3D printing material for gelatinized confections and preparation method of 3D printing material

A gel candy, 3D printing technology, applied in confectionery, confectionary industry, food ingredients containing natural extracts, etc., can solve the problems of unsuitable fused deposition 3D printing, uneven output, slow gelation speed, etc. Achieve the effect of good sensory evaluation, fast gelation speed and flexible texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The required materials included: 12 g of oxidized starch, 0.4 g of low acyl gellan gum, 38 g of erythritol, 38 g of liquid maltitol, and 116 g of water.

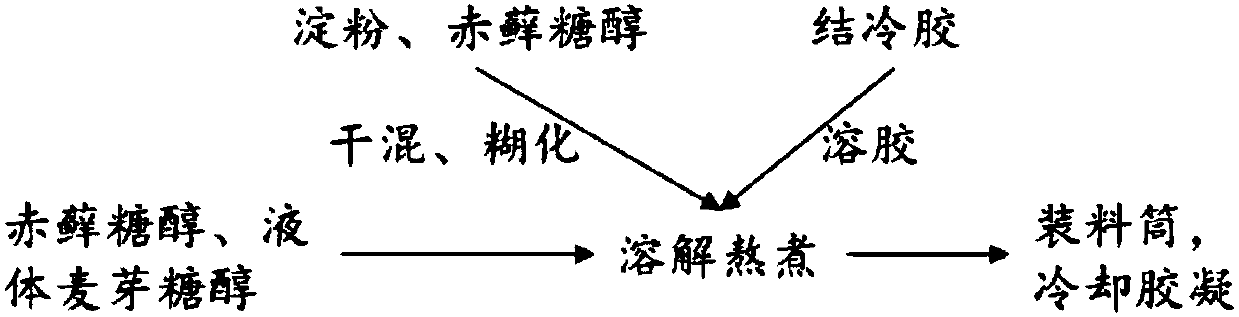

[0051] Then, prepare the jellybean 3D printing material according to the following steps:

[0052](1) Starch gelatinization: Mix 12g of potato oxidized starch and 24g of erythritol granules evenly, then add deionized water of 8 times the amount of starch, stir and gelatinize for 20 minutes in a water bath at 80°C, and the starch paste becomes translucent shape;

[0053] ⑵Preparation of sugar alcohol liquid: mix 14g erythritol and liquid maltitol, and fully stir and dissolve in an oil bath at 120°C to form sugar alcohol liquid;

[0054] (3) Sol: Slowly add low-acyl gellan gum into hot water, the quality of deionized water is 50 times that of gellan gum, stir and dissolve in a water bath at 80°C, and the dissolution time is 10 minutes;

[0055] (4) Add the starch paste obtained in step (1) to the sugar alcohol liquid ...

Embodiment 2

[0060] The required materials included: 14 g of oxidized starch, 0.6 g of low acyl gellan gum, 46 g of erythritol, 38 g of liquid maltitol, and 142 g of water.

[0061] Then, prepare the jellybean 3D printing material according to the following steps:

[0062] (1) Starch gelatinization: Mix 14g of potato oxidized starch and 24g of erythritol granules evenly, then add deionized water 8 times the amount of starch, stir and gelatinize for 20 minutes in a water bath at 80°C, and the starch paste becomes half Transparent;

[0063] ⑵Preparation of sugar alcohol liquid: mix 22g of erythritol and liquid maltitol, and fully stir and dissolve in an oil bath at 118°C to form a sugar alcohol liquid;

[0064] (3) Sol: Slowly add low-acyl gellan gum into hot water, the quality of deionized water is 50 times that of gellan gum, stir and dissolve in a water bath at 80°C, and the dissolution time is 10 minutes;

[0065] (4) Add the starch paste obtained in step (1) to the sugar alcohol liqui...

Embodiment 3

[0070] The sugar-free jelly candy prepared by the present invention has a good sugar retention effect. In this example, 10 g of lentinan is added on the basis of the original sugar-free jelly jelly printing material, and the embodiment is described in detail:

[0071] The required materials include: 16 g of oxidized starch, 0.4 g of low acyl gellan gum, 40.78 g of erythritol, 37.22 g of liquid maltitol, 10 g of lentinan, and 148 g of water.

[0072] Then, follow the steps below to prepare functional gel fondant printing materials suitable for 3D printing:

[0073] (1) Starch gelatinization: Mix 16g of potato oxidized starch and 24g of erythritol granules evenly, then add 8 times the amount of deionized water of the starch, stir and gelatinize for 20 minutes in a water bath at 80°C, and the starch paste becomes half Transparent;

[0074] ⑵Preparation of sugar alcohol liquid: mix 16.78g of erythritol and liquid maltitol, fully stir and dissolve in an oil bath at 118°C, and form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com