Interval reaction rectification process for synthesizing methacrylic anhydride

A technology of methacrylic anhydride and methacrylic acid, applied in the field of batch reaction rectification process, can solve problems such as blocking filters, achieve the effects of improving conversion rate and yield, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

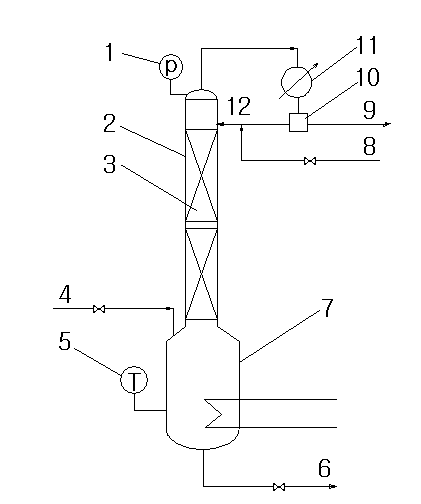

[0027] Attached figure 1 Shown technological process, concrete steps are as follows:

[0028] 1) After the raw materials acetic anhydride and methacrylic acid are mixed with the polymerization inhibitor, they are fed into the tower kettle through the pipeline 4. The molar ratio of the raw materials acetic anhydride and methacrylic acid is 1:1.5~1:4, and the feeding method is one-time feeding.

[0029] 2) Turn on the heating and control the initial top pressure at 10kPa. Then in the reaction process, the operating pressure of the tower is continuously reduced (taking the steam at the top of the tower as the standard, and when the steam at the top of the tower is no longer condensed, the vacuum degree of the tower is appropriately increased), so that one of the products, acetic acid, is continuously distilled from the rectification The tower steams out.

[0030] 3) When there is reflux at the top of the tower, dissolve part of the polymerization inhibitor with acetic acid and ...

Embodiment 2

[0037] Similar to the operation method of Example 1, the molar ratio of raw materials acetic anhydride and methacrylic acid is 1:1.5~1:4, and the feeding method is one-time feeding.

[0038] The reaction results are as follows: the reaction time is 5.58 hours, the conversion rate of methacrylic acid is 99.11%, the purity of acetic acid at the top of the tower is 99.82%, and the reaction yield of methacrylic anhydride is 85.99%.

Embodiment 3

[0040] Similar to the operation method of Example 1, the polymerization inhibitor is 2,4-di-tert-butyl-p-cresol (6BX), 2,6-di-tert-butyl-6-p-cresol (BHT), phosphoric acid triester (TOP ), the mixing ratio of the three is still mass ratio 1:2:3, and the amount of polymerization inhibitor is 0.5% of the raw material liquid quality. When the top of the tower starts to extract, set the reflux ratio to 1. After 2.5 hours of extraction, adjust the reflux ratio to 1.5. After continuous extraction for 1 hour, adjust the reflux ratio to 3 until the end of the reaction. Other operating conditions are the same as Example 1.

[0041] The reaction results are as follows: the reaction time is 4.75h, the conversion rate of methacrylic acid is 99.2%, the purity of acetic acid at the top of the tower is 99.1%, and the reaction yield of methacrylic anhydride is 86.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com