Patents

Literature

145results about How to "Avoid Polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion

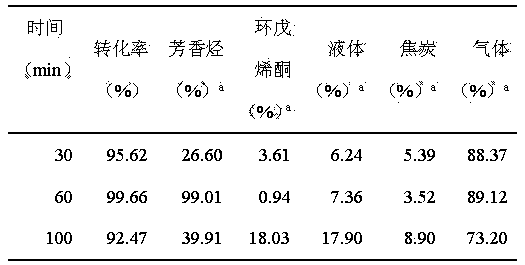

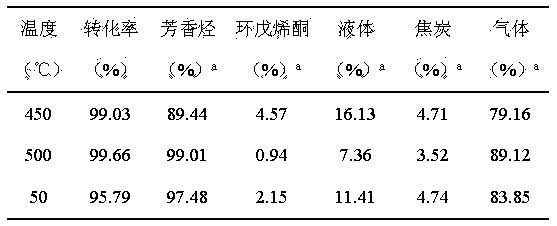

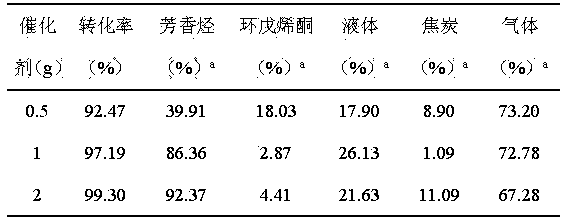

InactiveCN104230615AGood dehydrogenation performanceInhibition of partial polymerizationHydrocarbonsPreparation from heterocyclic compoundsLiquid productReaction temperature

The invention relates to a method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion, which comprises the following steps: (1) using biomass derivative gamma-valerolactone as a raw material, which is prepared by carrying out hydrogenation reaction on levulinic acid; (2) introducing one or more transition metals into a zeolite molecular sieve, and preparing a reaction catalyst at the reaction temperature of 350-550 DEG C by using a fixed bed or fluid bed as a reactor; (3) in an inert or reducing atmosphere, carrying out contact reaction on the raw material gamma-valerolactone and catalyst under the reaction pressure of 0-10 MPa; and (4) after the pyrolysis gas is condensed, collecting the liquid product in the condensation receiver, thereby obtaining the aromatic hydrocarbon product (of benzene, toluene and xylene) and the cyclopentenone product. By using the renewable biomass derivative gamma-valerolactone as the raw material, the method has the advantage of milder reaction conditions, and the catalyst is simple to prepare and easy to recover and reuse.

Owner:湖南清欣绿色环保有限公司

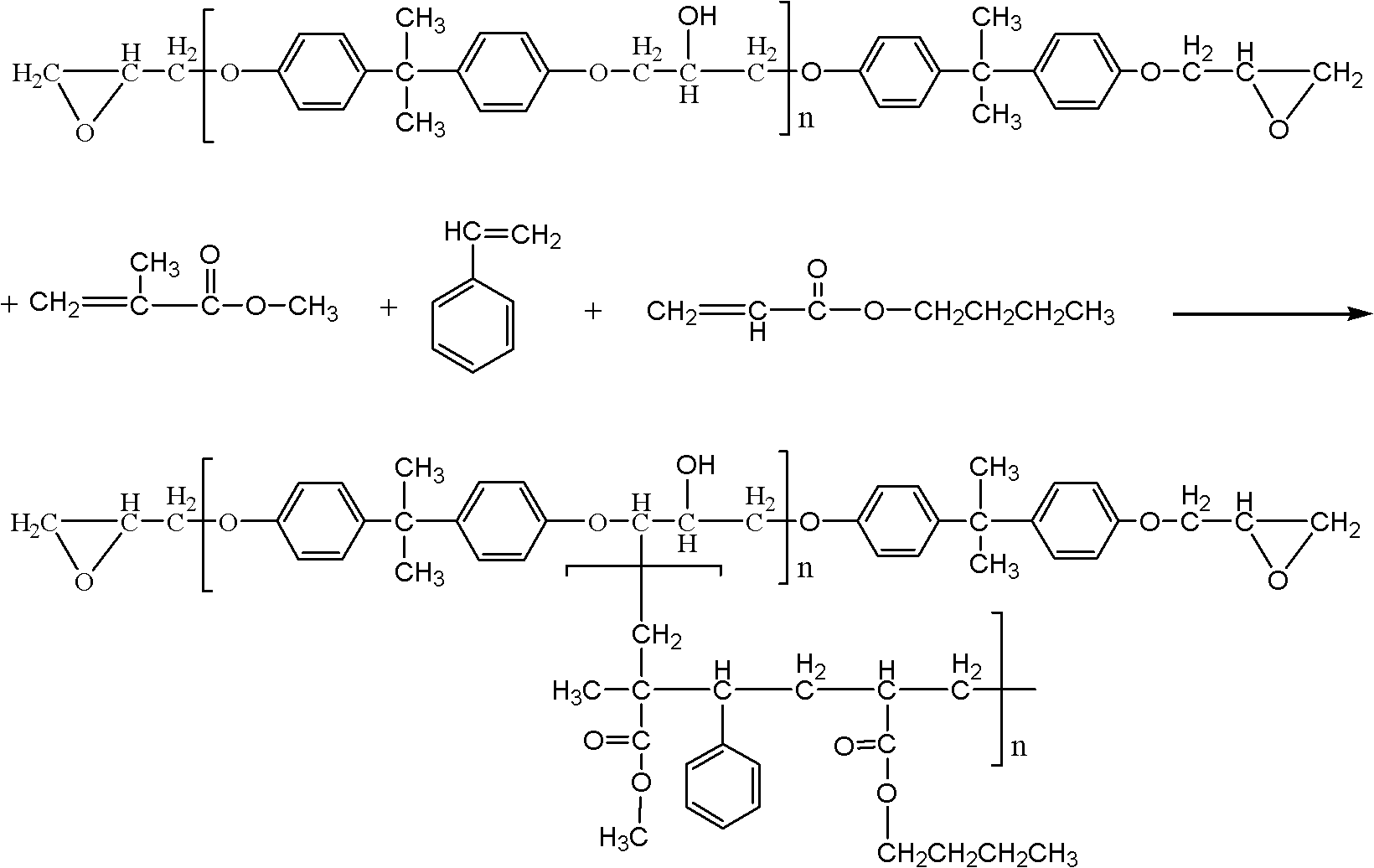

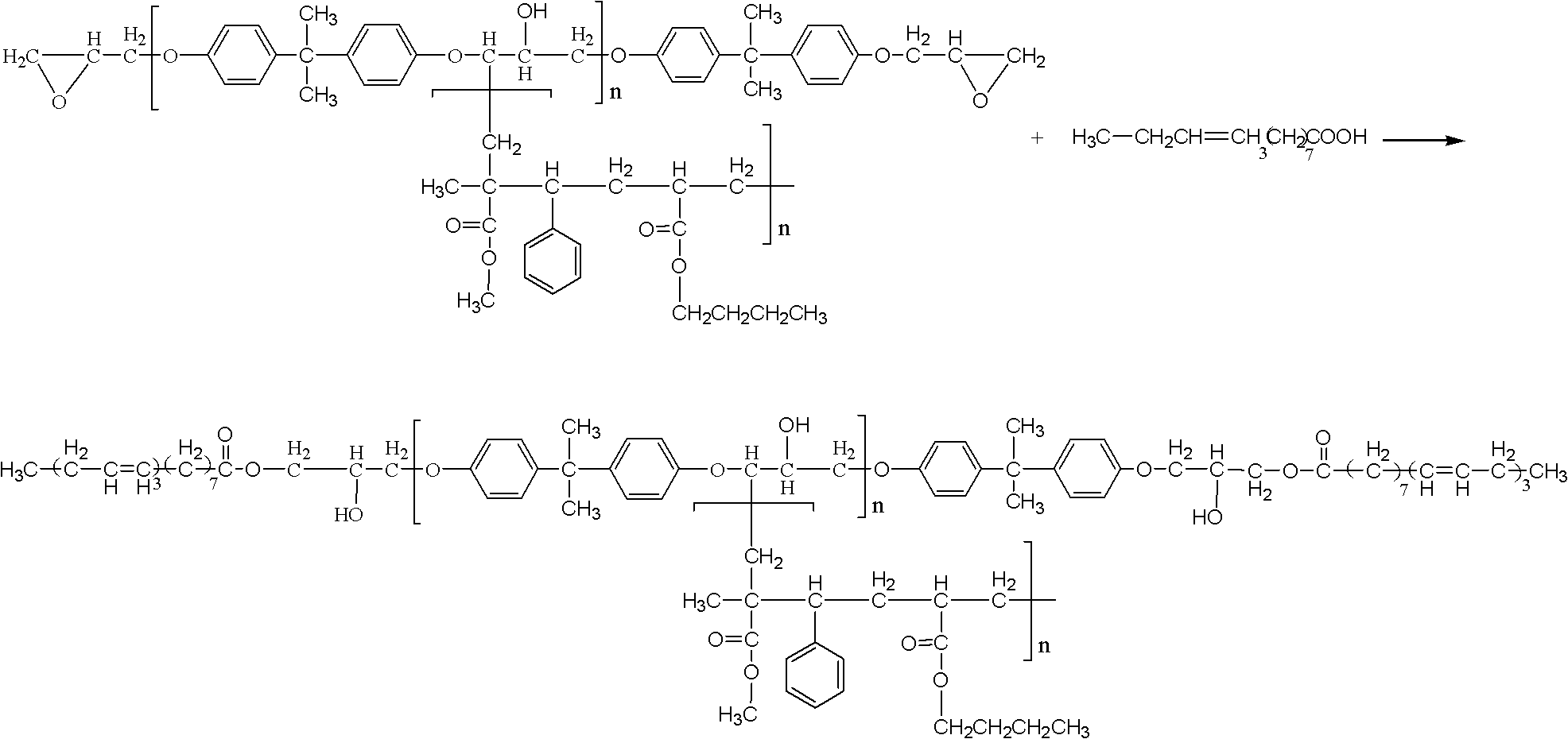

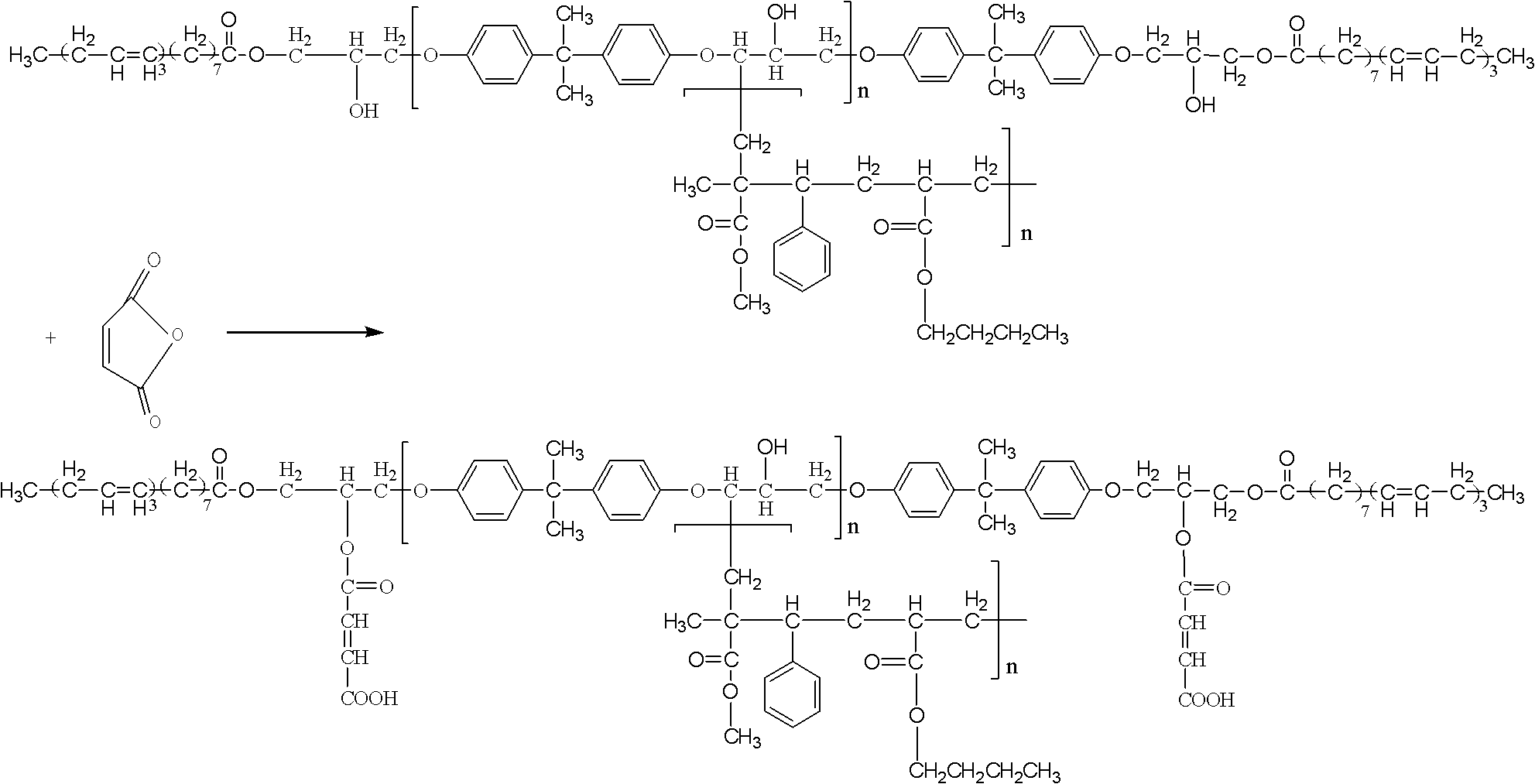

Single-component aqueous epoxy resin emulsion capable of being self-cured at normal temperature, and preparation method thereof

The invention discloses single-component aqueous epoxy resin emulsion capable of being self-cured at normal temperature, and a preparation method thereof. The method comprises the following steps of: adding epoxy resin, n-butyl alcohol, and ethylene glycol monobutyl ether into a reactor, heating to form a homogeneous phase, controlling temperature to be 110 to 120 DEG C, and dripping acrylic ester monomers in which initiator benzoyl peroxide (BPO) is dissolved to obtain an acrylic ester monomer modified epoxy resin; and heating the acrylic ester monomer modified epoxy resin to 120 to 150 DEG C, adding unitary unsaturated fatty acid and catalyst triphenylphosphorus, adding maleic anhydride, reacting for 1.0 to 2.0 hours, reducing temperature to 50 to 55 DEG C, adding triethylamine, neutralizing for 0.5 to 1.0 hour, adding water and dispersing for 0.5 to 1.0 hour to obtain the single-component aqueous epoxy resin emulsion capable of being self-cured at normal temperature. The aqueous epoxy resin emulsion which is obtained by the method can be cured at normal temperature to form a film under the condition of not adding a curing agent, is convenient to use, and high in water resistance and corrosion resistance, and can be used for metal corrosion-resistant paint and the like.

