Patents

Literature

105results about How to "Flexible texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing nano-fibre bracket material with levorotation polylactic acid as base material

InactiveCN101401955AFlexible textureGood tissue compatibilityStentsPhysical treatmentPorosityTissue Compatibility

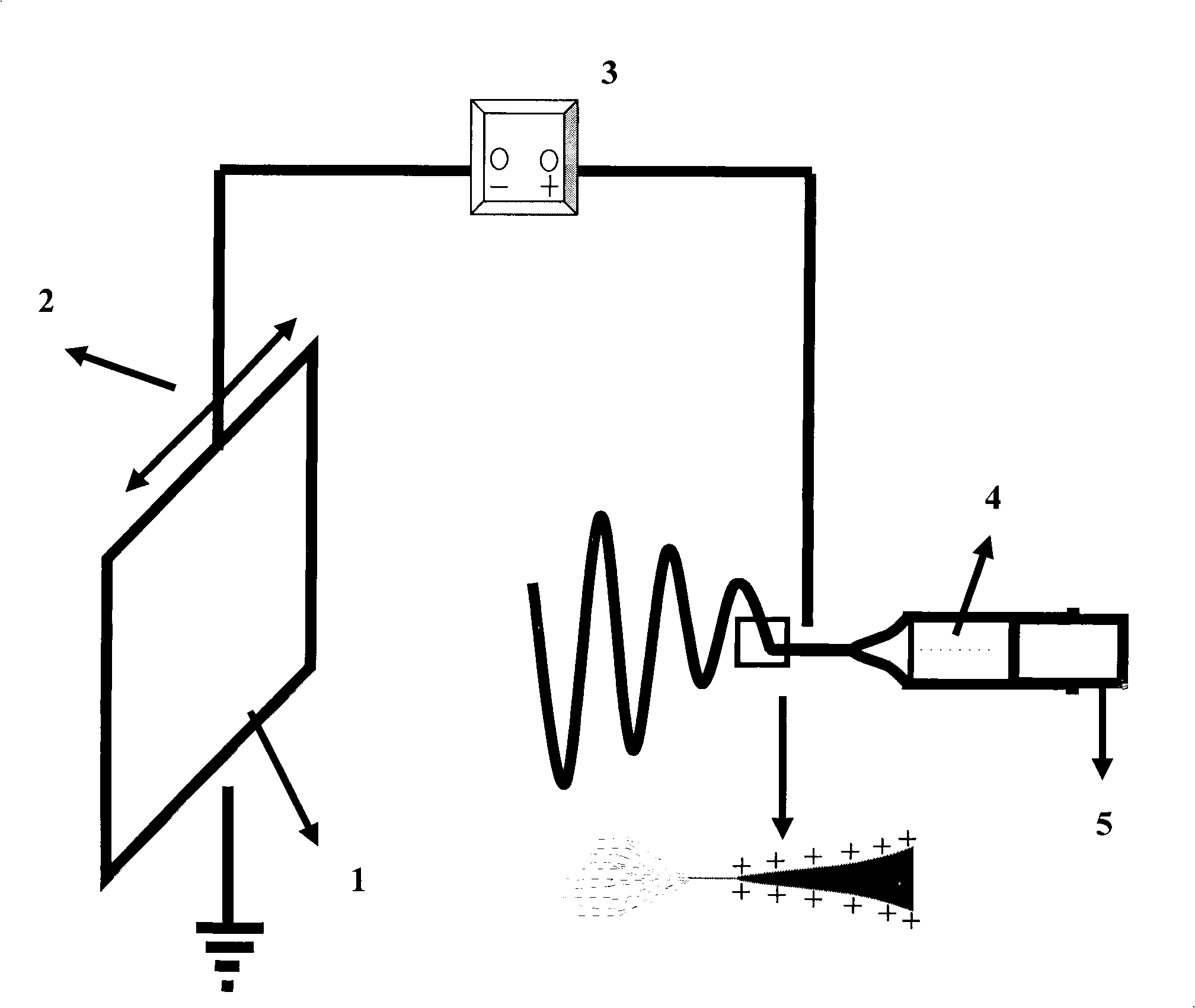

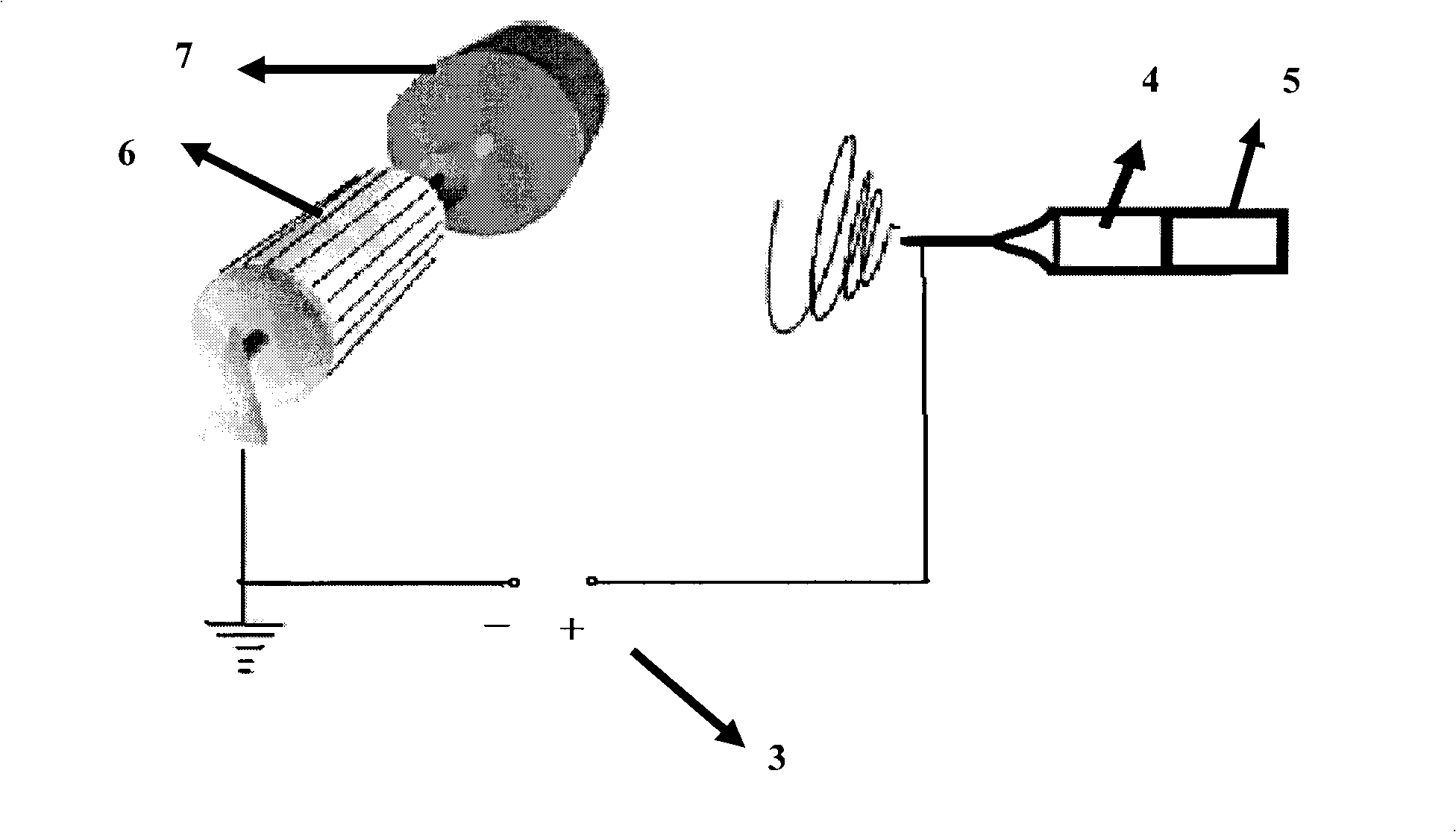

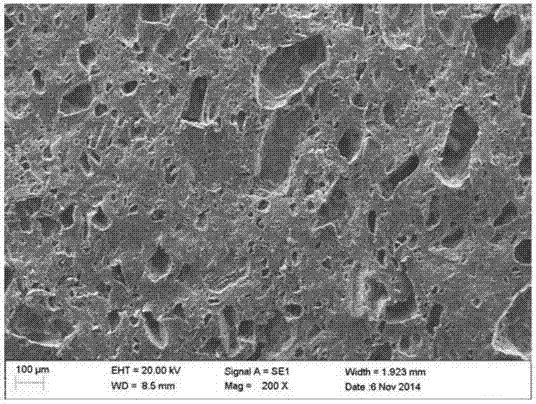

The invention relates to a method for preparing a nanofiber bracket material using levorotatory polylactic acid as matrix. The method comprises the following steps: dissolving the levorotatory polylactic acid as the matrix in a solution of dichloromethane and dimethyl formamide, and stirring and centrifuging the mixture to obtain an electrostatic spinning solution; placing a polylactic acid solution into a 5 milliliter glass syringe, and applying high voltage on the glass syringe; advancing the levorotatory polylactic acid solution in the glass syringe; preparing the mixed solution into a nanofiber material film through a electrostatic spinning technology; and modifying the nanofiber material film to obtain the nanofiber bracket material of which the fiber diameter is between 50 and 500 nanometers and the fiber porosity is more than 90 percent. The method solves the defects that a PLLA porous bracket still has too long degradation time, and degradation products can cause tissue inflammations easily and the like. The method has the advantages of flexible texture, better water permeability and air permeability, excellent tissue compatibility, controllable biodegradability, and no antigenicity.

Owner:THE AFFILIATED DRUM TOWER HOSPITAL MEDICAL SCHOOL OF NANJING UNIV

Biophysical method for removing endopleura of walnut

InactiveCN102972850AEasy to operateMild treatment conditionsFood preservationHuskingPectinaseWalnut Nut

The invention provides a biophysical method for removing the endopleura of a walnut. The walnut with the shell is soaked by tap water for 12 to 24 hours, the shell is removed, the kernel is taken out, pectinase with the activity being 30000 IU is dissolved into disodium hydrogen phosphate-citric acid buffer liquid with the pH being 3.2 to 3.8, and 3 percent to 5 percent of pectic enzyme liquid is prepared and is heated to 50 DEG C. The soaked walnut kernel is soaked in the pectic enzyme liquid and is placed into an ultrasonic generator with the power being 250W and the work frequency being 40KHZ, the enzymolysis and the ultrasonic treatment are carried out for 2.5 to 5 hours at the constant temperature being 50 DEG C, the walnut kernel is fished out and is sprayed and flushed by flowing water with the pressure being 7 to 10 MPa until the endopleura is completely removed, the walnut kernel with the advantages that the color and the luster are opacified, the kernel fruit is complete, the texture is flexible, the mouth feeling and the flavor are pure and sweet as those of the fresh walnut kernel can be obtained, and when the walnut kernel is in vacuum package and freezing storage, a fresh walnut kernel storage method is obtained. The biophysical method adopts the advanced biological enzyme technology to be combined with the ultrasonic physical technology and has the obvious characteristics that the operation is simple, the processing condition is mild, no chemical pollution exists, the kernel and the nutrition are kept complete, and the sensory quality is good.

Owner:BEIJING UNION UNIVERSITY

Medicine carrying method of medical sponge

InactiveCN102078639ASubsequent processing is simpleEasy to industrializeAbsorbent padsBandagesCross-linkControlled release

The invention discloses a medicine carrying method of a medical sponge. In the method, a macromolecular compound with a medicine slow release or controlled release effect is used as a carrier for coating a medical compound with a therapeutic function, the holes of the medical sponge are used for adsorbing a mixed solution carrying medicines and the carrier, and simultaneously, a compound with a physical or chemical cross-linking effect on the carrier macromolecular compound is added to be dried and sterilized to obtain a medicine carrying medical sponge. The medicine carrying medical sponge prepared by the method can be cut into a proper size according to the size of an operation cavity to be put into a corresponding position, so that the ambient pressure is balanced, and the damage to the mucous membrane of the operation cavity is small. The medicine carrying medical sponge prepared by the method disclosed by the invention has good biocompatibility and adhesivity, has an active function of promoting wound healing, has a hemostatic effect and a better medicine slow release effect, can be combined with partial antibacterial medicines for treating infection, can relieve the pain and discomfort of a patient, can be possibly used for replacing imported products, and has obvious social and economic benefits.

Owner:许高琴 +1

Dry rice noodle and manufacturing method thereof

InactiveCN104187389AWhite and bright appearanceFlexible textureFood shapingFood preparationDying processesEngineering

The invention discloses a manufacturing method of dry rice powder. The method comprises the steps as follows: rice selection, soaking, milk grinding, filter pressing, smashing, accessory adding, rice dough kneading, pressing, threading, aging, loosing and dying processes. Compared with the prior art, the method is characterized by further comprising the milk grinding, stock screening, dewatering, filter pressing and smashing steps. According to the method, after dewatering, an accessory is added, so that compared with conventional dry rice powder, the manufactured dry rice powder is white and bright in surface, flexible in texture, not prone to be burnt by poaching and uneasy to break by dry cooking; and compared with fresh wet rice powder, the dry rice powder is smooth in texture, fragrant, flavorful and good in taste.

