Large-volume and room-temperature cured epoxy resin glue filling material

An epoxy resin, room temperature curing technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve problems such as harmful gas leakage, achieve good sealing performance, low gas leakage rate, and good sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and comparative example

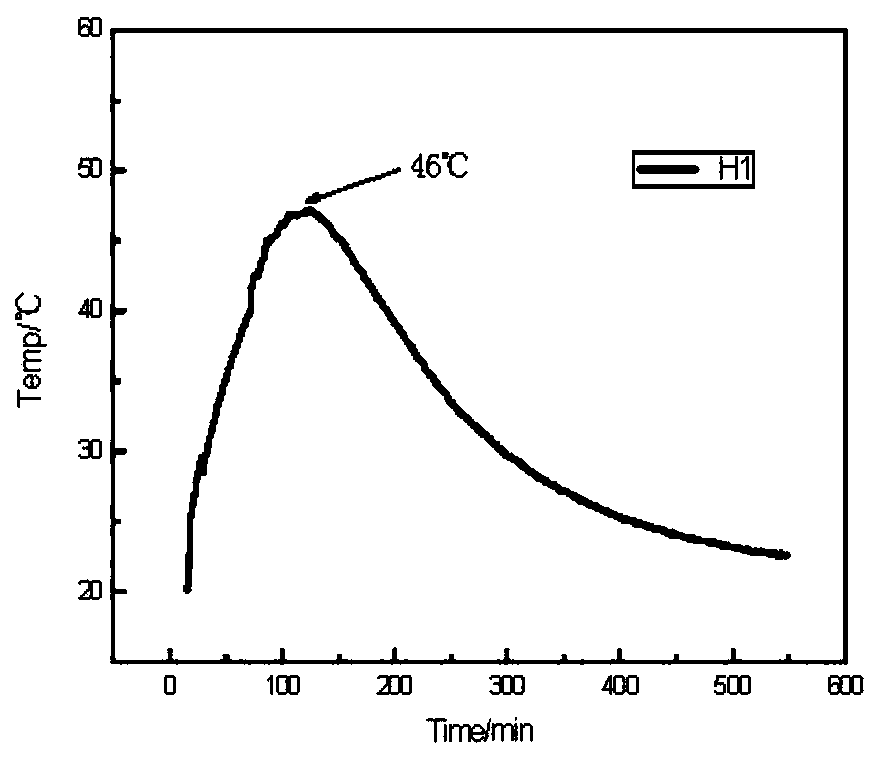

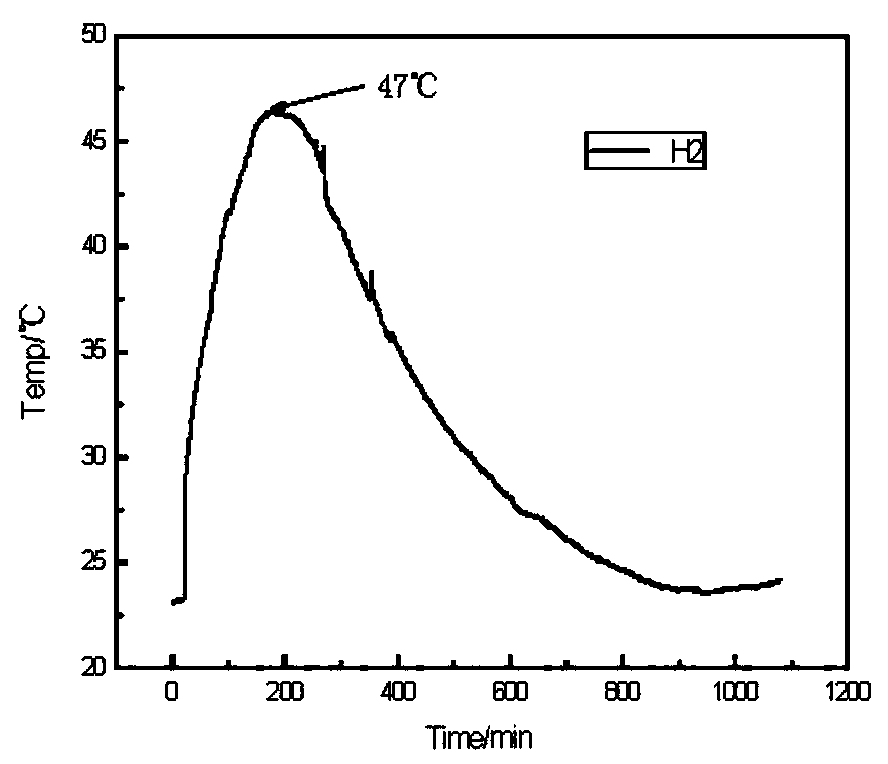

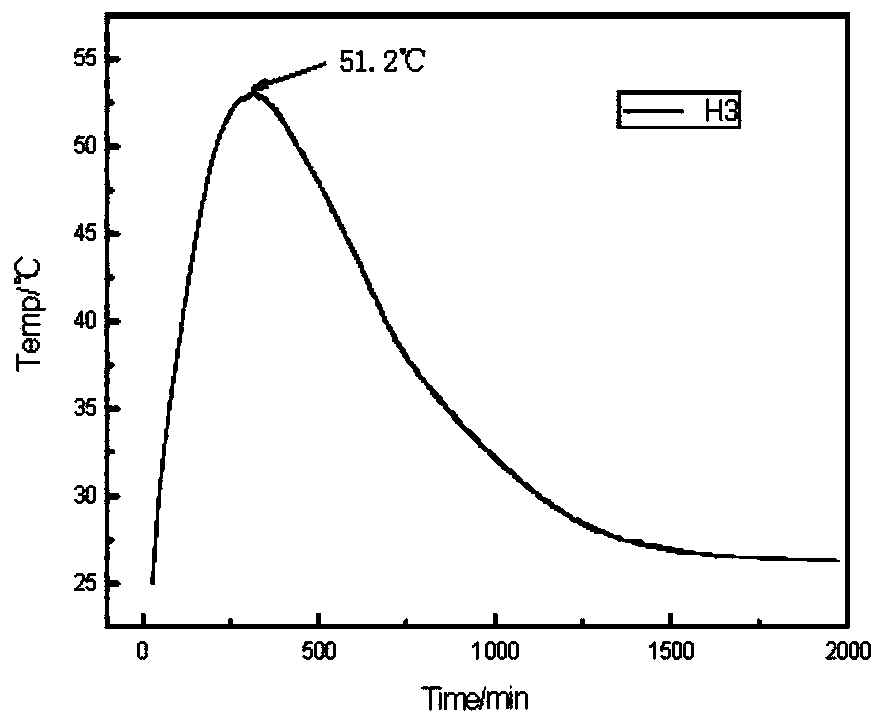

[0036] Weigh 100 parts of epoxy resin, 12 parts of dibutyl phthalate, 8 parts of acetone, 4.15 parts of triethylenetetramine and 20 parts of DMP-30. Put epoxy resin, dibutyl phthalate and acetone into the mixing tank first, stir continuously with a mixer at low speed for 3~5min, then pour triethylenetetramine and DMP-30 into the mixing tank, stir quickly for 5min, and finally pour Put it into a steel channel of 50cm×50cm×50cm. Insert a pt100 thermal resistance temperature probe in the center of the steel tank, and use a paperless recorder to continuously monitor the curing reaction temperature. The curing time is measured by indentation method. When the probe cannot penetrate the surface of the sample, it is considered cured; digital viscosity is adopted The tester measures the viscosity of the epoxy glue. Put the above glue into a 10cm×10cm×10cm mold, and test its compressive strength under standard curing conditions. The quality of epoxy resin is 0.5kg, 2.5kg, 12.5kg, 60kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com