Patents

Literature

314results about How to "Simple process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

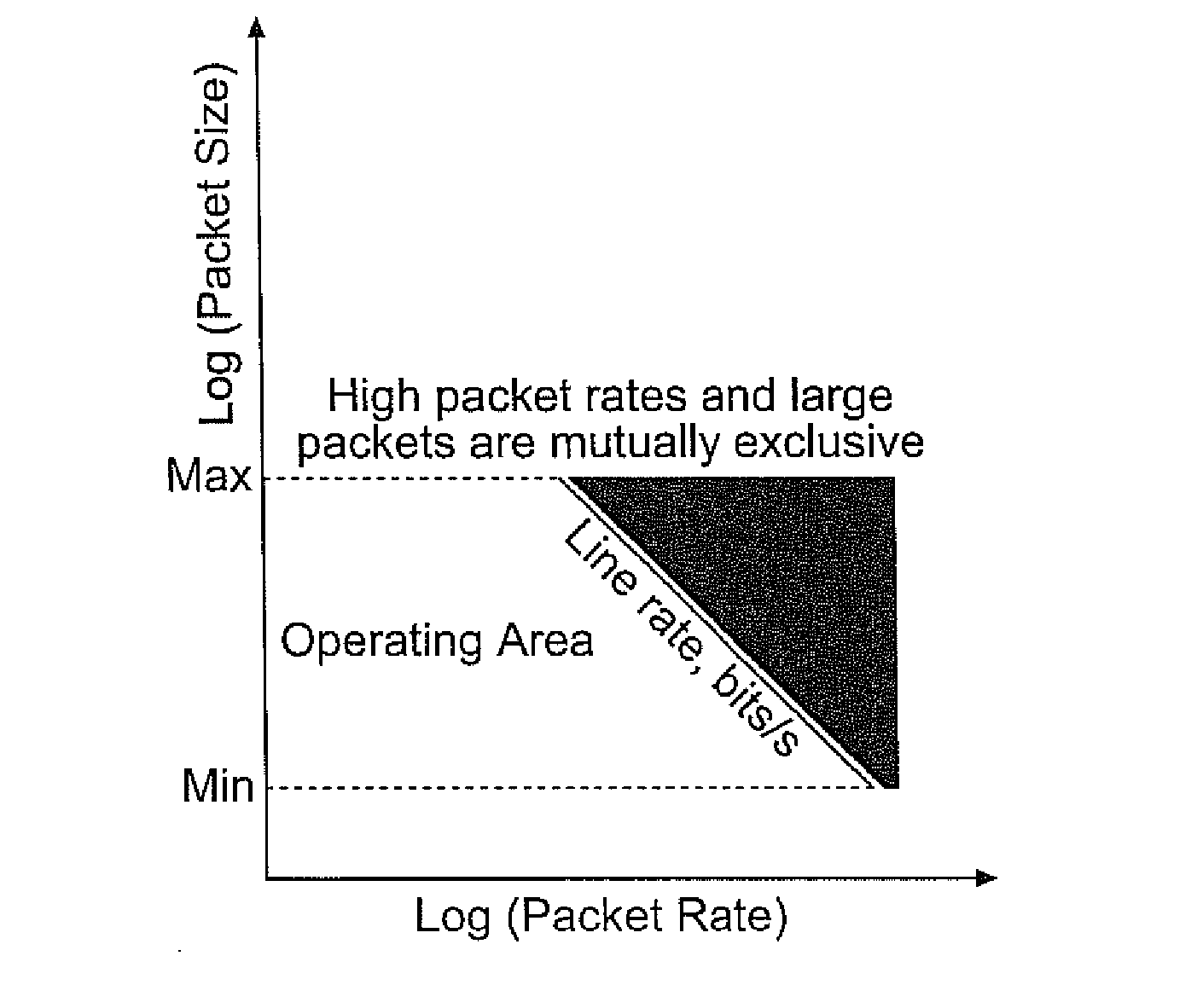

High-throughput, low-latency next generation internet networks using optical tag switching

InactiveUS6111673AEfficient comprehensive utilizationSignificant overheadMultiplex system selection arrangementsLaser detailsSignal routingInternet network

An optical signaling header technique applicable to optical networks wherein packet routing information is embedded in the same channel or wavelength as the data payload so that both the header and data payload propagate through network elements with the same path and the associated delays. The header routing information has sufficiently different characteristics from the data payload so that the signaling header can be detected without being affected by the data payload, and that the signaling header can also be removed without affecting the data payload. The signal routing technique can be overlaid onto the conventional network elements in a modular manner using two types of applique modules. The first type effects header encoding and decoding at the entry and exit points of the data payload into and out of the network; the second type effects header detection at each of the network elements.

Owner:RGT UNIV OF CALIFORNIA +1

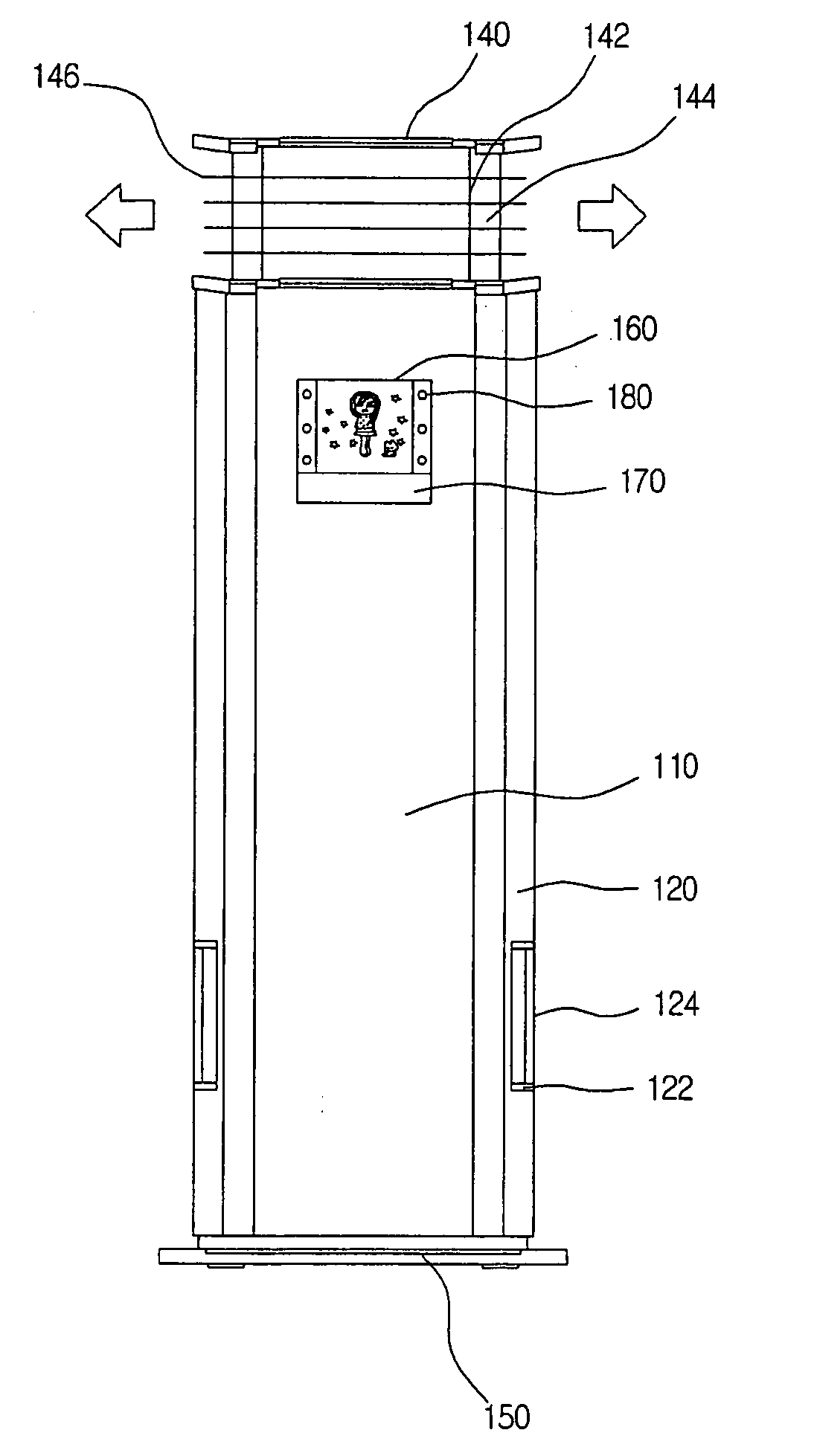

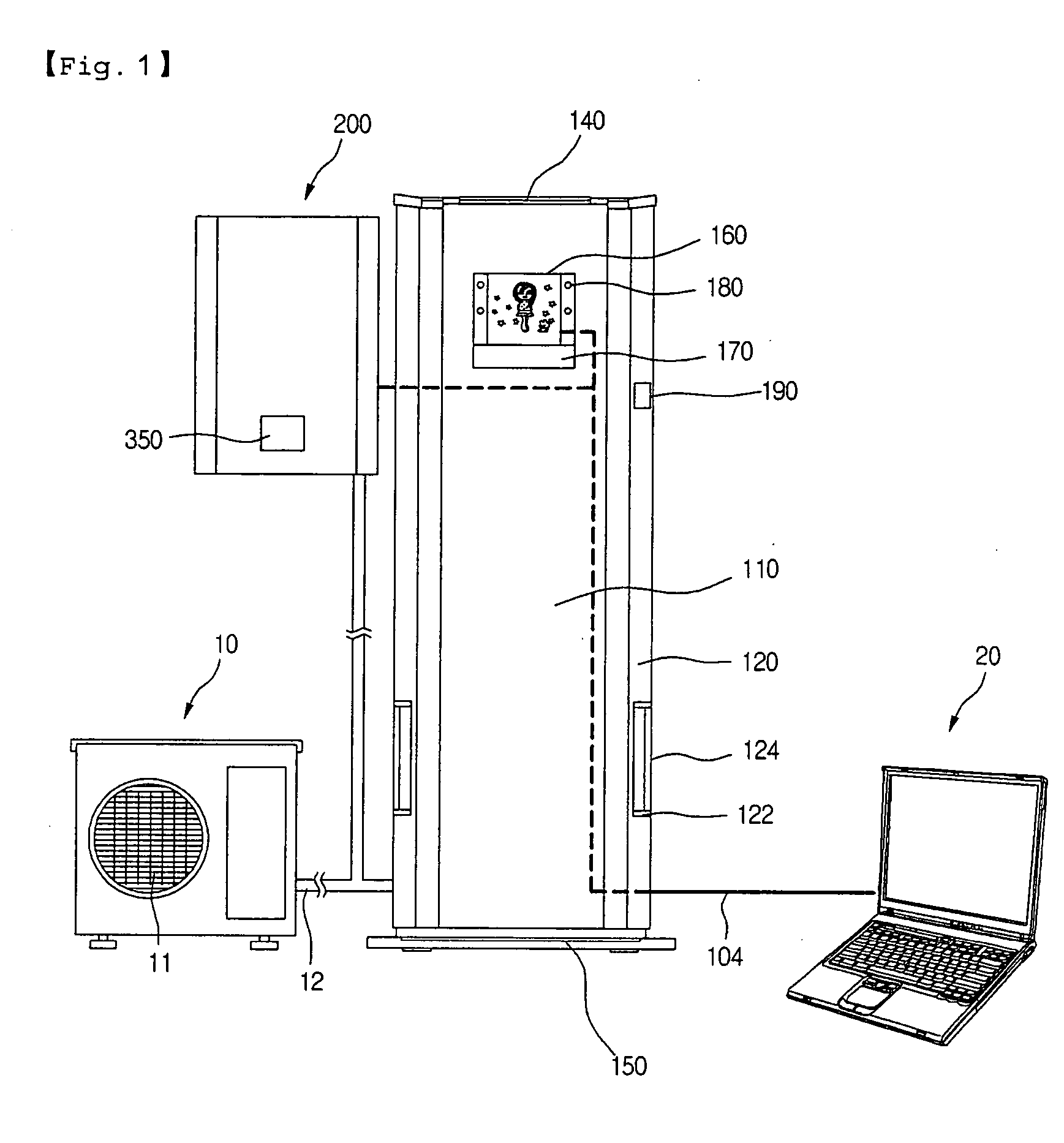

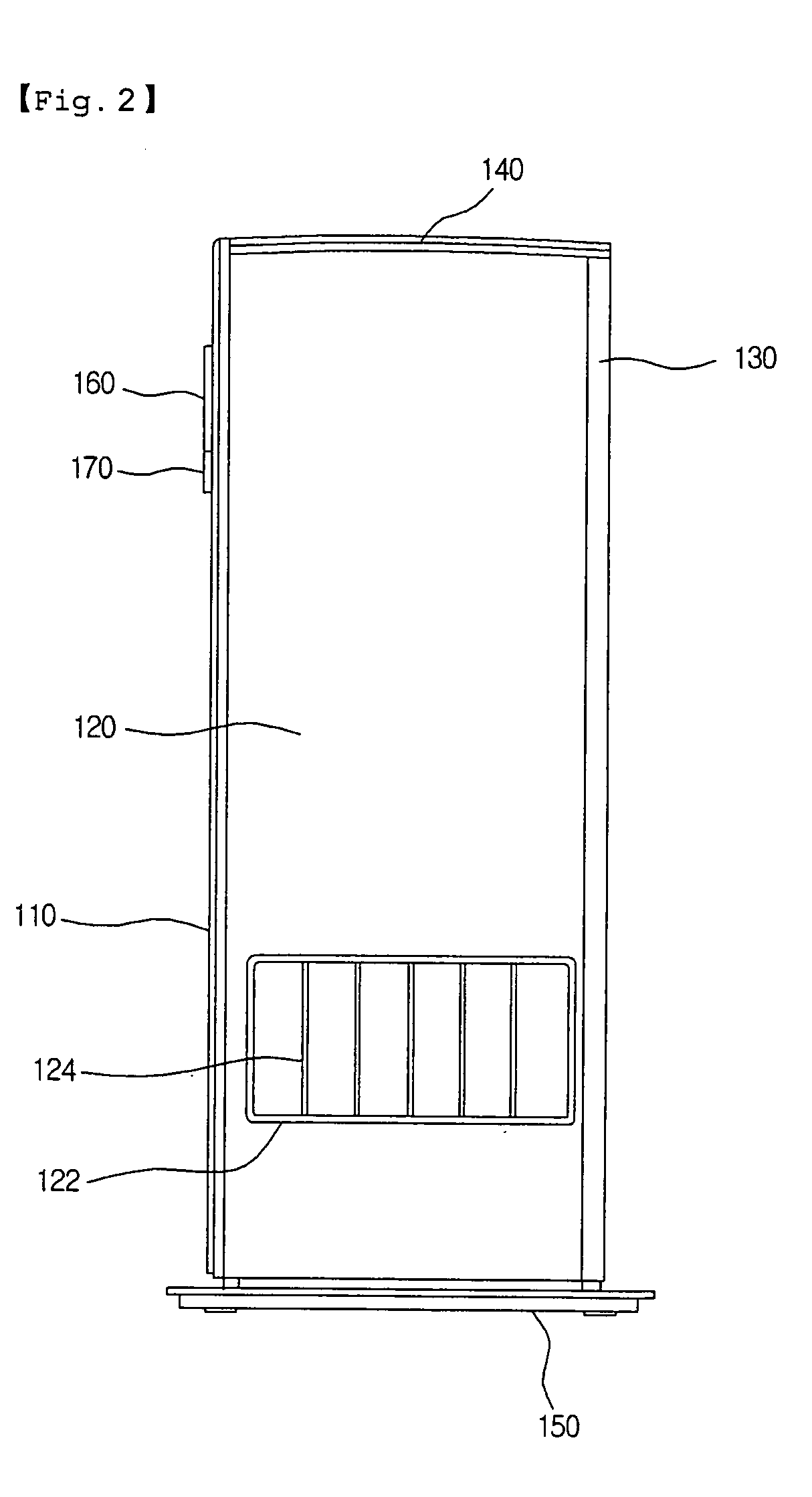

Air conditioner having an enhanced user perception

InactiveUS20050109048A1Improve satisfactionSatisfying greatMechanical apparatusSpace heating and ventilation safety systemsUser perceptionUsers perceptions

An air conditioner having an enhanced user perception and a controlling method thereof are provided. A predetermined character and / or its applied character image are / is displayed on a display window of the air conditioner. The character and / or the character image are / is changed depending on the operational states of the air conditioner, so that the user perceives the operational state of the air conditioner more conveniently. The air conditioner has advantages in that the user can perceive the operational state of the air conditioner more conveniently, the user can be stimulated to purchase the product, and a use term of the air conditioner can be extended.

Owner:LG ELECTRONICS INC

Method for extracting high-content mogroside V from dried momordica grosvenori swingle

The invention discloses a method for extracting high-content mogroside V from dried momordica grosvenori swingle. The extraction technique includes the following steps: extraction, concentration, filtration, adsorption, decoloration, concentration and drying, so that the mogroside V product is obtained. The method adopts the dried momordica grosvenori swingle as material for production, the content of the obtained product is high, the taste and the color are good, the adopted equipment required by the technique is simple, continuous production can be carried out, and moreover, because the used solvents are ethanol and water, no pollution is generated.

Owner:HILL PHARMA

Flocked articles and methods of making same

InactiveUS7351368B2Raise the possibilityGreat formability possibilityLiquid surface applicatorsMouldsEngineering

A method of manufacturing a molded article using lamination of a flocked surface onto a backing film is provided. Also provided is a flocked article comprising an antimicrobial agent.