Owner:广州玖盈化工材料有限公司

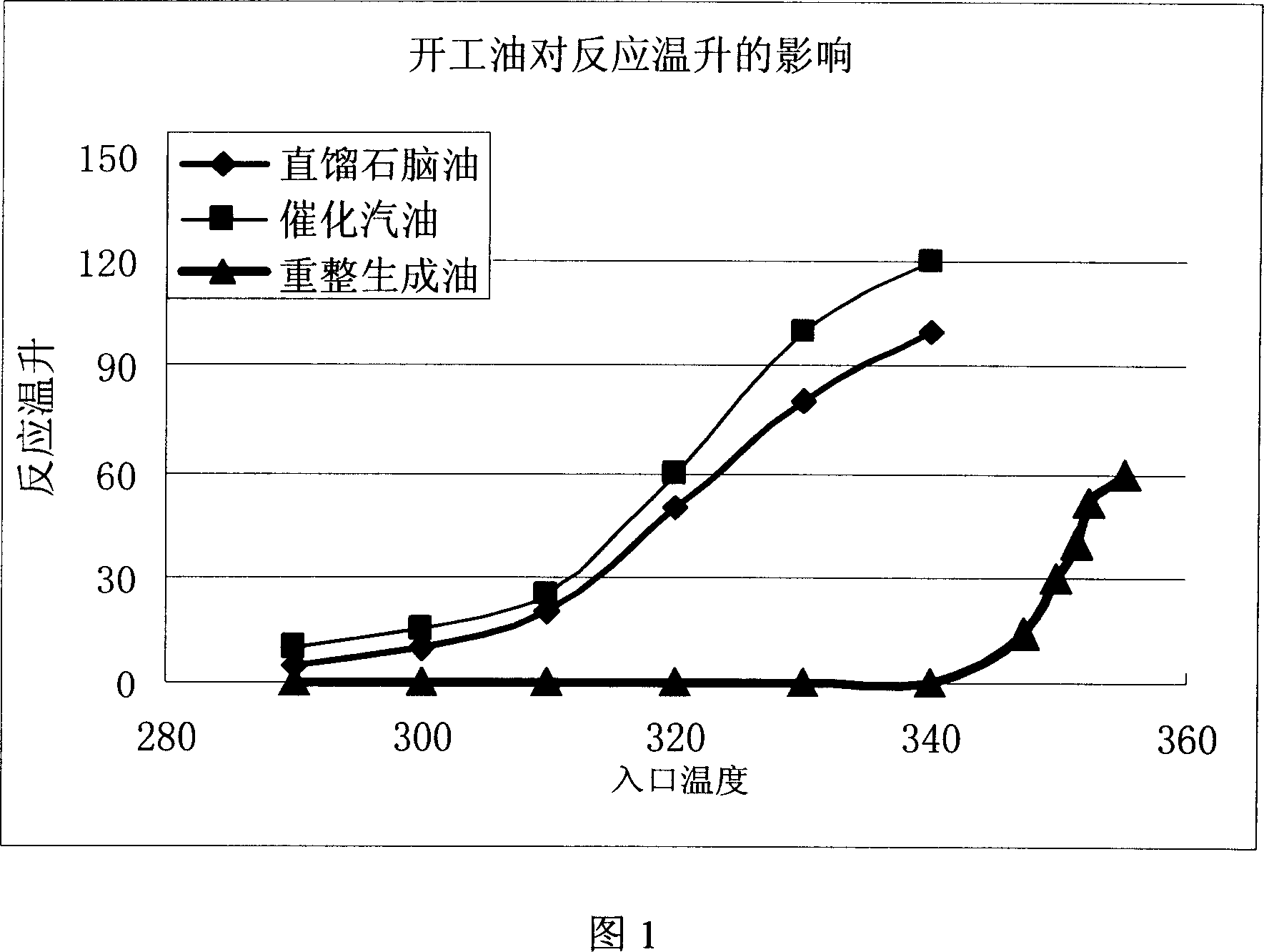

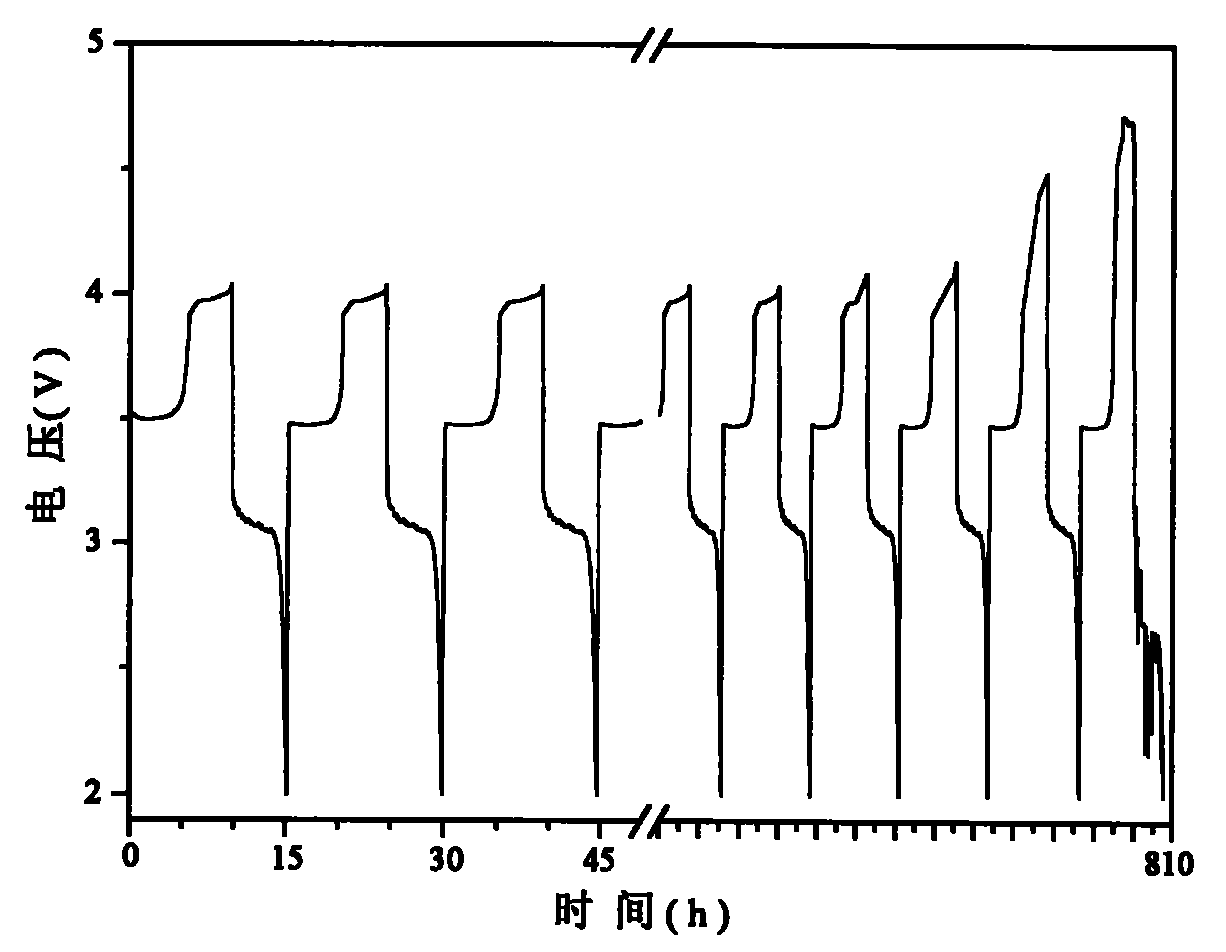

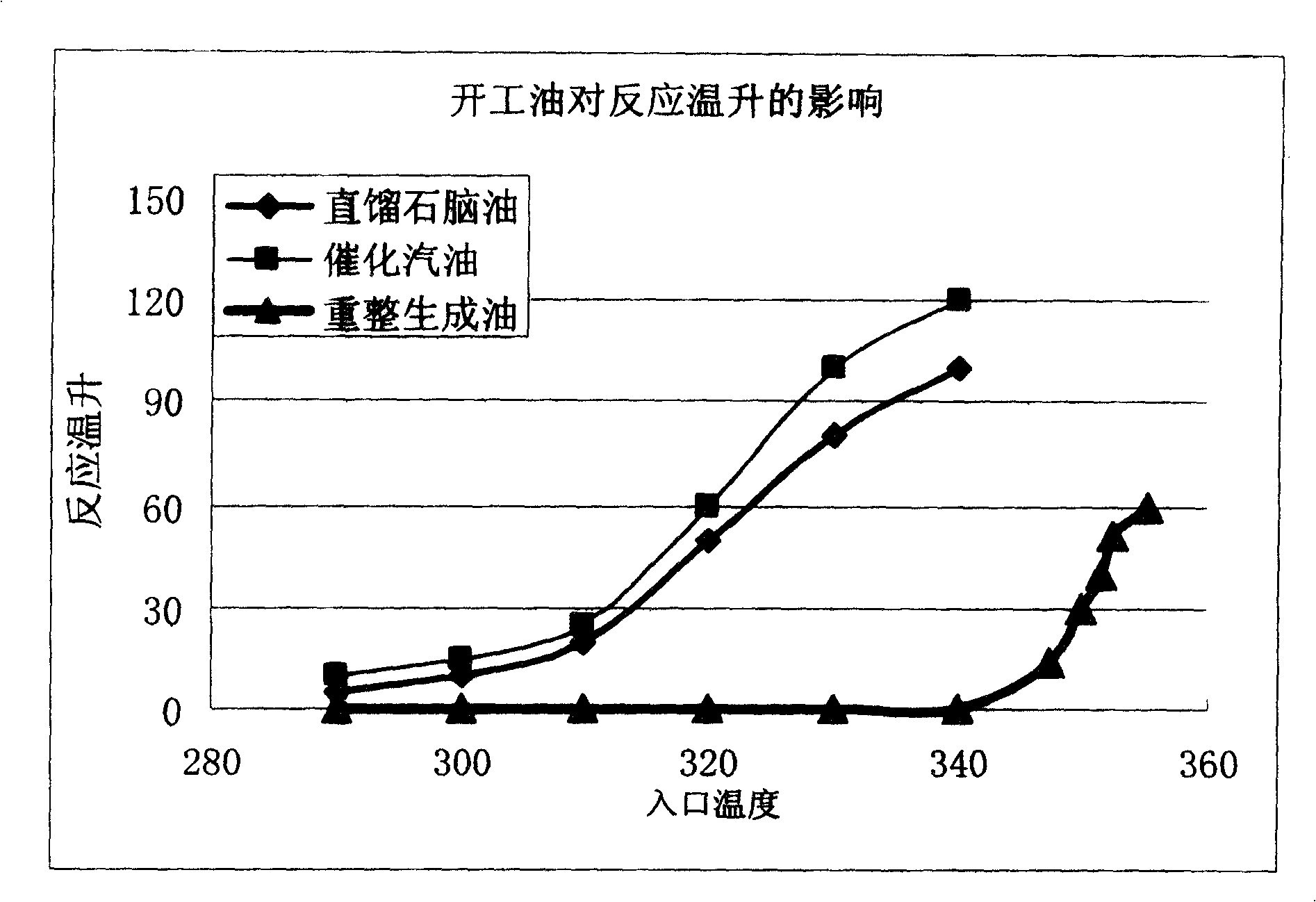

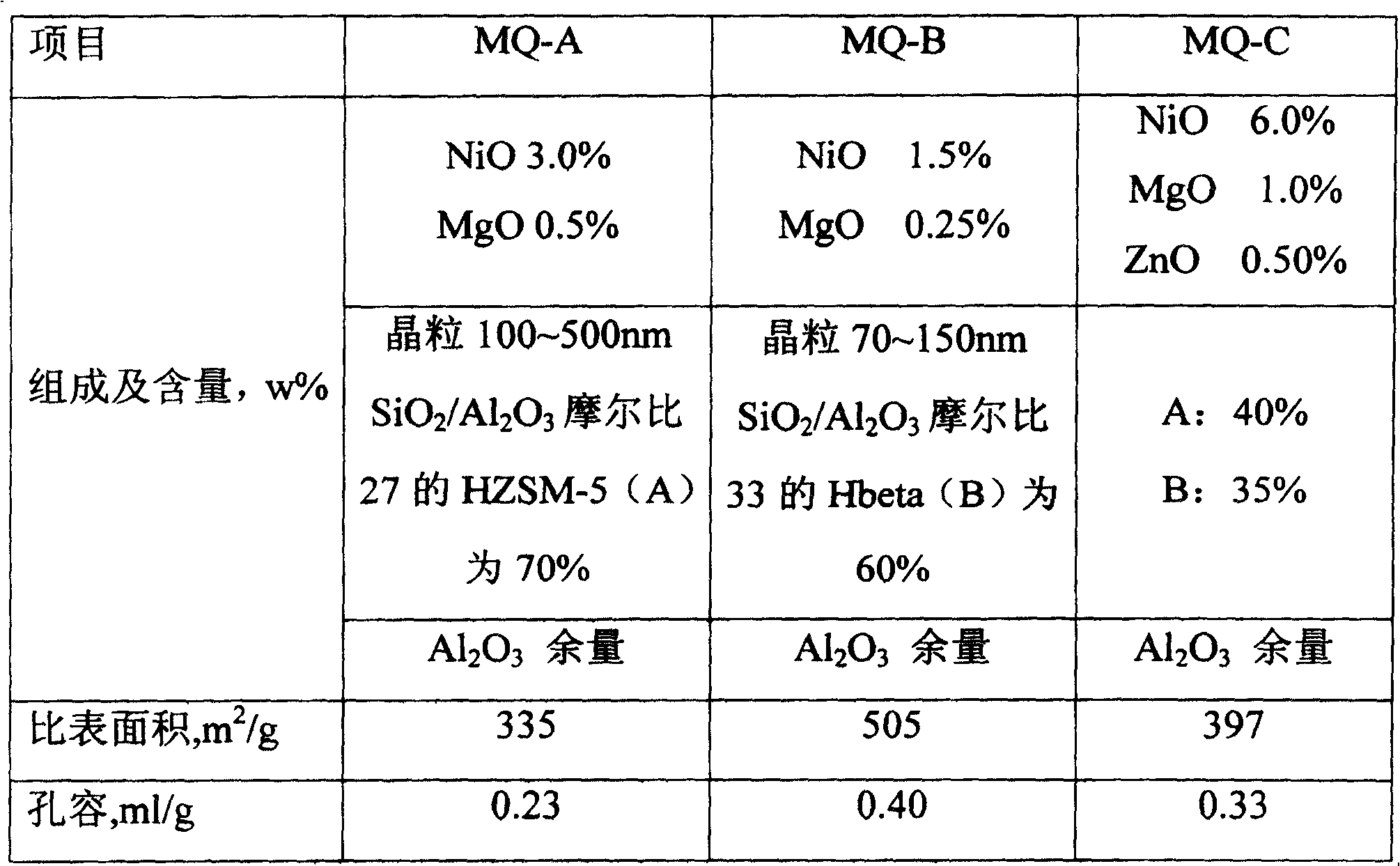

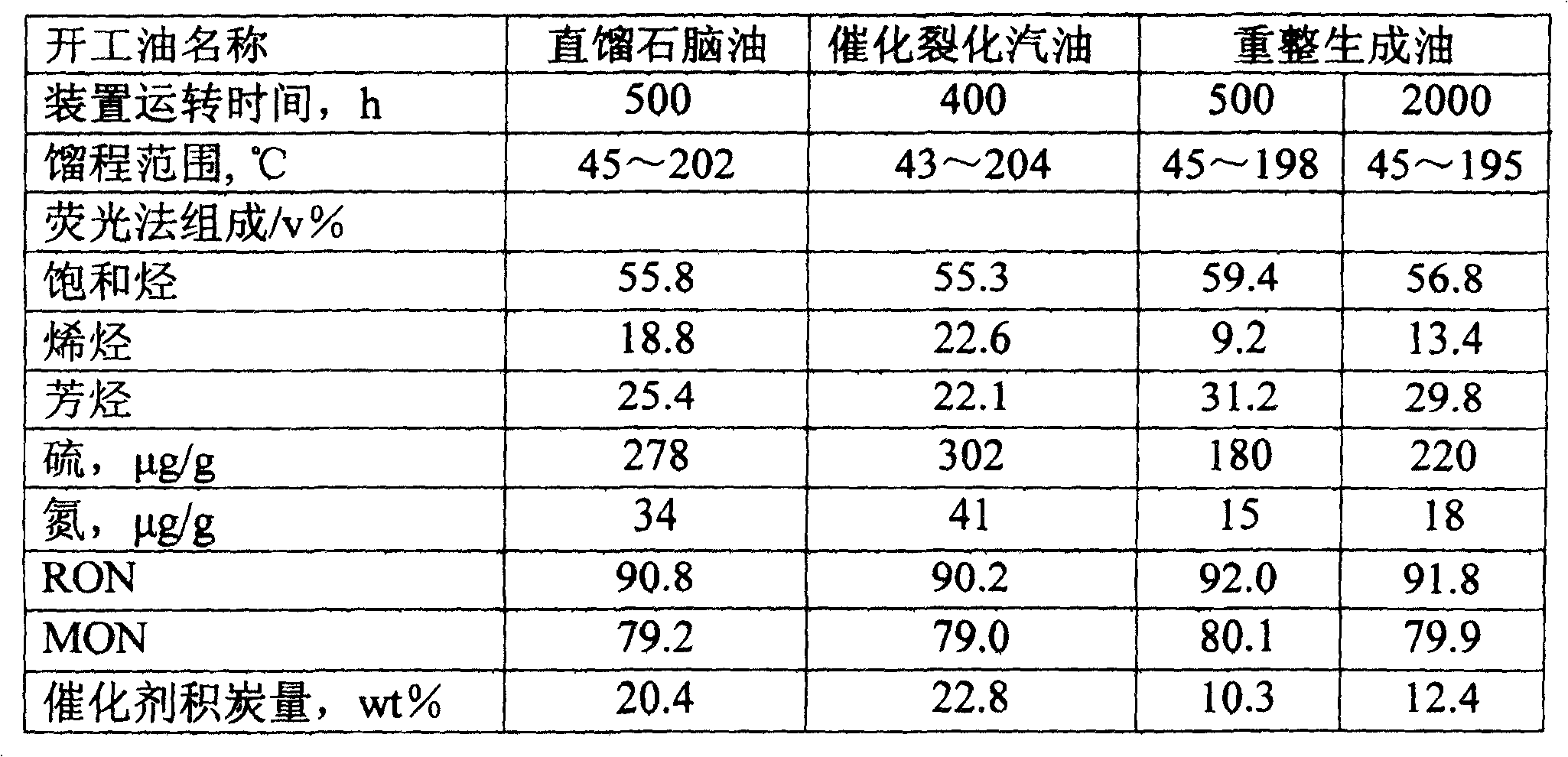

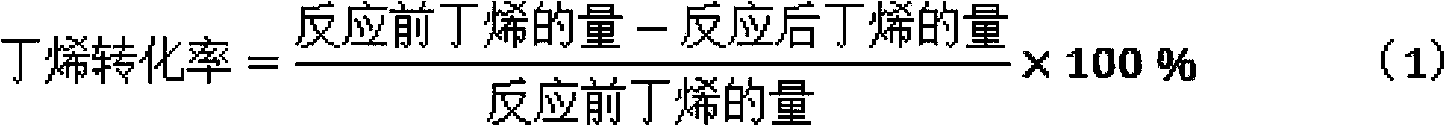

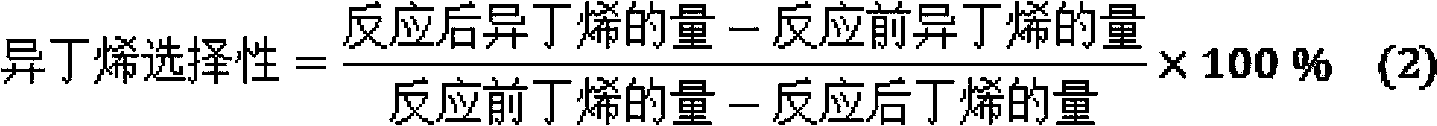

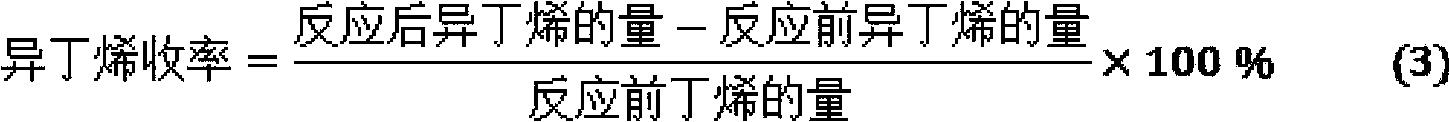

Method for FCC gasoline proceeding hydrodesulphurization and olefin removal

ActiveCN1952058AAvoid PolymerizationAvoid type-selective cleavage reactionsHydrocarbon oils refiningMolecular sieveCarbon deposition

The invention relates to a work-starting method of FCC gasoline hydrodesulfurization to degrade the alkenes. According to the invention, on the basis of regular wet process thiolaction, it adopts reformed generating oil as the sulfurized oil so as to avoid the extra high temperature in the early starting time, decrease the carbon deposition of the catalyst and increase the stability and activity of the catalyst. The invention can be used in different kinds of gasoline that contains molecular sieve reforming catalyst thiolaction, especially the gasoline that contains high molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

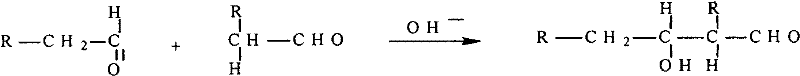

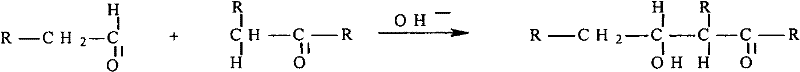

Aldehyde and ketone inhibitor for alkaline washing tower of ethylene unit

ActiveCN102531822AInhibition formationSuppress generationHydrocarbon purification/separationHydrocarbonsAntioxidantKetone

The invention relates to an aldehyde and ketone inhibitor for an alkaline washing tower of an ethylene unit, wherein the inhibitor comprises the components by mass percent: 10-25% of antioxidant, 10-20% of metal deactivator, 15-20% of polymerization inhibitor, 10-20% of dispersing agent and the balance of solvent. The aldehyde and ketone inhibitor can be used for effectively inhibiting the condensation reaction between aldehyde and ketone in oil phase and water phase in the alkaline washing tower with pertinence; the aldehyde and ketone inhibitor has antioxidant and polymerization inhibition functions at the same time, thus having an effective inhibition function for polymerization reaction caused by unsaturated hydrocarbon; the aldehyde and ketone inhibitor can be reacted with sulfide, so that polysulfide can further be prevented from being formed by the sulfide, and the generation of scaling substance can be inhibited; and the dispersing agent is added into the aldehyde and ketone inhibitor, so that the generated large polymers can be dispersed into small polymers; and therefore, the small polymers can be dispersed and dissolved in waste alkali liquid to be discharged, the blockage of equipment can be reduced, and the operation cycle of the equipment can be prolonged.

