Low-modulus epoxy resin system and preparation method thereof

An epoxy resin system and epoxy resin technology, applied in the field of microelectronic packaging materials, can solve the problems of difficult control, low mechanical strength, and underfills that cannot completely fill chips and substrates, and achieve broad application prospects and low curing temperature. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

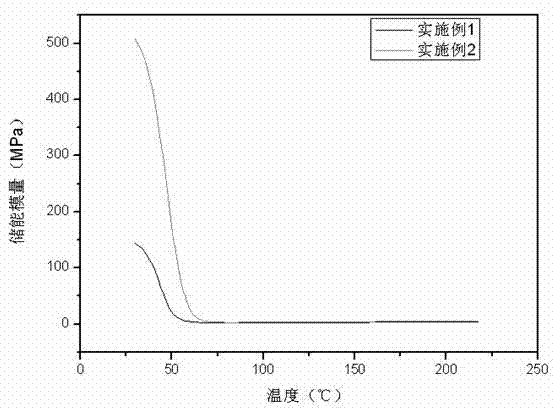

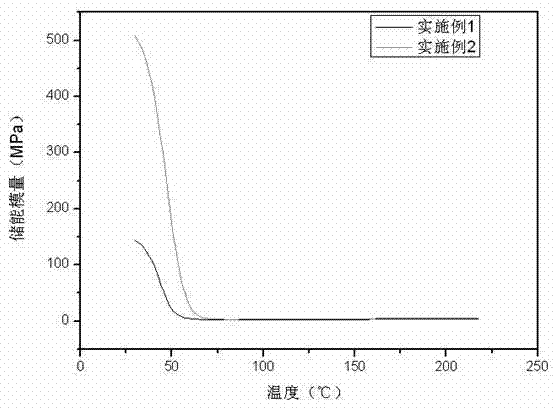

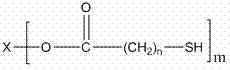

[0020] Example 1 Aliphatic polythiol curing system: Bisphenol A diglycidyl ether (10 g, Dow Chemical Company DER 332) and aliphatic polythiol (10 g, Corning 3800) were mixed evenly, and placed in a vacuum After degassing in the oven, add the curing accelerator DMP-30 (0.5 g), mix well, put it into the mold, and heat it in an oven at 80°C for 30 minutes to make it fully cured. The glass transition temperature of the cured product is 18°C, the storage modulus is 150 MPa (25°C), and the linear expansion coefficient is 209×10 -6 / °C (50-200°C), the volume resistivity is 2.0×10 10 Ω·m.

Embodiment 2

[0021] Example 2 Aromatic polythiol curing system: Bisphenol A diglycidyl ether (10 g, Dow Chemical Company DER 332) and aromatic polythiol (7.1 g, Sakai Chemical Co. 804) were mixed evenly, and placed in a vacuum After degassing in the oven, add the curing accelerator DMP-30 (0.5 g), mix well, put it into the mold, and heat it in an oven at 80°C for 30 minutes to make it fully cured. The glass transition temperature of the cured product is 47°C, the storage modulus is 508 MPa (25°C), and the coefficient of linear expansion is 185×10 -6 / °C (40-200°C), the volume resistivity is 2.1×10 10 Ω·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com