Owner:GUILIN QUANZHOU MILANXIANG FOOD

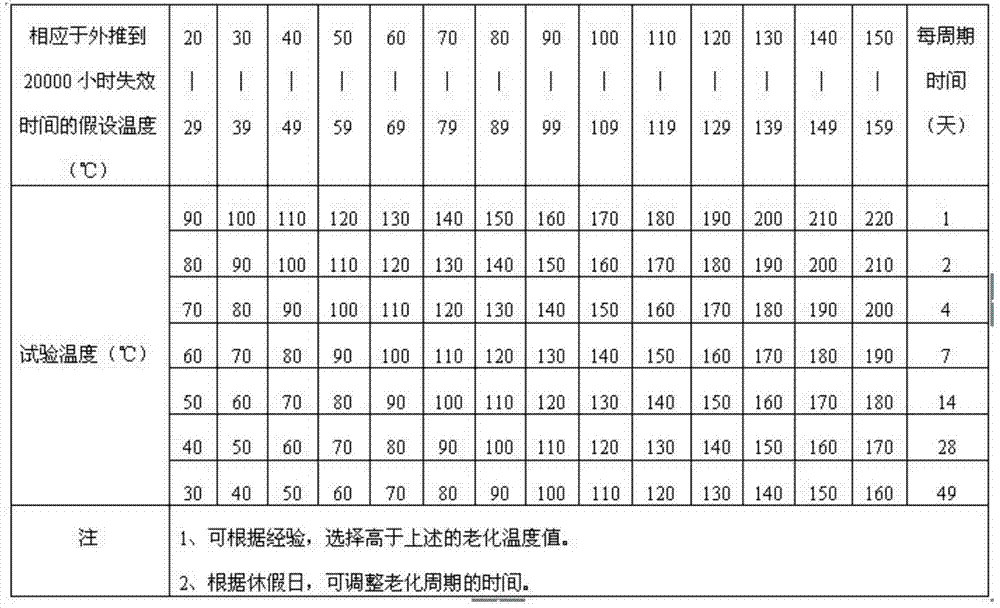

High-temperature-resistant silicone rubber foam material and preparation method thereof

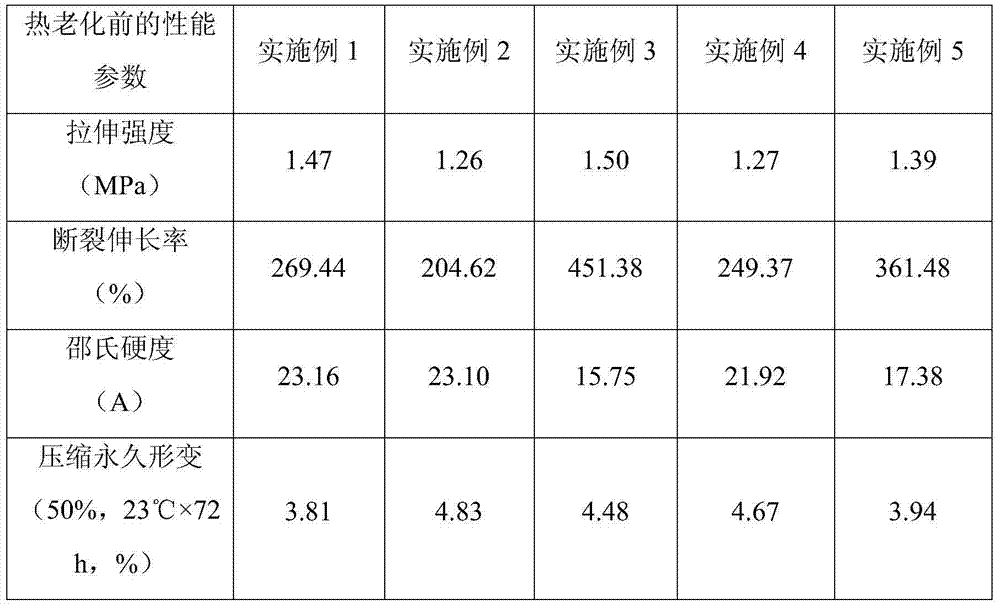

The invention discloses a high-temperature-resistant silicone rubber foam material and a preparation method thereof. The preparation method of the high-temperature-resistant silicone rubber foam material is characterized by comprising the following steps: mixing 100 parts of silicone rubber base stock, 20-35 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 0-0.2 part of colour master batch, 60-150 parts of a pore-forming agent and 4-5 parts of a radiation sensitizer, moulding, crosslinking through gamma ray radiation, forming pores through subsection dissolving-out, and drying, so that the silicone rubber foam material which is resistant to high temperature of 250 DEG C and still maintains excellent performance after equivalent time of 20000 hours can be obtained. The preparation method of the high-temperature-resistant silicone rubber foam material has the advantages that radiation crosslinking and dissolving-out pore forming are combined, so that crosslinking is uniform, control is easy, energy conservation and environmental protection are realized, a technology is concise, reproducibility is good, and production efficiency is high; the high-temperature-resistant silicone rubber foam material still maintains high tensile strength, high weight loss, low longitudinal deformation and low surface hardness after the equivalent time of 20000 hours at the temperature of 250 DEG C, permanent compressive deformation is slightly increased, the high-temperature-resistant silicone rubber foam material does not become brittle or hard, and the high-temperature-resistant silicone rubber foam material can serve as filling and positioning, sealing cushion, cable insulation as well as buffer and vibration-absorptive materials or parts which are used in high-temperature environment.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Manufacturing method for ultra-high molecular weight polyethylene staple fiber yarn and viscose blended tooling fabric

The invention discloses a manufacturing method for an ultra-high molecular weight polyethylene staple fiber yarn and viscose blended tooling fabric. The high-level tooling fabric adopts yarn formed by blending ultra-high molecular weight polyethylene staple fiber and viscose as raw materials and manufactured through a weaving production method. The method comprises the specific steps that warp and weft form piled yarn through plying and doubling of the ultra-high molecular weight polyethylene staple fiber yarn and viscose blended yarn, a warp beam is manufactured through sectional warping, the ultra-high molecular weight polyethylene staple fiber yarn and viscose blended tooling fabric is produced on a gripper loom, and a finished product is obtained through dyeing treatment after off-machine finishing. According to the method, the technological process is simple, the production efficiency is high, the product quality is stable, the warp tensile strength of the fabric reaches more than 1500 N, the weft tensile strength reaches more than 1000 N, the warp and weft tearing strength is larger than 60 N, the air permeability reaches more than 80 mm / s, the moisture permeability reaches 180 g / m<2>.h, and various color fastnesses reach more than 4 grades.

Owner:IANGSU COLLEGE OF ENG & TECH

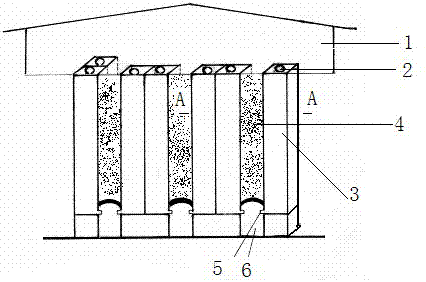

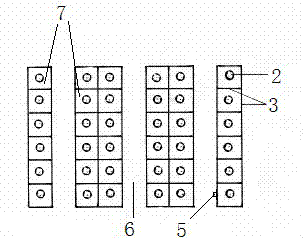

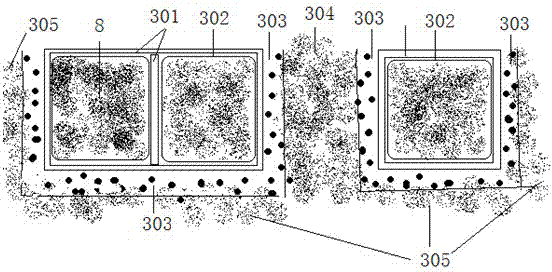

Underground bionic honeycomb granary

ActiveCN102287068AAdvanced ideasReasonable and unique structureAgricultural buildingsClimate change adaptationBrickAgricultural engineering

The invention belongs to the technical field of grain storage, and in particular relates to an underground bionic honeycomb granary and a grain storage method. The granary is designed through the reference and absorption of the original ecological honeycomb structure principle and comprises a granary body positioned below the ground surface, wherein the granary body consists of a plurality of rows of honeycomb silos among which gaps are formed in the transverse direction; each row of honeycomb silo comprises a plurality of silos which are tightly arranged along the longitudinal direction in turn; a silo upper opening is formed at the upper end of each silo and is provided with a closed cover; each silo comprises a reinforced concrete layer or a brick-concrete masonry layer; a polyethylenefilm layer is arranged in each silo; a spodosol layer is backfilled in an outer wall gap of each silo; and soil or sandstone or a soil and sandstone mixed material is backfilled among the spodosol layers. Grain is stored in the polyethylene film layers and isolated from outside, so that four ecological factors such as moisture, temperature, oxygen and light rays which can cause the deterioration of the stored grain are inhibited from the source, the stored grain is free from insects, mildew, rat damage, fires, floods and earthquakes, and the shelf life of the stored grain is prolonged by morethan one time.

Owner:蔡天印

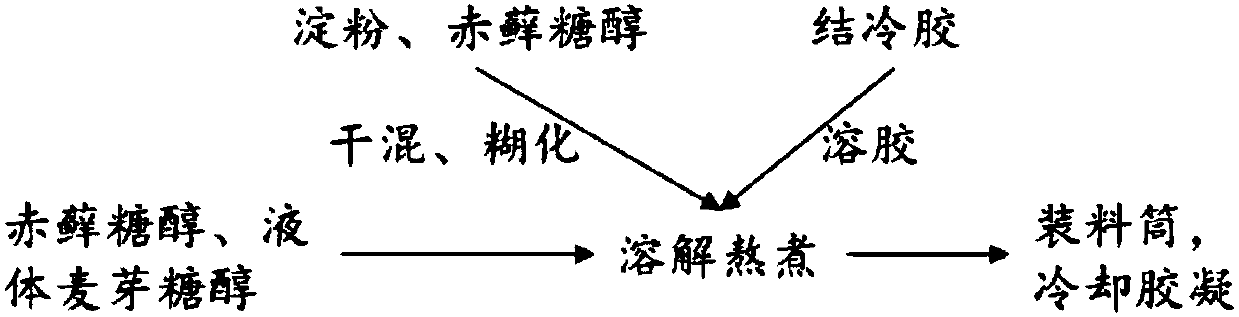

3D printing material for gelatinized confections and preparation method of 3D printing material

InactiveCN107668306AFlexible textureThe group ratio is reasonableConfectioneryFood preservationGellan gumRoom temperature

The invention relates to the technical field of food, in particular to a 3D printing material for gelatinized confections and a preparation method of the 3D printing material. Starch and low-acyl gellan gum in the 3D printing material are taken as gel, remelting is facilitated, rapid gelling at room temperature can be realized, smooth discharge can be guaranteed during 3D printing, stability of the printing material can be improved with application of plant extract, so that the printed confections can be stored for a long time, and sugar crystals are avoided. Experiments prove that the 3D printing material can be printed successfully, sensory evaluation of the obtained products is good, and sugar crystals or sugar dissolution does not occur when the products are placed at room temperaturefor 60 d.

Owner:INFINITUS (CHINA) CO LTD

Processing method of preserved Haihong fruit

The invention discloses a processing method of preserved Haihong fruit. The processing method comprises the following steps of: after cleaning and denucleating Haihong fruit, soaking the Haihong fruit in an aqueous solution of a hardening and color-protecting agent at 50 DEG C for heat preservation and digestion; then putting the Haihong fruit in boiling water for blanching, washing by using clear water and draining; putting the drained Haihong fruit into saccharifying liquid for saccharifying, and after the saccharifying is completed, soaking the Haihong fruit in the saccharifying liquid; fishing out the soaked Haihong fruit, draining, and microwave vacuum drying. The preserved Haihong fruit prepared by the processing method is full in shape, bright red and lucent in color and luster, flexible in texture, rich in fruity flavor and low in browning degree, and does not contain sulfur residue or cause harm to the human health. The processing method is easy and feasible in processing flow, and can be used for inhibiting the Maillard non-enzymatic reaction of the Haihong fruit by adopting the microwave vacuum drying, greatly reducing the drying time, shortening the production cycle, reducing the energy consumption in production, and improving the appearance and the taste of the preserved fruit, and can be applied to the development of Haihong fruit resources.

