A kind of ultra-low temperature curing epoxy anticorrosion coating

A technology of epoxy anti-corrosion coatings and anti-corrosion coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of high curing temperature, reduced adhesion, narrow application range, etc., to reduce the curing reaction temperature, improve climate tolerance, Effect of improving volume change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

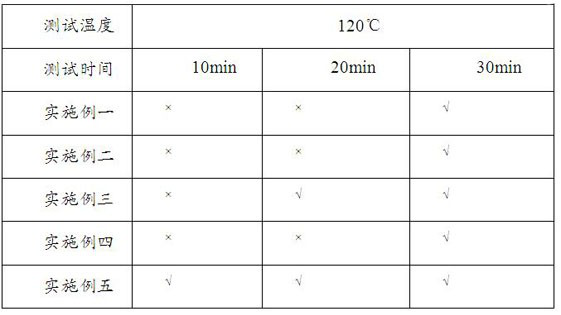

Examples

Embodiment 1

[0018] An ultra-low temperature curing epoxy anti-corrosion coating, the ultra-low temperature curing epoxy anti-corrosion coating includes: component A and component B, and the addition ratio between the raw material A and raw material B is 20:3;

[0019] The component A includes 25 parts of bisphenol F epoxy resin, 20 parts of silane-modified epoxy resin, 2 parts of auxiliary agents compounded by coupling agent, degassing agent and leveling agent, 15 parts of nano silicon dioxide part, 2 parts of lignocellulose, 3 parts of titanium dioxide, and 10 parts of deionized water, the coupling agent is a silane coupling agent in the compounding auxiliary agent, the degassing agent is benzoin, and the leveling agent is butyl acrylate, The butyl acrylate also has the effect of increasing light, and the compounding ratio is 3:9:9;

[0020] The component B is a curing agent prepared in a ratio of 10 parts of phenalkamine, 2 parts of ethylenediamine, 2 parts of polyamide, and 10 parts of...

Embodiment 2

[0028] An ultra-low temperature curing epoxy anti-corrosion coating, the ultra-low temperature curing epoxy anti-corrosion coating includes: component A and component B, and the addition ratio between the raw material A and raw material B is 20:3;

[0029] The component A includes 25 parts of bisphenol F-type epoxy resin, 40 parts of silane-modified epoxy resin, 3 parts of auxiliary agents compounded by coupling agent, degassing agent and leveling agent, 20 parts of nano-silica part, 8 parts of lignocellulose, 4 parts of titanium dioxide, and 15 parts of deionized water, the coupling agent is a silane coupling agent in the compounding auxiliary agent, the degassing agent is benzoin, and the leveling agent is butyl acrylate, The butyl acrylate also has the effect of increasing light, and the compounding ratio is 3:9:9;

[0030] The component B is a curing agent prepared in a ratio of 3 parts of phenalkamine, 5 parts of ethylenediamine, 5 parts of polyamide, and 5 parts of deion...

Embodiment 3

[0038] An ultra-low temperature curing epoxy anti-corrosion coating, the ultra-low temperature curing epoxy anti-corrosion coating includes: component A and component B, and the addition ratio between the raw material A and raw material B is 5:1;

[0039] The component A includes 45 parts of bisphenol F type epoxy resin, 40 parts of silane modified epoxy resin, 4 parts of auxiliary agents compounded by coupling agent, degassing agent and leveling agent, 25 parts of nano silicon dioxide part, 10 parts of lignocellulose, 5 parts of titanium dioxide, and 20 parts of deionized water, the coupling agent is a silane coupling agent in the compounding auxiliary agent, the degassing agent is benzoin, and the leveling agent is butyl acrylate, The butyl acrylate also has the effect of increasing light, and the compounding ratio is 1:5:5;

[0040] The component B is a curing agent prepared in the proportion of 10 parts of phenalkamine, 3 parts of ethylenediamine, 3 parts of polyamide, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com