Preparation method of high-conductivity graphene membrane

A graphene film and high conductivity technology, applied in the field of graphene material preparation, can solve problems such as not being suitable for large-scale industrial production of graphene, affecting electron transmission at the basal surface of graphene sheets, and limiting large-scale industrial production and application , to achieve large-scale industrial production, easy large-scale industrial production, and less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The concrete process that present embodiment prepares high-conductivity graphene film is:

[0023] (1) Get 1g graphite and 6g potassium permanganate and join in the there-necked flask, slowly add concentrated sulfuric acid (98%) and concentrated phosphoric acid (85%) mixed acid 120ml that the volume ratio is 9:1, stir 30min; , the reaction temperature is 30-35 degrees;

[0024] (2) The three-necked flask was moved to a 50-degree water bath and stirred for 12 hours to obtain a purple graphite oxide solution;

[0025] (3) Add 5ml of hydrogen peroxide (30%) to 100ml of distilled water to freeze into ice cubes, then pour the graphite oxide solution into the ice cubes, filter until the ice cubes are completely dissolved (the solution is bright yellow at this time), and then use a mass Washing with 100ml of dilute hydrochloric acid with a fraction of 10%, then washing with distilled water until the solution is neutral, drying in vacuum at 40°C for 12h to obtain graphene oxid...

Embodiment 2

[0034] The other steps of this embodiment are the same as in Example 1, only the volume ratio of hydroiodic acid and ethanol is changed to 1:1, and the conductivity of the graphene film obtained is 1.7*10 4 S / m.

Embodiment 3

[0036]The other steps of this embodiment are the same as in Example 1, only the volume ratio of hydroiodic acid and ethanol is changed to 1:5, and the conductivity of the graphene film obtained is 2.1*10 4 S / m.

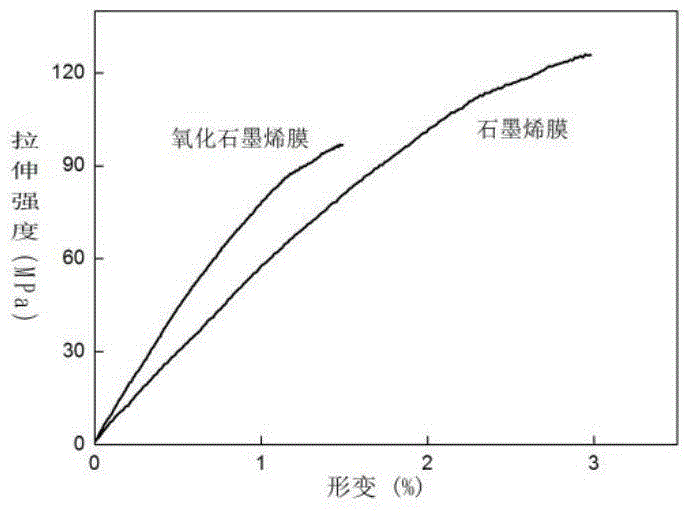

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com