Patents

Literature

31results about How to "Lower curing reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

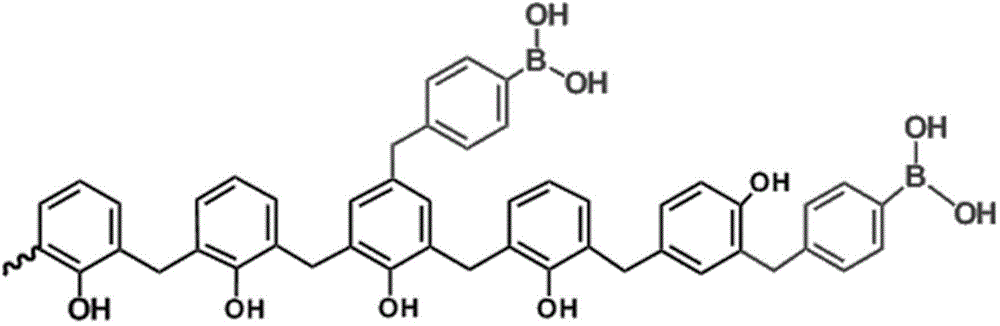

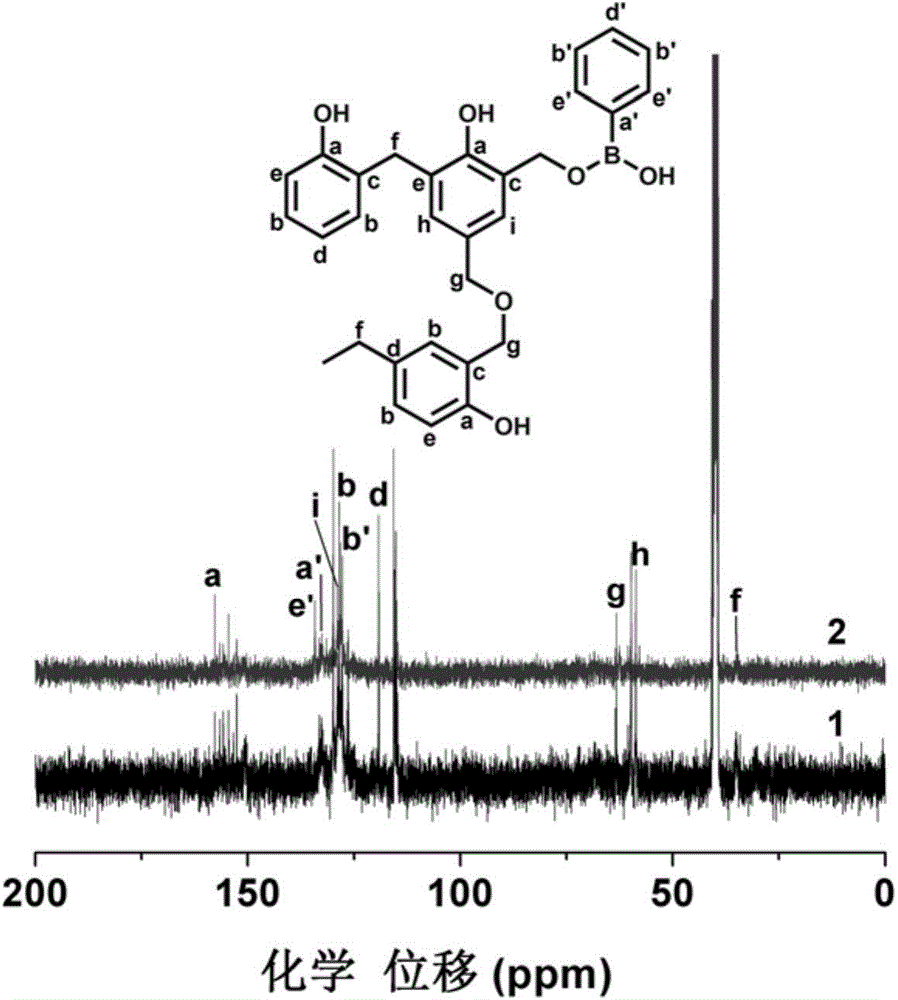

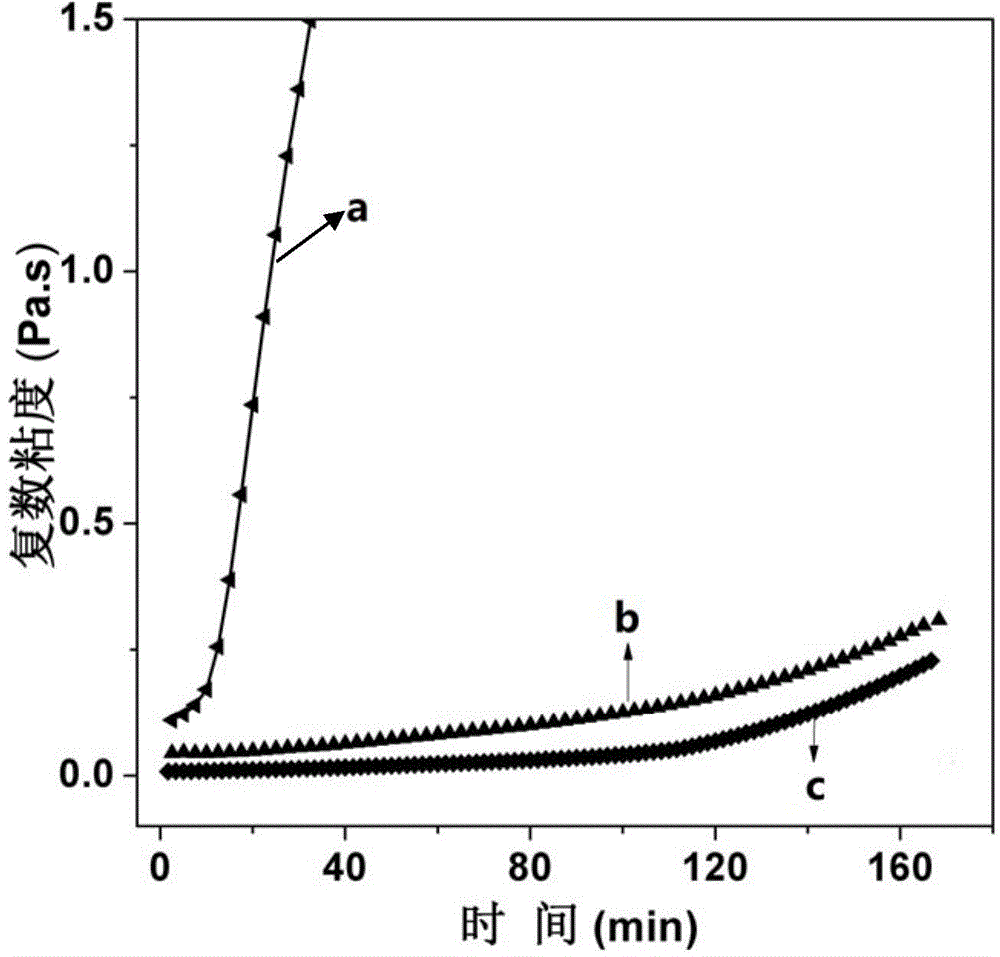

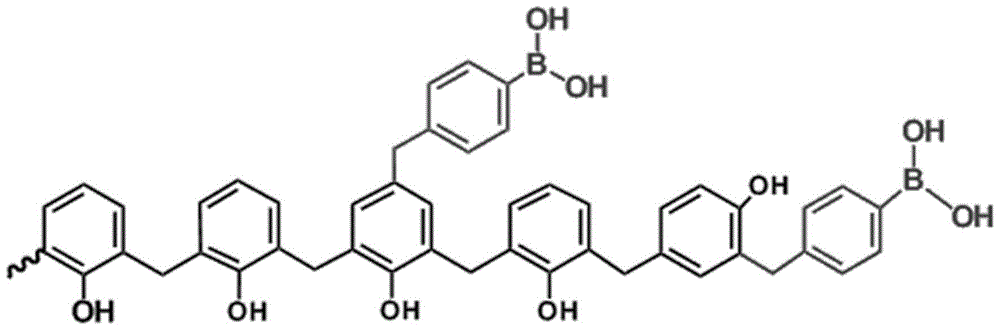

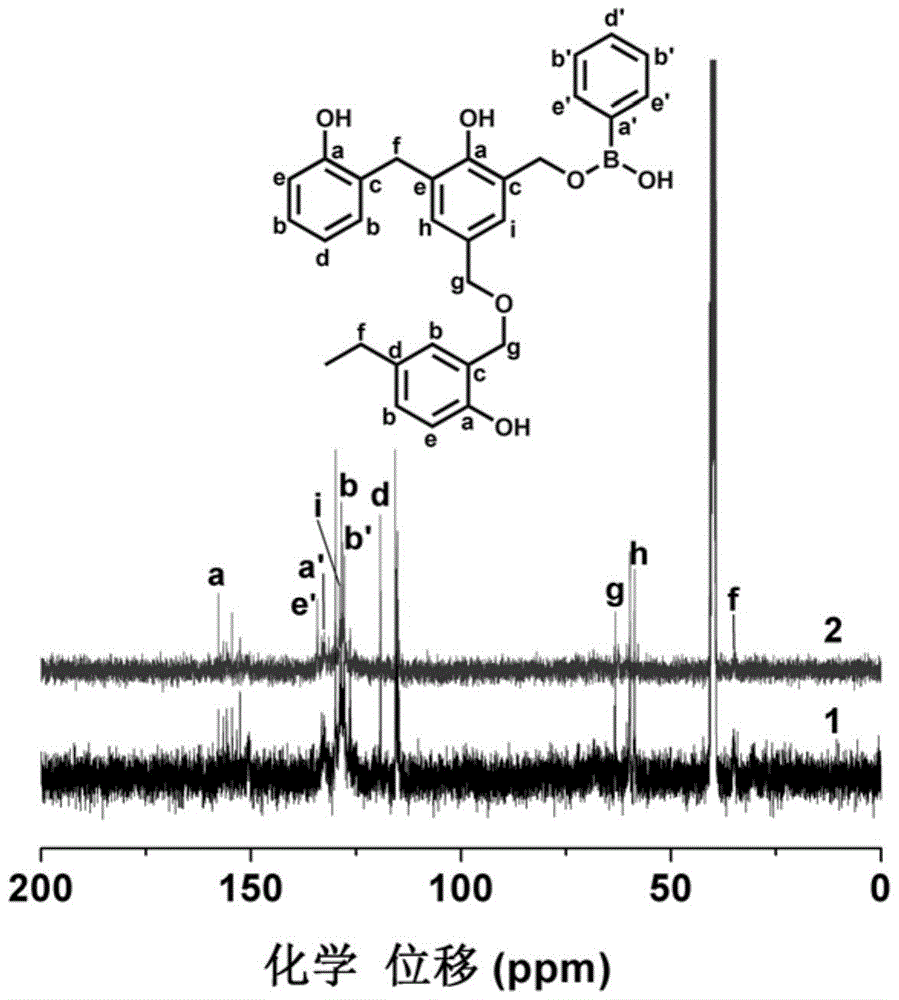

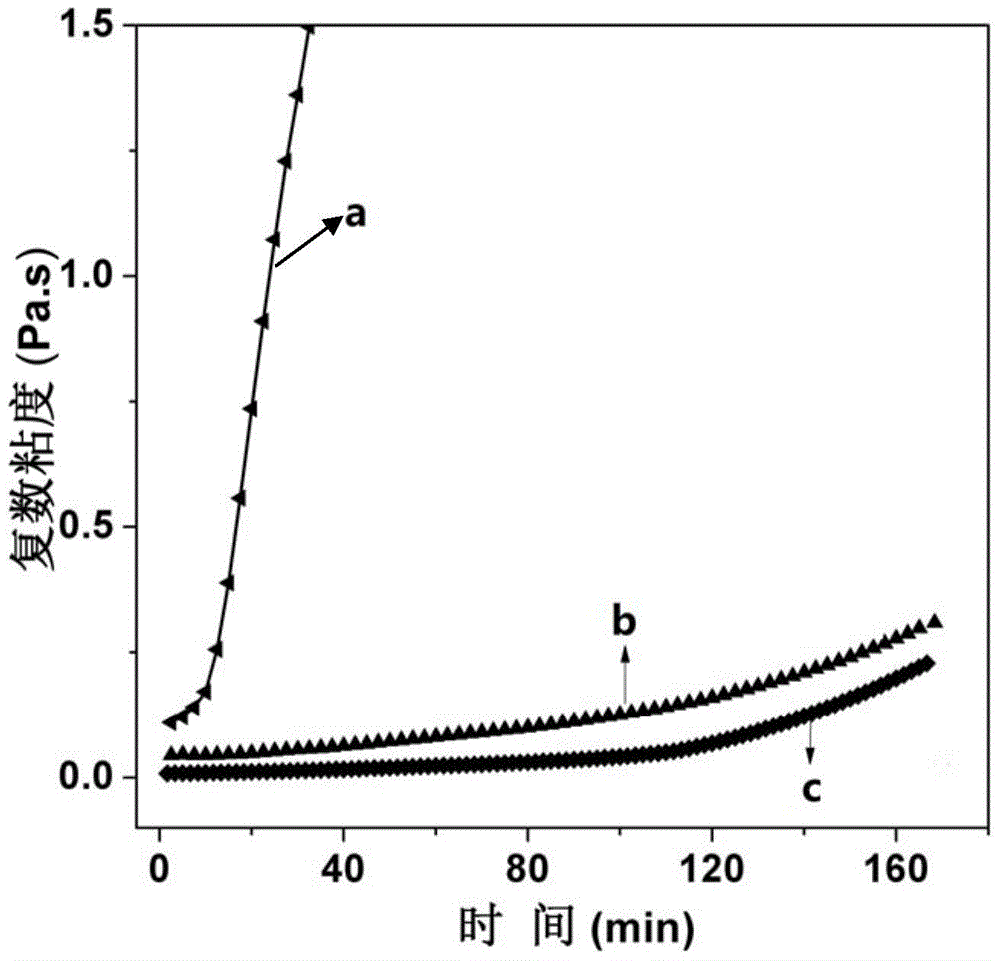

Preparation method of aryl-containing boron thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

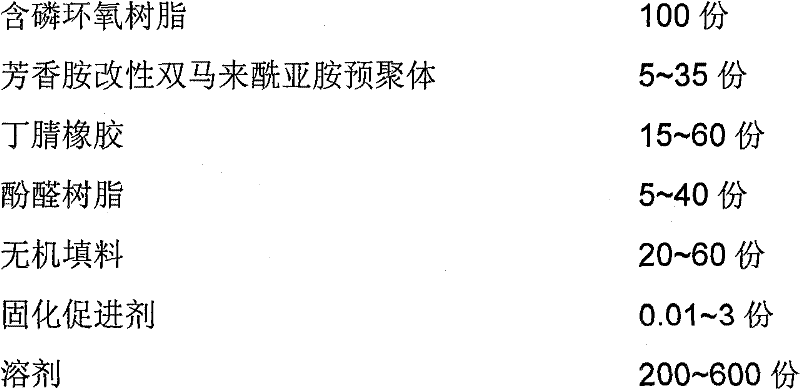

