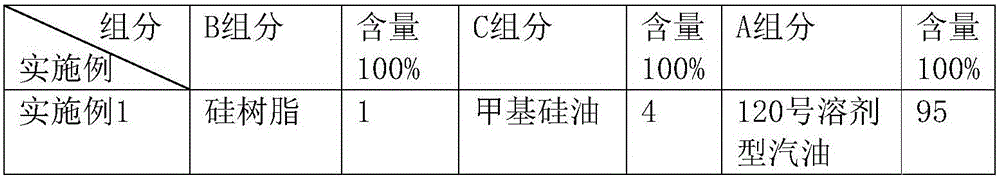

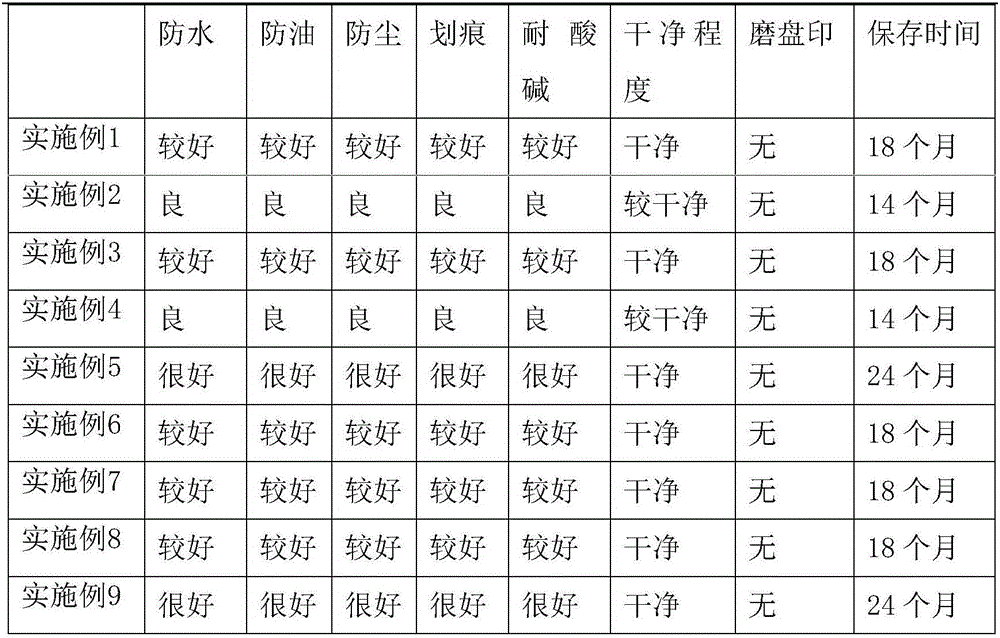

Matte brick stain-proofing agent and preparation method thereof

ActiveCN105860831AAntifoulingExtended service lifeAntifouling/underwater paintsPaints with biocidesOrganic solventBrick

The invention discloses a matte brick stain-proofing agent. The matte brick stain-proofing agent is prepared from a component A, a component B and a component C, wherein the component A is an organic solvent, the component B is silicon resin, and the component C is at least one of silicone oil and organosiloxane monomers. The invention further provides a preparation method of the matte brick stain-proofing agent. By compounding the components, the matte brick stain-proofing agent can achieve a good stain-proofing effect when used for performing stain-proofing treatment on the surfaces of matte bricks in follow-up application; besides, the matte brick stain-proofing agent has a very long shelf life and service life; moreover, the preparation technology is simple and easy to implement and can be conveniently applied to industrial production.

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

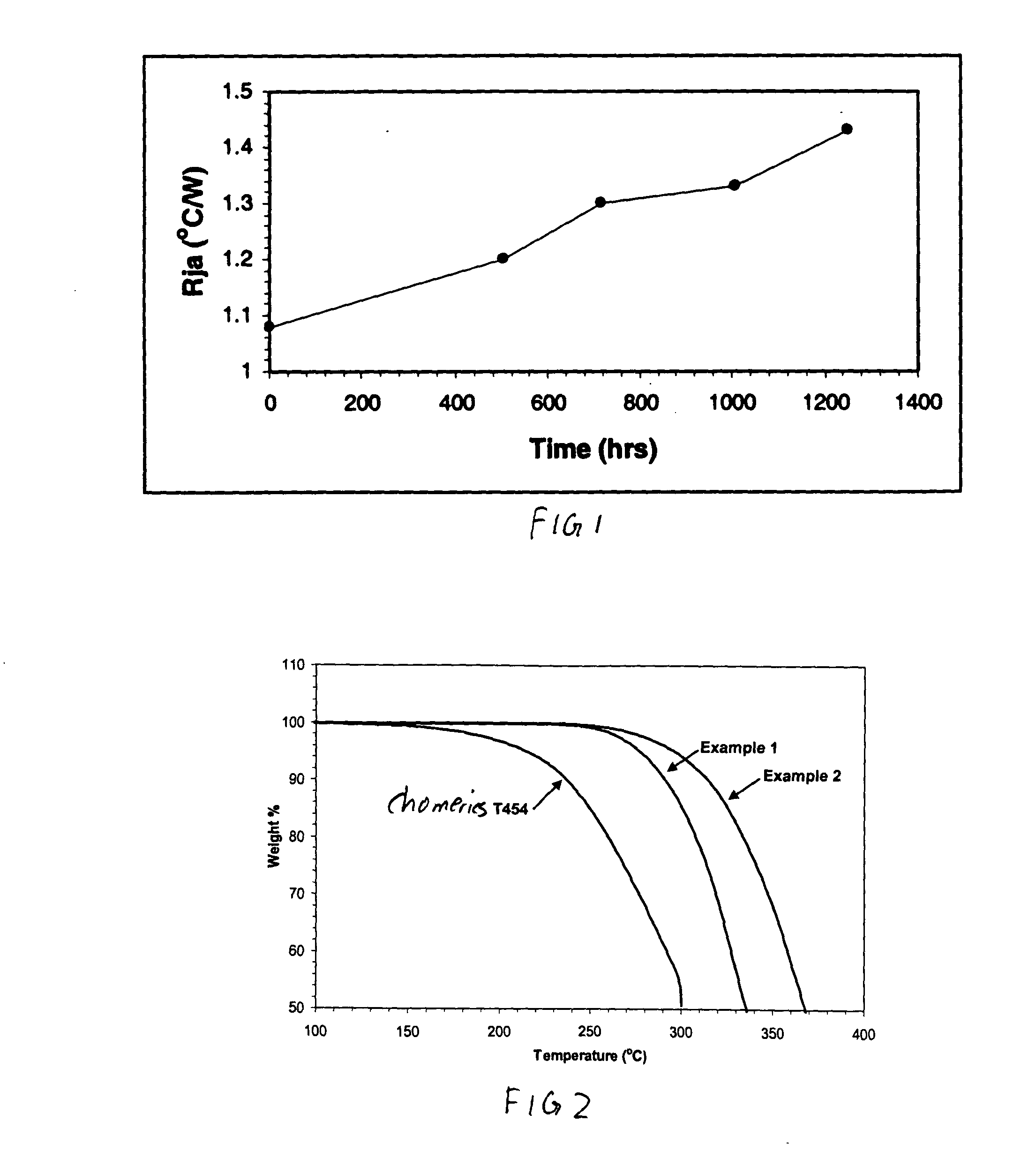

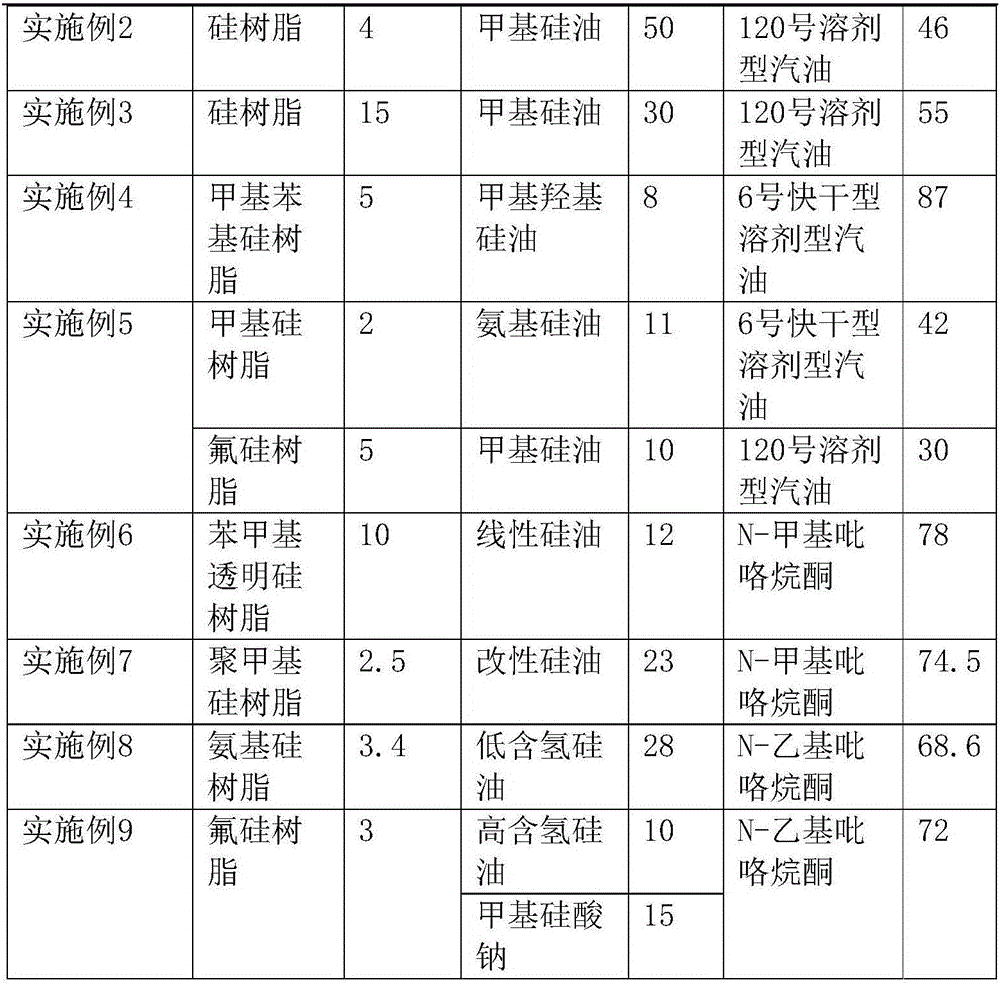

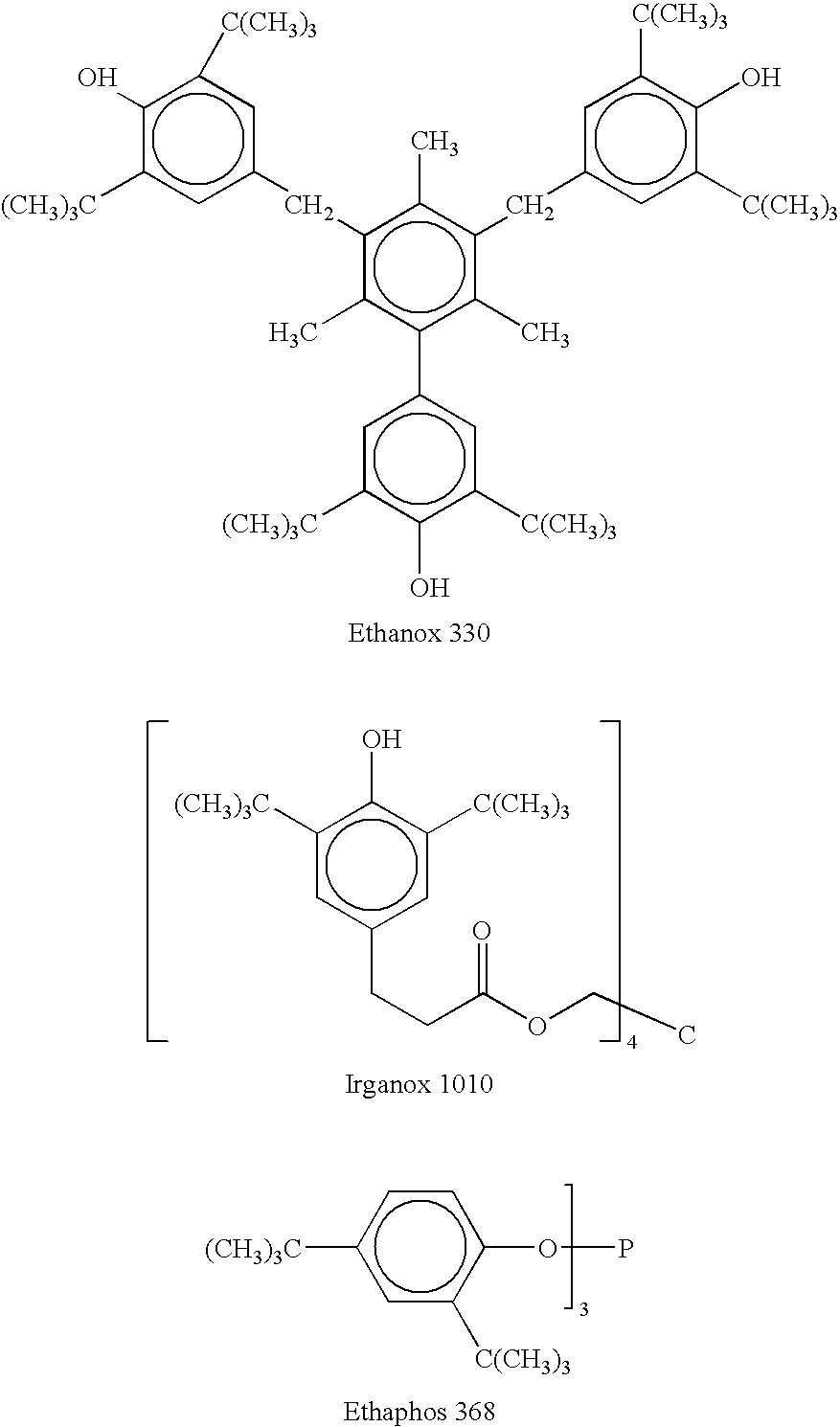

Enhanced thermo-oxidative stability thermal interface compositions and use thereof in microelectronics assembly

InactiveUS20070161521A1Improve thermo-oxidative stabilityLiquid carbonaceous fuelsHeat-exchange elementsPHENOL LIQUIDEngineering

Liquid compositions containing a specific hindered phenol or a hindered phenol in combination with an aromatic phosphite are provided which are used as a thermal interface between a heatsink and a chip during a test procedure for electronic components which compositions enhance the thermal conductivity between the heatsink and the chip, are easily removed from the heatsink and the chip after the test procedure without any deleterious residue and which allow the use of high temperatures for extended periods during the test procedure without any significant degradation of the composition. A method for using the compositions in electronic component test procedures such as burn-in procedures is also provided.

