Patents

Literature

96results about How to "Gel fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

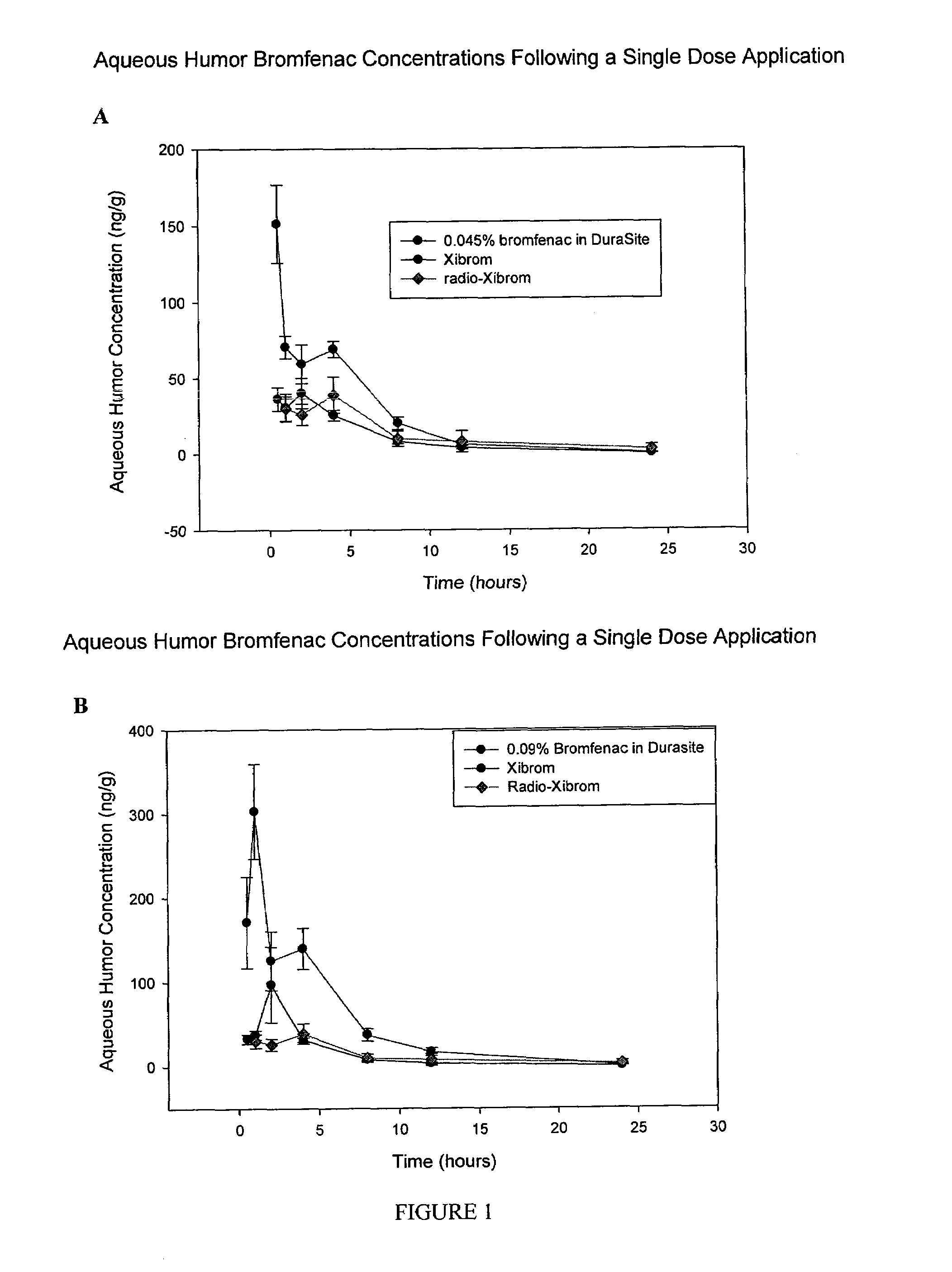

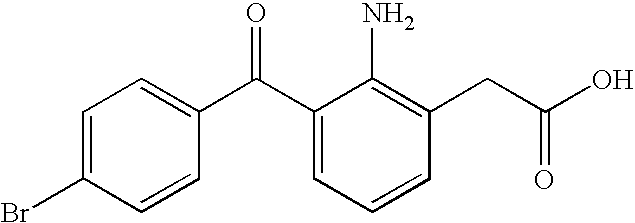

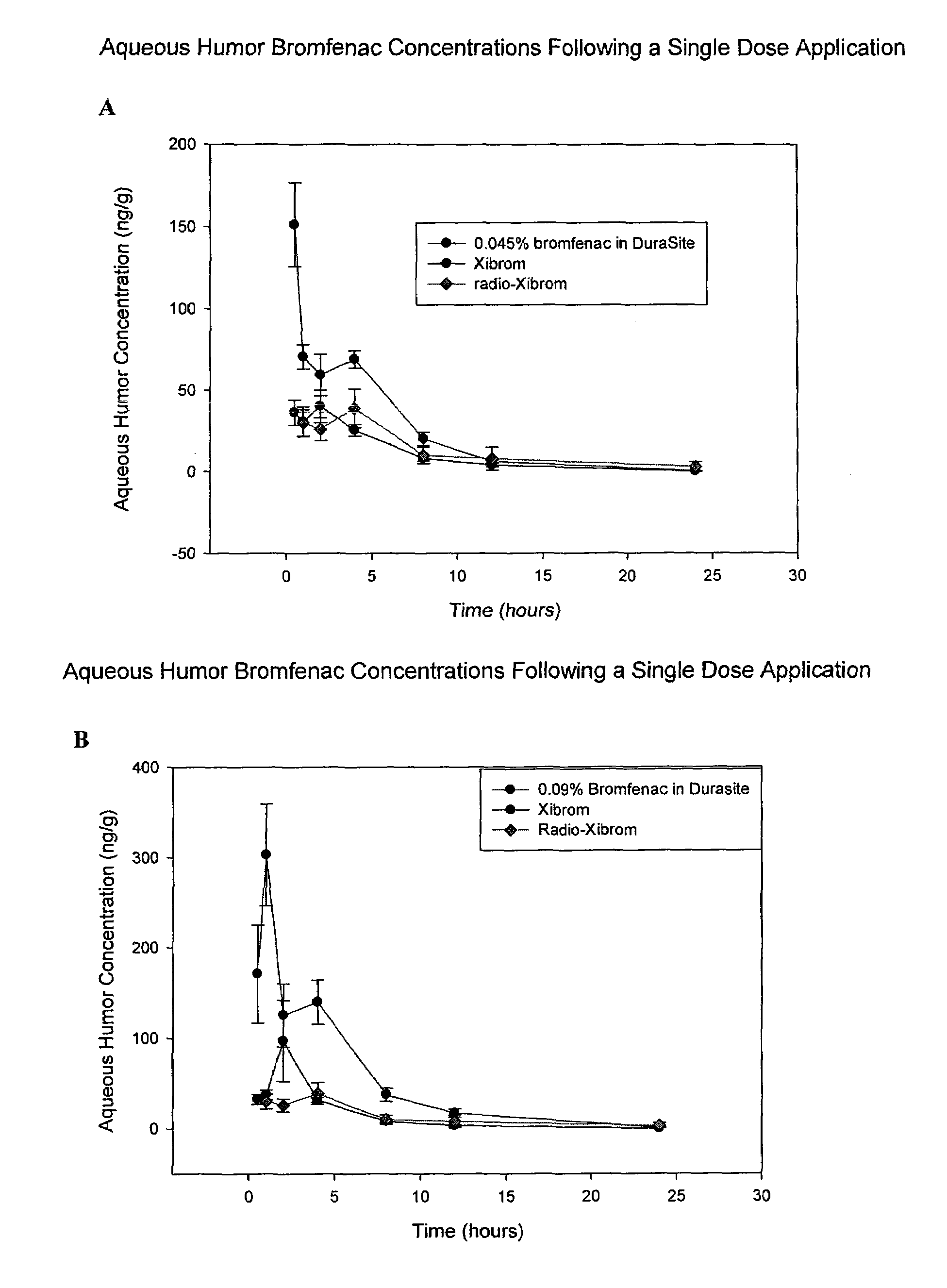

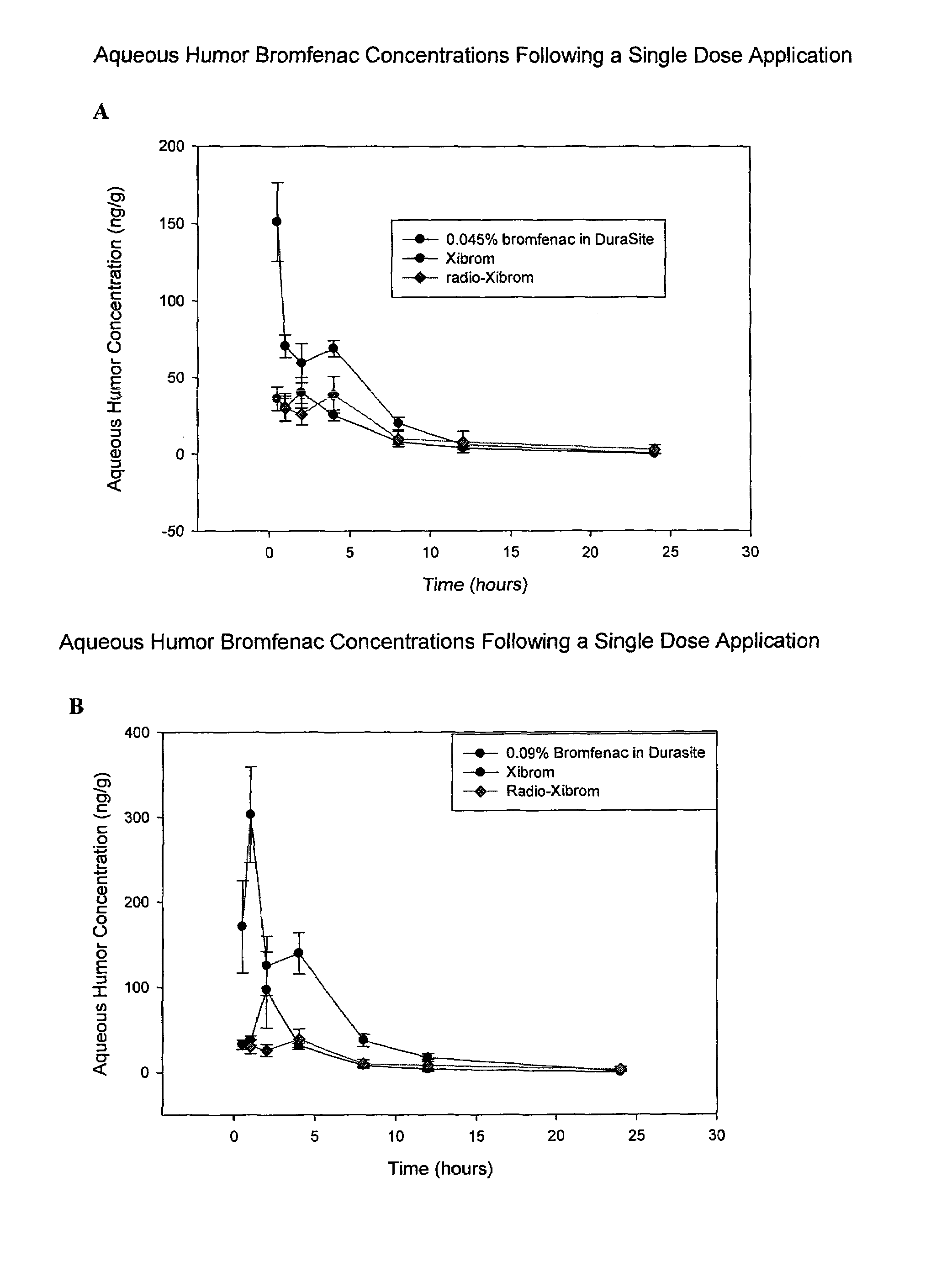

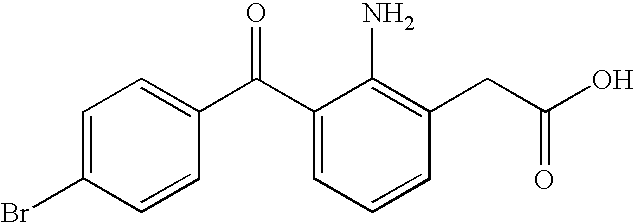

Non-steroidal Anti-inflammatory ophthalmic compositions

The disclosure provides compositions and systems for topical ophthalmic application, which include an aqueous mixture of bromfenac and flowable mucoadhesive polymer, for treating inflammation and inflammatory conditions of the eye.

Owner:SUN PHARMA INDS

Low-cost method for preparing aerogel by means of atmospheric pressure drying

Owner:CHENDU NEW KELI CHEM SCI CO LTD

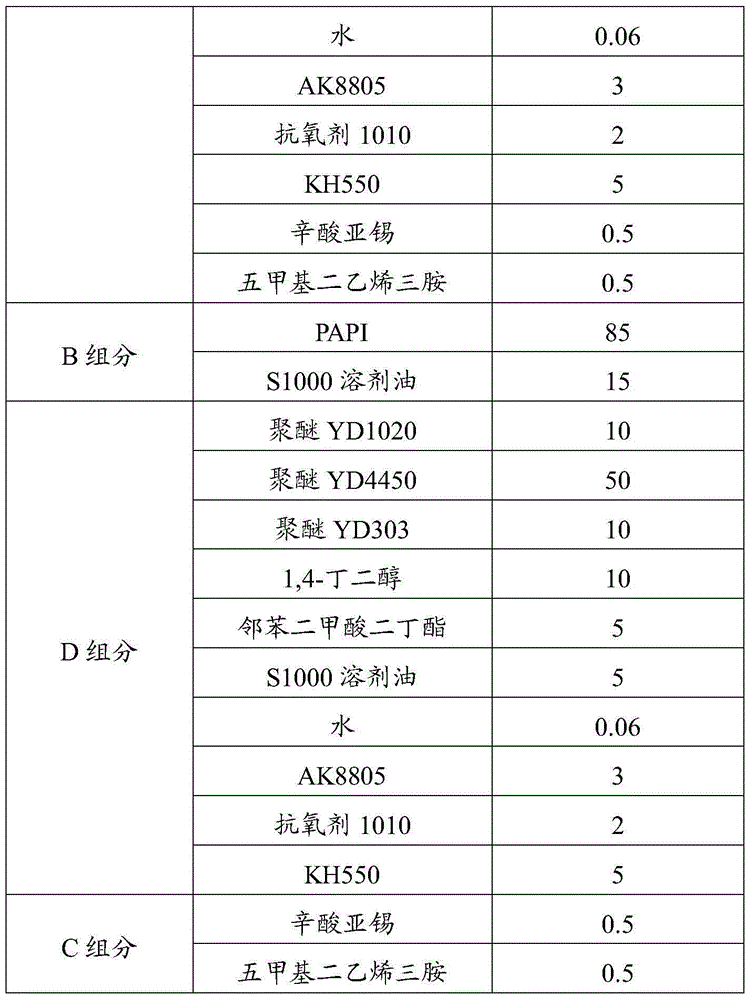

Injecting paste material for administering soil rising of plate-type ballastless track and preparation method and application method thereof

ActiveCN104448207AGel fastFast intensity rise rateBallastwayRailway track constructionAlcoholPlasticizer

The invention provides an injecting paste material for a plate-type ballastless track. The injecting paste material includes a component A and a component B, wherein the component A includes the following materials in parts by weight: 40-80 parts of polyhydric alcohols, 5-10 parts of cross-linking agents, 1-50 parts of plasticizers, 4-20 parts of chain extenders, 1-50 parts of diluents, 0.1-10 parts of curing accelerators, 1-5 parts of antioxygen, 1-5 parts of coupling agents, 0.04-0.2 part of water and 0.5-5 parts of foam stabilizer; the component B includes the following materials in parts by weight: 50-150 parts of isocyanate or isocyanate prepolymers and 1-50 parts of diluents; when temperature changes, a component C or D can be added into the mixture of the components A and B to meet the construction requirements at different temperatures, the solidification strength of the injecting paste material is not influenced by humid environment, and the mechanical properties of the material are excellent.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