Owner:西安春和方进出口贸易有限公司

Preparation method of ultra-strong flame-retardant special protective garment fabric

The invention discloses a preparation method of an ultra-strong flame-retardant special protective garment fabric. The ultra-strong flame-retardant special protective garment fabric is prepared from yarns, which are formed by blending ultra-high molecular weight polyethylene short fibers and flame-retardant polyester fibers and is taken as a raw material, by virtue of a weaving production method. The preparation method comprises the following steps: combining wefts and warps, which adopt blended yarns of ultra-high molecular weight polyethylene short fibers and flame-retardant polyester fibers, into strands and twisting the strands into plied yarns; then performing sectional warping to obtain a live axle so as to produce an ultra-strong flame-retardant special protective garment fabric blank on a gripper loom; discharging and performing fabric finishing; and then performing dyeing treatment, thereby obtaining a finished product. The prepared ultra-strong flame-retardant special protective garment fabric is capable of giving full play to the unique excellent performance of the ultra-high molecular weight polyethylene fibers; if the stab-resistant anti-cutting performance of the ultra-strong flame-retardant special protective garment fabric is required to be enhanced, the use amount of the ultra-high molecular weight polyethylene short fibers in the blended yarns can be increased.

Owner:黑龙江省锟龙泽医药有限公司

Sea tangle vermicelli and method of producing the same

The invention relates to sea kelp vermicelli and a processing method thereof. The sea kelp vermicelli is processed by washing sea kelp, soaking, heating together with table salt, water and soda until pasty, cooking, pulping and milling; weighing a certain amount of thickening starch, mixing with warm water and sea kelp slurry, stirring thoroughly, adding boiling water 7-8 times the weight of starch, and quickly stirring for gelatinization to obtain a paste; adding starch into the paste, repeatedly kneading to make small dough; removing air bubbles from the small dough; molding in a vermicelli-making machine; gelatinating in boiling water; cooling by spraying with tap water and then soaking in cold water; cutting, placing on a rack, curing in a high-humidity dark place indoor, and freezing step by step; defrosting, loosening and drying until the water content is in the range from 10% to 15%. The sea kelp vermicelli retains the nutrients of starch and sea kelp; has no odor or astringent taste; is jade green in color, transparent and lustrous; has good taste; and is chewy after cooking. The processing method has the advantages of reasonable process, easy operation and adaptability to large-scale production.

Owner:山东俚岛海洋科技股份有限公司

Manufacturing method of tea-fragrance lotus seed nutritional rice noodles

InactiveCN107397131AThe process steps are simpleShorten the production cycleFood shapingFlavorAdditive ingredient

The invention belongs to the technical field of food processing, and more specifically relates to a manufacturing method of tea-fragrance lotus seed nutritional rice noodles. The manufacturing method comprises following steps: lotus seed powder preparation, rice selection and immersion, pulping, adding of tea powder, pulp steaming and drying, standing and cooling, noodle cutting, and packaging and warehousing. According to the manufacturing method, green tea powder, containing nutritients such as tea polyphenols, catechin, chlorophyll, caffeine, amino acids, and vitamins, is taken as a raw material to be added into rice noodles, so that the nutritional value of rice noodles is increased, the obtained rice noodles contains the nutrients and functional ingredients of tea, and rice noodle flavor is improved; the manufacturing method is capable of increasing the nutritional value of rice noodles, improving the mouthfeel; the obtained rice noodles are pliable, tough, and chewy in texture, burnt is not caused by boiling with water, fracture is not easily caused by dried frying, tea flavor is achieved, nutrients are abundant, the tea-fragrance lotus seed nutritional rice noodles can be digested conveniently, and possess excellent health care effect.

Owner:广西南宁市百桂食品有限责任公司

Grinded dry rice noodles and preparing method thereof

The invention discloses a method for preparing grinded dry rice noodles comprises the following steps: selecting rice; soaking; crushing; adding auxiliary materials; kneading into flour dough; steaming; pressing and extruding noodles; and airing. the method is characterized by also comprising the steps of grinding, screening and dehydrating. Since the steps of grinding, screening the stock and dehydrating are added in the method, compared with the traditional dry rice noodles, the dry rice noodles prepared by the method have white and bright appearance, tough texture, do not become thick paste when boiled with water or are not broken easily when fried drily; and compared with the fresh rice, the grinded dry rice noodles have smooth texture, strong rice flavor and good taste.

Owner:GUILIN QUANZHOU MILANXIANG FOOD

Preparation method for environment-friendly plasterboard

The invention discloses a preparation method for an environment-friendly plasterboard, belonging to the technical field of plasterboards. The preparation method comprises the following steps: (1) preparation of gypsum having undergone oxidative desulfurization; (2) preparation of modified fiber reinforced particles; (3) preparation of a base material; (4) preparation of mixed slurry; (5) preparation of a semi-finished product; and (6) preparation of the finished plasterboard. The preparation method provided by invention is convenient to operate and low in cost; and the prepared plasterboard has good water resistance, low water absorption rate and high strength and is not prone to coming off.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

