Synthetic method of N,N'-dibenzyl-1,2-ethanediamine

A technology of dibenzylethylenediamine and dibenzylideneethylenediamine, which is applied in the field of catalytic hydrogenation to prepare N,N-dibenzylethylenediamine, can solve side reactions, slow down reaction speed, hydrogenolysis and Polymerization and other problems, to achieve good stability, speed up the reaction speed, improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

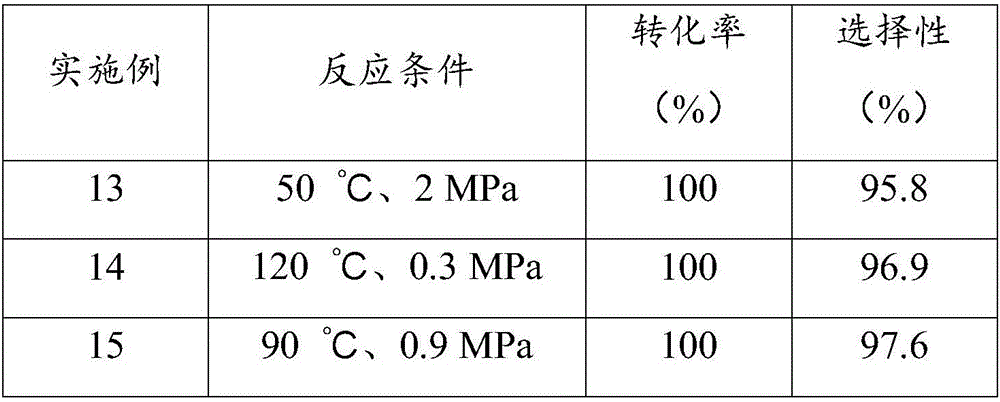

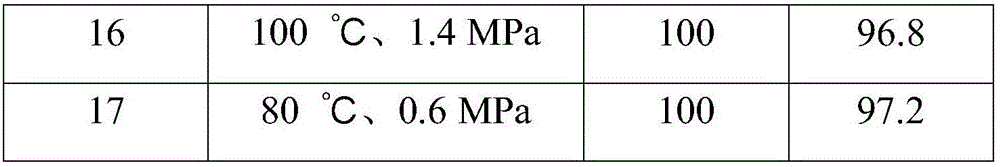

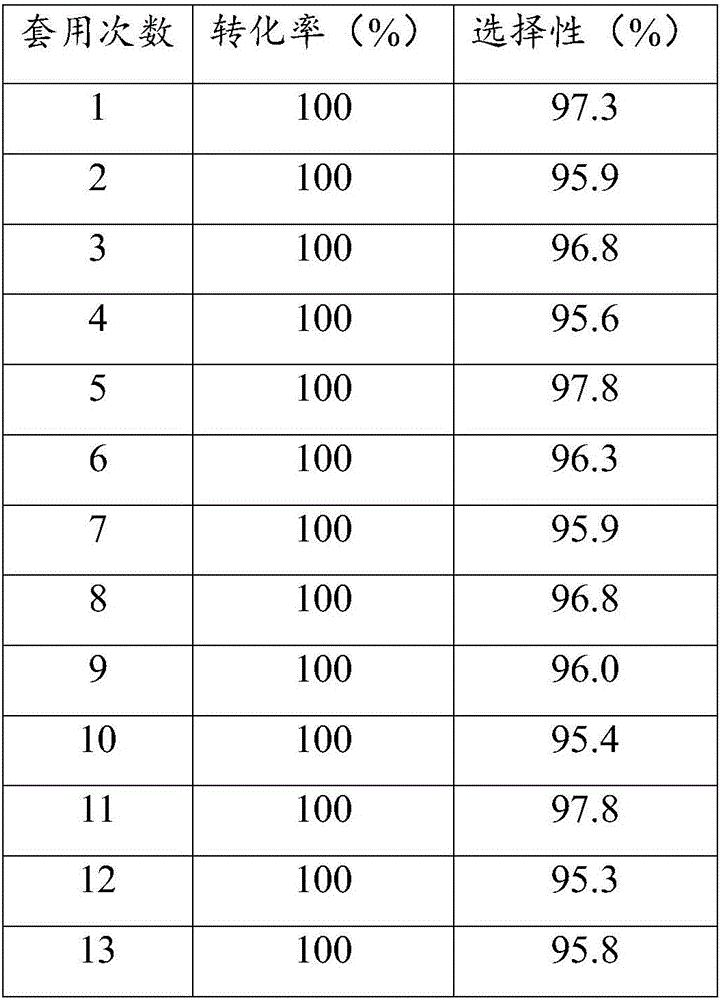

Examples

Embodiment 1

[0036] Weigh 10g of mesoporous carbon, the particle size of mesoporous carbon is 600 mesh, and the specific surface area is 1400m 2 / g, with an average pore diameter of 4nm, it was mixed with 0.6g urea uniformly, and treated at 1000°C for 5h under a nitrogen atmosphere to obtain nitrogen-doped mesoporous carbon. Then, the above-mentioned nitrogen-doped mesoporous carbon was prepared in 100ml of deionized water to form a slurry at a temperature of 80°C, and 10ml of H 2 PdCl 4 solution (the Pd content is 0.1g / ml), stirred for 2.5h; the pH value of the solution was adjusted to 8 with 10wt% NaOH solution, and the temperature was lowered to room temperature, filtered, and the filter cake was washed to neutrality with deionized water; The filter cake was configured into a slurry at 80°C, 10ml of 85% hydrazine hydrate solution was added dropwise, stirred for 2 hours, filtered, the filter cake was washed with deionized water until neutral, and vacuum-dried at 100°C to obtain nitrogen...

Embodiment 2

