Two-component casting glue for capsulation of solar photovoltaic module and preparation method thereof

A solar photovoltaic, two-component technology, used in photovoltaic power generation, chemical instruments and methods, adhesives, etc., can solve problems such as harsh environmental conditions, current damage to battery panels, safety accidents and subsequent problems that cannot be well resolved. , to achieve the process requirements and equipment is not harsh, the weather resistance and corrosion resistance are ideal, the effect of inhibiting water vapor transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

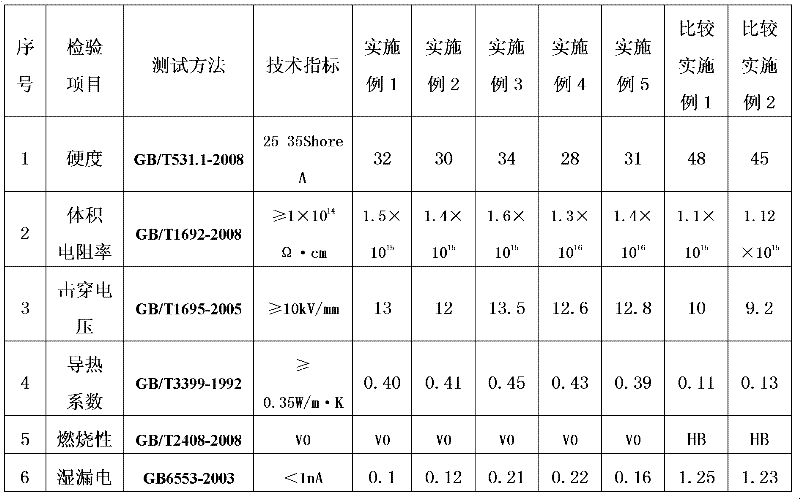

Examples

Embodiment 1

[0034] The steps of the preparation method of the two-component encapsulant for solar photovoltaic module encapsulation provided by the invention are as follows:

[0035] A) To prepare component A, 100 parts of α-ω-dihydroxypolydimethylsiloxane and 30 parts of dimethyl silicone oil are white powder with a particle size of 18-22nm and specific surface area ≥ 50m 2 80 parts of nano-alumina / g, 25 parts of flame-retardant fillers, namely active aluminum hydroxide and active magnesium hydroxide (50 parts in total) and 30 parts of nano-calcium carbonate treated with resin acid are added to the vacuum kneader and kneaded. The vacuum degree is controlled at -0.07MPa, the kneading temperature is 110°C, kneading and copolymerizing for 100min, and the A component is obtained;

[0036] B) To prepare component B, 100 parts of vinyl silicone oil, 20 parts of crosslinking agent methyltrimethoxysilane, coupling agent hexamethyldisiloxane and γ-[2,3-glycidyloxypropoxy ]Propyltrimethoxysilane...

Embodiment 2

[0039] A) To prepare component A, mix 110 parts of α-ω-dihydroxypolydimethylsiloxane, 40 parts of vinyl silicone oil, 90 parts of aluminum oxide, and flame retardant filler active hydrogen according to the weight ratio or number of parts Add 30 parts of alumina and 25 parts of active magnesium hydroxide to a total of 55 parts, add 40 parts of nano-calcium carbonate into a vacuum kneader, control the vacuum degree of the kneader at -0.08MPa, kneading temperature 120°C, and knead and copolymerize for 90 minutes to obtain component A ;

[0040] B) To prepare component B, 110 parts of vinyl silicone oil, 30 parts of crosslinking agent methyltrimethoxysilane, coupling agent γ-[2,3-glycidyloxy]propyltrimethoxysilane and 2.5 parts of γ-aminopropyltriethoxysilane compounded according to 1:1, 1 part of catalyst dibutyl tin diacetate, 1.5 parts of YL-II type colored slurry with black color and put into double planetary high-speed mixer In the process, the rotation speed is 400n / min and...

Embodiment 3

[0043] A. To prepare component A, mix 120 parts of α-ω-dihydroxypolydimethylsiloxane, 50 parts of methyl vinyl silicone oil, 100 parts of aluminum oxide, and hydrogen Add 56 parts of magnesium oxide and 50 parts of nano-calcium carbonate into a vacuum kneader. The vacuum degree of the kneader is controlled at -0.06MPa, the kneading temperature is 115°C, and kneading and copolymerization is carried out for 105 minutes to obtain component A;

[0044] B. To prepare component B, 120 parts of vinyl silicone oil, 25 parts of crosslinking agent methyltrimethoxysilane, and 2.6 parts of coupling agent γ-[2,3-glycidoxy]propyltrimethoxysilane , 0.7 parts of catalyst dibutyl tin diacetate, 1.2 parts of YL-II-A type gray colored slurry are put into the double planetary high-speed mixer, the rotation speed is 550n / min, the revolution speed is 40n / min, blending and stirring 60min, get B component. All the other are the same as the description to embodiment 1.

[0045] In actual use, compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com