Elastic epoxy resin curing system and preparing method thereof

A technology for curing epoxy resin and epoxy resin, which is applied in the field of epoxy resin production, can solve the problems of restricting the application of resin systems and waste of resources, and achieve the effects of moderate viscosity, simple operation and strong scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of elastic curing resin system is realized through the following steps:

[0028] (1) Mix 20-30 parts of E-51 epoxy resin, 5-7 parts of imidazole latent curing agent and 2-3 parts of organic urea accelerator in parts by weight, and grind it three times with a three-roll mill after stirring evenly. Obtain a composite curing agent;

[0029] (2) Add 20-30 parts of E-51 epoxy resin, 15-20 parts of E-03 epoxy resin and 15-20 parts of novolac epoxy resin into the reaction kettle by weight, set at 160°C-170°C , stir while heating until a transparent liquid is obtained, that is, composite epoxy resin;

[0030] (3) Mix 25-35 parts of the curing agent obtained in step (1) with 65-75 parts of the composite epoxy resin obtained in step (2), and mix evenly in a reaction kettle at 65-70°C to obtain a liquid epoxy resin system ;

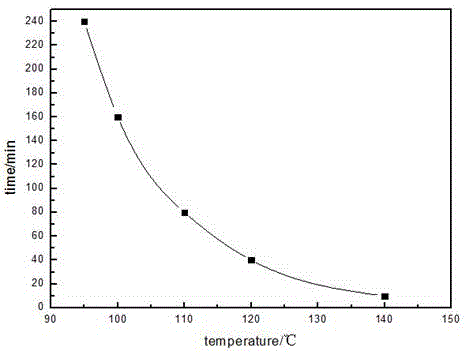

[0031] (4) Keep the epoxy resin liquid system obtained in step (3) at a temperature of 70°C-80°C for 4-5h, and then heat up (95°C-1...

Embodiment 2

[0033] The specific steps are the same as in Example 1, except that in step (1), 23-27 parts of E-51 epoxy resin, 6 parts of imidazole latent curing agent and 2-3 parts of organic urea accelerator are mixed in parts by weight.

Embodiment 3

[0035] The specific steps are the same as in Example 1, except that in step (1), 25 parts of E-51 epoxy resin, 6 parts of imidazole latent curing agent and 2.5 parts of organic urea accelerator are mixed in parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com