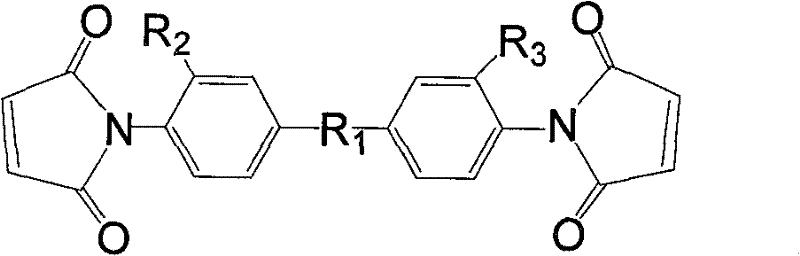

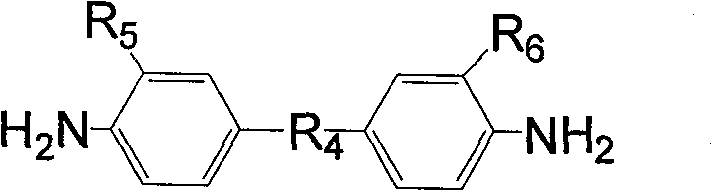

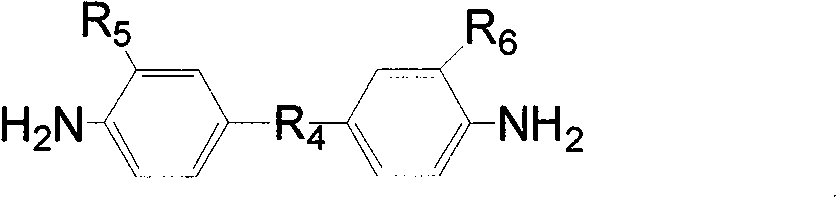

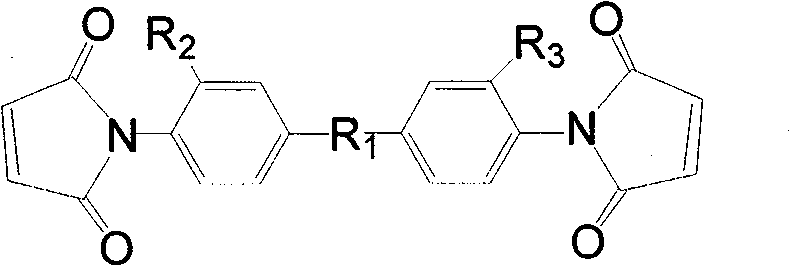

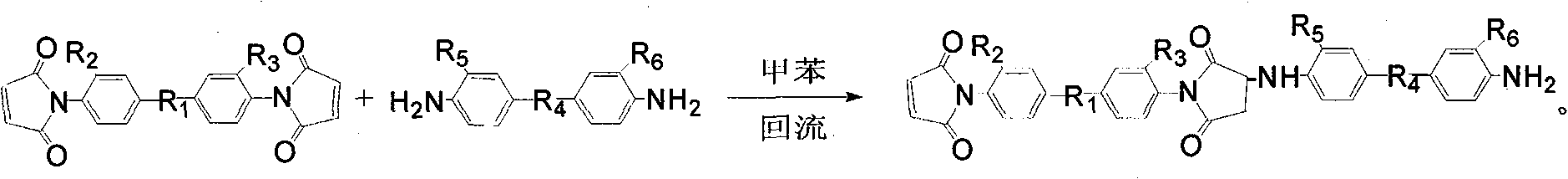

High temperature resistant halogen-free flame-retardant adhesive for flexible copper clad foil substrate and preparation thereof

InactiveCN101323773AImprove solubilityReduce adverse effectsAldehyde/ketone condensation polymer adhesivesEpoxy resin adhesivesEpoxyChemical reaction