Owner:天津市瑞德赛恩新材料开发有限公司

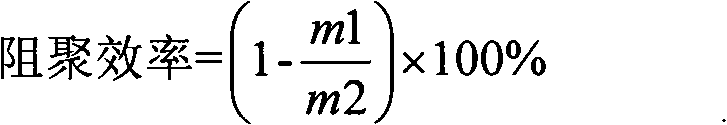

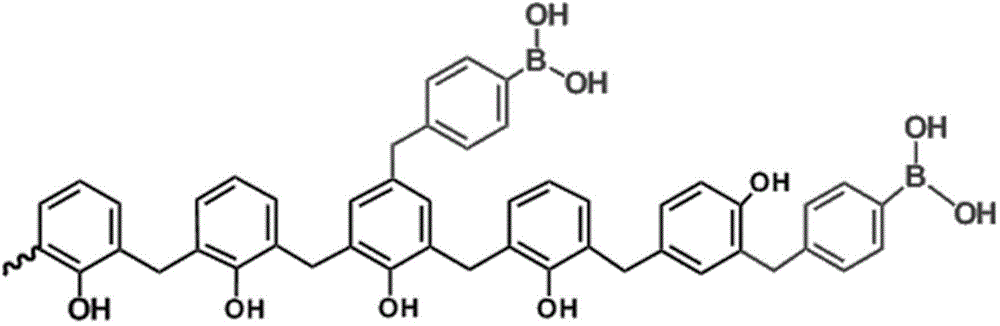

Preparation method of aryl-containing boron thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

Method for modifying attapulgite clay

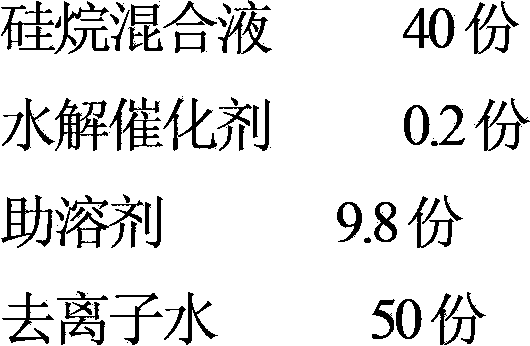

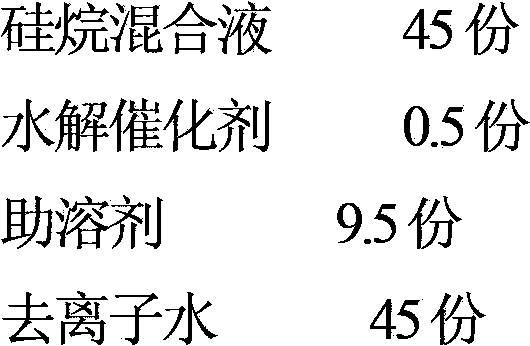

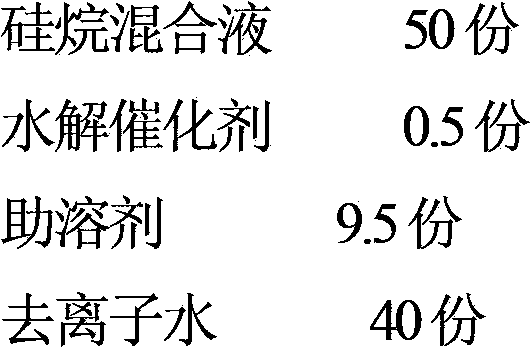

InactiveCN102627873AAvoid PolymerizationPromote infiltrationPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsOrganic solventActive agent

The invention discloses a method for modifying attapulgite clay. The method comprises the following steps: adding an organic water repellent compound in attapulgite clay powder with the fineness of 200 to 400 meshes; adding an organic solvent and stirring for 1-4 hours; then standing for 2-3 hours to obtain slurry; adding a nonionic surfactant in the slurry, heating at the temperature of 60-80 DEG C for 3-7 hours and filtering; and drying the filtered powder to obtain the modified attapulgite clay powder. The modified attapulgite obtained by the method disclosed by the invention is favorable in dispersity in water and is suitable for preparing water-based paint.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Method for modifying attapulgite clay

InactiveCN102627872AAvoid reactionAvoid PolymerizationPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsInorganic particleAlcohol

The invention discloses a method for modifying attapulgite clay. The method comprises the following steps: adding inorganic particles into attapulgite clay powder; adding mixer in water and stirring for 2-4 hours; then standing for 1-4 hours and drying; adding a compound activating agent of organic carboxylic acid and a nonionic surfactant; stirring for 3-7 hours, standing for 2-4 hours; and filtering and drying to obtain modified attapulgite clay powder. According to the method disclosed by the invention, the compatibility and the dispersity of attapulgite in an alcohol-based solution are improved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