Owner:GLOBALFOUNDRIES INC

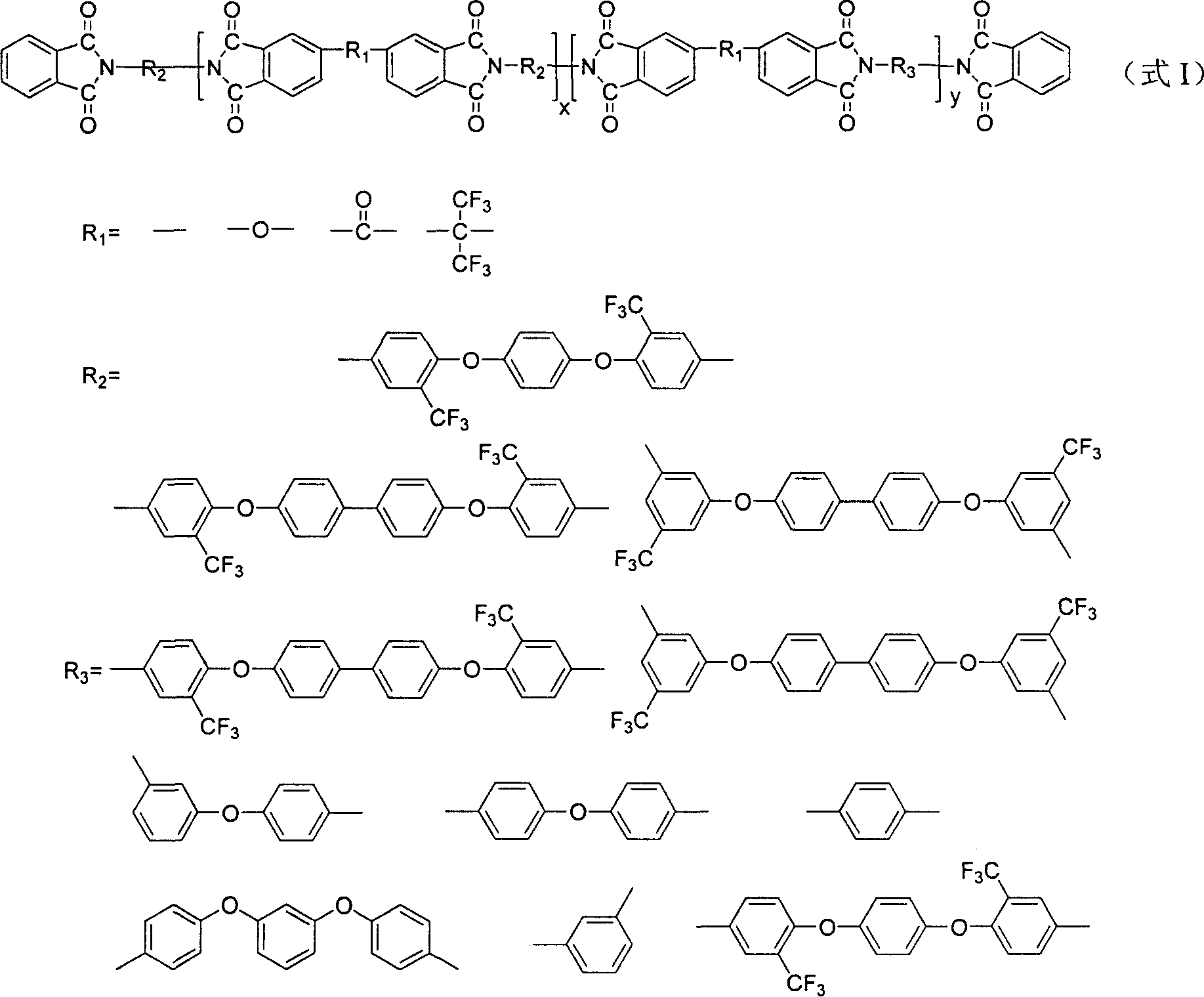

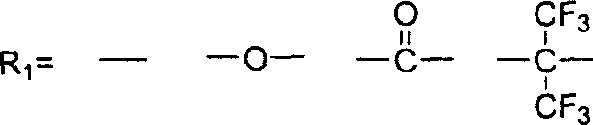

Fluorine-containing thermoplastic polyimide polymer and preparation method thereof

The invention discloses a thermoplastic polyimide polymer with fluorine and preparing method, which is characterized by the following: setting the structural formula as formula I; proceeding condensed and polymeric reaction with aromatic dianhydride, aromatic diamine and sealing end agent; synthesizing thermoplastic polyimide; introducing fluorine-containing group and flexible ether link in polyimide backbone structure; decreasing molecular chain rigidity and acting force of molecular chain; possessing good function to improve dissolving property and flux processability of polyimide; decreasing specific absorption of the material through introduction of fluorine-containing group; increasing stability of thermal oxidation. This product possesses good heat endurance and mechanics mechanical property, which can be used to outer-space, electron, micro electron, petrochemical, car and so on domain.

Owner:INST OF CHEM CHINESE ACAD OF SCI

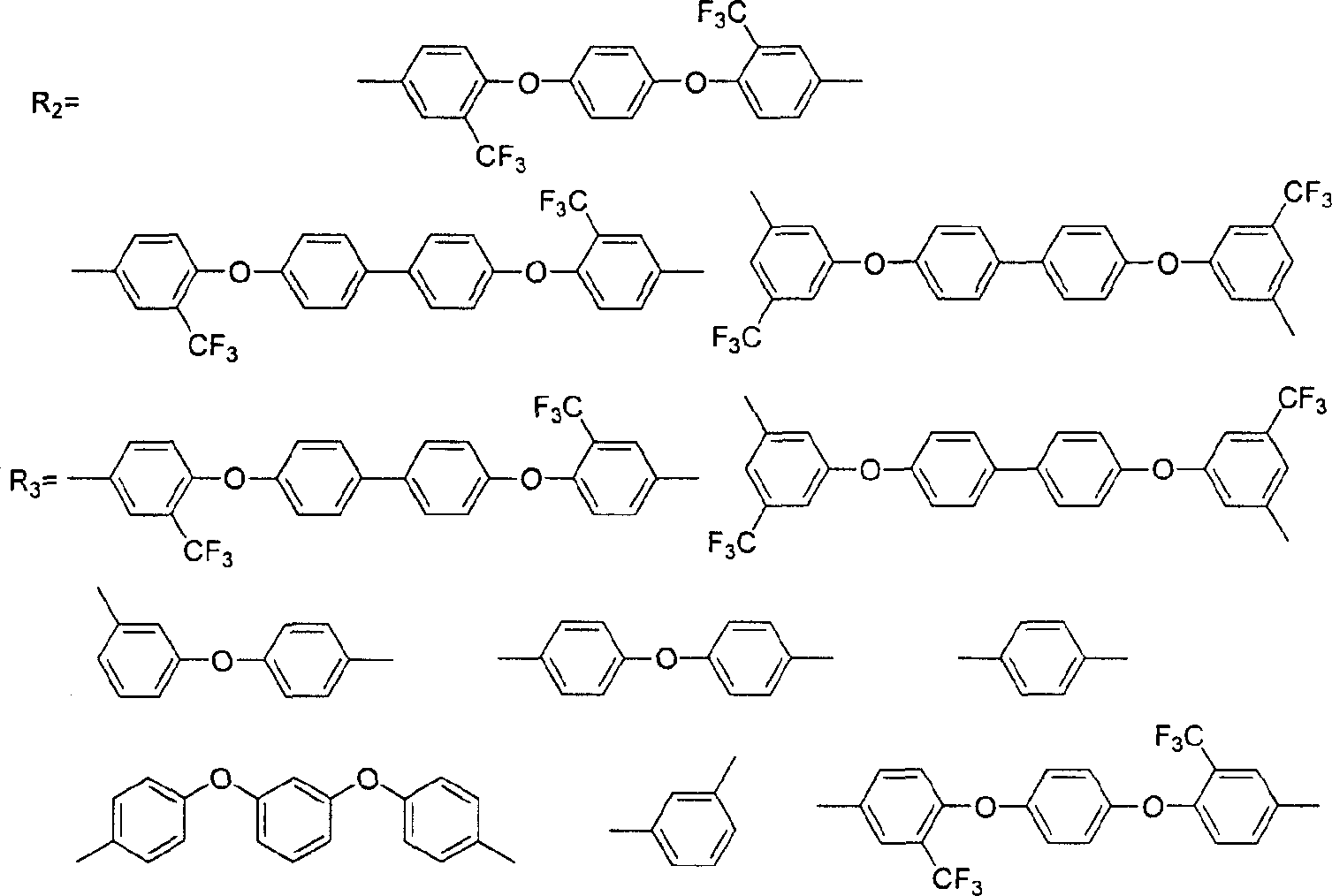

Lignin-containing polyurethane sealant and preparation method thereof

InactiveCN103215005AImprove aging resistanceImprove light aging resistanceNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePlasticizer

The invention discloses lignin-containing polyurethane sealant and a preparation method thereof, and relates to sealant and a preparation method thereof. In order to solve the technical problem that the existing polyurethane sealant is easily aged due to ultraviolet light, the lignin-containing polyurethane sealant is prepared from a lignin-containing prepolymer, catalyst, latent curing agent, plasticizer and filler. The preparation method of the lignin-containing polyurethane sealant comprises the following steps of: preparing the lignin-containing prepolymer; and stirring the lignin-containing prepolyer, the catalyst, the latent curing agent, the plasticizer and the filler for one hour at 80 DEG C to obtain the lignin-containing polyurethane sealant. After the ageing is quickened up by 1000 hours by the ultraviolet light, the fracturing elongation retention of the lignin-containing polyurethane sealant can reach 50%. The invention belongs to the preparation field of the sealant.

Owner:NORTHEAST FORESTRY UNIVERSITY

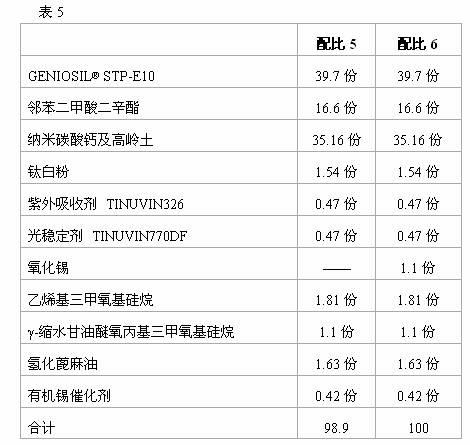

Heat resistance single-component silane modified polyurethane sealant and preparation method thereof

InactiveCN102516917AImprove heat resistanceImprove mechanical propertiesNon-macromolecular adhesive additivesOther chemical processesSilanesHeat resistance

The invention relates to a heat resistance single-component silane modified polyurethane sealant and a preparation method thereof, which belong to the technical field of sealant. Use temperature of the existing silane modified polyurethane sealant all ranges from 0 to 100 DEG C, the existing silane modified polyurethane sealant can bear 120 DEG C for a short time, and a problem of remarkable mechanical property weakening exists if the existing silane modified polyurethane sealant is under a high temperature condition for a long time. The heat resistance single-component silane modified polyurethane sealant is mainly characterized by comprising (A) 30-40% Wt of silane modified polyurethane base polymer, (B) 30-45% Wt of filler, (C) 8-15% Wt of plasticizer, (D) 1-5% Wt of colorant, (E) 0.5-1% Wt of ultraviolet absorber, (F) 0.5-1% Wt of light stabilizer, (G) 0.4-1.5% Wt of heat resisting synergist, (H) 0.5-2% Wt of additive TI, (I) 0.5-2% Wt of silane coupling agent, (K) 0.5-2% Wt of thixtropic agent and (L) 0.2-1% Wt of catalyst. The heat resistance single-component silane modified polyurethane sealant has the advantages that heat resistance performance is greatly improved, and mechanical property after high-temperature ageing is kept well. The heat resistance single-component silane modified polyurethane sealant is mainly used in the industrial fields of automobile industry, railway transportation industry, and new energy industry and the like.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

