Method for preparing mono dispersed micrograde polymer microsphere

A micron-scale, polymer technology, applied in the field of preparation of monodisperse micron-scale polymers, can solve the problems of difficult to obtain monodisperse polymer microspheres, small particle size of microspheres, large heat consumption, etc., to avoid secondary Nucleation and process requirements are simple, and the effect of improving monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

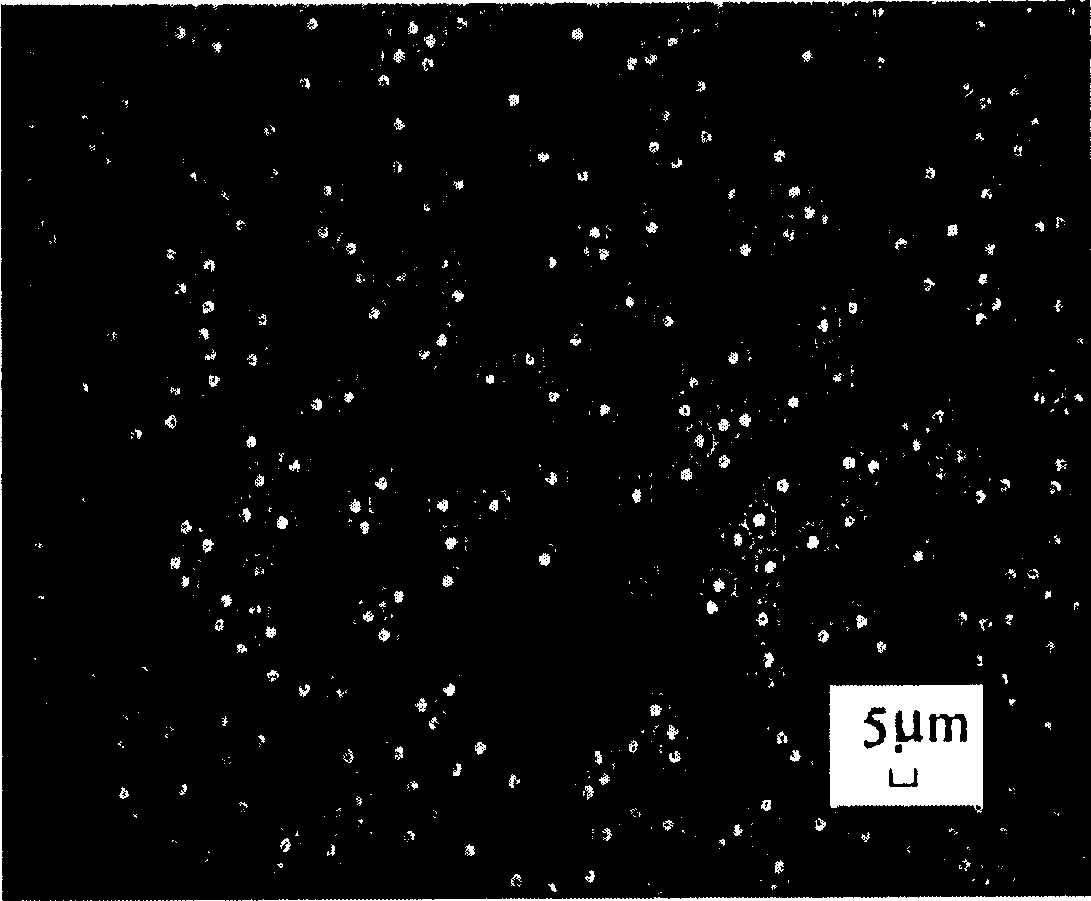

[0027] In a 250mL four-necked reaction flask with a condenser, add 60g of absolute ethanol, 30g of styrene, 0.3g of AIBN, and 1.2g of PVP K-30 to form a transparent solution. Pass N 2 After 15 minutes, the reaction system was heated to raise the temperature to 70°C. When the temperature rises to 70°C, start timing. After the reaction was carried out for 1 hour, 1 mL of a 10 g / L ethanol solution of p-benzoquinone was added. The reaction was continued for 12 hours and stopped. Separate the obtained emulsion with a centrifuge, remove the supernatant, add ethanol and water to wash, repeat several times, and finally dry the product at low temperature to obtain a polymer microsphere sample with a particle size of 3.6 μm and a dispersion coefficient of 1.10. Good dispersion. SEM photo see figure 1 .

Embodiment 2

[0029] In a 250mL four-necked reaction flask with a condenser, add 60g of 95% ethanol, 15g of styrene, 0.2g of AIBN, and 0.6g of PVP K-30 to form a transparent solution. Pass N 2 After 15 minutes, the reaction system was heated to raise the temperature to 75°C. start the timer. After the reaction was carried out for 2 hours, 0.5 mL of a 10 g / L ethanol solution of p-benzoquinone was added. The reaction was continued for 12 hours and stopped. Separate the obtained emulsion with a centrifuge, remove the supernatant, add ethanol and water to wash, repeat several times, and finally dry the product at low temperature to obtain a polymer microsphere sample with a particle size of 3.1 μm and a dispersion coefficient of 1.04. Good dispersion.

Embodiment 3

[0031] In a 250mL four-necked reaction flask with a condenser, add 60g of anhydrous methanol, 20g of methyl methacrylate, 0.2g of AIBN, and 1.0g of PVP K-30 to form a transparent solution. Pass N 2 After 15 min, the reaction temperature was raised to 70 °C. Start timing, and after the reaction has been carried out for 2 hours, add 1 mL of a 10 g / L ethanol solution of p-benzoquinone. After the reaction was continued for 12 hours, the reaction was stopped. Centrifuge the obtained emulsion, remove the supernatant, add ethanol and water to wash, repeat several times, and finally dry the product at low temperature to obtain a polymer microsphere sample with a particle size of 2.4 μm, a dispersion coefficient of 1.02, and a monodisperse it is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com