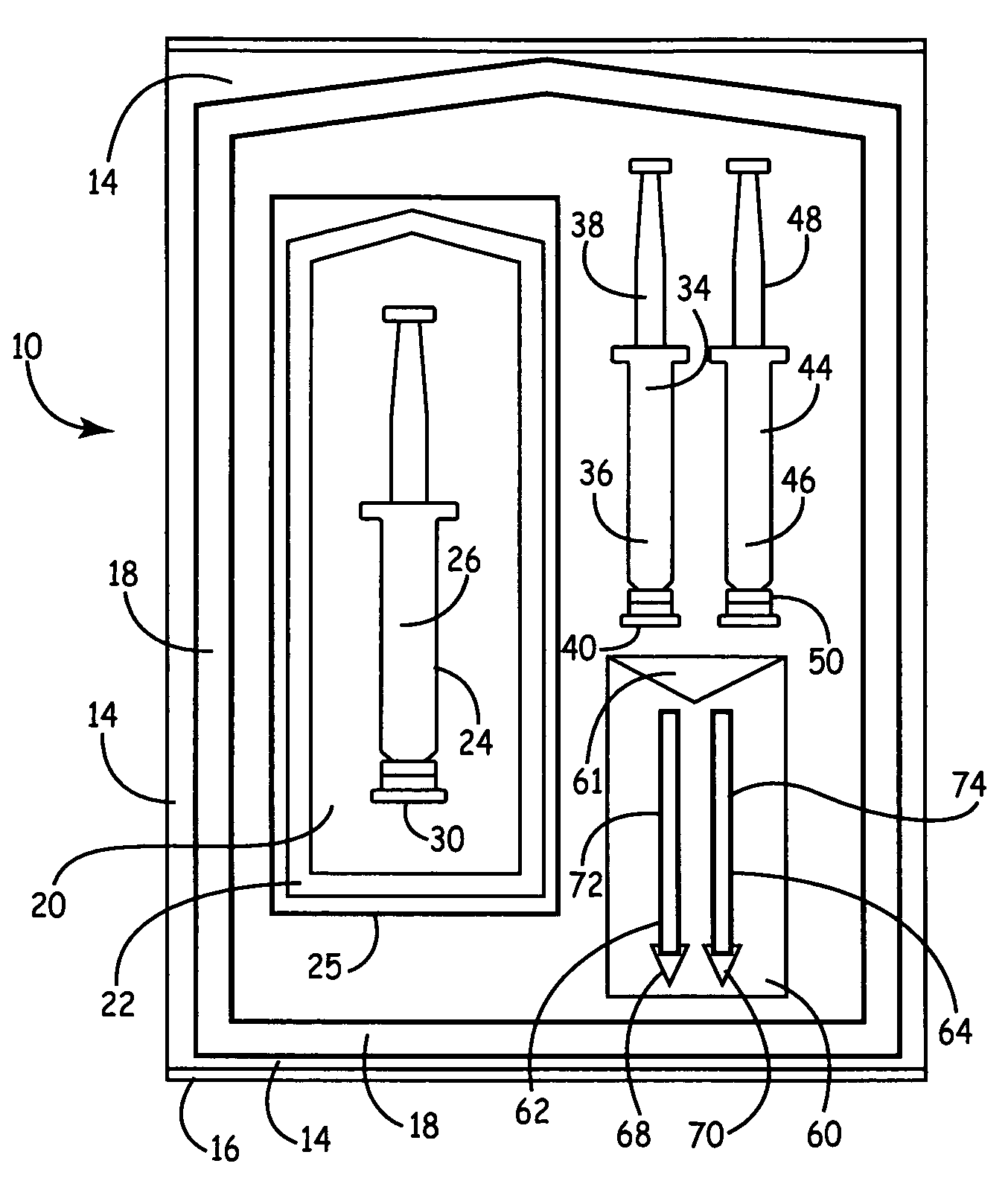

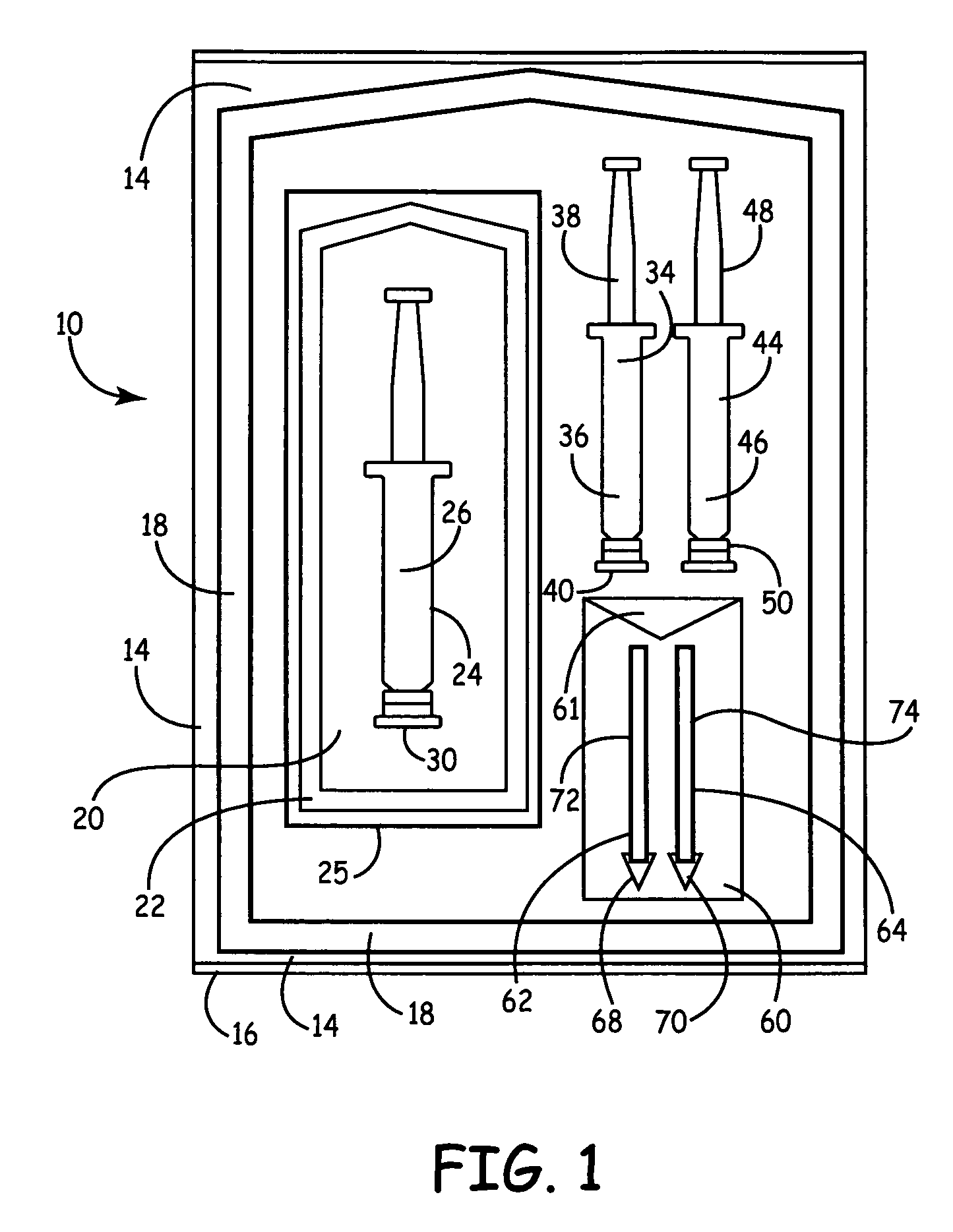

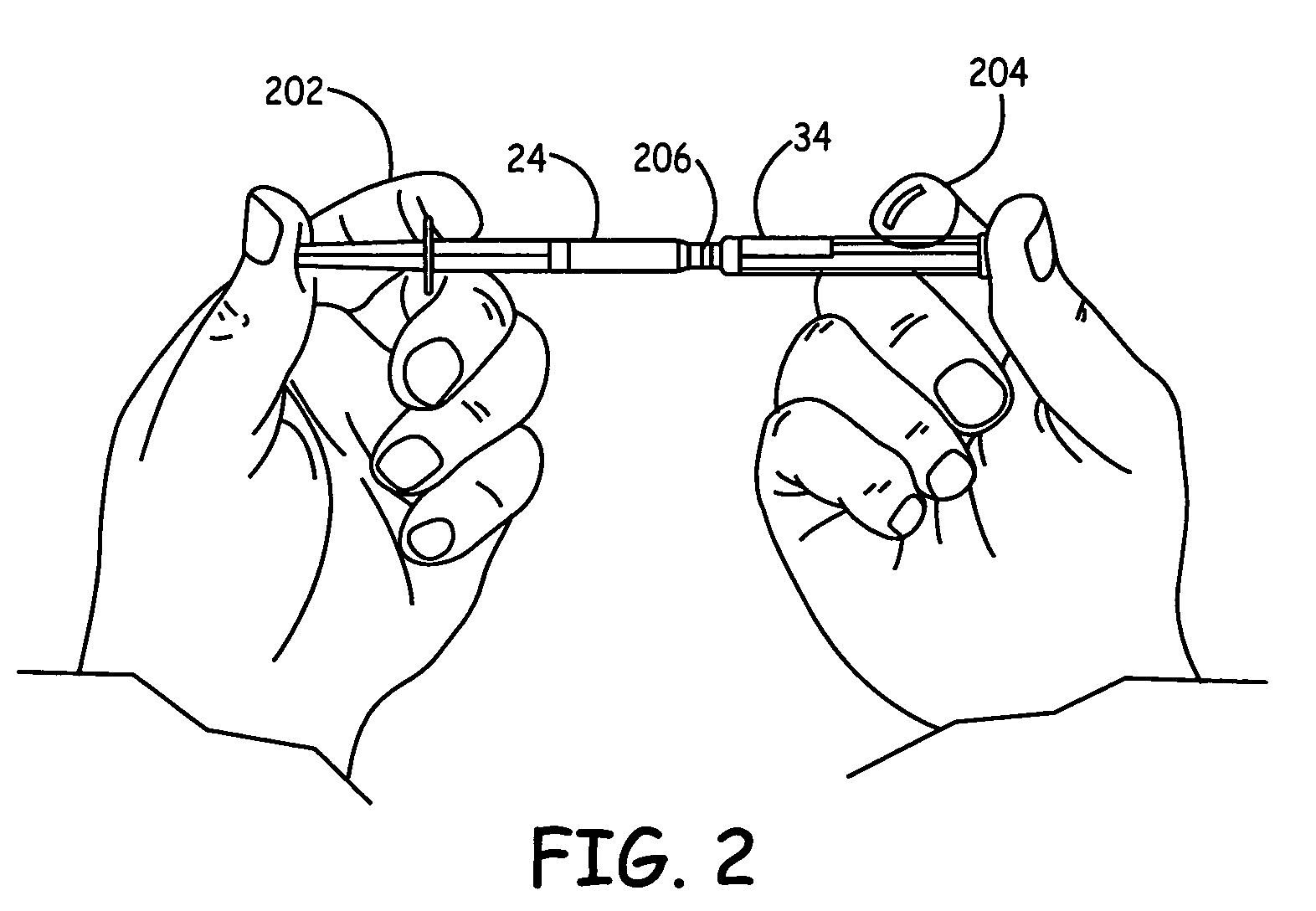

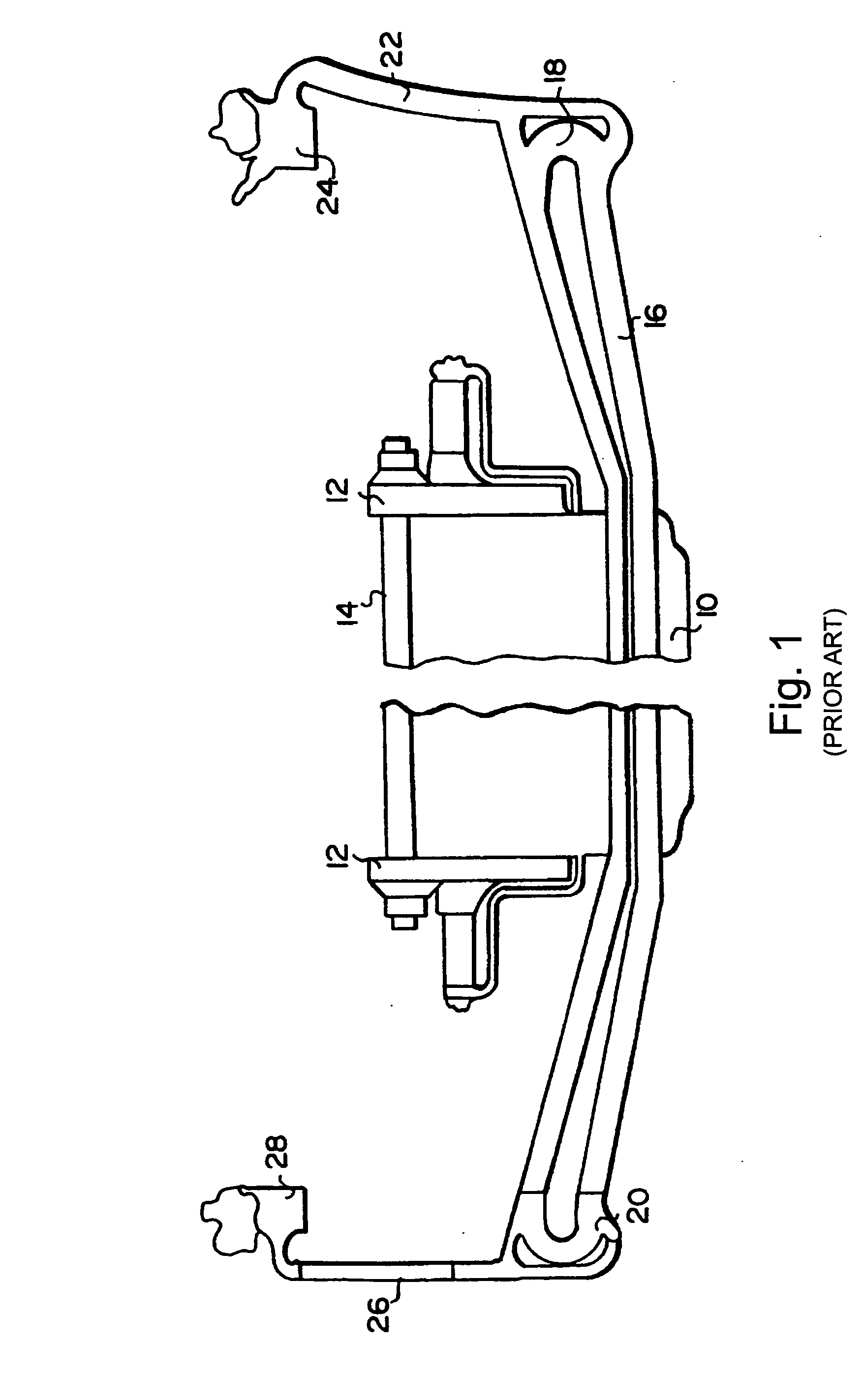

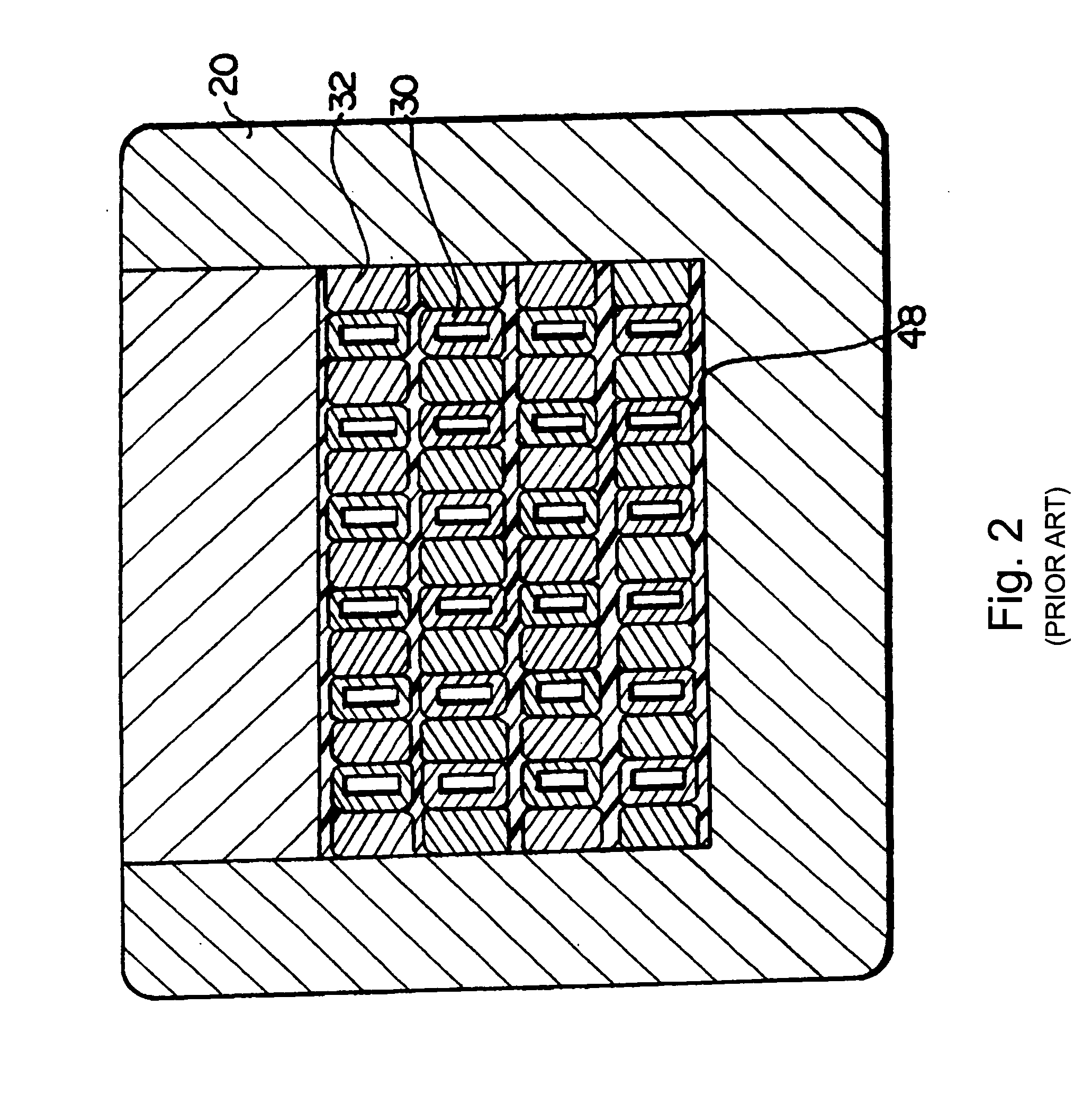

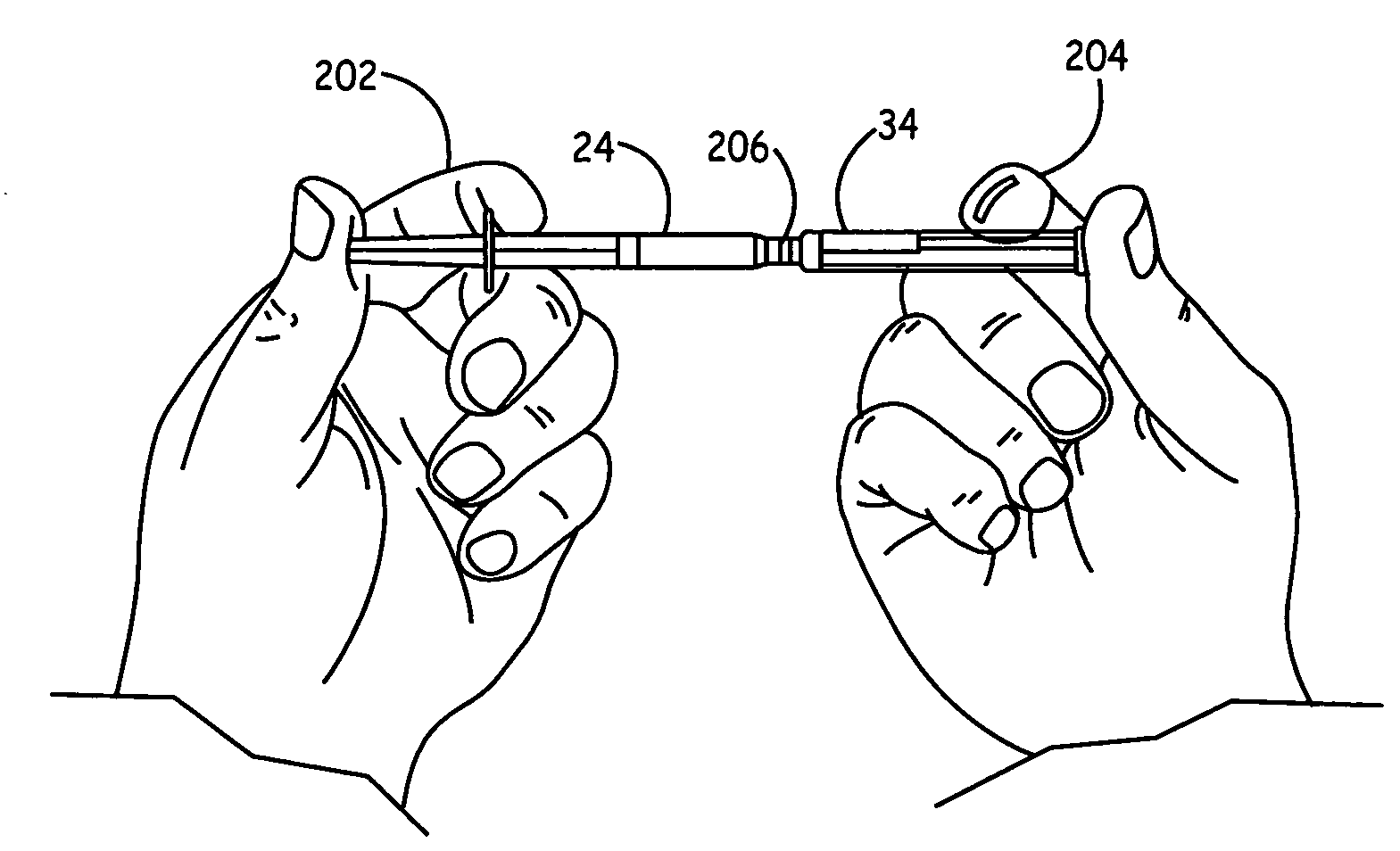

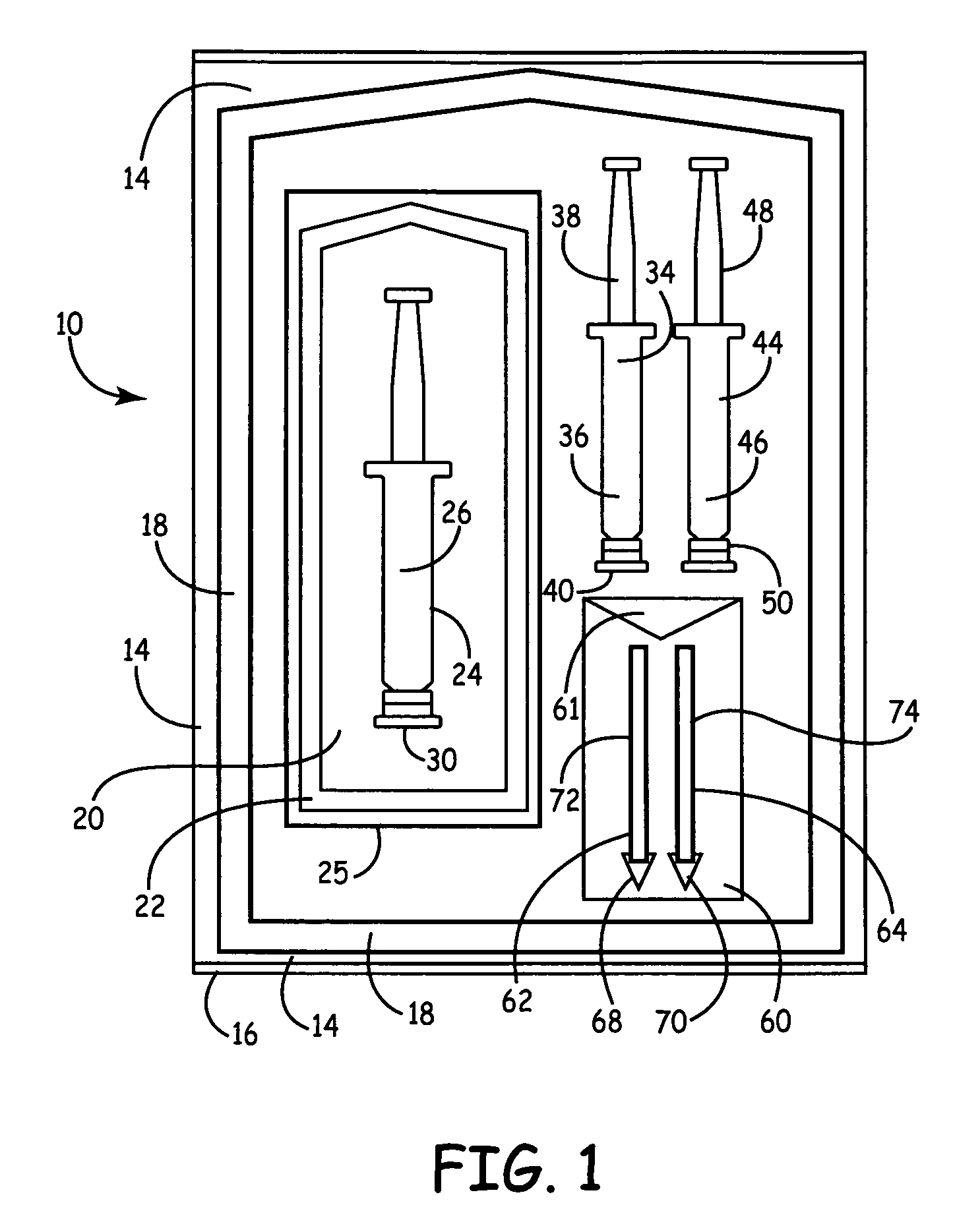

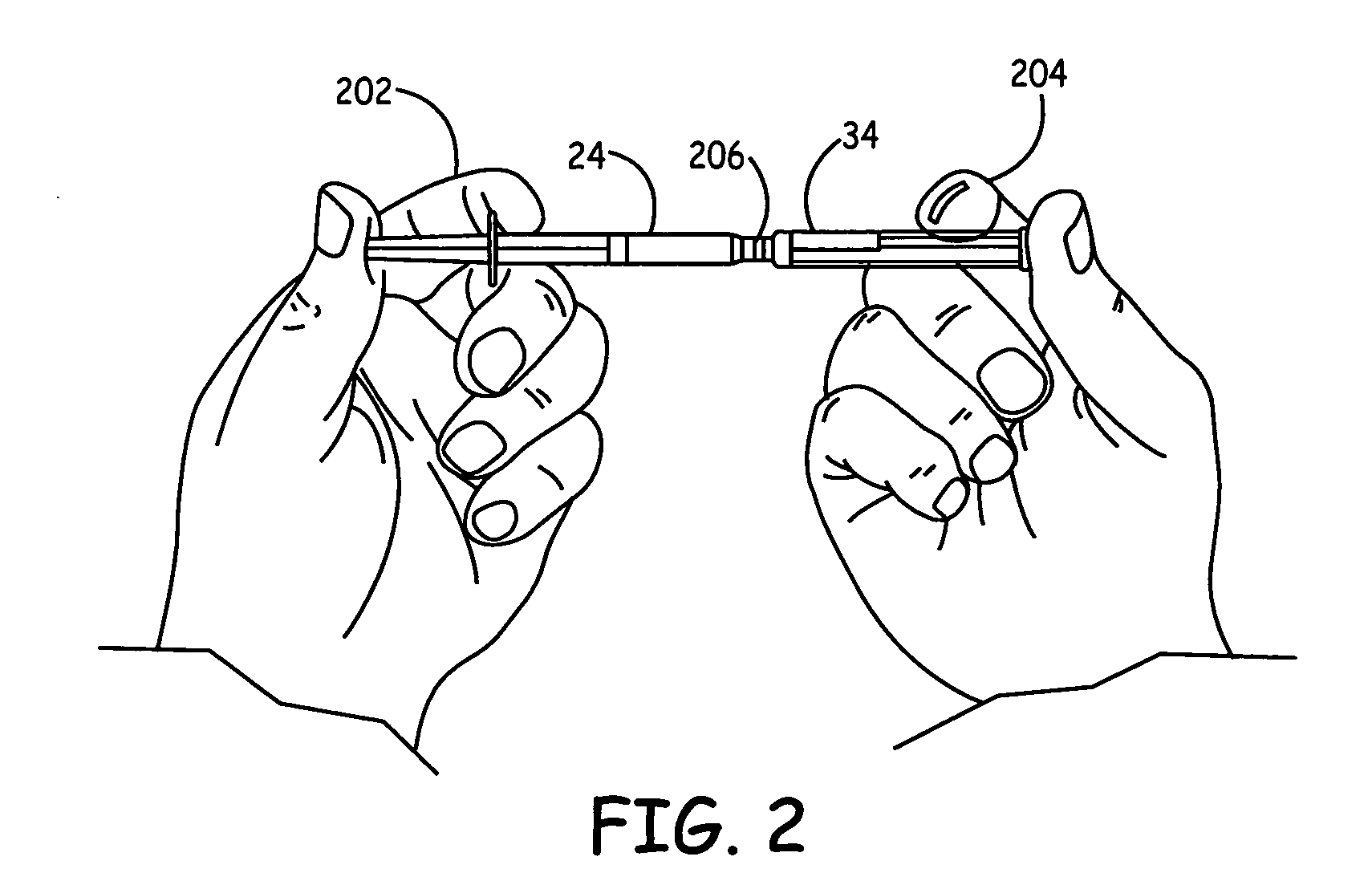

Surgical delivery system for medical sealant

Described herein are systems for packaging dual or multiple-component adhesive systems that provide enhanced convenience and efficacy. In one aspect, the components of such a system may be divided into containers that allow for foolproof mixing schemes to avoid mixing the wrong components while also providing a sterile surface for mixing materials, with the sterile surface having optimal physical properties for mixing the materials, especially in small amounts. Certain embodiments include a surgical delivery system for a medical sealant including a packaging system with a detachable a sterile surface for mixing the sealant as needed for application.

Owner:INCEPT LLC

Preparation method of high-flux porous membrane

InactiveCN1504257AGood water permeabilityEasy to separateSemi-permeable membranesChemical reactionOrganic solvent

A process for preparing high-pass porous membrane mainly comprising, dissolving polymer (polyethersulfone orpolyacrylonitile) and inorganic additive into suitable organic solvent, mixing the mixture into casting film liquid uniformly after complete dissolution, slobbering the casting film liquid onto the nonwoven fabric supporting body, immersing the nonwoven fabrics with casting film liquid into suitable gel agent, the additive reacting with the gel medium, the membrane liquid on the nonwoven fabrics simultaneously forming porous membrane in the gel bath, and submerging the porous membrane in acid solution. The invention can be applied for obtaining membrane having increased water flux.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

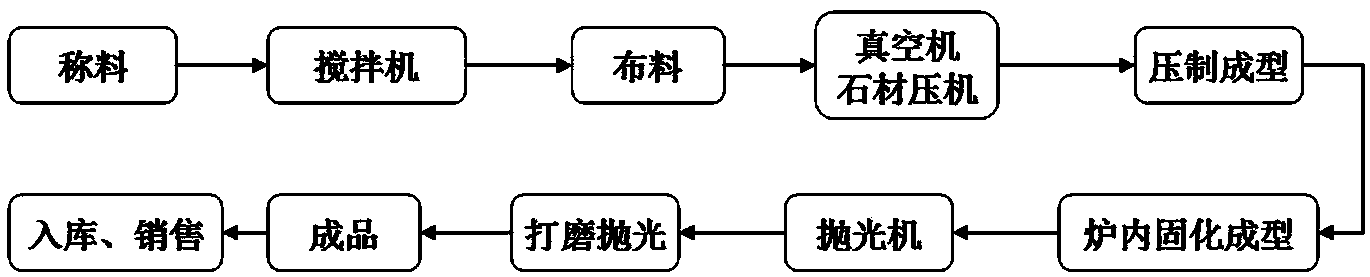

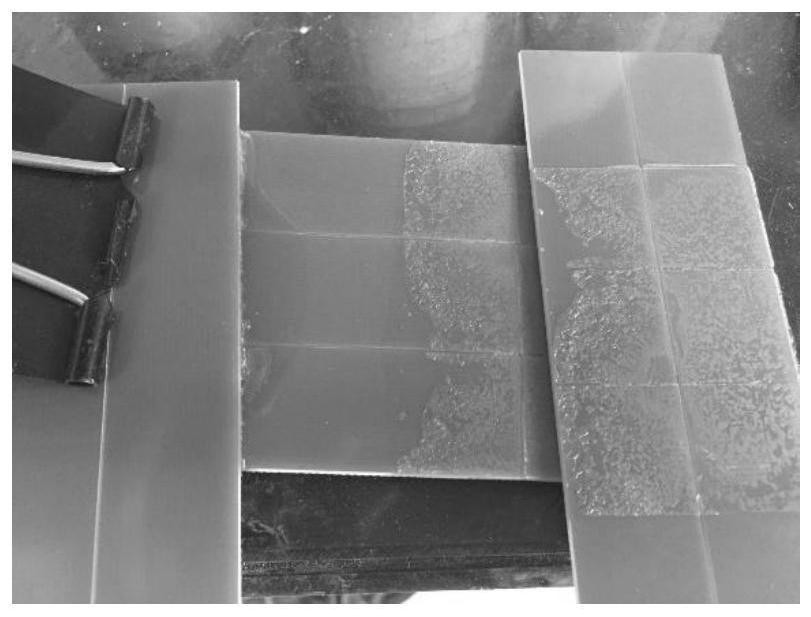

Artificial stone and preparation method thereof

The invention discloses an artificial stone and a preparation method thereof. The artificial stone comprises the following raw materials in percentage by weight: 30-60% of quartz, 30-60% of crushed glass, 5-10% of alloy resin, 0.01-3% of alloy powder, 0.01-0.5% of pigment, 0.01-0.5% of a coupling agent and 0.01-0.5% of a curing agent. The artificial stone has the characteristics of art attractiveness, health and environment-friendliness. Due to addition of the