[0038] Weigh 10g of mesoporous carbon, the particle size of mesoporous carbon is 1000 mesh, and the specific surface area is 1200m 2 / g, the average pore size is 5nm, put it in NH 3 In , the gas flow rate is 1 L / h, and the nitrogen-doped mesoporous carbon is obtained by treating at 800 ° C for 10 h. The above nitrogen-doped mesoporous carbon was prepared in 100ml of deionized water to make a slurry at a temperature of 60°C, and 6ml of H 2 PtCl 6 solution (Pt content is 0.1g / ml), stirred for 2h; the pH value of the solution was adjusted to 8.5 with 10wt% KOH solution, and the temperature was lowered to room temperature, filtered, and the filter cake was washed to neutral with deionized water; The cake was prepared into a slurry at 60°C, 10ml of formaldehyde was added dropwise, stirred for 2 hours, filtered, the filter cake was washed with deionized water until neutral, and vacuum-dried at 90°C to obtain a nitrogen-doped mesoporous carbon-supported platinum catalyst.

Embodiment 3

[0040] Weigh 10g of mesoporous carbon, the particle size of mesoporous carbon is 100 mesh, and the specific surface area is 1500m 2 / g, with an average pore diameter of 10nm, mix it with 4g of melamine evenly, and treat it at 1200°C for 3h under a helium atmosphere to obtain nitrogen-doped mesoporous carbon. The above nitrogen-doped mesoporous carbon was prepared in 100ml of deionized water into a slurry at a temperature of 40°C, and 10ml of Pd(NO 3 ) 2 solution (with a Pd content of 0.005g / ml), stirred for 4h; the pH value of the solution was adjusted to 9 with ammonia water, and the temperature was lowered to room temperature, filtered, and the filter cake was washed with deionized water until neutral; Prepare a slurry, add 30ml of formic acid dropwise, stir for 4 hours, filter, wash the filter cake with deionized water until neutral, and dry it in vacuum at 80°C to obtain a nitrogen-doped mesoporous carbon-supported palladium catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com