Formula and method for preparing anode steel talon protection ring

A technology for anode steel claw and protection ring, which is applied to the formulation and preparation field of anode steel claw protection ring, can solve the problems of rising energy consumption of electrolysis production, loss of protection of anode steel claw, affecting the life of an electrolytic cell, etc., so as to reduce the cost of raw materials , The effect of reducing the sintering temperature and improving the fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

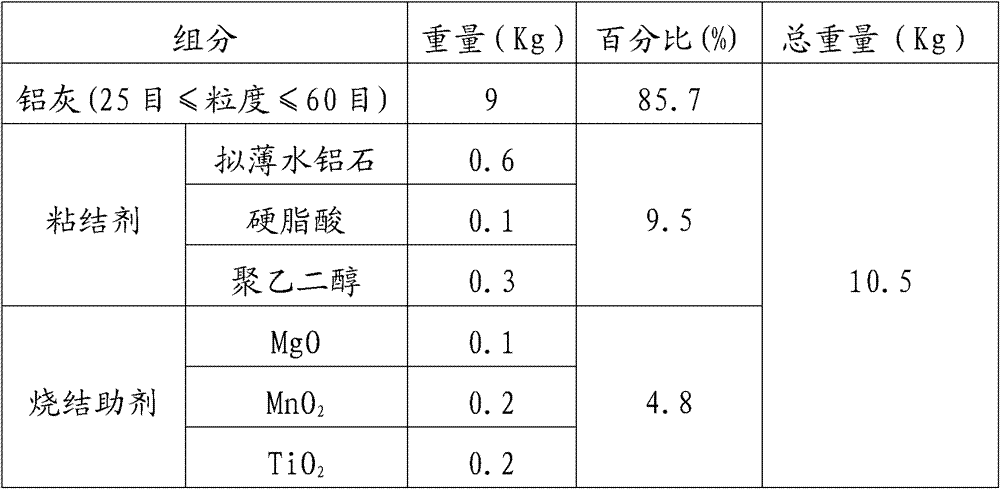

[0028] Recipe for preparing anode steel claw guard rings:

[0029]

[0030] The preparation method is as follows:

[0031] (1) Ball milling: Grind the aluminum ash in a ball mill for 1-2 hours, sieve the aluminum ash after grinding, and weigh 9kg of aluminum ash below 30 mesh;

[0032] (2) Mixing: add an appropriate amount of water to the binder in Example 1, stir evenly, and mix and stir with the sieved aluminum ash for 0.5 hour to make a slurry;

[0033] (3) Degassing: let the slurry stand for 1-2 hours, until no air bubbles are discharged, add the sintering aid described in Example 1, and stir evenly. After testing, the solid content of the slurry is 60%, and the viscosity is 960Pa·s;

[0034] (4) Forming: inject the slurry into the mold of the anode protection ring, pressurize at 10-15MPa, and keep for 10-30 seconds to obtain the raw material of the anode steel claw protection ring;

[0035] (5) Drying: After demoulding, dry the green body in an oven at 105°C for 2 h...

Embodiment 2

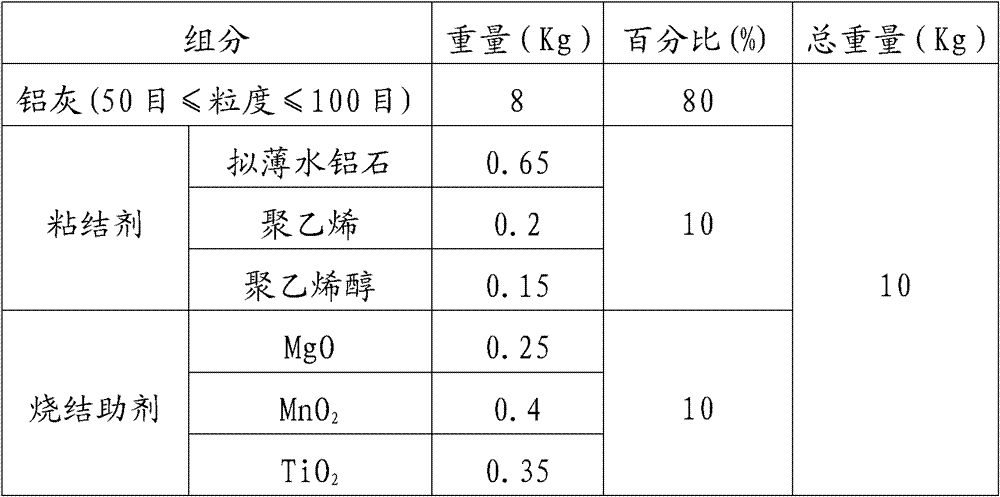

[0038] Recipe for preparing anode steel claw guard rings:

[0039]

[0040] The preparation method is as follows:

[0041] (1) Ball milling: Grind the aluminum ash in a ball mill for 1-2 hours, sieve the aluminum ash after grinding, and weigh 8kg of aluminum ash below 100 mesh;

[0042] (2) Mixing: add an appropriate amount of water to the binder in Example 2, stir evenly, and mix and stir with the sieved aluminum ash for 0.5 hour to make a slurry;

[0043] (3) Degassing: let the slurry stand for 1-2 hours, until no air bubbles are discharged, add the sintering aid described in Example 2, and stir evenly. After testing, the solid content of the slurry is 61%, and the viscosity is 950Pa·s;

[0044] (4) Forming: inject the slurry into the mold of the anode protection ring, pressurize at 12-15MPa, and keep for 20-30 seconds to obtain the raw material of the anode steel claw protection ring;

[0045] (5) Drying: After demoulding, dry the green body in an oven at 100°C for 1....

Embodiment 3

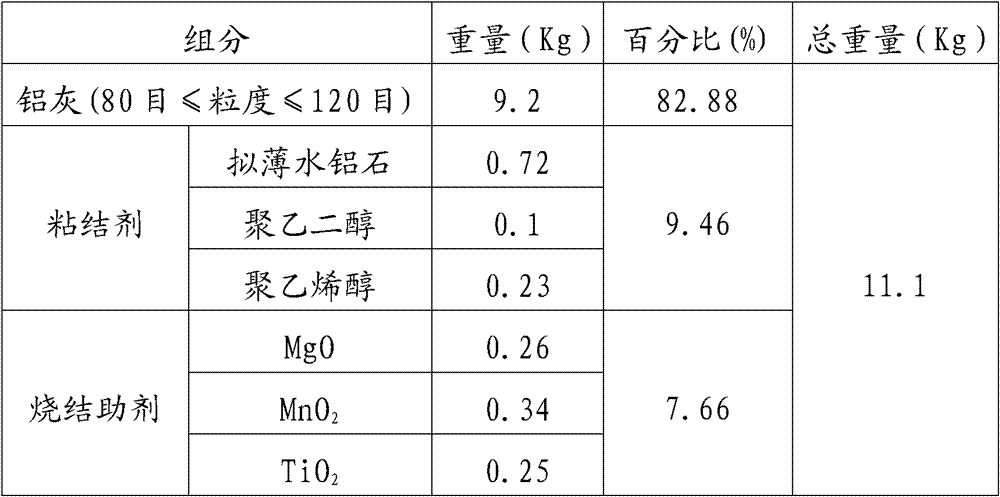

[0048] Recipe for preparing anode steel claw guard rings:

[0049]

[0050] The preparation method is as follows:

[0051] (1) Ball milling: Grind the aluminum ash in a ball mill for 1-2 hours, sieve the aluminum ash after grinding, and weigh 9.2kg of aluminum ash below 120 mesh;

[0052] (2) Mixing: Add an appropriate amount of water to the binder in Example 3, stir evenly, mix and stir with the sieved aluminum ash for 0.5 hour, and make a slurry;

[0053] (3) Degassing: let the slurry stand for 1-2 hours, until no air bubbles are discharged, add the sintering aid described in Example 3, and stir evenly. After testing, the solid content of the slurry is 72%, and the viscosity is 940Pa·s;

[0054] (4) Forming: inject the slurry into the mold of the anode protection ring, pressurize at 10-13MPa, and keep for 20-30 seconds to obtain the raw material of the anode steel claw protection ring;

[0055] (5) Drying: After demoulding, dry the green body in an oven at 85°C for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com