Owner:HIGH VOLTAGE GRAPHICS

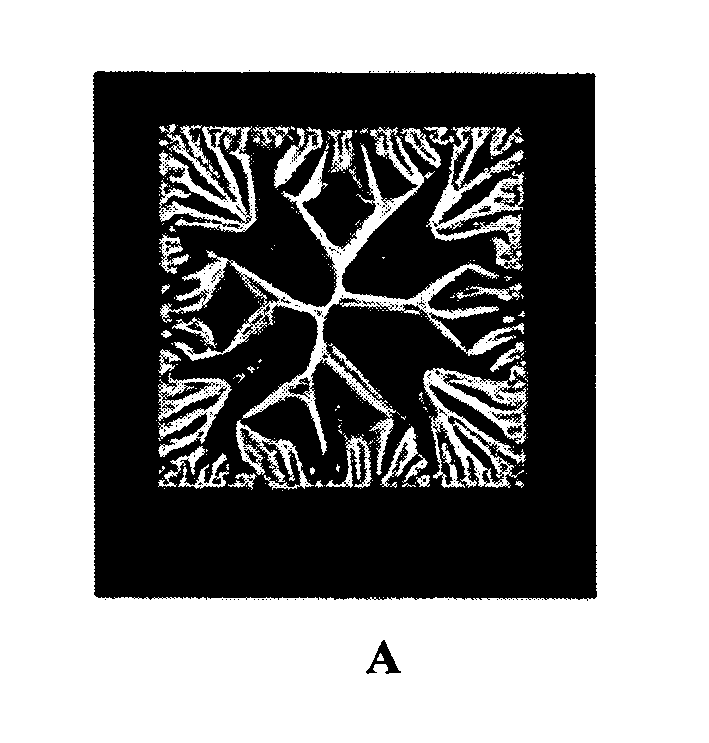

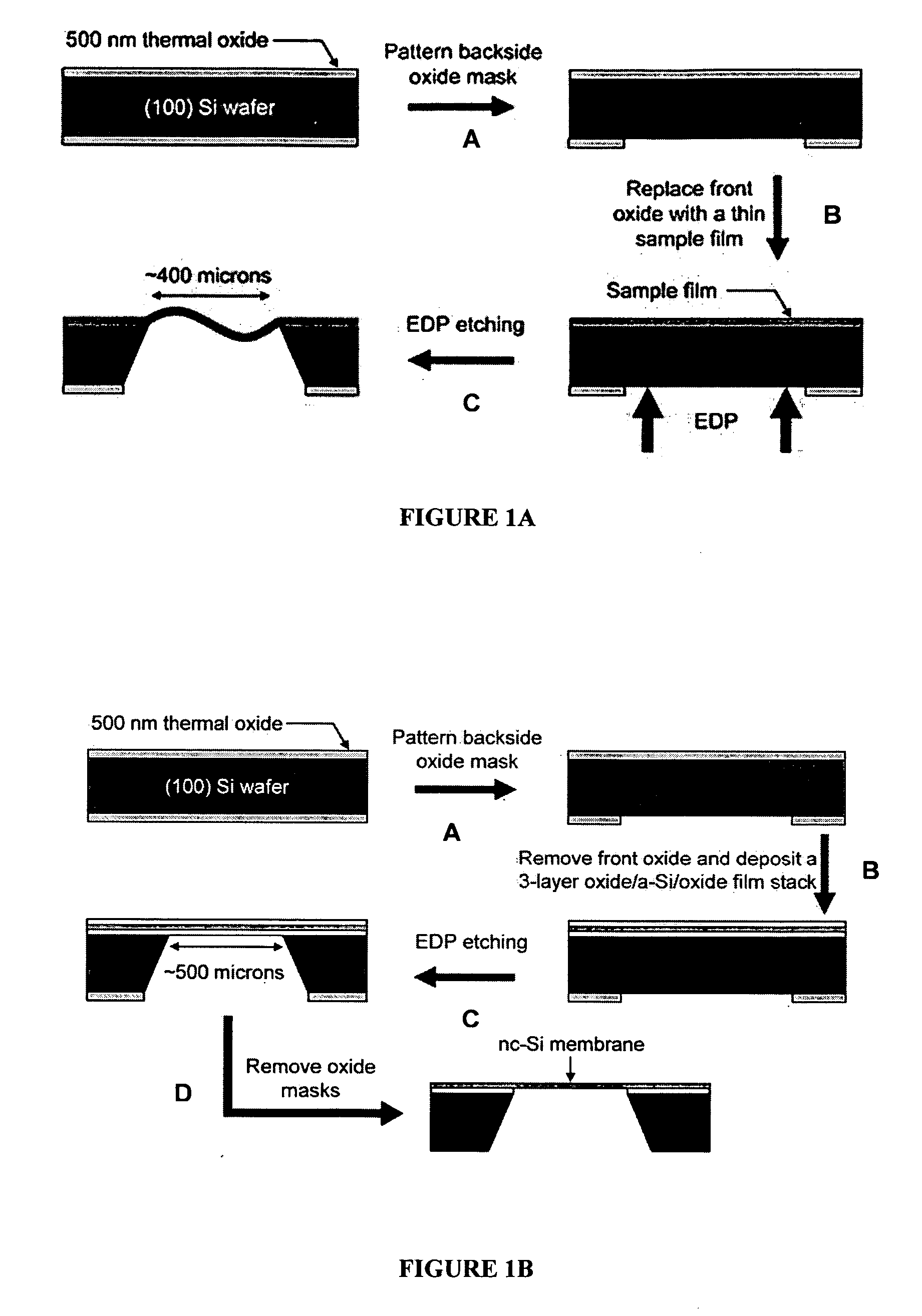

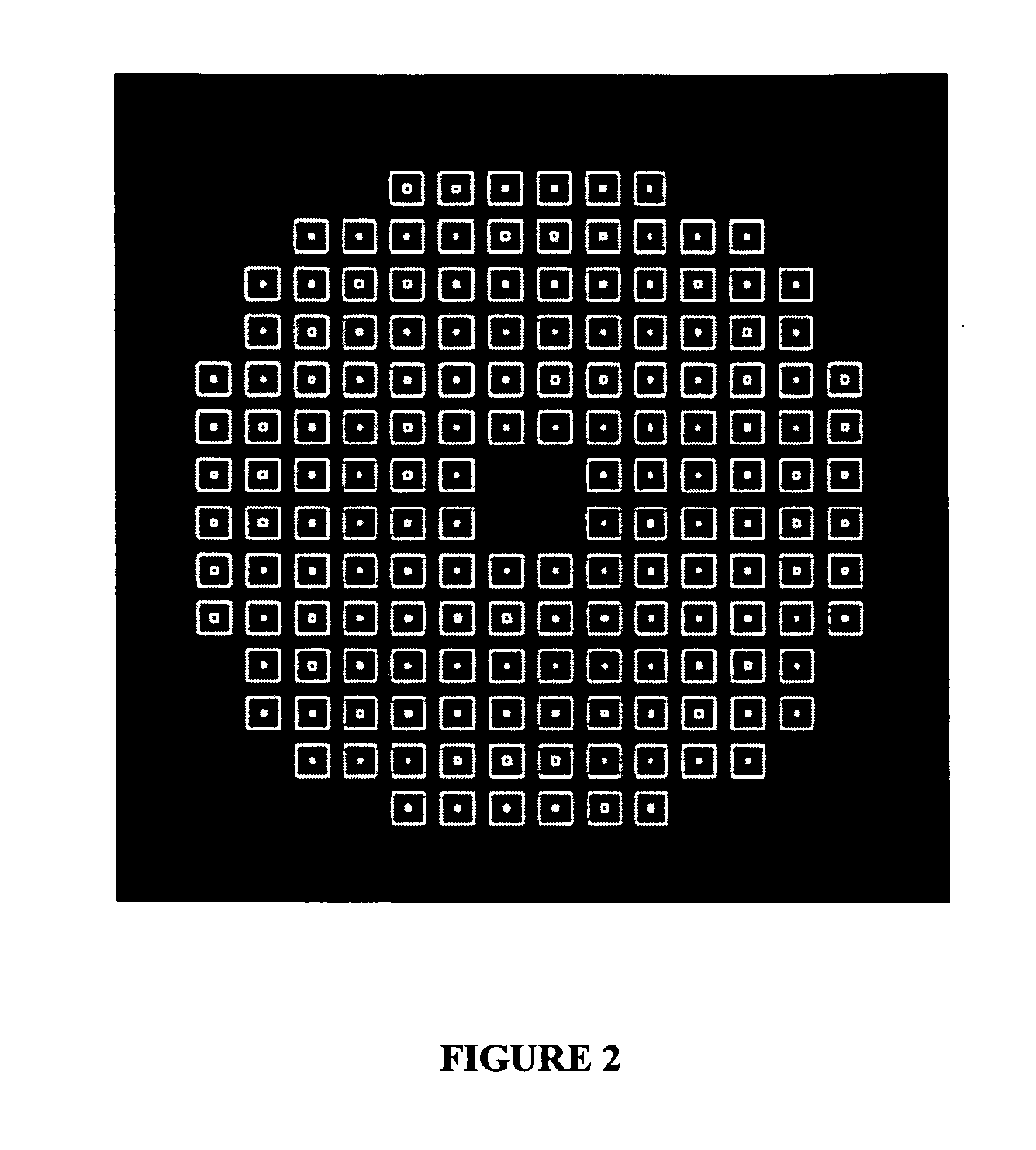

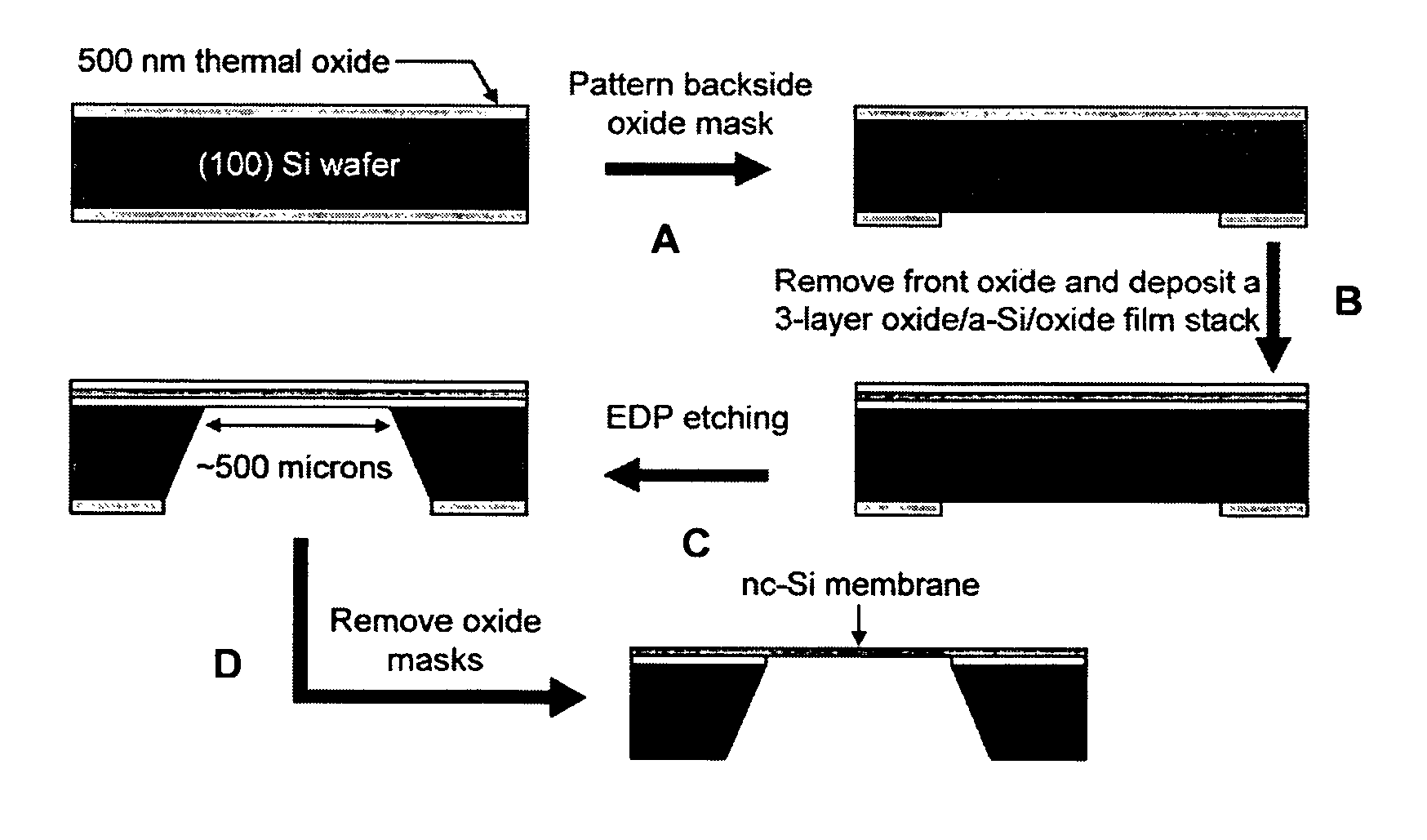

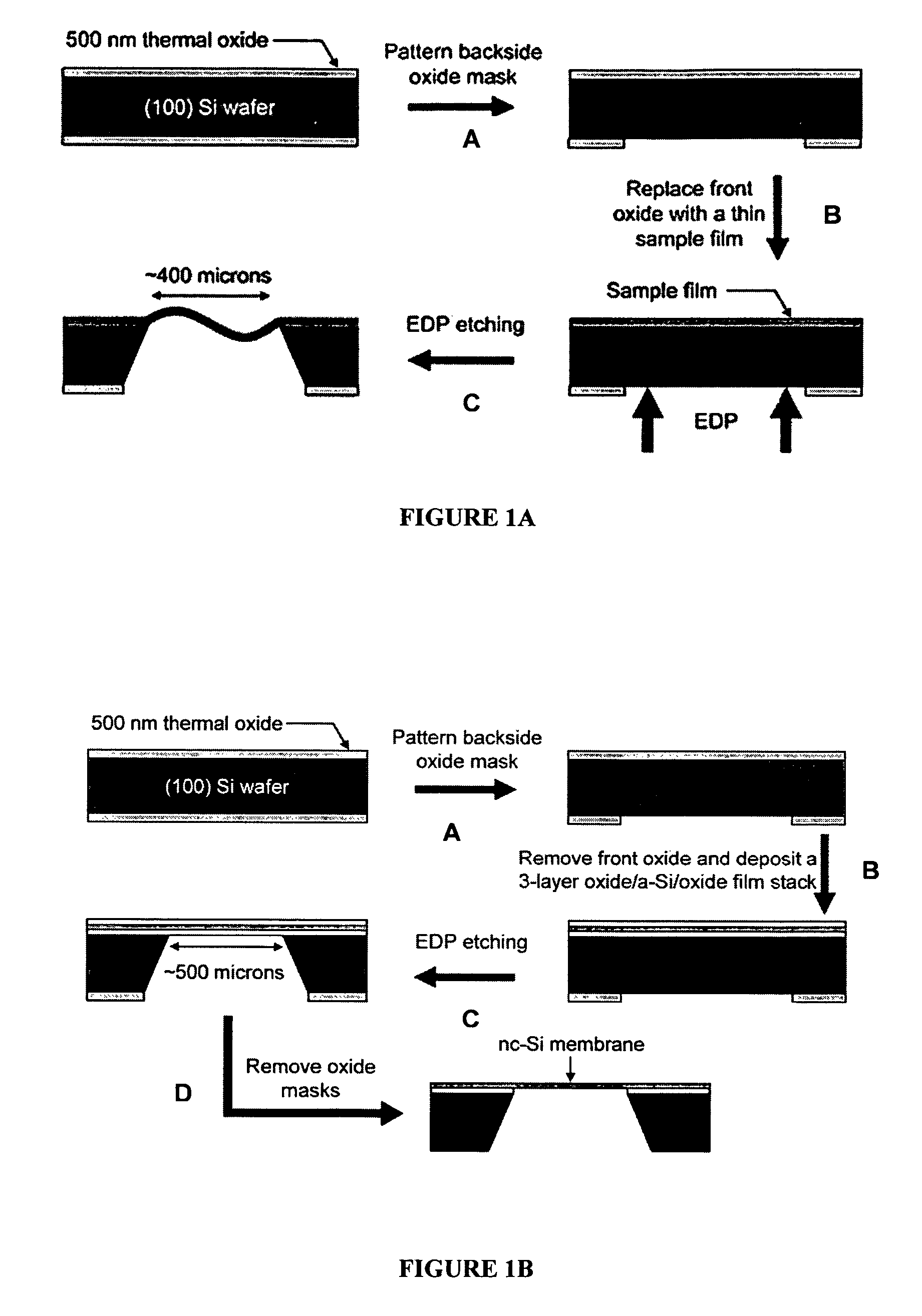

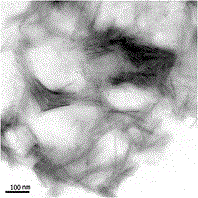

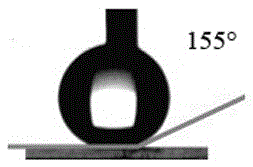

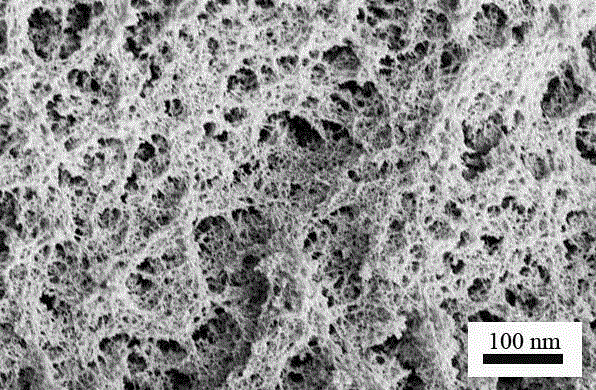

Ultrathin nanoscale membranes, methods of making, and uses thereof

ActiveUS20060243655A1Simple process requirementsAccessiblePaper/cardboard articlesFuel cell auxillariesFuel cellsElectron microscope

A nanoscale membrane exposed on opposite sides thereof and having an average thickness of less than about 100 nm, and a lateral length to thickness aspect ratio that is more than 10,000 to 1 is disclosed. Also disclosed are methods of making such membranes, and use thereof in a number of devices including fuel cells, sensor devices, electrospray devices, and supports for examining a sample under electron microscopy.

Owner:UNIVERSITY OF ROCHESTER

Method of continuously preparing 1,2-dihydroxypropane by glycerin catalytic hydrogenation

The invention discloses a making method of 1, 2-propanediol under mild condition, which is characterized by the following: adopting copper, zinc and manganese and or aluminium catalyst; aerating glycerin and hydrogen continuously from the top of reactor; hydrogenating glycerin at 200-250 deg.c under 2.5-5Mpa; outputting and collecting reacting product from the bottom of reactor continuously; separating gas; returning to recycle; setting the weight rate of metal element of catalyst at 16-48:24-48:0.15-4:0-8.

Owner:NANJING TECH UNIV

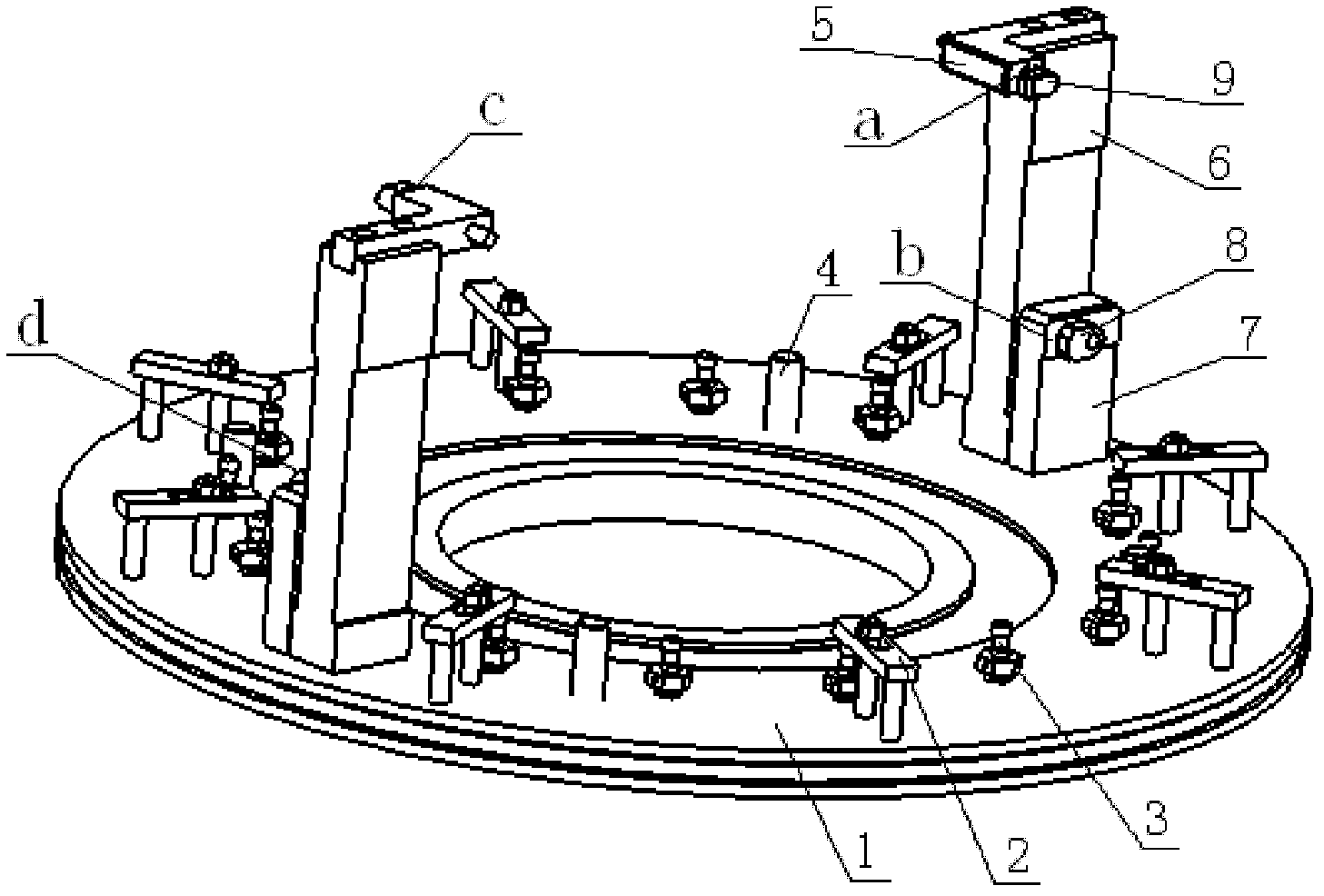

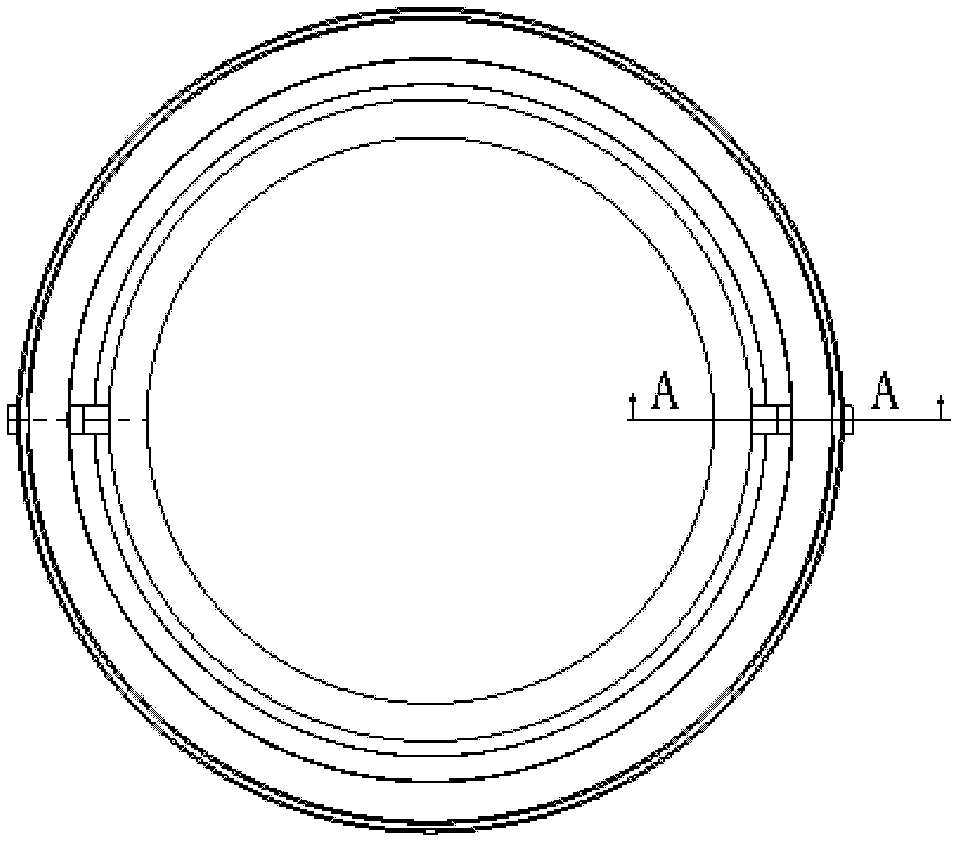

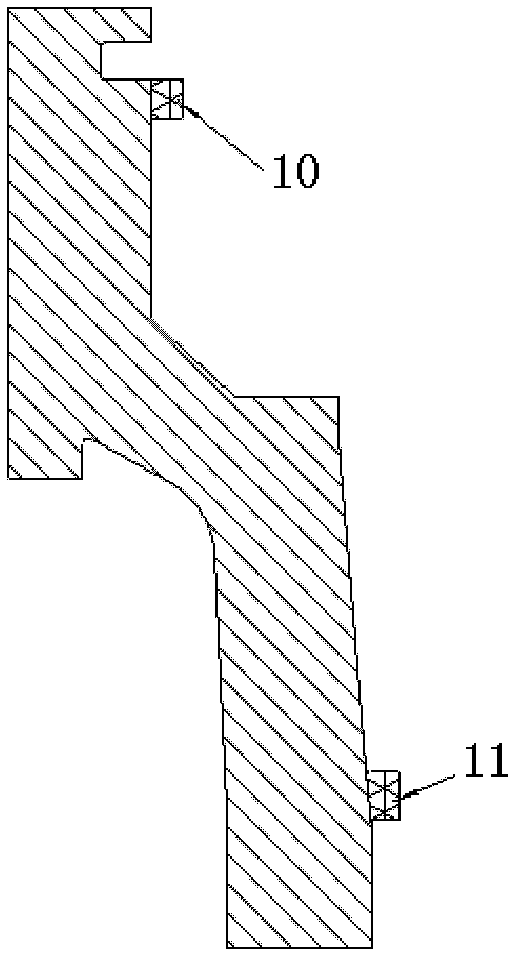

Technical method for constructing reference surface of assembled folio cartridge receiver and special clamp

ActiveCN102513803AReasonable layoutCompact structurePositioning apparatusMetal-working holdersCentrosymmetryMachining

The invention provides a technical method for constructing a reference surface of an assembled folio cartridge receiver and a special clamp. The special clamp comprises a base, pressing plates, adjustable supports, support screws and two sets of positioning components, wherein each positioning component comprises a front-end positioning block, a front-end hook-shaped pressing plate, a connection block, a rear-end positioning block and a rear-end hook-shaped pressing plate; and the two sets of positioning components are in centrosymmetry about a central axis of the base. The technical process comprises the following steps of: performing rough turning machining on an annular blank of the folio cartridge receiver, retaining flange edges, splitting the annular piece of the cartridge receiver,cutting off the flange edges on different sides, fixing two half cartridge receivers on the special clamp, and constructing the reference surface of the assembled folio cartridge receiver by adjusting the clamp. Compared with the conventional method, the technical method has the advantages that: the technical requirement of the whole machining flow is easy to realize; the whole machining flow canbe finished on the vertical lathe; the machining efficiency is high; and the reference surface of the folio cartridge receiver is machined during one-time clamping.