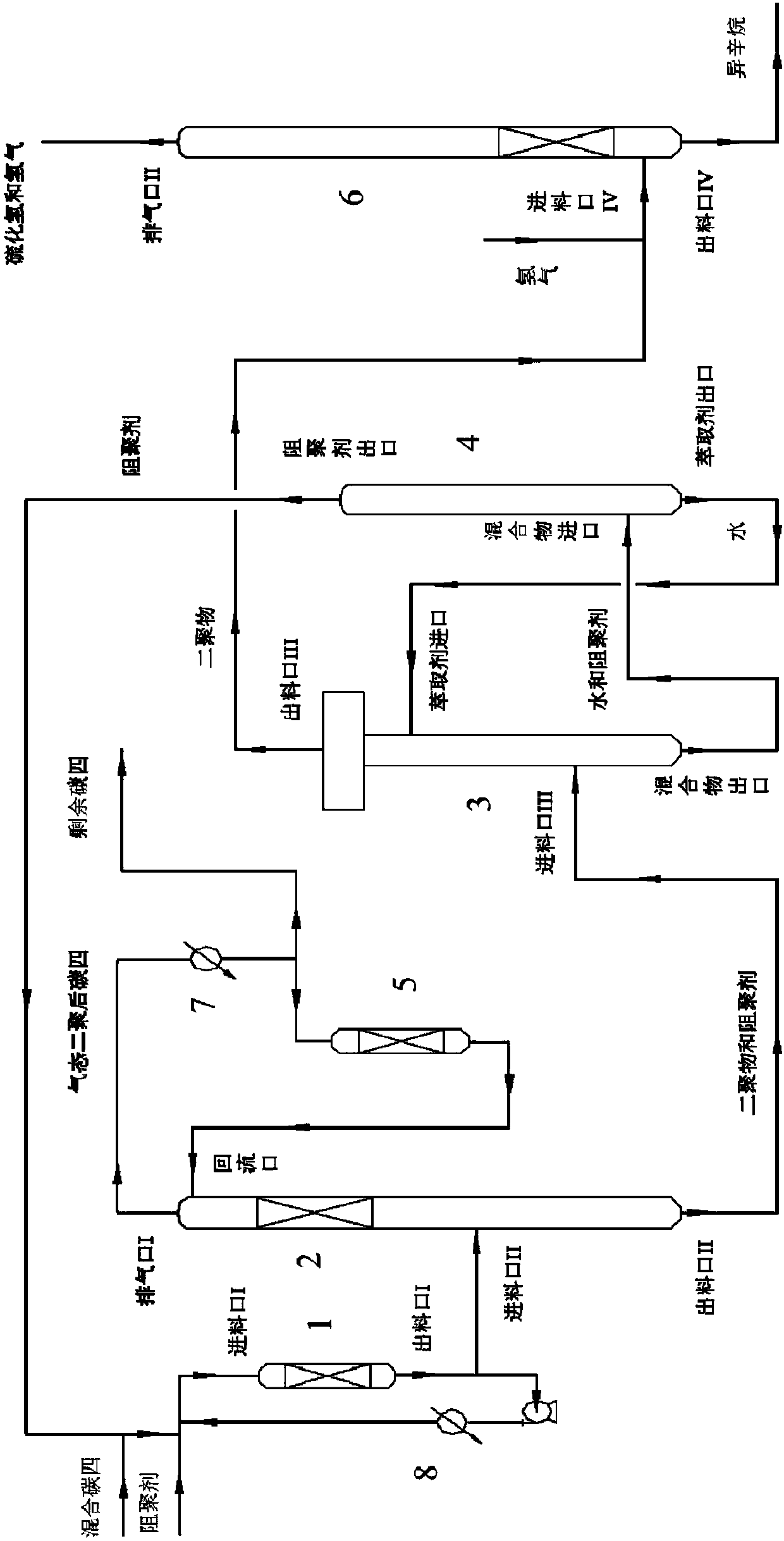

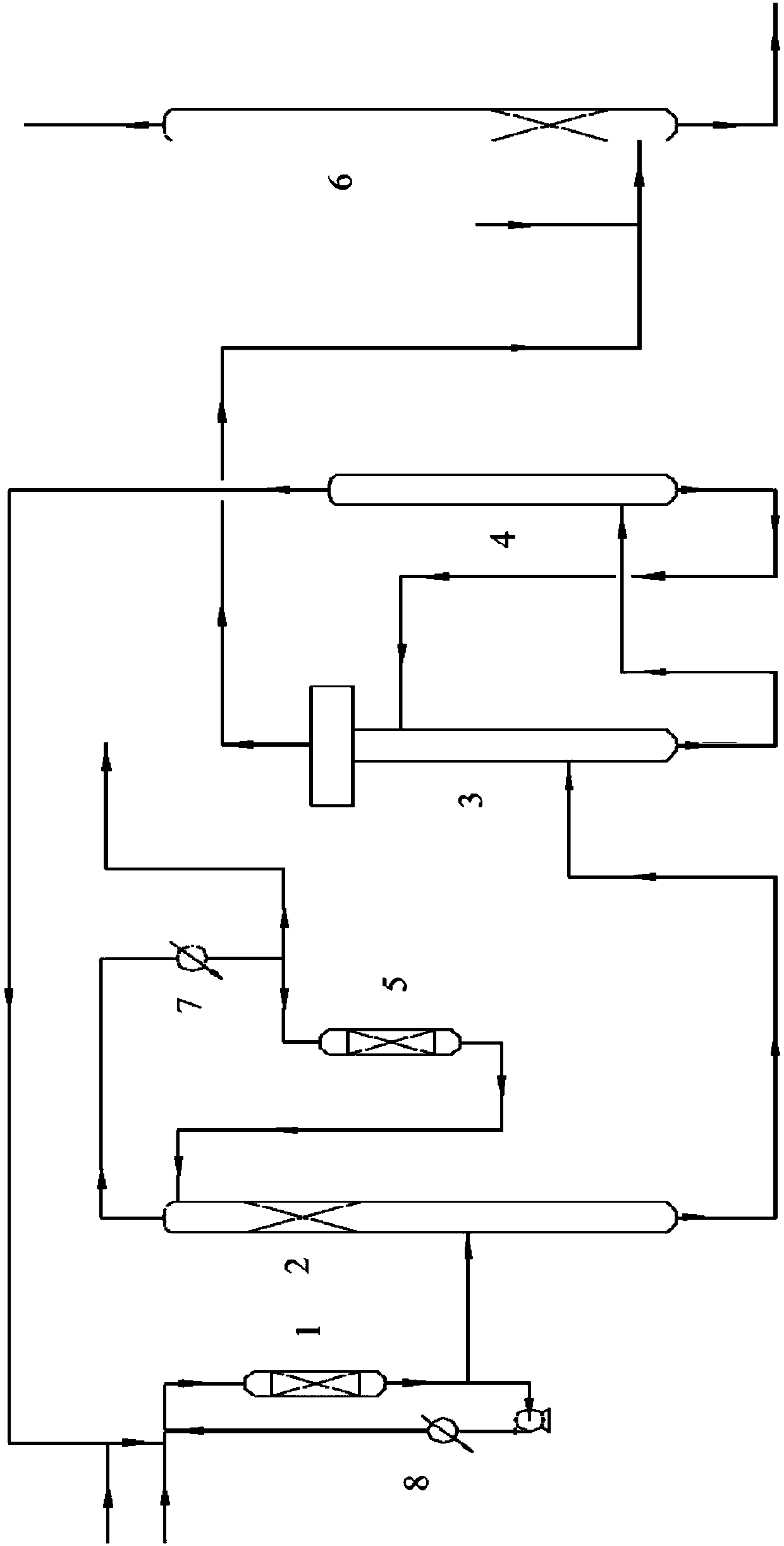

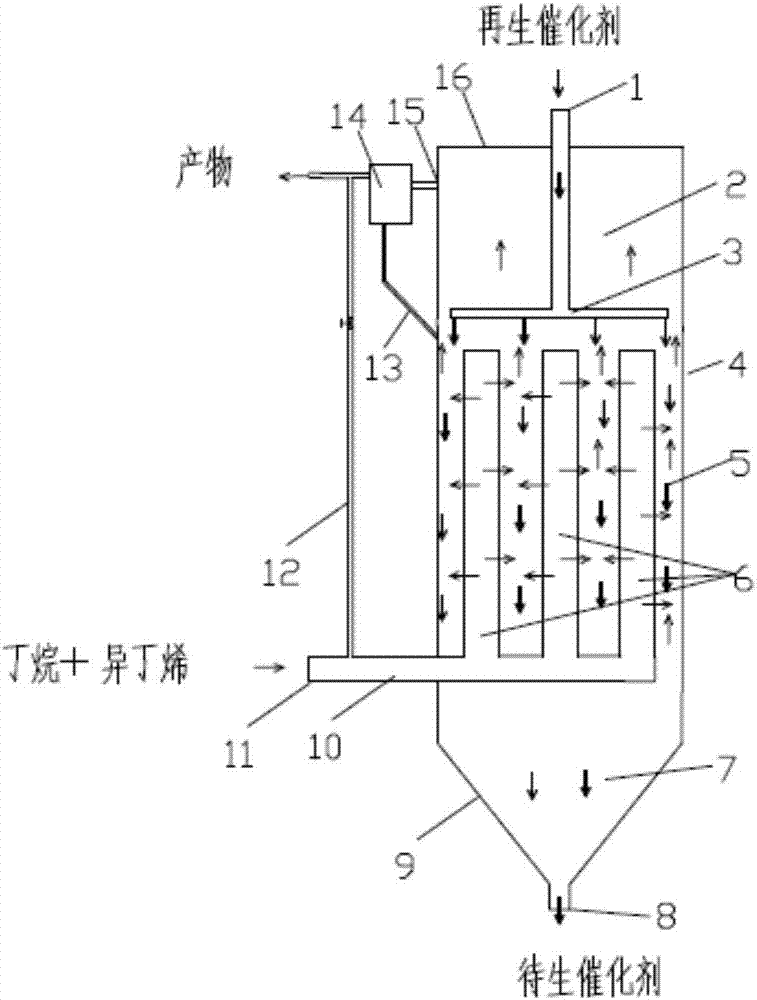

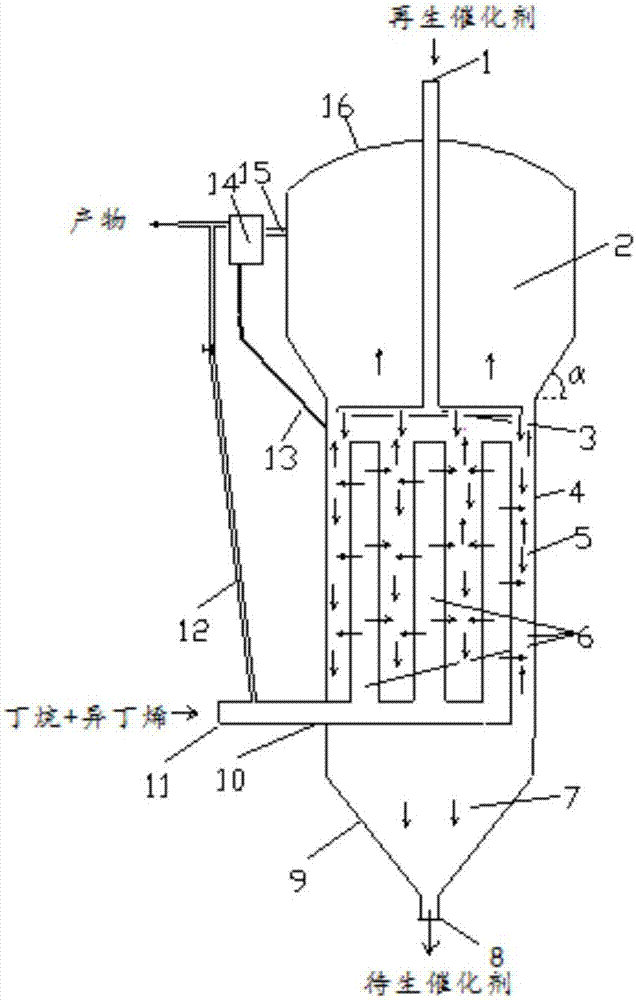

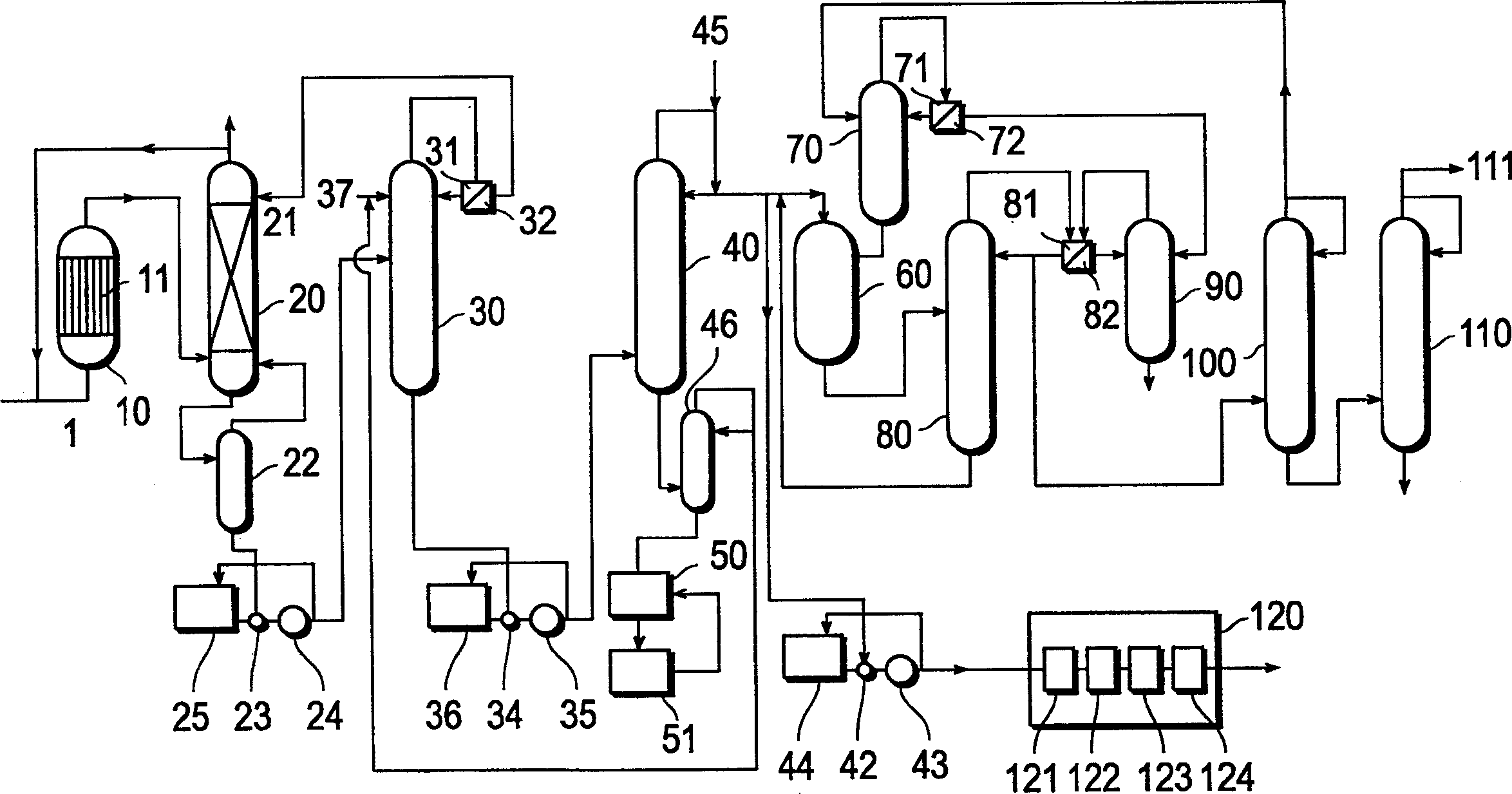

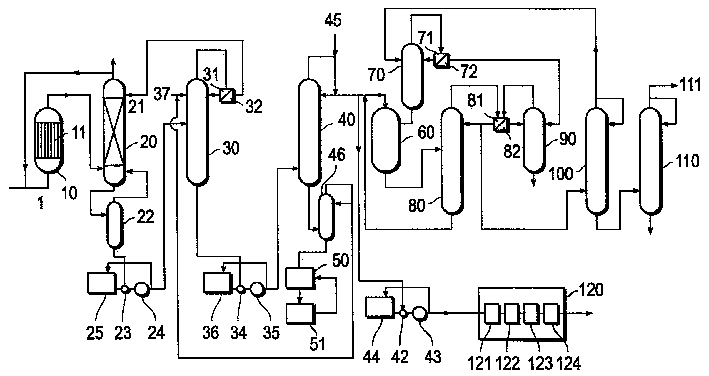

Apparatus and method to produce isooctane by indirect alkylation technique

PendingCN107827694ATemperature controlImprove conversion rateHydrocarbon by hydrogenationChemical industryAlkyl transferHydrogen

The invention discloses an apparatus and method to produce isooctane by an indirect alkylation technique. The apparatus comprises fixed-bed reactor I, a catalytic distilling column, an extracting column and a recycling column which are connected in sequence. The method comprises: allowing mixed C4 and a polymerization inhibitor to react in reactor I, feeding part of the product into the catalyticdistilling column, and removing reaction heat from the other part by a heat exchanger before returning; after catalytic distillation, feeding the overhead product into fixed-bed reactor II, reflowingafter reacting, and feeding the bottom product into the extracting column; after extracting, feeding overhead biopolymer into a desulfurizing column, and feeding the bottom product into the recyclingcolumn; after recycling, returning an extracting agent into the extracting column and the polymerization inhibitor to the reactor I; subjecting the biopolymer and hydrogen to hydrodesulfurization in the desulfurizing column to obtain isooctane that may act as a gasoline blend component. Existing MTBE (methyl tert-butyl ether) production equipment is modified into isooctane production equipment; the produced isooctane may act as an ethanol-gasoline blend component; byproducts of the isooctane may also act as other materials for reuse.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Preparation method of hydrogenation catalyst

ActiveCN103100384AExtended service lifeAvoid PolymerizationHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsCarboxylic acidCarbon.organic

The invention discloses a preparation method of a hydrogenation catalyst. The hydrogenation catalyst takes activated carbon as a carrier, and adopts palladium as an active metal component. The catalyst has a palladium content of 0.1wt%-0.7wt%. An impregnation method is employed to prepare the catalyst. Specifically, a palladium-containing impregnation solution is prepared by: dissolving palladium acetylacetonate in an organic solvent, and using a low carbon organic carboxylic acid to regulate the pH value of the impregnation solution. The method adopts a special process to prepare the palladium acetylacetonate impregnation solution, can make palladium crystal grains highly dispersed and loaded on the inner and outer surfaces of the activated carbon carrier, and at the same time, no inorganic ion is introduced, no high-temperature roasting is needed, and migration and grain growth of the palladium metal are effectively controlled, thus improving the activity and selectivity of the catalyst. Moreover, the utilization rate of noble metal palladium is enhanced, noble metal waste is avoided, and the cost is reduced. The hydrogenation catalyst is applicable to a selective hydrogenation process of unsaturated C4 hydrocarbon fraction. The polymerization reaction of unsaturated hydrocarbon on the catalyst surface can be effectively inhibited, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

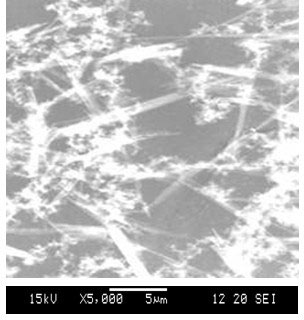

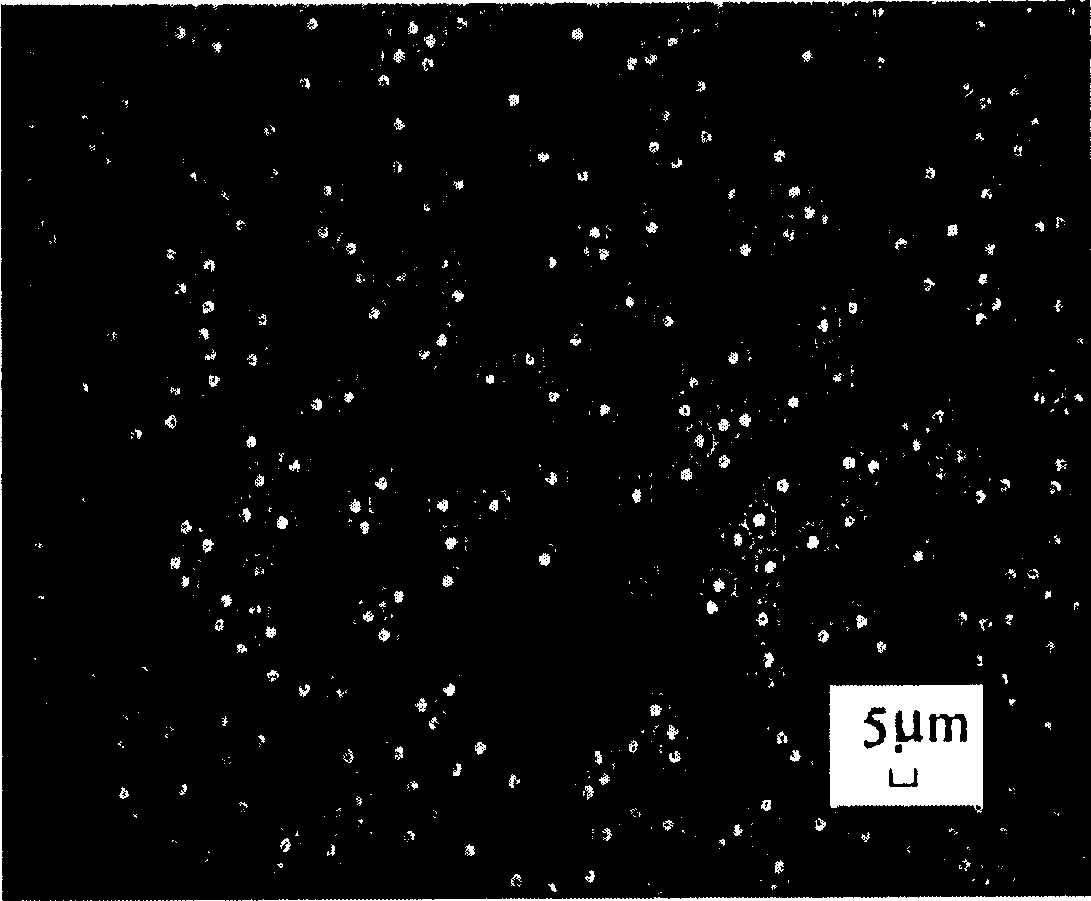

Method for preparing mono dispersed micrograde polymer microsphere

The invention discloses the preparing method of monodisperse micron-size polymer microballoon. The method comprises the following steps: adding organic solvent containing monomer, initiating agent and dispersing agent into inhibitor at 50-80Deg.C, carrying out reaction for 10-14 hours, getting the product. The invention obtains the monodisperse microballoon whose diameter is 1- 10 mum.

