High-insulation easily-rheological thermocouple boron nitride-based filling material and filling method

A technology of filling materials and boron nitride, which is applied in the direction of insulators, inorganic insulators, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve problems such as the inability to ensure effective insulation of thermocouples, and achieve stable and reliable quality. Simple, rheologically enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (a) Mix 85 parts of boron nitride, 15 parts of glass powder, and 1.5 parts of binder to form a mixed powder;

[0025] (b) One-step grinding of the mixed powder;

[0026] (c) Weighing the ground mixed powder and putting it into a tablet press to prepare a filling material block;

[0027] (d) Put the filling material block and thermocouple wire into the stainless steel casing, set the temperature rise program for heat treatment and drawing.

Embodiment 2

[0028] Embodiment 2: 80 parts of boron nitride, 10 parts of glass micropowder, and 1 part of binder are mixed evenly to form a mixed powder;

[0029] (a) One-step grinding of the mixed powder;

[0030] (c) Weighing the ground mixed powder and putting it into a tablet press to prepare a filling material block;

[0031] (d) Put the filling material block and thermocouple wire into the stainless steel casing, set the temperature rise program for heat treatment and drawing.

Embodiment 3

[0033] (a) 90 parts of boron nitride, 20 parts of glass powder, and 2 parts of binder;

[0034] (a) One-step grinding of the mixed powder;

[0035] (c) Weighing the ground mixed powder and putting it into a tablet press to prepare a filling material block;

[0036] (d) Put the filling material block and thermocouple wire into the stainless steel casing, set the temperature rise program for heat treatment and drawing.

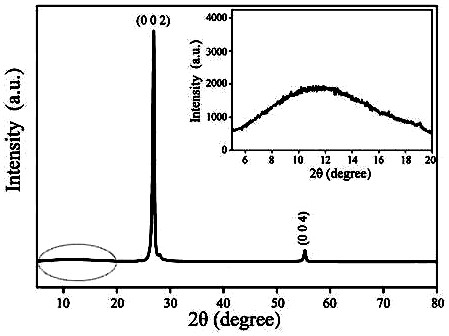

[0037] Boron nitride is h-BN layered structure powder, the size of h-BN layered structure powder is 5-8μm, and the coefficient of thermal expansion (CTE) is 10.3×10-6 K-1. The thermal expansion coefficient and particle size of glass micropowder are selected to match, such as SiO2-Na2O-K2O3 system.

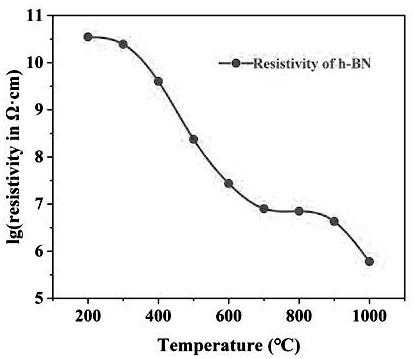

[0038] combined with figure 1 And attached figure 2 As shown, the h-BN layered structure micropowder is a polar covalent bond system, there is an intermolecular force between the layers, and there are no free electrons in the h-BN crystal layer structure, so it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com