A high-toughness flame-retardant medium-low temperature curing epoxy resin system and its preparation method

A technology for curing epoxy resin and epoxy resin, which is applied in the field of advanced polymer material science and can solve problems such as difficulty in ensuring particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

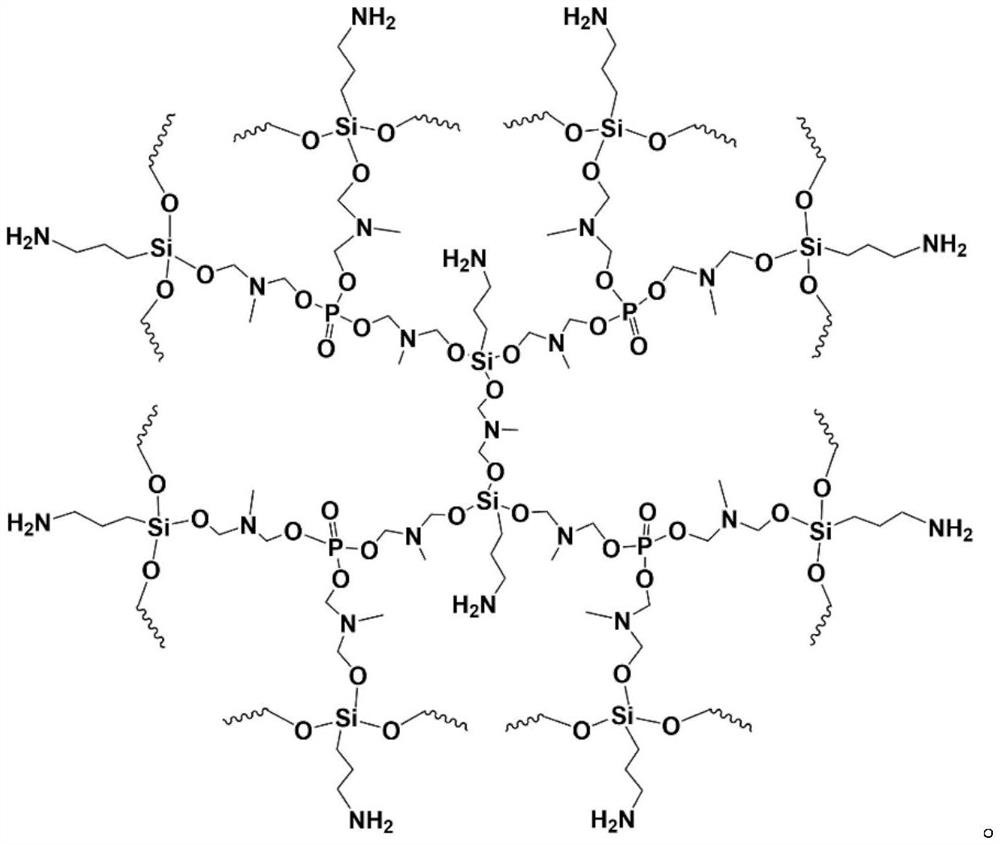

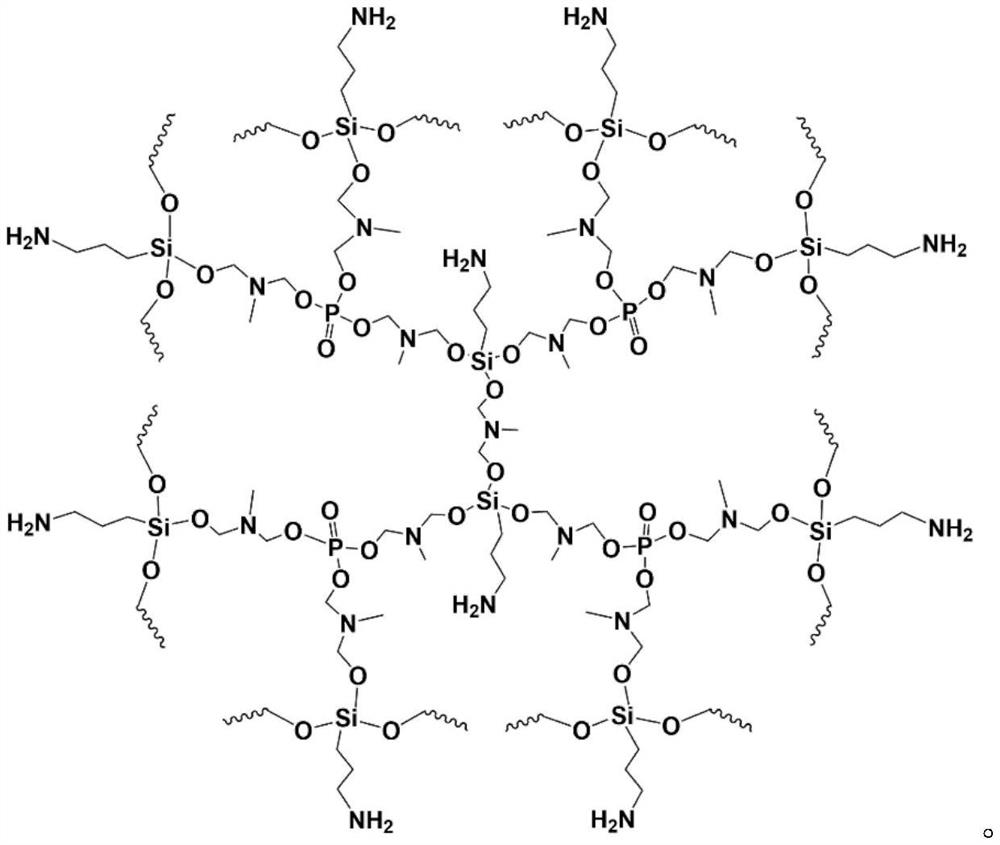

[0032] Add γ-aminopropyltriethoxysilane, triethyl phosphate and N-methyldiethanolamine into a three-necked flask at a molar ratio of 1:1:4.375, and stir in an oil bath under the protection of nitrogen to control the reaction The temperature is between 80-150 DEG C, and the reaction is carried out for 10-12 hours until no distillate is produced to obtain the product hyperbranched polysilicon phosphate.

[0033]Mix 12 parts of bisphenol A epoxy resin and 48 parts of tetraglycidylamine epoxy resin, add 3 parts of hyperbranched polysilicon phosphate, and stir at room temperature for 10-15 minutes to prepare a resin prepolymer. Then, add 60 parts of acid anhydride curing agent into the above-mentioned prepolymer, stir for 5-10 minutes, pour into the preheated mold, vacuumize to remove air bubbles in a vacuum oven at 60-80°C, and put Blast drying oven for staged heating and curing, the curing process is 90~120°C / 2~4h+140~160°C / 2~3h, cooling, after demoulding, and then post-treatment...

Embodiment 2

[0035] Add γ-aminopropyltriethoxysilane, triethyl phosphate and N-methyldiethanolamine into a three-necked flask at a molar ratio of 1:1:4.375, and stir in an oil bath under the protection of nitrogen to control the reaction The temperature is between 80-150 DEG C, and the reaction is carried out for 10-12 hours until no distillate is produced to obtain the product hyperbranched polysilicon phosphate.