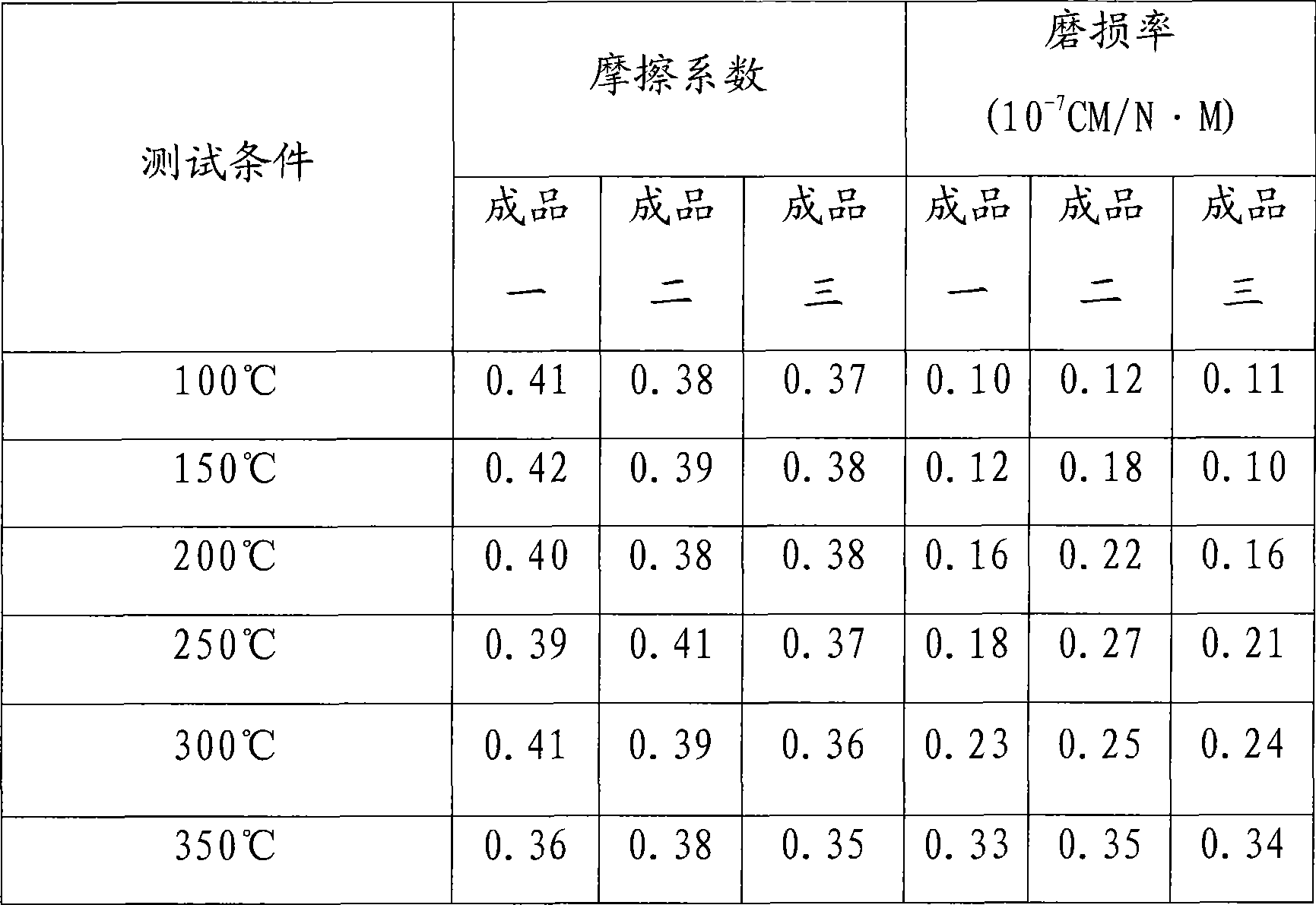

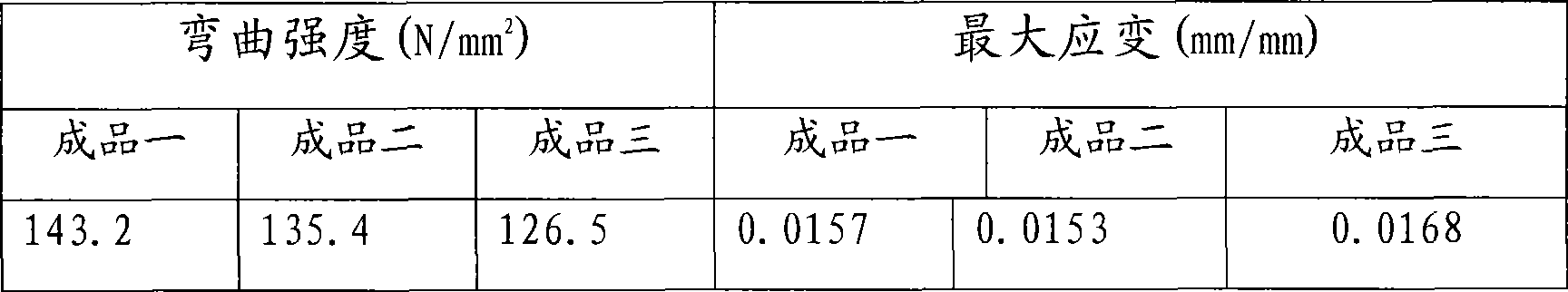

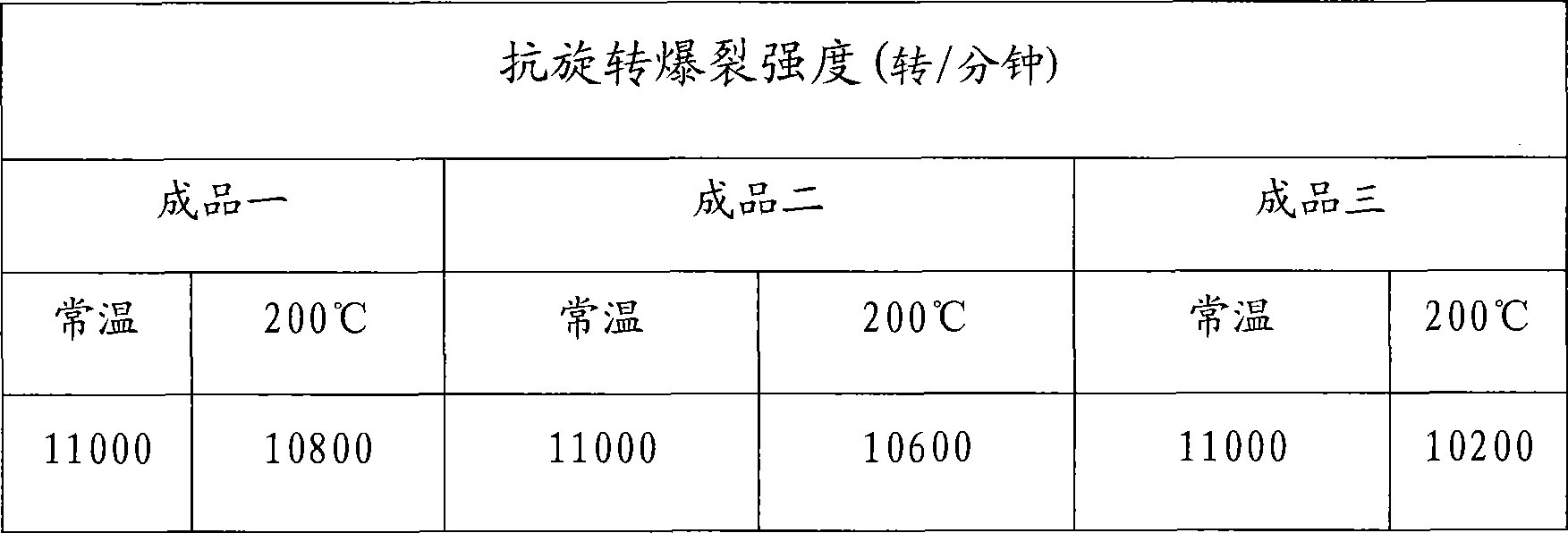

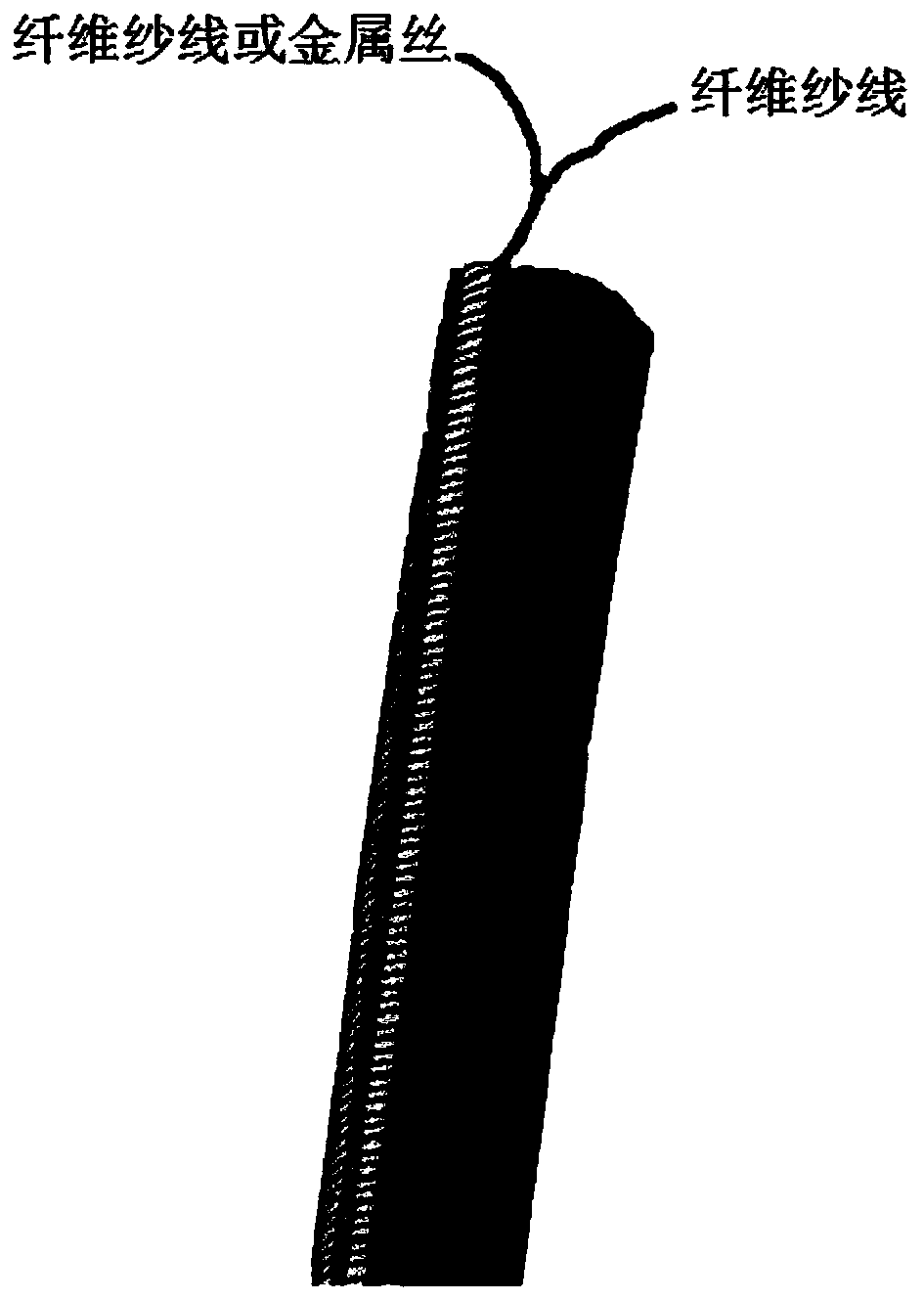

Clutch face sheet for cars

InactiveCN101429976AFlexible textureImprove impregnation effectFriction clutchesFriction liningAcrylonitrileEngineering

The invention relates to a method for producing automobile clutch facing patches. The particular technological steps of the method comprise the following: weaving natural vegetable fiber and metal wires into twill fabrics, and mixing and stirring hot setting cashew nut shell oil flaky resin, butadiene-acrylonitrile rubber modified water soluble phenol liquid resin, NBR latex, filling materials and water into slurry, and the like. Compared to the prior art, the method has the following advantages: firstly, the method has the characteristic of environmental protection; secondly, the method has low cost; thirdly, the method overcomes the defects of low high-temperature resistance of the prior process products; and finally, the products produced by the method has obvious performance advantage, namely good high-temperature resistant performance and high strength on rotation bursting resistance.

Owner:ZHEJIANG DUALRAY FRICTION MATERIAL

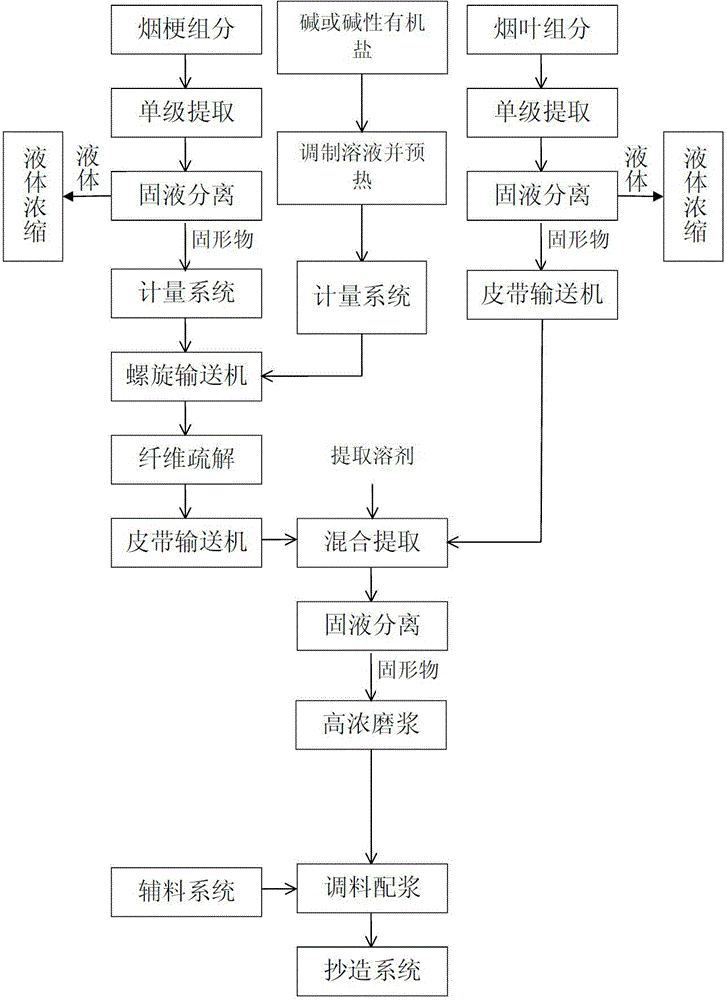

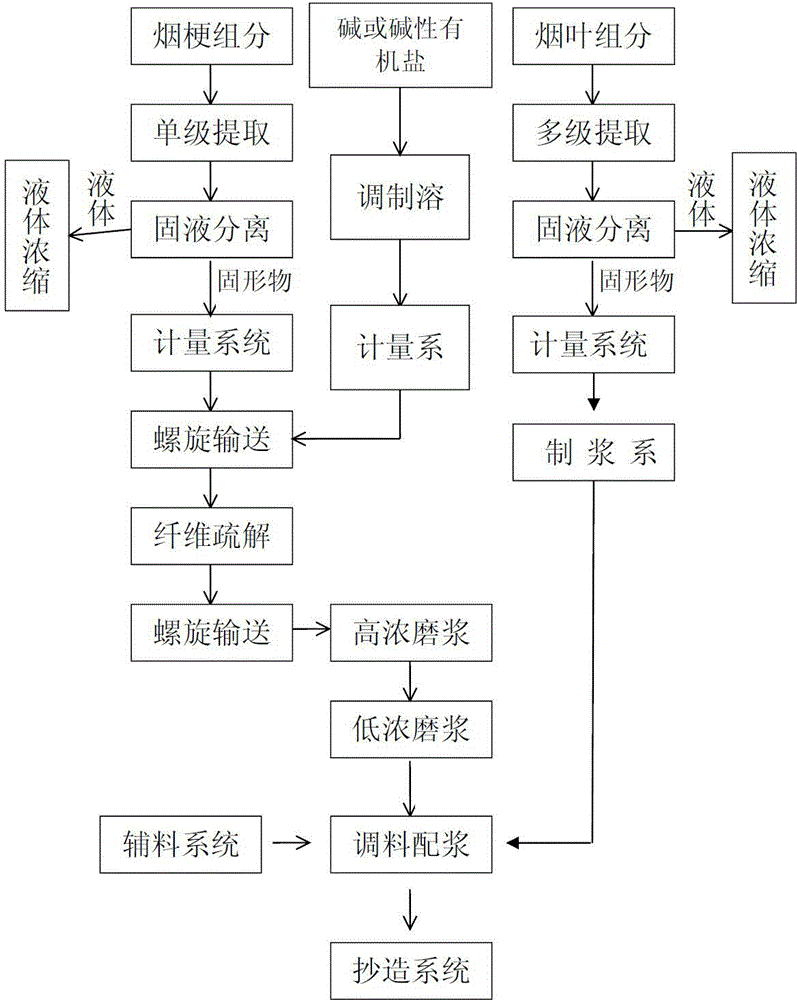

Tobacco stem modified processing method for paper-making process reconstituted tobaccos

InactiveCN104886755AReduce utilizationImprove qualityTobacco preparationEnvironmental chemistrySolid matter

The invention relates to a tobacco stem modified processing method for paper-making process reconstituted tobaccos. The method includes the steps that soft chemical modified processing is firstly carried out on solid matter parts obtained after extraction processing on tobacco stems with alkali or alkaline organic salt, and then modified solid matter parts obtained after solid-liquid separation are used for manufacturing the reconstituted tobaccos; and soft chemical modified processing is characterized in that the alkali or the alkaline organic salt which is 0.2%-5.0% of the solid matter oven dry weight is mixed into a solution with the mass ratio concentration being 10%-12%, preheating is carried out until the temperature ranges from 30 DEG C to 70 DEG C, and the solution is added into solid matter. By means of the tobacco stem modified processing method, the quality of tobacco stem components can be improved and enhanced, the using value of tobacco stem raw materials is improved, and the production cost of the reconstituted tobaccos is reduced.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Preparation method of fireproof, heat-resistant and light-weight partition plate

The invention discloses a preparation method of a fireproof, heat-resistant and light-weight partition plate, and relates to the technical field of partition plates. The preparation method comprises the following steps: (1) preparing a fiber enhancer; (2) preparing modified expansible graphite; (3) preparing a flame-retardant covering agent; (4) preparing a matrix; and (5) preparing a finished product. The fireproof, heat-resistant and light-weight partition plate is excellent in fireproofing and heat resisting performance and high in stability, difficult to deform under heat, and safe and convenient to use.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