Owner:SHANGHAI HUAMING HI TECH GRP

Synthetic method of N,N'-dibenzyl-1,2-ethanediamine

ActiveCN106748813AHigh selectivityAvoid PolymerizationOrganic compound preparationAmino compound preparationHydrogenation reactionBenzyl-EDTA

The invention discloses a synthetic method of N,N'-dibenzyl-1,2-ethanediamine. The synthetic method comprises the following components: in a reaction vessel, a liquid phase catalytic hydrogenation reaction is carried out for N,N'-dibenzylidene-1,2-ethanediamine in the effects of a nitrogen doped meso pore carbon loaded precious metal catalyst in order to prepare and obtain N,N'-dibenzyl-1,2-ethanediamine. In the nitrogen doped meso pore carbon loaded precious metal catalyst, the precious metal is Pd or Pt, and the load capacity of the precious metal is 1-10wt%. The synthetic method has the advantage of high selectivity of target products.

Owner:ZHEJIANG UNIV OF TECH

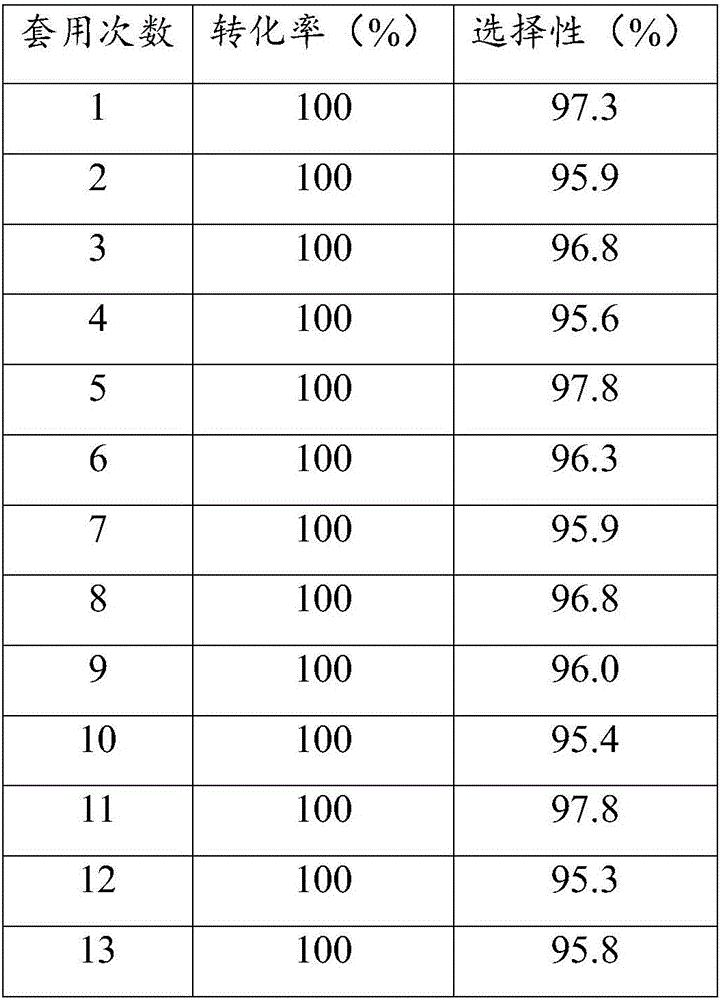

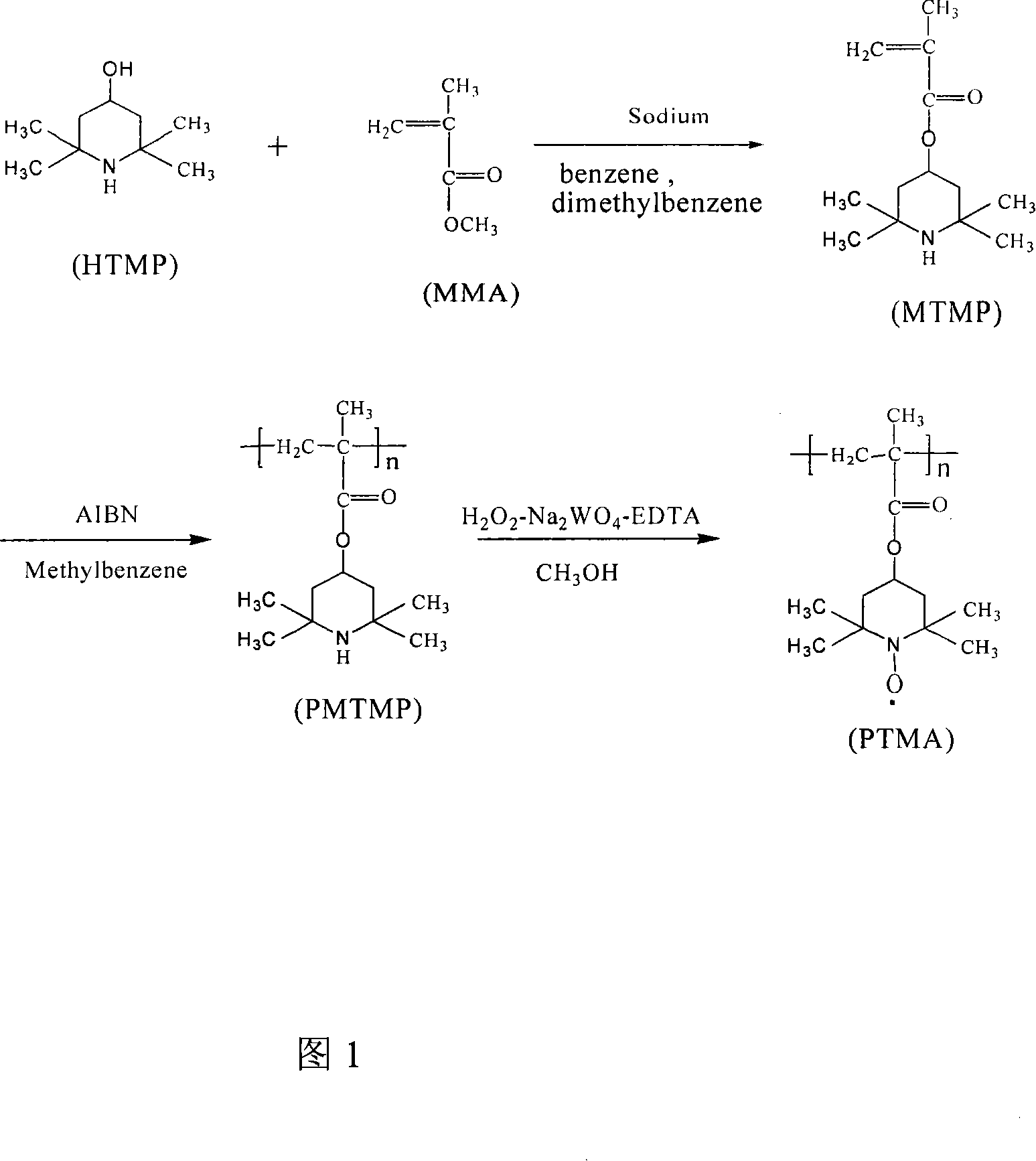

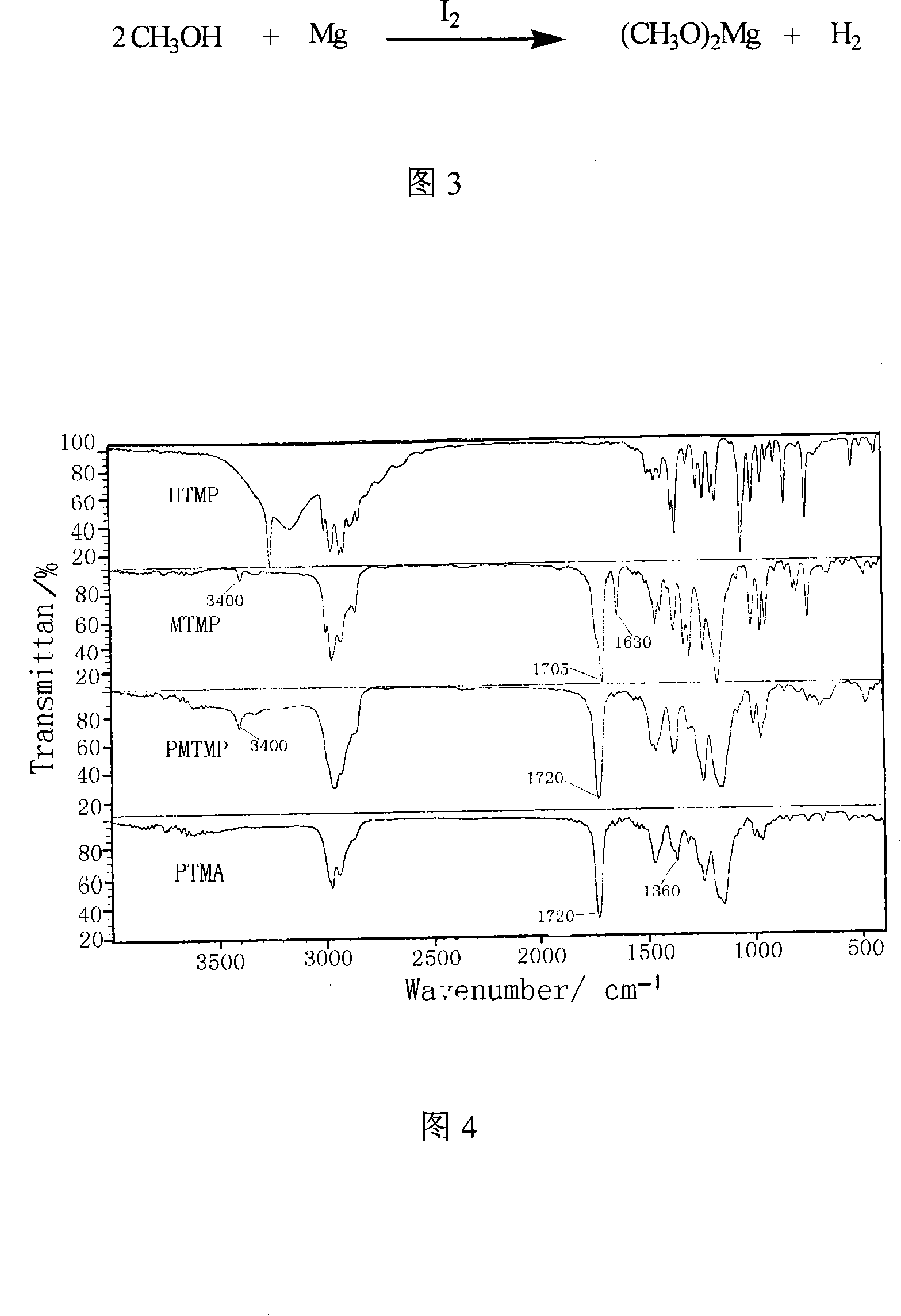

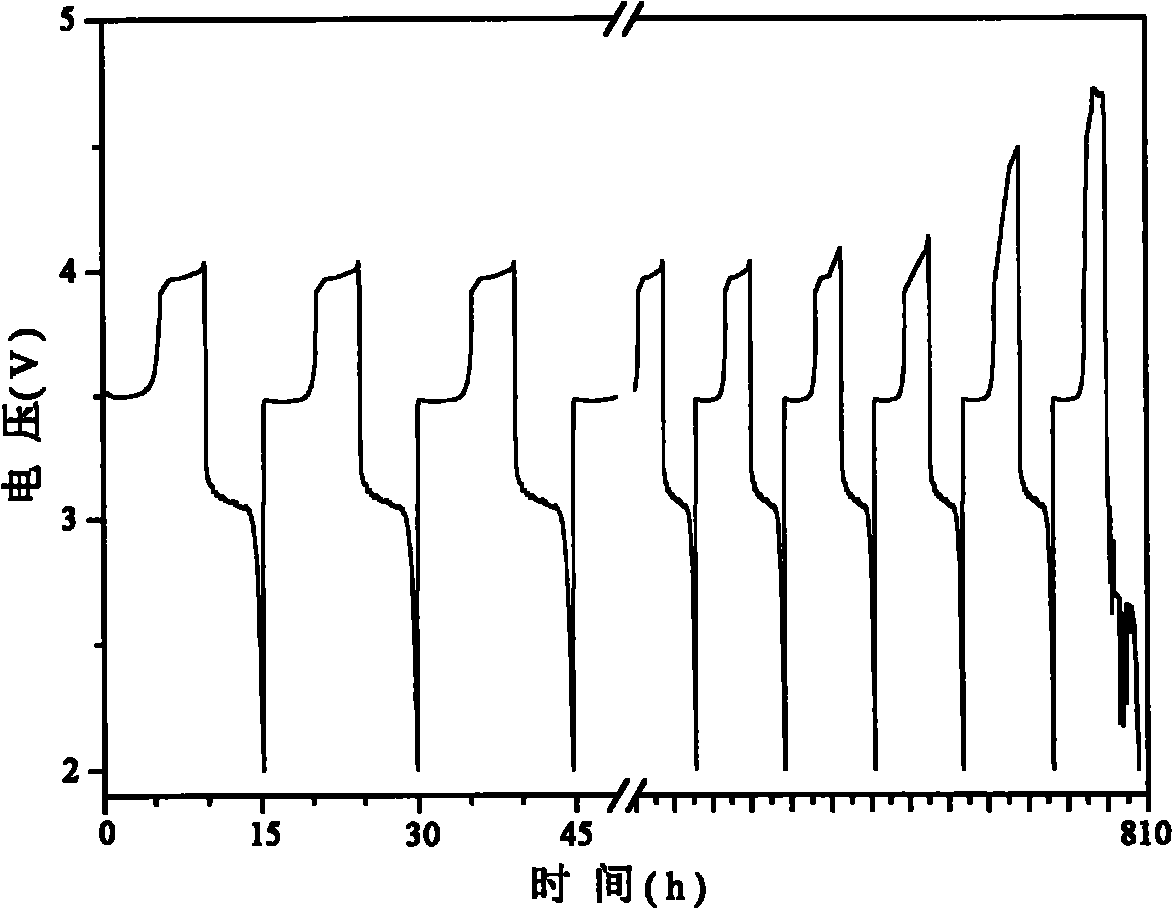

Synthesis of organic free radical polyalcohol PTMA anode material of lithium secondary battery and uses of the same

InactiveCN101130583ABiodegradableStable discharge voltageElectrode carriers/collectorsSide chainOxygen

The invention discloses a synthesis of Li twice battery organic free radical polymer PTMA polar material and application, which comprises the following steps: choosing HTMP and MMA as forerunner; adopting optimum ester interchange synthesized method; preparing MTMP; choosing eldopaque or metal copper as inhibitor; choosing metallic sodium or magnesium methylate as accelerant; preparing MTMP; using MTMP as monomer; choosing AIBN trigger; polymerizing through free radical body in toluene solution; preparing polymer PMTMP; using Na2WO4-H2O2-EDTA as oxidant in the methanol solution; getting PTMA with side chain as nitrogen oxygen stabilizing free radical. This invention can eliminate safe hidden danger of temperature increment, which possesses good electrolytic solution mutual dissolving property.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

