Preparation method of durable and flame retardant preparation for cotton fabric

A durable flame-retardant, cotton fabric technology, applied in the direction of flame-retardant fibers, plant fibers, textiles and papermaking, etc., can solve the problems of limited washable times and unsatisfactory products, and achieve low cost, short reaction time and soft hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

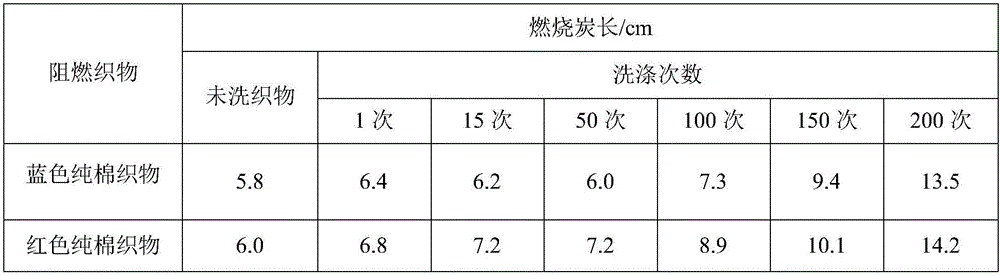

[0021] Add 80 parts by mass of tetrakismethylolphosphine chloride, 20 parts by mass of tetrakishydroxymethylphosphorus sulfate and 15 parts by mass of dicyandiamide into the ceramic mixing reactor, while slowly heating the reactor and stirring continuously; Completely dissolve, add phosphoric acid solution to the reaction kettle to adjust the pH value of the reaction mixture to 4.8, then slowly add 0.2 parts by mass of magnesium chloride to the reaction kettle, when the temperature of the system rises to 60°C, stop heating the reaction kettle, and continue the reaction for 2 hours, Then add 15 parts by mass of 0.1 wt% sodium dimethyl dithiocarbamate aqueous solution, stir evenly, cool down to normal temperature by cooling cycle, and obtain a durable flame retardant for cotton fabrics. The flame retardant and washable properties of the finished cotton fabrics are shown in Table 1.

[0022] Table 1 Washability of flame retardant fabrics

[0023]

Embodiment 2

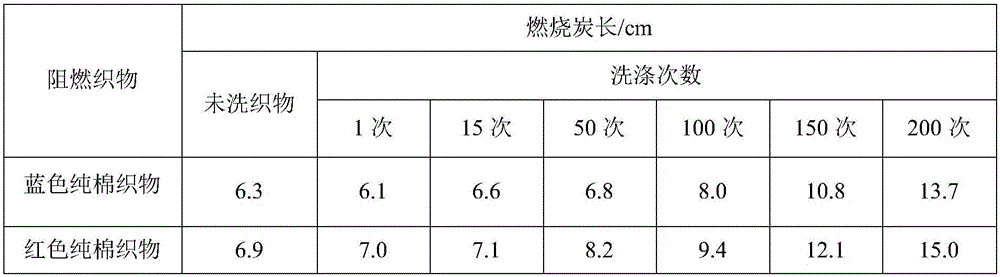

[0025] Add 75 parts by mass of tetrakismethylolphosphine chloride, 25 parts by mass of tetrakishydroxymethylphosphorus sulfate and 12.5 parts by mass of guanidine into the ceramic mixing reactor, while slowly heating the reactor and stirring continuously; until the dicyandiamide is completely dissolved , add phosphoric acid solution to the reactor to adjust the pH value of the reaction mixture to 5.5, then slowly add 0.1 parts by mass of aluminum chloride and 0.2 parts by mass of potassium chloride to the reactor, and stop heating the reactor when the temperature of the system rises to 65 °C , and continue to react for 1.5 hours, then add 12 parts by mass of 0.5wt% sodium polysulfate aqueous solution, stir evenly, cool down to normal temperature by cooling cycle, and obtain a durable flame retardant for cotton fabrics. The flame retardant and washing durability of cotton fabrics after finishing are shown in Table 2.

[0026] Table 2 Washing resistance of flame retardant fabric...

Embodiment 3

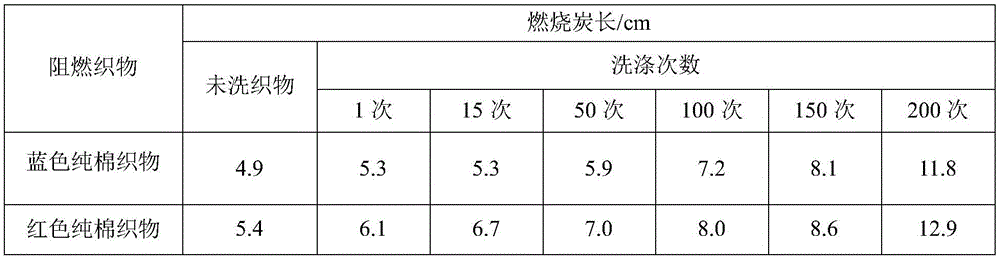

[0029] Add 70 parts by mass of tetrakishydroxymethylphosphorus chloride, 20 parts by mass of tetrakishydroxymethylphosphorus sulfate and 25 parts by mass of urea into the ceramic mixing reactor, while slowly heating the reactor and stirring continuously; when the dicyandiamide is completely dissolved , add phosphoric acid solution to the reaction kettle to adjust the pH value of the reaction mixture to 6, then slowly add 0.2 parts by mass of aluminum phosphate to the reaction kettle, when the temperature of the system rises to 70°C, stop heating the reaction kettle, and continue the reaction for 1.5 hours, then Add 14 parts by mass of 0.3wt% sodium nitrite aqueous solution, stir evenly, cool down to normal temperature by cooling cycle, and obtain a durable flame retardant for cotton fabrics. The flame retardancy and washability of the finished cotton fabrics are shown in Table 3.

[0030] Table 3 Washability of Flame Retardant Fabrics

[0031]

[0032] Note:

[0033] Flam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com