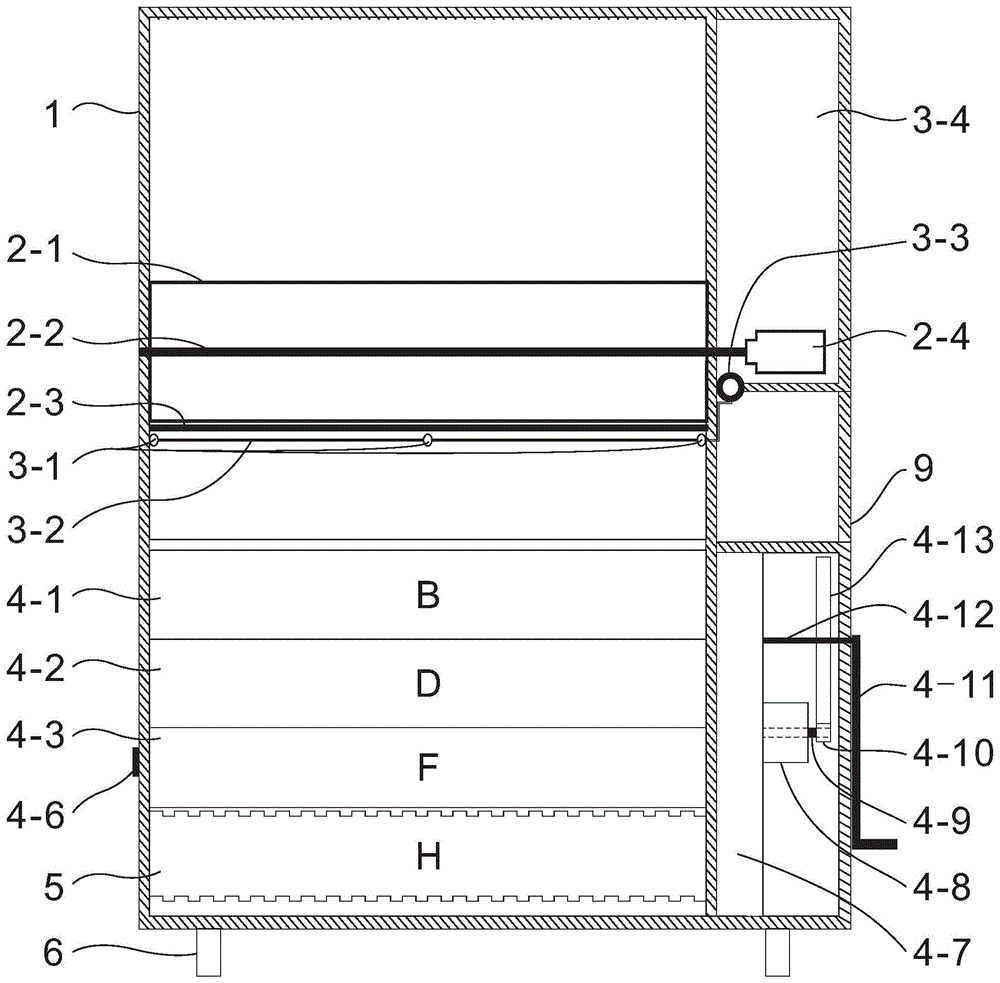

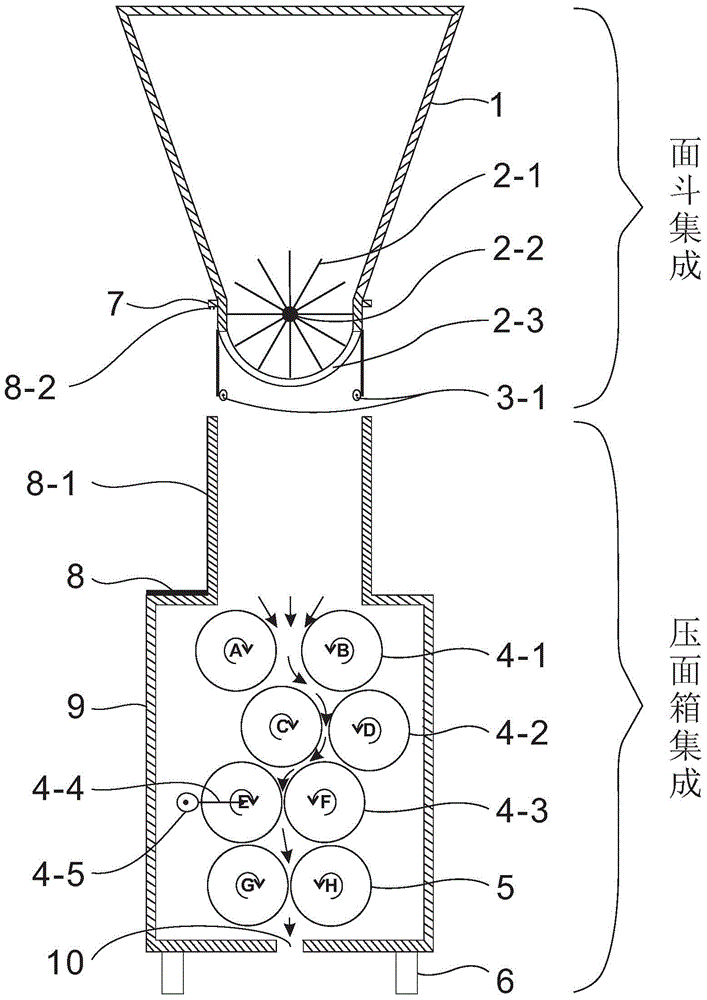

Instant automatic noodle making machine

InactiveCN104543766AOvercome defectsOvercome deficienciesMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsEngineeringMechanical engineering

The invention relates to an instant automatic noodle making machine. The instant automatic noodle making machine mainly comprises a control device, a flour grain forming device, a water atomization device, and a flour grain, wrapper pressing and noodle slitting device. The working mode of the instant automatic noodle making machine is as follows: flour is dispersed to form fine grains by the flour grain forming device, the fine grains are contacted and mixed with atomized water to form wet grains, then the grain is pressed into the wrapper by the flour grain and wrapper pressing device and then the wrapper is slit into noodles by the slitting device.

Owner:王勇

Thermal mortar and preparation method thereof

InactiveCN108002775AEasy constructionNot easy to produce surface hollowingCeramicwarePortland cementCoal

The invention discloses thermal mortar and a preparation method thereof and relates to the technical field of thermal mortar. The thermal mortar comprises the following raw materials in parts: 65-75 parts of portland cement, 45-55 parts of modified coal ash, 40-45 parts of modified fiber reinforced particles, 25-35 parts of modified glass beads, 20-25 parts of glutinous rice glue, 15-20 parts of modified nanocarbon, 15-20 parts of an additive and 120-150 parts of water. The thermal mortar preserves heat, is toughened, has good workability, has low probability arousing such problems as surfacehollowing, cracking and falling, and is prolonged in service life.

Owner:明光市泰丰新材料有限公司

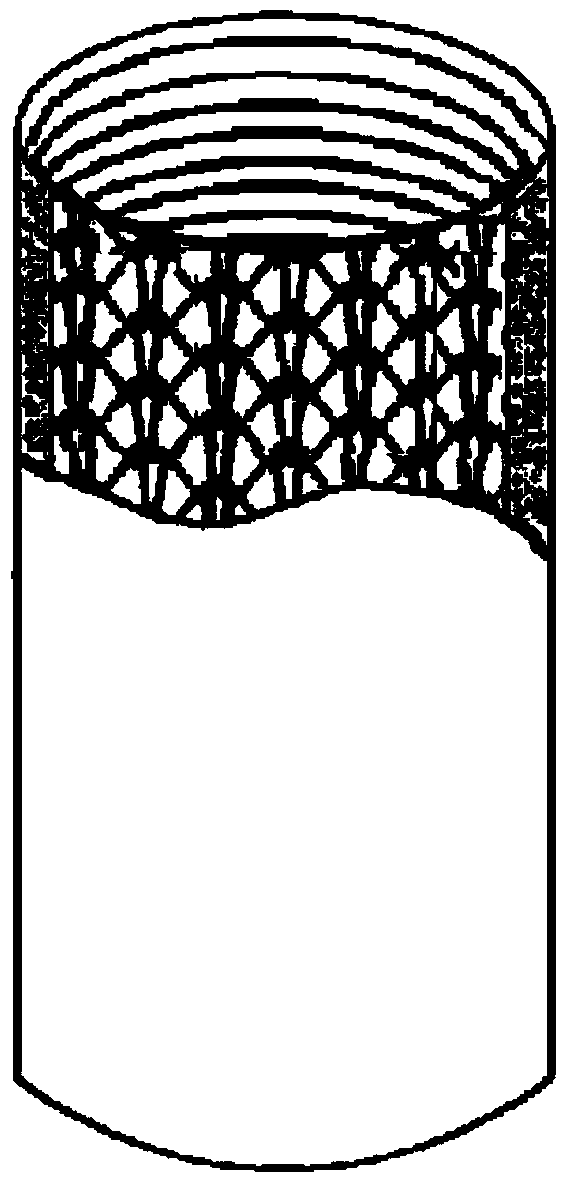

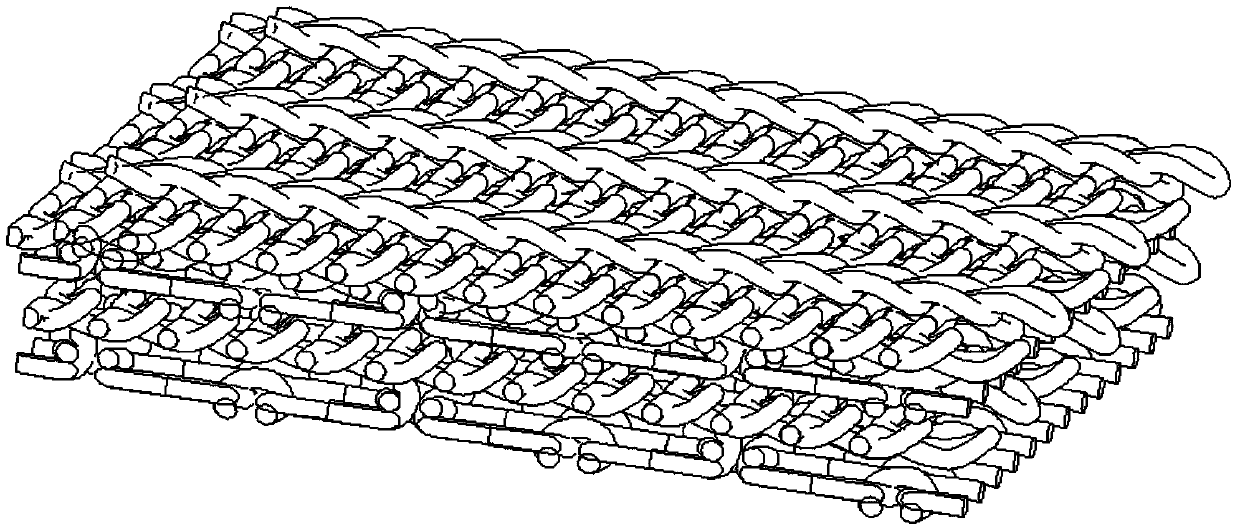

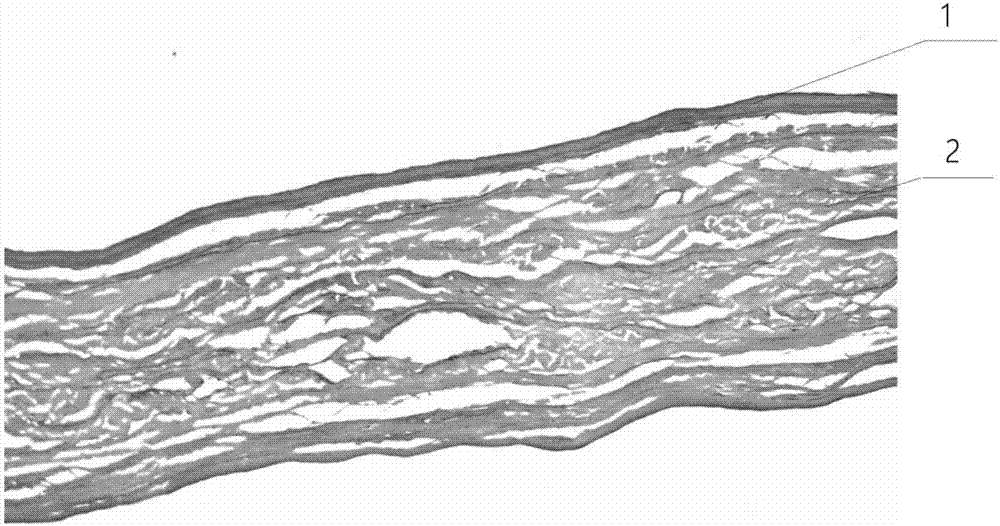

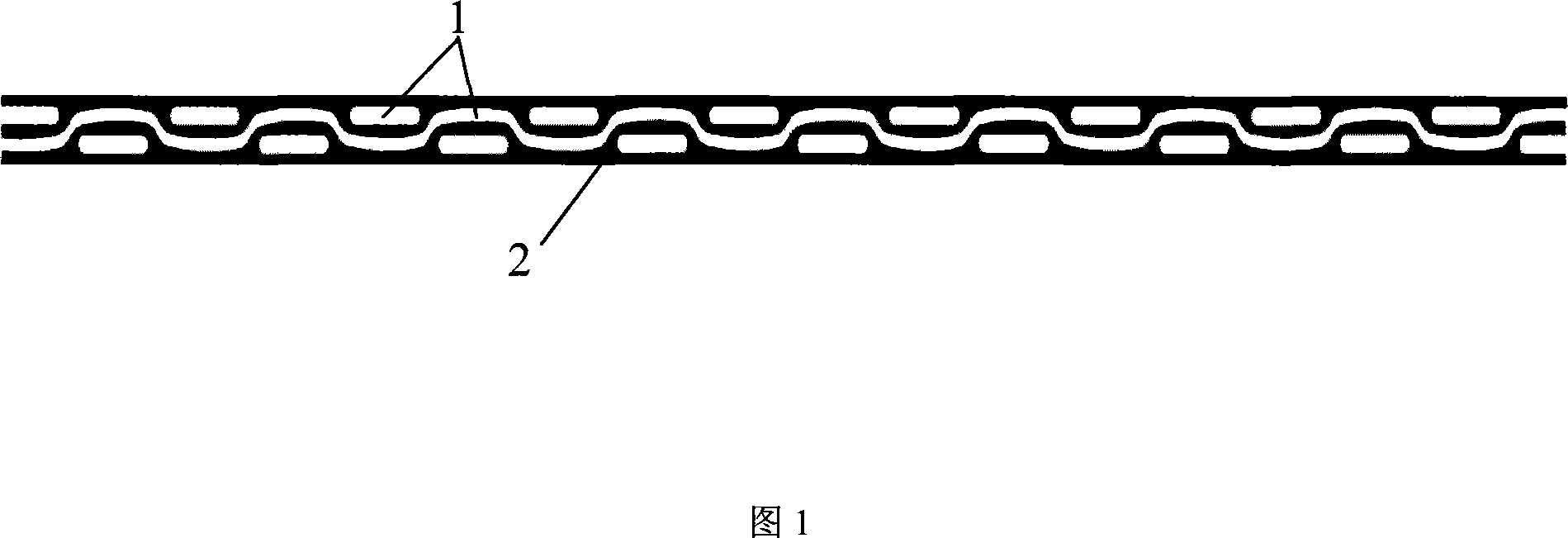

Composite material and flexible rubber hose

The invention discloses a composite material and a flexible rubber hose. The composite material comprises a lamellar flexibility main body layer, wherein the main body layer is internally provided with a skeleton; the skeleton is a weft-knitted fabric in a stereoscopic texture structure; the skeleton is arranged between the inner wall and the outer wall of the body of the flexible rubber hose; the skeleton is the weft-knitted fabric in a stereoscopic texture structure; through the setting of the weft-knitted fabric in the stereoscopic texture structure, the composite material (rubber hose) is integrally elastic and flexible.