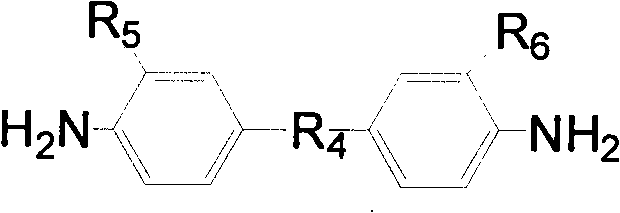

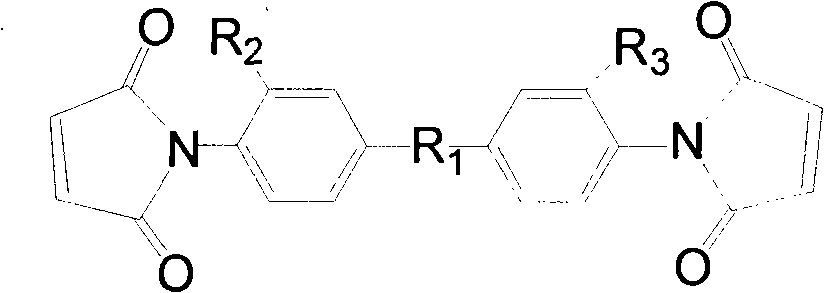

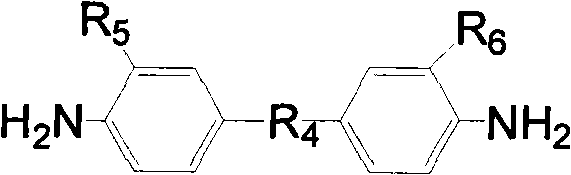

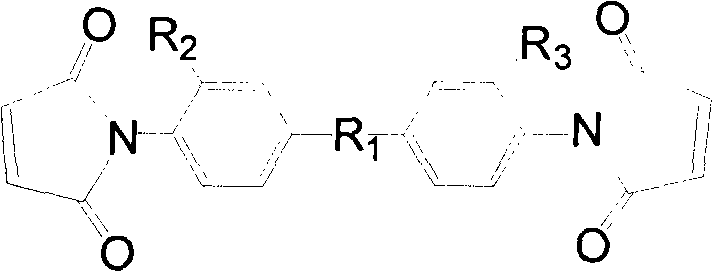

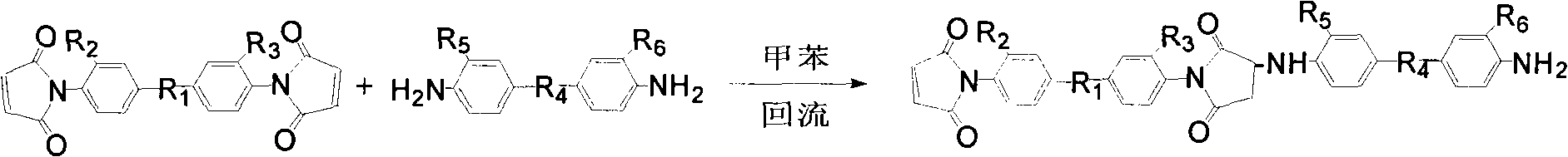

The invention provides a high-temperature resistant halogen-free fire-resistant adhesive used in flexible copper-clad baseplates and a preparation method thereof. The adhesive consists essentially of aromatic amine modified bismaleimide performed polymer, phosphorus epoxy resin, chemigum, phenolic resin, inorganic filler, a curing catalyst and a solvent. The preparation method comprises the steps that: first of all, toluene is taken as the solvent; under the reflow temperature of the toluene, aromatic diamine, aniline and bismaleimide polymerize to obtain a aromatic amine modified bismaleimide performed polymer solution which is then added with the phosphorus epoxy resin and then added with the chemigum, the phenolic resin, the inorganic filler, the curing catalyst and the solvent after chemical reaction or physical mixture so as to form the high-temperature resistant halogen-free fire-resistant adhesive which is used for bonding the polyimide film and copper foil of the flexible copper-clad baseplate; the prepared flexible copper-clad baseplate has excellent heat resistance, flame resistance, dimensional stability and comparatively high peeling strength.

Owner:WUHAN TEXTILE UNIV

High-strength high-permeability chemical sand prevention agent, and preparation method and application thereof

InactiveCN104650840AObvious advantageObvious effectFluid removalDrilling compositionHigh humidityOil water

The invention provides a high-strength high-permeability chemical sand prevention agent, and a preparation method and an application thereof. The high-strength high-permeability chemical sand prevention agent is composed of a proppant, a cementing agent, an accelerator, a curing agent and a coupling agent according to a certain ratio. The preparation method comprises the following steps: above raw materials are mixed at a specific temperature, and are stirred, and the obtained mixture is cured for a certain period of time to obtain the high curing strength sand prevention agent. The sand prevention agent has good tolerance to acid, water, salt and oil, has high stability in high temperature and high humidity environment, and is mainly used in chemical sand prevention well extract production, serious casing deformation well sand prevention, and sand prevention of wells without mechanical sand prevention and oil water wells with low reservoir temperature in order to increase liquid production of the oil well, prolong the period of validity of well sand prevention, increase the amount of oil and reduce the production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

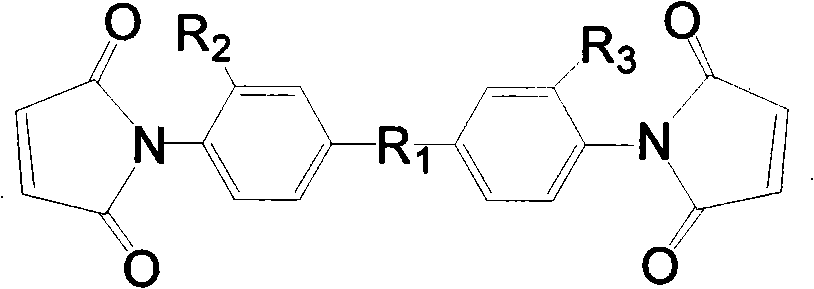

Poly(amino bimaleimide) resin composition, preparation and use thereof in copper clad laminate

The invention relates to a poly-amino-bismaleimide resin composite, a preparation method and the applications thereof in copper clad plates. The composite essentially consists of a poly-amino-bismaleimide resin, a phosphorous epoxy, a cyanate resin, a novolac epoxy resin, an inorganic stuffing, a curing catalyst and a solvent. The poly-amino-bismaleimide resin in use is pre-polymerized from bismaleimide and aromatic amine under the reflow temperature with toluene as the solvent. The poly-amino-bismaleimide resin composite used in copper clad plates has good processing properties, low curing temperature (195 DEG C) and short high temperature curing time (1 to 1.5 hours). The prepared copper clad plates have excellent heat resistance, with the vitrification transition temperature ranging from 204 DEG C to 230 DEG C, good fire retardant effect, comparatively high peeling strength, bending strength and comparatively low water absorption ratio.

Owner:SHENZHEN TONGXIN CIRCUIT ELECTRONICS

Epoxy resin system and preparation method thereof

The invention relates to the field of epoxy resin production, in particular to an epoxy resin system and a preparation method thereof. The epoxy resin system is prepared from, by weight, 85-95 parts of bisphenol-F epoxy resin, 0-10 parts of bisphenol-A epoxy resin, 0-5 parts of toughening agents, 5-7 parts of latent curing agents and 1-3 parts of accelerators. The preparation method is simple, easy to operate, strong in scientificity and applicable to industrial production.

Owner:TAISHAN SPORTS IND GRP

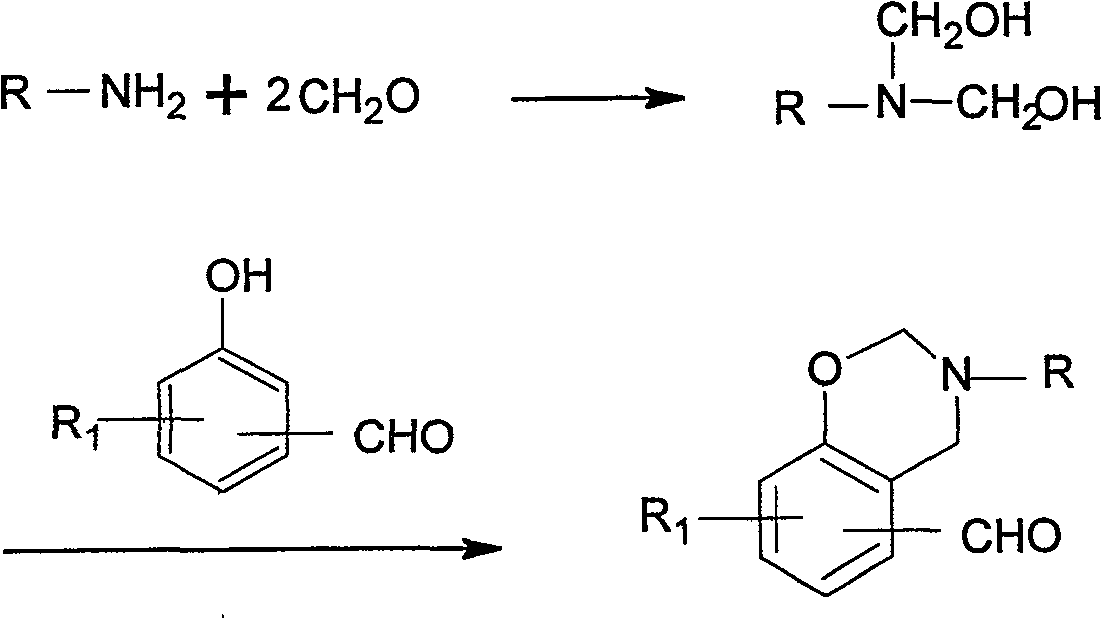

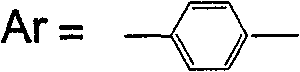

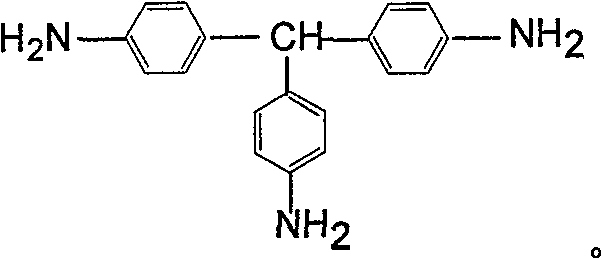

Benzo oxaxine intermediate containing aldehyde group and its preparation method

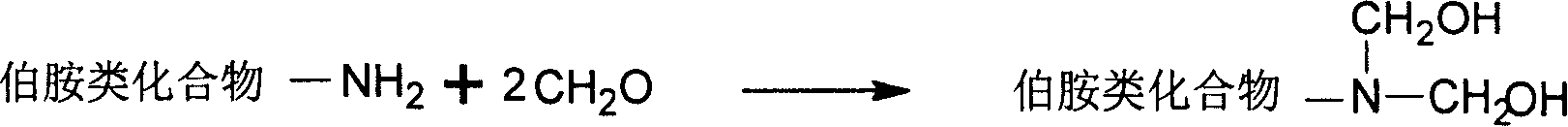

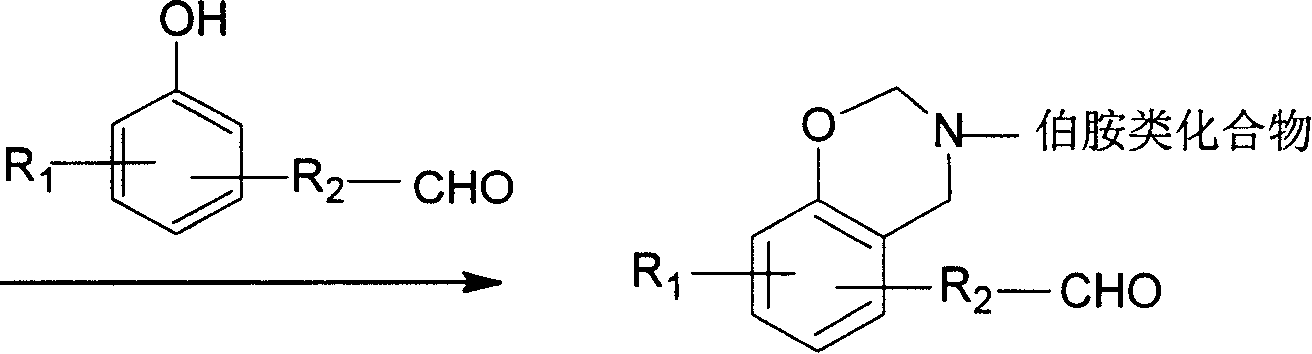

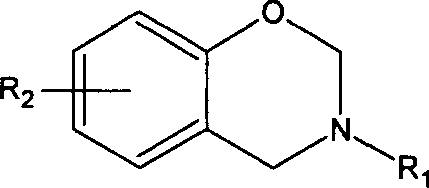

InactiveCN1865250AIncrease crosslink densityImprove thermal stabilityOrganic chemistryDistillationOrtho position

This invention relates to an aldehyde group-containing benzoxazine intermediate and and method for making same, characterizing: (1)add aminated compound 80-30wt and formaldehyde 20-110wt into the solvent 50-180wt at 4-20Deg C to react to produce N-dimethylol compound, adjust pH to 8-10 with base solution to stabilize the N-dimethylol compound in the solution; (2) add in aldehyde group-containing phenol derivatives 20-70wt to cause the N-dimethylol compound, phenolic hydroxyl group and the ortho-position of the benzene ring thereof for condensation reaction, and thus produce the aldehyde group-containing benzoxazine intermediate solution by dehydration and ring-closure, remove the solvent from the solution by press-decreasing distillation to produce the yellow aldehyde group-containing benzoxazine intermediate solid.

