Novel ceramic nanofiltration membrane preparation method

A ceramic nanofiltration membrane, ceramic ultrafiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of membrane cracking, high process requirements, complicated operation, etc. Craftsmanship requires simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

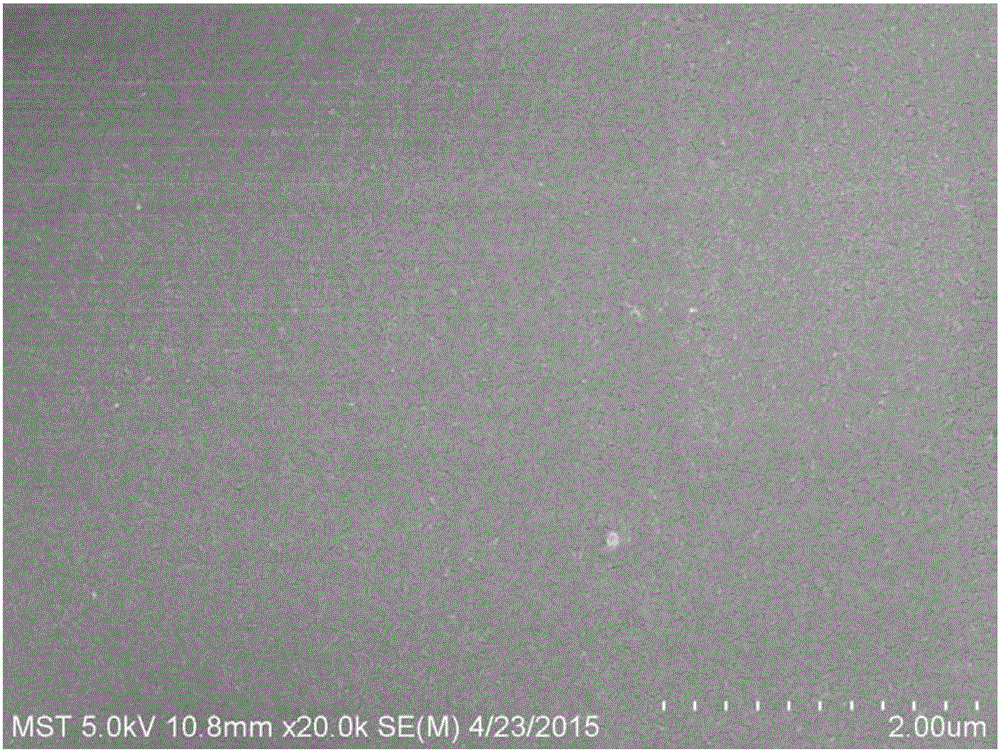

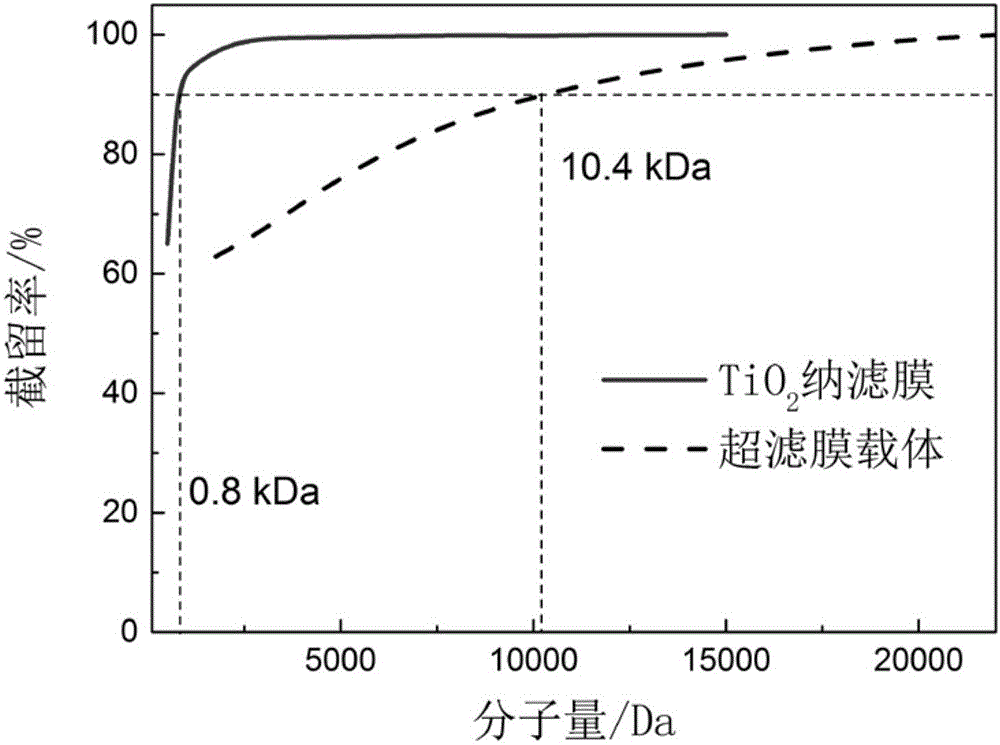

Embodiment 1

[0022] Using ceramic ultrafiltration membranes with an average pore size of about 5, 10 and 20nm as the carrier, the corresponding molecular weight cut-offs are 10, 50 and 250kDa, and the corresponding pure water fluxes are 40, 120 and 310L m -2 h -1 · bar -1 . Titanium isopropoxide is used as a precursor, and isopropanol is used as a solvent. A 20wt% precursor solution was prepared, and a ceramic ultrafiltration membrane dried at 200°C was immersed in it so that it was completely infiltrated by the solution under capillary force. Take it out after soaking at room temperature for 10 hours, and dry it in a ventilated place at room temperature. Then, the samples were transferred to an oven at 60 °C for 20 h to dry. Finally, the samples were calcined in a muffle furnace at 600 °C for 0.5 h with a heating rate of 0.1 °C / min. After the sample is cooled with the furnace, TiO 2 Nanofiltration. The TiO 2 The pore diameters of nanofiltration membranes are about 1.4, 1.6 and 2.2...

Embodiment 2

[0024] With three kinds of TiO obtained in embodiment 1 2 Nanofiltration membrane as carrier. Titanium isopropoxide is used as a precursor, and a mixture of isopropanol and ethanol with a mass ratio of 2:1 is used as a solvent. Prepare a 0.1wt% precursor solution and dry TiO at 150°C 2 The nanofiltration