Owner:CHANGSHU GUOGUANG MACHINERY

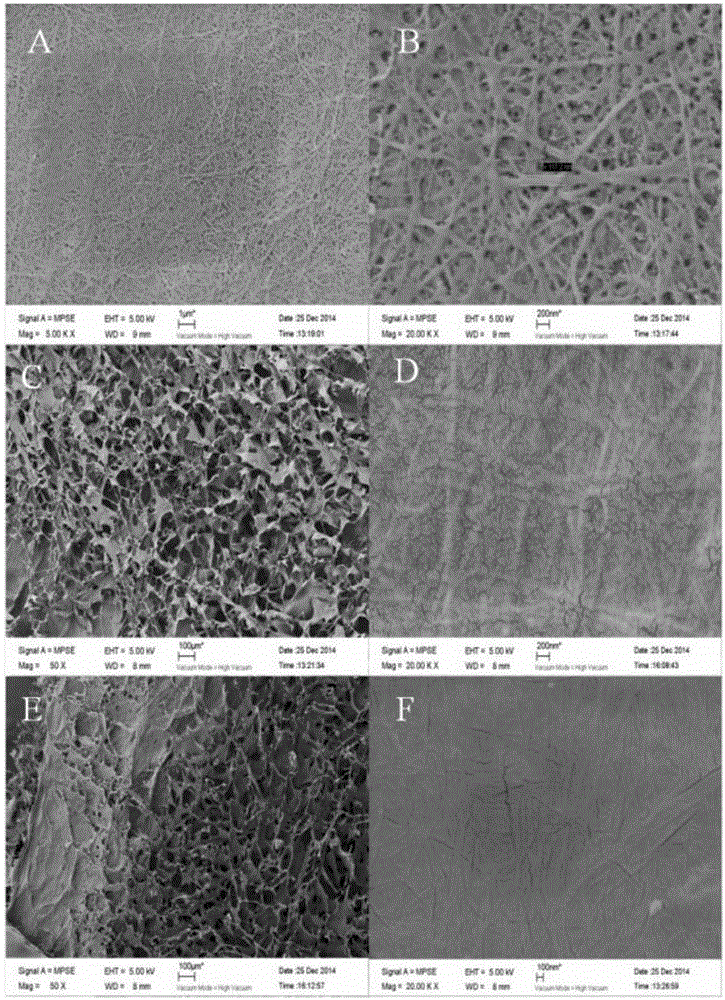

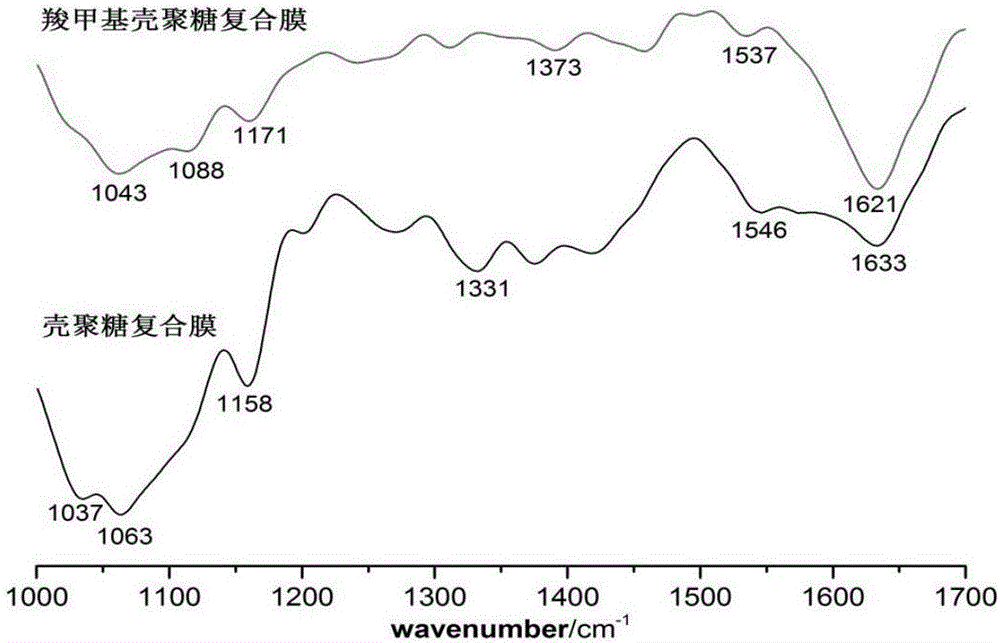

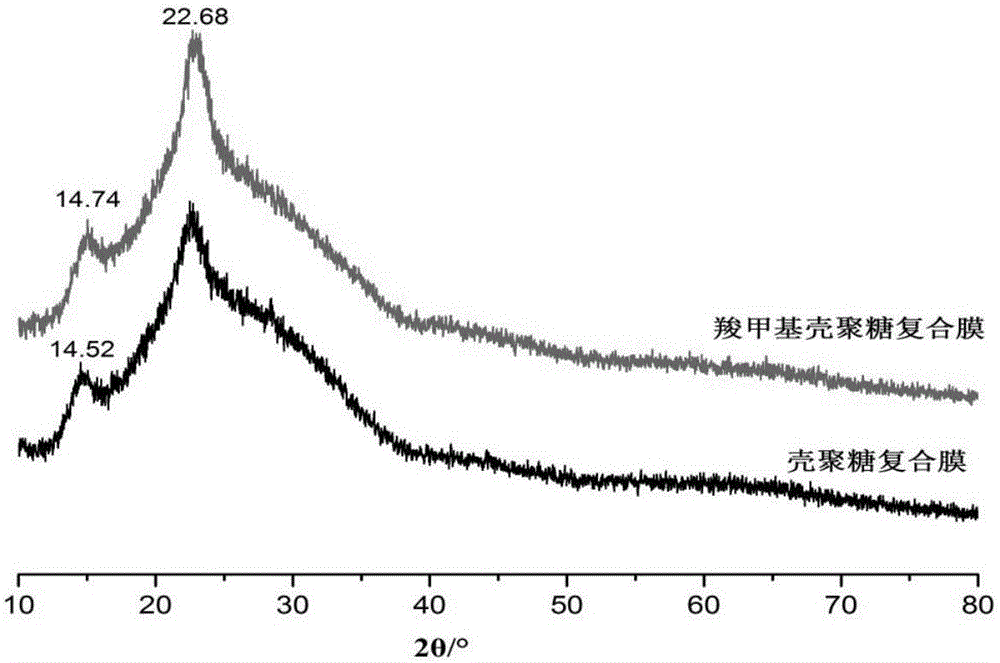

Preparation method of antibacterial composite bacterial cellulose membrane

The invention discloses a preparation method of an antibacterial composite bacterial cellulose membrane. The preparation method comprises the following steps: by adopting gluconacetobacter xylinus TJU-S8 as a starting strain, standing for culture to generate bacterial cellulose, and by adopting the bacterial cellulose as a material and combining with chitosan / carboxymethyl chitosan, preparing the composite bacterial cellulose membrane with an antibacterial property and compact fiber structure. The preparation method disclosed by the invention has the advantages that the defect of no antibacterial property of the bacterial cellulose is solved, a preparation process of an antibacterial composite membrane capable of inhibiting growth of escherichia coli and staphylococcus aureus is formed, the antibacterial activity of the bacterial cellulose composite membrane is improved, and a new path is provided for expanding the application field of bacterial cellulose. The antibacterial composite bacterial cellulose membrane obtained by the method is economic and environment-friendly, and is good in antibacterial effect.

Owner:TIANJIN UNIV

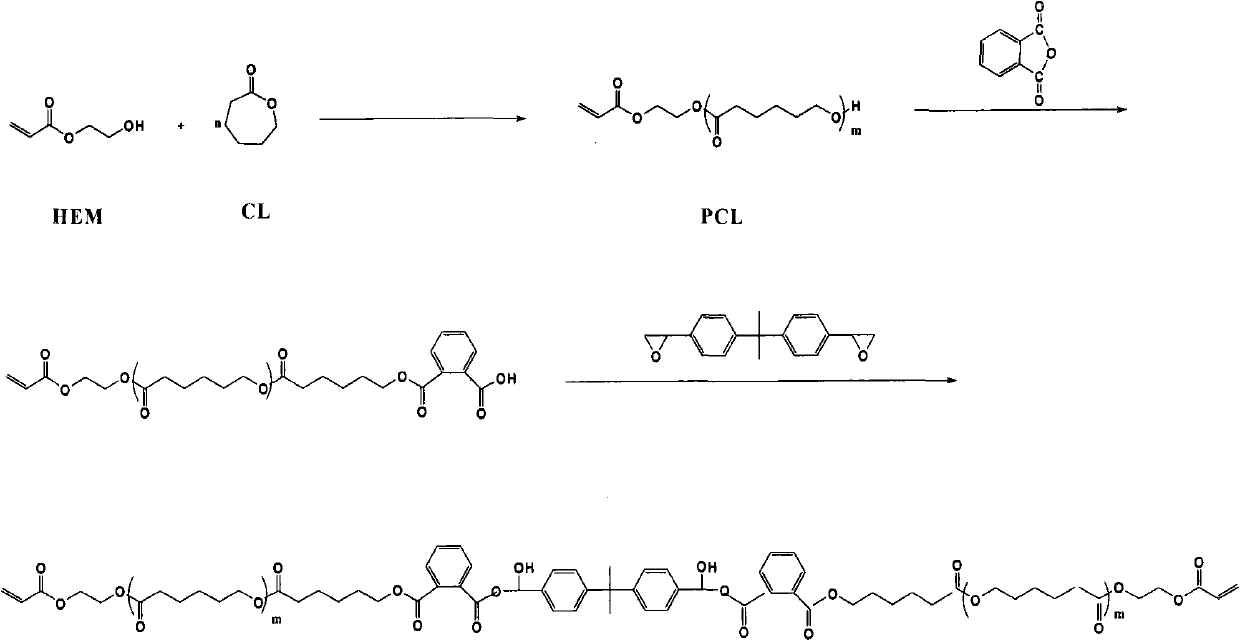

Coating composite and optical fiber containing same

ActiveCN101906268AFast curingImprove curing speedCladded optical fibreCoatingsCross-linkUltrasound attenuation

The invention provides a coating composite, which comprises poly(zeta-caprolactone) modified epoxy acrylate, activated monomer, a cross-linking agent, a photoinitiator, nanometer pigment and reasonable amount of auxiliary material. The invention also provides an optical fiber coated with the coating composite. The optical fiber colored by using the coating composite has pure and bright color and soft texture, is anti-bacteria and has small additional attenuation; and simultaneously, the coating composite can improve the coloring speed of the optical fiber.