Owner:AECC AVIATION POWER CO LTD

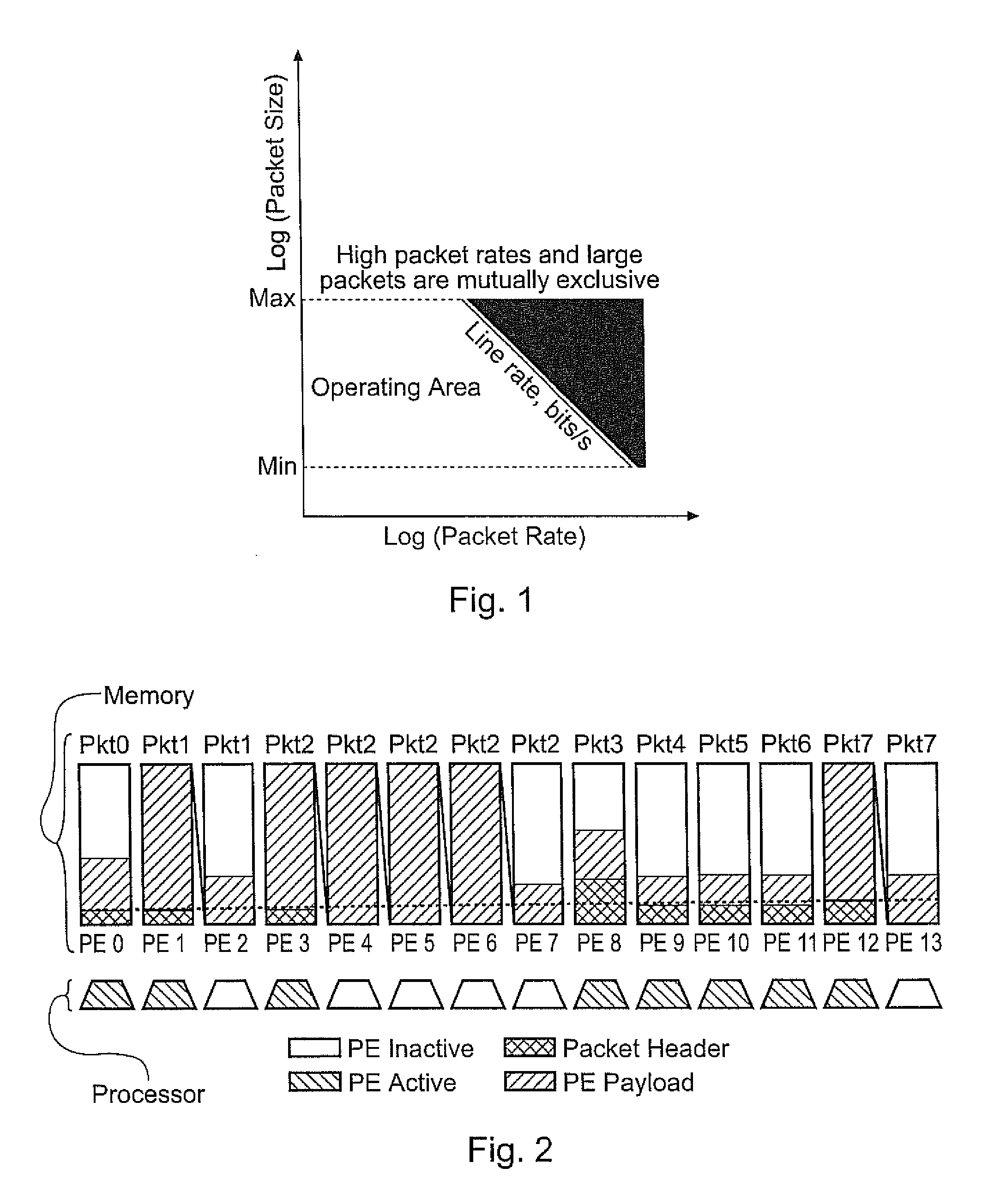

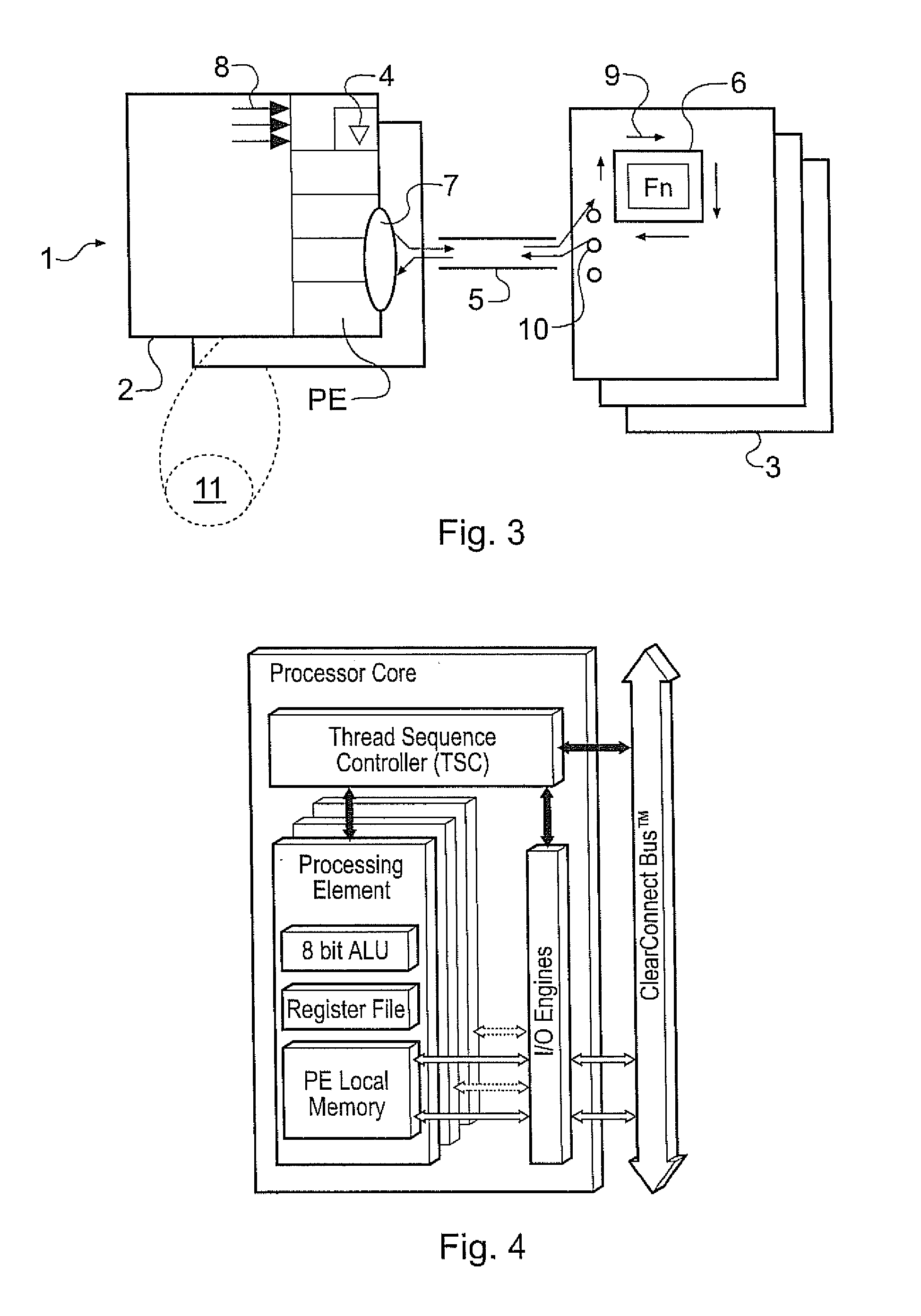

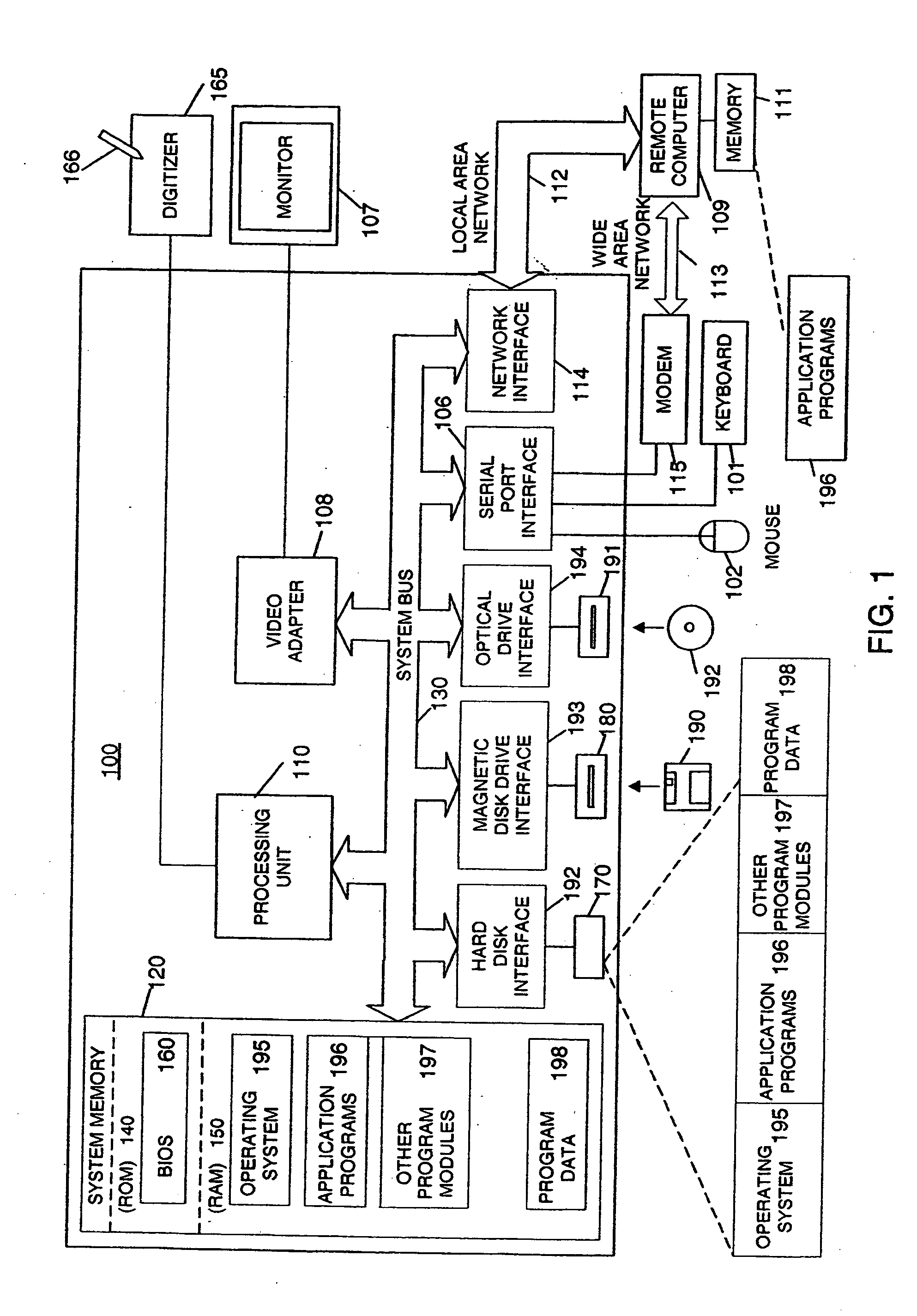

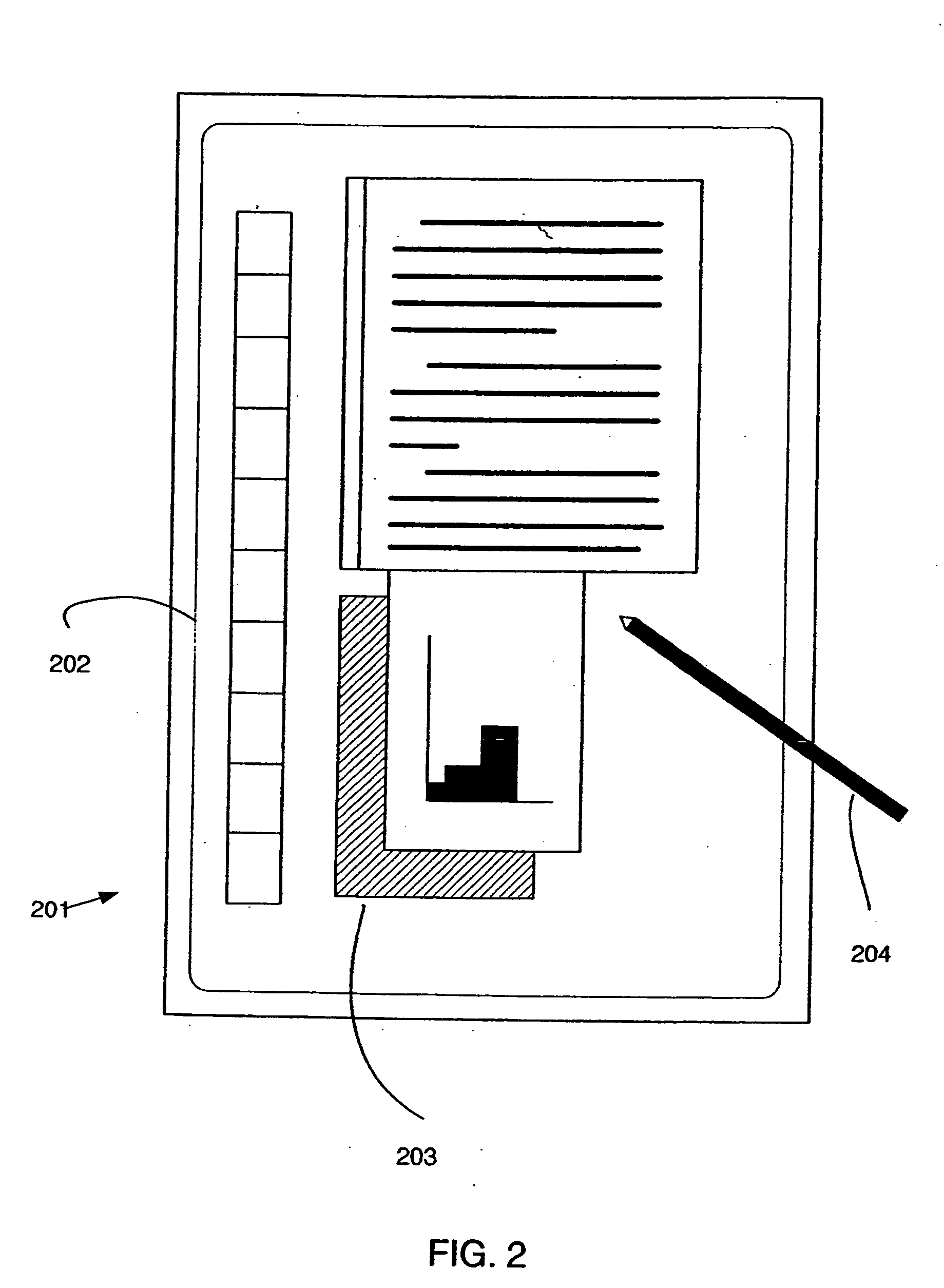

Data Processing Architectures

InactiveUS20070220232A1Increase data rateSimple process requirementsSingle instruction multiple data multiprocessorsData switching by path configurationProcessing elementInput device

A data processing architecture comprising: an input device for receiving an incoming stream of data packets; and a plurality of processing elements which are operable to process data received thereby; wherein the input device is operable to distribute data packets in whole or in part to the processing elements in dependence upon the data processing bandwidth of the processing elements.

Owner:RAMBUS INC

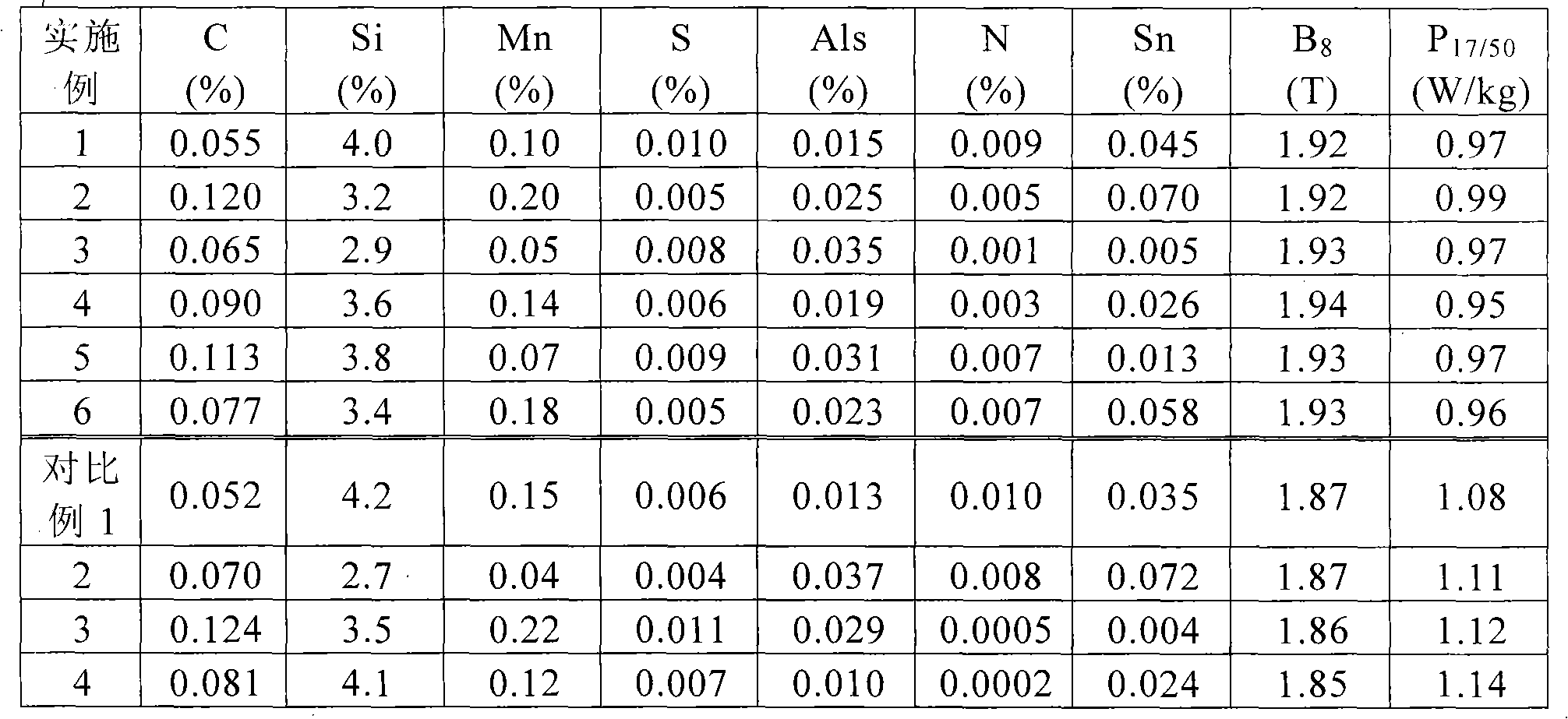

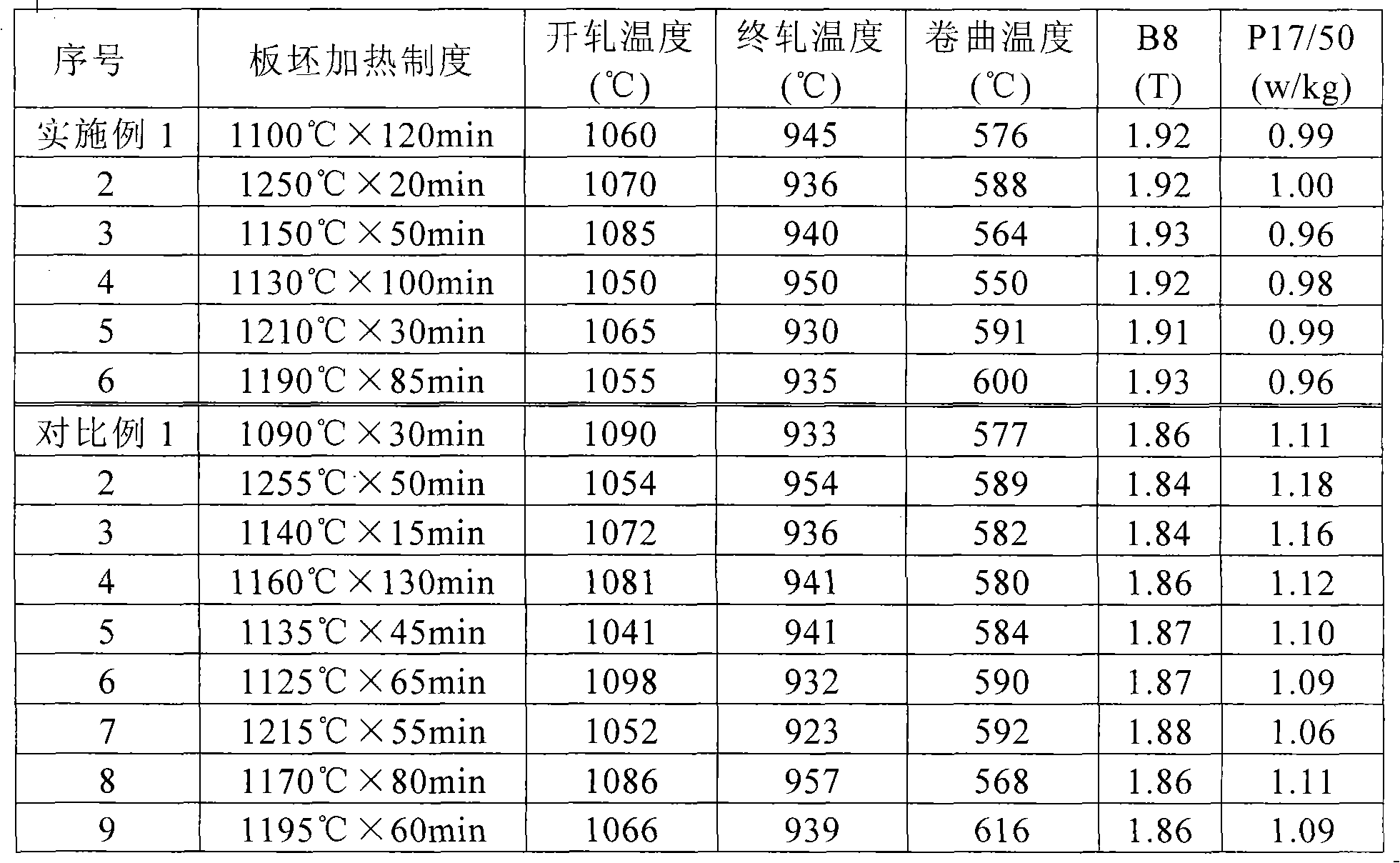

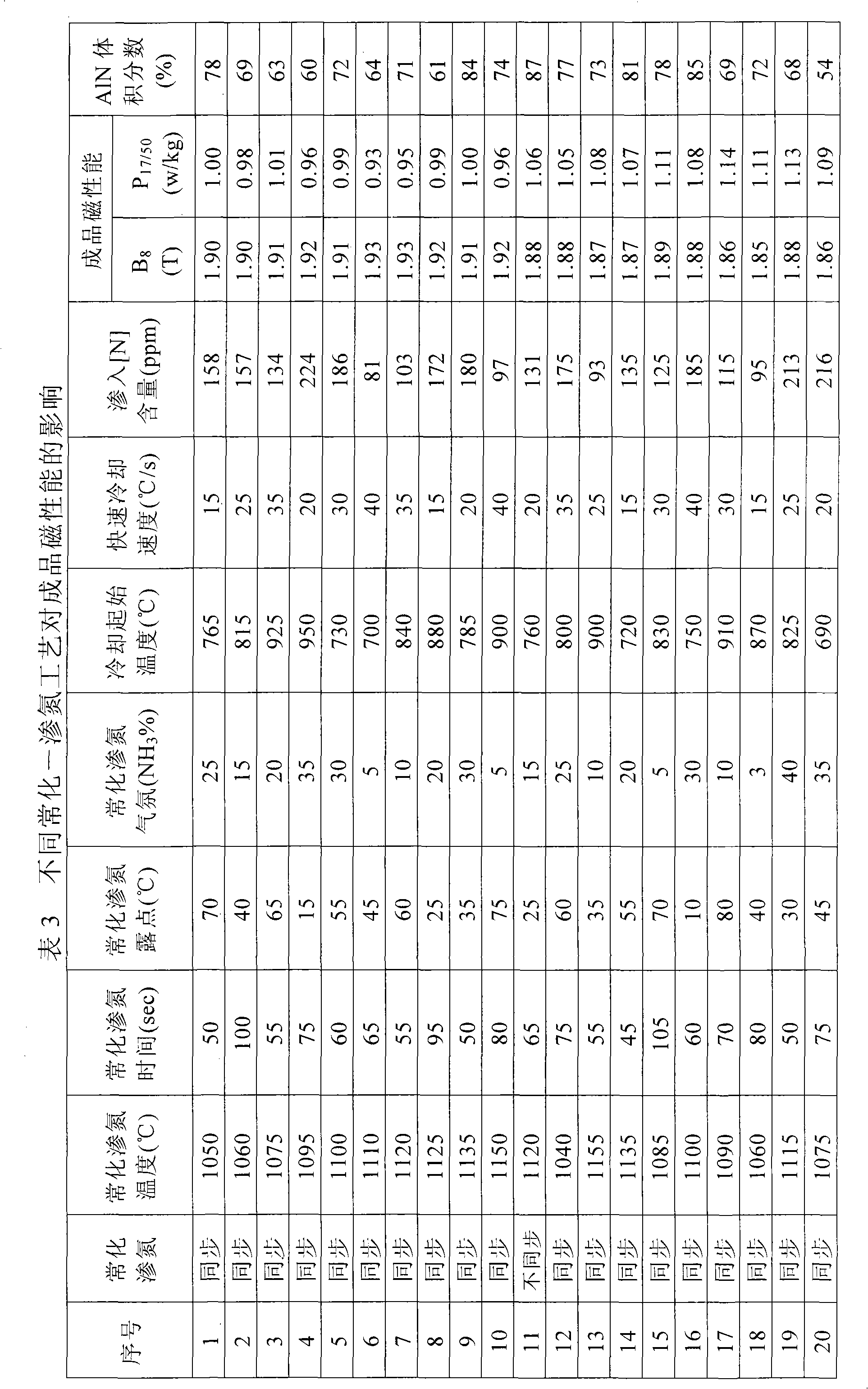

Production method of high magnetic induction oriented silicon steel

ActiveCN101845582AIncrease contentPrevent transverse crackingSolid state diffusion coatingSiliconAtmosphere