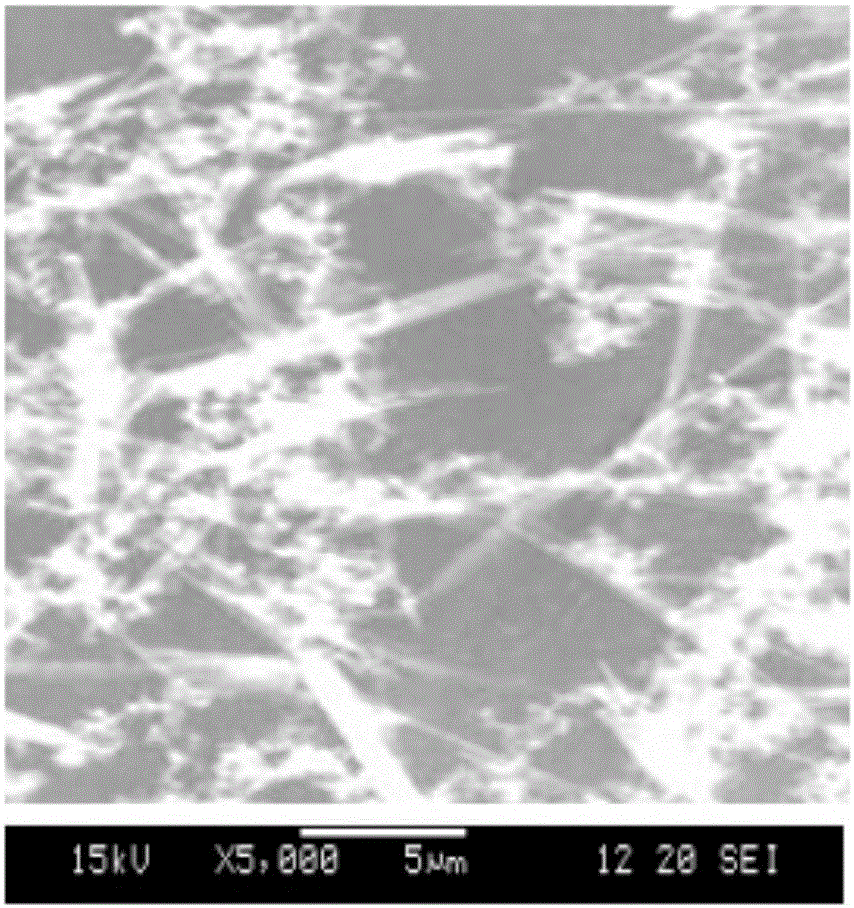

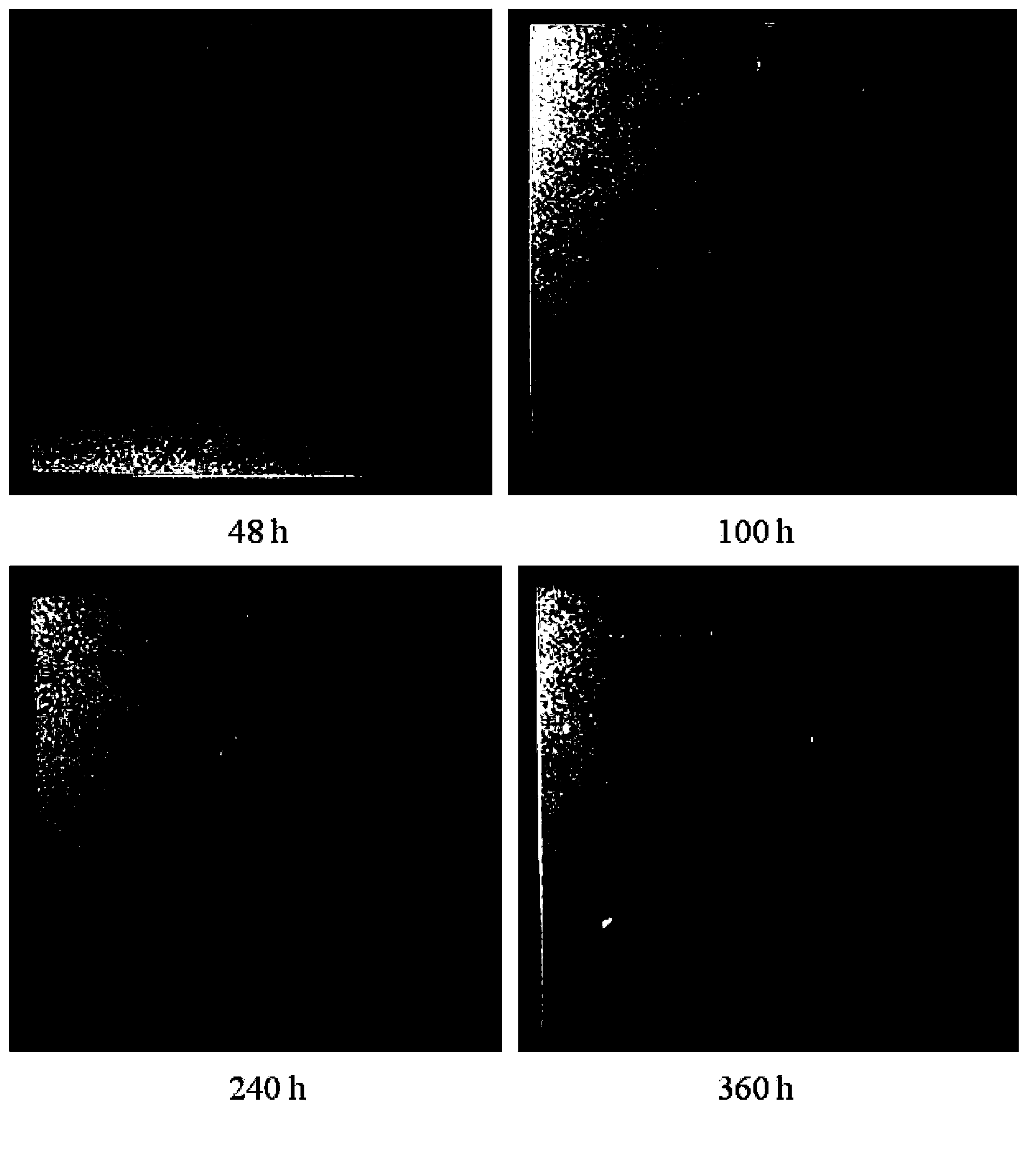

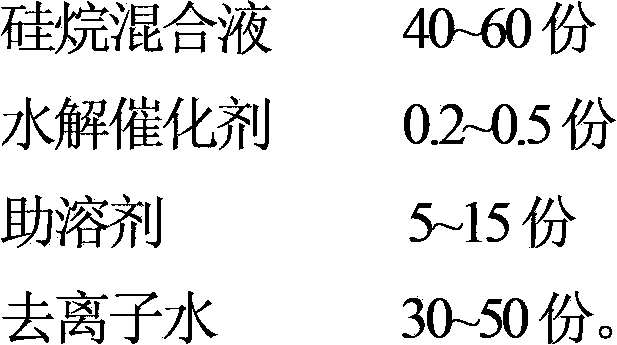

Preparation method of micro-arc oxidation-composite chemical nickel plating coating layer on surface of magnesium alloy

InactiveCN104141138APromote hydrolysis reactionAvoid PolymerizationAnodisationLiquid/solution decomposition chemical coatingSurface brightnessMicro arc oxidation

The invention discloses a preparation method of a micro-arc oxidation-composite chemical nickel plating coating layer on the surface of a magnesium alloy, and belongs to the technical field of metal surface treatment. The preparation method comprises the following steps: firstly, the micro-arc oxidation is performed for the surface of a magnesium alloy matrix to form a porous ceramic coating layer on the surface; then, the hole sealing treatment is performed for the matrix with the porous ceramic coating layer by adopting nanometer self-assembly penetrant containing nickel salt; the nickel preplating treatment is performed for the matrix, after the hole sealing treatment, by adopting alcohol solution of sodium borohydride; and finally, the composite chemical nickel plating treatment is performed for the matrix, after the nickel preplating treatment, to form the micro-arc oxidation-composite chemical nickel plating coating layer on the surface of the magnesium alloy. The micro composite coating layer, prepared by the method, has better protective thickness, good binding force with the matrix, good corrosion resistance, high hardness, good surface brightness and full luster, effectively solves the protective requirements of high wear resistance and corrosion resistance of the magnesium alloy, and provides powerful guarantee to the further application of the magnesium alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

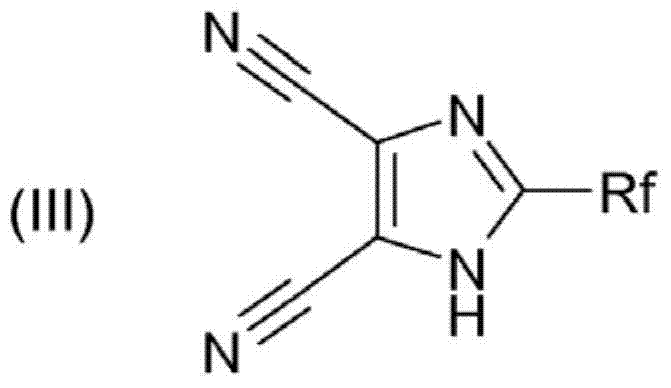

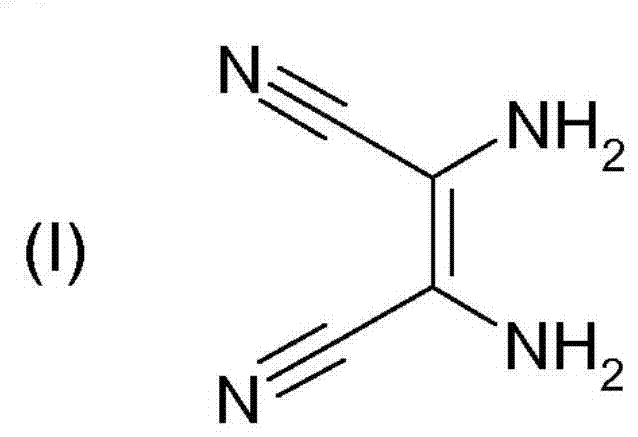

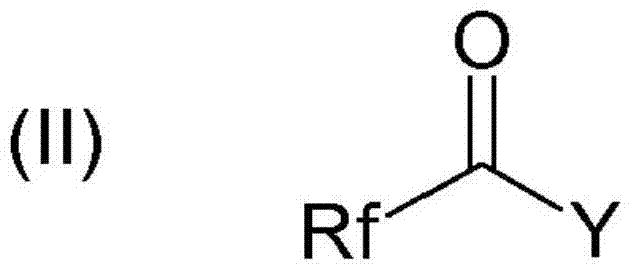

Method for preparing pentacyclic anion salt

ActiveCN103930405AHigh yieldInhibit aggregationHybrid capacitor electrolytesCarboxylic acid nitrile preparationEthyl ChloridePhotochemistry

The invention relates to a method for preparing an imidazole compound with the following formula: wherein Rf is a fluorinated alkyl group comprising between 1 and 5 carbon atoms, said method comprising: (a) the reaction of the diaminomaleonitrile with the following formula: with the compound with the following formula: wherein Y represents a chlorine atom or the OCORf group to form the salified amide compound with the following formula: at temperature Tau1, and (b) the dehydration of the salified amide compound with formula (IVa) and / or the corresponding amino (IVb) to form the imidazole compound with formula (III), at temperature T2 higher than T1.

Owner:ARKEMA FRANCE SA

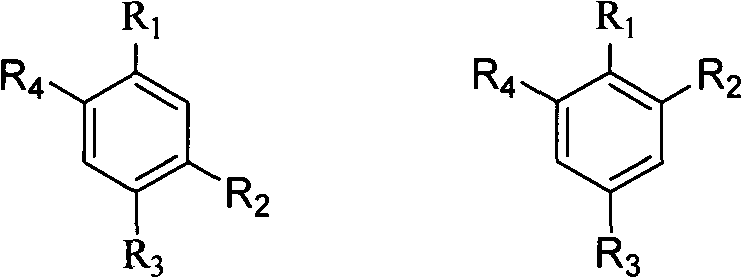

Redox couple for lithium ion battery overcharge-resistant mixed additive

InactiveCN102005619AAvoid PolymerizationSolve the problem of prone to electrooxidative polymerizationSecondary cells servicing/maintenanceElectricityPhysical chemistry

The invention discloses a redox couple for a lithium ion battery overcharge-resistant mixed additive, belonging to the technical field of lithium ion battery overcharge protection additives. The invention aims to provide the redox couple for a lithium ion battery overcharge-resistant mixed additive, which has better circulation stability and high steric effect, so that polymerization cannot be carried out on the redox couple per se in the overcharge protection process, and meanwhile, the redox couple per se and an electric polymerization monomer are not reacted in the presence of the electric polymerization monomer so that the overcharge protection performance of the redox couple is improved. The redox couple additive is an aromatic ring class compound containing two or more high steric-hindrance substituents, and the addition quantity is saturated concentration in electrolyte. The redox couple per se is not polymerized and not reacted with the electric polymerization monomer. In the use process of the redox couple / electric polymerization mixed additive, two overcharge protection systems separately and sequentially protect the battery, thus, the safe use performance of the battery is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for FCC gasoline proceeding hydrodesulphurization and olefin removal

ActiveCN100432191CReduce carbon depositionAvoid reactionHydrocarbon oils refiningMolecular sieveHydrodesulfurization

The invention relates to a work-starting method of FCC gasoline hydrodesulfurization to degrade the alkenes. According to the invention, on the basis of regular wet process thiolaction, it adopts reformed generating oil as the sulfurized oil so as to avoid the extra high temperature in the early starting time, decrease the carbon deposition of the catalyst and increase the stability and activity of the catalyst. The invention can be used in different kinds of gasoline that contains molecular sieve reforming catalyst thiolaction, especially the gasoline that contains high molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin isomerization catalyst passivation treatment method

ActiveCN103785482ALow costSimple procedureHydrocarbon by isomerisationCatalyst protectionSide reactionBy-product

The invention relates to an olefin isomerization catalyst passivation treatment method which is as follows: a passivation agent is led alone, or led simultaneously with an olefin isomerization reaction raw material, into a catalyst bed for contacting with a catalyst for 2-10 hours, the passivation agent is a by-product of an olefin isomerization process, and preferably is a heavy component in by-products. By means of the passivation treatment method, the problems that the initial-stage reaction activity of the catalyst in the olefin isomerization reaction is high, polymerization side reactions are serious, the catalyst bed temperature is risen, and the like can be solved, and the yield and selectivity of isomerization target products can be effectively improved. At the same time, because the passivation agent used is the by-product of the olefin isomerization process itself, the passivating agent after use can directly enter into follow-up processes together with the isomerization products, energy sources of a reaction system itself can be fully used, the postprocessing process is simplified, the pollution is reduced, and the cost is reduced. In addition, the method has the advantages of simple operation, easy control of the process and good passivation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reaction-activity-controllable acrylate emulsion and preparation method thereof

ActiveCN105418824AImprove stain resistanceImprove hydrophilicityCoatingsOrganic acidIsooctyl acrylate

The invention discloses reaction-activity-controllable acrylate emulsion. The reaction-activity-controllable acrylate emulsion is characterized by being prepared from, by mass, 100 parts of water, 10-40 parts of 2-ethylhexyl acrylate, 10-50 parts of methyl methacrylate, 5-25 parts of styrene, 30-50 parts of hydrophilicity unsaturated organic acid, 10-30 parts of functional monomers, 5-10 parts of emulgator and 1-3 parts of initiator. The reaction-activity-controllable acrylate emulsion has high water resistance, and activity in the reaction process can be controlled.

Owner:佛山市顺德区巴德富实业有限公司

Method for preparing composite nickel coating on surface of magnesium alloy micro-arc oxidation film

InactiveCN103695905AInhibition of polymerizationImprove overall protection performance and bonding performanceSuperimposed coating processMicro arc oxidationNickel coating

The invention discloses a method for preparing a composite nickel coating on the surface of a magnesium alloy micro-arc oxidation film, and belongs to the technical field of metal surface treatment. The method comprises the following steps: putting a magnesium alloy matrix in a silicate series electrolyte to prepare a micro-arc oxidation ceramic layer, carrying out surface hole sealing and pre-nickeling treatment of the matrix ceramic layer by adopting a nickel salt-containing self-assembled nano-penetrant and an alcoholic solution of sodium borohydride, and carrying out composite chemical nickeling treatment to form the composite nickel coating on the surface of the film. The method is an improvement on tradition chemical nickeling technologies, and adopts a palladium salt-free activation process at room temperature, so the composite chemical nickeling operation is simplified, and the pollution of the process to the environment is reduced. The prepared composite coating has the advantages of good protection thickness, good bonding force with the substrate, good corrosion resistance, high hardness, good surface brightness, shininess, effective solving of the protection requirements on the high wear resistance and the corrosion resistance of a magnesium alloy, and provision of a powerful guarantee for the further application of the magnesium alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Attapulgite-clay-based electromagnetic wave absorber in metal-surface-coated electromagnetic wave-absorbing coating and preparation method of attapulgite-clay-based electromagnetic wave absorber

InactiveCN106479253ALoss EfficientImprove absorbing performanceCoatingsElectromagnetic wave absorberChemical plating

The invention discloses an attapulgite-clay-based electromagnetic wave absorber in a metal-surface-coated electromagnetic wave-absorbing coating. The electromagnetic wave absorber refers to the attapulgite-clay-based electromagnetic wave absorber which is prepared by combining carbon nano-tubes with high-temperature-resistant attapulgite clay powder. Particularly, a preparation method of the attapulgite-clay-based electromagnetic wave absorber includes the steps of activating and dispersing common attapulgite clay to obtain attapulgite clay suspension excellent in activation performance, adding a specific number of carbon nano-tubes, using activity of the surface of the attapulgite clay to absorb the carbon nano-tubes to obtain one-dimensional nano-tube / attapulgite clay compound powder, plating metal ions on the surface of the compound powder through chemical plating, centrifuging and drying so as to obtain the attapulgite-clay-based electromagnetic wave absorber. The attapulgite-clay-based electromagnetic wave absorber is excellent in electromagnetic wave absorption performance, high in absorption performance and wide in spectrum band and is capable of absorbing 90% of electromagnetic waves within a range of 5-18 GHz, and the maximum reflection loss can be up to -44 dB (5 GHz).