Owner:HUNAN SOKAN NEW MATERIAL

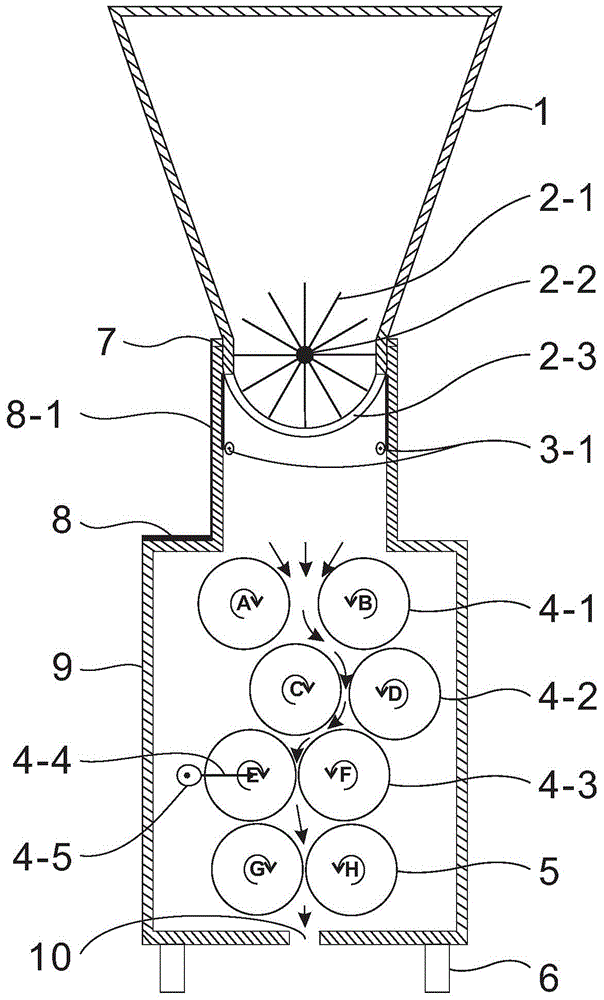

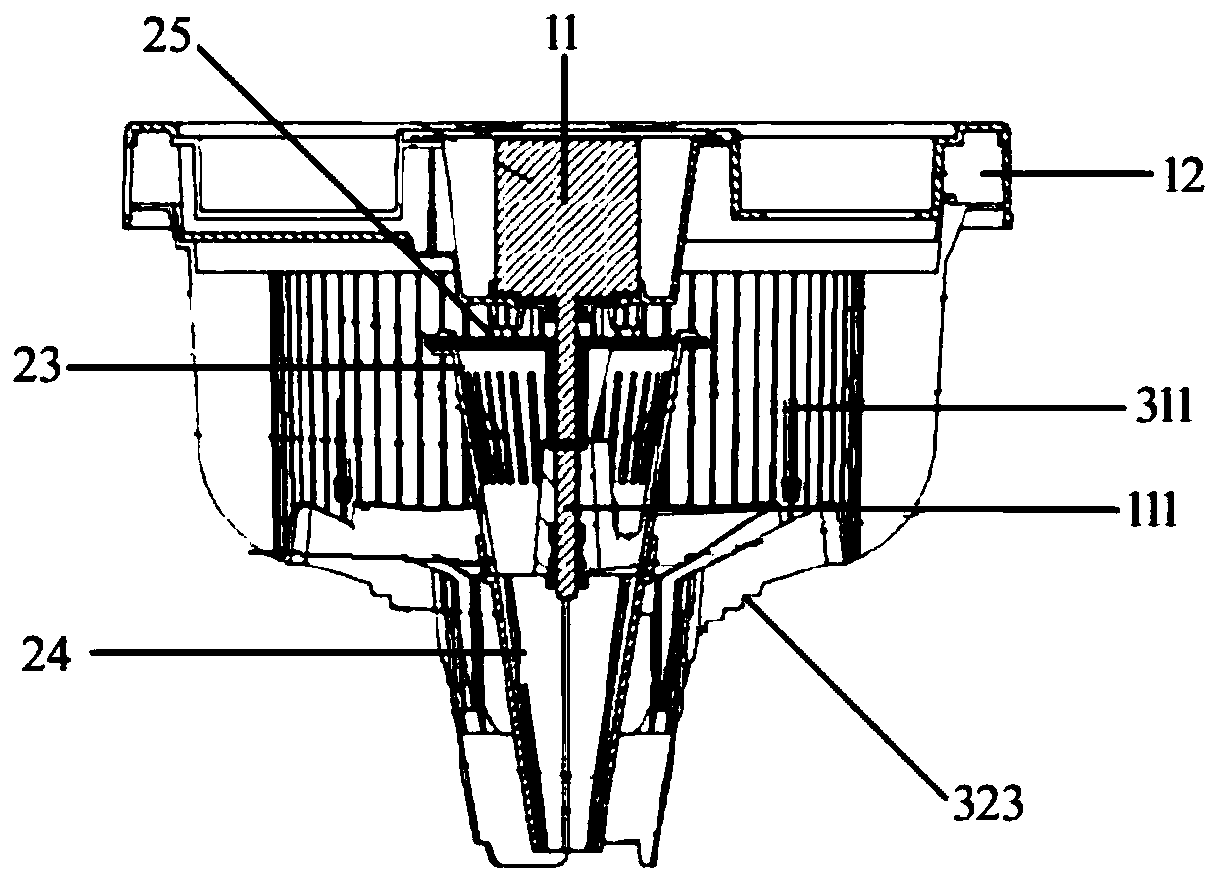

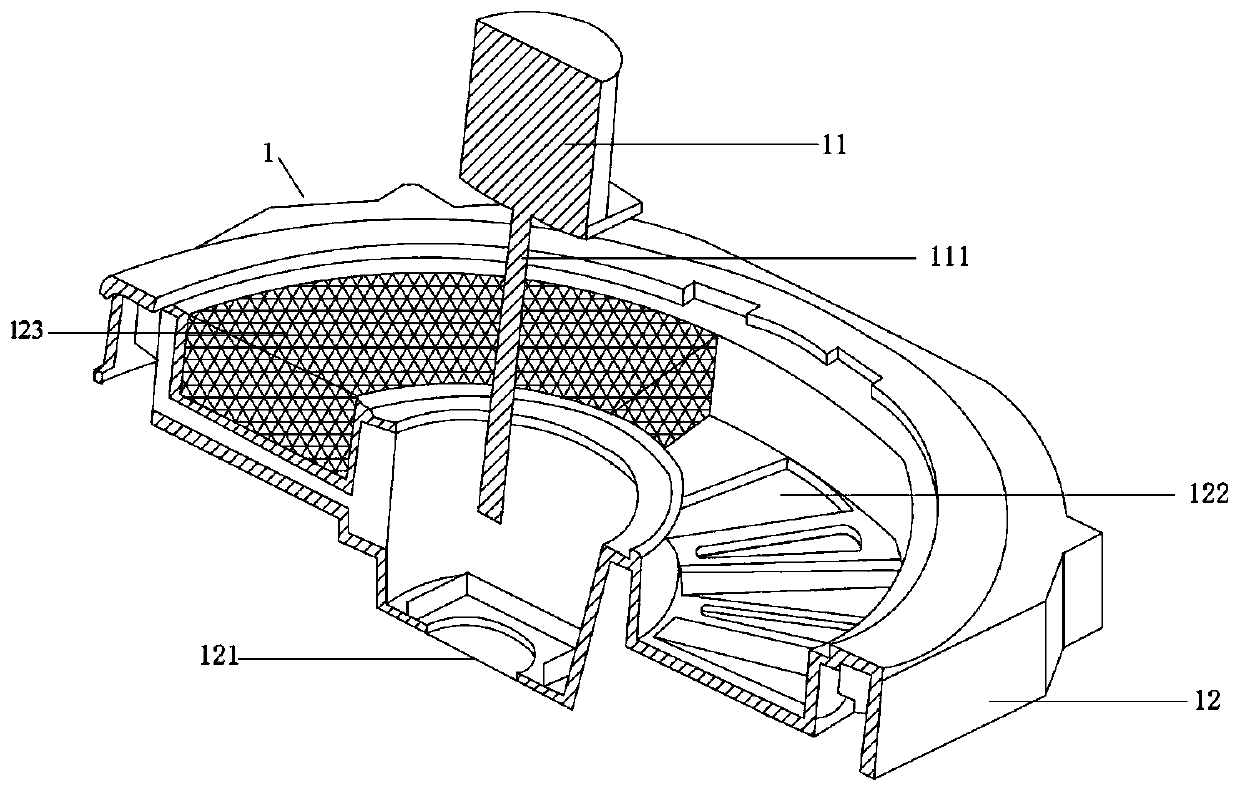

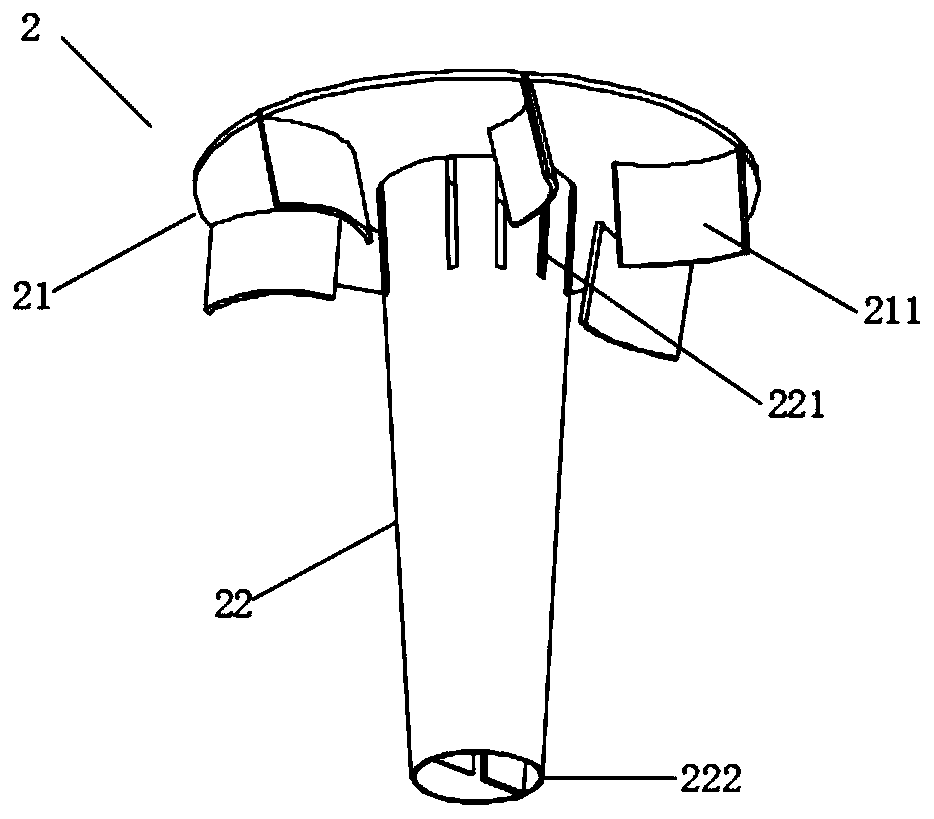

Spray cleaning device for water-washing type air purifier and corresponding air purifier

PendingCN110523175ASimple structureReduce manufacturing costGas treatmentUsing liquid separation agentPulp and paper industryAir purifier

The invention provides a spray cleaning device for a water-washing type air purifier. The spray cleaning device for the water-washing type air purifier comprises a motor unit, a water suction unit anda drainage unit, wherein the motor unit is connected with the water suction unit; the water suction unit is arranged inside the drainage unit; the motor unit comprises a motor and a motor fixing plate; the motor is arranged in the motor fixing plate; a central hole is formed in the motor fixing plate; the motor shaft of the motor penetrates through the central hole and is connected with the watersuction unit; the motor fixing plate is provided with an air outlet hole; the whole water suction unit is in the shape of an inverted circular truncated cone formed integrally and comprises a circular-truncated-cone-shaped portion and a tubular portion; a shaft hole is formed in the circular-truncated-cone-shaped portion; the motor shaft is inserted in the shaft hole; a plurality of water spraying holes which are arranged in the circumferential direction are formed in the side wall of the upper portion of the tubular portion; and a plurality of baffles are arranged on the bottom of the circular-truncated-cone-shaped portion. The invention also provides a corresponding air purifier. The spray cleaning device and the corresponding air purifier are simple in manufacturing mold, low in production cost and good in purification effect.

Owner:北京智享新科技有限公司

Dry rice powder and manufacturing method thereof

InactiveCN103478564AWhite and bright appearanceFlexible textureFood ingredientsFood preparationRice flourEngineering

The invention discloses a manufacturing method of dry rice powder. The method comprises the steps as follows: rice selection, soaking, milk grinding, filter pressing, smashing, accessory adding, rice dough kneading, pressing, threading, aging, loosing and dying processes. Compared with the prior art, the method is characterized by further comprising the milk grinding, stock screening, dewatering, filter pressing and smashing steps. According to the method, after dewatering, an accessory is added, so that compared with conventional dry rice powder, the manufactured dry rice powder is white and bright in surface, flexible in texture, not prone to be burnt by poaching and uneasy to break by dry cooking; and compared with fresh wet rice powder, the dry rice powder is smooth in texture, fragrant, flavorful and good in taste.

