Method for preparing nano calcium carbonate with low viscosity and medium thixotropic property

A nano-calcium carbonate, low-viscosity technology, applied in the treatment of dyed low-molecular-weight organic compounds, dyed high-molecular organic compounds, fibrous fillers, etc. problems, to achieve the effect of good product dispersion, reasonable process, and easy control of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

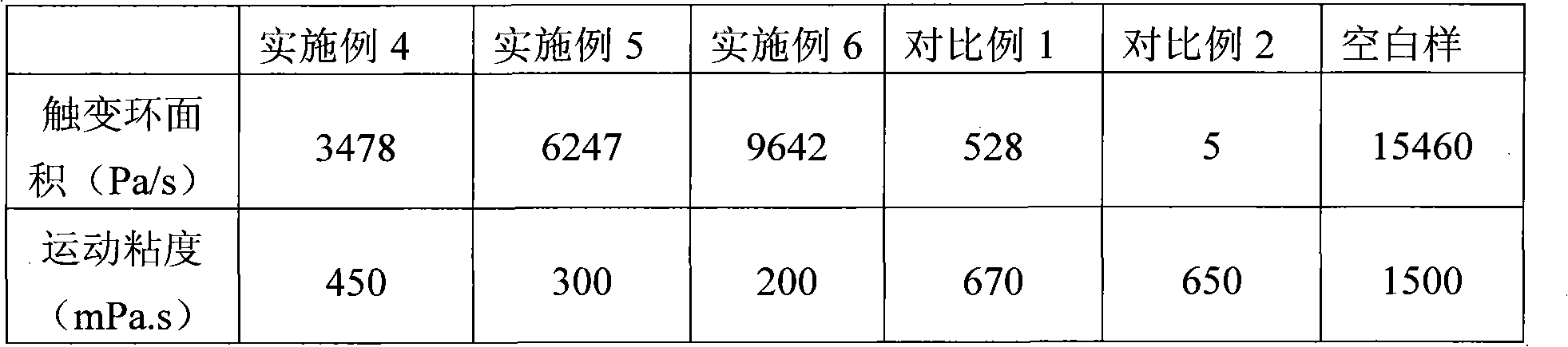

Embodiment 1

[0025] After the limestone is cleaned, it is transferred to the kiln, calcined at 1000°C, and digested with water at 80°C to obtain 10% Ca(OH) 2 slurry; the Ca(OH) 2 Put the slurry into a proprietary membrane dispersion carbonization reactor, add 1.5% crystal form control agent, and pass through 30% (v) CO 2 Control the temperature at 20°C for carbonization. When the pH value drops to 6.8, continue to ventilate for 8 minutes to obtain the original slurry of nano-calcium carbonate, and ensure that the apparent sedimentation volume of each 100ml slurry is 85-99ml in three hours. Add 8% (accounting for fatty acid) caustic soda and saponification in 70°C water to 3% (accounting for dry basis nano-calcium carbonate) fatty acid, react for 20min, form 6% saponification liquid, add 2% (accounting for dry basis) to the above-mentioned saponification liquid Nano calcium carbonate) polyester dispersant; the specific surface area of the powder after drying is preferably 20-40m 2 / g sl...

Embodiment 2

[0027] After the limestone is cleaned, it is transferred to the kiln, calcined at 1200°C, and digested with water at 100°C to obtain 15% Ca(OH) 2 slurry; the Ca(OH) 2 Put the slurry into a proprietary membrane dispersion carbonization reactor, add 2.5% sugar crystal form control agent sucrose, beet sugar, maltose or a mixture of more than one, and pass through 50% (v) CO 2 Control the temperature at 30°C for carbonization. When the pH value drops to 7.0, continue to ventilate for 10 minutes to obtain the original slurry of nano-calcium carbonate, and ensure that the apparent sedimentation volume per 100ml of slurry is 85-99ml in three hours. Add 14% (accounting for fatty acid) caustic soda and saponification in 80°C water to 6% (accounting for dry basis nano-calcium carbonate) fatty acid, react for 30min, form 1% saponification liquid, add 0.1% (accounting for dry basis) to the above saponification liquid Nano calcium carbonate) polyester dispersant; the specific surface area...

Embodiment 3

[0029] After the limestone is cleaned, it is transferred to the kiln, calcined at 800°C, and digested with water at 70°C to obtain 5% Ca(OH) 2 slurry; the Ca(OH) 2 Put the slurry into a proprietary membrane dispersion carbonization reactor, add 0.1% crystal form control agent, and pass through 15% (v) CO 2 Control the temperature at 5°C for carbonization. When the pH value drops to 6.5, continue to ventilate for 5 minutes to obtain the original slurry of nano-calcium carbonate, and ensure that the apparent sedimentation volume per 100ml of slurry is 85-99ml in three hours. Add 5% (accounting for fatty acid) caustic soda and saponification in 60°C water to 0.5% (accounting for dry basis nano-calcium carbonate) fatty acid, react for 10min, form 10% saponification liquid, add 10% (accounting for dry basis) to the above saponification liquid Nano calcium carbonate) polyester dispersant; the specific surface area of the powder after drying is preferably 20-40m 2 / g slurry, heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com