alloy powder and the alloy resin in the formula, the artificial stone has an outstanding antibacterial function, is relatively high in anti-permeability and moisture resistance, long in service life and relatively good in glossiness, fullness and moisturizing property, the waste glass and the waste gel can be utilized again, thus being energy-saving and environmentally friendly; flowers can be also made according to demands, and thus artificial stone with patterns can be manufactured.

Owner:GUOJIA NEW MATERIAL HUBEI ENVIRONMENTAL PROT GEL IND PARK CO LTD

Room-temperature rapid-curing polyurea adhesive and preparation method thereof

InactiveCN103694939AGel fastRapid viscosity increasePolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention relates to a room-temperature rapid-curing polyurea adhesive and a preparation method thereof. The polyurea adhesive comprises A and R components, wherein the A component comprises polyether polyol and polyisocyanate; the R component comprises amino polyether and an amine chain extender. The polyurea adhesive is applied to the surface of bonded buoyancy material modules, has the effects of rapid curing and rapid tackifying, is higher in primary adhesive force and can reach the machining strength in the short time; the modules do not need to be clamped and fixed in splicing, bonding and curing processes and can be bonded on machining site, and the operation is convenient and reliable.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

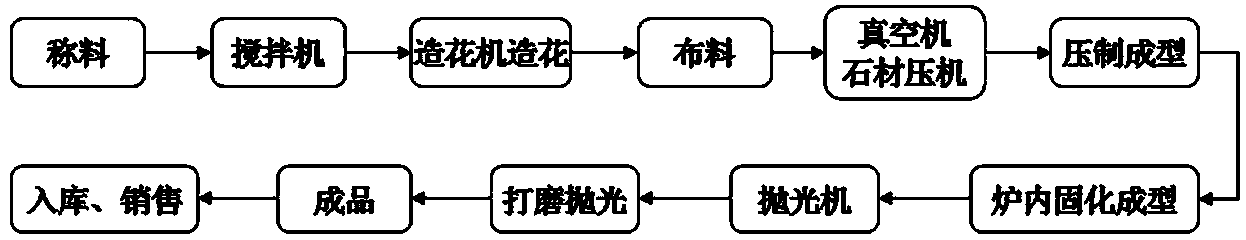

3D printing material for gelatinized confections and preparation method of 3D printing material

InactiveCN107668306AFlexible textureThe group ratio is reasonableConfectioneryFood preservationGellan gumRoom temperature

The invention relates to the technical field of food, in particular to a 3D printing material for gelatinized confections and a preparation method of the 3D printing material. Starch and low-acyl gellan gum in the 3D printing material are taken as gel, remelting is facilitated, rapid gelling at room temperature can be realized, smooth discharge can be guaranteed during 3D printing, stability of the printing material can be improved with application of plant extract, so that the printed confections can be stored for a long time, and sugar crystals are avoided. Experiments prove that the 3D printing material can be printed successfully, sensory evaluation of the obtained products is good, and sugar crystals or sugar dissolution does not occur when the products are placed at room temperaturefor 60 d.