Owner:SICHUAN UNIV

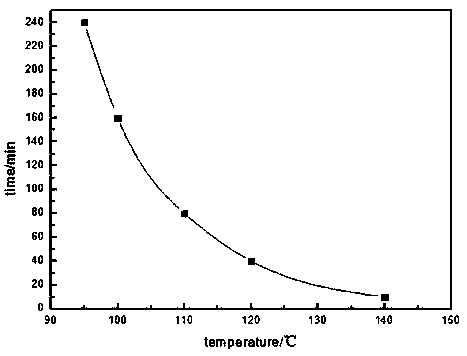

Cyanate ester/bimaleimide modified resin and preparation method

The invention discloses the ethylene rhodanate / bimaleimide modified resin catalyzed and solidified by organotin compound. The solidification reaction of the ethylene rhodanate / bimaleimide modified resin requires high temperature and long term to be completely solidified, and the harsh solidification condition restricts the application. The organotin compound is a high-activity catalyst, the adoption of which in catalyzing and solidifying the solidification reaction of the ethylene rhodanate / bimaleimide can obtain completely solidified resin with excellent performance under the condition of reducing solidification reaction temperature and shortening reaction time.

Owner:TONGJI UNIV

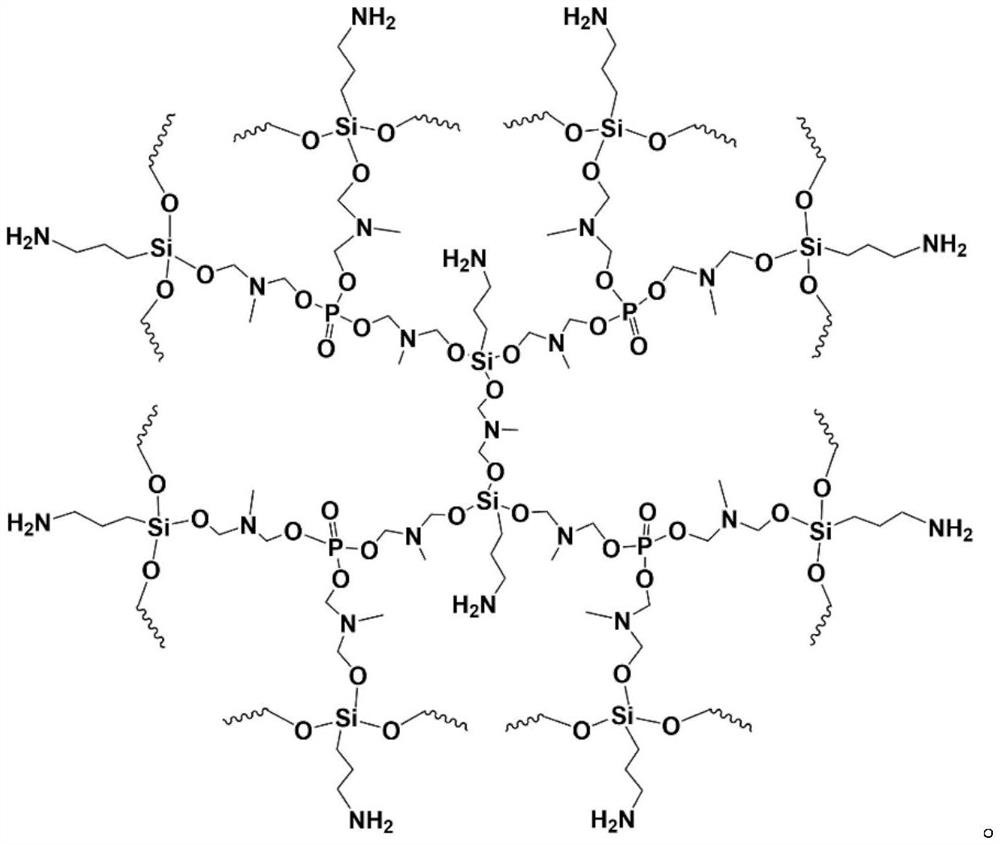

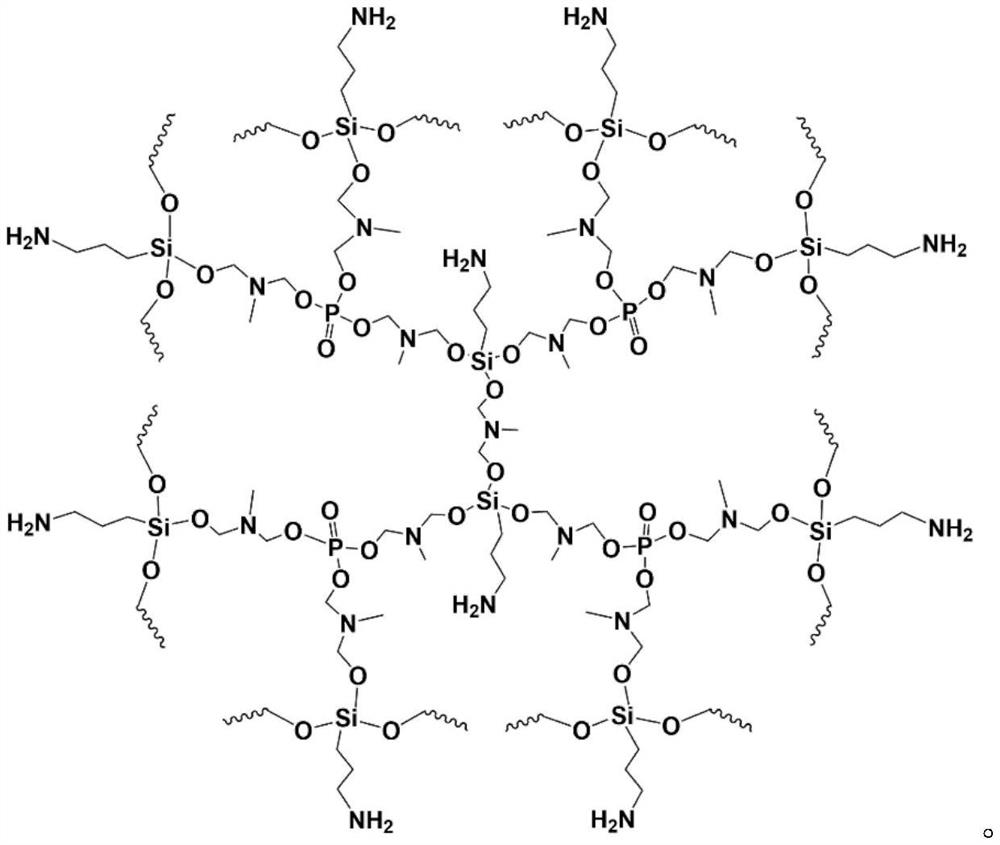

High-toughness flame-retardant medium-and-low-temperature cured epoxy resin system and preparation method thereof