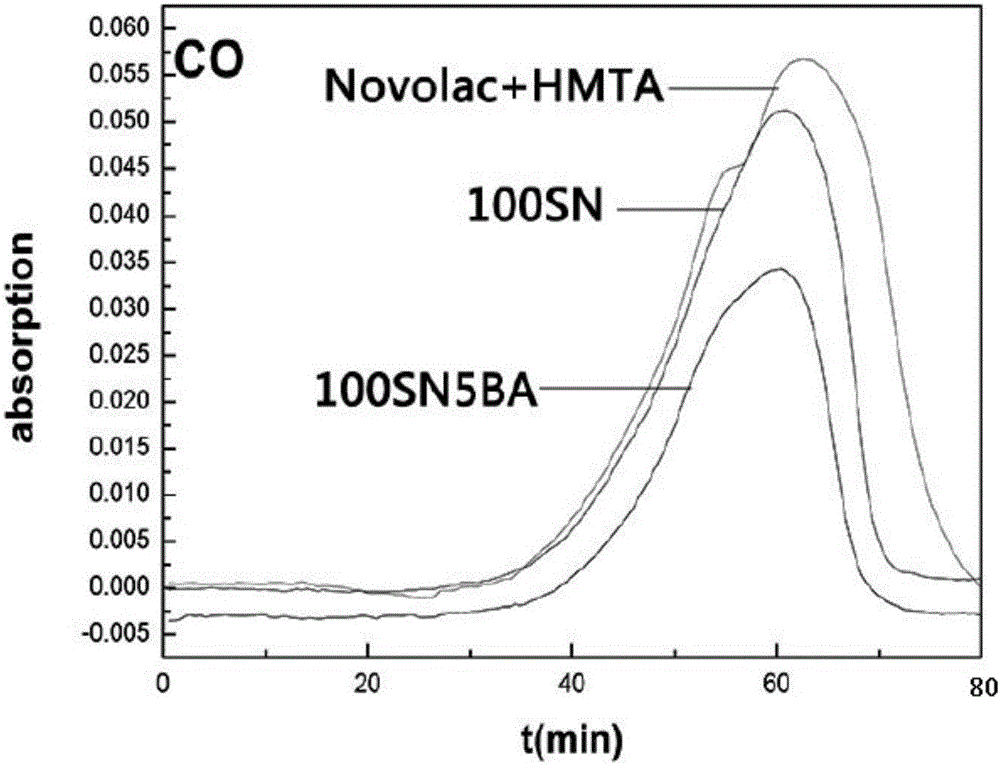

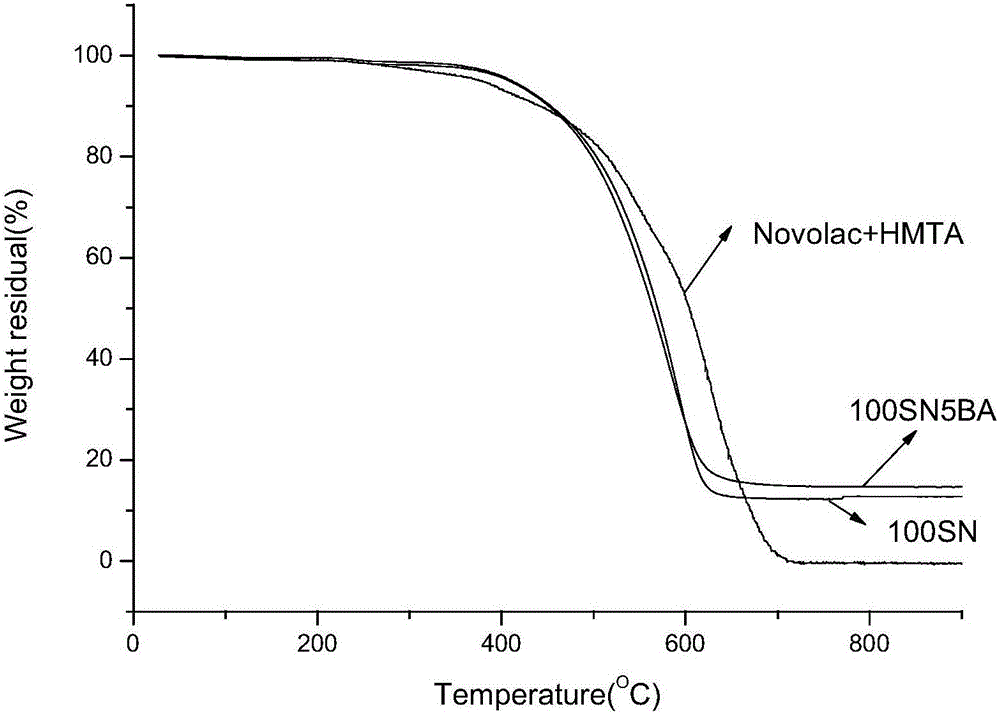

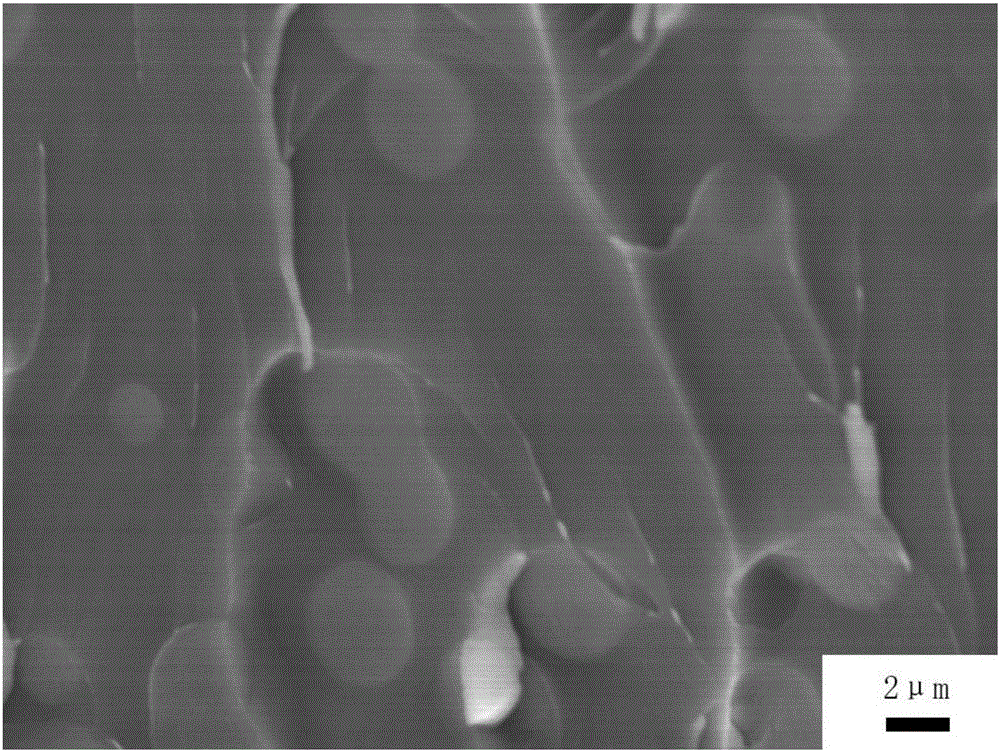

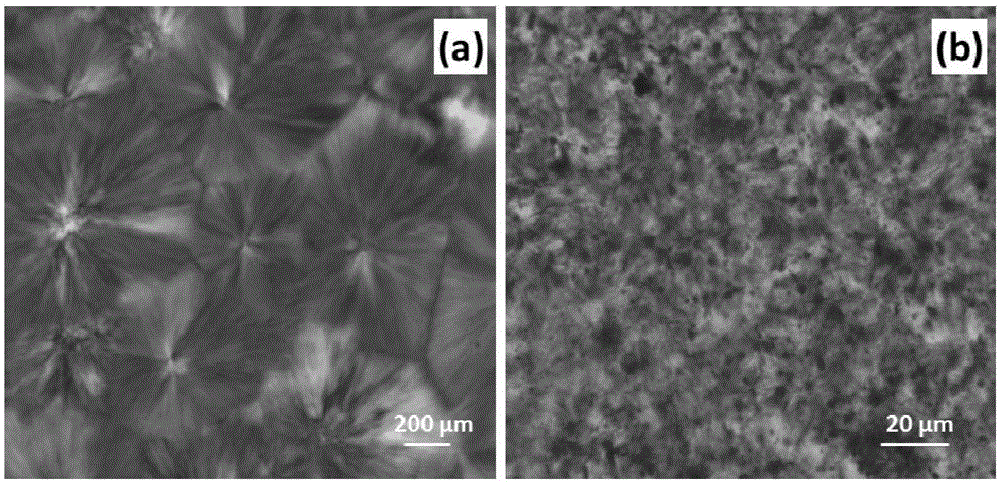

Silicon/boron-modified phenolic resin and preparation method thereof

ActiveCN105968705ADecentralized state of controlAvoid macro phase splitsSilanesHexamethylenetetramine

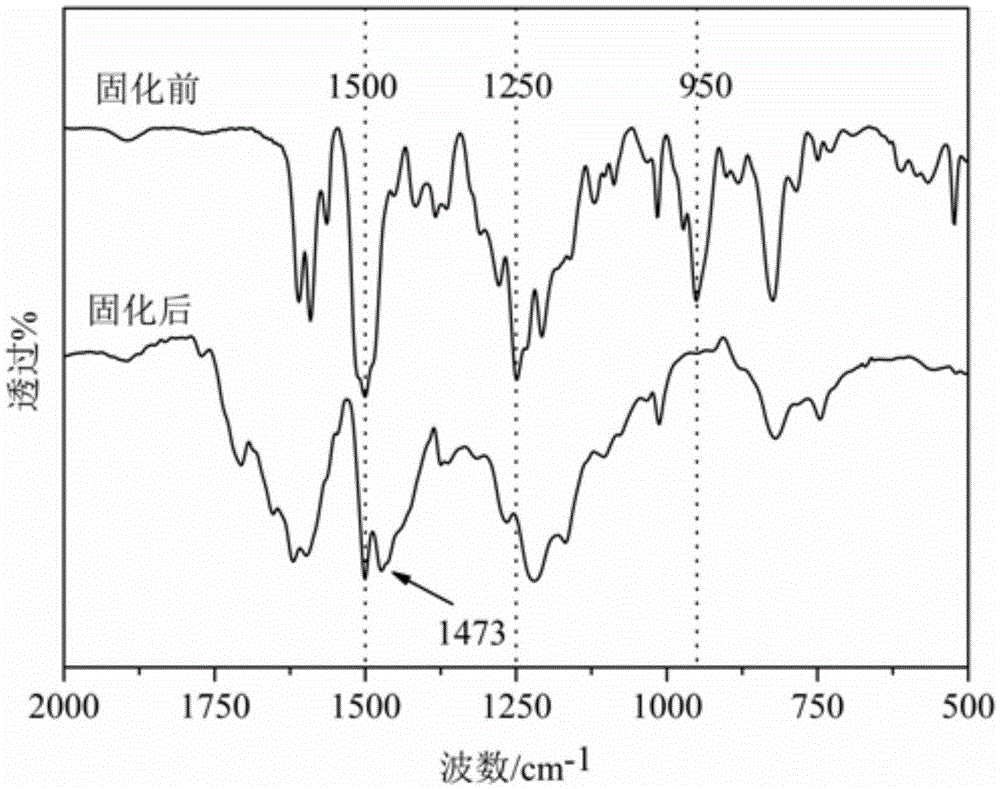

The invention discloses a silicon / boron-modified phenolic resin and a preparation method thereof. The preparation method comprises the following steps: (1) preparation of silicon-modified phenolic resin: adding linear phenol formaldehyde into a silane monomer, stirring to form a solution, adding a catalyst, heating to carry out esterification reaction, and carrying out reduced pressure distillation to obtain the silicon-modified phenolic resin; and (2) preparation of silicon / boron-modified phenolic resin: dissolving the silicon-modified phenolic resin in a solvent to obtain a resin solution, adding boric acid and hexamethylenetetramine, blending, and carrying out vacuum drying to obtain the silicon / boron-modified phenolic resin. The modified phenolic resin is in an island-like phase separation structure, and has obviously higher thermal oxidation stability. Besides, the preparation method has the advantages of simple steps, low cost and controllable process, and is suitable for popularization.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Nano aluminum nitride heat radiation paint for LED lamp and preparation method thereof

The invention provides a nano aluminum nitride heat radiation paint for an LED lamp, wherein the paint is prepared by the raw materials by weight (Kg): 30-34 parts of organic silicone resin, 12-14 parts of E-12 epoxy resin, 6-8 parts of methylenebiscyclohexanamine, 12-15 parts of nano aluminum nitride powder, 1-2 parts of hydroquinone, 4-5 parts of silane coupling agent KH550, 1-2 parts of cross-linking agent TAC, 2-3 parts of alumina, 2-3 parts of silicon carbide, 1-2 parts of sodium metasilicate, 1-2 parts of triethanolamine, 4-6 parts of PEVE fluorocarbon resin, 3-4 parts of glass bead, 1-2 parts of ammonium polyphosphate, 8-10 parts of xylene, 10-12 parts of ethyl acetate, and 4-5 parts of film forming auxiliary agent. Nano aluminum nitride powder is added so as to greatly raise heat conduction rate of the paint, and to make the paint have good heat radiation effect; silicon carbide is added so as to raise the wear resistance of the paint; the paint has advantages of large paint adhesion stress, not-easy shedding, and good fireproof performance; and the organic silicone resin is used as a base material, so as that the paint has good insulating property and excellent thermo-oxidative stability.