Owner:INFINITUS (CHINA) CO LTD

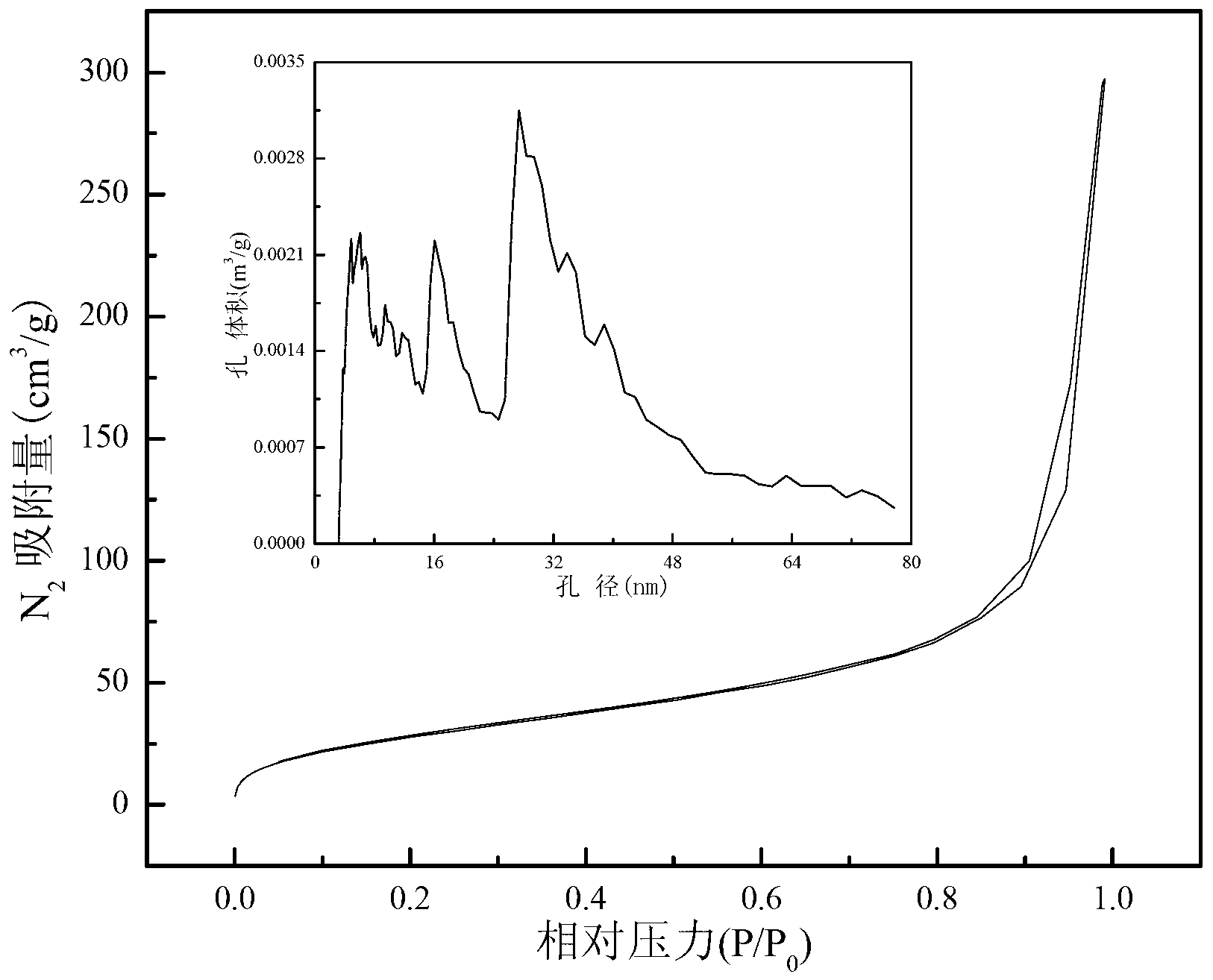

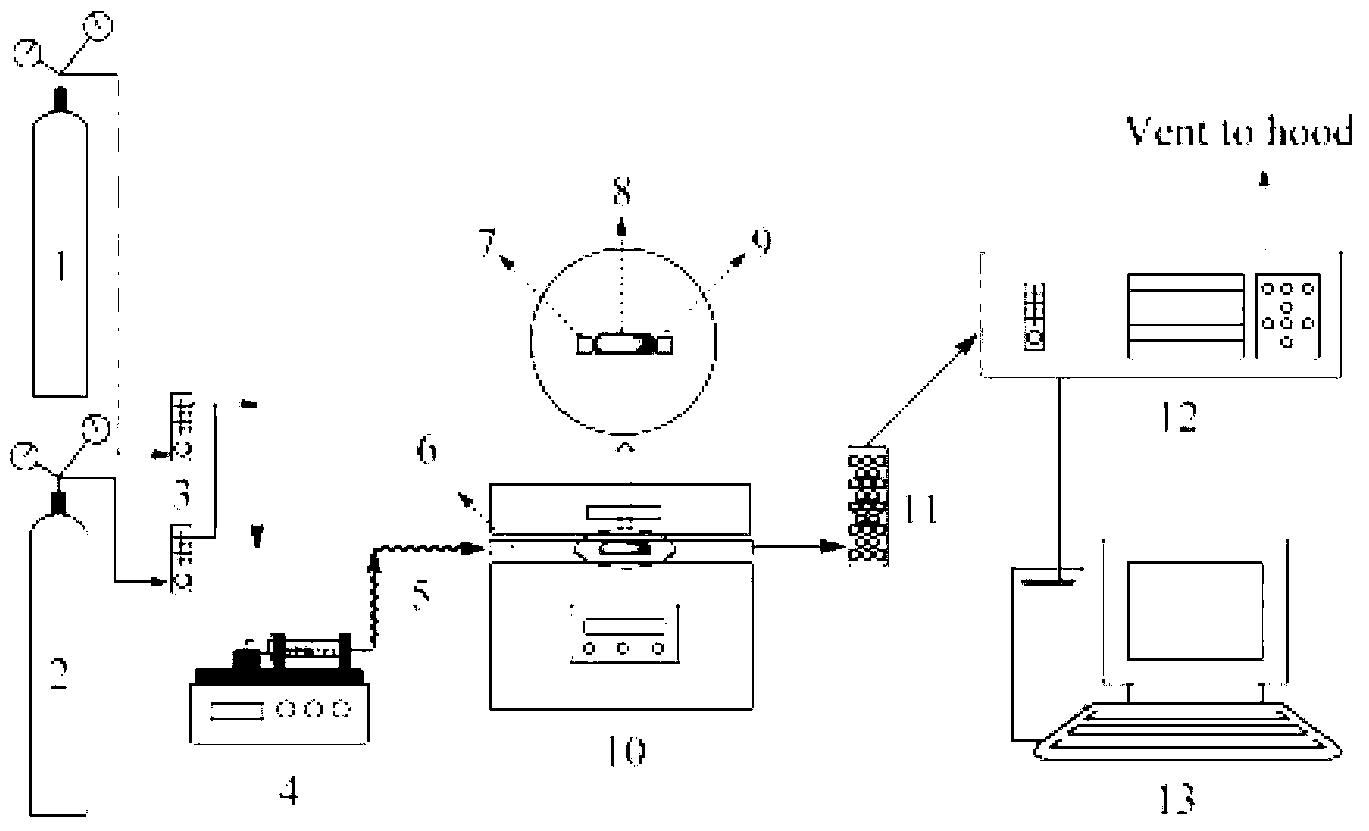

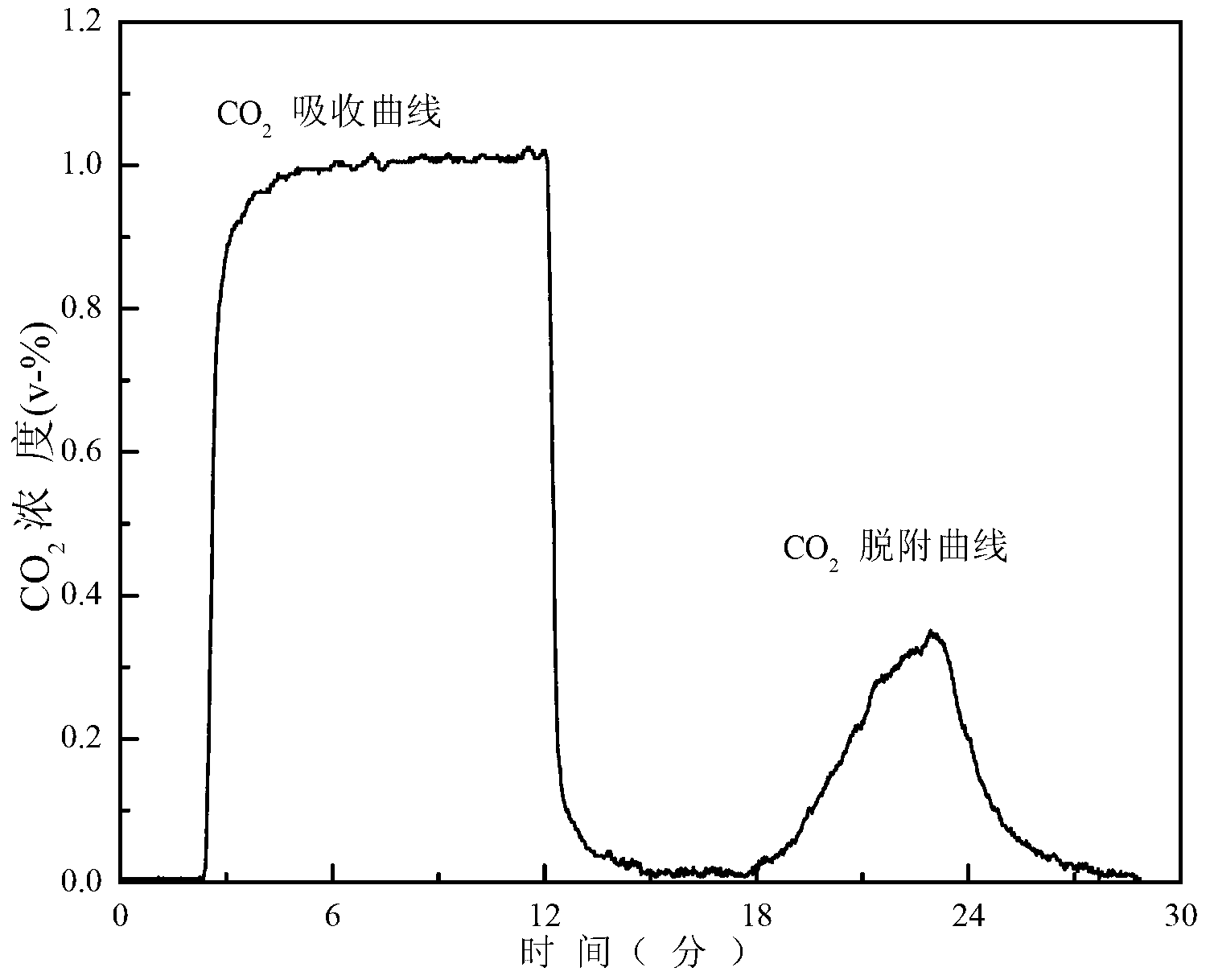

Solid absorbent with high CO2 adsorption capacity and preparation method thereof

InactiveCN103230778AFast decarbonizationFastOther chemical processesDispersed particle separationSupercritical dryingCorrosion

The invention discloses a solid absorbent with high CO2 adsorption capacity and a preparation method thereof. The solid absorbent comprises active components and a carrier; the active components are alkali carbonate and an amino group at the surface of the carrier, and are 15-60% of total quality of the solid absorbent; the molar ratio of the alkali carbonate and the amino group is 1 to (0.5-25); and the carrier is monox, and is 40-85% of total quality of the solid absorbent. The preparation method comprises the following steps of mixing and stirring the materials into emulsion; putting the emulsion into air to form cross-linking gel; putting the gel into a sealed dryer; soaking the gel by ethanol; and drying and screening the gel by a supercritical drying method, so as to prepare the solid absorbent with high CO2 adsorption capacity. The absorbent is low in price, stable in structure, high in carbonic acid conversion ratio, not easy to inactivate, and small in corrosion on equipment, and has certain mechanical strength, and high cyclic utilization rate; and the preparation method of the absorbent is convenient to operate, and low in expenses.

Owner:SOUTHEAST UNIV

Method for preparing reinforcing epoxy resin material capable of being fast cured at medium/low temperature

InactiveCN103554835AModerate curing temperatureGuaranteed dimensional stabilityPolymer scienceFirming agent

The invention discloses a method for preparing a reinforcing epoxy resin material capable of being fast cured at medium / low temperature and belongs to the technical field of materials. The epoxy resin material is characterized in that the epoxy resin material is formed by mixing a resin component A and a curing agent component B, wherein the resin component A consists of epoxy resin and an epoxy diluent; the curing agent component B consists of a curing agent and an accelerant. The method comprises the following steps: uniformly mixing and stirring the component A and the component B, and performing vacuum defoamation treatment; pouring the components into a preheated die, heating the components under the vacuumizing condition until the components are completely cured, thus obtaining the reinforcing epoxy resin system capable of being fast cured. The problems that the epoxy resin product is high in energy consumption during high-temperature curing and the dimensional accuracy of the product is difficultly controlled are solved. The composite material prepared by the method has the advantages of being fast cured and low in manufacturing cost. The method is simple and feasible in operation; the cured product is high in strength, excellent in heat resistance and high in adhesive property and is particularly suitable for repairing and reinforcing various equipment, pipelines and other epoxy resin composite material products.

Owner:佛山市沃隆化工有限公司

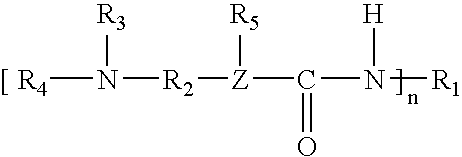

Low-cure powder coatings and methods for using the same

InactiveUS7091286B2Reduced stabilityHigh levelOrganic chemistrySynthetic resin layered productsEpoxyPolymer science

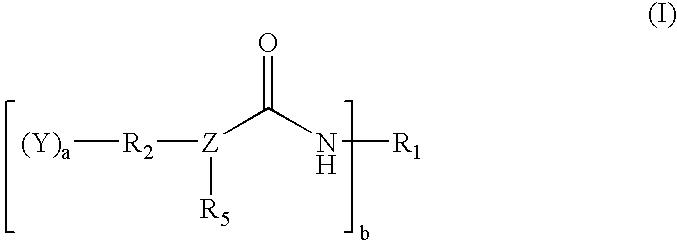

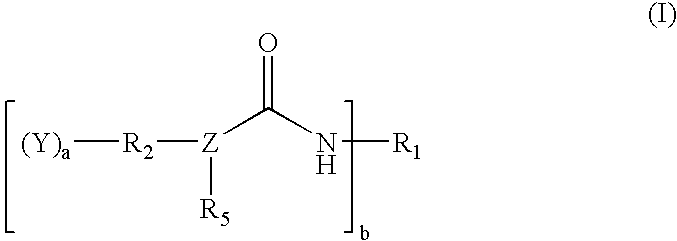

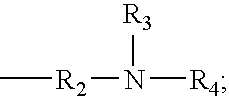

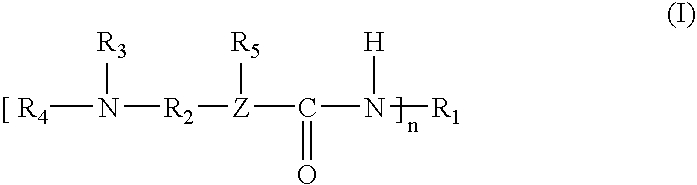

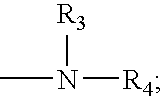

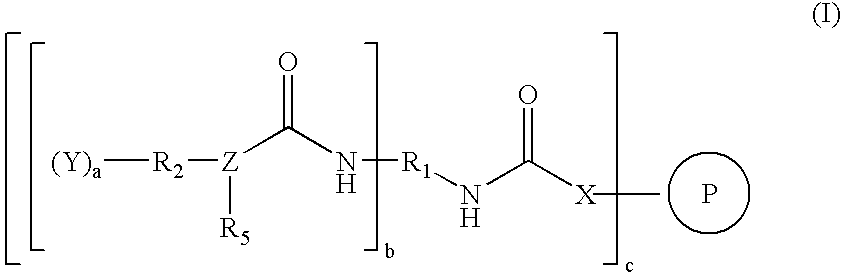

Low-cure powder coating compositions are disclosed, comprising at least one epoxy-containing resin and / or at least one siloxane-containing resin, and at least one material having the structurewherein R1 is an organic radical having 6 to 25 carbon atoms; each R2 is independently a multivalent hydrocarbon group having 1 to 20 carbon atoms; Y iseach R3 and R4 are independently alkyl or aryl groups having 1 to 8 carbon atoms; each Z is independently oxygen or nitrogen; R5 is absent when Z is oxygen and R5 is hydrogen, an alkyl or aryl group having 1 to 20 carbon atoms, or (Y)a —R2— when Z is nitrogen; a and b are integers; a is at least 1; b is 1 to 3; and (b) at least one epoxy-containing resin and / or at least one siloxane-containing resin. The material can optionally be reacted with an acidic hydrogen-containing compound. Some compositions are curable without using crosslinking agents or accelerators. Methods for coating a substrate using these compositions, the coated substrates, and additional catalysts useful for the same purpose are also disclosed.