Owner:NANJING UNIV OF INFORMATION SCI & TECH

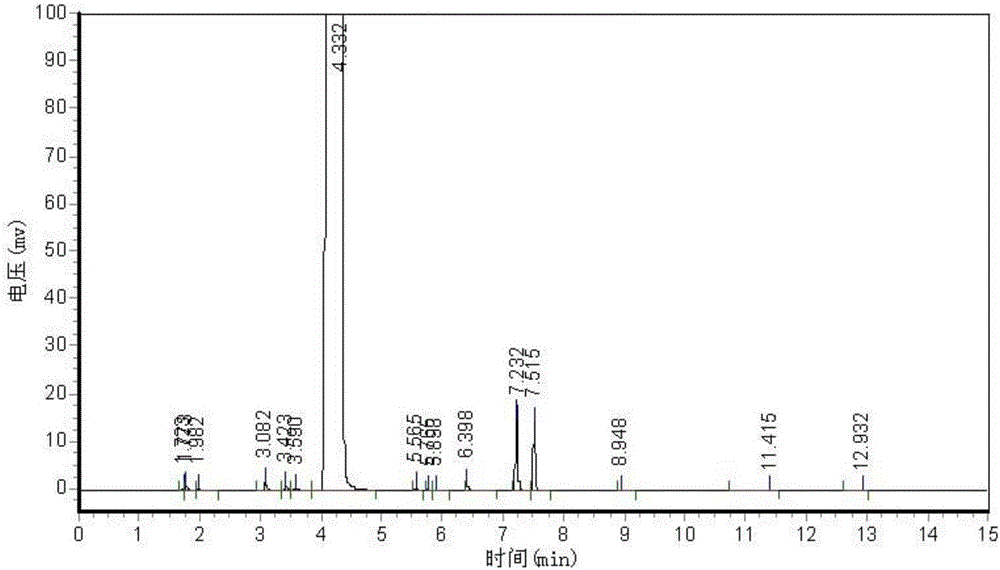

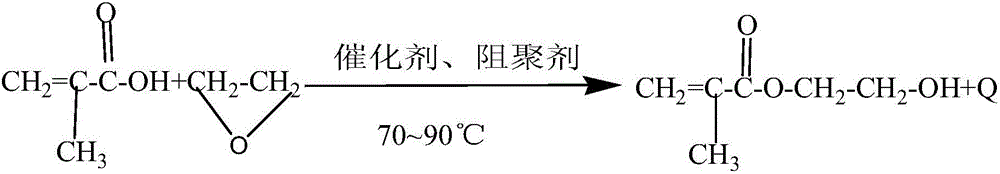

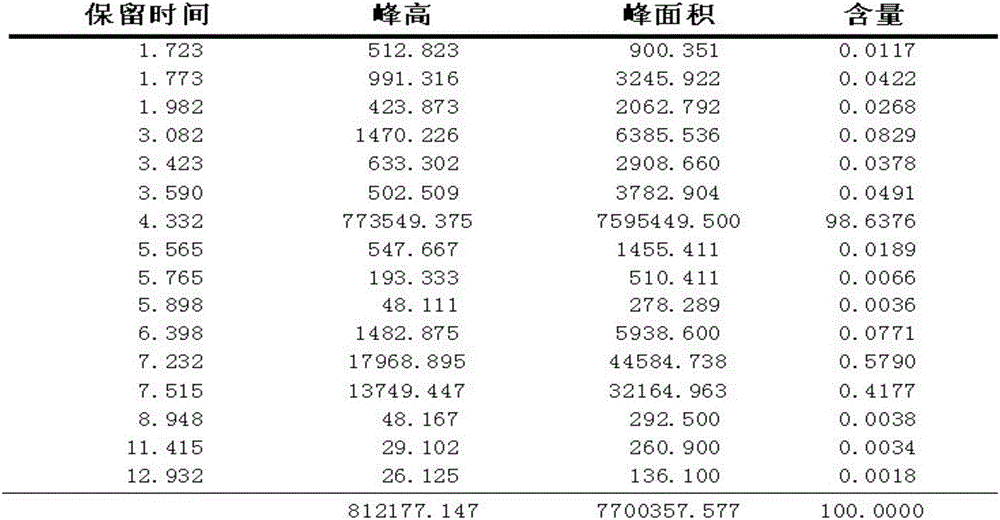

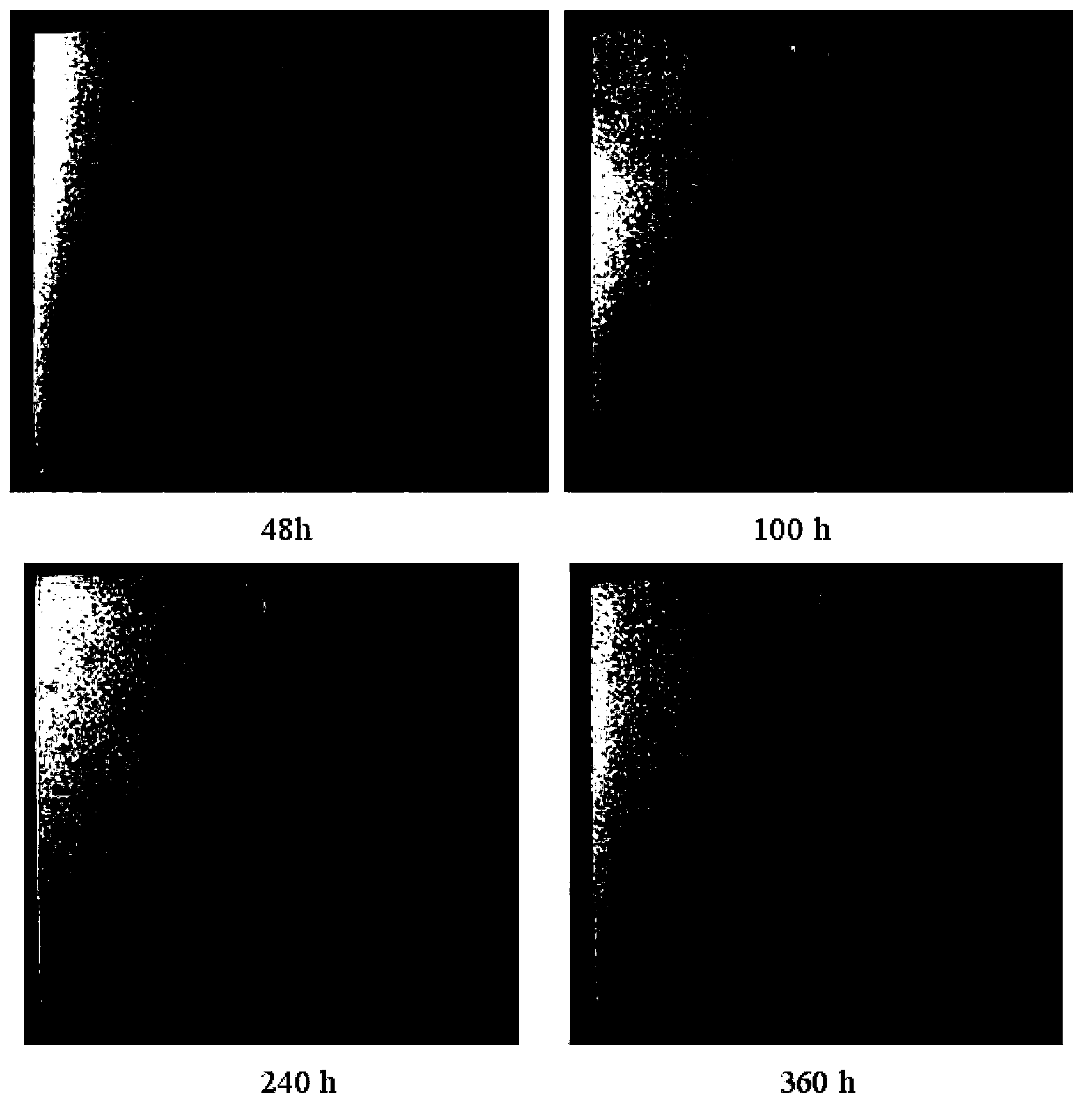

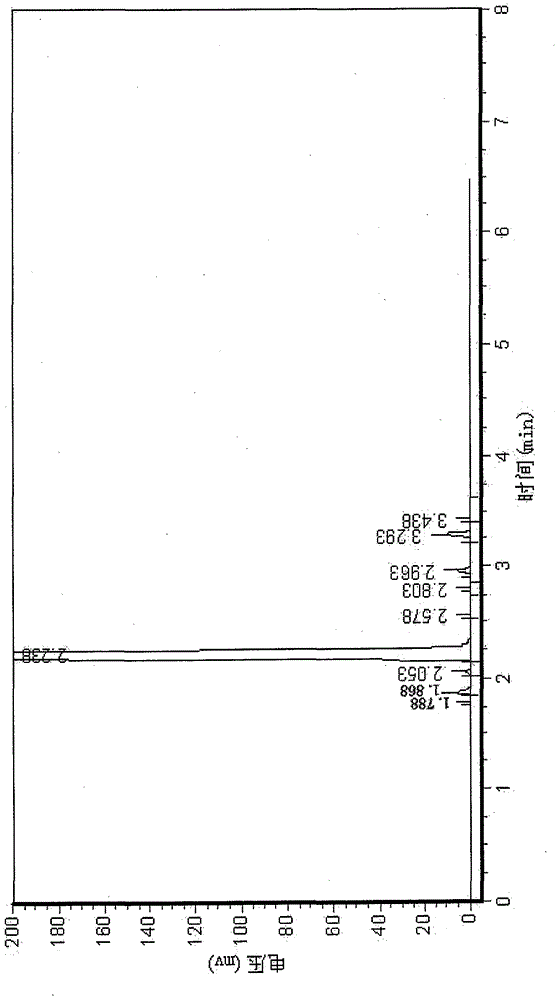

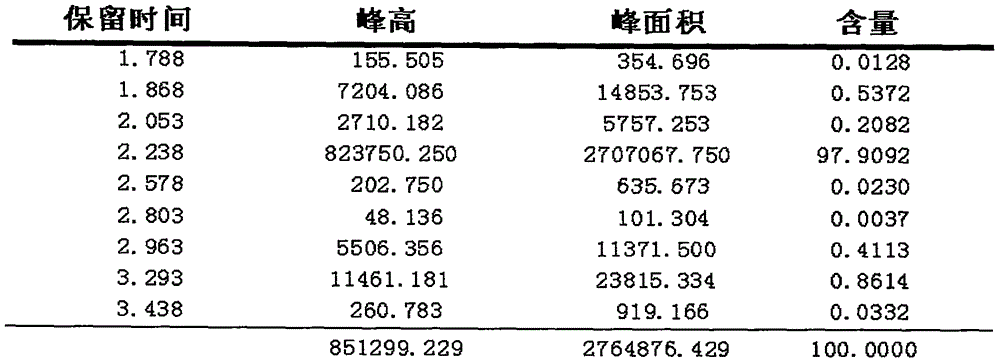

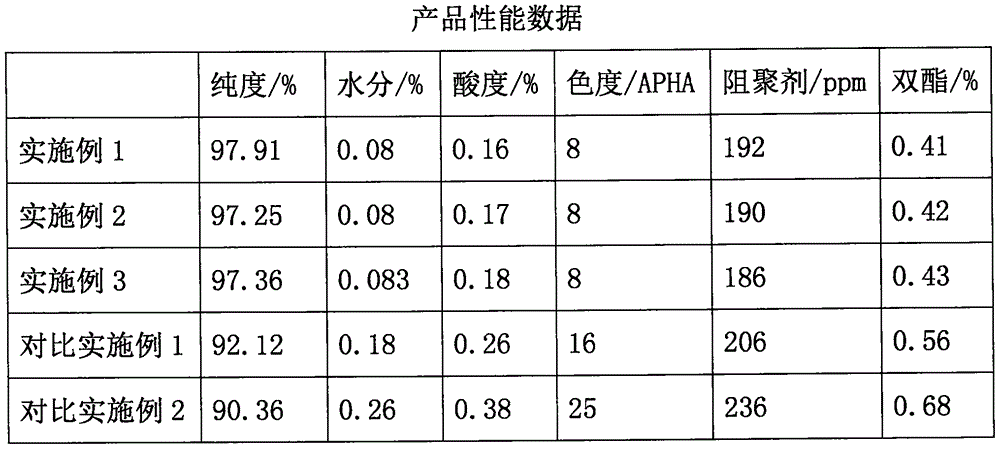

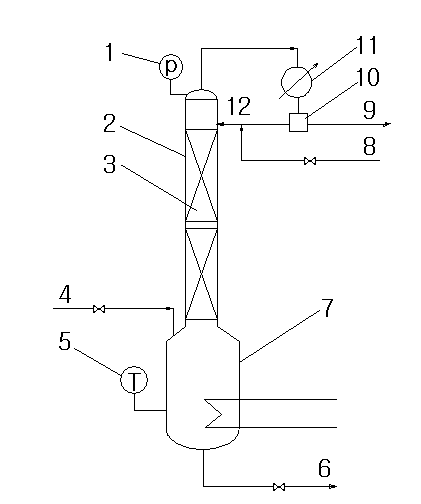

Preparation technique of high-purity hydroxyethyl methacrylate

InactiveCN105968011AImprove dispersionImprove the inhibition effectOrganic compound preparationCarboxylic acid esters preparationChemistry(Hydroxyethyl)methacrylate

The invention provides a preparation technique of high-purity hydroxyethyl methacrylate. A rectification process is added in a purification process; a polymerization inhibitor is replenished through a spraying way in a phase transformation process of the rectification process; meanwhile, the vacuum degree and the working temperature of a tower top are controlled; the flash polymerization, in a rectifying tower, of the hydroxyethyl methacrylate is avoided, so as to achieve the purposes of being stable in operation, being capable of effectively preventing polymerization and improving product quality, thereby improving the purity of a hydroxyethyl methacrylate product.

