Lubricant composition used in electric mechanical transmission device

A technology of lubricant composition and transmission device, which is applied in the direction of lubricating composition and petroleum industry, which can solve the problems of high manufacturing and installation precision, and achieve the effects of improving bearing capacity, reducing friction coefficient, and excellent energy-saving and anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

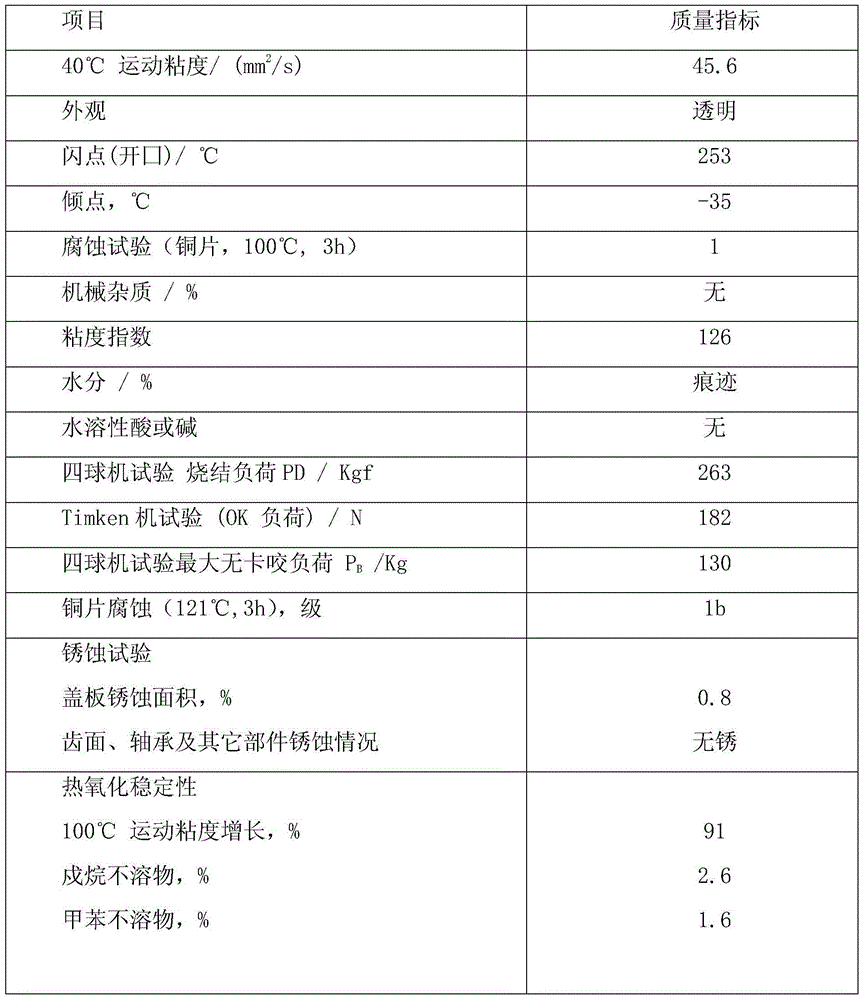

Image

Examples

Embodiment 1

[0024] It is formed by blending the following components in mass percentage:

[0025] components

Embodiment 2

[0027] It is formed by blending the following components in mass percentage:

[0028] components

Embodiment 3

[0030] It is formed by blending the following components in mass percentage:

[0031] components

Content (mass percentage)

The mass ratio is 75% trimellitate and 25% polya-olefin composite

85.2425%

The mass ratio is 45% petroleum barium silicate and 55% imidazoline derivative compound

0.85%

Mass ratio of 45% alkylphenol phosphite and 55% phenyl-a-naphthylamine composite

1.25%

Combination of 25% benzotriazole fatty acid amine salt and 75% oleic acid oxalate by mass ratio

2.5%

Combination of 45% triformyl phosphate and 55% vulcanized tetrapropylene

4.5%

Compound of 45% benzotriazole derivatives and 55% thiadiazole derivatives by mass

0.75%

Mass ratio of 45% alkyl phosphite and 55% ethyl palmitate

0.9%

The mass ratio is 45% of simethicone and 55% of acrylate and ether copolymer

0.0075%

The mass ratio of 45% of methyl benzotriazole and 55% of molybdenum dithiophosphate composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com