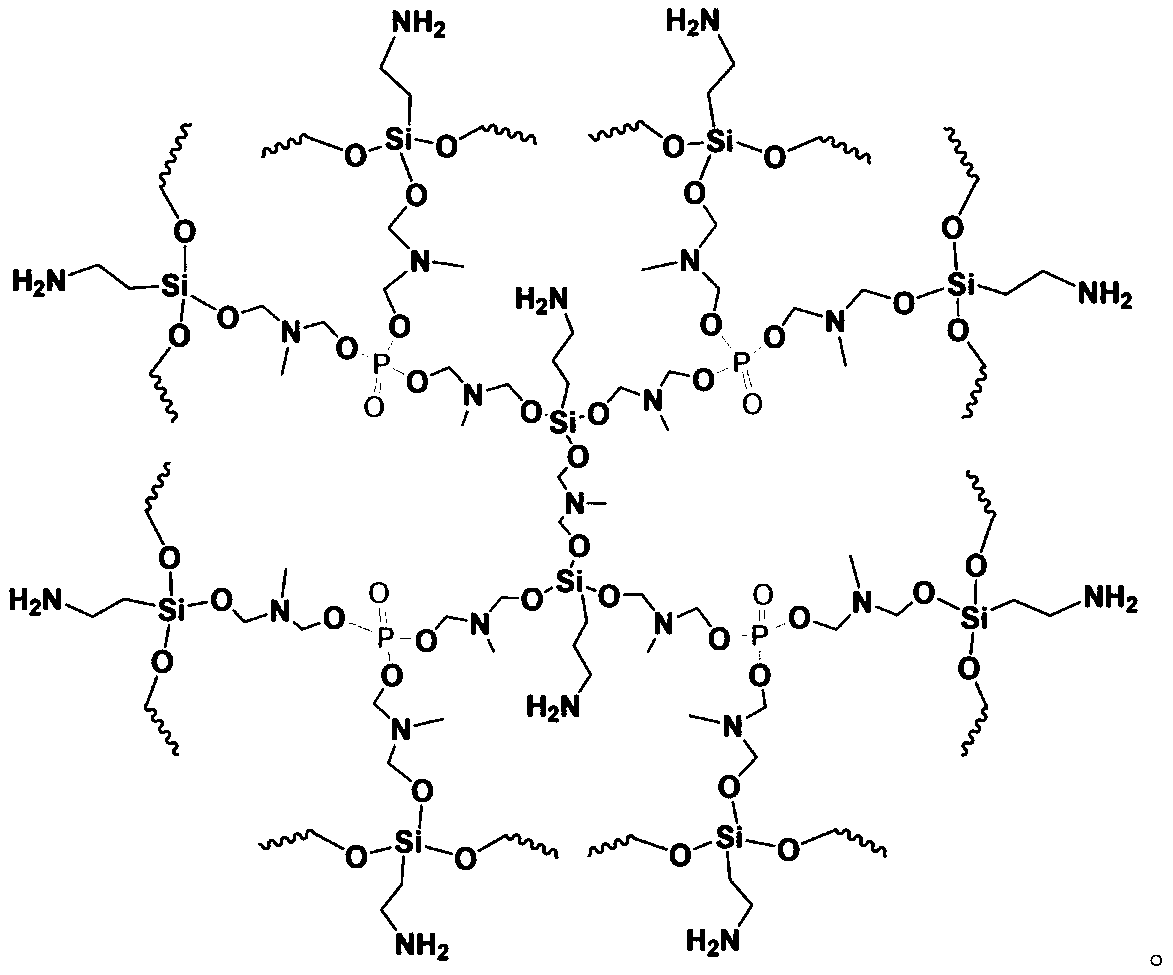

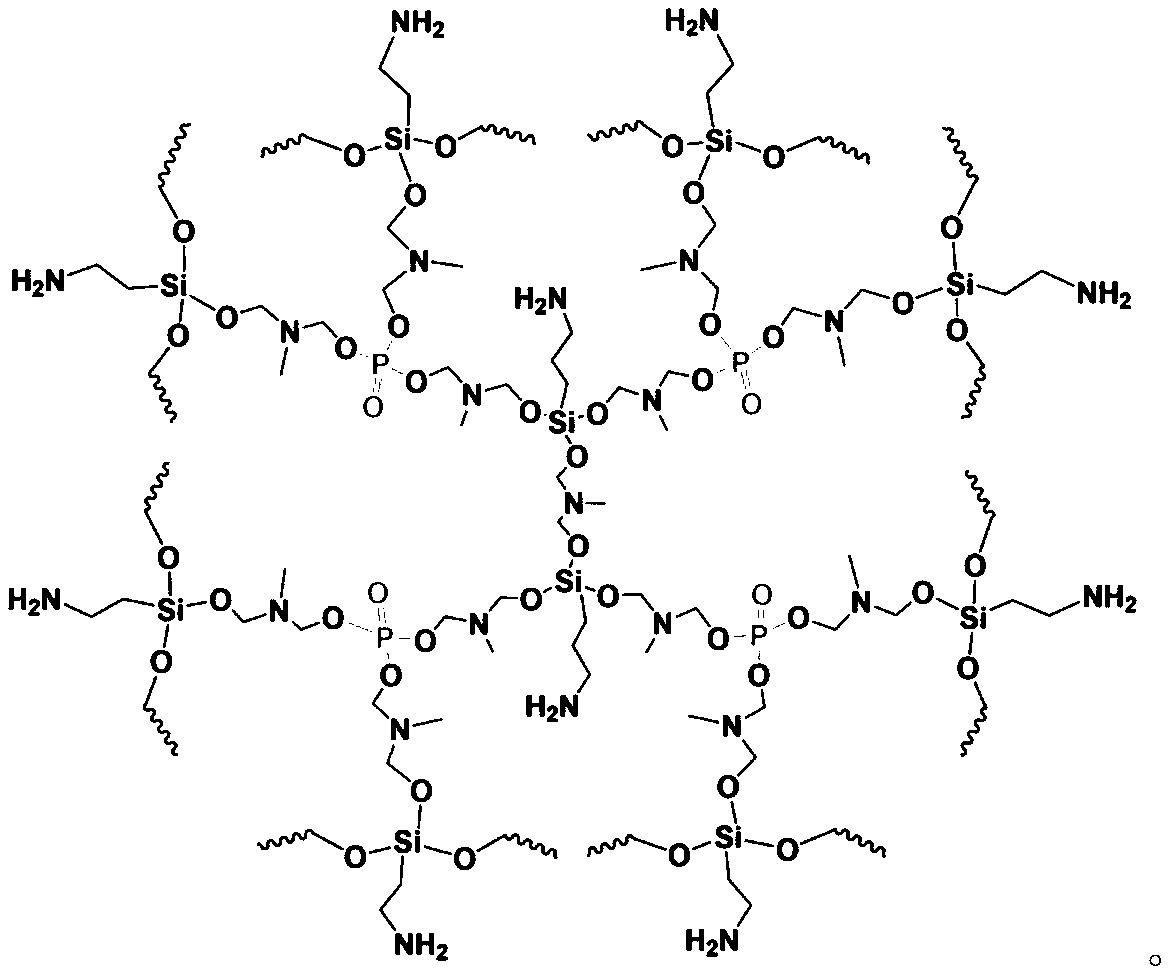

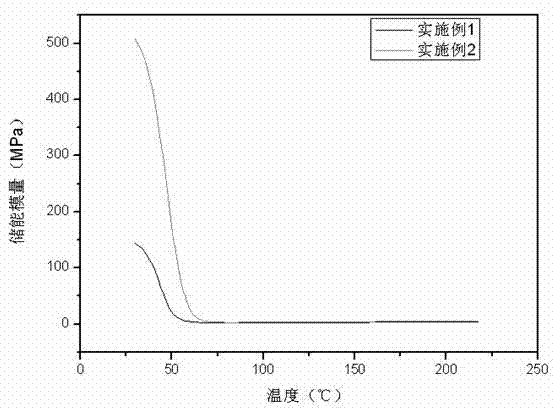

ActiveCN110628000AImprove flame retardant performanceLower curing reaction temperatureLow temperature curingCatalytic effect

The invention relates to a high-toughness flame-retardant medium-and-low-temperature cured epoxy resin system and a preparation method thereof. The high-toughness flame-retardant medium-and-low-temperature cured epoxy resin system is composed of silicon-phosphorus-nitrogen containing hyperbranched polysilicophosphate, bisphenol A type epoxy resin, tetraglycidyl amine type epoxy resin and an anhydride curing agent. The silicon-phosphorus-nitrogen synergistic flame retardant with the hyperbranched structure contains various flame retardant elements at the same time, the active terminal primary amine group of the silicon-phosphorus-nitrogen synergistic flame retardant can directly participate in a curing crosslinking reaction of epoxy resin and has good compatibility with a resin matrix, andmeanwhile, an Si-O-Si flexible chain segment is introduced into the epoxy resin, so that the toughness of the resin system is effectively improved. A tertiary amine functional group in the hyperbranched polysilicophosphate plays a role in promoting resin curing, can promote the reaction between an anhydride curing agent and epoxy resin, has a certain catalytic effect on curing, and can complete acuring reaction at a relatively low temperature. The system has a wide application prospect in the aspects of flame retardance of coatings, textiles, furniture, buildings and thermosetting resins.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-modulus epoxy resin system and preparation method thereof

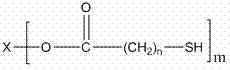

The invention belongs to the technical field of electronic packaging materials, and particularly relates to a low-modulus epoxy resin system and a preparation method thereof. The low-modulus epoxy resin system of the invention comprises the following main components: epoxy resin, a polymercaptan curing agent, a tertiary amine curing accelerator and the like, and has the characteristics of low curing temperature, adjustable gel reaction speed, low modulus of curing products, and adjustable modulus by the addition of inorganic fillers. The low-modulus epoxy resin system can be used as a substrate resin of electronic packaging materials such as bottom fillers, encapsulation agents, chip adhesives and the like for reducing packaging internal stress, and has wide application prospects in the electronic packaging field.

Owner:FUDAN UNIV

Human body canal cast filler and preparation method thereof

InactiveCN102391617AEasy to prepareSimple and fast operationDead animal preservationEducational modelsHuman bodyPolymer science

The invention provides a human body canal cast filler and a preparation method of the human body canal cast filler; and the human body canal cast filler is good in physicochemical performance, strong in acid-base resistance, good in flexibility and stronger in support force. The human body canal cast filler is prepared by the components according to the volume ratio: 100ml of cyclodextrin (CYD)-128 type epoxy resin, 20-24ml of liquid-state nitrile rubber, 35-40ml of polypropylene glycol diglycidyl ether, 15ml of 2, 4, 6-tri-(dimethylamino methyl) phenol (DMP-30), 45ml of modified polyether amine epoxy resin curing agent ZY-1784 and 40-45ml of high-performance epoxy resin toughening modifier (RF-400). The human body canal cast filler is easy in preparation as well as simple and convenient in operation, can be completed by once injection without after-teeming, and can be immediately prepared when injection is not sufficient. The invention has the characteristics of being good in fluidity, low in injection resistance, full in molding, fin and attractive, low in contractibility rate, environment-friendly and the like.