Owner:PPG IND OHIO INC

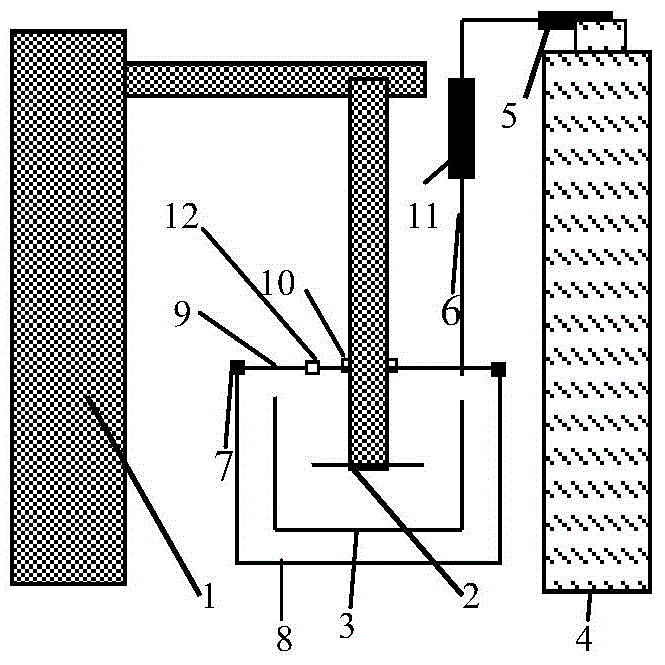

Method and device for preparing porous ceramic by heavy gas-protective direct-foaming technology

The invention belongs to the field of inorganic non-metallic materials and relates to a method and device for preparing porous ceramic by a heavy gas-protective direct-foaming technology. The method comprises preparing suspension slurry, carrying out vacuum bubble-removal, removing environment air by heavy gas, carrying out heavy gas-protective stirring foaming, carrying out pouring, carrying out demolding, carrying out drying and carrying out sintering. The foamed ceramic is prepared by heavy gas (such as argon or carbon dioxide)-protective stirring foaming and the water-based ceramic slurry foaming special-purpose device is designed. The method for preparing the foamed ceramic adopts a stirring foaming method adopting heavy gas to extrude air upward, utilizes simple equipment and is convenient for operation. The foamed ceramic slurry undergoes a free radical polymerization reaction for gelation curing, has a fast gelation rate, has uniform blank aperture distribution and is suitable for preparation of a porous ceramic material with apertures of 50-300 microns.

Owner:AVIC COMPOSITES

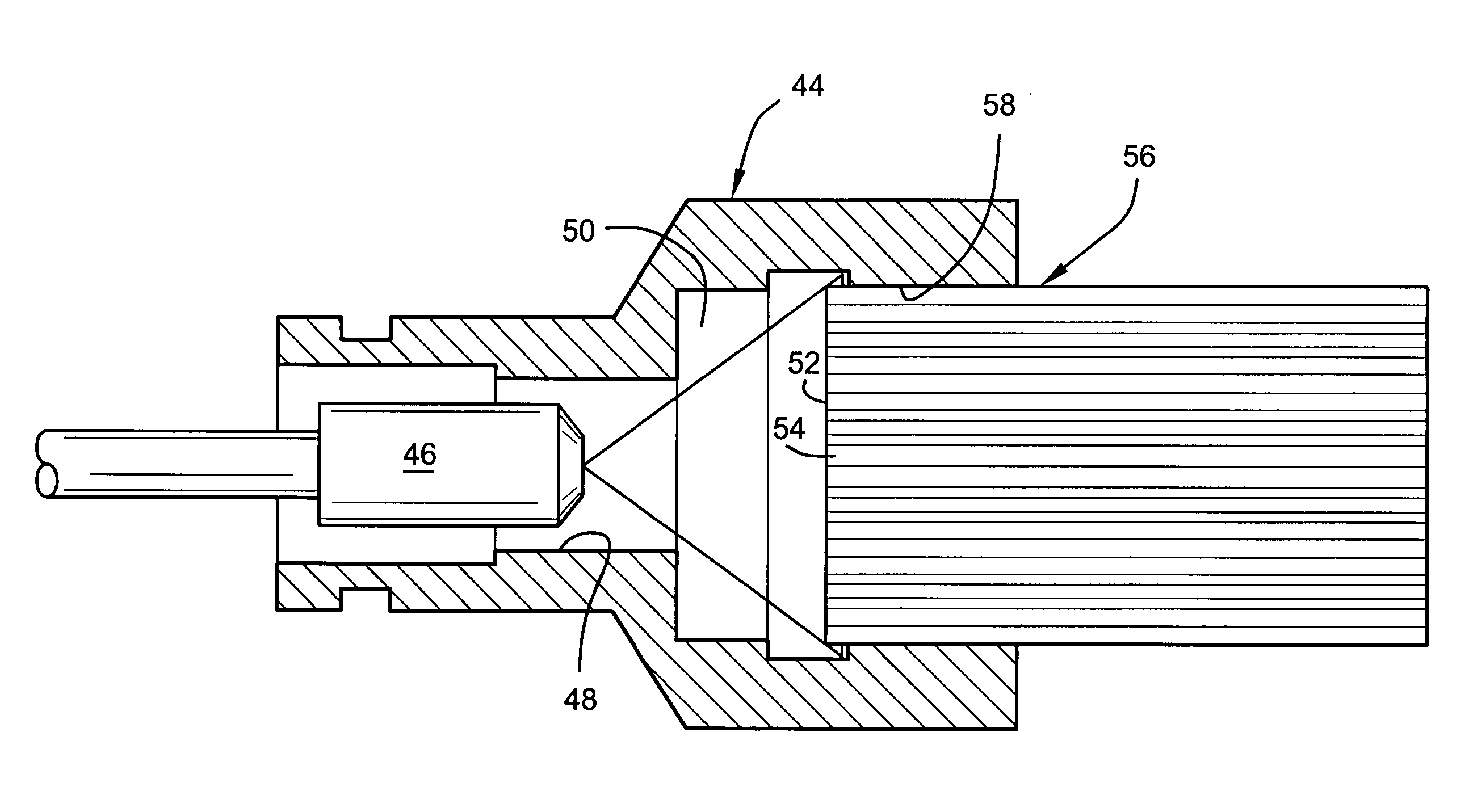

Epoxy spray lining for liquid-cooled generator stator bar clips

InactiveUS20050227009A1Gel fastPretreated surfacesManufacturing dynamo-electric machinesEpoxyEngineering

A method of coating a stator bar end inserted through an opening within a stator bar end fitting, the fitting having a chamber and the stator bar end having free ends of solid and hollow strands exposed within the chamber, the method including inserting a spray head nozzle through another opening in the fitting and in proximity to the free ends of the solid and hollow strands; spraying an epoxy resin composition so as to form a coating over the free ends of the solid and hollow strands and over at least a portion of adjoining wall surfaces of the fitting within the chamber; and curing the coating.

Owner:GENERAL ELECTRIC CO

Low-cure powder coatings and methods for using the same

InactiveUS7244801B2Reduced stabilityHigh levelOrganic chemistrySynthetic resin layered productsPtru catalystOrganic group

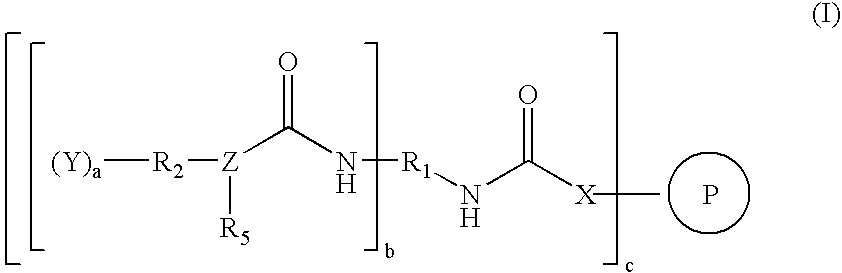

Low-cure powder coating compositions are disclosed. The compositions comprise a polyepoxide and a material having the structurewherein R1 is an organic radical having 6 to 25 carbon atoms; R2 is an organic radical having 1 to 20 carbon atoms; R3 and R4 are independently alkyl or phenyl groups having 1 to 8 carbon atoms; Z is oxygen or nitrogen, and when Z is oxygen R5 is absent and when Z is nitrogen R5 is hydrogen or isand n is 1 to 4. The material can optionally be reacted with an acidic hydrogen-containing compound. The compositions are curable without the use of crosslinking agents or accelerators. Methods for coating a substrate using these compositions, and substrates coated thereby, are also disclosed, as are additional catalysts useful for the same purpose.

Owner:PPG IND OHIO INC

Catalysts for low-cure powder coatings and methods for using the same

ActiveUS6998365B2Reduced stabilityHigh levelOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsArylPolymer science

Catalysts useful for low-cure powder coating compositions are disclosed, having the structure (I): wherein R1 is an organic radical having 6 to 25 carbon atoms; each R2 is independently a multivalent hydrocarbon group having 1 to 20 carbon atoms; Y is each R3 and R4 are independently alkyl or aryl groups having 1 to 12 carbon atoms; each Z is independently oxygen or nitrogen; R5 is absent when Z is oxygen and R5 is hydrogen, an alkyl or aryl group having 1 to 20 carbon atoms, or (Y)a —R2— when Z is nitrogen; a, b, and c are integers; each X is independently S, O, or N(R6); each R6 is independently hydrogen or an alkyl or aryl group having 1 to 12 carbon atoms; and P is a polymeric material.