The invention relates to a production method of high magnetic induction oriented silicon steel, comprising the steps of smelting, continuous casting, hot rolling, normalization, decarbonization and annealing, MgO coating, high-temperature annealing and insulation coating, wherein the normalization comprises the steps that: normalization is carried out on a hot rolling plate, nitridation is finished synchronously, the temperature of normalization and nitridation is 1050-1150 DEG C, the atmosphere is 5-35% NH3 (volume percentage), and the balance of gas is N2; after the normalization and nitridation, the N content nitrided into the hot rolling plate is 60-250ppm; and normalization cooling is carried out, the initial temperature of fast cooling is 700-950 DEG C, and the fast cooling speed with the temperature of being reduced to 550 DEG C is 15-40 DEG C / sec. The production method solves the problem of difficult nitridation in the decarbonization procedure when a low-temperature plate blank heating technology is used for producing the high magnetic induction oriented silicon steel, carries out synchronous nitridation on the hot rolling plate in the normalization procedure, and leads the following procedure of decarbonization and annealing techniques to be simplified and easily controlled, thus not only being capable of obtaining a high magnetic induction oriented silicon steel product with excellent performance and simultaneously leading the production cost to be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultrathin nanoscale membranes, methods of making, and uses thereof

ActiveUS7922795B2Simple process requirementsAccessibleMembranesSemi-permeable membranesFuel cellsElectron microscope

A nanoscale membrane exposed on opposite sides thereof and having an average thickness of less than about 100 nm, and a lateral length to thickness aspect ratio that is more than 10,000 to 1 is disclosed. Also disclosed are methods of making such membranes, and use thereof in a number of devices including fuel cells, sensor devices, electrospray devices, and supports for examining a sample under electron microscopy.

Owner:UNIVERSITY OF ROCHESTER

Low-melting-point alloy with melting point being 40-60 DEG C and preparation method of low-melting-point alloy

The invention relates to the field of heat conduction materials and provides low-melting-point alloy. The low-melting-point alloy comprises, by mass, 47.0-50.8% of indium, 29.5-32.3% of bismuth, 13.5-16.3% of tin and 0.67-10% of gallium. A preparation method of the low-melting-point alloy comprises the steps that A, all the constituents are weighed according to requirements; B, the furnace temperature is increased to 350 DEG C, the bismuth and the tin are placed into a ceramic crucible, the ceramic crucible is placed into a smelting furnace to be heated, after the bismuth and the tin are melted, surface oxide is removed, and stirring is conducted; C, the furnace temperature is adjusted to 200 DEG C, the indium is added, and after the indium is completely melted, surface slagging-off and stirring are conducted; D, the furnace temperature is adjusted to 100 DEG C, the gallium is added, and slagging-off and standing are conducted after stirring; and E, the crucible is taken out, the alloy is poured into a mold, and cooling is conducted. The melting point of the low-melting-point alloy is 40-60 DEG C, the low-melting-point alloy is used for low-junction-temperature occasions in a phase-change mode, and the application space of liquid metal thermal interface materials is enlarged; harmful elements such as lead and cadmium are not contained in the low-melting-point alloy product, and environment protection is facilitated. The preparation method is simple in technological requirement, and the whole process can be conducted in the atmospheric environment.

Owner:SUZHOU TIANMAI THERMAL TECH

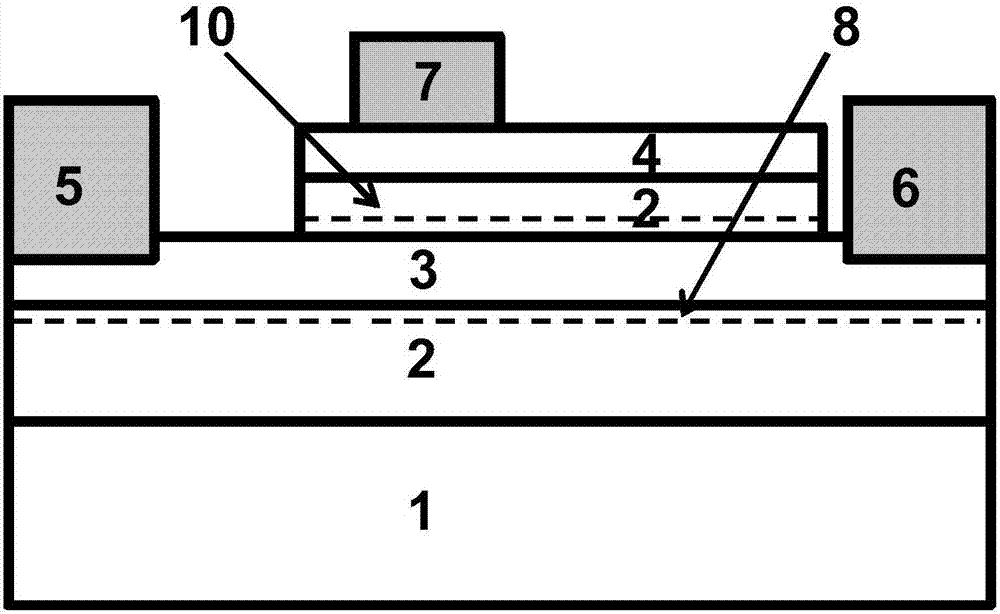

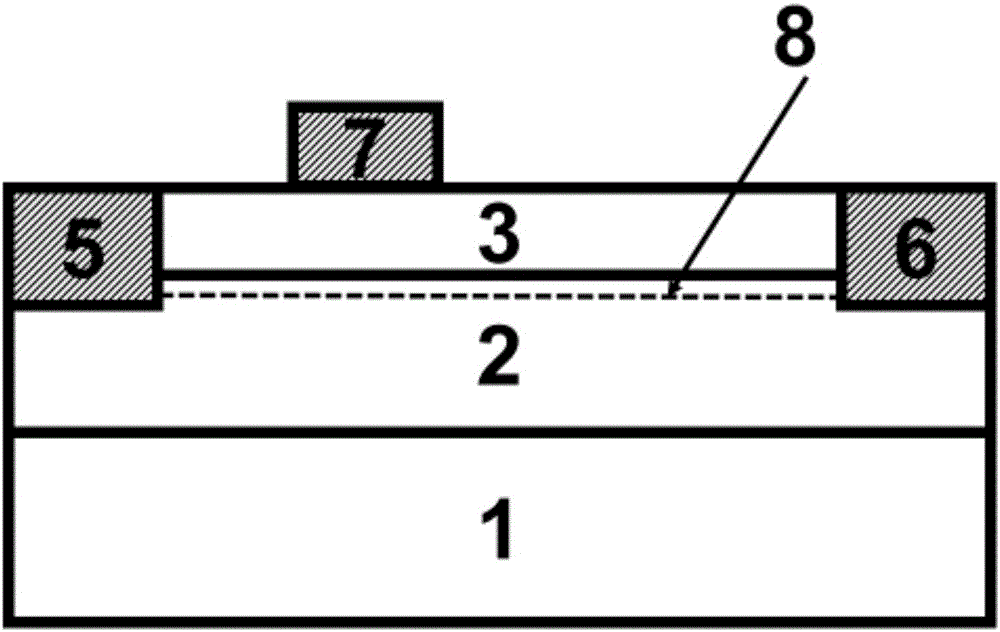

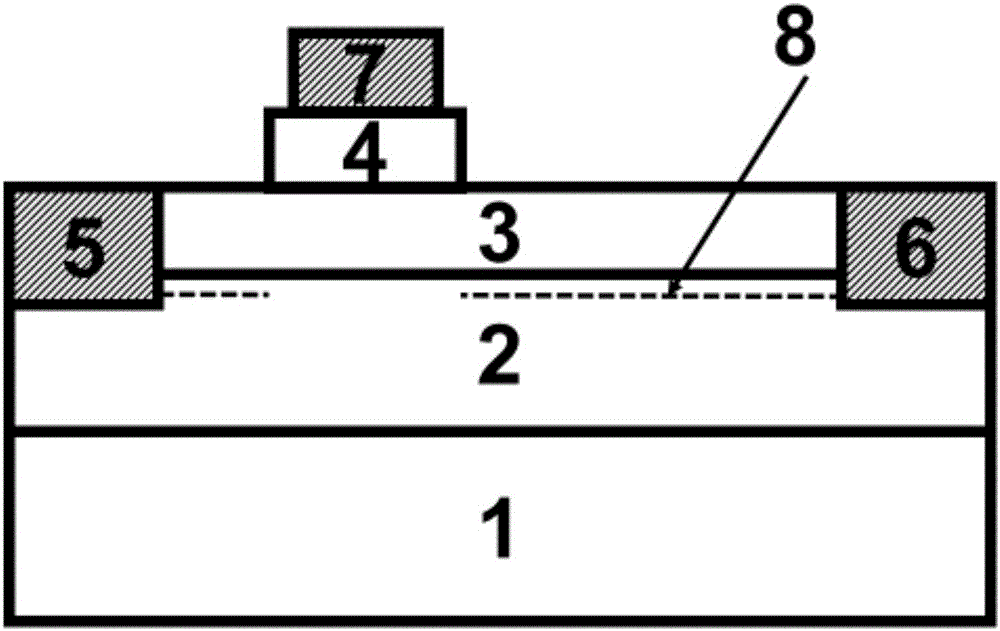

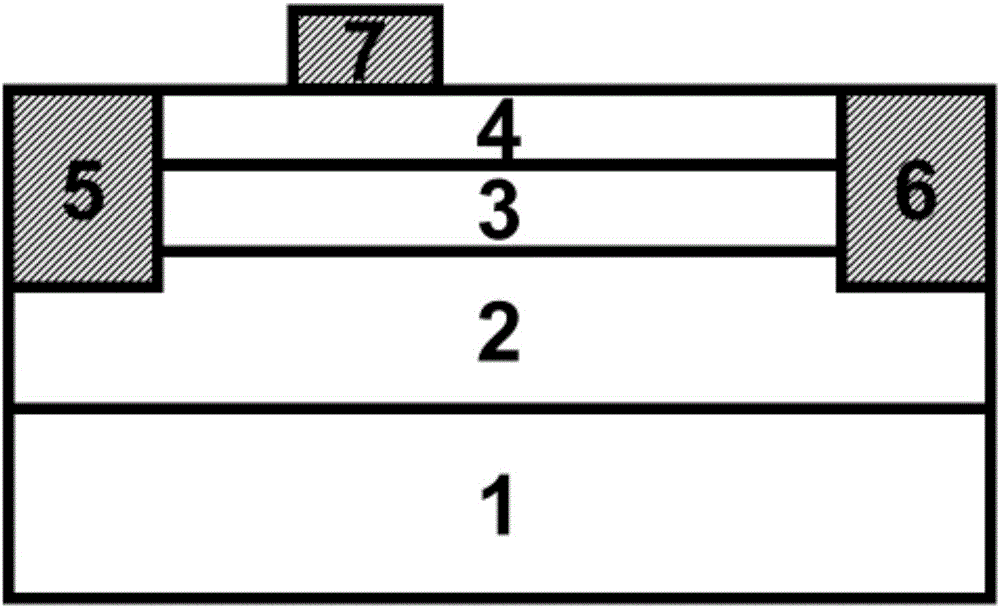

High-resistance cap layer-based III-nitride polarization super-junction high electron mobility transistor (HEMT) device and fabrication method thereof

InactiveCN106981513ASimple structureAvoid damageSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceHeterojunction

The invention discloses a high-resistance cap layer-based III-nitride polarization super-junction high electron mobility transistor (HEMT) device and a fabrication method thereof. The device comprises a first heterojunction, a second heterojunction, a p-type doping fourth semiconductor, a source, a drain and a gate, wherein the first heterojunction comprises a first semiconductor and a second semiconductor, the second semiconductor is formed on the first semiconductor and is provided with a band gap wider than the first semiconductor, a two-dimensional electron gas is formed in a first heterojunction structure, the second heterojunction comprises the second semiconductor and a third semiconductor, the third semiconductor is formed on the second semiconductor and is provided with a band gap narrower than the second semiconductor, a two-dimensional electron gas is formed in a second heterojunction structure, the fourth semiconductor is formed on the second semiconductor, the fourth semiconductor and the third semiconductor are closely connected in a horizontal direction, the source and the drain are connected with the first heterojunction and can be electrically connected through the two-dimensional electron gases, and the gate is arranged between the source and the drain and is connected with the fourth semiconductor.

Owner:SUZHOU NENGWU ELECTRONICS TECH

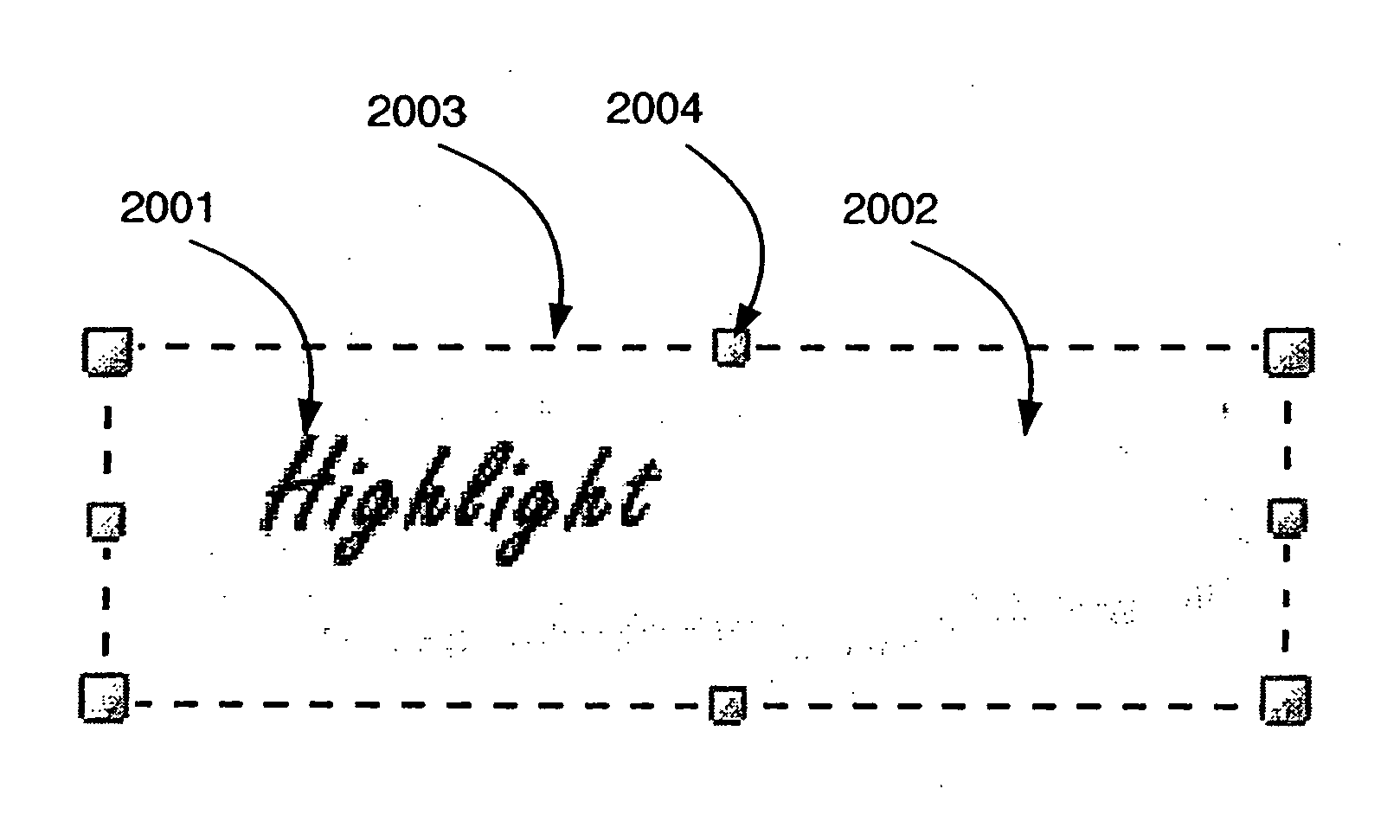

Method for hollow selection feedback

InactiveUS20050149882A1Simple process requirementsDrawing from basic elementsInput/output processes for data processingGraphical user interfaceGraphics

An improved approach to highlighting a graphical object in a graphical user interface is disclosed. A body of a highlighted graphical object may, upon selection or highlighting, be changed to a transparent color, and a graphical outline, or “halo,” is added surrounding the original graphical object's body. The halo may be in the same color as the graphical object originally was, preserving any meaning attributed to the color of the graphical object and simplifying the user's ability to identify the selected object(s), as well as the ability to select the highlighted object for further processing. The highlighted graphical object may also be displayed with a bounding box to further identify the selected object(s). A moving version of the highlighted graphical object may be drawn during a moving process, in which the moving version has an appearance distinct from the original object.

Owner:MICROSOFT TECH LICENSING LLC

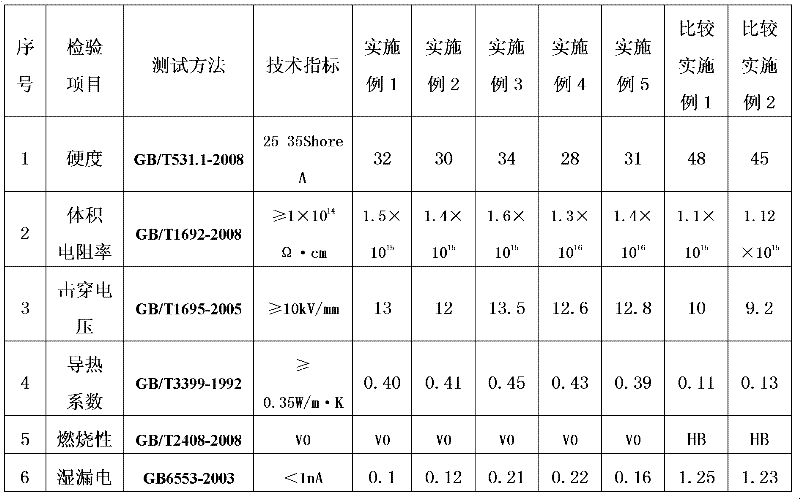

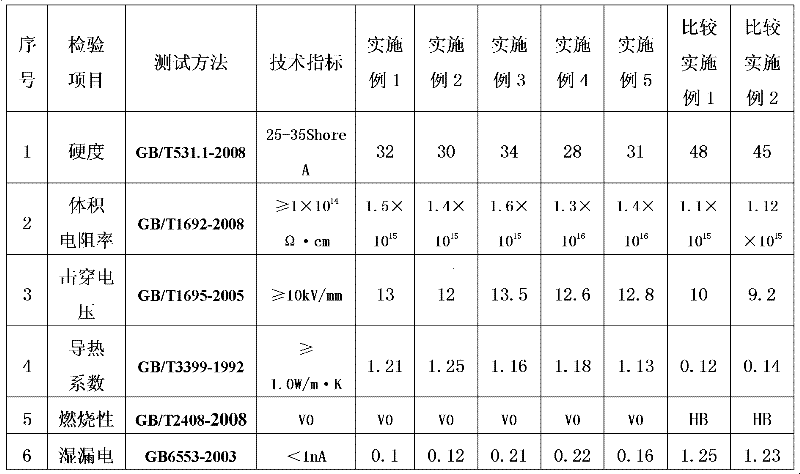

Two-component casting glue for capsulation of solar photovoltaic module and preparation method thereof

InactiveCN102516927AImprove flame retardant performanceTimely and effective exportNon-macromolecular adhesive additivesOther chemical processesWater vaporHeat conducting

The invention provides a two-component casting glue for capsulation of a solar photovoltaic module, which belongs to the field of high polymer sealing materials. The two-component casting glue comprises component A and component B; component A comprises the following raw materials of 100 to 120 parts by weight of alpha-omega-dihydroxy polydimethylsiloxane, 30 to 50 parts by weight of silicone oil, 80 to 100 parts by weight of a heat conducting filling material, 50 to 60 parts by weight of a flame retardant filling material and 30 to 50 parts by weight of nanometer calcium carbonate; and component B comprises the following raw materials of 100 to 120 parts by weight of silicone oil, 20 to 40 parts by weight of a cross-linking agent, 2 to 3 parts by weight of a coupling agent, 0.5 to 1 part by weight of a catalyst and 1 to 1.5 parts by weight of colored slurry. The two-component casting glue has the advantages of effectively promoted flame resistance, a substantially improved heat conducting effect, capacity of timely and effectively conducting out heat emitted by a bypass diode, excellent performance in inhibiting permeability of water vapor, excellent electrical properties and ideal weatherability and corrosion resistance. A recommended preparation method for the two-component casting glue is simple and terse and does not have strict requirements on a process and equipment.

