Making method of whole-grain rice noodles (cut noodles)

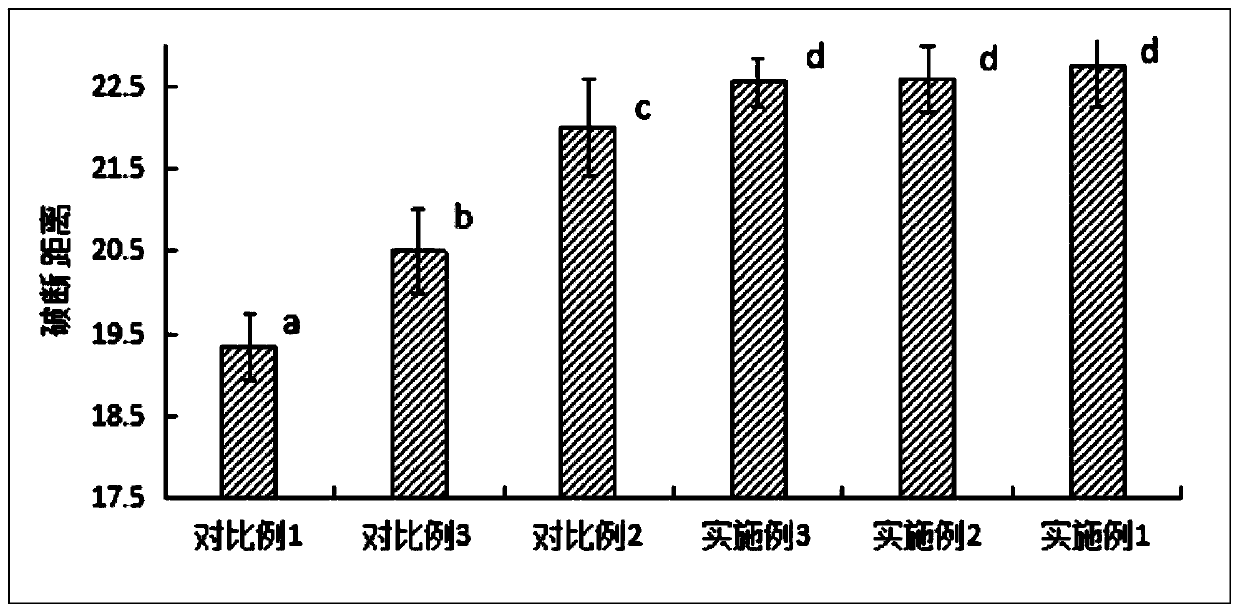

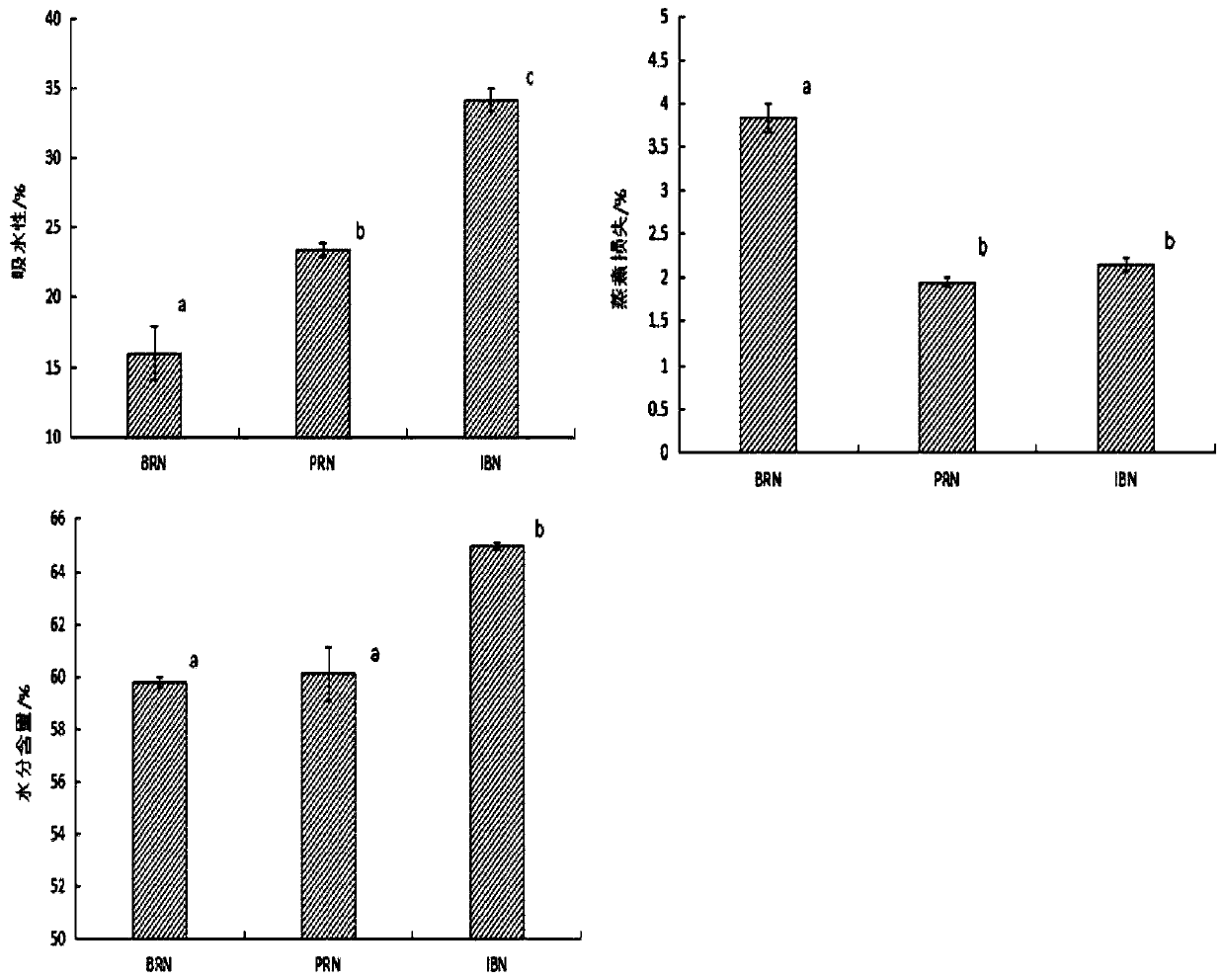

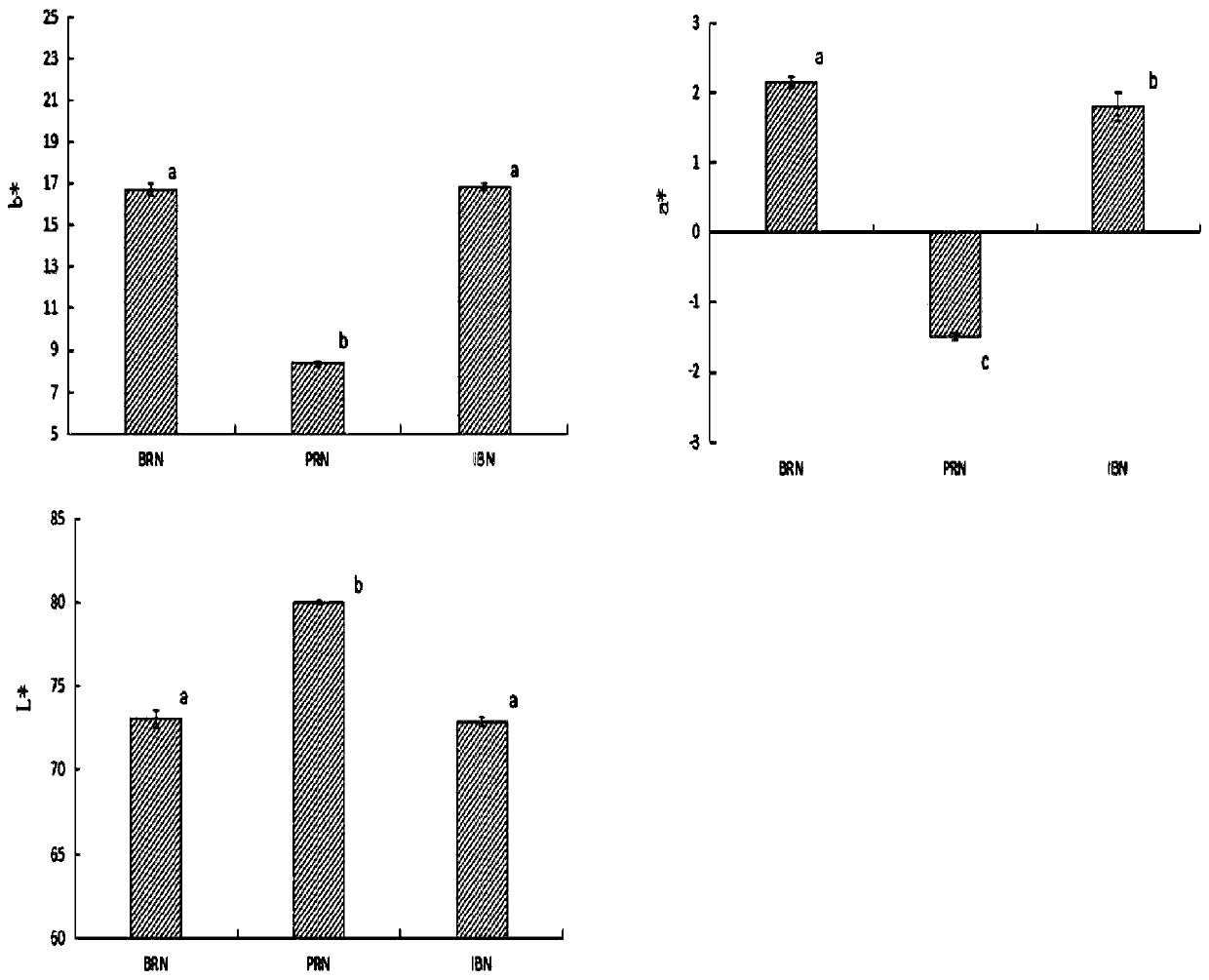

A technology of whole grains and rice noodles, which is applied in food science, food ingredients as thickeners, food ingredients, etc., can solve the problems of rough taste, high strip breaking rate, and difficulty in forming brown rice noodles, so as to improve the taste and texture, enhance The effect of taste and texture flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Step 1: material selection, get 37 parts of raw material brown rice and pass through 50~70 mesh sieves;

[0025] Step 2: Rice milling, mechanically milling selected brown rice raw materials;

[0026] Step 3: Divide the ingredients. In Step 2, two processed products of polished rice and bran are produced. The bran is placed in a dry storage container and stored at 4 degrees Celsius; at the same time, the polished rice part is stored separately;

[0027] Step 4: soaking rice, washing and soaking the polished rice in step 3;