Owner:GUILIN QUANZHOU MILANXIANG FOOD

Artificial biological cardiac and vascular valve on basement membrane component surface layer and preparation method thereof

PendingCN107412871ABarrier depositionIsolation toxicityPharmaceutical delivery mechanismTissue regenerationSurface layerCalcification

The invention relates to an artificial biological cardiac and vascular valve on a basement membrane component surface layer and a preparation method thereof. The artificial biological cardiac and vascular valve comprises a biovalve material and the basement membrane component surface layer tightly covering the biovalve material. On the basis that the good strength and toughness of a crosslinking biovalve are reserved, rapid endothelialization of the smooth and dense basement membrane component surface layer can be achieved, and calcium salt deposition can be obstructed, so that cytotoxicity and immunogenicity reducing which are caused by calcification and isolation crosslinking of the biovalve are prevented, and the service life of the artificial biological cardiac and vascular valve is prolonged.

Owner:EXCELLENCE MEDICAL TECH SUZHOU CO LTD +1

Multifunctional thermoplasticity aramid fiber bulletproof tablet and bulletproof spine-resistant clothes thereof

InactiveCN101201231AImprove mechanical propertiesStable chemical propertiesPersonal protection gearThermoplasticMoisture absorption

The invention belongs to the field of protective equipments, in particular to a multi-functional thermoplastic aramid fiber bullet-proof slice and a bullet-proof and stab-proof vest. The invention mainly solves the technical problems of low bullet-proof and blunt trauma-proof functions, and no stab-proof function existing in soft aramid fiber bullet-proof materials in the prior art, and provides a multi-functional thermoplastic aramid fiber bullet-proof slice and a bullet-proof and stab-proof vest not only with better bullet-proof and blunt trauma-proof functions, but also with very good stab-proof function. Meanwhile, the invention also solves the difficulties of high water and moisture absorption rate, and easiness in photodecomposition of the aramid fiber bullet-proof cloth in the prior art. The provided multi-functional thermoplastic aramid fiber bullet-proof slice and a bullet-proof and stab-proof vest has the functions of permanent water and moisture proof, and prevention of photodecomposition. The main technical proposal of the invention is that the aramid fiber bullet-proof cloth is composited with the thermoplastic resin; the resin evenly penetrates on the surface of the aramid fiber bullet-proof cloth and fills in the pores of filament bundle binding points, and is shaped into a multi-functional thermoplastic aramid fiber bullet-proof slice through thermoplastics.

Owner:申屠年

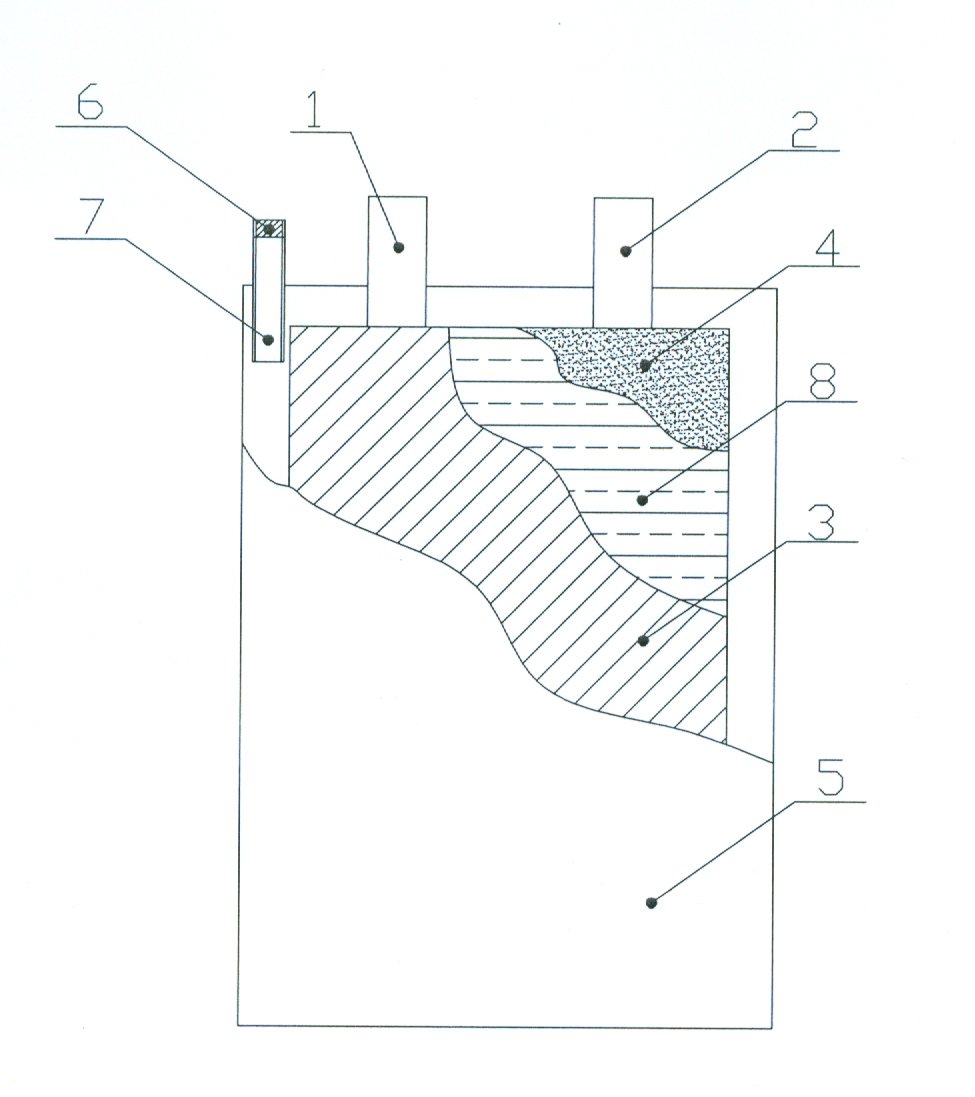

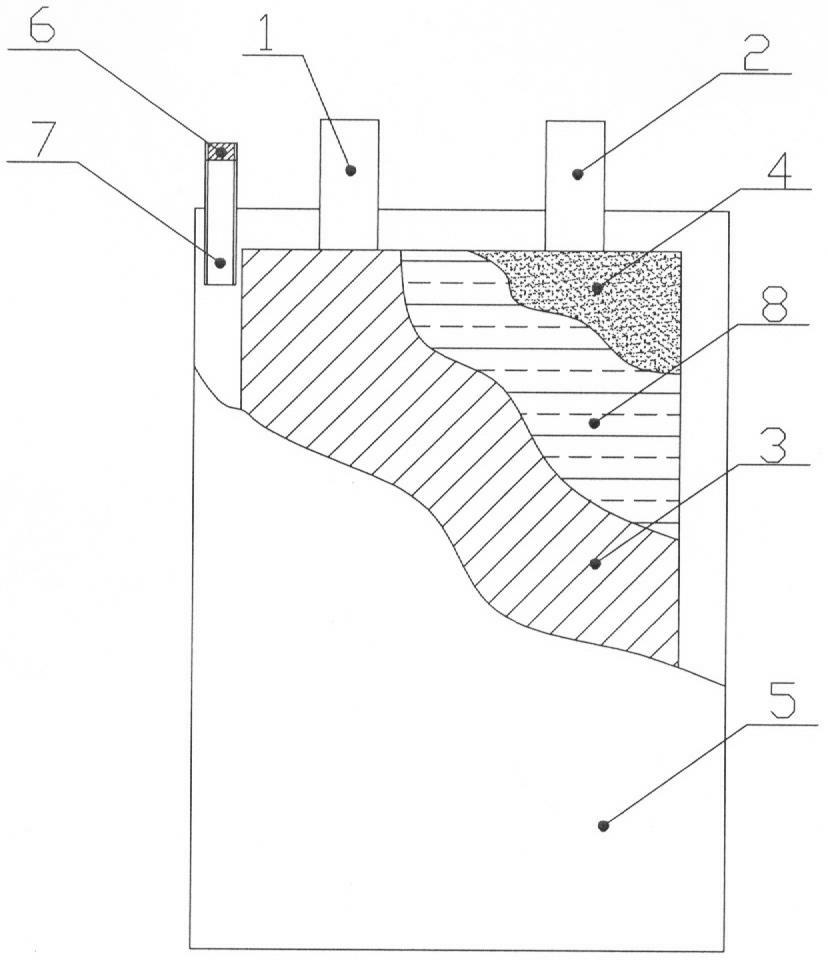

Super capacitor of flexible package water system

InactiveCN102082035AFlexible textureImprove sealingLiquid electrolytic capacitorsCapacitor housing/encapsulationSupercapacitorEngineering

The invention provides a super capacitor of a flexible package water system. The super capacitor is characterized in that a polyethylene film, a polypropylene film, an aluminum-plastic film and other packaging films are taken as shells; the packaging films can be cut into any shaped packaging films as needed; the any shaped package films are subjected to heat seal to obtain good sealing effect. The upper part of the super capacitor is provided with an exhaust pipe which is used for discharging gas generated by using the super capacitor for a long time; meanwhile, the upper part of the exhaust pipe is filled with polytetrafluoroethylene filtrate sheets, so that leakage can be effectively prevented. Due to adoption of the flexible package, the super capacitor is low in cost, is not restricted by common shell sizes, is simple in production process, light in product quality and small in volume, and is convenient to freely assemble; and in addition, the power-to-weight ratio of the super capacitor is large. The novel flexible package and an exhaust pipe structure are adopted for the super capacitor, thus effectively solving the problem of shell package for super capacitors of existing water systems.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

Quick propagation method suitable for scale production of high-quality seedlings of aronia melanocarpa

ActiveCN108575752AShorten seedling timeShorten the cultivation cycleGrowth substratesCulture mediaActivated carbonGrowth regulator

The invention relates to a high-efficiency quick propagation method for scale production of aronia melanocarpa. The high-efficiency quick propagation method comprises the following steps of primary culture, differentiating culture, subculture culture, seedling sounding culture, rooting culture and domesticating transplanting, wherein a tissue culture seedling is directly differentiated into seedlings without a callus forming phase by adjusting the type and proportional ratio of the growth regulator in a differentiating culture medium, the differentiating coefficient is high, and the seedling grows strong; a rooting culture medium added with a certain amount of activated carbon is adopted, the dark environment is provided, and the metabolism harmful matters in the culture medium are absorbed, so that the root quickly grows, is strong and soft and is not liable to break, and the root is easy to survive in transplanting. The high-efficiency quick propagation method has the advantages thatthe culture cycle is shortened, and the production cost is greatly reduced.

Owner:SHANXI LUAN SHIGEJIE ZHIHUA BIOTECHNOLOGY CO LTD

Making method of whole-grain rice noodles (cut noodles)

The invention discloses a making method of whole-grain rice noodles (cut noodles), which is applied to the field of food producing and processing. The making method is characterized by comprising thefollowing steps of step I, selecting materials: selecting 30-45 parts of carefully-selected brown rice, and performing screening with a 50-70-mesh sieve; step II, performing brown rice milling: milling off bran from the carefully-selected brown rice; step III, performing distribution: for two processed products of polished rice and the bran produced in the step II, loading the bran with a dry storage vessel, performing storage at 4 DEG C, and independently preserving the polished rice; step IV, soaking rice: flushing and soaking the polished rice obtained in the step III; step V, performing backfilling and pulp grinding: performing pulp grinding on the soaked rice, besides, filling back the bran obtained in the step III to rice pulp, and performing milling and mixing; step VI, performing blending and stirring; step VII, performing slice steaming; and step VIII, performing strip cutting and performing shaping. The rice noodles have nutrient value of whole grains, and the mouth feel andthe texture are close to those of ordinary rice and flour.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Dyeing method for cool ultrahigh-molecular-weight polyethylene bedding

The invention discloses a dyeing method for cool ultrahigh-molecular-weight polyethylene bedding. The dyeing method comprises the following steps: weaving; pre-setting; cold dyeing; washing and dehydrating; baking; and preparation of a finished product. The method gives full play to the respective performance advantages of ultrahigh-molecular-weight polyethylene and viscose fibers and allows the functions of ultrahigh-molecular-weight polyethylene and viscose fibers to complement each other for development of a high-grade cool bedding fabric; and ultrahigh-molecular-weight polyethylene and viscose fibers are blended according to a ratio of 35: 65, blended yarns with fineness of 18.5 tex are used as a raw material for warp and weft yarns, and reasonable fabric specification and process design are selected, so a prepared product has a smooth cloth surface, moisture-absorption performance, air permeability and soft and tough texture, feels cool and comfortable, can be easily to clean andis a high-grade fabric for summer quilts. According to the invention, only 65% of viscose fibers are dyed, so fried-dough-twist-like dyeing effect is obtained, and the problem that ultrahigh-molecular-weight polyethylene cannot be dyed is overcome. The dyeing method employs a cold dyeing process, does not need heating during dyeing, saves energy, reduces cost, and is clean and environment-friendlyin production.

Owner:IANGSU COLLEGE OF ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com