Owner:黄海龙

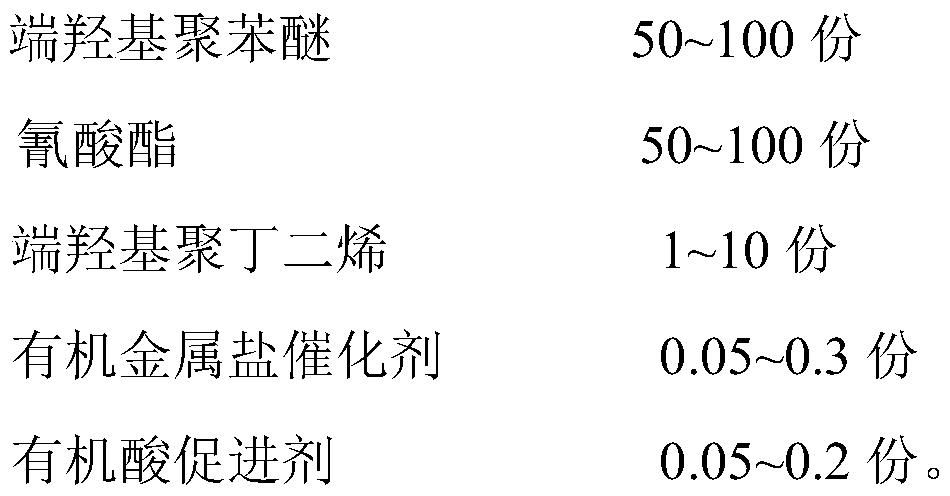

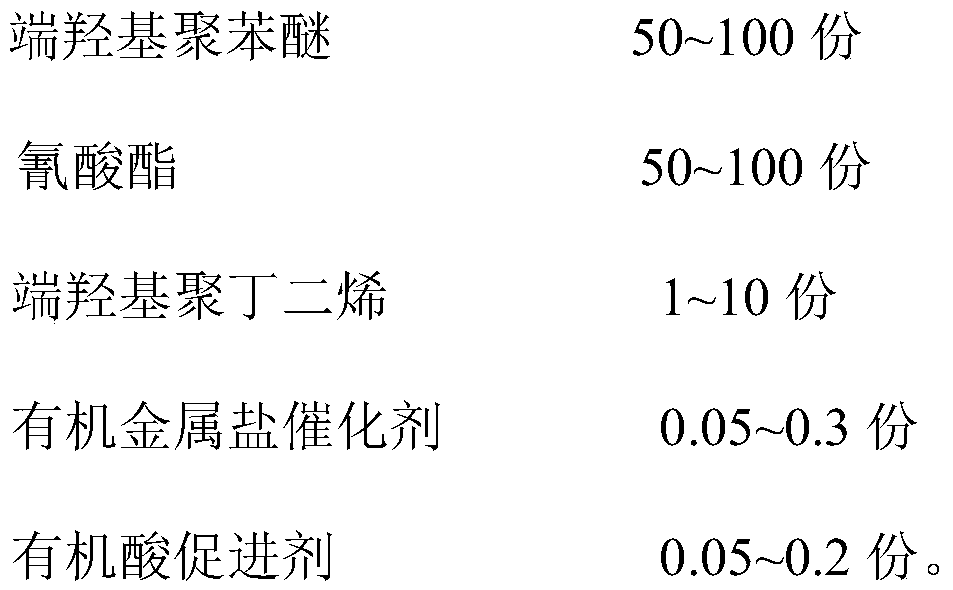

Polyphenyl ether resin composition and application thereof

ActiveCN109749396AExcellent dielectric propertiesGood storage stabilitySynthetic resin layered productsMetal layered productsOrganic acidOrganic solvent

The invention relates to a polyphenyl ether resin composition and application thereof. The composition specifically comprises hydroxyl-terminated polyphenyl ether, cyanate ester, hydroxyl-terminated polybutadiene, an organic metal salt catalyst, an organic acid promoter as well as an inorganic filler, a flame retardant and an organic solvent. Compared with the prior art, the polyphenyl ether resincomposition has the advantages that a reaction temperature for curing hydroxyl-terminated polybutadiene and cyanate ester can be greatly reduced by introducing the organic acid promoter, cyanate ester resin further can be prevented from being crystallized and separated out from a glue solution, and storage stability of the glue solution is improved; and hydroxyl-terminated polybutadiene is introduced, so that a copper-clad plate prepared from the resin composition effectively improves toughness and solvent resistance, and further improves adhesive property of a copper foil.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD +1

High temperature resistant halogen-free flame-retardant adhesive for flexible copper clad foil substrate and preparation thereof

InactiveCN101323773BIncrease responsivenessLower curing reaction temperatureAldehyde/ketone condensation polymer adhesivesEpoxy resin adhesivesEpoxyChemical reaction

The invention provides a high-temperature resistant halogen-free fire-resistant adhesive used in flexible copper-clad baseplates and a preparation method thereof. The adhesive essentially consists of aromatic amine modified bismaleimide performed polymer, phosphorus epoxy resin, chemigum, phenolic resin, inorganic filler, a curing catalyst and a solvent. The preparation method comprises the stepsthat: first of all, toluene is taken as the solvent; under the reflow temperature of the toluene, aromatic diamine, aniline and bismaleimide polymerize to obtain an aromatic amine modified bismaleimide performed polymer solution which is then added with the phosphorus epoxy resin and then added with the chemigum, the phenolic resin, the inorganic filler, the curing catalyst and the solvent after chemical reaction or physical mixture so as to form the high-temperature resistant halogen-free fire-resistant adhesive which is used for bonding the polyimide film and copper foil of the flexible copper-clad baseplate; the prepared flexible copper-clad baseplate has excellent heat resistance, flame resistance, dimensional stability and comparatively high peeling strength.

Owner:WUHAN TEXTILE UNIV

A kind of high-strength and high-permeability chemical sand control agent and its preparation method and application

InactiveCN104650840BHigh curing temperatureShort curing timeFluid removalDrilling compositionHigh humidityCompound (substance)

The invention provides a high-strength high-permeability chemical sand prevention agent, and a preparation method and an application thereof. The high-strength high-permeability chemical sand prevention agent is composed of a proppant, a cementing agent, an accelerator, a curing agent and a coupling agent according to a certain ratio. The preparation method comprises the following steps: above raw materials are mixed at a specific temperature, and are stirred, and the obtained mixture is cured for a certain period of time to obtain the high curing strength sand prevention agent. The sand prevention agent has good tolerance to acid, water, salt and oil, has high stability in high temperature and high humidity environment, and is mainly used in chemical sand prevention well extract production, serious casing deformation well sand prevention, and sand prevention of wells without mechanical sand prevention and oil water wells with low reservoir temperature in order to increase liquid production of the oil well, prolong the period of validity of well sand prevention, increase the amount of oil and reduce the production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

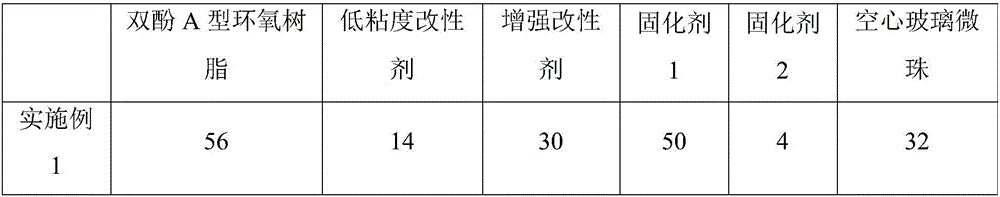

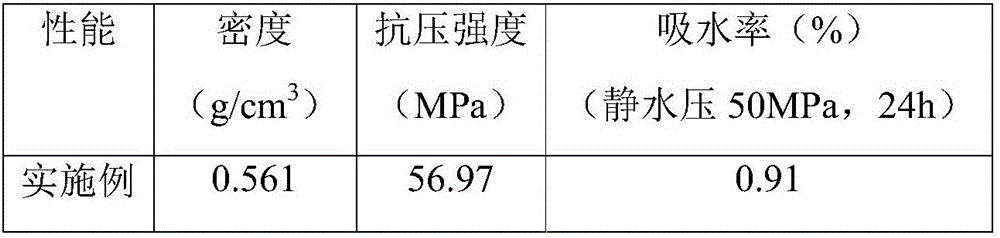

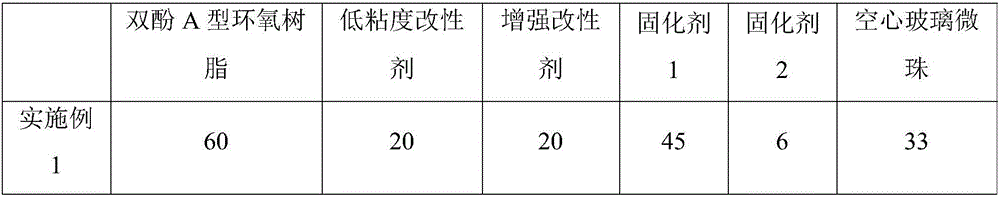

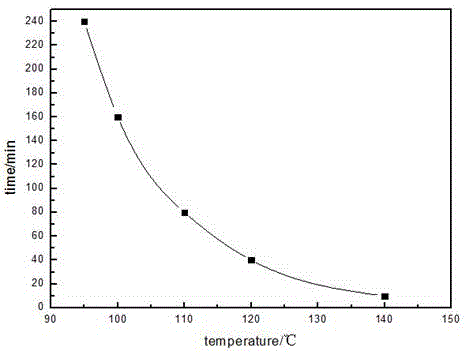

Light pressure-resistant buoyancy material for deep submergence vehicle and preparation method of buoyancy material

The invention provides a light pressure-resistant buoyancy material for a deep submergence vehicle and a preparation method of the buoyancy material. The buoyancy material is prepared from, in parts by mass, 50-60 parts of bisphenol-A epoxy resin, 20-40 parts of a reinforced modifier, 10-20 parts of a low-viscosity modifier, 40-60 parts of a first curing agent, 2-8 parts of a second curing agent and 30-40 parts of hollow glass beads, wherein the reinforced modifier is hexahydrophthalic diglycidyl ester, the low-viscosity modifier is neopentyl glycol diglycidyl ether, the first curing agent is a liquid-state organic acid anhydride curing agent, and the second curing agent is a liquid-state imidazole curing agent. The prepared light pressure-resistant buoyancy material for the deep submergence vehicle has the density of 0.50-0.57 g / cm<3>, the compression strength reaching 40-60 MPa and the isostatic hydrostatic pressure water absorption rate smaller than 1% and can meet requirements of the deep sea submergence vehicle at 3,000-5,000 m underwater.

Owner:HARBIN ENG UNIV

Elastic epoxy resin curing system and preparing method thereof

The invention relates to the field of epoxy resin production, and particularly discloses an elastic epoxy resin curing system and a preparing method thereof. The elastic epoxy resin curing system is characterized by being prepared from, by weight, 50-60 parts of E-51 epoxy resin, 15-20 parts of E-03 epoxy resin, 15-20 parts of novolac epoxy resin, 5-7 parts of imidazole latent curing agent and 2-3 parts of organic urea accelerant. The elastic epoxy resin curing system is simple in fat method, easy to operate, high in scientificity and suitable for industrial production, the curing aim of the epoxy resin system at the different temperatures can be achieved, the good technology processing performance which is moderate in viscosity and long in service life is achieved, and the mechanical performance of the cured epoxy resin is also quite good.