Owner:天长市天泰光电科技有限公司

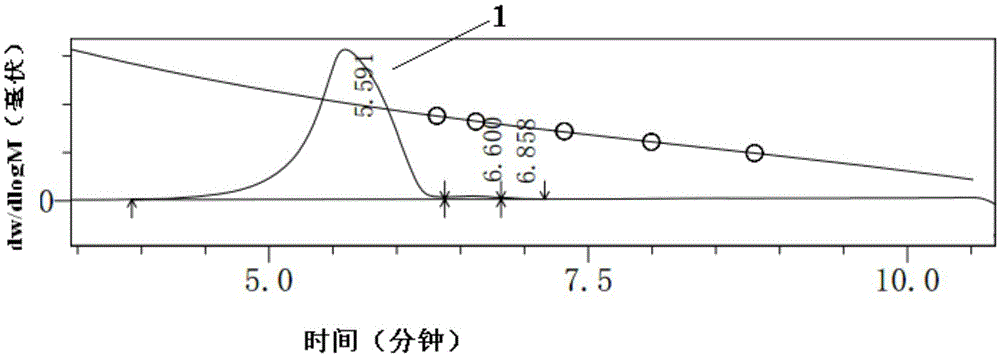

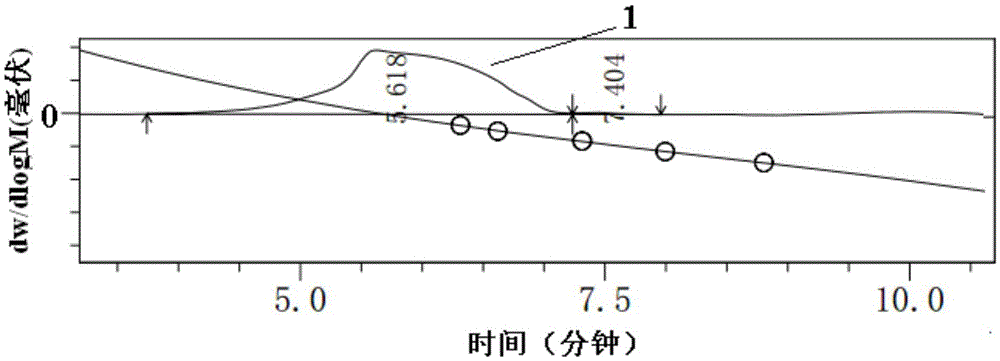

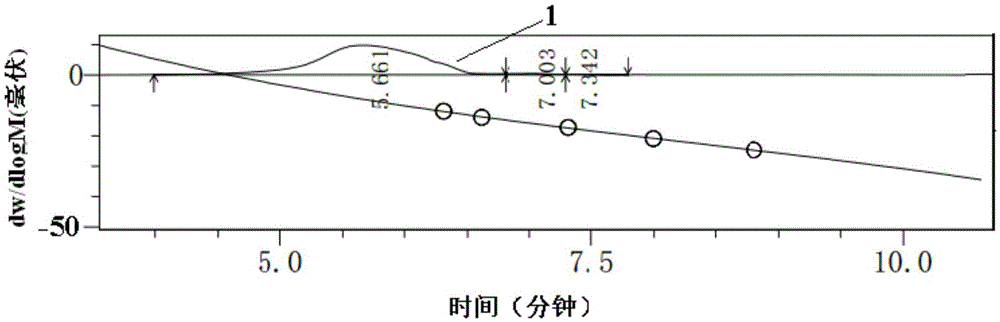

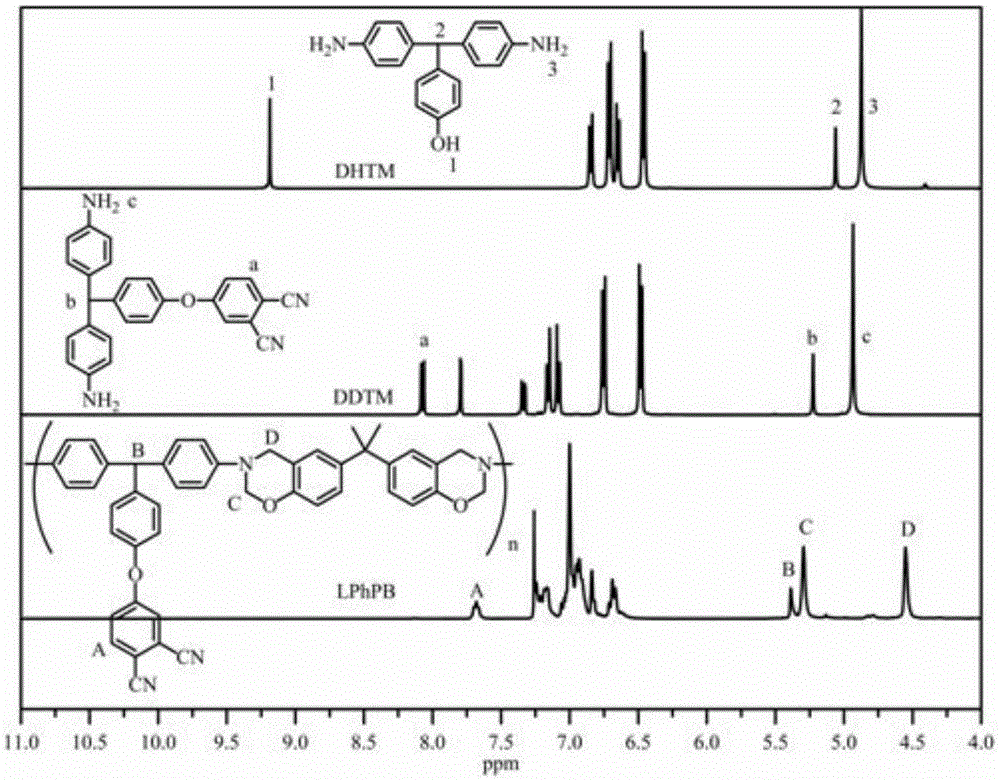

Phthalonitrile modified benzoxazine and epoxy resin composite material, preparation and application

InactiveCN105255109ASmall water absorptionShort synthesis cycleOrganic chemistryChemistryPhthalonitrile

The invention discloses a phthalonitrile modified benzoxazine and epoxy resin composite material, preparation and an application. According to the invention, phthalonitrile modified benzoxazine and epoxy resin are composited, and the hthalonitrile modified benzoxazine and epoxy resin composite material is a novel high-performance thermoset polymer composite material; phenolic hydroxyl groups produced through benzoxazine curing not only can be taken as a phthalonitrile curing catalyst, but also can be taken as an epoxy resin curing agent, through synthetic curing of phthalonitrile, benzoxazine and epoxy resin, the crosslinking density of the material is further increased, and properties such as thermal oxidation stability, radiation resistance, high temperature resistance, flame retardancy, corrosion resistance, low water absorption property and the like are further improved, so that the material has excellent comprehensive performance to attract broad attention and is taken as high-performance resin material for wide application in the high-technology fields such as electronic industry, aerospace and the like. According to the monomer preparation method, the synthesis period is greatly shortened, raw materials for monomer synthesis are cheap and easily available, the preparation method is simple and convenient, and the yield is high. The related processing technology of the composite material is simple, and the performance is good.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Anti-aging method for polymer materials

The invention discloses an anti-aging method for polymer materials, which is to add plant polyphenol into the polymer materials as a free radicals capturing agent, wherein the plant polyphenol mass content in the polymers is 0.1 to 10 percent. In the invention, the plant polyphenol is added into the polymer materials as the free radicals capturing agent, so the thermal stability, thermal oxygen stability, light stability, light oxygen stability and other aging performances of the polymer materials are improved, and the service lives of the polymer materials are prolonged. The plant polyphenol has the advantages of naturalness, wide source, high efficiency, no toxicity and the like, and can be used by mixing with the polymers in the conventional processing equipment without special process treatment. The invention opens a new field for the application of the plant polyphenol and provides a new anti-aging method for the polymer materials.

