Polyurethane elastomer modified by using hydroxylation carbon nanotube and preparation method of polyurethane elastomer

A technology of polyurethane elasticity and polyurethane elastomer, applied in the field of polyurethane elastomer and its preparation, can solve the problems of difficulty in dispersion, large interfacial interaction force, poor compatibility, etc., and achieves improved storage time, enhanced mechanical properties and thermal stability. , to avoid the effect of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

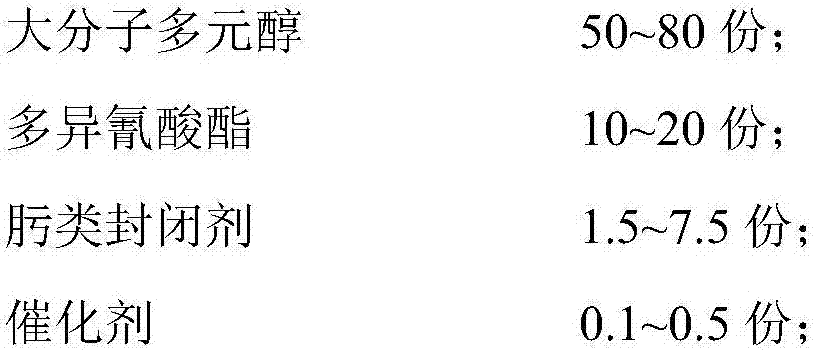

[0041] A polyurethane elastomer modified by hydroxylated carbon nanotubes, by weight, comprises the following components:

[0042] Component A: 50 parts of polyoxypropylene ether glycol; 10 parts of isophorone diisocyanate; 2.3 parts of cyclohexanone oxime; 0.1 part of catalyst.

[0043] Component B: 3 parts of hydroxylated carbon nanotubes; 1 part of dispersant.

[0044] The preparation method comprises the following steps:

[0045] (1) Put 50 parts of polyoxypropylene ether glycol into the reaction kettle, vacuum dehydrate at 100°C for 2 hours, and cool down to 50°C;

[0046] (2) Put 10 parts of isophorone diisocyanate and 0.1 part of zinc isooctanoate into the reaction kettle, stir and heat up to 90°C for 3 hours, then cool down to 50°C;

[0047] (3) Put 2.3 parts of cyclohexanone oxime into the reaction kettle, stir and heat up to 70°C for 5 hours to obtain a closed polyurethane prepolymer;

[0048] (4) Mix the closed polyurethane prepolymer obtained in step (3) with 3 ...

Embodiment 2

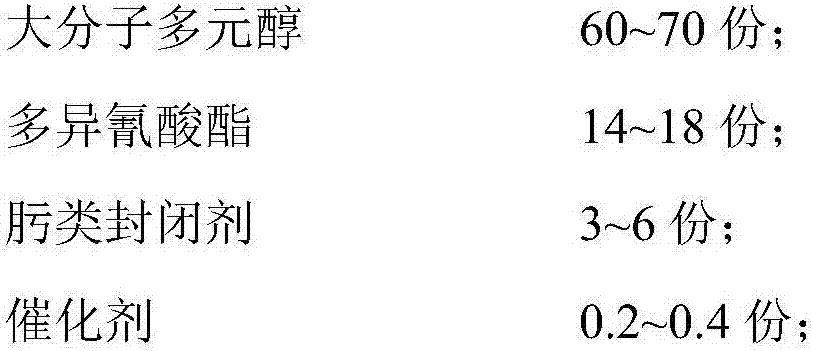

[0050] A polyurethane elastomer modified by hydroxylated carbon nanotubes, by weight, comprises the following components:

[0051] Component A: 70 parts of polytetrahydrofuran diol; 17.5 parts of diphenylmethane diisocyanate; 3 parts of methyl ethyl ketone oxime; 0.2 parts of catalyst.

[0052] Component B: 4 parts of hydroxylated carbon nanotubes; 2 parts of dispersant.

[0053] The preparation method comprises the following steps:

[0054] (1) Put 70 parts of polytetrahydrofuran diol into the reaction kettle, vacuum dehydrate at 110°C for 2 hours, and cool down to 50°C;

[0055] (2) Put 17.5 parts of diphenylmethane diisocyanate and 0.2 parts of zinc acetylacetonate into the reactor, stir and heat up to 80°C for 3 hours, then cool down to 50°C;

[0056] (3) Put 3 parts of methyl ethyl ketone oxime into the reaction kettle, stir and heat up to 70°C for 4 hours to obtain a closed polyurethane prepolymer;

[0057] (4) Mix the closed polyurethane prepolymer obtained in step (...

Embodiment 3

[0059] A polyurethane elastomer modified by hydroxylated carbon nanotubes, by weight, comprises the following components:

[0060] Component A: 80 parts of polyethylene adipate; 18 parts of isophorone diisocyanate; 3.5 parts of methyl ethyl ketone oxime; 0.2 parts of catalyst.

[0061] Component B: 3 parts of hydroxylated carbon nanotubes; 2 parts of dispersant.

[0062]Its preparation method comprises the following steps:

[0063] (1) Put 80 parts of polyethylene adipate into the reaction kettle, vacuum dehydrate at 110°C for 2 hours, and cool down to 50°C;

[0064] (2) Put 18 parts of isophorone diisocyanate and 0.2 parts of stannous octoate into the reaction kettle, stir and heat up to 90°C for 3 hours, then cool down to 50°C;

[0065] (3) Put 3.5 parts of methyl ethyl ketone oxime into the reaction kettle, stir and heat up to 70°C for 4 hours to obtain a closed polyurethane prepolymer;

[0066] (4) Mix the closed polyurethane prepolymer obtained in (3) with 3 parts of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com