Modified epoxy resin and preparation method

An epoxy resin and modified technology, applied in the field of powder coatings, can solve the problems of poor mechanical properties and chemical resistance, and achieve the effects of good mechanical properties, simple preparation method and good chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

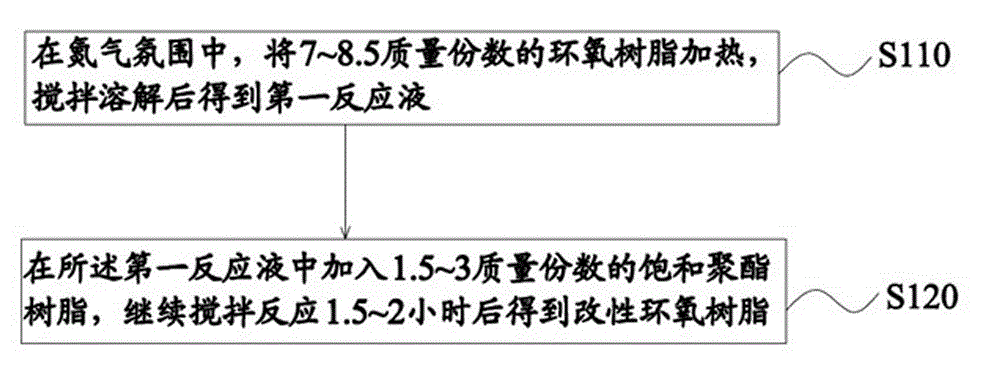

[0033] see figure 1 , a preparation method of modified epoxy resin, comprising the following steps:

[0034] S110. In a nitrogen atmosphere, heat 7-8.5 parts by mass of epoxy resin, stir and dissolve to obtain a first reaction solution.

[0035] Wherein, the epoxy resin is bisphenol A type epoxy resin.

[0036] Specifically, in the step of obtaining the first reaction solution after heating 7-8.5 parts by mass of epoxy resin with stirring and dissolving, the heating temperature is 110°C-150°C.

[0037] Preferably, in the step of obtaining the first reaction liquid after heating 7-8.5 parts by mass of epoxy resin with stirring and dissolving, the heating temperature is 120°C-130°C.

[0038] It can be understood that step S110 may also include a preheating step, that is, first heating to 85° C. to 95° C., and then introducing nitrogen gas. In a nitrogen atmosphere, heat 7 to 8.5 parts by mass of epoxy resin and stir to dissolve Afterwards, the first reaction solution is obtai...

Embodiment 1

[0050] In a nitrogen atmosphere, heat 400g of bisphenol A epoxy resin to 110°C, stir and dissolve, add 100g of saturated polyester resin, and continue stirring for 1.5 hours to obtain a modified epoxy resin.

[0051]The epoxy equivalent of the modified epoxy resin measured by the hydrochloric acid-acetone method is 951g / eq, and the softening point of the modified epoxy resin measured by the FP90 thermal system analysis method is 92.1°C.

Embodiment 2

[0053] In a nitrogen atmosphere, 375g of bisphenol A epoxy resin was heated to 120°C, stirred and dissolved, then 125g of saturated polyester resin was added, and the reaction was continued for 2 hours to obtain a modified epoxy resin.

[0054] The epoxy equivalent of the modified epoxy resin measured by the hydrochloric acid-acetone method is 989g / eq, and the softening point of the modified epoxy resin measured by the FP90 thermal system analysis method is 94.4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com