Owner:PPG IND OHIO INC

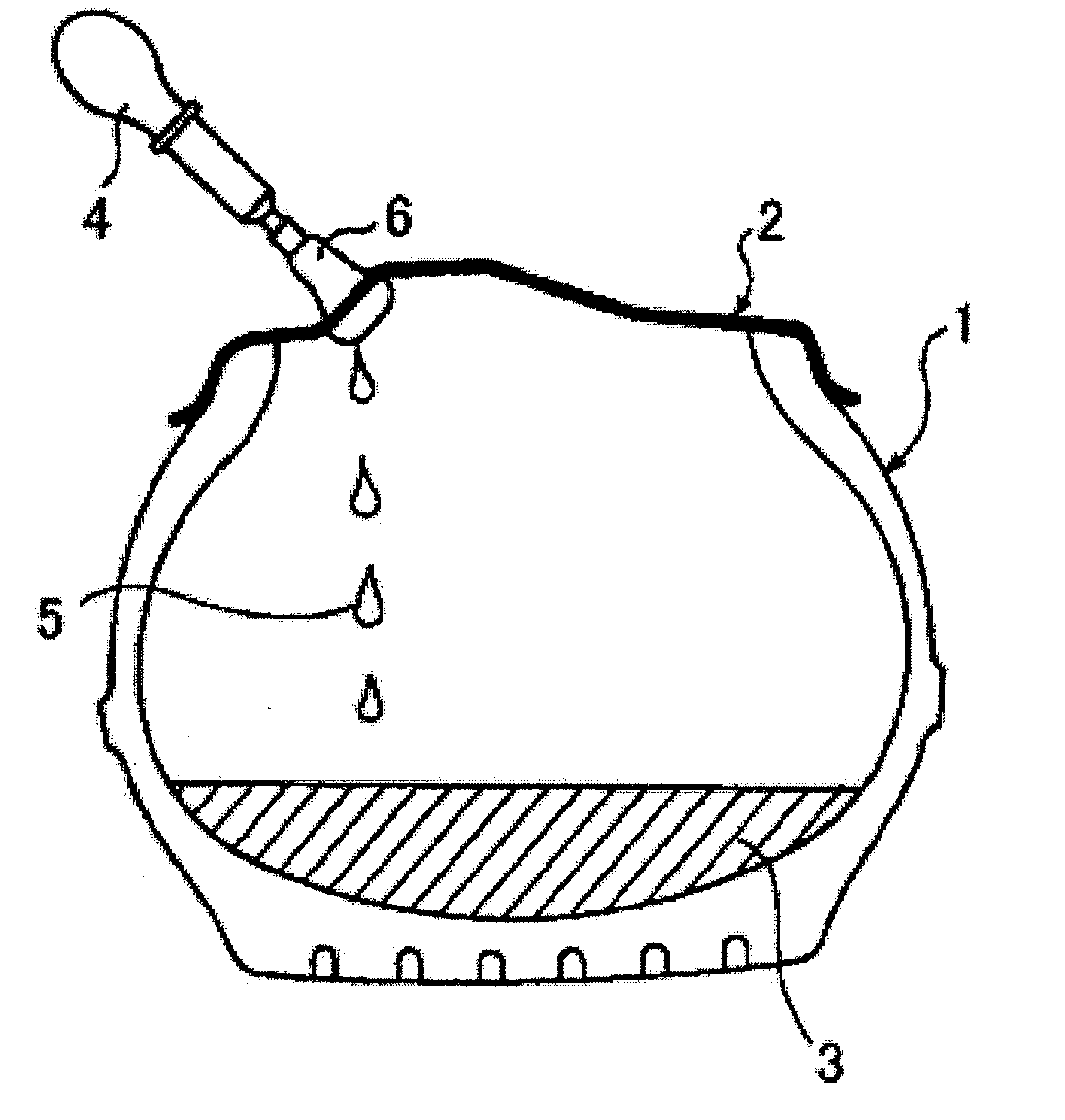

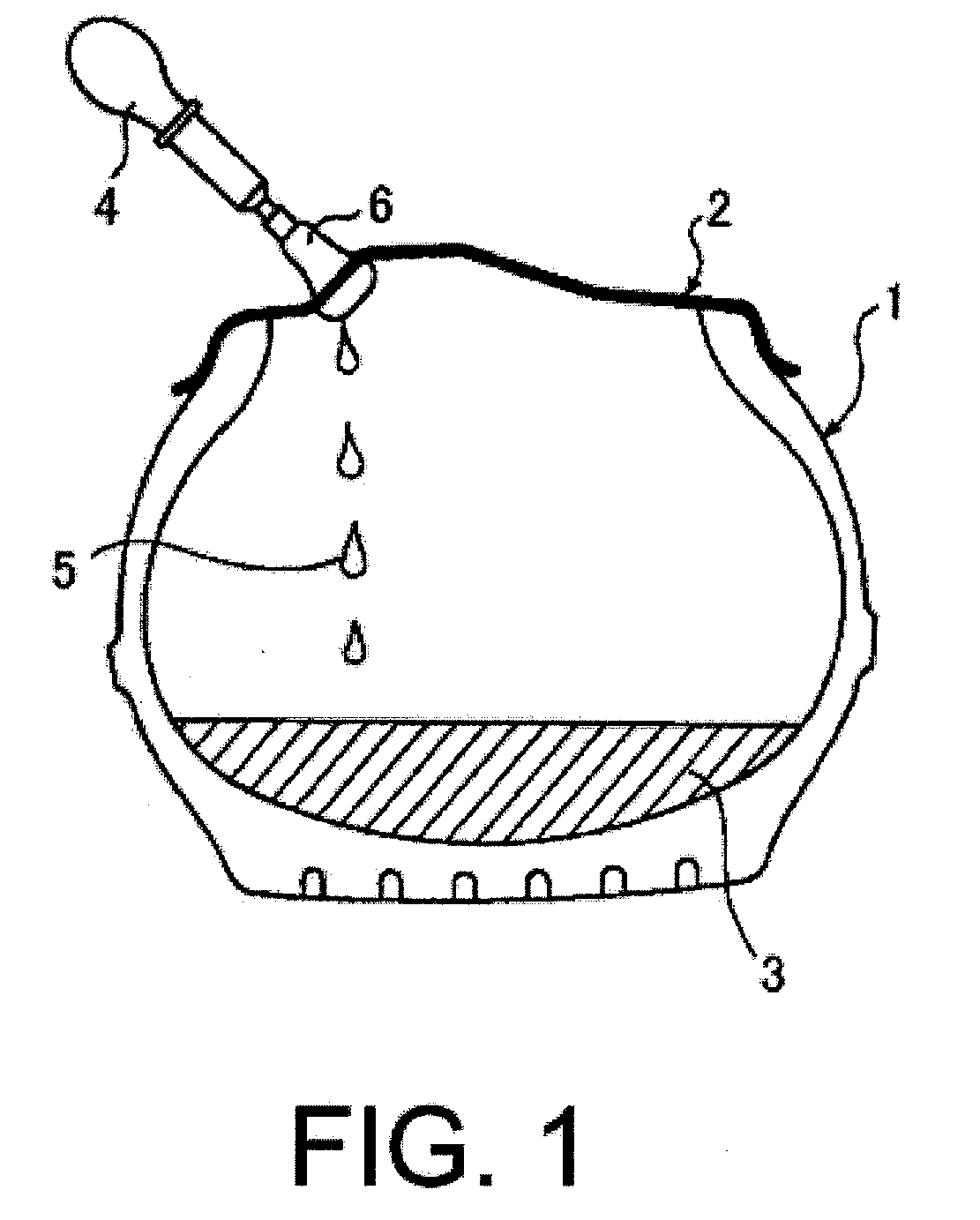

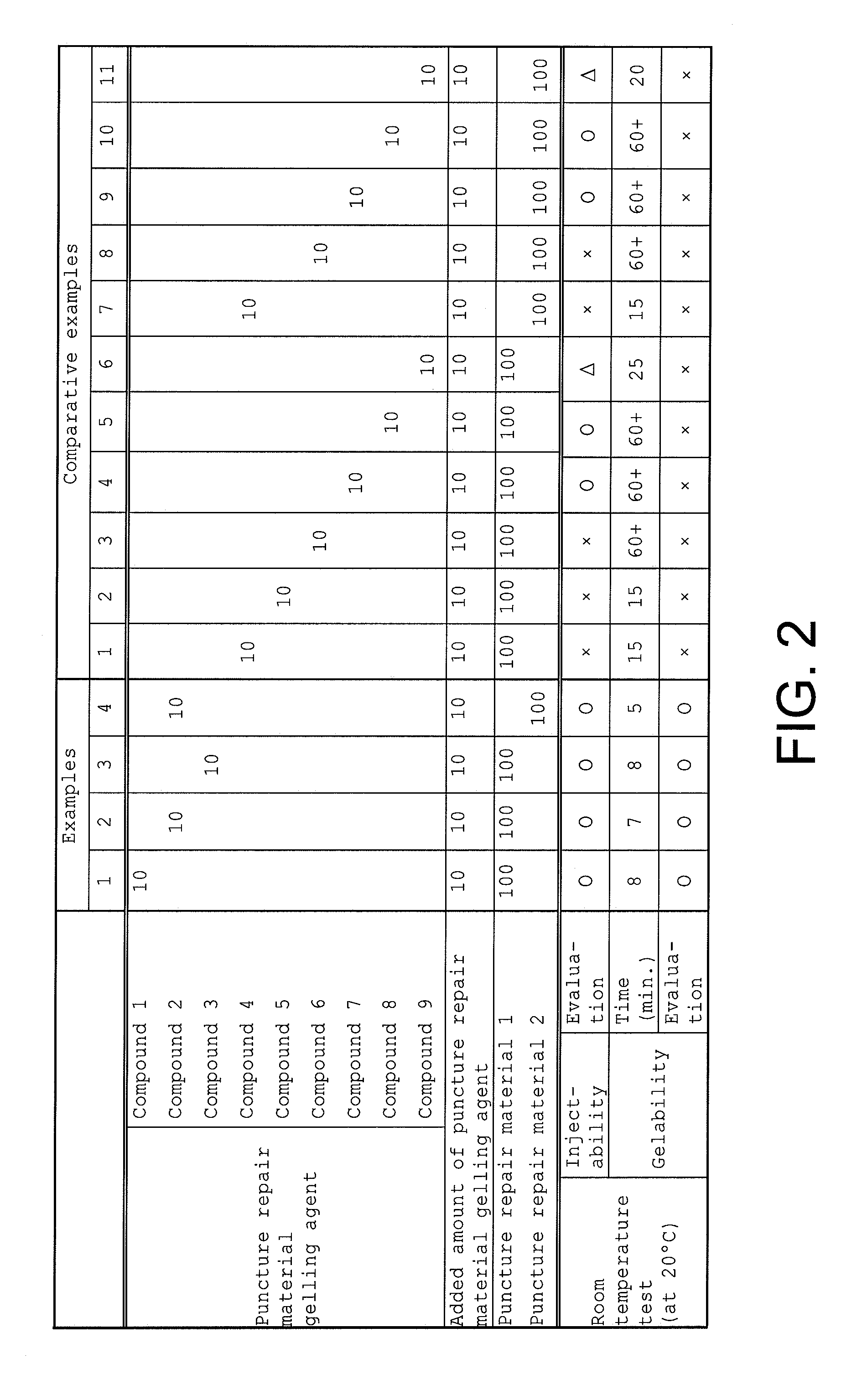

Puncture Repair Material Recovery System

ActiveUS20110077327A1Gel fastMaterial becomes quickOrganic chemistryTyresNatural rubber latexEmulsion

A gelling agent, and a method of use for the same, for gelling a puncture repair material, the puncture repair material including a natural rubber latex, a resin emulsion, and an antifreezing agent, the gelling agent comprising a compound (α) of the following Formula (1). In the following Formula 1, R1 is an alkyl group having from 13 to 30 carbon atoms or an alkenyl group having from 13 to 30 carbon atoms.

Owner:YOKOHAMA RUBBER CO LTD

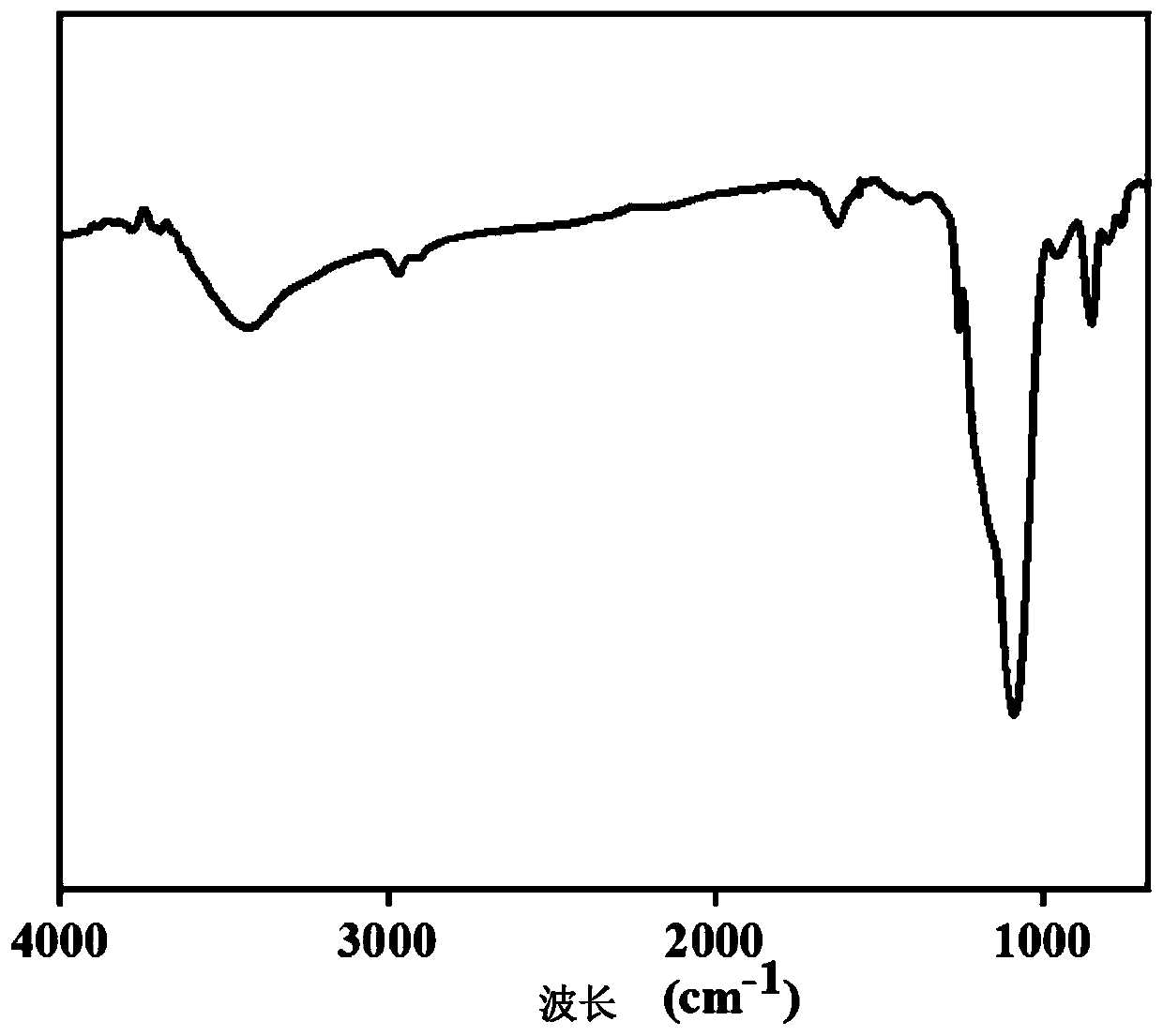

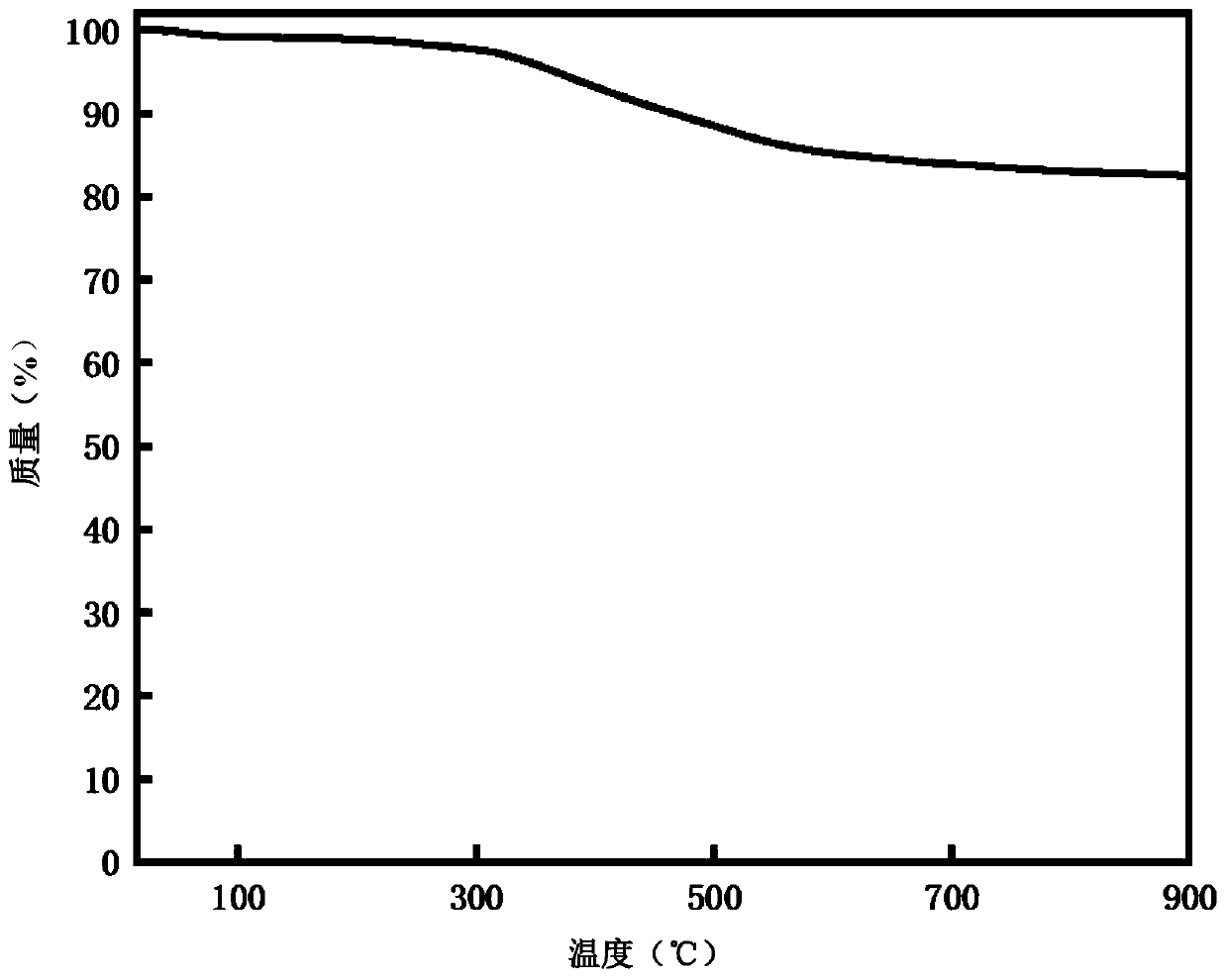

Silica aerogel fiber with adjustable transparency and hydrophobicity as well as preparation method and application

ActiveCN110983490AControllable transparencyControllable hydrophilicity and hydrophobicityFibre chemical featuresFiberSpinning

The invention discloses a silica aerogel fiber with adjustable transparency and hydrophobicity, as well as a preparation method and an application. The silica aerogel fiber has a communicated three-dimensional porous network structure, wherein the transparency of the silica aerogel fiber is 20-95%, the contact angle with water is 0-158 degrees, the porosity is 80-99.9%, the specific surface area is 100-2000 m2 / g, the thermal conductivity is 0.010-0.030W / (m*K), the diameter is 10[mu]m to 3mm and the length-diameter ratio is greater than 10. The preparation method comprises the following steps of providing a spinning solution containing a linear organosiloxane polymer with a multifunctional group; and adopting a wet spinning method, injecting the spinning solution into an alkaline coagulation bath, obtaining silica gel fiber, and carrying out drying treatment to obtain the silica aerogel fiber. The silica aerogel fiber disclosed by the invention is low in thermal conductivity, has a spinnability, is adjustable in transparency, is controllable in hydrophobicity, and has a huge application prospect.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Cold-gelling thixotropic glaze composition

A cold-gelling thixotropic glaze composition has a Brix value in the range of 20-65; containing at least 0.1 wt. % and less than 2.5 wt. % of low methoxylated-amidated (LMA) pectin; and containing at least 34 wt. % of water, the composition being characterised in that after it has been sheared sufficiently to become pourable, it forms a firm gel under quiescent conditions. The glaze composition according to the present invention exhibits significant shear thinning and subsequently forms a firm, non-sticky gel on standing. Thus, the present glaze composition can be made pourable by applying sufficient shear, e.g. by shaking and / or stirring it. The shear-thinned pourable glaze composition can be applied directly onto the surface of a food product, following which it will rapidly gel to produce a firm glaze.

Owner:CSM NEDERLAND

Non-steroidal anti-inflammatory ophthalmic compositions

ActiveUS8778999B2Promote degradationOptimal in flowabilityBiocideSenses disorderOphthalmologyBromfenac

The disclosure provides compositions and systems for topical ophthalmic application, which include an aqueous mixture of bromfenac and flowable mucoadhesive polymer, for treating inflammation and inflammatory conditions of the eye.

Owner:SUN PHARMA INDS

Method for preparing monolithic porous carbon with basic magnesium carbonate for catalyzing phenolic aldehyde to be polymerized

InactiveCN106744796AGel fastLarge specific surface areaProductsGas treatmentAbsorption capacityPorous carbon

The invention discloses a method for preparing a monolithic porous carbon with basic magnesium carbonate for catalyzing phenolic aldehyde to be polymerized, which includes the following steps: (1) a saturated basic magnesium carbonate solution is prepared; (2) resorcinol and formaldehyde are sequentially added into the saturated basic magnesium carbonate solution sealed after being stirred, and after four hours of reaction under 70 DEG C to 100 DEG C, a wet gel is obtained; (3) after being dried, the wet gel obtained in step (2) is put into a tubular carbonization furnace, reacts under the protection of inert gas for two hours after being heated to 650 DEG C to 1050 DEG C, and is then naturally cooled to room temperature, and thereby the monolithic porous carbon is obtained. With resorcinol and formaldehyde as carbon soruces, the method utilizes the catalytic effect and easy decomposition property of basic magnesium carbonate to prepare the monolithic porous carbon by rapid gelation and carbonization control, and the mechanical strength reaches 9.4MPa. The method has high gelation speed, the specific surface area of the prepared product is large, and the CO2 equilibrium absorption capacity is high.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

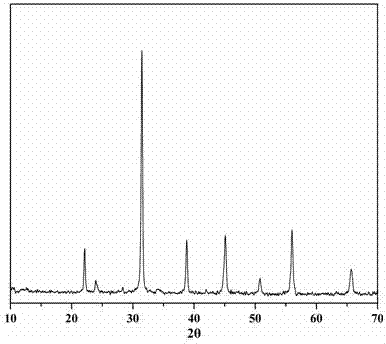

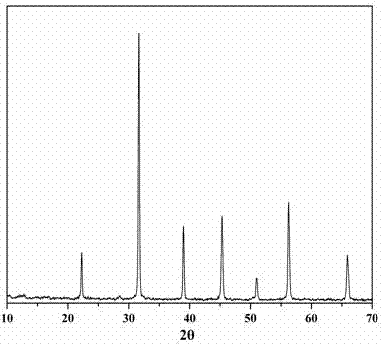

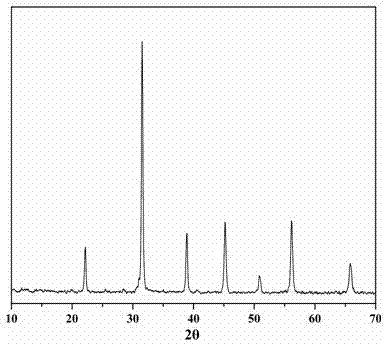

Method for preparing barium titanate compounds

InactiveCN103693680ASuitable for doping modificationControl doping amountTitanium compoundsBarium titanateTitanium ion

The invention relates to a novel method for preparing barium titanate compounds, namely a hydrothermal-gel method, which combines the advantages of traditional hydrothermal method and sol-gel method and combines the characteristics of the hydrothermal synthesis method of mild reaction conditions and good repeatability and the characteristics of the sol-gel method that quantitative trace elements can be uniformly added and uniform mixing in molecular level can be realized. The method has the main advantages that firstly, the method is simple and easy to operate, has good repeatability, and has no strict requirements on solution acidity, moisture content, gelation temperature and gelation time in gelation process; secondly, the gelation speed is high, the quality of the gel is good, and the calcined powder granules are uniform and thin; thirdly, the method has low requirement on reaction conditions, thus being applicable to modifying barium titanate by doping by most metal ions; fourthly, by controlling the use level of metal ions, the doping amount of metal ions substituting titanium ions or barium ions in the barium titanate can be well regulated and controlled.