membrane is immersed in it so that it is completely wetted by the solution under capillary force. Take it out after immersing at room temperature for 1 hour, and dry it in a ventilated place at room temperature. Subsequently, the samples were dried in an oven at 180 °C for 0.5 h. Finally, the sample was calcined at 450 °C for 1 h in a muffle furnace with a heating rate of 1 °C / min. After the sample is cooled with the furnace, TiO 2 Nanofiltration. TiO with an average pore size of approximately 1.4, 1.6 and 2.2 nm 2 Nanofiltration membrane is used as the carrier to obtain TiO with smaller pore size 2 The pore diameters of nanofiltration membranes are about 1.2, 1.4 and ...

Embodiment 3

[0026] Al with an average pore size of about 5 nm 2 o 3 、TiO 2 and ZrO 2 The ultrafiltration membrane is used as the carrier, the corresponding molecular weight cut-off is about 10kDa, and the corresponding pure water fluxes are 40, 62 and 54L m -2 h -1 · bar -1 . A mixture of titanium isopropoxide and zirconium isopropoxide at a molar ratio of 1:1 is used as a precursor, and isopropanol is used as a solvent. A 10wt% precursor solution was prepared, and a ceramic ultrafiltration membrane dried at 110°C was immersed in it so that it was completely infiltrated by the solution under capillary force. Take it out after soaking at room temperature for 20 hours, and dry it in a room temperature ventilated place. Then, the samples were transferred to an oven at 70 °C for 2 h to dry. Finally, the samples were calcined in a muffle furnace at 350 °C for 4 h with a heating rate of 5 °C / min. After the sample is cooled with the furnace, a series of ZrO 2 -TiO 2 Composite nanofilt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com