Owner:江苏明昊新材料科技股份有限公司

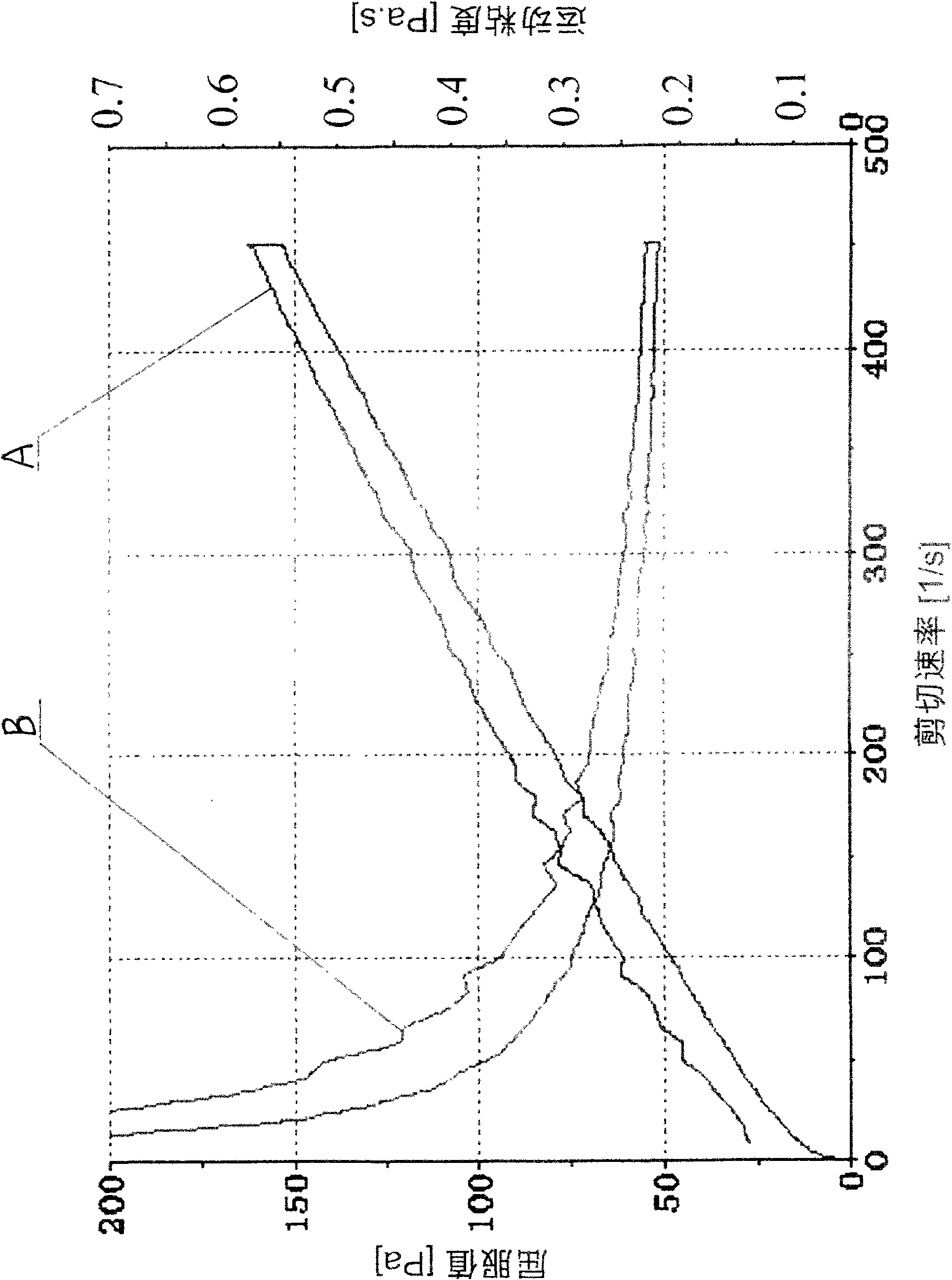

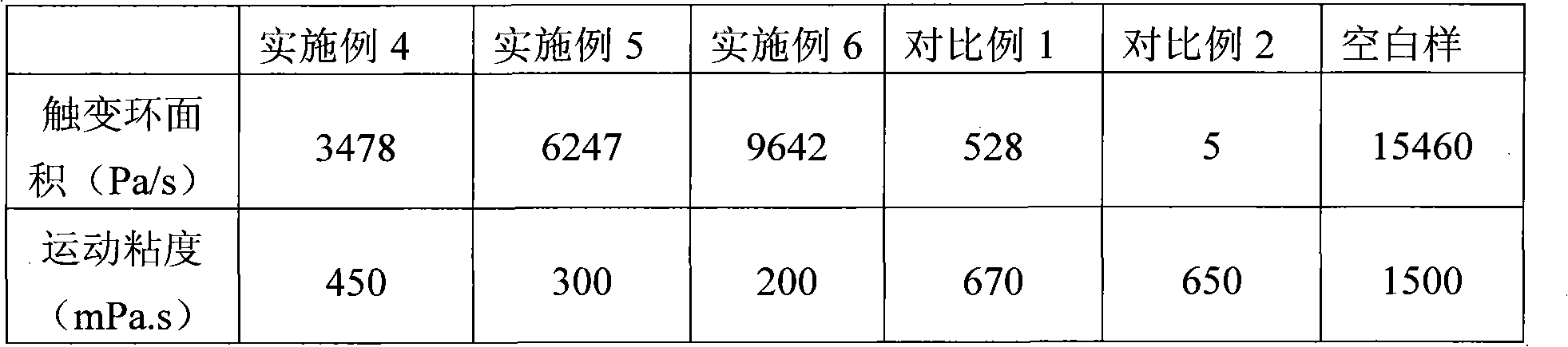

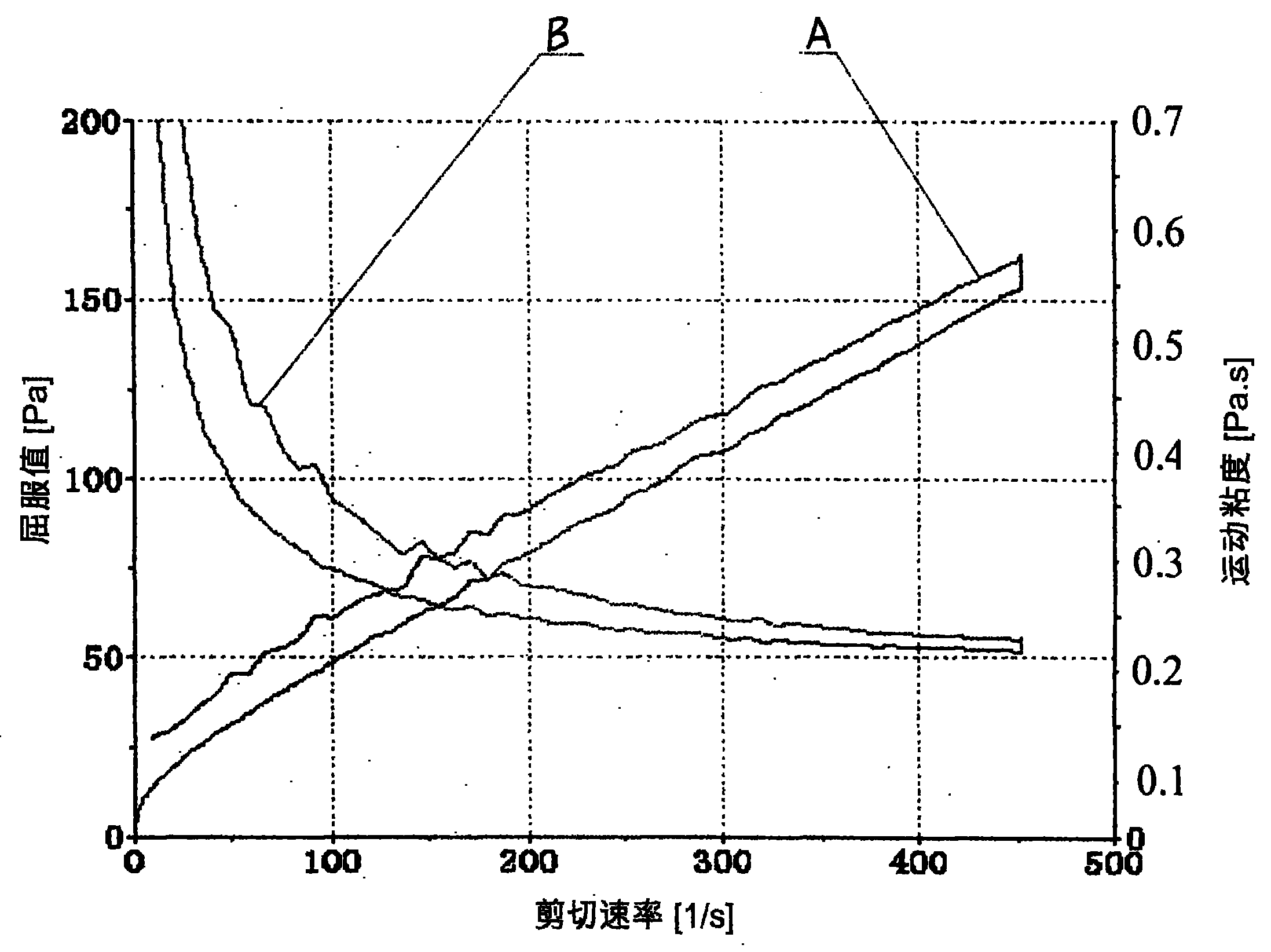

Method for preparing nano calcium carbonate with low viscosity and medium thixotropic property

InactiveCN101967310AImproved rheological propertiesRaw materials are easy to getPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolyesterCarbonization

The invention discloses a method for preparing nano calcium carbonate with low viscosity and medium thixotropic property, which comprises the following steps of: calcining and slaking preferred limestone, then controlling carbonization in a membrane reactor to obtain raw nano calcium carbonate slurry, performing composite surface modification treatment on the nano calcium carbonate by using polyester dispersant and fatty acid (or sodium salt), and finally dehydrating, drying, crushing and grading the wrapped slurry. The obtained powder has good dispersion performance, low viscosity and medium thixotropic property, and is suitable for situations with different requirements such as high-performance silicone adhesive, epoxy glue, polysulfide glue, polyurethane glue, automobile prime coat, floor patient and the like. The method has remarkable advantages of easily obtained raw materials, simple process requirement, low production cost and the like, and is easy to control the production process.

Owner:山东海泽纳米材料有限公司

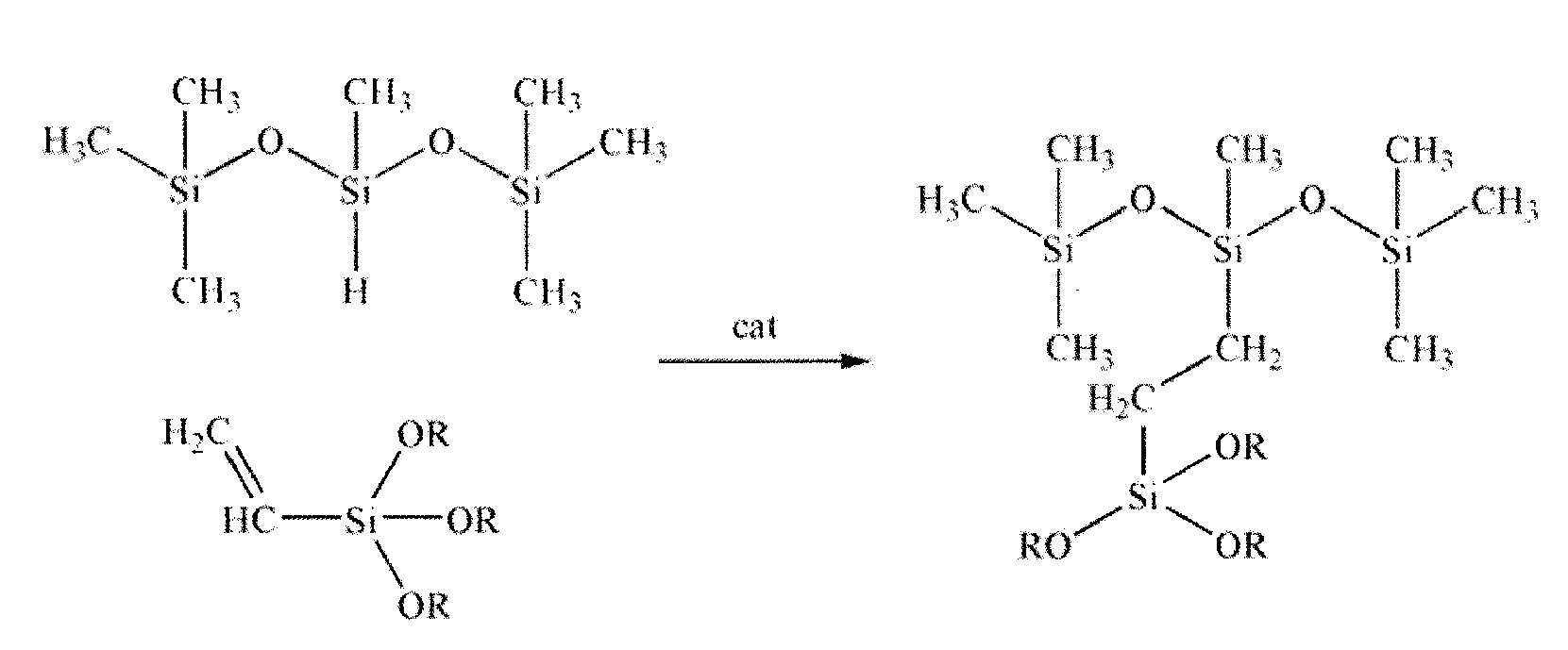

Hydrophobic-surface treatment agent and preparation method thereof

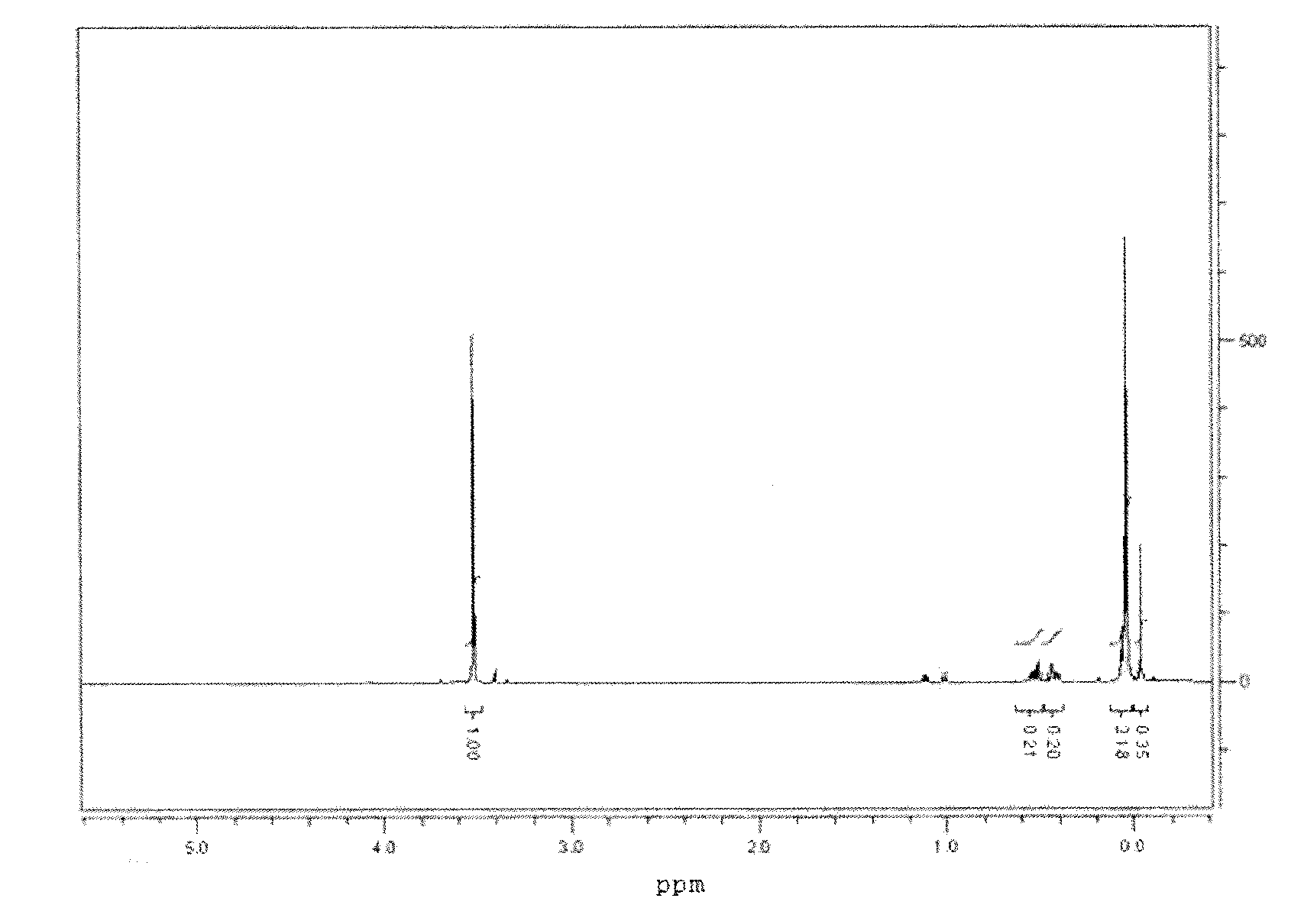

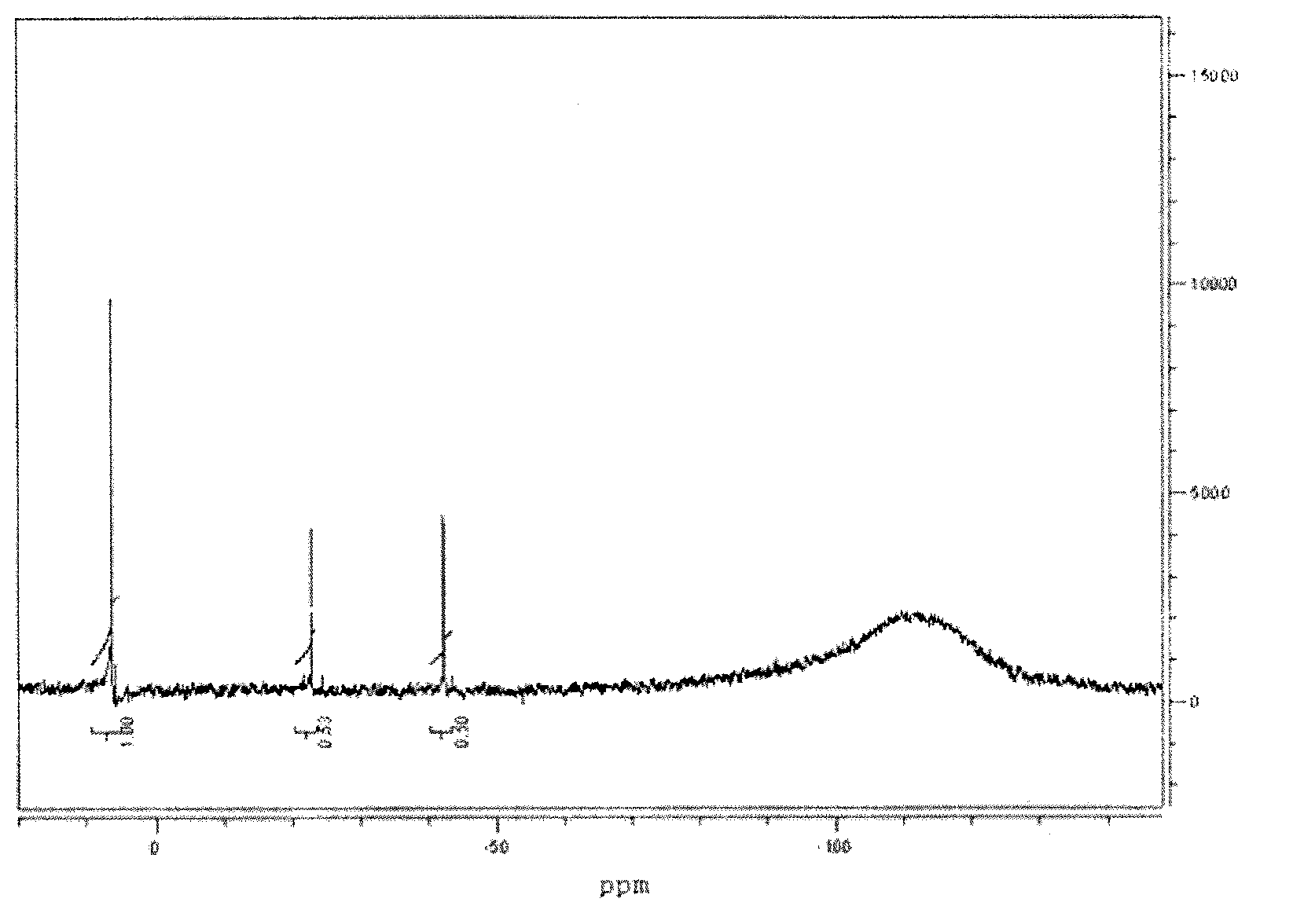

InactiveCN103224511AHigh yieldLower surface energyGroup 4/14 element organic compoundsSilanesSynthesis methods

The invention discloses a hydrophobic-surface treatment agent and a preparation method thereof. The preparation method comprises adding 1,1,1,3,5,5,5-heptamethyltrisiloxane and a catalyst into a reactor under 35-65 DEG C, adding vinyl trimethoxysilane or vinyl triethoxysilane in drops, after the reaction, adding active carbon for adsorption processing, filtering, and distilling filtrate under a reduced pressure to obtain the hydrophobic-surface treatment agent. According to the invention, the 1,1,1,3,5,5,5-heptamethyltrisiloxane with high-activity silicon-hydrogen bonds and the vinyl silane with double bonds are used as raw materials, a high-yield hydrosilylation reaction is utilized, and the product is prepared by a one-step synthesis method. The agent is high in reaction activity of function groups, low in surface energy, mild and controllable in reaction conditions, high in product yield and low in production cost.

