Hydrophobic-surface treatment agent and preparation method thereof

A hydrophobic surface treatment agent technology, applied in the field of hydrophobic surface treatment agent and its preparation, can solve the problems of expensive fluorine-containing low surface energy reagents, complex preparation process, weak matrix binding force, etc., and meet the requirements of fast and simple production, The method has the advantages of simple operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

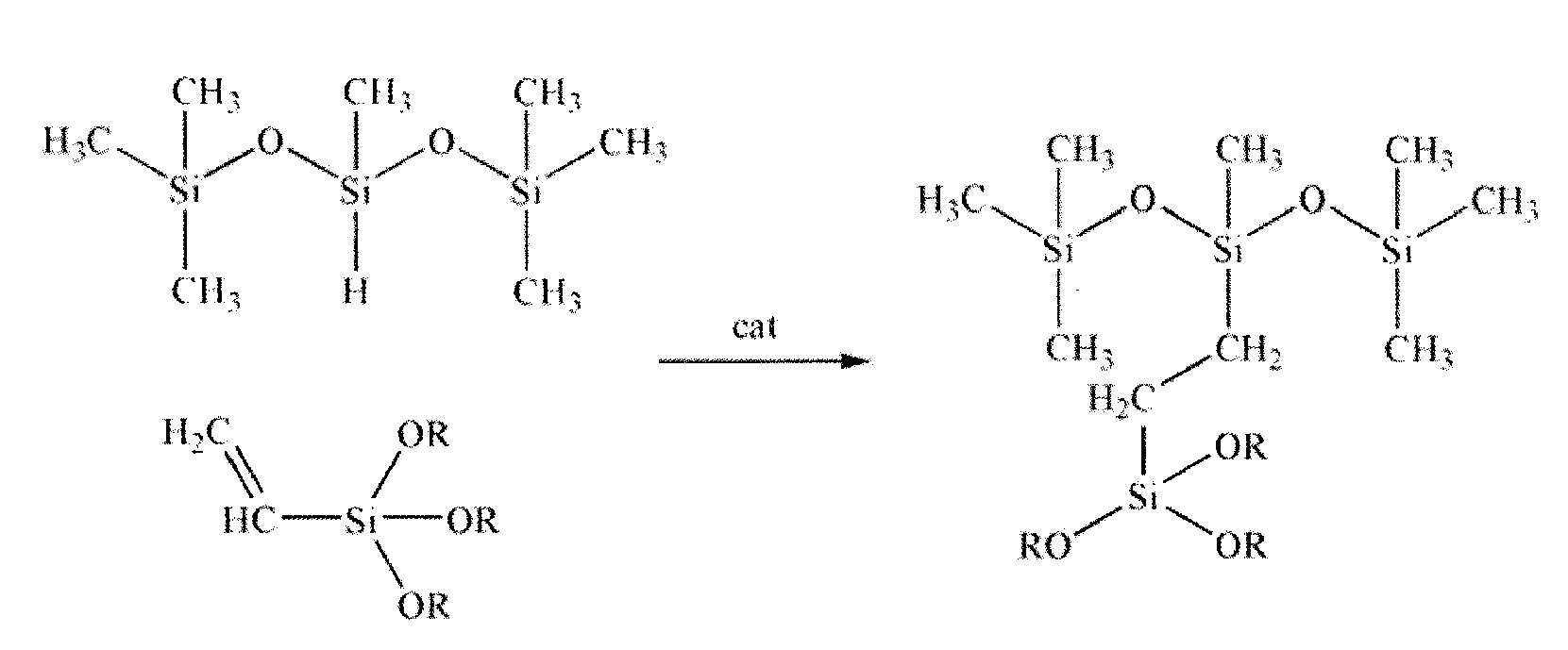

Method used

Image

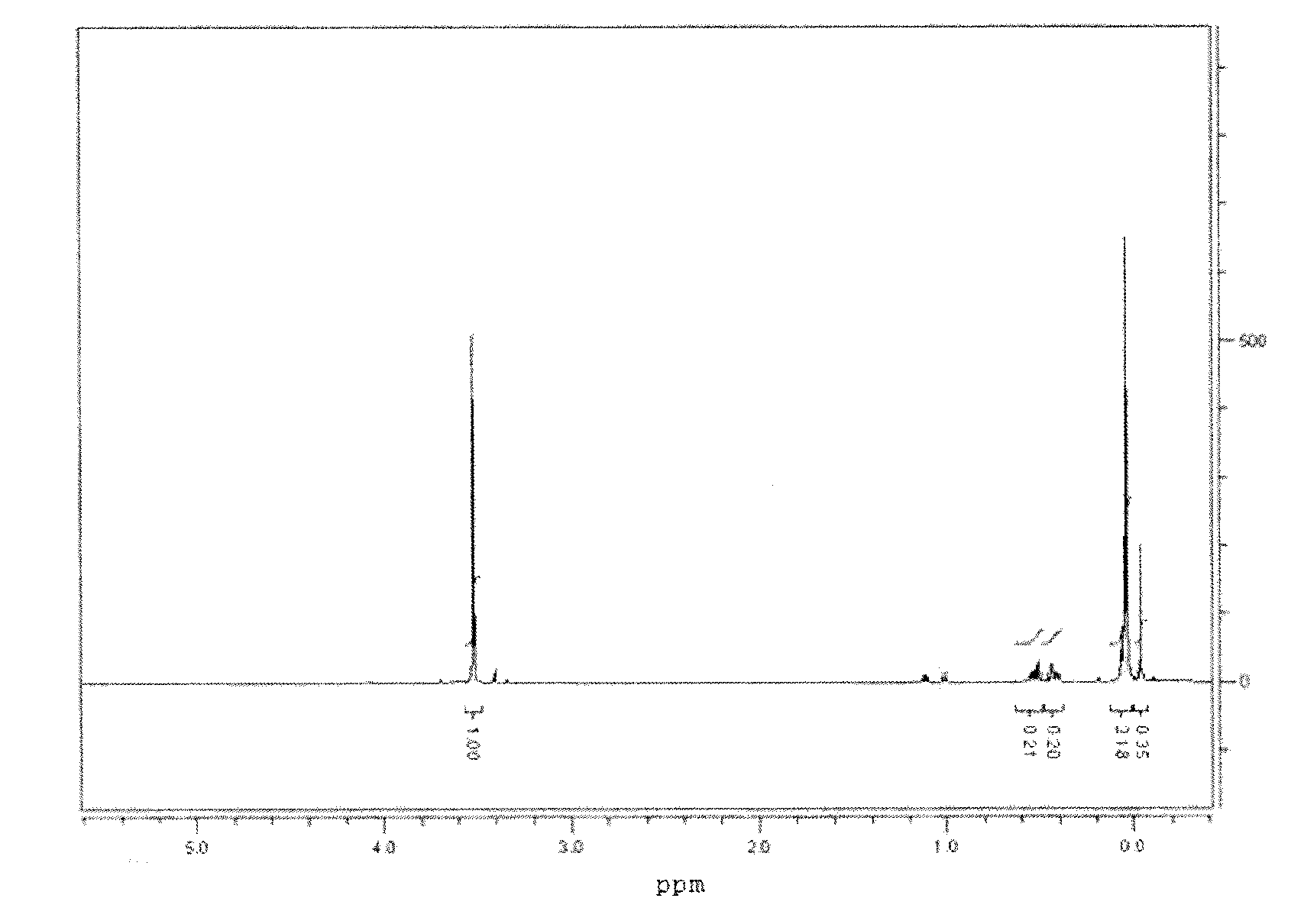

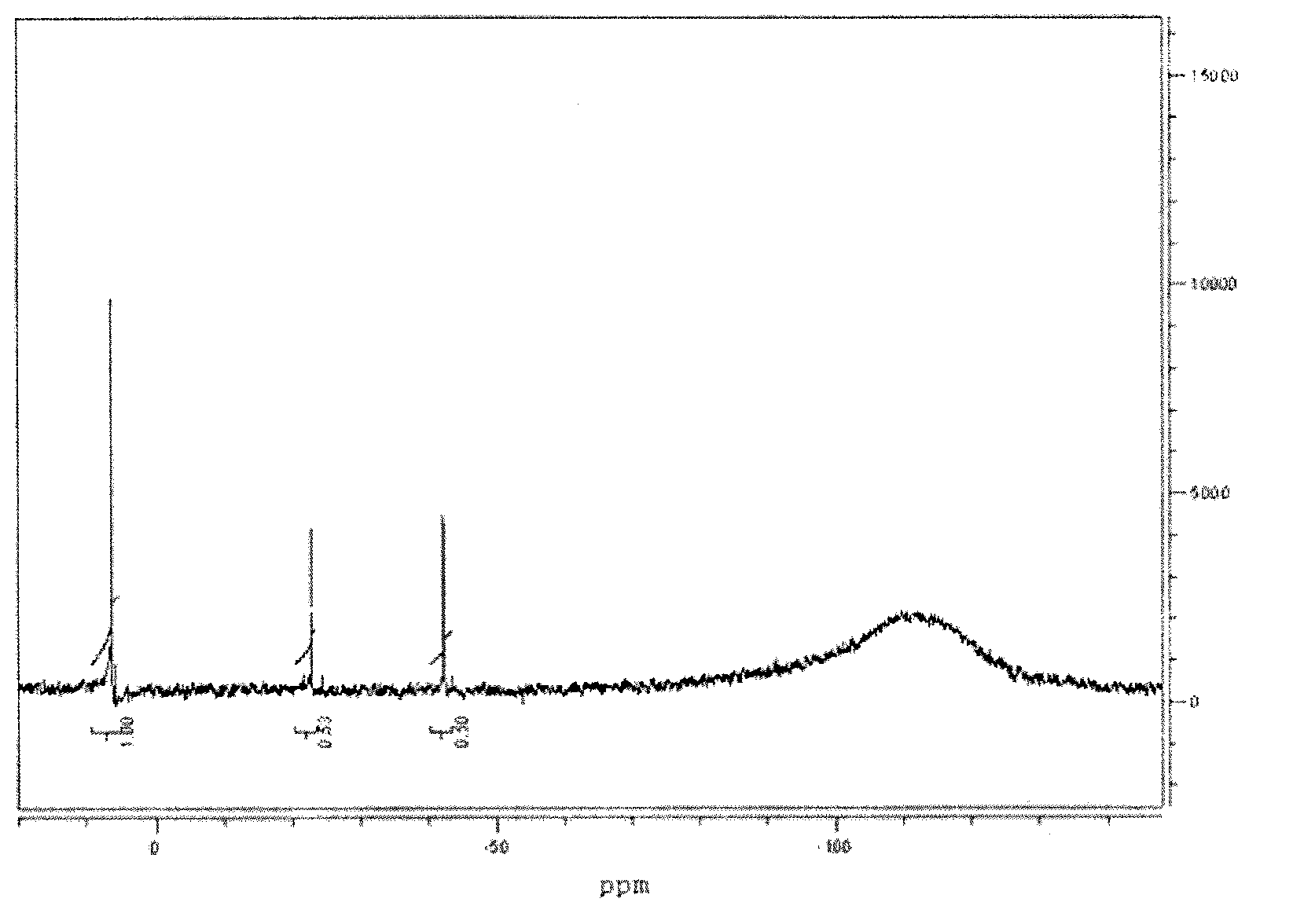

Examples

Embodiment 1

[0030] 1. Raw materials

[0031] 1,1,1,3,5,5,5-heptamethyltrisiloxane; vinyltrimethoxysilane; catalyst: isopropanol solution containing chloroplatinic acid 6.0mmol / L; activated carbon.

[0032] Wherein, the molar ratio of 1,1,1,3,5,5,5-heptamethyltrisiloxane to vinyltrimethoxysilane is 1:1.5, and the consumption of catalyst is 1,1,1,3, 0.2‰ of the total weight of 5,5,5-heptamethyltrisiloxane and vinyltrimethoxysilane.

[0033] 2. Preparation

[0034] Step 1: Add 1,1,1,3,5,5,5-heptamethyltrisiloxane and catalyst to the reactor at 35°C;