Owner:SHANDONG TAISHAN SPORTS EQUIP CO

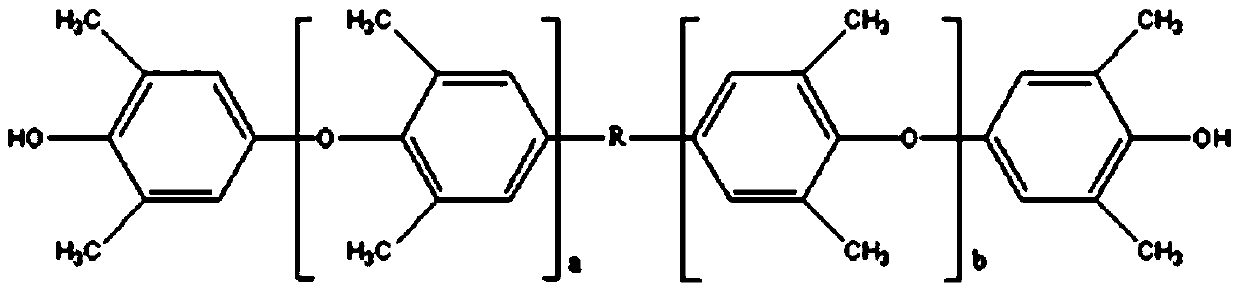

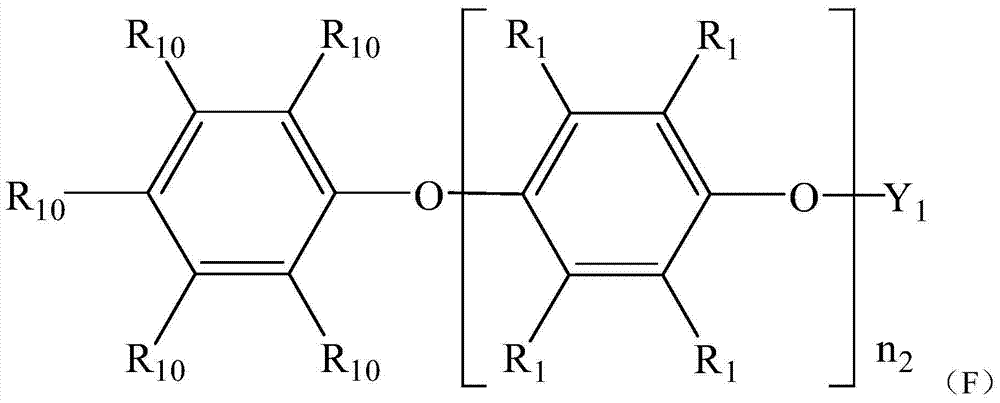

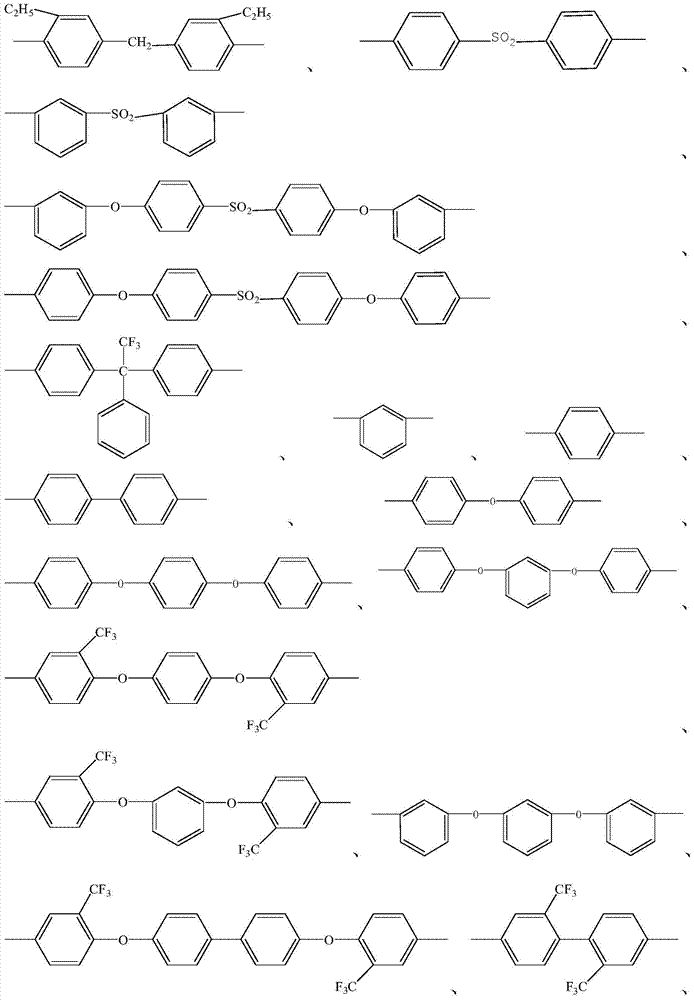

Crosslinkable polyphenyl ether resin, preparation method and use thereof

ActiveCN103102484BLower curing reaction temperatureGood compatibilityCircuit susbtrate materialsMetal layered productsVitrificationHeat resistance

The invention relates to a crosslinkable polyphenyl ether resin. The crosslinkable polyphenyl ether resin has a structure in a chemical formula (F). A preparation method of the polyphenyl ether resin is also disclosed by the invention. A high-frequency circuit substrate prepared from the crosslinkable polyphenyl ether resin disclosed by the invention is high in glass-transition temperature, good in heat resistance, low in water absorption rate, high in interlayer binding force, and excellent in dielectric property.

Owner:GUANGDONG SHENGYI SCI TECH

A kind of preparation method of aryl boron-containing thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

Ultralow-temperature curable epoxy anticorrosive coating

ActiveCN109867992AImprove volume change rateImprove climate toleranceAnti-corrosive paintsCelluloseEthylenediamine

The invention discloses an ultralow-temperature curable epoxy anticorrosive coating. The ultralow-temperature curable epoxy anticorrosive coating is composed of a component A and a component B; the component A consists of film-forming resin, an auxiliary agent, filler, pigment and deionized water, wherein the film-forming resin consists of 25-45 parts of bisphenol F epoxy resin and 20-40 parts ofsilane modified epoxy resin, the weight parts of the auxiliary agent are 2-4 parts, the filler comprises 15-25 parts of nano silicon dioxide and 2-10 parts of lignocelluloses, the pigment is 3-5 partsof titanium dioxide, and the weight parts of the deionized water are 10-20 parts; and the component B is a curing agent and is composed of 3-10 parts of phenolic amine, 2-5 parts of ethylenediamine,2-5 parts of polyamide and 5-10 parts of deionized water. Through the formula system, climate tolerance of the coating can be effectively improved, cracking is prevented, and the coating has the advantages of good corrosion resistance and relatively high adhesive force. The used curing agent is a mixed curing system taking the phenolic amine as a main body, so that the reaction speed of epoxy resin can be effectively accelerated, the curing reaction temperature is reduced, and consumption of curing energy is reduced.

Owner:CHANGSHU FANGTA COATING CHEM

Large-volume and room-temperature cured epoxy resin glue filling material

InactiveCN109777334ASolve the problem of explosive polyLow gas leak rateEpoxy resin adhesivesReaction temperatureFatty amine

The invention discloses a large-volume and room-temperature cured epoxy resin glue filling material which is divided into glue filling formulas of different quality grades and can reach a maximum of grade 150 kg. The formula of grade 150 kg is prepared by the following raw materials by weight: 100 parts by weight of epoxy resin, 12 parts by weight of dibutyl phthalate, 8 parts by weight of acetone, 4.15% of triethylene tetramine and 0.2 percent of DMP-30. The epoxy resin glue filling material disclosed by the invention adopts a manner of mechanical mixing and stirring of bisphenol A epoxy resin, a non-reactive diluent, a fatty amine curing agent and an accelerant at a normal temperature; through performing an amplification experiment step by step, the dosages of a diluent and a curing agent are optimized; on the premise of ensuring the appropriate curing time, the curing reaction temperature is reduced to below 55 DEG C, so that the curing reaction heat and the curing temperature riseare greatly reduced, and the problem of high explosive polymerization possibility of the epoxy resin in the normal-temperature curing under large volume is solved.

Owner:63653 FORCES PLA

Epoxy polyester orange-figure powder coating and preparation method thereof

InactiveCN109517497AReduce the activation energy of the crosslinking curing reactionIncrease crosslink densityEpoxy resin coatingsPolyester coatingsEpoxyPhenol

The invention discloses an epoxy polyester orange-figure powder coating and a preparation method thereof and belongs to the field of chemical engineering and solves the problem that a proper oil absorbency cannot be provided as a conventional epoxy polyester orange-figure powder coating uses single filler. The coating is prepared from the following raw materials in parts by weight: 20-22 parts ofepoxy resin, 29-30 parts of polyester resin, 6-7 parts of titanium dioxide, 9-11 parts of barium sulfate, 27-30 parts of calcium carbonate, 1-1.5 parts of an electric power increaser, 1-1.2 parts of adry powder flowing agent, 1-1.2 parts of a wetting dispersant, 0.5-0.8 part of benzoin, 0.1-0.2 part of a phenol accelerant, 0.3-0.5 parts of an antioxidant and 0.04-0.06 part of a pigment. The product design is free of any curing agent. Based on a way of matching filler with different oil absorbencies as a design concept, the raw materials are environment-friendly and non-toxic, and the coatingdoes not harm the physical health of constructors and is an environment-friendly product.

Owner:西北永新涂料有限公司

High-ortho toughened phenolic foam material and preparation method thereof

The invention discloses a high-ortho toughened phenolic foam material and a preparation method thereof. The high-ortho toughened phenolic foam material comprises, by mass, 60-70 parts of high-ortho phenolic resin, 15-25 parts of hydroxymethyl polyamide resin, 8-15 parts of a curing agent, 5-10 parts of an emulsifier, and 10-15 parts of a foaming agent. The high-ortho phenolic resin is adopted as a foamed resin main agent; hydroxymethyl polyamide resin is adopted as a chain extender and toughening component; the curing agent, the emulsifier, and the foaming agent are added; the mixture is well mixed, and is uniformly coated on non-woven fabric; cross-linking and foaming are carried out within 30min under a maintained temperature of 50-60 DEG C in a constant-temperature oven, such that the high-ortho toughened phenolic foam material is obtained. The high-ortho toughened phenolic foam material provided by the invention has the advantages of low curing temperature, high cohesive energy, low dreg rate, and good impact toughness.

Owner:NANTONG DEMING PLASTIC NEW MATERIALS

A kind of elastic curing epoxy resin system and preparation method thereof

ActiveCN106117513BLower curing reaction temperatureIncrease crosslink densityPolymer scienceFirming agent

The invention relates to the field of epoxy resin production, and particularly discloses an elastic epoxy resin curing system and a preparing method thereof. The elastic epoxy resin curing system is characterized by being prepared from, by weight, 50-60 parts of E-51 epoxy resin, 15-20 parts of E-03 epoxy resin, 15-20 parts of novolac epoxy resin, 5-7 parts of imidazole latent curing agent and 2-3 parts of organic urea accelerant. The elastic epoxy resin curing system is simple in fat method, easy to operate, high in scientificity and suitable for industrial production, the curing aim of the epoxy resin system at the different temperatures can be achieved, the good technology processing performance which is moderate in viscosity and long in service life is achieved, and the mechanical performance of the cured epoxy resin is also quite good.