Owner:DONGHUA UNIV

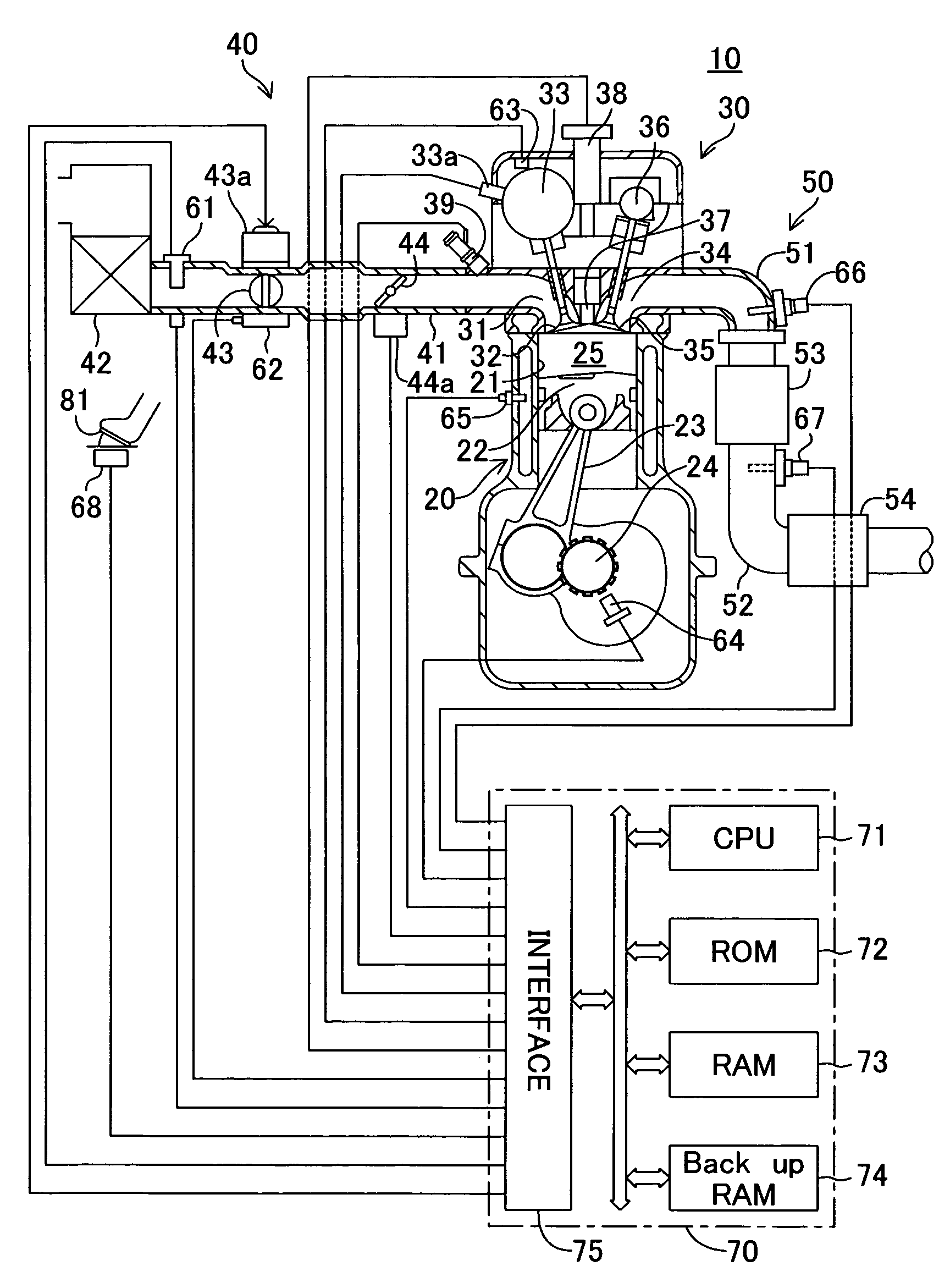

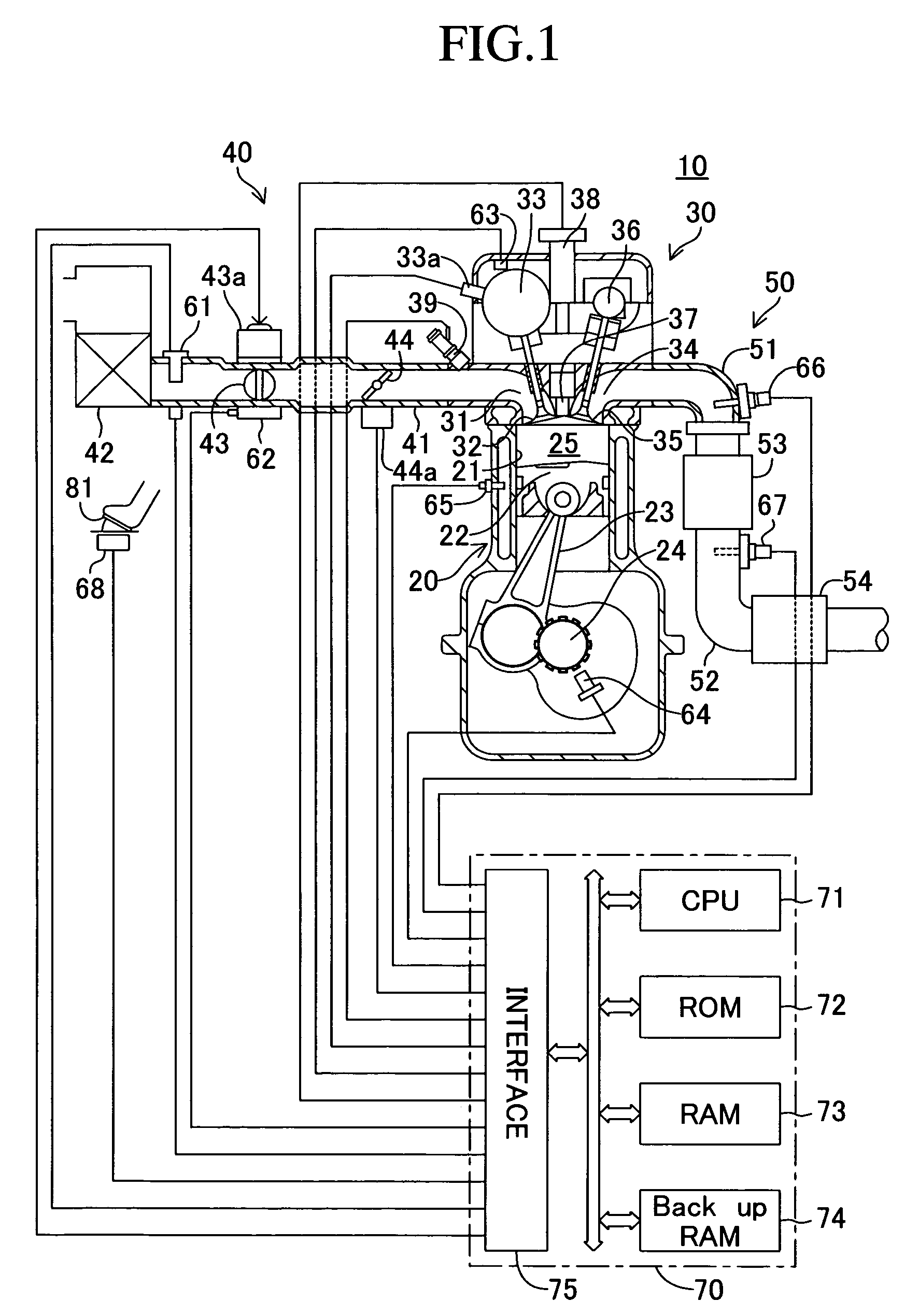

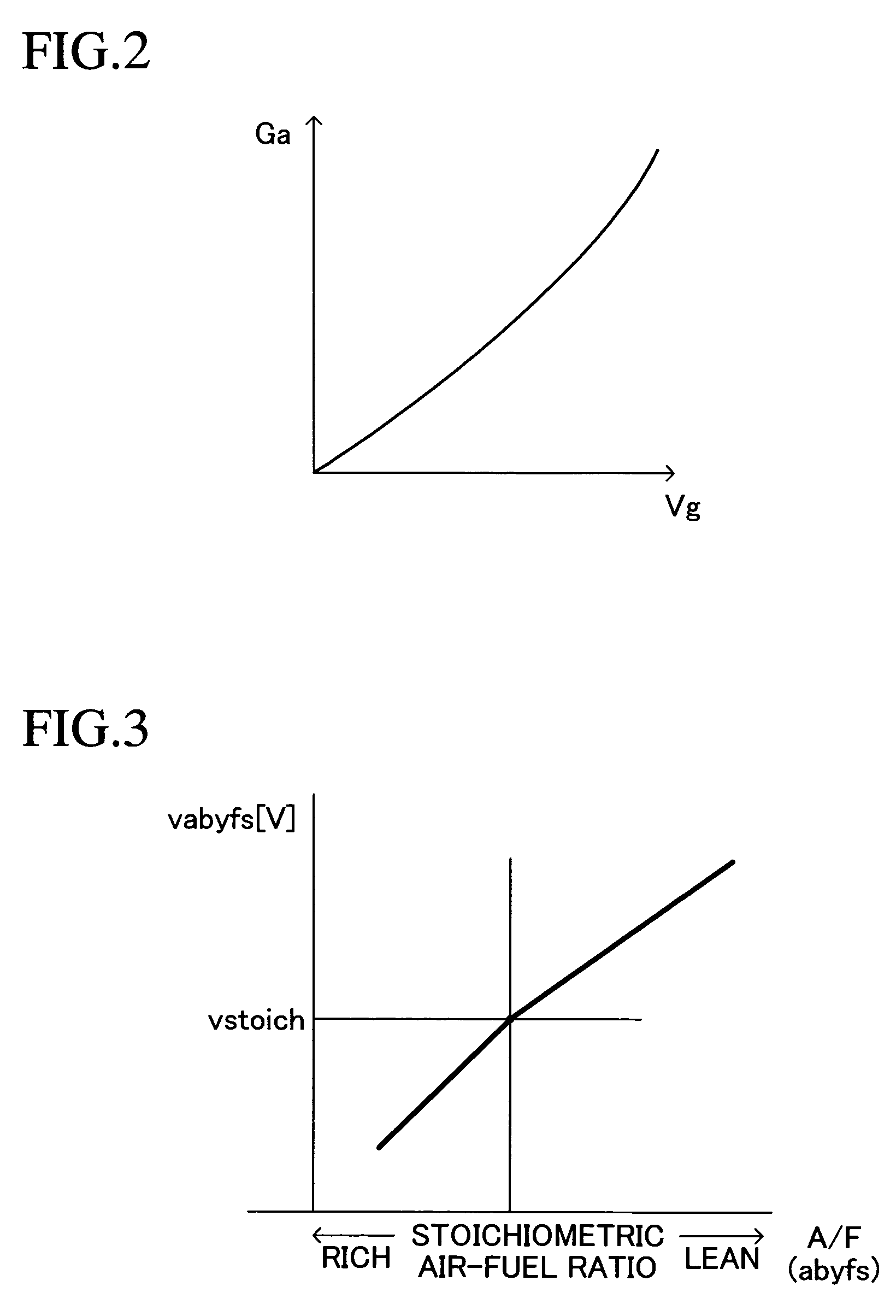

Exhaust purification apparatus for internal combustion engine

ActiveUS7032374B2Simple process requirementsSimple processElectrical controlInternal combustion piston enginesFeedback controllerExternal combustion engine

Owner:TOYOTA JIDOSHA KK

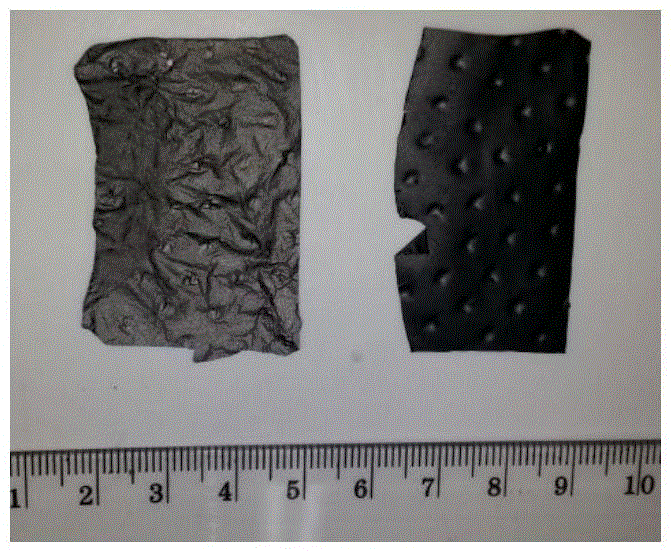

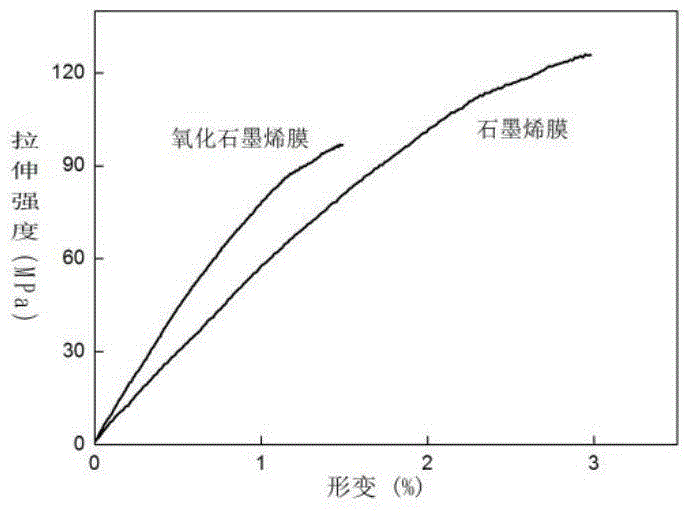

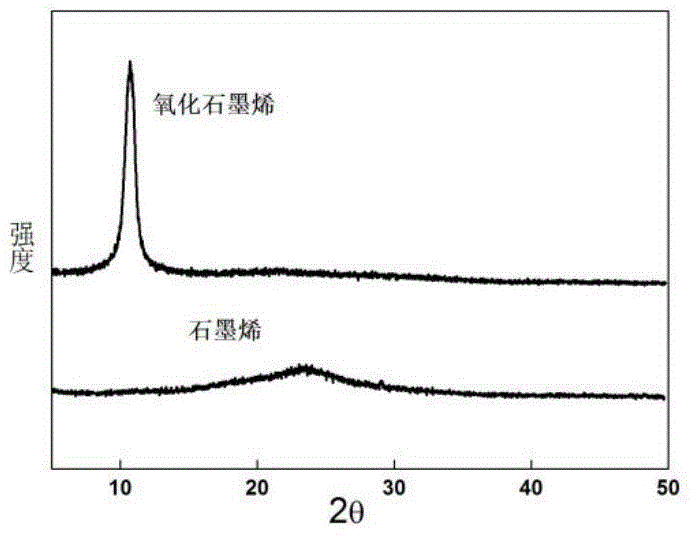

Preparation method of high-conductivity graphene membrane

The invention belongs to the technical field of preparation of graphene materials, and particularly relates to a preparation method of a high-conductivity graphene membrane. The preparation method comprises the following steps: preparing graphene oxide through an improved Hummer method in the presence of phosphoric acid protective agent, filtering through a polyester fiber filter membrane to obtain a graphene oxide membrane, and reducing the obtained graphene oxide membrane in a hydriodic acid-ethanol mixed solution to obtain the graphene membrane. The preparation method is simple and convenient to operate, has simple requirements for equipment and technology, and is cheap in raw materials and low in cost; and the prepared graphene membrane has few defects and high conductivity. The preparation method is easy to realize large-scale industrial production.

Owner:QINGDAO UNIV OF SCI & TECH

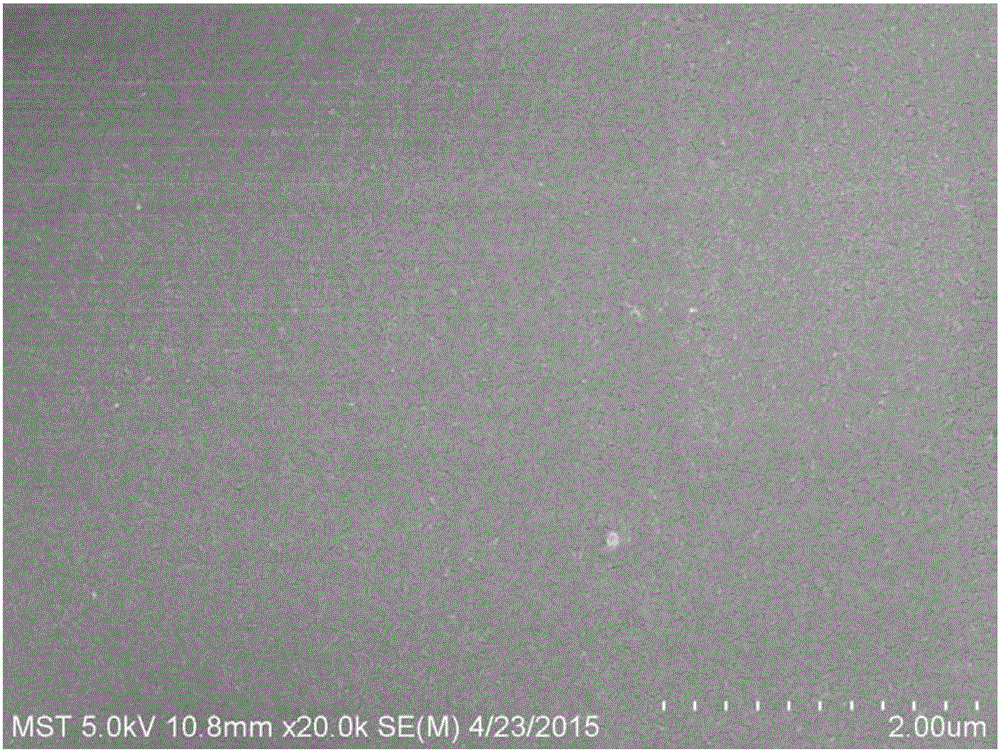

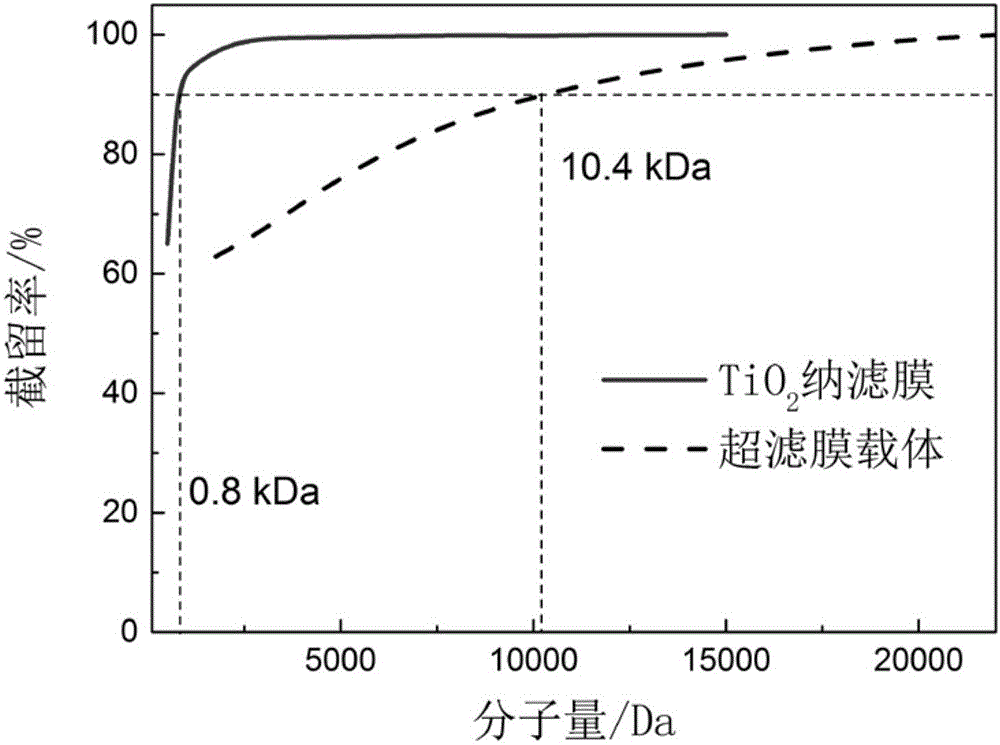

Novel ceramic nanofiltration membrane preparation method

The invention relates to a novel ceramic nanofiltration membrane preparation method. The method includes: dissolving a precursor into an organic solvent to obtain a precursor solution; drying to-be-treated ceramic ultrafiltration membranes; impregnating the dried ceramic ultrafiltration membranes into the precursor solution until complete impregnation is realized, taking out, airing, drying and calcining to obtain ceramic nanofiltration membranes. By addition of active components to pore passages of the ceramic ultrafiltration membranes and in-situ hydrolysis reaction of the active components, ceramic nanoparticles are obtained in the pore passages of the membranes after thermal treatment, and accordingly regulation of membrane pore diameters can be realized; by control of precursor types, precursor concentration, solvents, thermal treatment process and the like, continuous regulation of the pore diameters of the ceramic ultrafiltration membranes can be realized. Due to freeness of new membrane layers formed on the surfaces of the ceramic ultrafiltration membranes, the problem of proneness to cracking of the membrane layers in preparation of the ceramic nanofiltration membranes is avoided, and a series of ceramic nanofiltration membranes different in material and microstructure can be obtained. The novel ceramic nanofiltration membrane preparation method is a novel method for preparing the ceramic nanofiltration membranes.

Owner:NANJING UNIV OF TECH

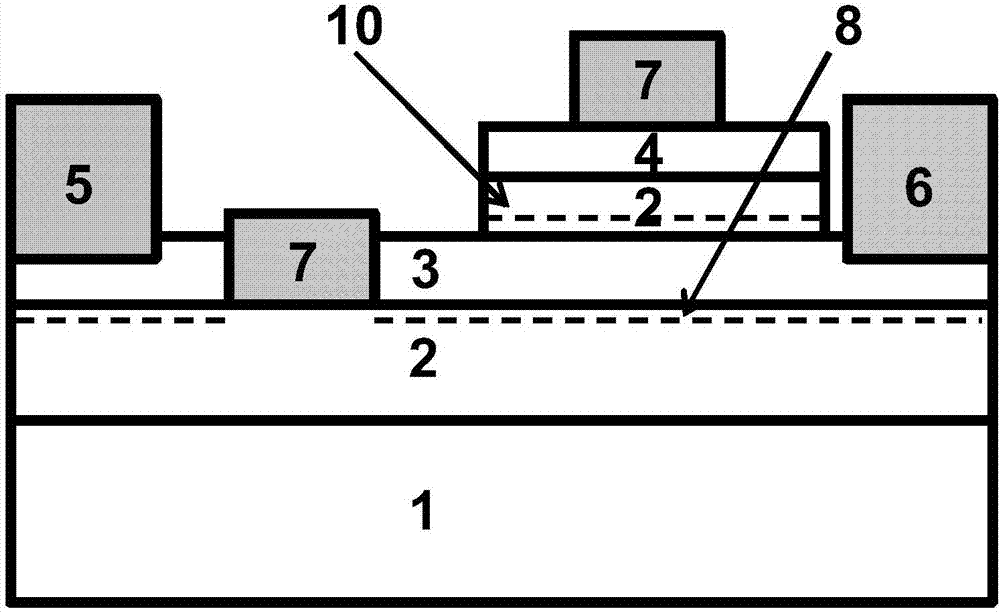

Method for realizing enhanced HEMT (High Electron Mobility Transistor) by virtue of p-type passivation and enhanced HEMT

InactiveCN105870013AAvoid damageLower interface stateSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorRepeatability

The invention discloses a method for realizing an enhanced HEMT (High Electron Mobility Transistor) by virtue of p-type passivation. The method comprises the following steps: providing a heterostructure which mainly comprises a first semiconductor and a second semiconductor, wherein the second semiconductor is distributed on the first semiconductor and is provided with a band gap wider than the first semiconductor, and two-dimensional electron gas is formed in the heterostructure; forming a p-type doped third semiconductor on the second semiconductor, performing passivation treatment on a residual region, except for an under-gate region, of the third semiconductor, so that the p-type doped region only exists at the under-gate region, and the under-gate region is distributed under a gate electrode of an HEMT device; manufacturing a source electrode, a drain electrode and a gate electrode connected with the heterostructure, electrically connecting the source electrode and the drain electrode through the two-dimensional electron gas, and enabling the gate electrode to be distributed between the source electrode and the drain electrode. The invention further discloses the enhanced HEMT. The method has the advantages of simple process, high repeatability, stable and favorable device performance, low cost, easiness for large-scale production and the like.