Owner:ZHEJIANG SCI-TECH UNIV

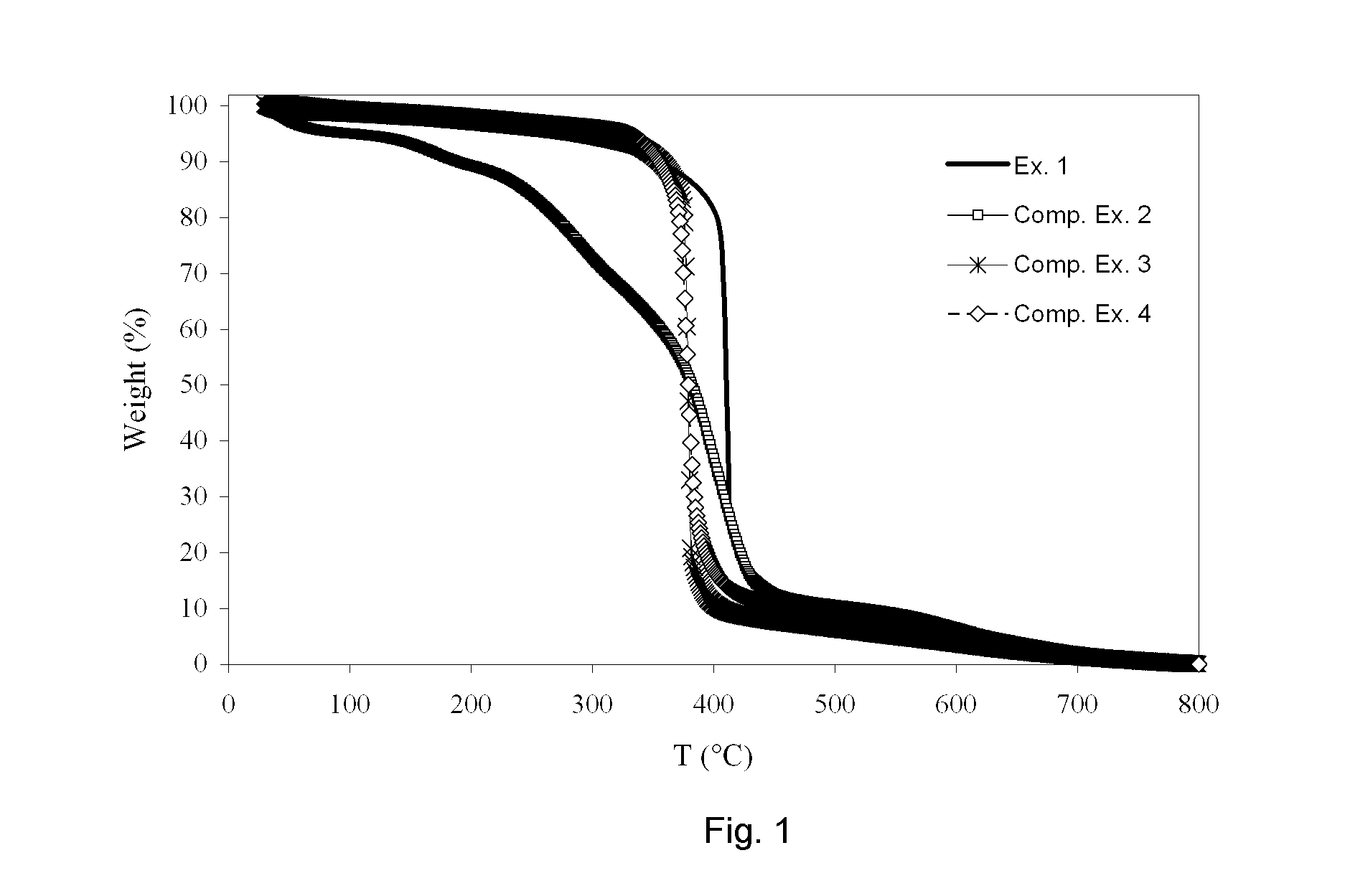

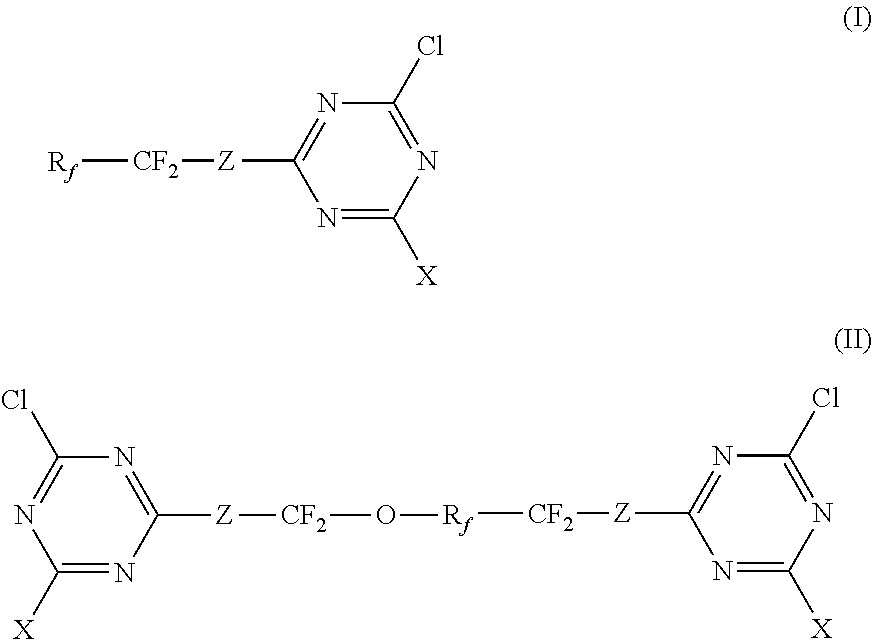

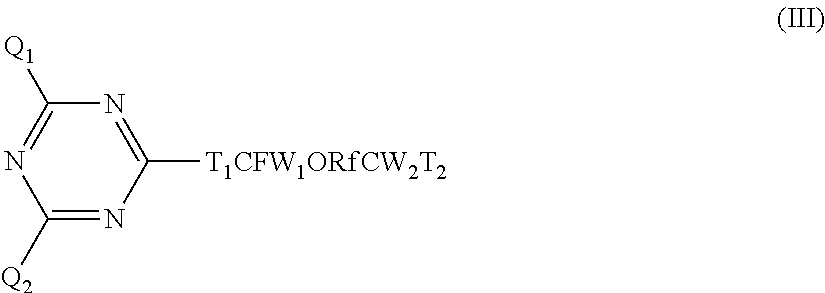

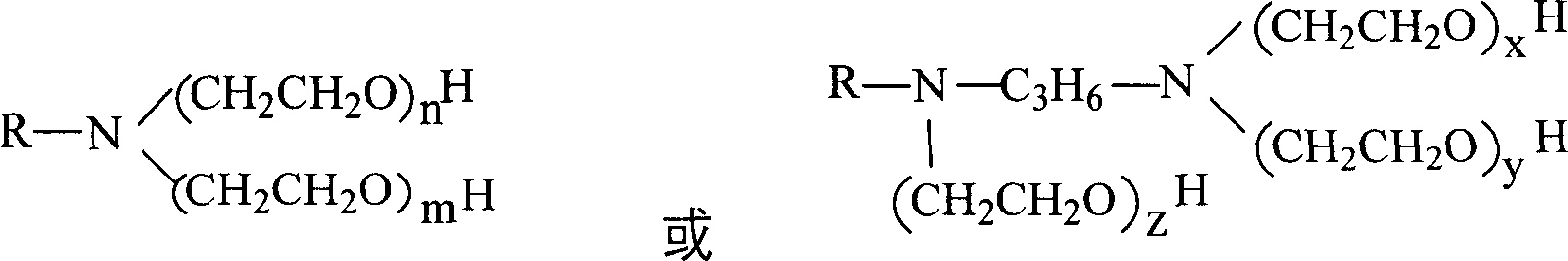

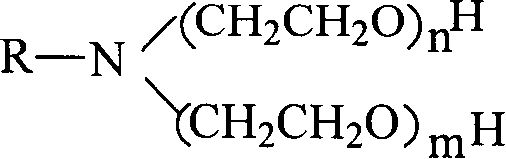

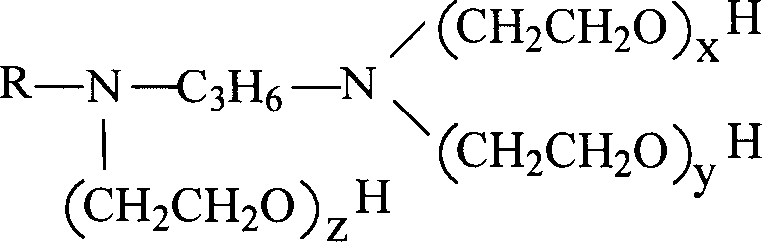

Triazine derivative

ActiveUS20130237462A1Improve lubricate behaviourImprove stabilityOrganic chemistryAdditivesLubricationChemical compound

The invention pertains to certain (per)fluoropolyether triazine derivatives comprising at least one triazine group and at least one fluoropolyoxyalkene chain (chain Rf) comprising a fluorocarbon segment having ether linkages in main chain, said chain Rf comprising at least one hydroxyl group, to a method for their manufacture and to their use in lubrication, in particular for lubricating sliding or moving parts of magnetic recording media.

Owner:SOLVAY SOLEXIS

Method for producing phosphor boronation ashless dispersant

ActiveCN101173201AExcellent thermo-oxidative stabilityImprove anti-wear performanceAdditivesPhosphorous acidPhosphoric Acid Esters

The invention relates to a preparation method of phosphorus boronizing ashless dispersant, which comprises the following steps: ashless dispersant, phosphorus-containing additive, boracic acid, ethoxylation aliphatic amine, water and fatty alcohol are mixed and react at 70 to 100 degree centigrade, and then a product is separated and collected. The phosphorus-containing additive is phosphoric acid, phosphorous acid, phosphoric acid ester or phosphite ester. The preparation method of the phosphorus boronizing ashless dispersant provided by the invention improves the boronizing quality, and no boron slag is produced in the preparation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

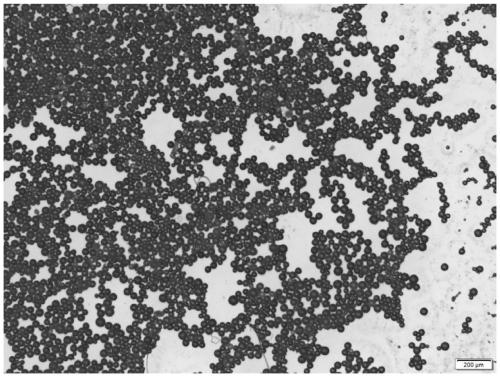

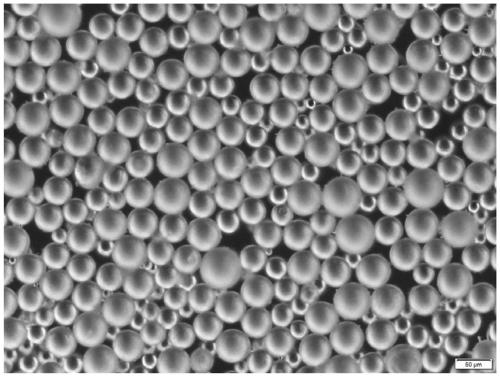

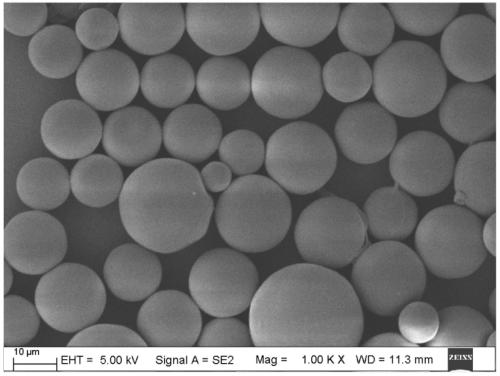

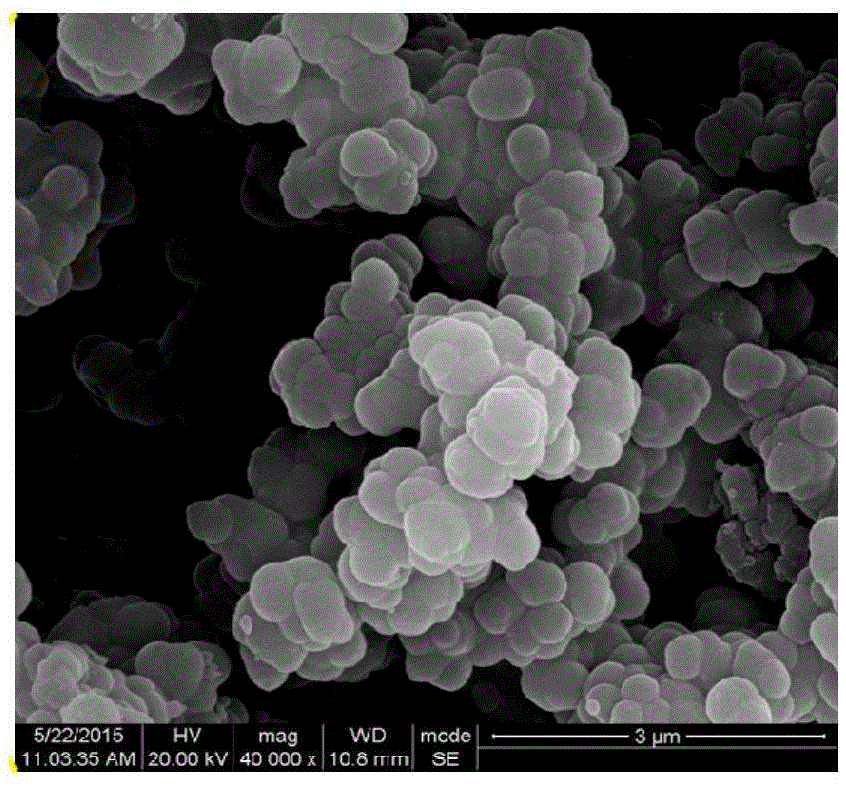

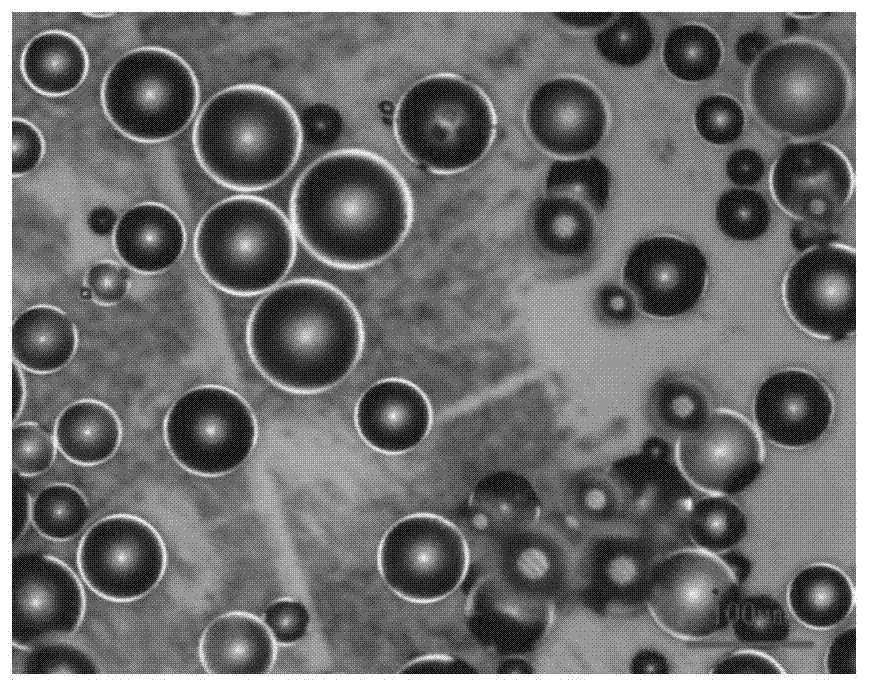

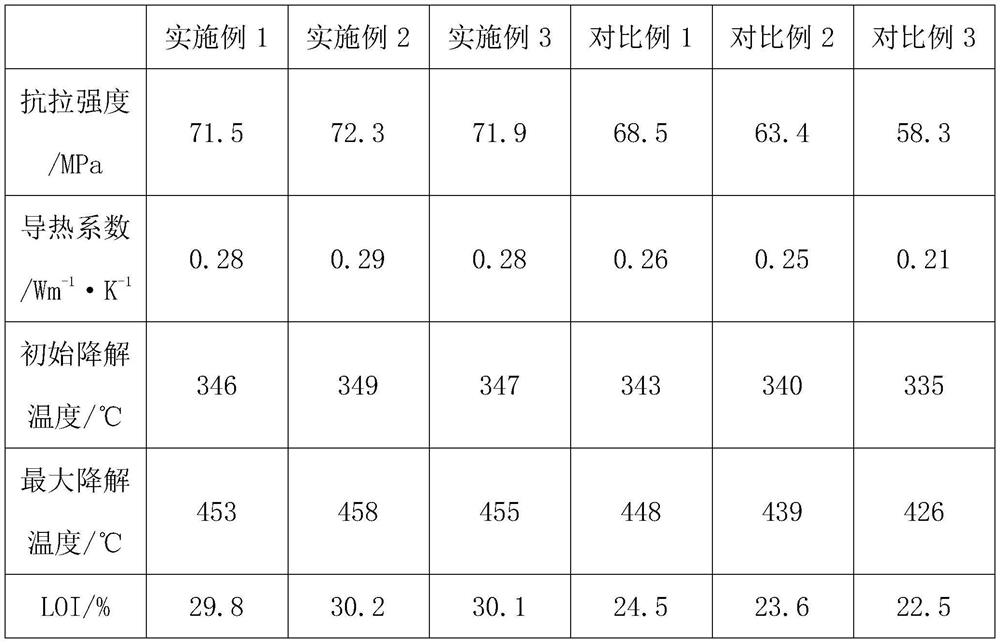

Phase change energy storage microcapsule taking polyurethane modified organic silicon resin as shell material and preparation method of phase change energy storage microcapsule

ActiveCN111054283AImprove flame retardant performanceReduce manufacturing costHeat-exchange elementsMicroballoon preparationPolymer sciencePtru catalyst