Owner:NANCHANG HANGKONG UNIVERSITY

Polyurethane coating material for shoe coating and preparation method of polyurethane coating material

ActiveCN109762456AReduce coefficient of frictionGel fastAntifouling/underwater paintsPaints with biocidesALUMINUM POTASSIUM SULFATEIsocyanate

The invention provides a polyurethane coating material for shoe coating and a preparation method of the polyurethane coating material. The preparation method comprises the following steps that step (1) isocyanate, polyester polyol, a moisture scavenger and a diluent are added into a reaction kettle in proportion and mixed evenly, reaction is carried out for 6-8 hours under the condition of 80-120DEG C, vacuum bubble removal is carried out, and cooling is performed to obtain a component A; step (2) polyester polyol, a chain extender, a catalytic agent and a glycerin solution of dehydrated aluminum potassium sulfate dodecahydrate are added into the reaction kettle in proportion and mixed evenly and vacuumized for 2-3 hours to remove bubbles, and a component B is obtained; and step (3) the component A and the component B are evenly mixed in proportion, vacuum bubble removal is carried out for 30s, and the polyurethane coating material is obtained. The prepared polyurethane coating material is used for coating the surface of a shoe, once-forming can be achieved, and the problem that bubbles generated in the coating due to the fact that a known spraying polyurethane elastomer reacts with moisture is further solved.

Owner:FOSHAN NANHAI QIHONG SHOES MATERIAL CO LTD

Surgical delivery system for medical sealant

ActiveUS20090198177A1Improve convenienceImprove efficacySurgeryMedical devicesSurgical operationSealant

Certain embodiments include a surgical delivery system for a medical sealant including a packaging system with a detachable a sterile surface for mixing the sealant as needed for application.

Owner:INCEPT LLC

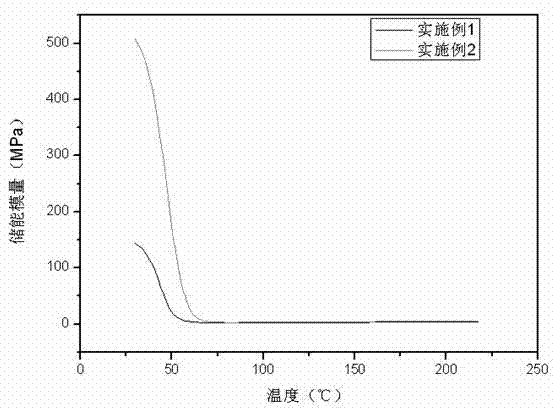

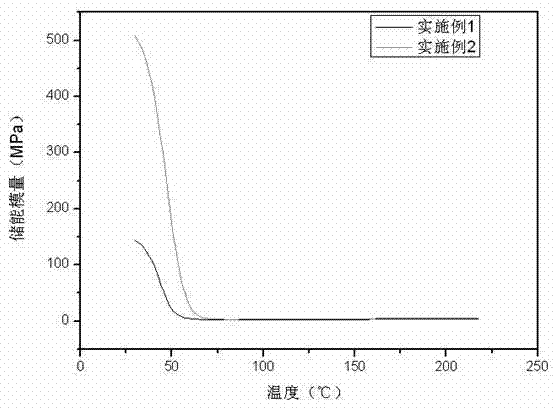

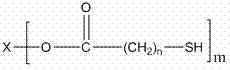

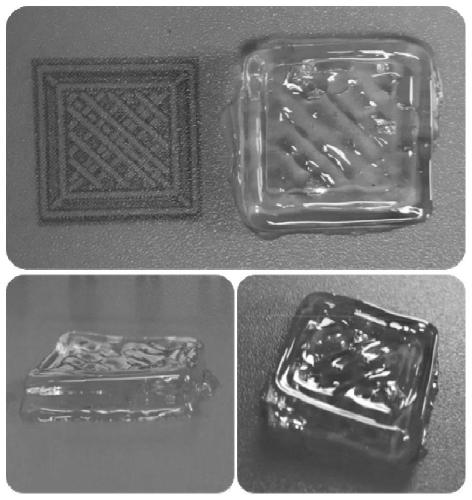

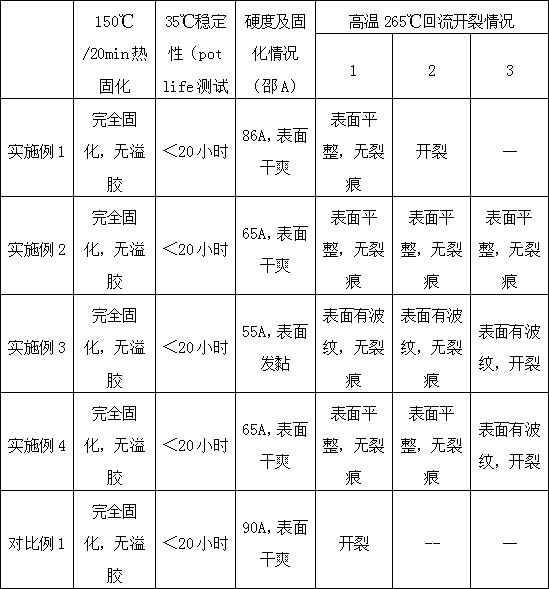

Low-modulus epoxy resin system and preparation method thereof

The invention belongs to the technical field of electronic packaging materials, and particularly relates to a low-modulus epoxy resin system and a preparation method thereof. The low-modulus epoxy resin system of the invention comprises the following main components: epoxy resin, a polymercaptan curing agent, a tertiary amine curing accelerator and the like, and has the characteristics of low curing temperature, adjustable gel reaction speed, low modulus of curing products, and adjustable modulus by the addition of inorganic fillers. The low-modulus epoxy resin system can be used as a substrate resin of electronic packaging materials such as bottom fillers, encapsulation agents, chip adhesives and the like for reducing packaging internal stress, and has wide application prospects in the electronic packaging field.

Owner:FUDAN UNIV

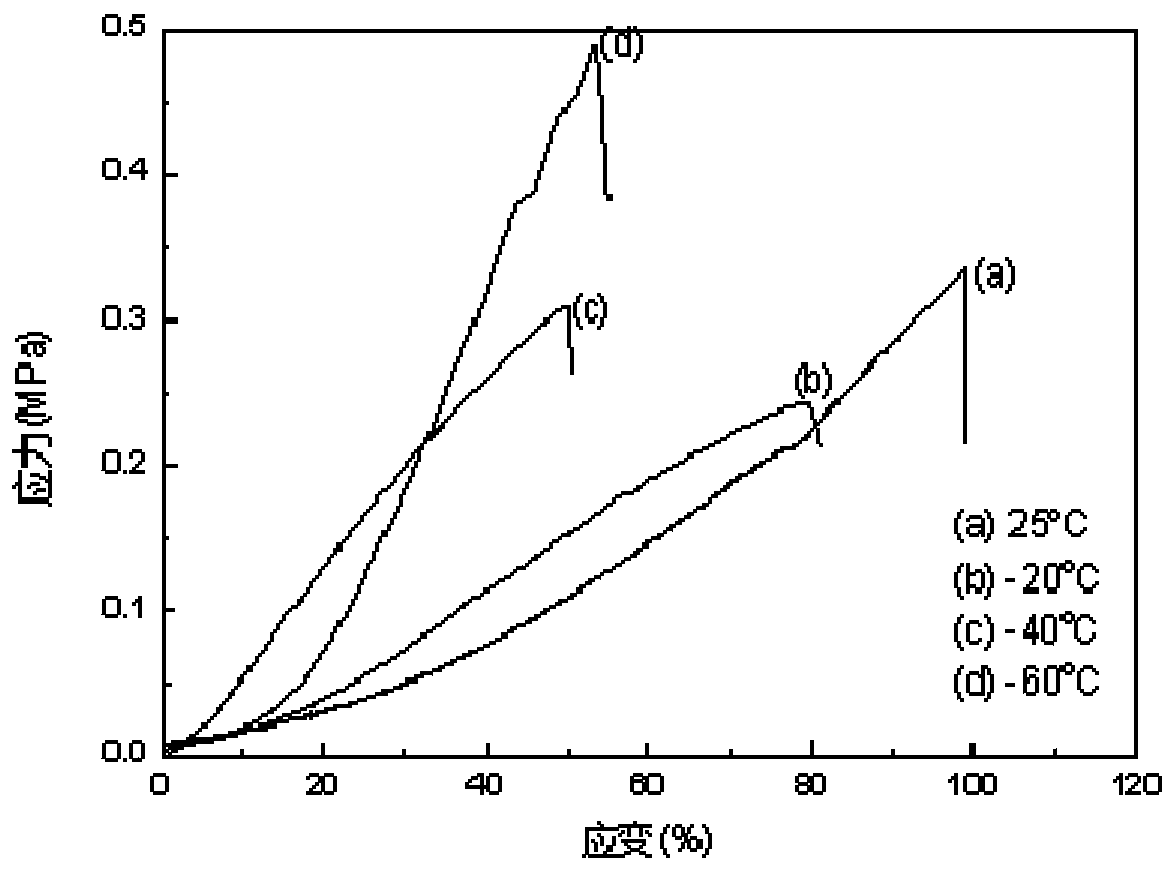

Preparation method of cellulose conducting hydrogel for 3D printing

InactiveCN109942838AIncrease gel speedWide variety of sourcesAdditive manufacturing apparatusCelluloseMechanical property

The invention discloses a preparation method of a cellulose conducting hydrogel for 3D printing. The preparation method comprises the following steps: preparing a mixed solution of ZnCl2 and CaCl2, adding cellulose, and stirring the mixture magnetically to 50-90 DEG C to dissolve the mixture for 10-90 min to be fully dissolved to obtain a cellulose solution; adding water or small molecular alcoholinto the cellulose solution, and stirring the mixture at 50-90 DEG C for 5-30 min till being uniform; and debubbling and cooling the mixture to obtain the cellulose conducting hydrogel. The celluloseconducting hydrogel has the advantages of being high in gelation rate, good in freezing resistance, good in thermal reversible mechanical property, high in transparency, high in conducting property and the like. The mechanical property of the cellulose conducting hydrogel prepared by the method at 20 DEG C below zero is equivalent to that at 25 DEG C, and the cellulose hydrogel at 60 DEG C belowzero is not frozen, too.

