Poly(amino bimaleimide) resin composition, preparation and use thereof in copper clad laminate

A technology of polyurethane bismaleimide resin and composition is applied in the field of high temperature resistant halogen-free flame retardant polyurethane bismaleimide composition, which can solve the problem that organic flame retardants are easily dissolved or extracted by organic solvents , moisture resistance, heat resistance and electrical properties are reduced, it is difficult to meet the problems of heat-resistant materials, etc., to achieve the effect of short curing time at high temperature, high flexural strength and peel strength, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

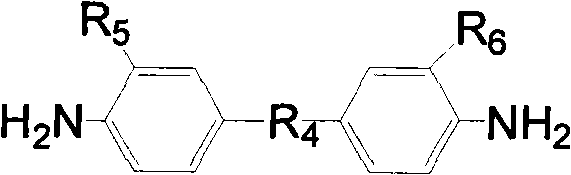

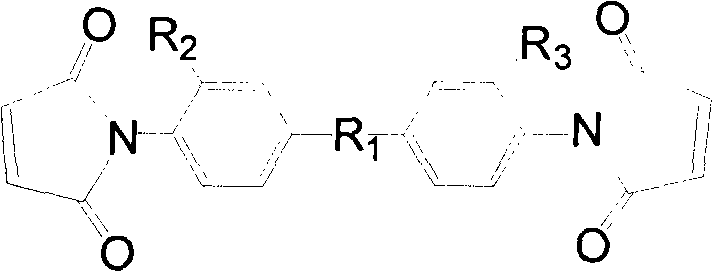

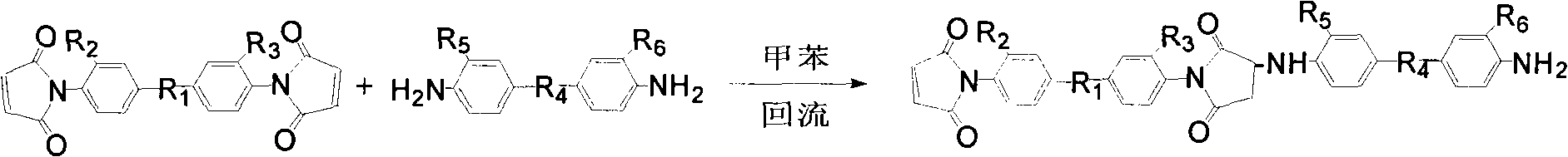

[0056] Embodiment 1 gets bismaleimide 50 grams (in the bismaleimide structural formula, R 1 for -O-, R 2 , R 3 Both are -H), 17.4 grams of aromatic diamine (in the structural formula of aromatic diamine, R 4 for -O-, R 5 , R 6 Both are -H) and 60 grams of toluene, after being heated to transparency in a 500 milliliter three-necked bottle with a stirrer, a condenser and a temperature sensor (industry can be enlarged to 50-500 liters of reactor production), Reflux temperature was reacted for 30 minutes, discharged after cooling, in batching container with 134.8 gram phosphorus-containing epoxy resin (phosphorus content is 2.55%), 67.4 gram novolac polyglycidyl ether (polymerization degree is 4), 179.7 gram bisphenol Type A cyanate, 100 grams of silicon dioxide, 79.7 grams of aluminum hydroxide, 4.5 grams of 2-methylimidazole, and finally add 290 grams of acetone and 600 grams of propylene glycol methyl ether and mix well to obtain a polyurethane with a solid content of 40%. ...

Embodiment 2

[0057] Embodiment 2 gets 2 kilograms of bismaleimide (in the bismaleimide structural formula, R 1 for -CH 2 -, R 2 , R 3 Both are -H), 559 grams of aromatic diamine (in the structural formula of aromatic diamine, R 4 for -O-, R 5 , R 6 Be all-H) and 2.5 kilograms of toluene, after being heated to transparent in 10 liters of three-neck bottles with stirrer, condenser, temperature sensor, react 45 minutes at reflux temperature, discharge after cooling, mix in batching container 3.41 kilograms of phosphorus-containing epoxy resin (phosphorus content is 3.66%), 0.43 kilograms of linear cresol formaldehyde polyglycidyl ether (polymerization degree is 3), 2.13 kilograms of novolac cyanate, 1.71 kilograms of silicon dioxide, 171 grams of 2- Ethylimidazole, finally add 3 kilograms of acetone and 4.9 kilograms of dimethylformamide and mix uniformly to obtain a polyurethane bismaleimide resin composition with a solid content of 50%, impregnate the glass fiber cloth with the composi...

Embodiment 3

[0058] Embodiment 3 gets 1 kilogram of bismaleimide (in the bismaleimide structural formula, R 1 for -CH 2 -, R 2 , R 3 Both are -C 2 h 5 ), 191 grams of aromatic diamine (in the structural formula of aromatic diamine, R 4 for -CH 2 -, R 5 , R 6 Be all-H) and 2 kilograms of toluene, after being heated to transparent in 5 liters of three-neck bottles with stirrer, condenser, temperature sensor, react at reflux temperature for 55 minutes, discharge after cooling, mix in batching container 2.14 kilograms of phosphorus-containing epoxy resin (phosphorus content is 4.52%), 0.48 kilograms of linear bisphenol A type novolac epoxy resin (polymerization degree is 2), 0.95 kilograms of bisphenol M type cyanate, 1 kilogram of silicon dioxide, 0.67 One kilogram of aluminum oxide, 24 grams of 2-phenylimidazole, finally add 3 kilograms of methyl ethyl ketone and 2.89 kilograms of dimethylacetamide and mix uniformly to obtain a polyamide bismaleimide resin composition with a solid co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com