The invention relates to a phase change energy storage microcapsule taking polyurethane modified organic silicon resin as a shell material and a preparation method of the phase change energy storage microcapsule, and particularly discloses the preparation method which comprises the following steps: (1) uniformly mixing monomers for generating organic silicon resin, adding a catalyst, and prepolymerizing to obtain a prepolymer of polysiloxane; (2) adding the polyurethane prepolymer into the step (1), and carrying out a reaction to obtain a polyurethane modified organic silicon resin prepolymer;(3) uniformly mixing a core material with the shell material prepolymer to obtain a core material and shell material prepolymer mixture; (4) preparing an aqueous solution of a surfactant; and (5) mixing and emulsifying the core material and shell material prepolymer mixture and the aqueous solution of the surfactant to obtain an emulsion, adding a catalyst until the reaction is finished, separating, and drying to obtain the polyurethane modified organic silicon resin shell phase change energy storage microcapsule. The method is green, pollution-free and simple to operate, and the obtained microcapsule is smooth in surface, good in compactness, adjustable in phase change temperature, controllable in particle size, good in heat resistance and high in phase change enthalpy value.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

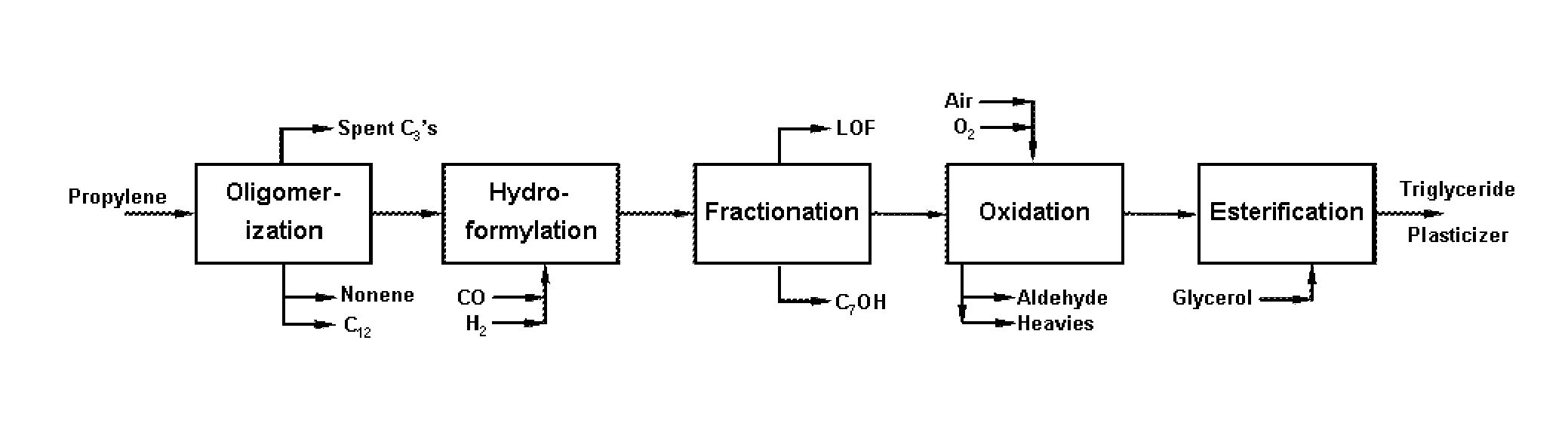

Polyol Ester Plasticizers and Process of Making the Same

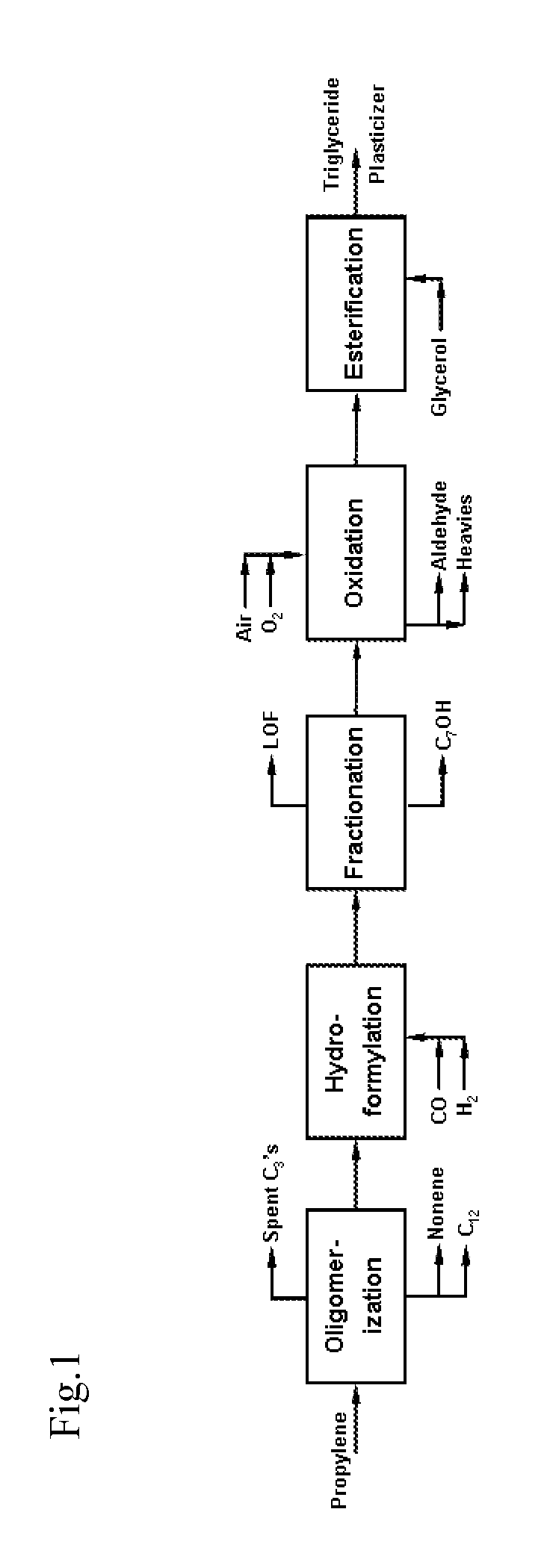

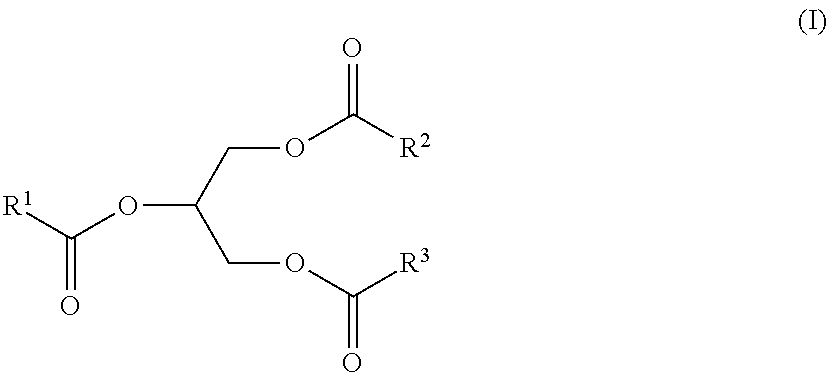

InactiveUS20110021680A1Efficiency benefitLow toxicityOrganic compound preparationCarboxylic acid esters preparationCarbon numberGlycerol

Triglyceride and other polyol ester PVC plasticizers can be produced by recovery of branched C6 to C9 aldehydes from a hydroformylation product, optional hydrogenation to the alcohol, oxidation to the acid with oxygen and / or air, recovery of the resulting acid, and esterification with glycerol, ethylene glycol, propylene glycol or mixtures thereof. The branched alkyl chains comprise at least 10% methyl branching. Special triglycerides are derived from branched aliphatic acids having alkyl chains with average carbon numbers from 6 to 9 and at least 10% methyl branching. These triglycerides are fast fusing plasticisers if before esterification with glycerol, an aryl acid is introduced together with the aliphatic acids.

Owner:EXXONMOBIL CHEM PAT INC

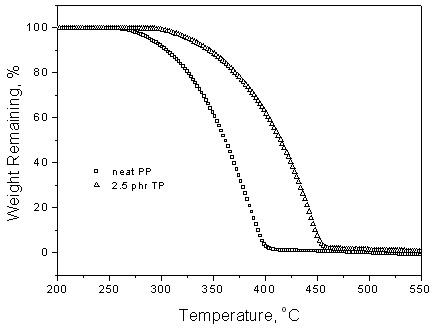

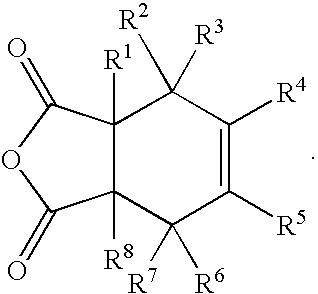

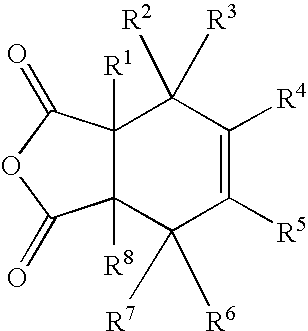

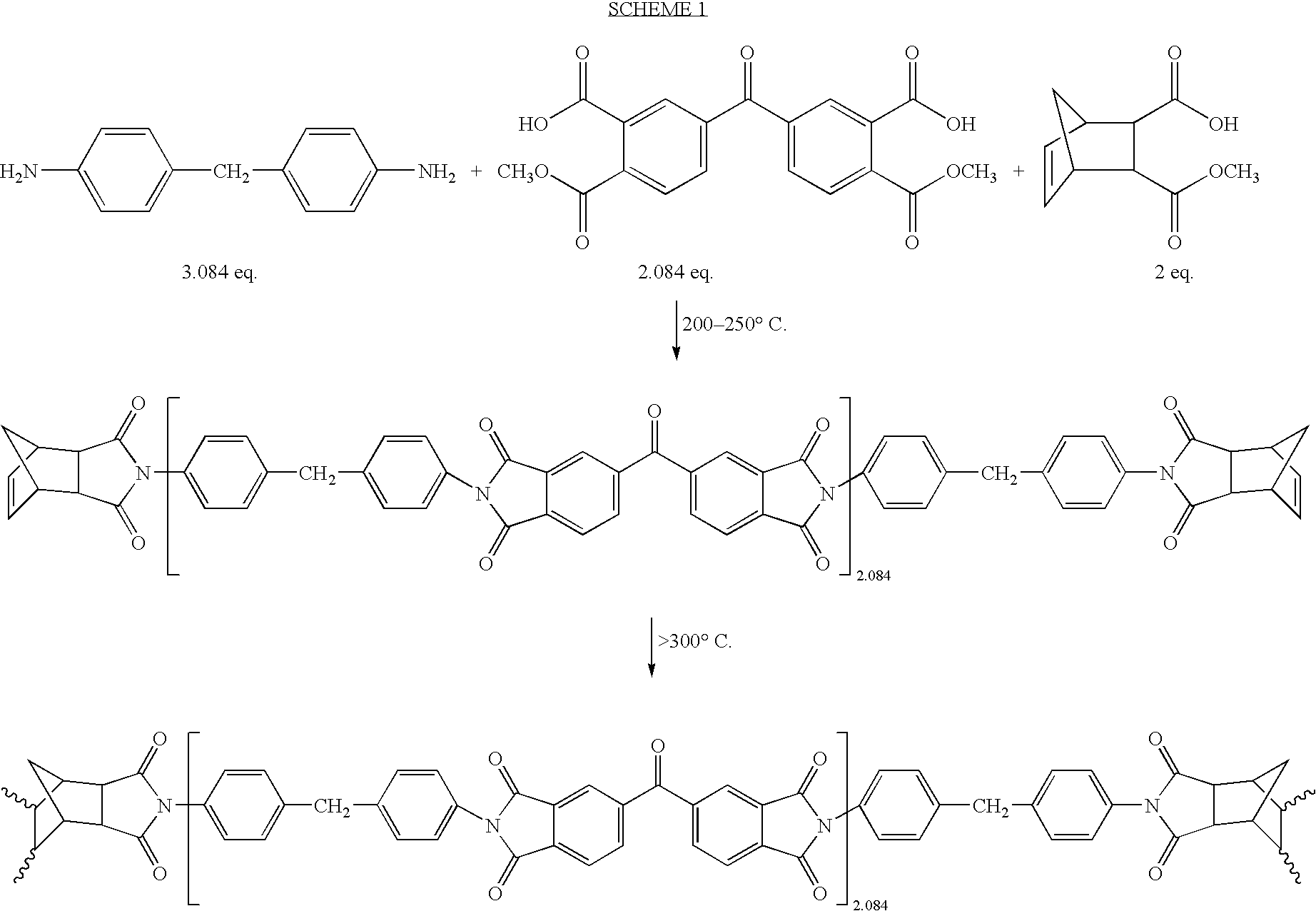

Substituted cyclohexene endcaps for polymers with thermal-oxidative stability

InactiveUS6979721B1Prolong lifeAllow useSynthetic resin layered productsThin material handlingFiberCarboxylic acid

This invention relates to polyimides having improved thermal-oxidative stability, to the process of preparing said polyimides, and the use of polyimide prepolymers in the preparation of prepregs and composites. The polyimides are particularly useful in the preparation of fiber-reinforced, high-temperature composites for use in various engine parts including inlets, fan ducts, exit flaps and other parts of high speed aircraft. The polyimides are derived from the polymerization of effective amounts of at least one tetracarboxylic dianhydride, at least one polyamine and a novel dicarboxylic endcap having the formula:

Owner:NASA

Echogenic needle catheter configured to produce an improved ultrasound image

InactiveUS7794402B2Improve thermo-oxidative stabilityEasy to processElectrocardiographyBlood flow measurement devicesNeedle catheterOrganic polymer

An echogenic catheter, such as a needle catheter, formed at least in part of an intrinsically conductive organic polymer for providing a highly conductive surface in combination with an improved ability to ultrasonically image the catheter, and a method of performing a medical procedure using a catheter of the invention.