Owner:NANJING FORESTRY UNIV

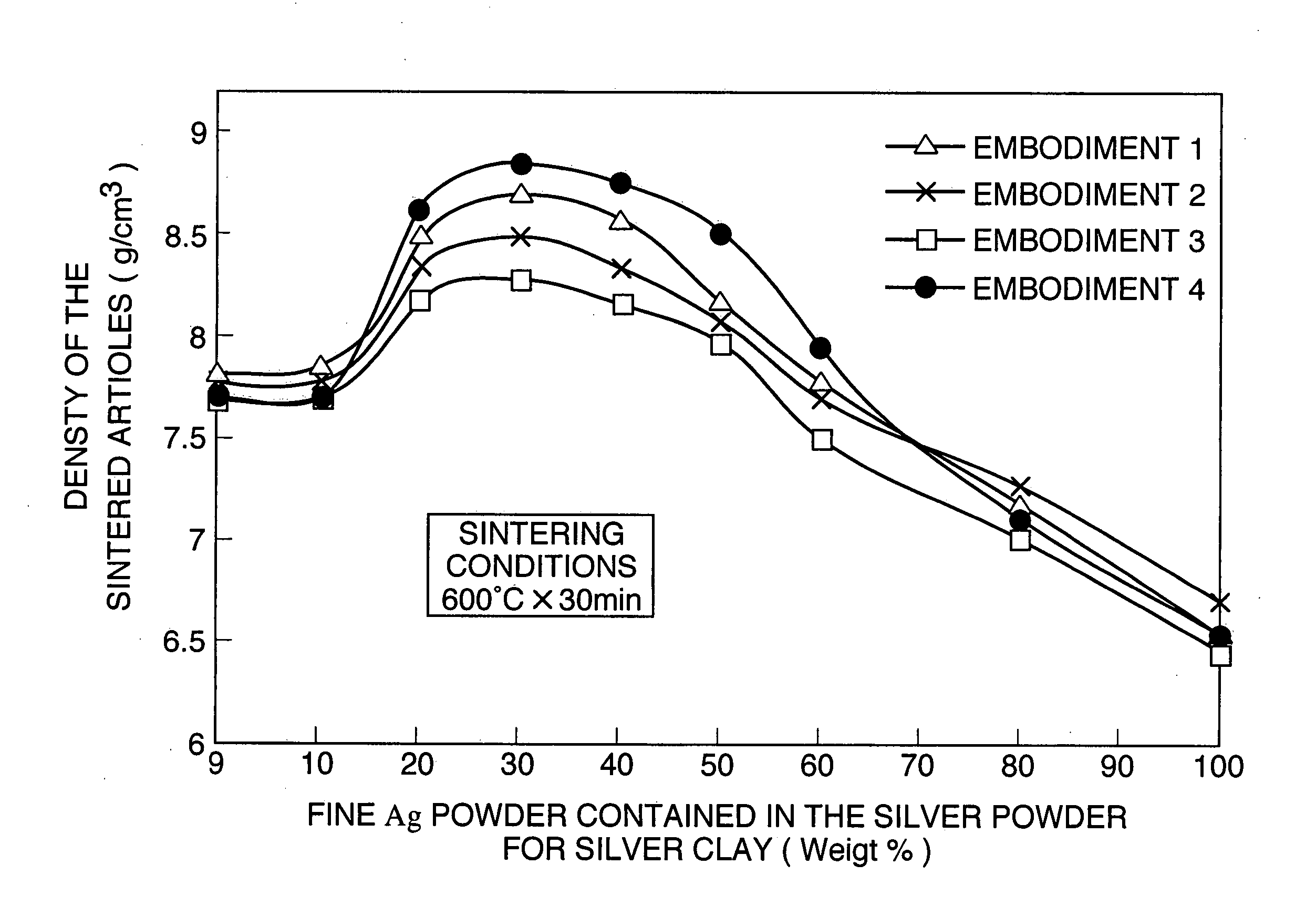

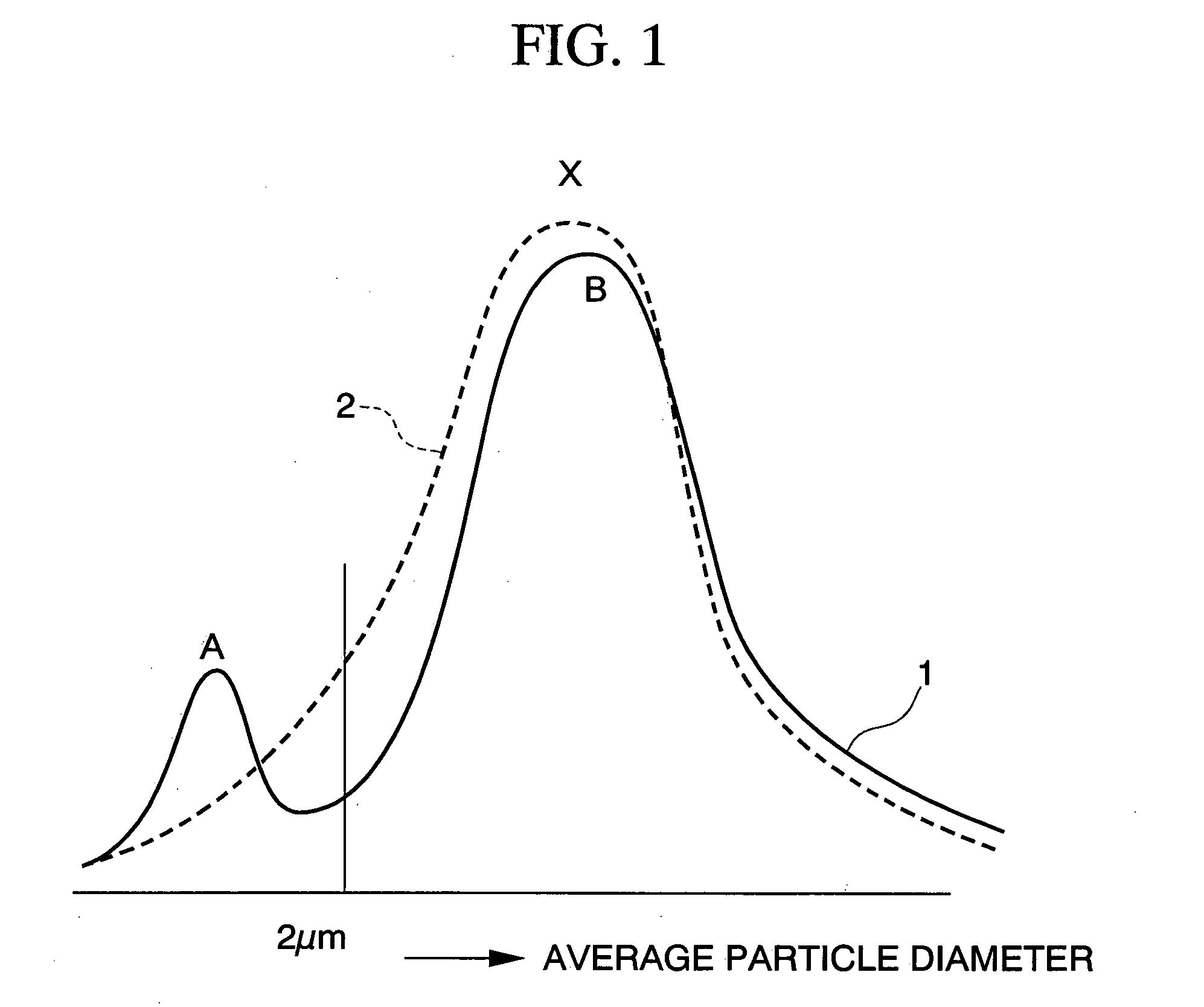

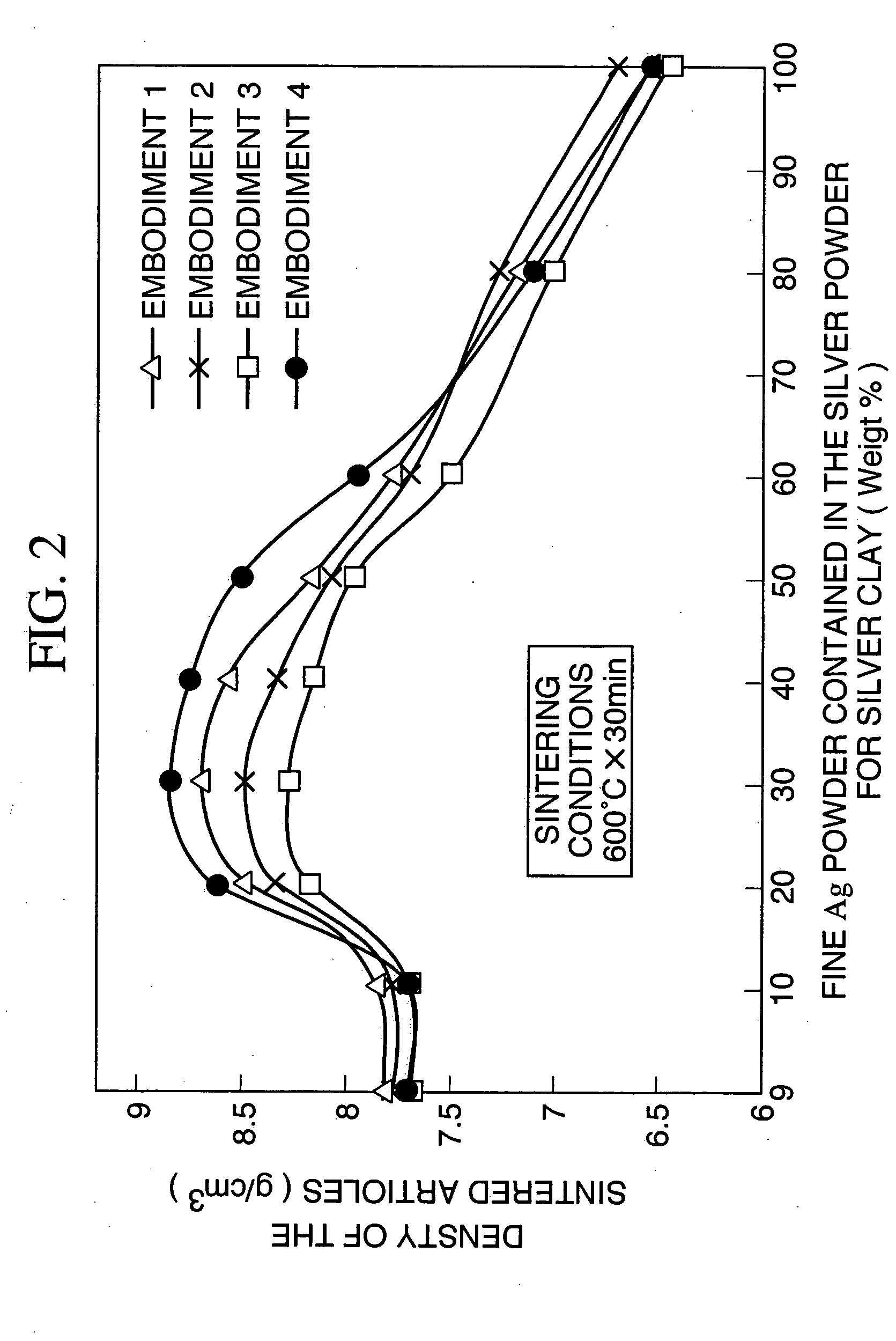

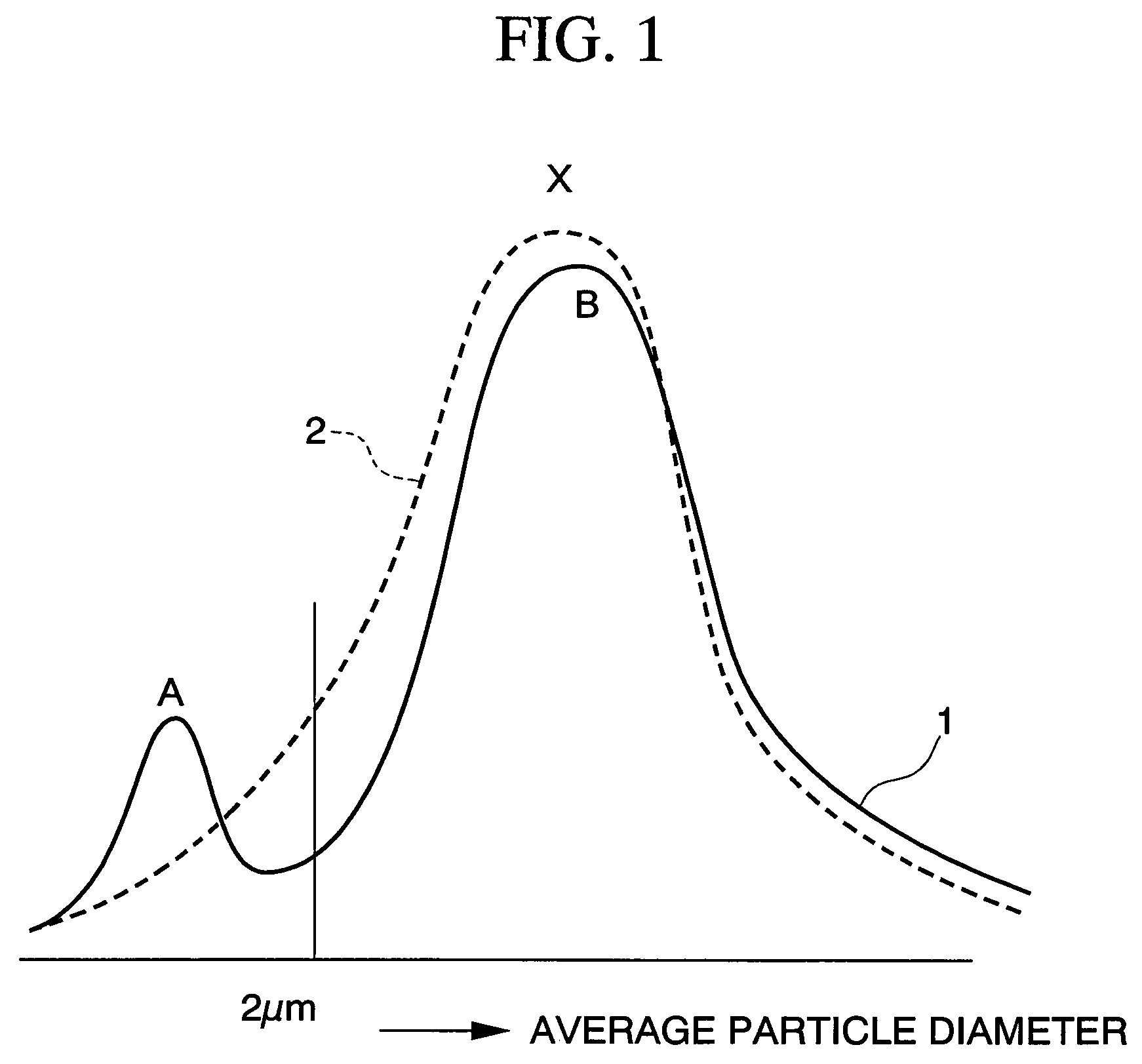

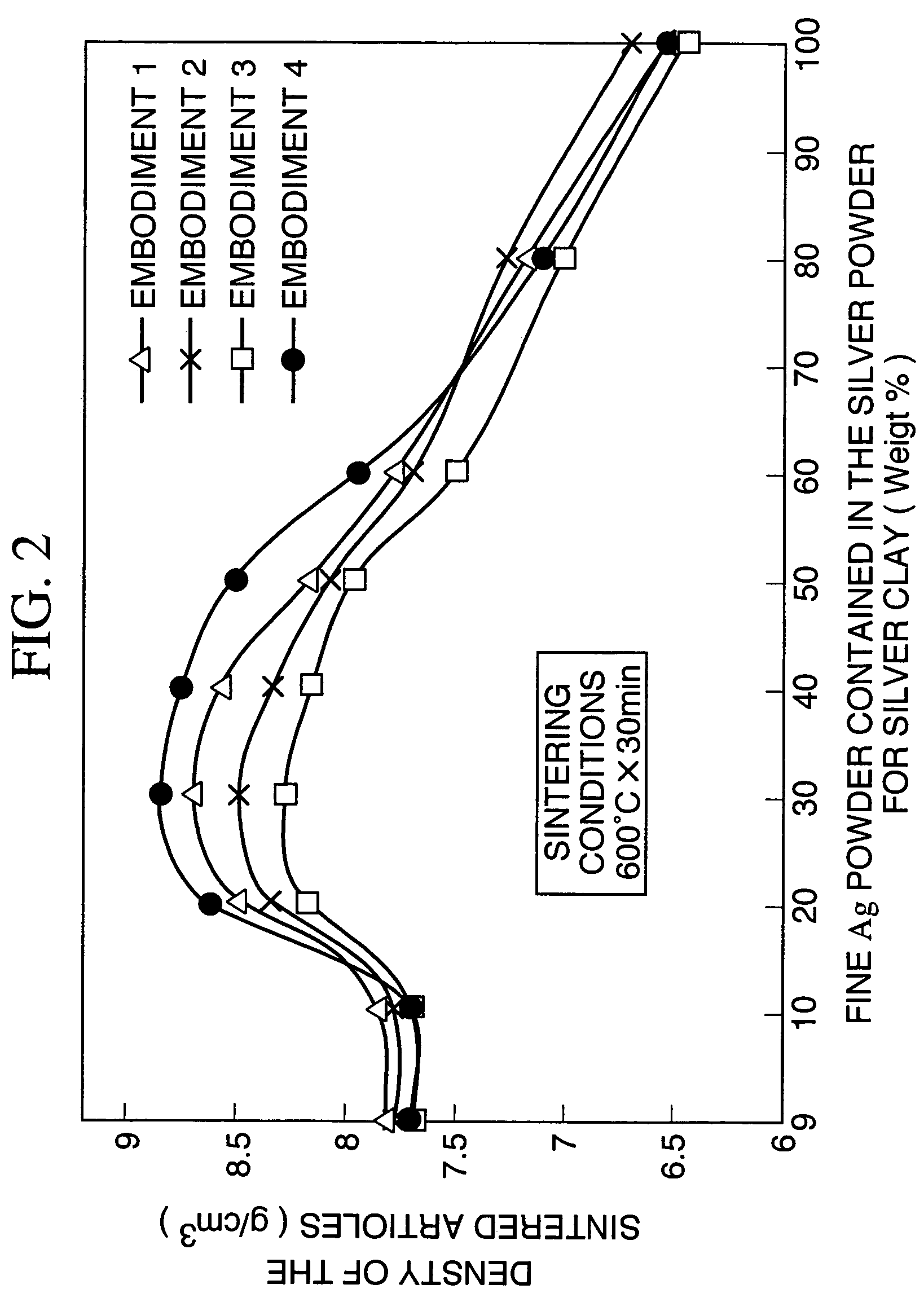

Silver powder for silver clay and silver clay comprising the silver powder

InactiveUS20050115466A1Effect be insufficientEasy maintenanceTransportation and packagingMetal-working apparatusSurface-active agentsMetallurgy

A silver clay that can be obtained by sintering at a low temperature. A silver powder for silver clay is a fine Ag powder having an approximate average particle diameter equal to or less than 2 μm incorporated at 15 to 50 weight %, with the remainder being an Ag powder having an average particle diameter that exceeds approximately 2 μm and is equal to or less than approximately 100 μm. The silver clay includes this silver powder incorporated at approximately 50 to 95 weight %, a binder at approximately 0.0 to 8 weight %, an oil at approximately 0.1 to 3 weight %, and a surface active agent at approximately 0.03 to 3 weight %, with the remainder being water.

Owner:MITSUBISHI MATERIALS CORP

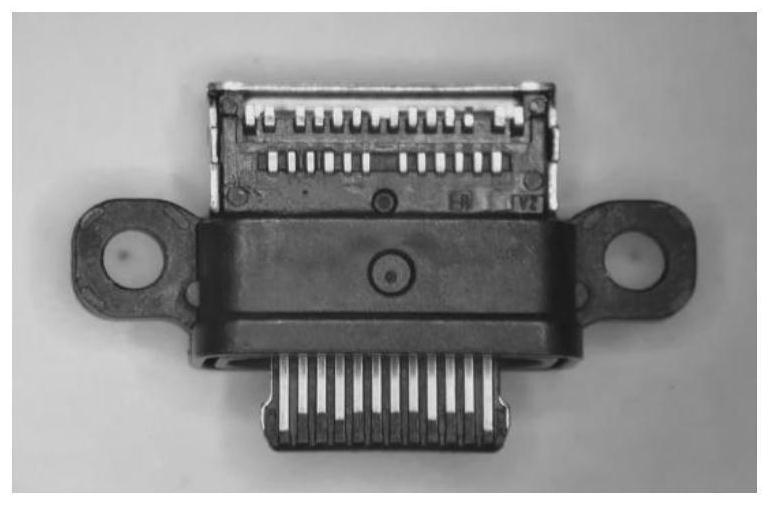

A kind of high temperature resistant flexible one-component epoxy sealing adhesive and preparation method thereof

ActiveCN111117542BGood flexibilityGel fastNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to the field of adhesives, in particular to a high-temperature-resistant flexible single-component epoxy sealing adhesive and a preparation method thereof. The high-temperature-resistant flexible single-component epoxy sealing adhesive is prepared from the following raw materials in parts by weight: 10-40 parts of epoxy resin, 10-30 parts of a mixed softening resin, 5-20 parts of an active diluent, 5-20 parts of a mixed curing agent, 0.01-1 part of a polymerization inhibitor, 0.1-5 parts of fumed silica, 0.01-1 part of an infiltration flow promoter and 5-30 parts of spherical silica powder, the mixed curing agent is a mixture of a modified amine latent heat curing agent and a modified imidazole latent heat curing agent, and the mixed softening resin is prepared from at least two of F100, F300, Capa3050, H2004, HEF750, HEF751, EP-4000L and EP-4000S. The adhesive disclosed by the invention can be widely applied to sealing processes of USB ports and high-temperature-resistant reflow soldering processes, has good bonding performance on PA46, stainless steel, PC and the like, and ensures excellent waterproof sealing performance and plugging resistance of the USB ports of electronic products.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

Method for preparing earthwork synthetic material adhesive

InactiveCN101104783AGel fastNo secondary pollutionAmide/imide polymer adhesivesPolyacrylamideAdhesive

Disclosed is a method of making adhesive for geosynthetics, which relates to the synthesis of modified polyacrylamide. The method comprises the steps: synthesizing polyacrylamide with low molecular weight, wherein the monomer is acrylamide and the initiator is ammonium persulphate and the chain transfer agent is sodium formate; hydroxymethylating the low- molecular- weight polyacrylamide with formaldehyde under alkaline condition; obtaining modified polyacrylamide through condensation reaction between hydroxymethylation polyacrylamide and acrylamide under alkaline condition; synthesizing gel under room temperature by rapidly crosslinking the modified polyacrylamide aqueous solution with crosslinking agent, initiator and accelerator; finally adding bentonite. The nontoxic modified polyacrylamide is provided with rapid crosslinking polymerization, less heat release during crosslinking polymerization, high gel strength and long service time, suitable for the preparation of geotechnical waterproof material when wrapped by bentonite.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Silver powder for silver clay and silver clay containing this silver powder

InactiveUS7081149B2Easy maintenanceGel fastTransportation and packagingMetal-working apparatusMetallurgySurface-active agents

A silver clay that can be obtained by sintering at a low temperature. A silver powder for silver clay is a fine Ag powder having an approximate average particle diameter equal to or less than 2 μm incorporated at 15 to 50 weight %, with the remainder being an Ag powder having an average particle diameter that exceeds approximately 2 μm and is equal to or less than approximately 100 μm. The silver clay includes this silver powder incorporated at approximately 50 to 95 weight %, a binder at approximately 0.0 to 8 weight %, an oil at approximately 0.1 to 3 weight %, and a surface active agent at approximately 0.03 to 3 weight %, with the remainder being water.

Owner:MITSUBISHI MATERIALS CORP

Hybrid gel comprising particulate decellularized tissue

A hybrid gel comprising a particulate decellularized tissue (obtained by pulverizing animal-derived biological tissues that are decellularized (decellularized biological tissues)), fibrinogen and thrombin; a cell culture material comprising the hybrid gel; a method for preparing the hybrid gel; and a kit comprising a particulate decellularized tissue and a biological tissue adhesive are provided. The hybrid gel of the present invention exerts the effect to promote differentiation and gain of function of stem cells and the therapeutic effect to a variety of diseases.

Owner:KM BIOLOGICS CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com