Owner:SUZHOU NENGWU ELECTRONICS TECH

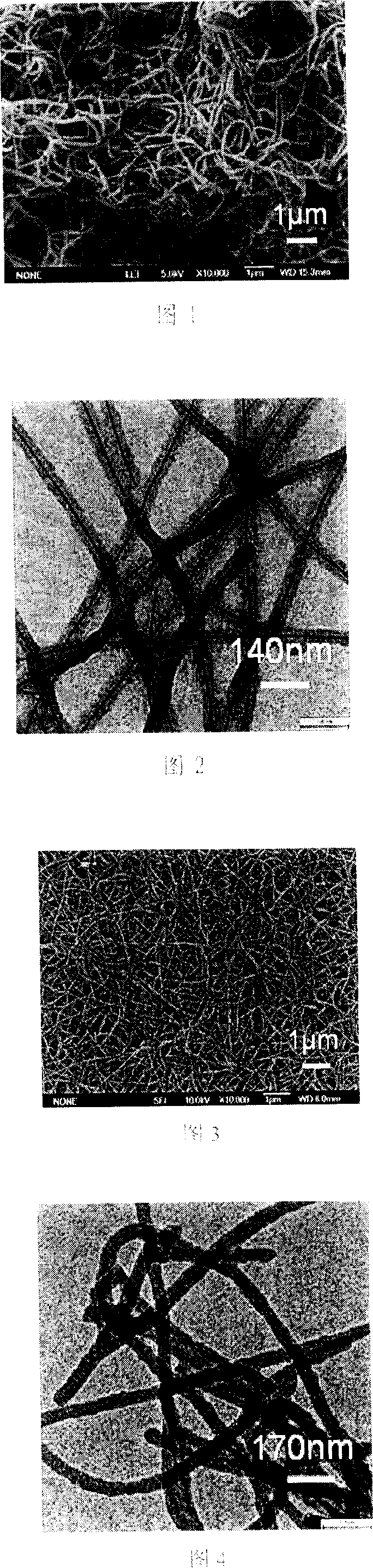

Method for preparing carbon nano fiber

InactiveCN1935638AMild preparation conditionsEasy to operateNanostructure manufactureFiberHydrazine compound

The invention is a method of preparing carbon nano fibers, characterized in adopting hydrazine hydrate and high molecular surface active agnet polyvinylpyrrolidone to hydrothermally synthesize nano lines of semiconductor Te at 160-200DEG C; then adopting the nano lines as template and adopting carbohydrate to react at 160-220DEG C for 4-20 h and synthesizing carbon-coated Te nano cables as intermediate for preparing carbon nano fiber; and oxidizing to remove Te cores from the nano cables and obtaining the carbon nano fibers. And it avoids production of carbon balls in the carbonizing course, and the surfaces of the obtained carbon-coated Te nano cables and carbon nano fibers all have large numbers of functional groups. And it is relatively suitable for industrialized production.

Owner:UNIV OF SCI & TECH OF CHINA

Silicone sealant used for electronic products, preparation method thereof, and application thereof

ActiveCN102516928AGuaranteed mixing effectTimely and effective exportNon-macromolecular adhesive additivesCross-linkSlurry

The invention relates to a silicone sealant used for electronic products. The invention belongs to the technical field of high-molecular materials. The sealant comprises a component A and a component B. The component A is composed of raw materials of, by weight: 100-110 parts of alpha-omega-dihydroxyl polydimethylsiloxane, 25-40 parts of silicone oil, 5-8 parts of a heat-conductive filling material, 35-65 parts of a fire-retarding filling material, and 20-35 parts of nano-grade calcium carbonate. The component B is composed of raw materials of, by weight: 90-110 parts of silicone oil, 12-15 parts of a cross-linking agent, 3-4 parts of a coupling agent, 1-1.5 parts of a catalyst, and 1.5-3 parts of a colored slurry. The silicone sealant is advantaged in excellent fire retardance, improved heat conductivity, ideal steam-penetration inhibiting capacity, excellent electrical property, excellent weathering resistance, and ideal corrosion resistance. A provided preparation method is advantaged in simple technology, and non-harsh requirements on technologies and equipments. With a provided application method, a mixing effect of the components A and B can be ensured.

Owner:江苏明昊新材料科技股份有限公司

Lubricating oil for cold reduction of tubes and preparation method thereof

ActiveCN103215112AEasy to cleanImprove antioxidant capacityLubricant compositionVegetable oilActive agent

The invention discloses lubricating oil for cold reduction of tubes and a preparation method thereof, belonging to the field of water-soluble lubricating oil and a preparation technology thereof. The lubricating oil is composed of the following raw materials in parts by weight: 25-65 parts of base oil, 25-75 parts of chlorinated paraffin, 0.2-3 parts of vegetable oil, 2-25 parts of surfactant, 1-5 parts of antioxidant and 2-6 parts of antirust agent. The preparation method comprises the following steps of: firstly adding 25-65 parts of base oil and 25-75 parts of chlorinated paraffin into a container with a stirring device and a heating device, and stirring in a heating state; adding 0.2-3 parts of vegetable oil, 1-5 parts of antioxidant and 2-6 parts of antirust agent, and continuously heating and stirring; adding 2-25 parts of surfactant, and heating and stirring; and cooling and discharging to obtain a finished product. The lubricating oil disclosed by the invention is harmless to environment and has excellent extreme-pressure abrasion resistance; and the process flow is simple, and the technological requirements are not harsh, thus the need for industrial production amplification can be met.

Owner:SUZHOU MEIBEIER IND OIL

High-strength magnesium alloy containing rare earth and preparation method thereof

The invention discloses high-strength magnesium alloy containing rare earth and a preparation method thereof. The alloy comprises, by weight, 3%-8% of Al, 0.5%-6.5% of Ca, 0.1%-1.2% of Mn, 1.5%-4.5% of Zn, 0.02%-2.5% of Zr, 0.05%-1.5% of Nd, 0.05%-1.5% of Sm and the balanced Mg and unavoidable impurities. The method comprises the steps that magnesium ingots are melted and alloyed; casting membersare produced, and dissolving treatment is conducted; uniform thermal processing is conducted, and aging treatment is conducted after deformation processing is conducted by squeezing and forging. According to the alloy and the method, high-strength magnesium alloy is provided, a magnesium material with diversified dimensions can be processed through plastic deformation treatment, demands on a lighthigh-strength material of automobile parts can be met, and the utilization field of the aluminum alloy is expanded.

Owner:SHANGHAI UNIV

Preparation method of hydrophobic nano cellulose aerogel

Owner:东莞市创进塑胶五金有限公司

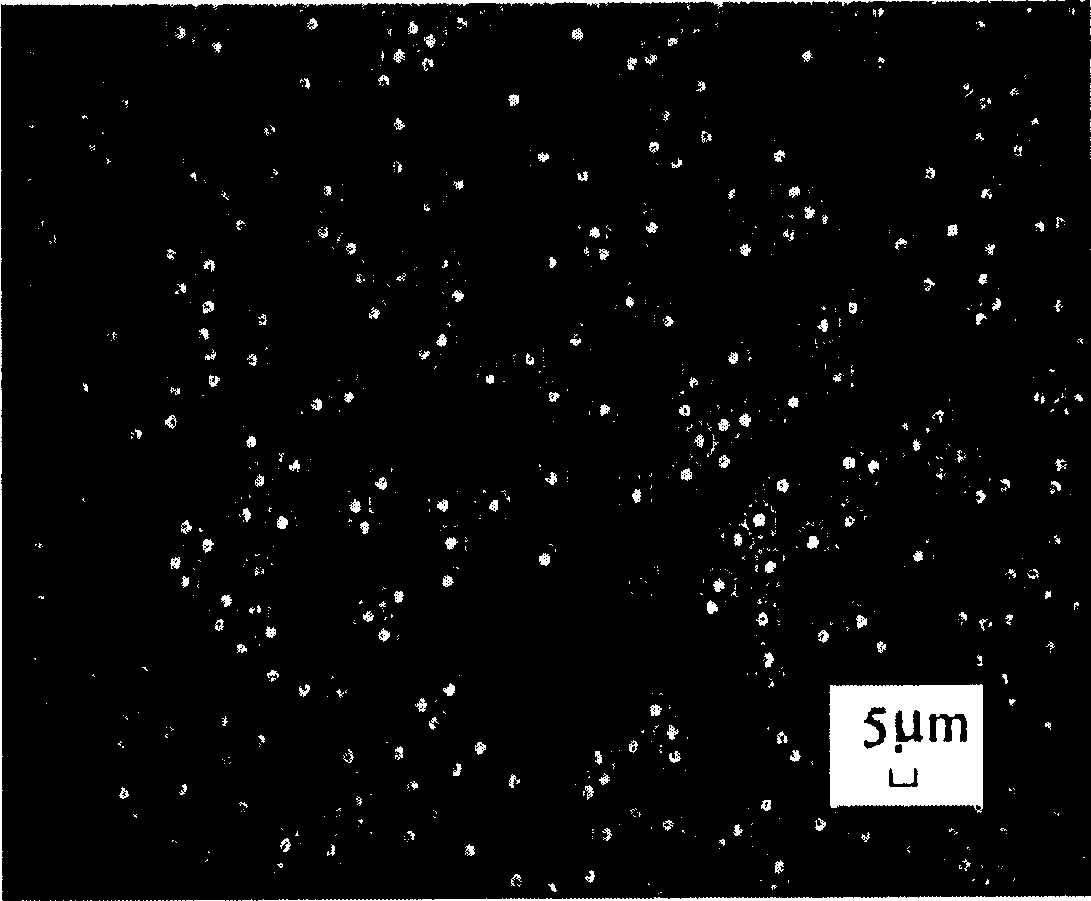

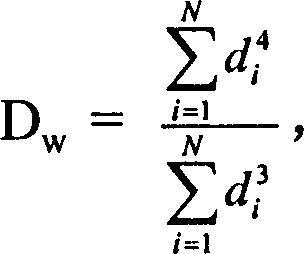

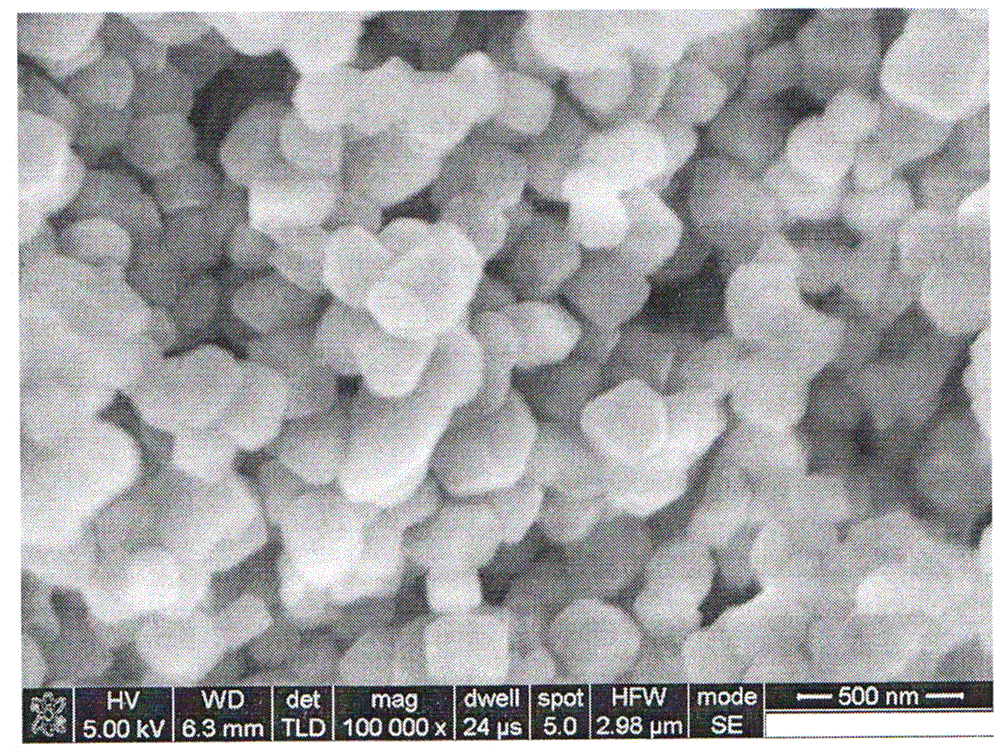

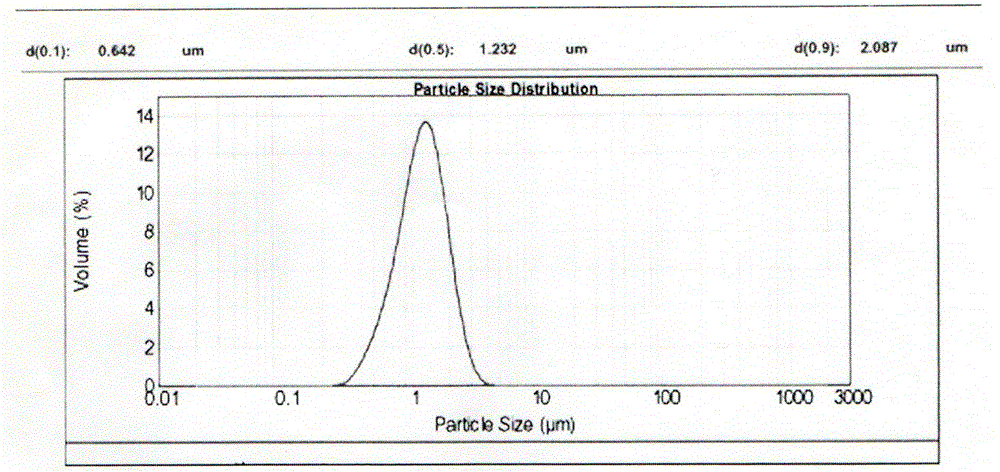

Method for preparing mono dispersed micrograde polymer microsphere

The invention discloses the preparing method of monodisperse micron-size polymer microballoon. The method comprises the following steps: adding organic solvent containing monomer, initiating agent and dispersing agent into inhibitor at 50-80Deg.C, carrying out reaction for 10-14 hours, getting the product. The invention obtains the monodisperse microballoon whose diameter is 1- 10 mum.