Owner:ABBOTT CARDIOVASCULAR

Environment-friendly stable polyamide acid solution and preparation method thereof

ActiveCN105461926AImprove thermo-oxidative stabilityHigh glass transition temperaturePolyamidePolyamic acid

The invention relates to a polyamide acid solution and a preparation method thereof, in particular to an environment-friendly stable polyamide acid solution and a preparation method thereof. The environment-friendly stable polyamide acid solution and the preparation method thereof aim at solving the problems of difficultly of large-scale preparation of a polyamide acid aqueous solution, wide molecular weight distribution and poor batch stability in the prior art. The environment-friendly stable polyamide acid solution is prepared from tertiary amine, aromatic primary amine, aromatic dianhydride, aromatic diamine and water, wherein repetitive units of polyamide acid in the polyamide acid aqueous solution are shown in the specification. The preparation method includes the steps that tertiary amine, aromatic primary amine, aromatic dianhydride, aromatic diamine and water are taken, and weighed tertiary amine is divided into tertiary amine A and tertiary amine B; water and aromatic primary amine are added into a three-necked bottle under certain conditions for a reaction; weighed tertiary amine A and weighed aromatic diamine are added into the three-necked bottle for a reaction, reaction liquid is heated, then weighed aromatic dianhydride is added into the three-necked bottle and stirred for a reaction, then the reaction liquid is cooled, weighed tertiary amine B is added and stirred for a reaction, and the reaction liquid is cooled and subjected to standing.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Side-chain phthalonitrile modified benzoxazine resin, preparation method and application

InactiveCN105254879AImprove thermodynamic performanceImprove flame retardant performanceChemical reactionSide chain

The invention belongs to the field of benzoxazine resin in polymer synthetic materials and discloses side-chain phthalonitrile modified benzoxazine resin, a preparation method and an application. The resin has a general structural formula shown in a formula I, wherein n is an integer larger than or equal to 1. By means of the characteristic of strong molecular structure design of a benzoxazine monomer, a polymerizable phthalonitrile group is introduced into an aromatic diamine compound through a conventional chemical reaction, then the aromatic diamine compound carrying the phthalonitrile group, paraformaldehyde and bisphenol A have condensation polymerization, and the side-chain phthalonitrile modified benzoxazine resin is prepared. Phthalonitrile which is a polymerizable group is introduced into benzoxazine, so that phthalonitrile can participate in curing, the crosslinking density of polybenzoxazine resin can be further increased, and the thermal stability of polybenzoxazine can be further improved. The preparation method is simple and convenient, a synthesis period is short, the yield is high, and raw materials are easy to obtain.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Phase change thermal interface materials including polyester resin

InactiveUS7408787B2Improve thermo-oxidative stabilitySemiconductor/solid-state device detailsSolid-state devicesPolyolefinPolyester resin

An embodiment of a phase change TIM of this invention comprises a polyester matrix with melting temperature near or below operating temperature (typically less than about 130° C.), thermally conductive filler with bulk thermal conductivity greater than about 50 W / mK, and optionally other additives. The polyester resin has improved thermo-oxidative stability compared to the polyolefin resins, thereby providing improved reliability performance during test.

Owner:INTEL CORP

Lubricant composition used in electric mechanical transmission device

InactiveCN104450071AMeet lubricitySatisfy coolingLubricant compositionAntioxidantOxidation resistant

The invention discloses a lubricant composition used in an electric mechanical transmission device. The lubricant composition is prepared from a complex of trimellitate and poly-alpha-olefin serving as base oil as well as a plurality of composite additives comprising a rust inhibitor, an antioxidant, an oiliness agent, an anti-wear agent, a metal deactivator, a friction modifier, an anti-foaming agent, an oxidation-resistant and corrosion-resistant agent, a detergent and a dispersing agent. The lubricant composition disclosed by the invention has excellent detergency and dispersibility, cooling property, lubricating property, sealing property, friction property, rust-inhibiting property, corrosion resistance and extreme pressure anti-wear property; by the lubricant composition, a layer of uniform and continuous oil film having a certain thickness is easily formed in a movement friction pair, the coefficient of friction in the movement is decreased, the carrying capacity is increased and the phenomenon of adhesion of transmission members and vibration and noise are reduced.

Owner:GUANGXI UNIV

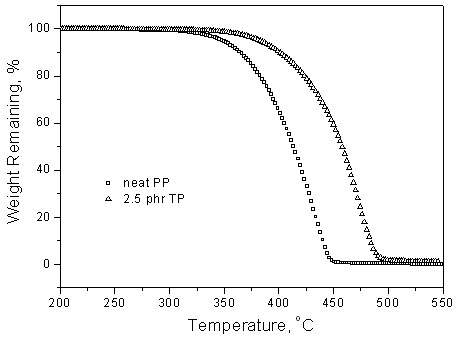

Polydopamine for Polypropylene beta nucleating agent and polydopamine/polypropylene composite

The invention belongs to the technical field of preparation of promoters for high polymer materials and particularly relates to a preparing method for a multifunctional and efficient beta nucleating agent for isotatic polypropylene materials. It is indicated that polydopamine can be used in the polypropylene beta nucleating agent. The multifunctional and efficient beta crystal nucleating agent is high in nucleating efficiency, good in compatibility with polypropylene matrixes, simple in preparing method and capable of improving the thermal oxidation stability of polypropylene materials.