[0035] The second step: add vinyltrimethoxysilane dropwise to the mixture obtained in the first step; control the dropwise flow rate of vinyltrimethoxysilane to be 1mol / h, and the reaction time is 10h after the dropwise addition is completed;

[0036] The third step: after the second step reaction is completed, add activated carbon to the above mixture at 65°C, the weight of activated carbon is 15% of the solution mass, and perform adsorptio...

Embodiment 2

[0043] 1. Raw materials

[0044] 1,1,1,3,5,5,5-heptamethyltrisiloxane; vinyltrimethoxysilane; catalyst: isopropanol solution containing chloroplatinic acid 6.0mmol / L; activated carbon.

[0045] Wherein, the molar ratio of 1,1,1,3,5,5,5-heptamethyltrisiloxane to vinyltrimethoxysilane is 1:0.5, and the consumption of catalyst is 1,1,1,3, 0.1‰ of the total weight of 5,5,5-heptamethyltrisiloxane and vinyltrimethoxysilane.

[0046] 2. Preparation

[0047] Step 1: Add 1,1,1,3,5,5,5-heptamethyltrisiloxane and catalyst to the reactor at 55°C;

[0048] The second step: add vinyltrimethoxysilane dropwise to the mixture obtained in the first step; control the dropwise flow rate of vinyltrimethoxysilane to 0.3mol / h, and the reaction time is 20h after the dropwise addition is completed;