Owner:SHANDONG TAISHAN SPORTS EQUIPMENT CO LTD

Poly(amino bimaleimide) resin composition, preparation and use thereof in copper clad laminate

The invention relates to a poly-amino-bismaleimide resin composite, a preparation method and the application thereof in copper clad plates. The composite essentially consists of a poly-amino-bismaleimide resin, a phosphoric epoxy resin, a cyanate resin, a novolac epoxy resin, an inorganic stuffing, a curing catalyst and a solvent. The poly-amino-bismaleimide resin in use is pre-polymerized from bismaleimide and aromatic amine under the reflow temperature with toluene as the solvent. The poly-amino-bismaleimide resin composite used in copper clad plates has good processing properties, low curing temperature (195 DEG C) and short high temperature curing time (1 to 1.5 hours). The prepared copper clad plates have excellent heat resistance, good fire retardant effect, comparatively high peeling strength, bending strength and comparatively low water absorption ratio, with the vitrification transition temperature ranging from 204 DEG C to 230 DEG C.

Owner:SHENZHEN TONGXIN CIRCUIT ELECTRONICS

Low-temperature preparation method of polyimide coated optical fiber

InactiveCN110007391ALower curing reaction temperatureGlass optical fibreOptical waveguide light guideReaction temperatureSlurry

The invention relates to the technical field of preparation of polyimide coated optical fibers, and discloses a low-temperature preparation method of a polyimide coated optical fiber, which comprisesthe following steps: taking pyromellitic dianhydride and phenylenediamine as raw materials, and synthesizing polyimide acid in an N, N-dimethyl formamide solvent; adding a maleic anhydride photocuringinitiator into the polyimide acid, and carrying out an ultraviolet photocuring reaction on polyamic acid slurry adhered to an optical fiber with a PDADMAC binder under the irradiation of ultravioletlight at the temperature of 80 DEG C under an ultraviolet lamp with the wavelength of 365 nm to generate a polyimide coating, so as to prepare the polyimide coated optical fiber. The technical problemthat the curing reaction temperature is relatively high in the preparation process of the preparation method of the polyimide coated optical fiber in the prior art is solved.

Owner:徐圣最

A high-toughness flame-retardant medium-low temperature curing epoxy resin system and its preparation method

ActiveCN110628000BImprove flame retardant performanceLower curing reaction temperaturePolymer scienceResin matrix

The invention relates to a high-toughness flame-retardant type medium and low-temperature curing epoxy resin system and a preparation method thereof. Composed of epoxy resin and acid anhydride curing agent. This hyperbranched silicon-phosphorus-nitrogen synergistic flame retardant contains a variety of flame retardant elements at the same time, and its active terminal primary amine group can directly participate in the curing and crosslinking reaction of epoxy resin, and has good compatibility with the resin matrix , while introducing Si-O-Si flexible chain segments into the epoxy resin, effectively improving the toughness of the resin system. The tertiary amine functional group in the hyperbranched polysilicon phosphate plays a role in promoting the curing of the resin, can promote the reaction between the anhydride curing agent and the epoxy resin, and has a certain catalytic effect on its curing, which can be completed at a lower temperature curing reaction. It has broad application prospects in coatings, textiles, furniture, construction and flame retardancy of thermosetting resins.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Benzo oxaxine intermediate containing aldehyde group and its preparation method

InactiveCN100548994CIncrease crosslink densityImprove thermal stabilityOrganic chemistrySolventPhenol

An aldehyde-containing benzoxazine intermediate and a preparation method thereof, which are characterized in that (1) 50-180 parts by weight of a solvent is added at a temperature of 4-20°C to 280-30 parts by weight of R-NH and 20-110 parts by weight of formaldehyde The reaction generates the N-dimethylol compound, and the pH value is adjusted between 8-10 with lye, so that the N-dimethylol compound is stable in the solution; (2) adding 20-70 weight of aldehyde-containing phenol derivative The N-dimethylol compound is condensed with the phenolic hydroxyl group and its ortho-position on the benzene ring, and dehydration and ring-closure are performed to form an aldehyde-containing benzoxazine intermediate solution. The solvent was distilled off from this solution under reduced pressure to obtain a yellow aldehyde group-containing benzoxazine intermediate solid.

Owner:SICHUAN UNIV

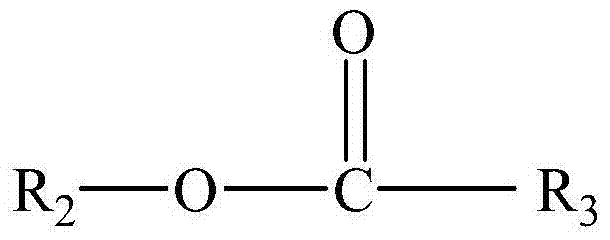

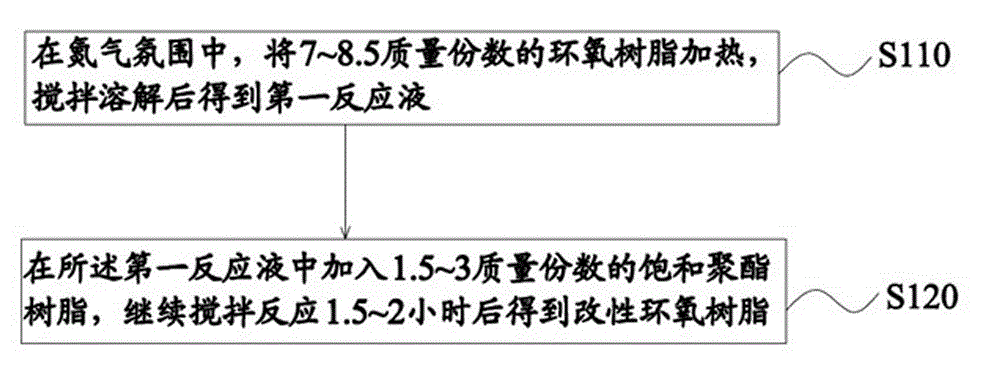

Modified epoxy resin and preparation method

InactiveCN105273202AEasy to prepareImprove mechanical propertiesPowdery paintsEpoxy resin coatingsEpoxyReaction temperature

The present invention provides a modified epoxy resin prepared from the following raw materials in parts by mass: 1.5-3 parts of a saturated polyester resin and 7-8.5 parts of an epoxy resin. The modified epoxy resin is a colorless and transparent solid, the modified epoxy resin epoxy equivalent is 900g / eq to 1050g / eq, and the softening point is 90-100 DEG C. The modified epoxy resin has good mechanical properties, and good chemical resistance. The present invention further provides a preparation method of the modified epoxy resin, the preparation method is simple, with the introduction of active groups with low temperature curing activity, the activation energy of the curing reaction is reduced, the curing reaction temperature of powder coating can be reduced, performances of the unsaturated polyester ester resin and epoxy resin can be complementary, energy is saved, and environmental pollution is reduced.

Owner:CHINA PETROLEUM & CHEM CORP

High-density fiberboard with antibacterial function and manufacturing process of high-density fiberboard

PendingCN113183275AHas antibacterial functionImprove antibacterial propertiesFlat articlesDomestic articlesMaleic anhydrideCarboxymethyl cellulose

The invention belongs to the technical field of fiberboard materials, particularly relates to a high-density fiberboard with an antibacterial function and a manufacturing process of the high-density fiberboard, and solves the problems that in the prior art, the antibacterial effect of a high-density fiberboard is poor and not lasting. The high-density fiberboard with an antibacterial function comprises the following raw materials in parts by weight: 30-50 parts of wood chips, 30-50 parts of straws, 15-25 parts of a polyethylene-maleic anhydride copolymer, 10-20 parts of poly (p-phenylene benzobisoxazole) fibers, 4-10 parts of solid paraffin, 3-5 parts of an adhesive, 3-7 parts of an antibacterial agent, 1-3 parts of carboxymethylcellulose and 2-5 parts of methyl tetrahydrophthalic anhydride. The high-density fiberboard with the antibacterial function is scientific in formula, rigorous in proportion, simple in preparation process and mild in preparation condition, and the obtained high-density fiberboard with the antibacterial function has excellent antibacterial performance and mechanical performance, almost does not release formaldehyde in the using process, is safe and environmentally-friendly and can be widely applied.

Owner:佳诺威集团股份有限公司

A kind of ultra-low temperature curing epoxy anticorrosion coating

ActiveCN109867992BImprove volume change rateImprove climate toleranceAnti-corrosive paintsCellulosePolymer science

The invention discloses an ultra-low temperature curing epoxy anticorrosion coating. The ultralow temperature curing epoxy anticorrosion coating is composed of two components A and B. The component A is composed of film-forming resin, auxiliary agent, filler, pigment and deionized Composed of water, the film-forming resin is composed of 25-45 parts of bisphenol F epoxy resin, 20-40 parts of silane-modified epoxy resin, 2-4 parts of the auxiliary agent, and the filler includes nano-silica 15~25 parts and 2~10 parts of lignocellulose, the pigment is 3~5 parts of titanium dioxide, and the deionized water is 10~20 parts; the component B is a curing agent, consisting of 3~10 parts of phenalkamine, B It consists of 2~5 parts of diamine, 2~5 parts of polyamide and 5~10 parts of deionized water. The above formulation system can effectively improve the weather resistance of the coating, prevent cracking, and has the advantages of good anti-corrosion properties and high adhesion. The curing agent used is a mixed curing system with phenalkamine as the main body, which can effectively Accelerate the reaction speed of epoxy resin, reduce the curing reaction temperature and reduce the curing energy consumption.

Owner:CHANGSHU FANGTA COATING CHEM

Human body canal cast filler and preparation method thereof

InactiveCN102391617BEasy to prepareSimple and fast operationDead animal preservationEducational modelsHuman bodyPolymer science

The invention provides a human body canal cast filler and a preparation method of the human body canal cast filler; and the human body canal cast filler is good in physicochemical performance, strong in acid-base resistance, good in flexibility and stronger in support force. The human body canal cast filler is prepared by the components according to the volume ratio: 100ml of cyclodextrin (CYD)-128 type epoxy resin, 20-24ml of liquid-state nitrile rubber, 35-40ml of polypropylene glycol diglycidyl ether, 15ml of 2, 4, 6-tri-(dimethylamino methyl) phenol (DMP-30), 45ml of modified polyether amine epoxy resin curing agent ZY-1784 and 40-45ml of high-performance epoxy resin toughening modifier (RF-400). The human body canal cast filler is easy in preparation as well as simple and convenient in operation, can be completed by once injection without after-teeming, and can be immediately prepared when injection is not sufficient. The invention has the characteristics of being good in fluidity, low in injection resistance, full in molding, fin and attractive, low in contractibility rate, environment-friendly and the like.

Owner:黄海龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com