Owner:SICHUAN UNIV

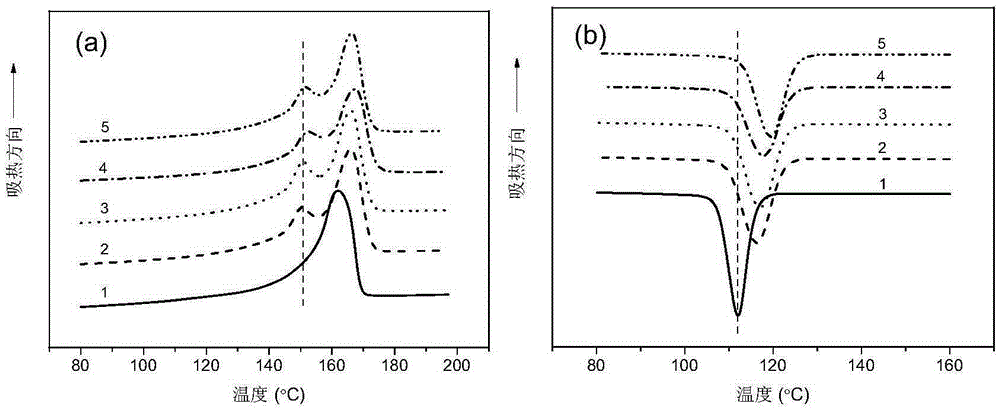

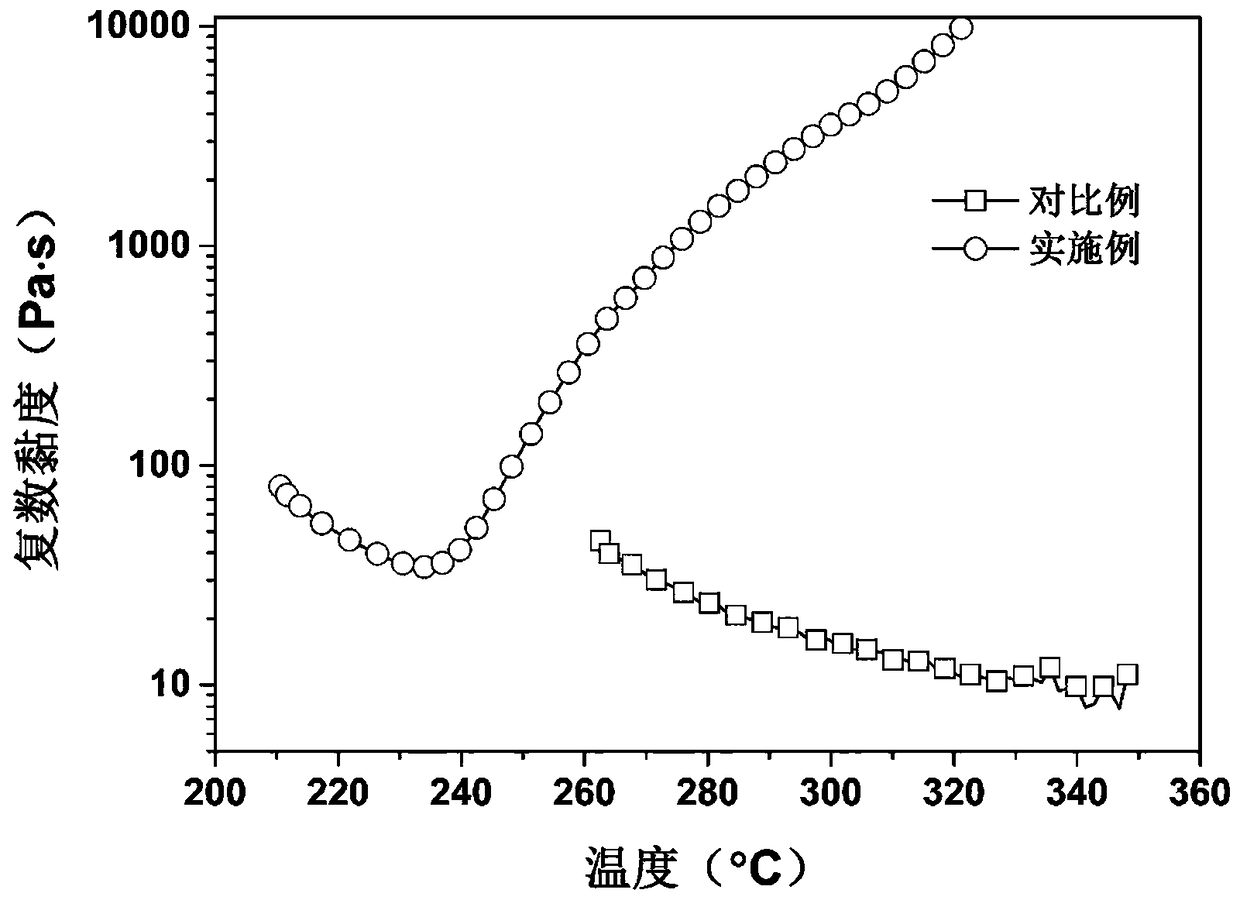

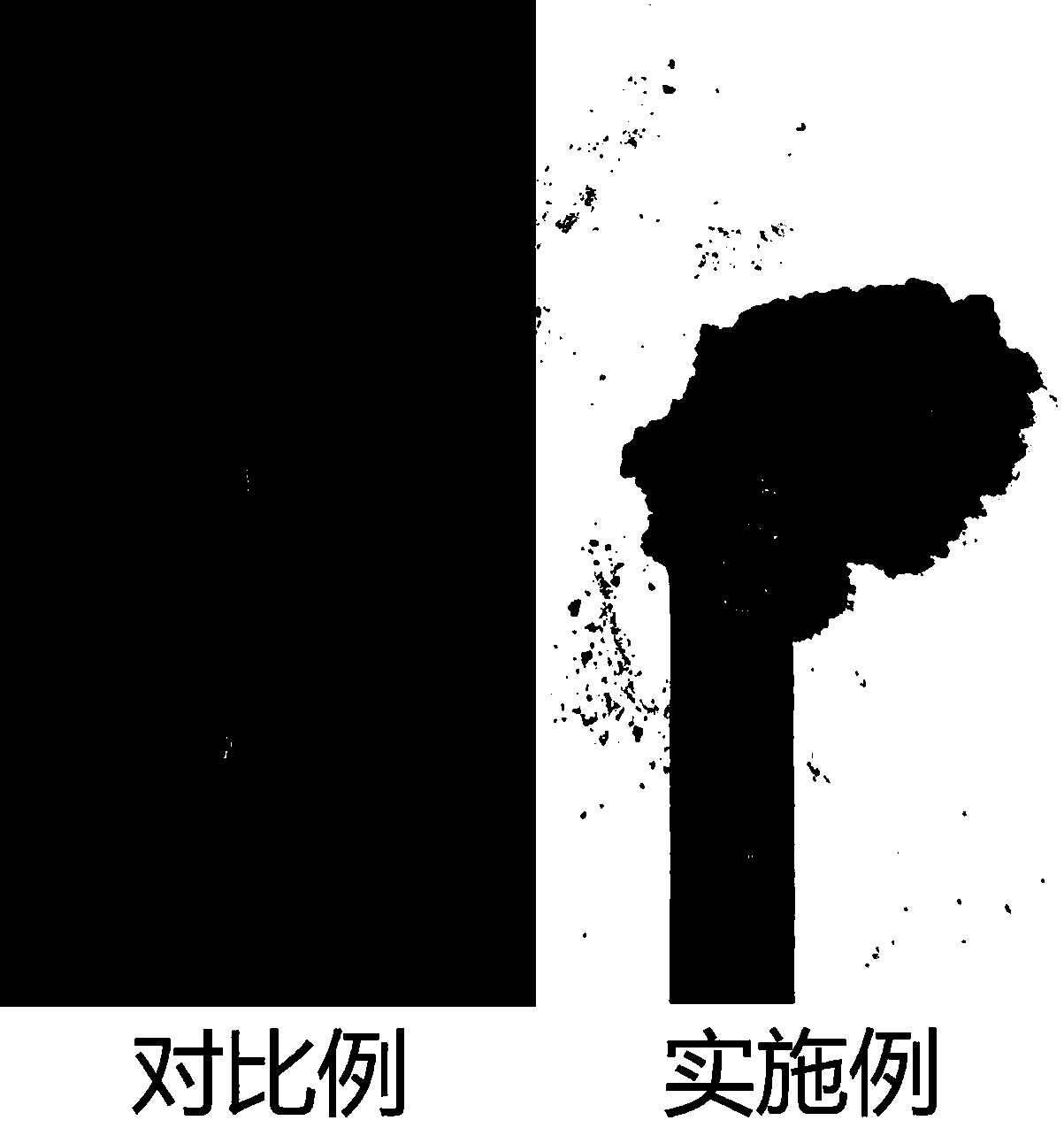

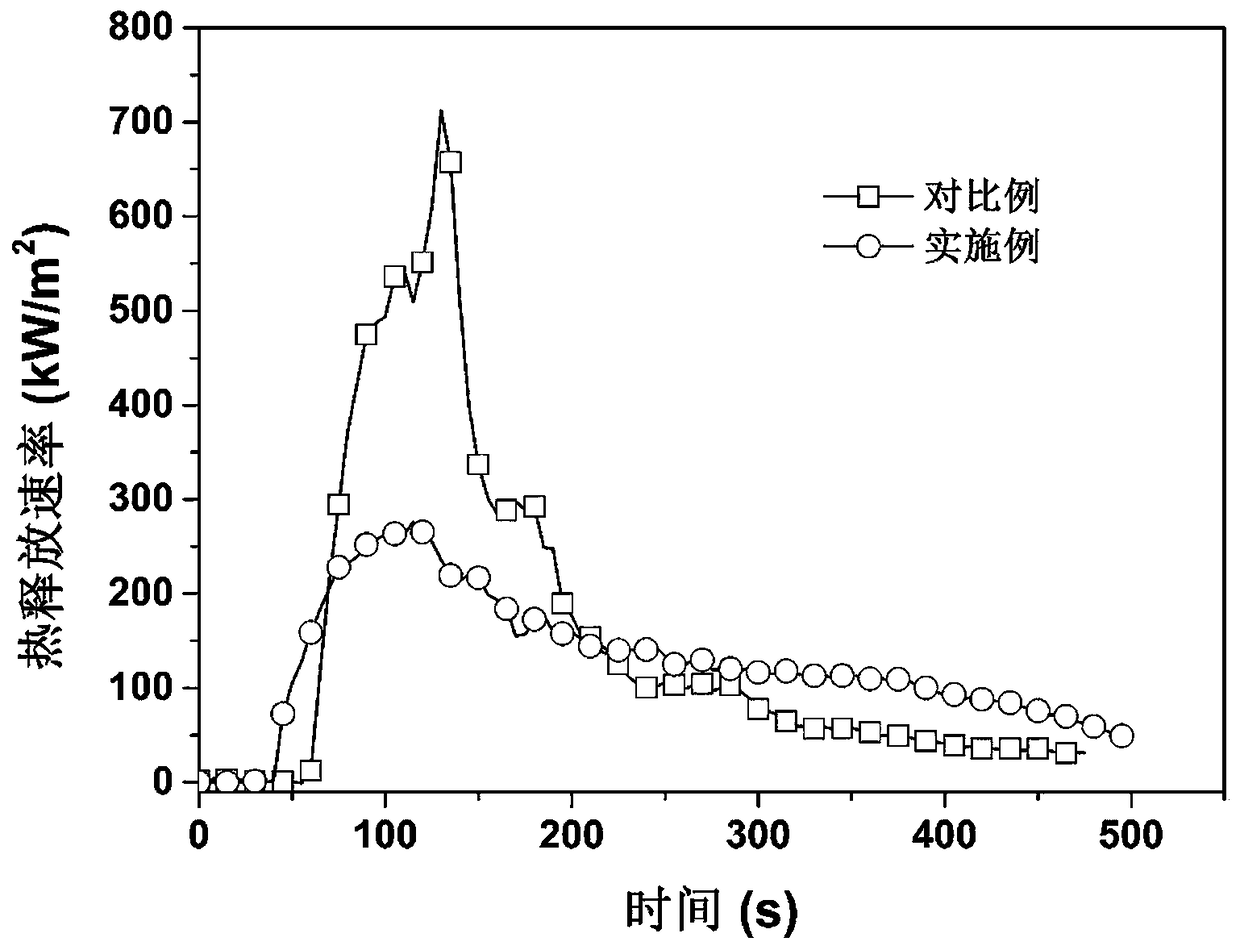

Benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance and preparation method of copolyester

ActiveCN108359084APreserve thermoplastic processabilityIncrease melt viscosityStructural unitStructure based

The invention discloses a benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance. Copolyester is prepared from structural units represented by I, II and III or structural units represented by I, II and IV through random copolymerization, wherein the characteristic viscosity [eta] of copolyester is 0.41-1.12 dL / g, and the limit oxygen index is 24.2%-38.7%; the vertical combustion class is in a range from V-2 to V-0; the p-HRR (peak of heat release rate) in a cone calorimetry test is reduced by 7.1%-72.1% as compared with that of pure PET, and total smoke release is decreased by 2.0%-59.2% as compared with that of pure PET. The invention further discloses a preparation method of copolyester. Ahigh-temperature self-crosslinking group introduced in the preparation process is a benzene imide group, and prepared copolyeste cannot be subjected to crosslinking during processing and polymerization, so that thermoplastic processability of polyester is retained; meanwhile, due to the tackifying effect and high charring property brought by the self-crosslinking action at high temperature or during combustion, prepared copolyester has excellent flame retardancy, smoke suppression and melt drop resistance effects.

Owner:SICHUAN UNIV

Environmental-friendly hydraulic oil composition and preparation method thereof

InactiveCN102329684AImprove hydrolytic stabilityImprove low temperature fluidityLubricant compositionEnvironmental engineeringAnoxomer

The invention discloses an environmental-friendly hydraulic oil composition and a production method thereof. The environmental-friendly hydraulic oil composition comprises the following raw material components per kilogram: 982 to 986.6 grams of base oil, 11 to 12 grams of antioxidant, 1.0 to 3.0 grams of extrcme pressure antiwear additive, 0.4 to 0.5 gram of metal deactivator and 1.2 to 2.0 gg of antirusting agent. The production method of the environmental-friendly hydraulic oil composition comprises the following steps of: after mixing component oils in the base oil according to a certain ratio, heating to a temperature of 75 to 85 DEG C and stirring for 4 hours; then adding other various additives together; and stirring for 4 hours at a temperature of 50 to 60 DEG C to obtain the the environmental-friendly hydraulic oil composition disclosed by the invention. The environmental-friendly hydraulic oil composition disclosed by the invention has low cost and has performances of excellent abrasion resistance, oxidation resistance, hydrolytic stability, anti-rusting property, biodegradability and the like.

Owner:SHANGHAI INST OF TECH

Wind power generation lubrication system

InactiveCN101196175AHigh biodegradation rateGood viscosity-temperature characteristicsMachines/enginesWind energy generationWater sourceEngineering

The invention provides a lubricating method for wind power generator, which comprises a lubricant, a wind power generator. Compound lubricant is adopted; the main lubricating parts of the wind power generator include a gear box, a generator bearing, a crab system bearing and gear, a hydraulic brake system and a min bearing. Compared with the ordinary mineral grease, the adopted compound lubricant has the advantages of excellent viscosity-temperature characteristics and little impact due to temperature change, is able to ensure easy startup under low temperature and no loss under high temperature, thereby providing sufficient lubrication for the friction parts. In addition, with excellent stability of thermal oxidation and little loss in vaporization, the lubricant can be used for a long time under rigid working condition and climatic situation. Especially, with high biodegradation rate, the compound lubricant can be widely promoted as it results in no pollution to the soil and water source.

Owner:苏州市南极风能源设备有限公司

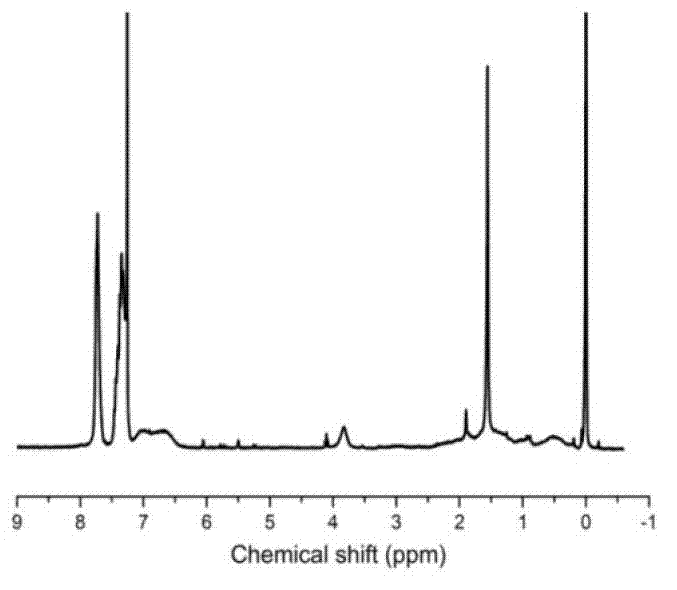

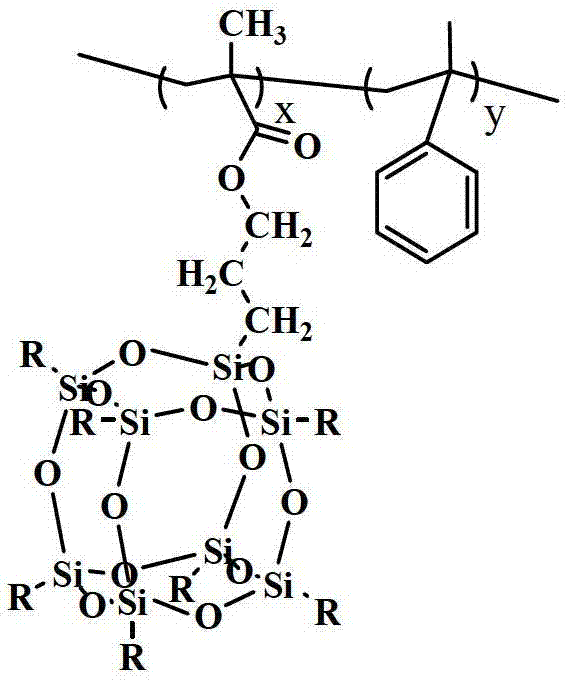

Optical diffusion agent for acrylic optical diffusion board and preparation method of optical diffusion board

ActiveCN103193914ACorrosion resistanceImprove thermo-oxidative stabilityDiffusing elementsPolymethyl methacrylateSilsesquioxane

The invention relates to an optical diffusion agent for an acrylic optical diffusion board and a preparation method of the optical diffusion board. The acrylic optical diffusion board comprises the following components in percentage by mass: 97.0-99.5 percent of polymethyl methacrylate and 0.5-3.0 percent of the optical diffusion agent which is a random copolymer of styrene and methylacryloyl propyl phenyl polyhedral oligomeric silsesquioxanes (MAPhPOSS). After the MAPhPOSS is copolymerized with styrene, even if the using amount of styrene monomers is small, the contribution of a nanoscale inorganic core can reach the same shading coefficient and light scattering property, and organic MMA groups in the POSS can avoid phase separation due to excessive addition amount, so that the optical diffusion board is uniform in surface, phase separation stripes are avoided, and a good diffusion body is obtained. The acrylic optical diffusion board can be applied to the field of outdoor photoelectric display of outdoor lamps, advertising light boxes, billboards, light source covers and the like with light-emitting diodes (LEDs) as light sources.

Owner:XIAMEN UNIV +1

Preparation process of graphene nanocomposite material

The invention discloses a preparation process of a graphene nanocomposite material. The preparation process comprises the following steps: 1, weighing raw materials; 2, preparing an epoxy resin prepolymer from bisphenol A type diglycidyl ether and diethyltoluenediamine; 3, preparing a mixed solution of an epoxy resin prepolymer and ethanol; 4, adding modified graphene oxide; and 5, conducting curing. According to the invention, epoxy resin is used as a matrix, and modified graphene oxide is added in a pre-compounding stage, so in the process of modifying the graphene oxide, a large number of nanometer SiO2 particles are deposited on a lamellar structure, a -NCO group is introduced into the surface of the material, and the mechanical property and the heat-resistant stability of the nanocomposite material can be remarkably improved; and since the nanometer SiO2 particles are deposited on the lamellar structure of the graphene, so the nanocomposite material can be converted into SiO2 nanosheets with high thermal oxidation stability and high radius-thickness ratio during combustion, and the nanocomposite material has excellent flame retardant property.

Owner:LANZHOU JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com