High-resistance cap layer-based III-nitride polarization super-junction high electron mobility transistor (HEMT) device and fabrication method thereof

A technology of capping layer and nitride, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reducing the concentration of two-dimensional electron gas and low current density of polarized superjunction devices, so as to avoid etching damage, compensate for low current density, and increase the effect of current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

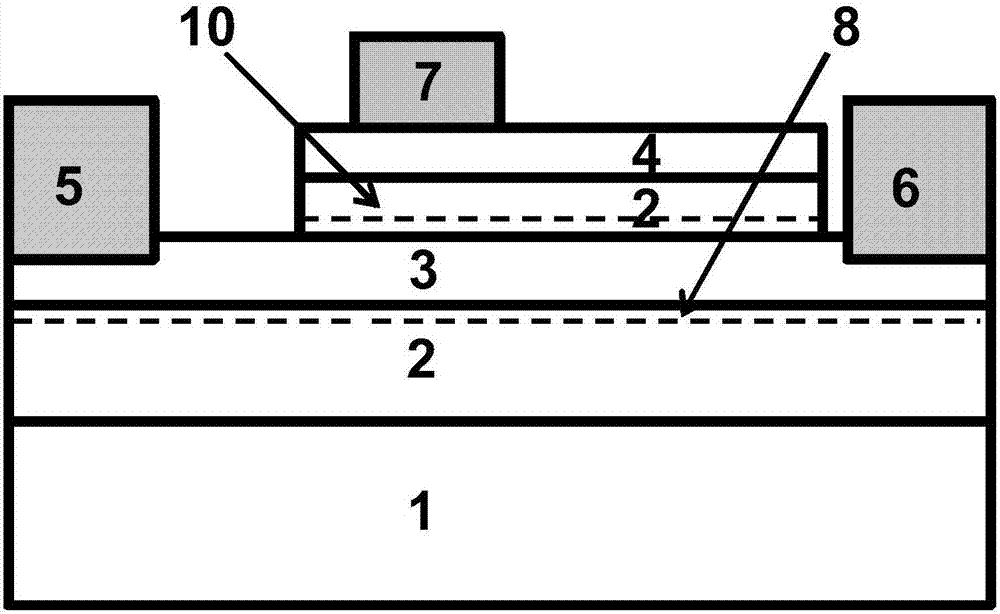

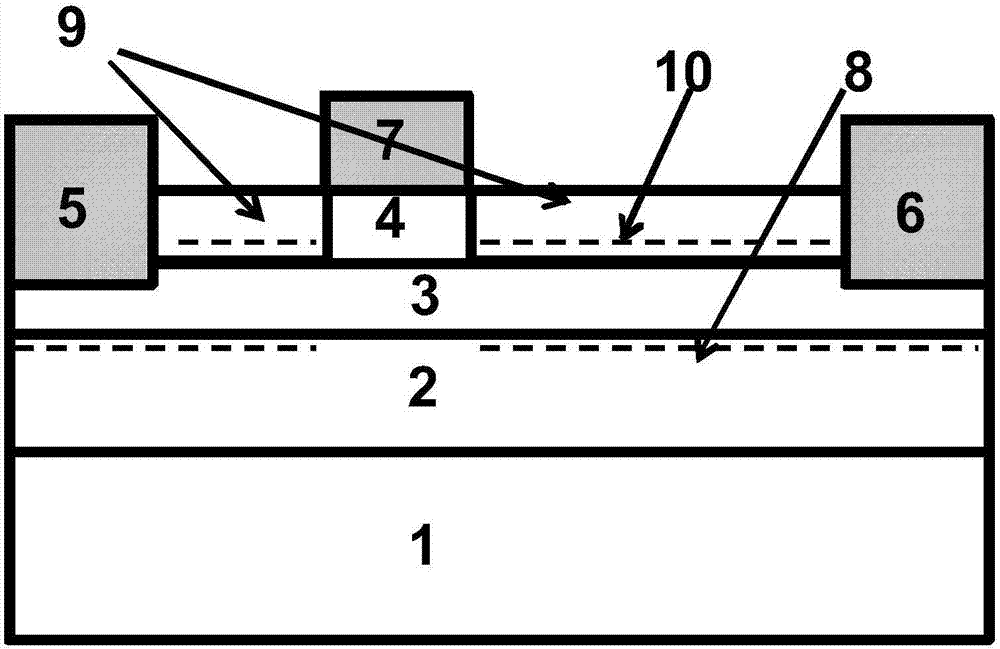

[0109] Example 1: Please see again image 3 and Image 6 In a typical implementation involved in this embodiment, a method for fabricating a polarized superjunction enhanced HEMT realized by using a high-resistance capping layer and a p-type gate technology includes the following steps:

[0110] (1) Treat the substrate surface in the reaction chamber of the epitaxial growth equipment;

[0111] (2) Epitaxial growth of AlGaN / GaN epitaxial layer and p-GaN on the substrate, wherein the thickness of GaN is 1μm-8μm, the thickness of AlGaN is 14nm-30nm, and the molar content of Al element is 15%-30%, p -GaN thickness is 50-110nm, Mg doping concentration is 10 19 After being taken out from the chamber, it is cleaned with an organic solution and purged with high-purity nitrogen;

[0112] (3) Perform photolithography and development on the cleaned device, the photoresist is AZ5214, the exposure time is 6.5s, the development time is 50s-60s, and the table is isolated, and ion implanta...

Embodiment 2

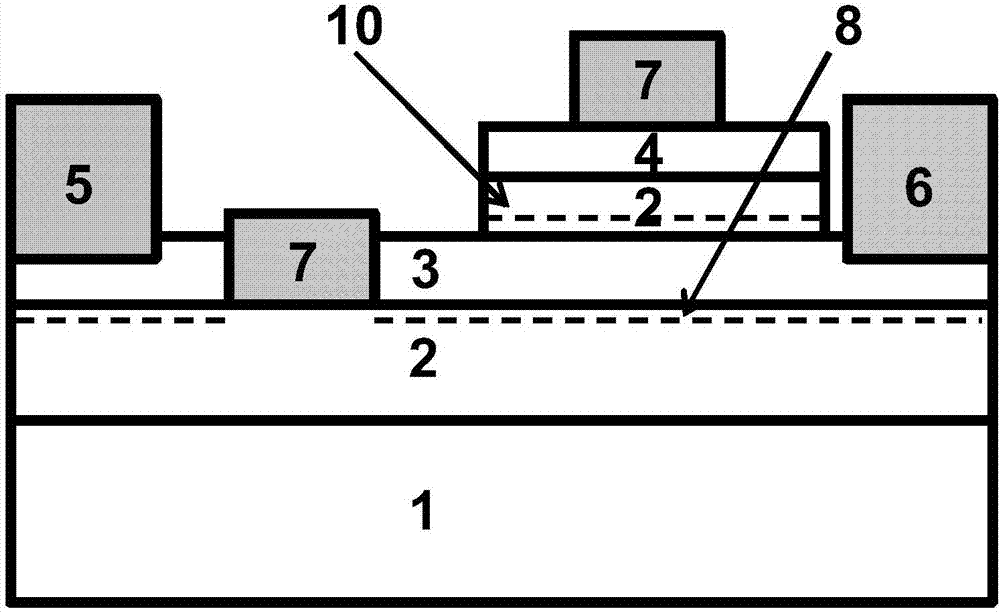

[0117] see again image 3 and Figure 7 In a typical implementation that this embodiment relates to, the method for making a polarized superjunction enhanced HEMT that adopts a high-resistance capping layer and a p-type gate technology includes the following steps:

[0118] (1) processing the substrate surface in the reaction chamber;

[0119](2) Epitaxial growth of AlGaN / GaN epitaxial layer and Mg-doped non-activated high-resistance GaN on the substrate, wherein the thickness of GaN is 1 μm-8 μm, the thickness of AlGaN is 14nm-30nm, and the molar content of Al element is 15 %-30%, the thickness of high-resistance GaN is 50-110nm, and the Mg doping concentration is 10 19 After being taken out from the chamber, it is cleaned with an organic solution and purged with high-purity nitrogen;

[0120] (3) Perform photolithographic development on the cleaned device, the photoresist is AZ5214, the exposure time is 6.5s, the development time is 50s-60s, and the table is isolated, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com