Owner:SHANGHAI HUAMING HI TECH GRP

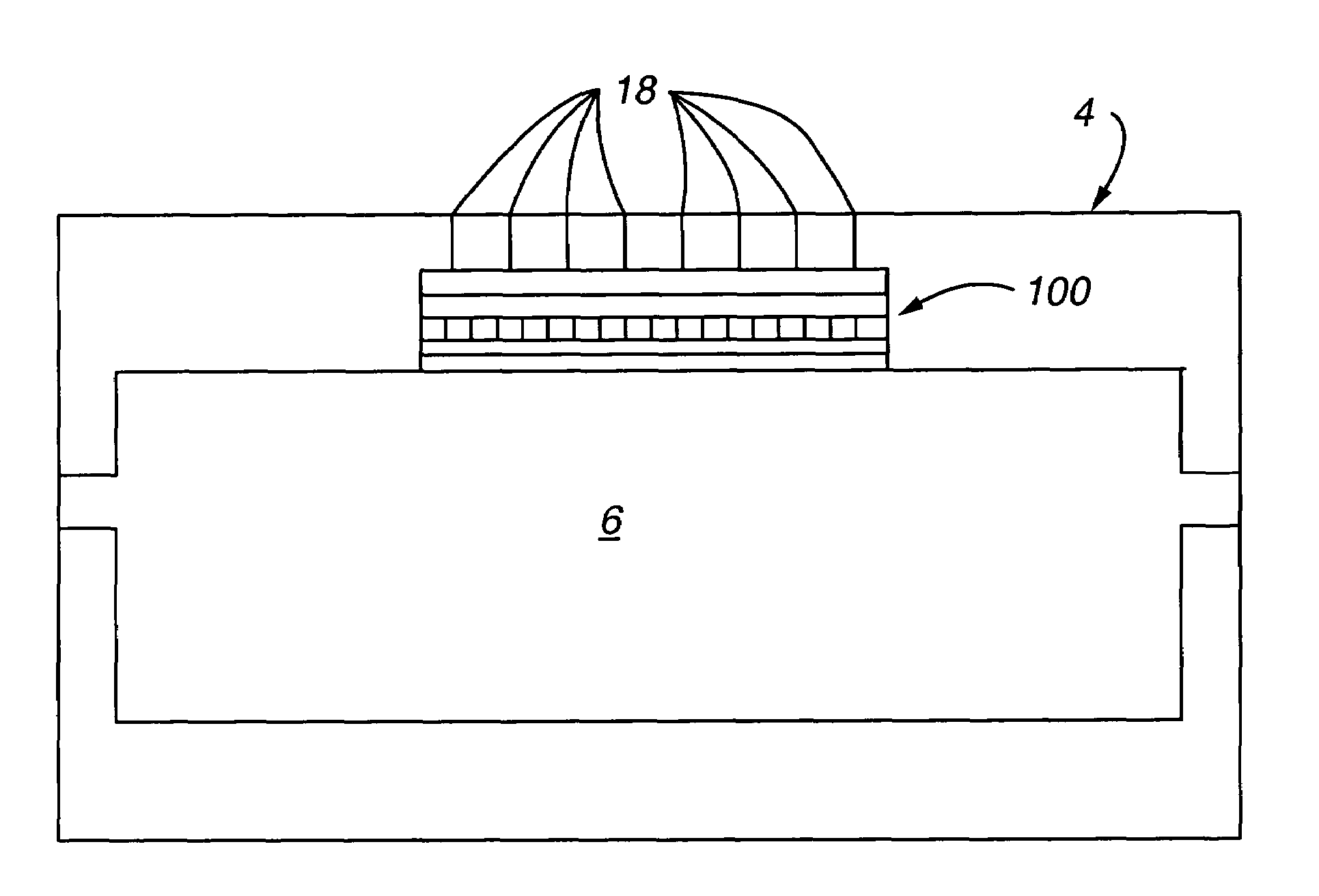

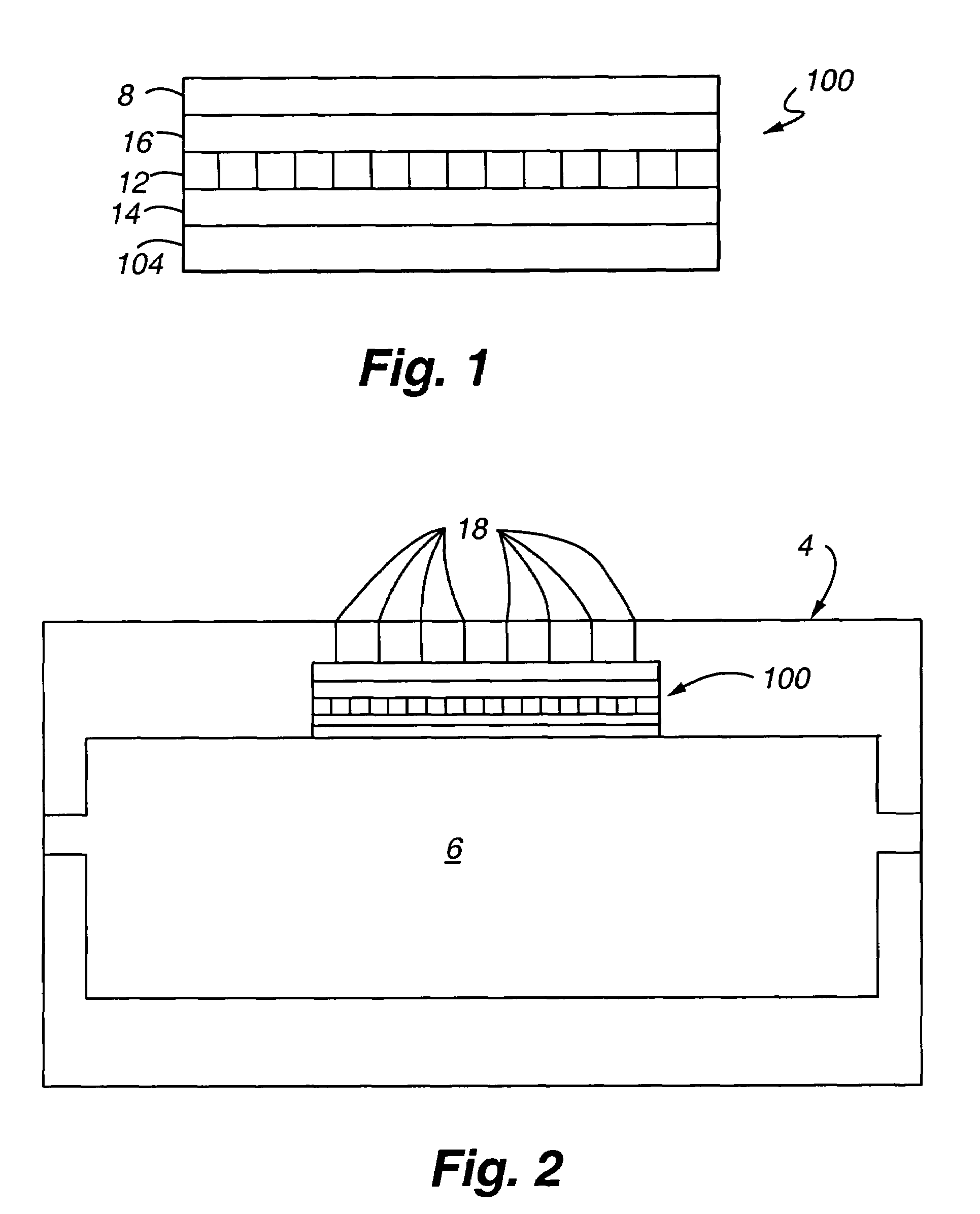

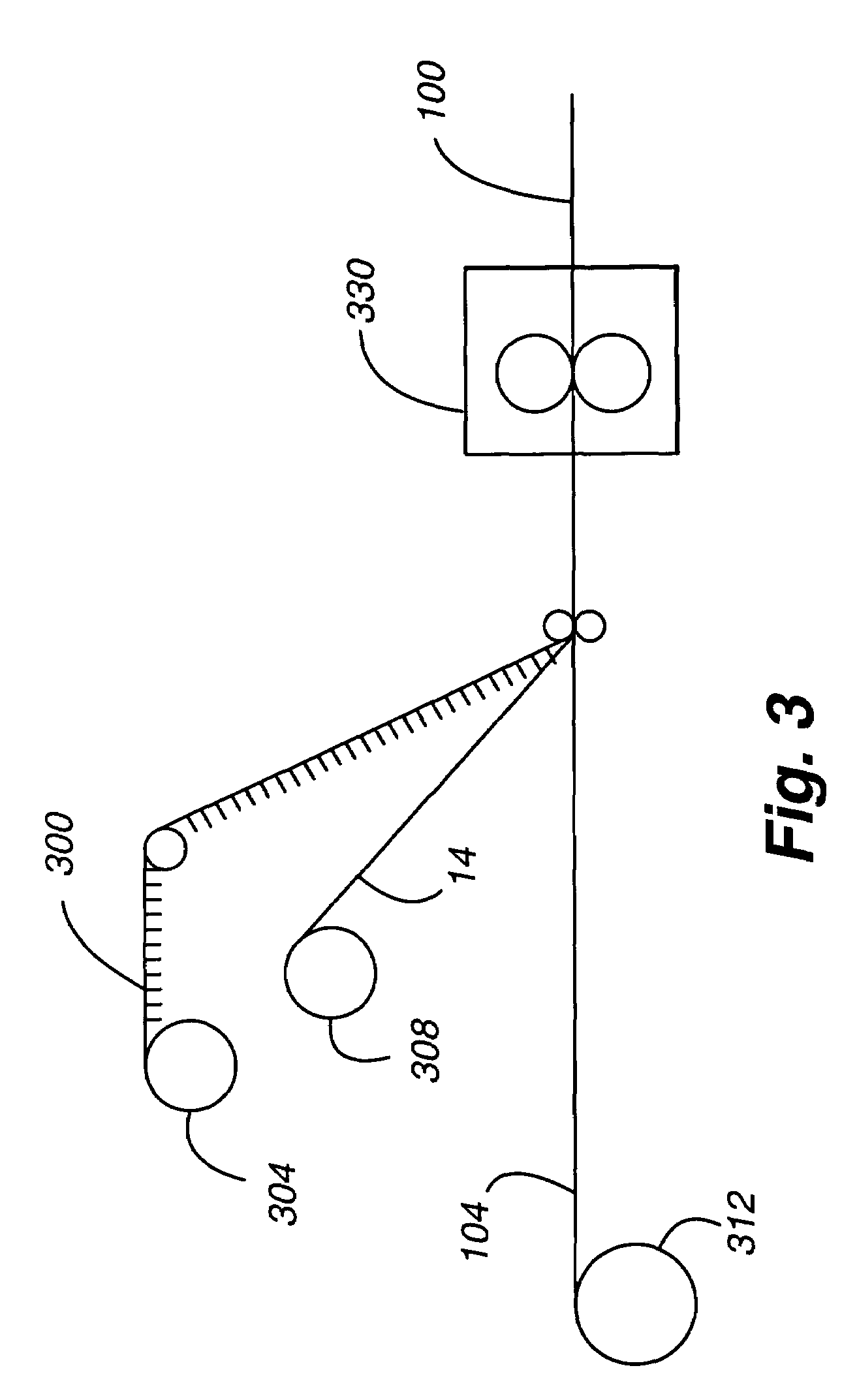

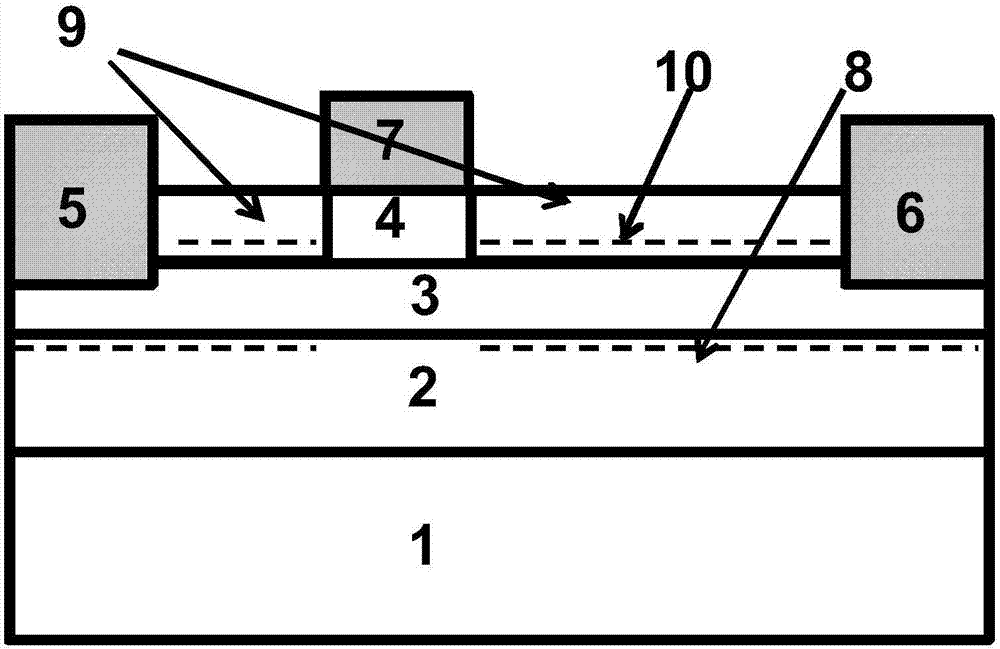

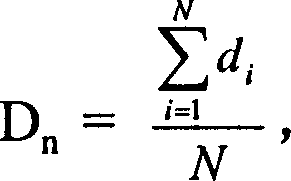

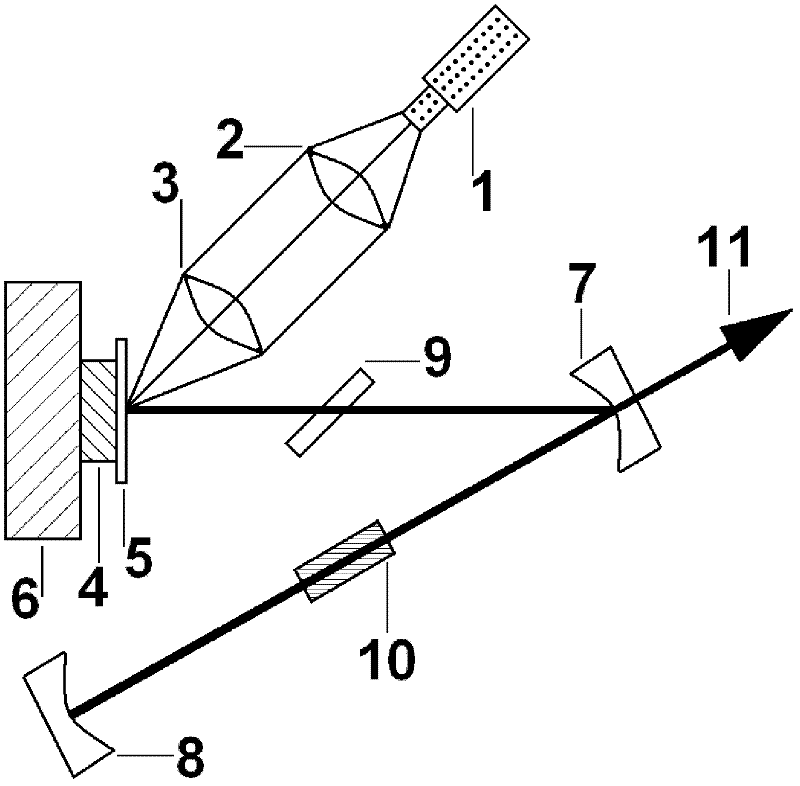

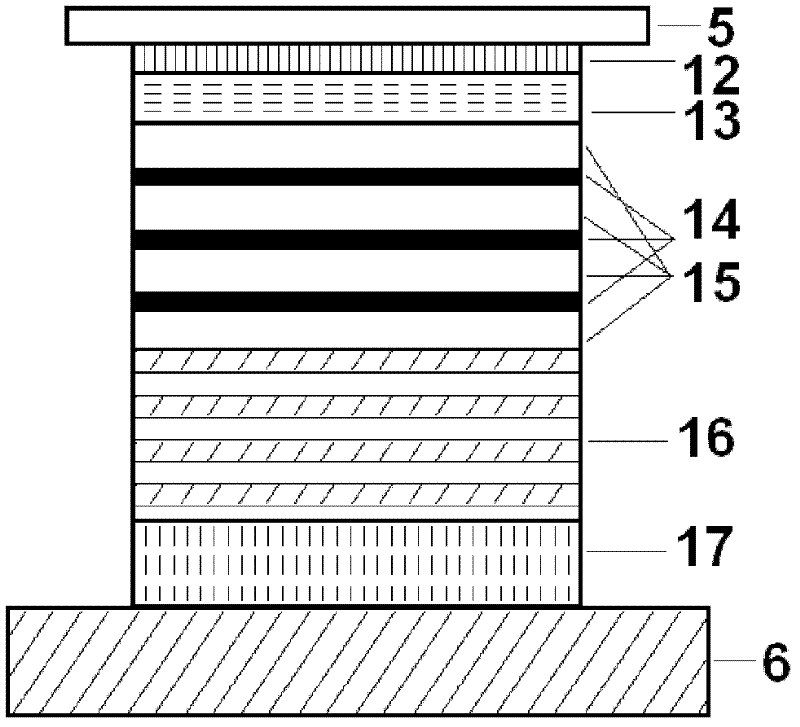

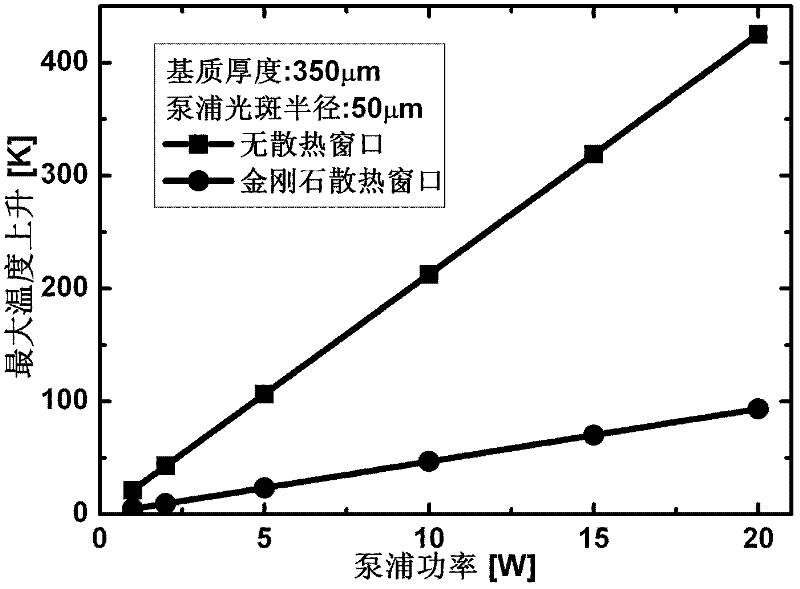

High-power intracavity frequency-doubled semiconductor disk laser

InactiveCN102570290AImprove cooling effectIncrease output powerLaser detailsLaser optical resonator constructionLine widthFundamental frequency

The invention relates to a high-power intracavity frequency-doubled semiconductor disk laser, which belongs to the technical field of semiconductor lasers. According to the invention, the heating effect of the laser is improved by using a heat-dissipating window, the frequency of fundamental-frequency lasers is stabilized and the line width of fundamental-frequency lasers is narrowed by using a filtering device, thereby improving the intracavity frequency-doubled efficiency. A pumping light subjected to collimating and focusing acts on a semiconductor disk gain medium (4), and a high-heat-conductivity heat-dissipating window (5) which is transparent to the pumping light and laser is bonded on the semiconductor disk gain medium; a photon-generated carrier in the gain medium has stimulated radiation in a quantum well (14), a laser cavity consisting of a rear-end mirror (8), an output coupling mirror (7), and a Bragg mirror (16) at the bottom of the semiconductor disk gain medium generates fundamental-frequency lasers, and a nonlinear crystal (10) generates frequency-doubled lasers (11); and the semiconductor disk laser is characterized in that: a filtering device (9) is arranged in the laser cavity, so that the frequency of fundamental-frequency lasers is stabilized effectively, and the line width of the fundamental-frequency lasers is narrowed many times, thereby improving the frequency-doubled efficiency.

Owner:BEIJING UNIV OF TECH

Preparation method of nano attapulgite adsorbent

ActiveCN103752263AHigh adsorption capacitySimple process requirementsOther chemical processesMycotoxinSolvothermal reaction

The invention discloses a preparation method of a nano attapulgite adsorbent. The preparation method comprises the steps of dispersing attapulgite clay in a solvent under a stirring condition according to a solid-to-liquid ratio of 1:(25-300), reacting for 48-120 hours at temperature of 120-200 DEG C in a high-pressure reaction kettle, centrifugally separating, washing and then drying to obtain the nano attapulgite adsorbent with a high adsorption capacity. According to the preparation method of the nano attapulgite adsorbent, the adsorption capacity of the nano attapulgite adsorbent is improved by using solvent thermal reaction; the nano attapulgite adsorbent is applicable to adsorption of feed mycotoxins, heavy metal ions and cationic dyes.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

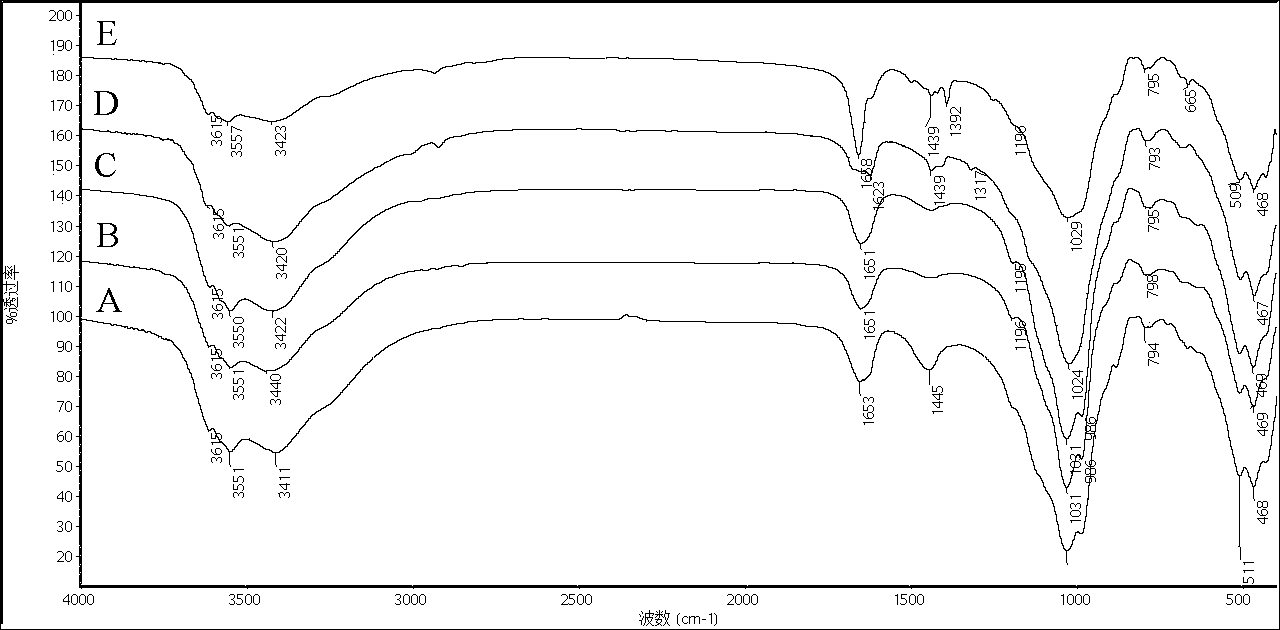

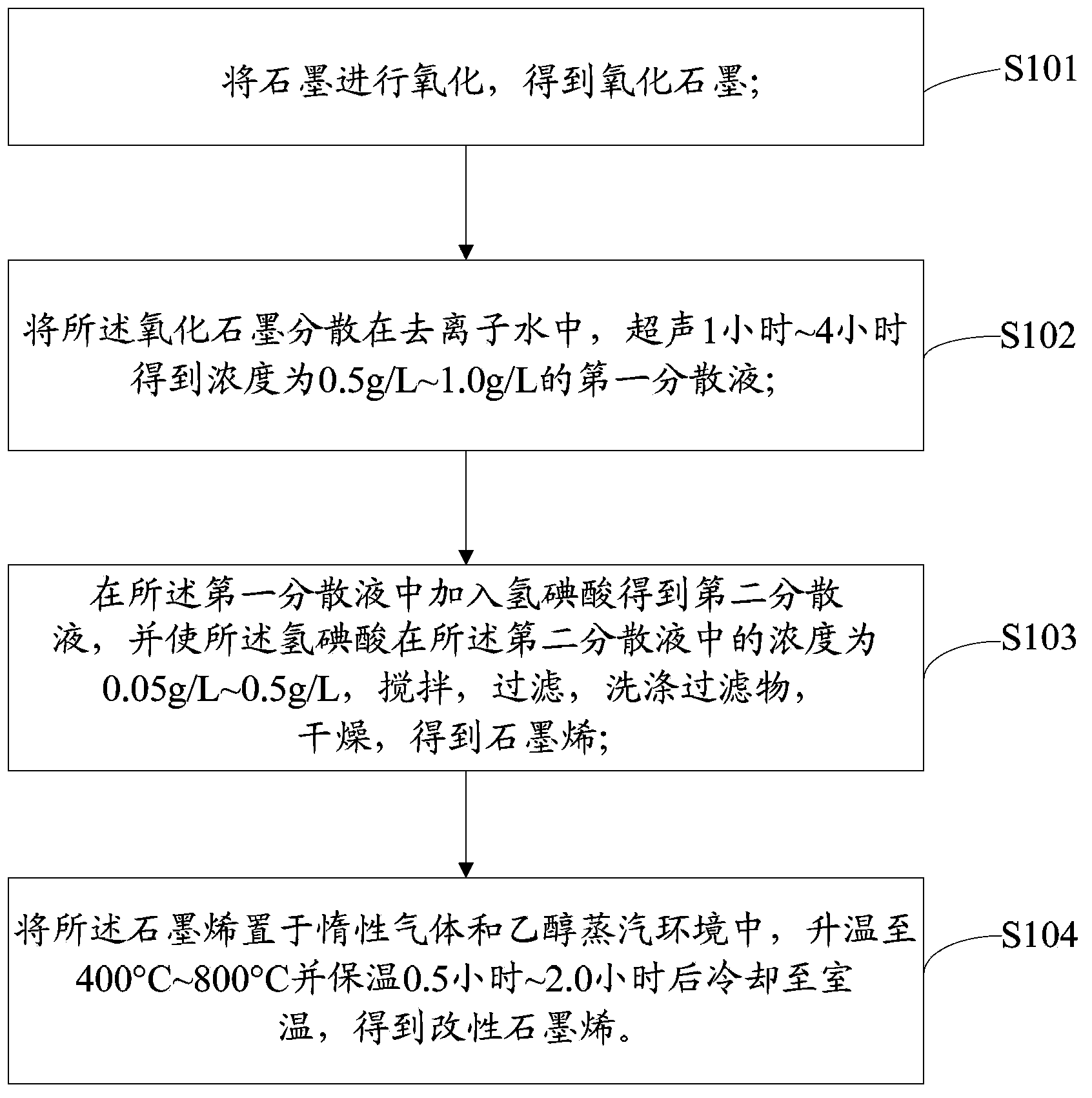

Preparation method of modified graphite

A preparation method of modified graphene is as below: oxidizing graphite to obtain graphite oxide; dispersing the graphite oxide in deionized water, conducting ultrasound treatment for 1-4 h to obtain a first dispersion with concentration of 0.5-1.0 g / L; adding hydroiodic acid in the first dispersion to obtain a second dispersion, wherein the hydroiodic acid in the second dispersion has concentration of 0.05-0.5g / L, stirring, filtering, washing filtering products, and drying to obtain graphene; and placing the graphene in inert gas and ethanol vapor environment, heating to 400-800 DEG C and insulating for 0.5-2.0 h and cooling to room temperature to obtain the modified graphene. According to the above preparation method of modified graphene, hydroiodic acid as a reducing reagent reacts with graphite oxide to obtain the graphite; and the graphite is restored under the effect of ethanol vapor to obtain the modified graphene. The prepared modified graphene material has high electrical conductivity. The preparation method has the advantages of simple requirement of equipment and process, easiness to operate, cheap raw materials and low cost, and is easy to realize large-scale industrialized production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

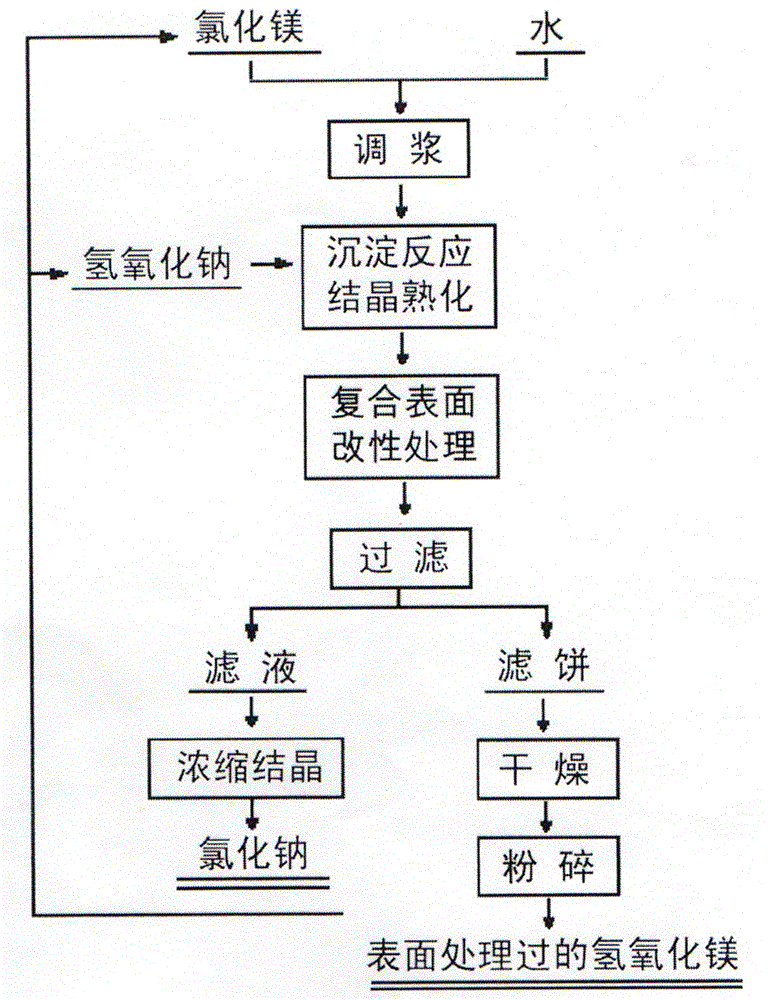

Method for preparing magnesium hydrate fire retardant through surface modification treatment by using composite wet method

InactiveCN103819935AGood dispersionWith progressMagnesium hydroxidePigment treatment with non-polymer organic compoundsMagnesium saltFatty acid

The invention discloses a method for preparing magnesium hydrate fire retardant through surface modification treatment by using a composite wet method. The method comprises the following steps: firstly, mixing a water solution of a soluble magnesium salt with an alkali water solution according to a chemical stoichiometric ratio so as to obtain a magnesium hydrate precipitate sizing agent, aging or performing hydro-thermal treatment on the obtained magnesium hydrate precipitate sizing agent, controlling the temperature to be 40-180 DEG C, subsequently performing hyperdispersant and fatty acid (or sodium / or sylvite) compounding wet method surface wrapping modification treatment on magnesium hydrate, and finally dehydrating, drying, crushing and grading the wrapped sizing agent. The powder modified by using the method is good in processing property, excellent and remarkable inflaming retarding and smoke inhibition function, and is applicable to situation of different demands. The method is reasonable in process, low in cost, wide in product application field, large in market potential, high in competitiveness and has remarkable economic and social benefits.

Owner:许营春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com