[0036] Mix 12 parts of bisphenol A epoxy resin and 48 parts of tetraglycidylamine epoxy resin, add 5 parts of hyperbranched polysilicon phosphate, and stir at room temperature for 10-15 minutes to prepare a resin prepolymer. Then, add 60 parts of acid anhydride curing agent into the above-mentioned prepolymer, stir for 5-10 minutes, pour into the preheated mold, vacuumize to remove air bubbles in a vacuum oven at 60-80°C, and put Blast drying oven for staged heating and curing, the curing process is 90~120°C / 2~4h+140~160°C / 2~3h, cooling, after demoulding, and then post-treatmen...

Embodiment 3

[0038] Add γ-aminopropyltriethoxysilane, triethyl phosphate and N-methyldiethanolamine into a three-necked flask at a molar ratio of 1:1:4.375, and stir in an oil bath under the protection of nitrogen to control the reaction The temperature is between 80-150 DEG C, and the reaction is carried out for 10-12 hours until no distillate is produced to obtain the product hyperbranched polysilicon phosphate.

[0039] Mix 20 parts of bisphenol A epoxy resin and 40 parts of tetraglycidylamine epoxy resin, add 3 parts of hyperbranched polysilicon phosphate, and stir at room temperature for 10-15 minutes to prepare a resin prepolymer. Then, add 60 parts of acid anhydride curing agent into the above-mentioned prepolymer, stir for 5-10 minutes, pour into the preheated mold, vacuumize to remove air bubbles in a vacuum oven at 60-80°C, and put Blast drying oven for staged heating and curing, the curing process is 90~120°C / 2~4h+140~160°C / 2~3h, cooling, after demoulding, and then post-treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com