[0049] The third step: after the second step reaction is completed, add activated carbon to the above mixture at 45°C, the weight of activated carbon is 5% of the solution mass, and perform adsorption ...

Embodiment 3

[0052] 1. Raw materials

[0053] 1,1,1,3,5,5,5-heptamethyltrisiloxane; vinyltriethoxysilane; catalyst: isopropanol solution containing chloroplatinic acid 6.0mmol / L; activated carbon.

[0054] Wherein, the molar ratio of 1,1,1,3,5,5,5-heptamethyltrisiloxane to vinyltrimethoxysilane is 1:1.75, and the consumption of catalyst is 1,1,1,3, 0.5‰ of the total weight of 5,5,5-heptamethyltrisiloxane and vinyltrimethoxysilane.

[0055] 2. Preparation

[0056] Step 1: Add 1,1,1,3,5,5,5-heptamethyltrisiloxane and catalyst to the reactor at 65°C;

[0057] The second step: add vinyltrimethoxysilane dropwise to the mixture obtained in the first step; control the dropwise flow rate of vinyltrimethoxysilane to be 15mol / h, and the reaction time is 5h after the dropwise addition is completed;

[0058] Step 3: After the reaction in the second step is completed, add activated carbon to the above mixture at 35°C, the weight of activated carbon is 10% of the solution mass, and perform adsorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com