Owner:CHANGZHOU HICKORY CHEM

Preparation method of magnesium alloy surface micro-arc oxidized nano self-assembling composite protective coating

InactiveCN103668393AMeet the protection requirementsWide variety of sourcesAnodisationPretreated surfacesWater basedMicro arc oxidation

The invention discloses a preparation method of a magnesium alloy surface micro-arc oxidized nano self-assembling composite protective coating, and belongs to the technical field of magnesium alloy surface treatment. The method comprises the following steps: firstly performing micro-arc oxidation on a magnesium alloy matrix surface to form a porous ceramic layer, spraying modified water-based paint on the porous ceramic layer surface to form a water-based coating so as to form a composite protective coating composed of the porous ceramic layer and the water-based coating on the magnesium alloy matrix surface. The multilayer composite protective coating formed on the magnesium alloy surface has the features of good binding force, good compactness, high hardness, high corrosion resistance, high wear resistance and the like; the preparation method is simple, convenient and environment-friendly; the composite protective coating is an expected composite protective coating of the magnesium alloy application, and the protective requirement on the magnesium alloy product in severe environment is satisfied.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

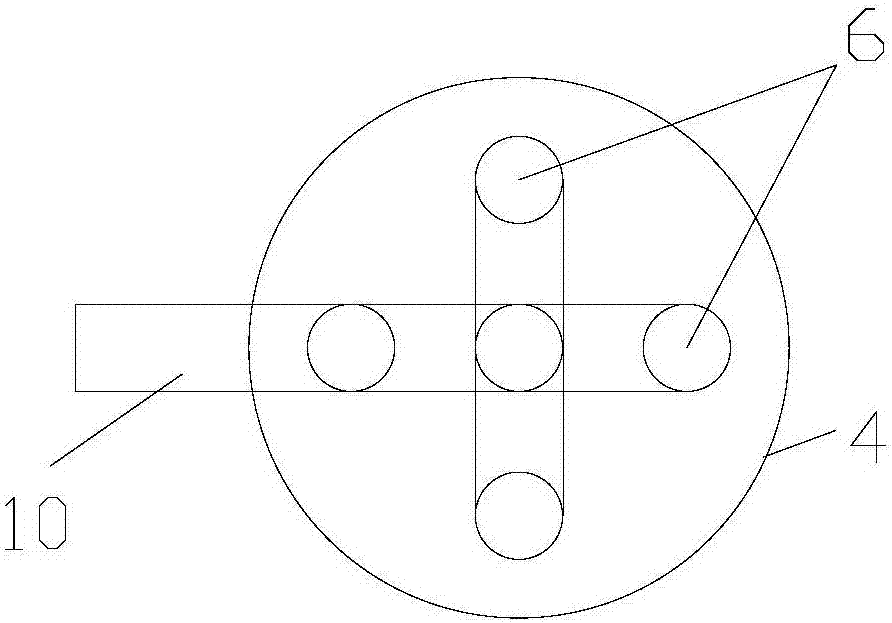

Moving-bed reactor, solid acid alkylation reaction system and solid acid alkylation reaction method

ActiveCN107983270AIncrease the concentration of alkanesIncrease exposureLiquid hydrocarbon mixtures productionChemical/physical processesAlkanePtru catalyst

The invention provides a moving-bed reactor, a solid acid alkylation reaction system and a solid acid alkylation reaction method. The moving-bed reactor comprises a reactor shell, a fluid distributor,a solid particle distributor and a feed system, wherein the internal space of the reactor shell is divided into a particle collecting area, a reaction area and a particle deposition area from bottomto top; the fluid distributor is arranged in the reaction area, the bottom of the fluid distributor is communicated with a fluid feed port, the solid particle distributor is located at the upper partof the reaction area, and the top of the solid particle distributor is communicated with a catalyst inlet; a catalyst outlet is formed in the bottom of the particle collecting area. The moving-bed reactor is suitable for a solid acid alkylation reaction, alkylation raw materials are subjected to cross-current and counter-current contact reactions with a catalyst in the reaction area, the ratio ofisomeric alkane to olefins in the reaction process is increased, an addition reaction between olefins is avoided, and selectivity of target products is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technology for preparing high-purity 2-hydroxyethyl acrylate

InactiveCN106631790AEfficient recyclingGood dispersionOrganic compound preparationCarboxylic acid esters preparationOperating temperaturePolymerization

The invention discloses a technology for preparing high-purity 2-hydroxyethyl acrylate and relates to the field of 2-hydroxyethyl acrylate preparation technologies. The technology has the advantages that a rectification process is added during purification, a polymerization inhibitor is supplemented through spraying during phase transformation in the rectification process, and the vacuum degree and the operating temperature of a tower top are controlled to eradicate flash polymerization of the 2-hydroxyethyl acrylate in a rectifying tower, so that operation stability is achieved, polymerization can be prevented effectively, the product quality is improved, and the purity of the 2-hydroxyethyl acrylate is enhanced.

Owner:CHANGZHOU HICKORY CHEM

Method for producing triacrylic ester of alkoxylating trimethylolpropane

ActiveCN101092354AInhibit aggregationAvoid PolymerizationOrganic compound preparationCarboxylic acid esters preparationDistillationOxygen

This invention relates to a method for producing alkoxylated trimethylolpropane tris-acrylate. The method comprises: dissolving alkoxylated trimethylolpropane into part of water-carrying agent, adding catalyst, polymerization inhibitor and acrylic acid, introducing 0.5-1.5 L / min air or oxygen, adding the rest normal-temperature water-carrying agent into the reaction kettle, collecting the azeotrope of water-carrying agent and water into a metered glass container, demixing, refluxing for 3.5-4.5 h, pumping the reaction solution into a neutralization kettle, adding soda solution for neutralization, washing with water until the pH value is 6-8, standing for demixing, transferring the upper layer organic phase into a distillation kettle, adding polymerization inhibitor, distilling, purifying to obtain alkoxylated trimethylolpropane tris-acrylate, stopping distillation when the content of polymerization inhibitor is below 300 ppm, and vacuum-filtering to obtain the product. The method has a high yield, and the chroma of the product is lower than 50# of Pt-Co color mark.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Polyurethane elastomer modified by using hydroxylation carbon nanotube and preparation method of polyurethane elastomer

The invention provides a polyurethane elastomer modified by using hydroxylation carbon nanotubes and a preparation method of the polyurethane elastomer. The polyurethane elastomer comprises the following components in parts by weight: component A including 50-80 parts of macromolecule polyhydric alcohols, 10-20 parts of polyisocyanates, 1.5-1.7 parts of an oxime sealing agent, 0.1-0.5 part of a catalyst, component B including 3-5 parts of hydroxylation carbon nanotubes, and 1-2 parts of a dispersing agent. The surfaces of the hydroxylation carbon nanotubes comprise hydroxyl groups which can react with isocyanic acid radicals, so that the problem that the carbon nanotubes are poor in compatibility with polyurethane can be solved, the carbon nanotubes can be used as a cross-linking agent, the mechanical property and the thermal stability of the polyurethane elastomer can be improved, and meanwhile the polyurethane elastomer has conductivity and heat conduction.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Preparing method for acrylic acid

InactiveCN1472187AAvoid formingImprove final yieldOrganic compound preparationCarboxylic compound separation/purificationOligomerFractionating column

Owner:NIPPON SHOKUBAI CO LTD

Interval reaction rectification process for synthesizing methacrylic anhydride

InactiveCN103058849AReduce the temperatureAvoid PolymerizationOrganic compound preparationCarboxylic acid anhydrides preparationAcetic acidEthylic acid

The invention discloses an interval reaction rectification process for synthesizing methacrylic anhydride. Reaction rectification equipment is an interval reaction rectification tower; and a reaction is mainly carried out in a tower kettle of the rectification tower. The process adopts a reaction rectification technology to move away byproduct acetic acid from a reaction system in time so that the reaction is carried out in a forward direction; and the conversion rate of methacrylic acid is improved. A polymerization inhibitor is respectively added from the tower kettle and a reflowing opening of the tower so as to effectively prevent the methacrylic acid from being polymerized. The methacrylic anhydride synthesized by the interval reaction rectification process has the characteristics of high reaction conversion rate, high purities of the acetic acid at the tower top, stable product quality and the like. The conversion rate of the methacrylic anhydride obtained by the process is more than 98% and the reaction yield of the methacrylic anhydride reaction exceeds 80%.

Owner:FUZHOU UNIV

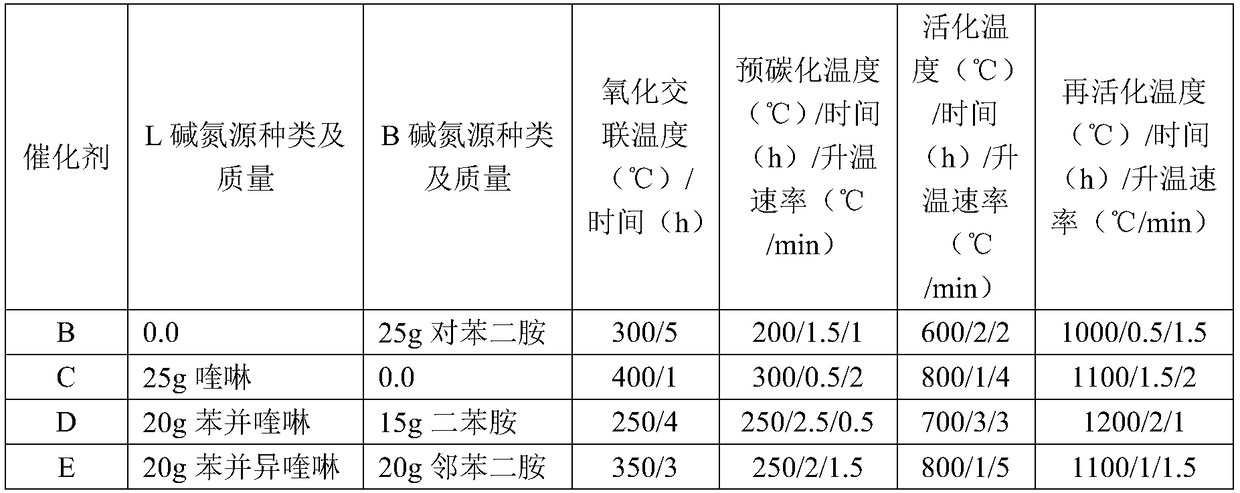

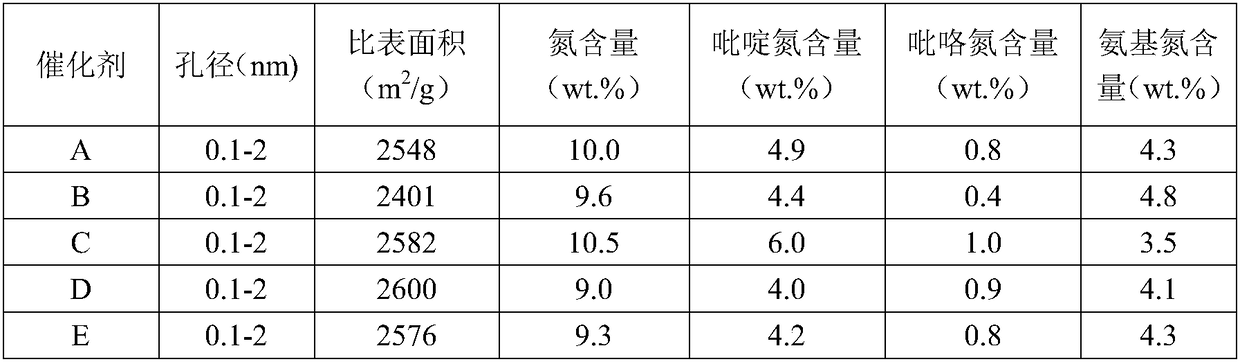

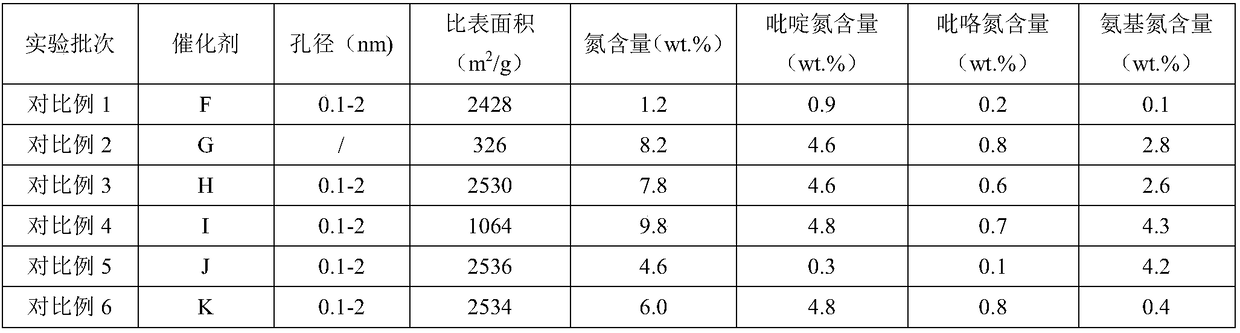

Nitrogen-doped porous carbon catalyst, preparation method of catalyst and preparation method of beta-isophorone

ActiveCN108579790AHigh value-added utilizationIncrease steric hindrancePhysical/chemical process catalystsOrganic compound preparationIsomerizationPorous carbon

The invention discloses a nitrogen-doped porous carbon catalyst, a preparation method of the catalyst and a preparation method of beta-isophorone. With coal-tar pitch as a raw material, the novel nitrogen-doped porous carbon catalyst containing L base and B base is prepared through the processes of oxidative crosslinking, pre-carbonization, activation and reactivation. The catalyst is used for preparing 3,5,5-trimethylcyclohex-3-alkene-1-ketone through an isomerization reaction of 3,5,5-trimethylcyclohex-3-alkene-2-ketone. The selectivity of the isomerization reaction reaches 99.6-99.9%. The preparation method has the advantages that the catalyst is easy to recycle, high in conversion rate and selectivity, environmentally friendly, high in space-time yield, capable of causing no corrosionto equipment and the like, and the high-additional-value utilization of coal resources is achieved.

Owner:WANHUA CHEM GRP CO LTD

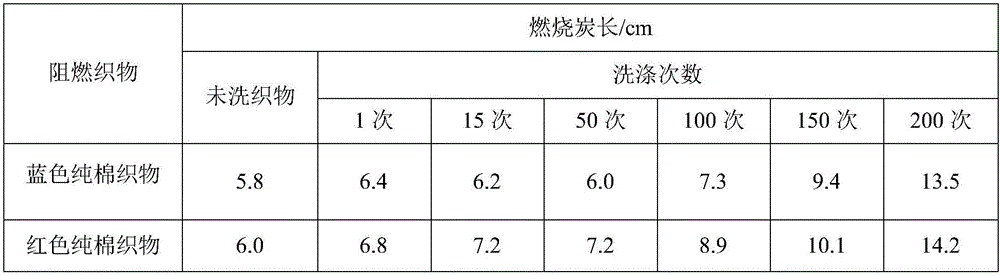

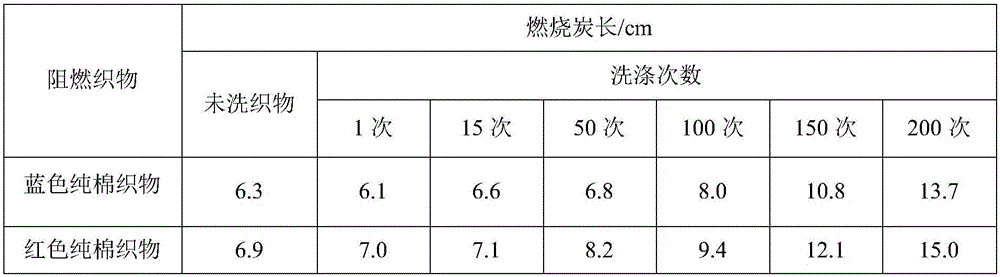

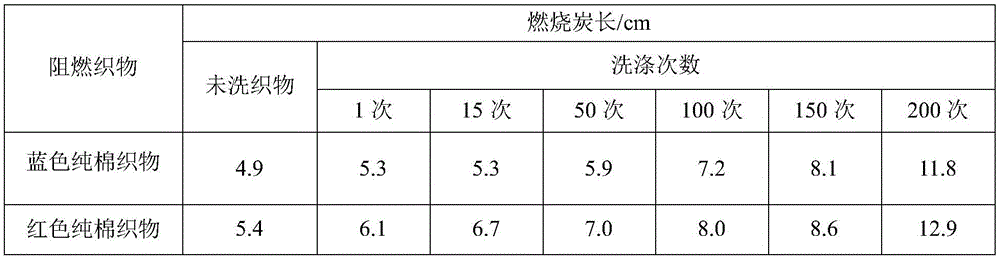

Preparation method of durable and flame retardant preparation for cotton fabric

InactiveCN106400485AAvoid PolymerizationImprove stabilityHeat resistant fibresGrip property fibresNormal levelPhosphoric acid

The invention discloses a preparation method of durable and flame retardant preparation for cotton fabric. The method is to put into a reaction kettle four hydroxymethyl phosphorus compound and high nitrogen content substance according to a ratio of 4:0.5-4:1, heating and stirring to dissolve; using the phosphoric acid solvent to adjust the pH value of the reaction mixture to 4.5-6, adding in catalyst; when the system temperature rises to 60-70 DEG, the heating is stopped and the reaction is continued for 1.5-2.0 hours; then adding in the terminator, stirring evenly, cooling and cycling to lower the temperature to the normal level, and obtaining the durable and flame retardant preparation for cotton fabric. The method is simple in preparation process, short in reaction time, low in cost, and good in flame retardant effect. The effect of the preparation is lasting and the wash durability lasts 200 times.

Owner:合肥市东方美捷分子材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com