[0028] Step 5: backfilling and refining, refining the soaked rice, and at the same time, backfilling the bran treated in step 3 to the rice milk part to realize synchronous grinding and mixing;

[0029] Step 6: Stir the ingredients, add additives to the rice milk in step 5, 4 parts of soybean protein isolate, 4 parts of tapioca starch, 0.7 part of salt, 4 parts of gluten powder, 0.3 part of guar gum, 50 parts of water , and stir well ...

Embodiment 2

[0032] Embodiment 2: Step 1: material selection, get 35 parts of raw material brown rice and pass through 50~70 mesh sieves;

[0033] Step 2: Rice milling, mechanically milling selected brown rice raw materials;

[0034] Step 3: Divide the ingredients. In Step 2, two processed products of polished rice and bran are produced. The bran is placed in a dry storage container and stored at 4 degrees Celsius; at the same time, the polished rice part is stored separately;

[0035] Step 4: soaking rice, washing and soaking the polished rice in step 3;

[0036] Step 5: backfilling and refining, refining the soaked rice, and at the same time, backfilling the bran treated in step 3 to the rice milk part to realize synchronous grinding and mixing;

[0037] Step 6: Stir the ingredients, add additives to the rice milk in step 5, 3 parts of soybean protein isolate, 5 parts of tapioca starch, 0.6 parts of salt, 5 parts of gluten powder, 0.4 parts of guar gum, and 51 parts of water , and stir...

Embodiment 3

[0040] Embodiment 3: Step 1: material selection, get 38 parts of raw material brown rice and pass through 50~70 mesh sieves;

[0041] Step 2: Rice milling, mechanically milling selected brown rice raw materials;

[0042] Step 3: Divide the ingredients. In Step 2, two processed products of polished rice and bran are produced. The bran is placed in a dry storage container and stored at 4 degrees Celsius; at the same time, the polished rice part is stored separately;

[0043] Step 4: soaking rice, washing and soaking the polished rice in step 3;

[0044] Step 5: backfilling and refining, refining the soaked rice, and at the same time, backfilling the bran treated in step 3 to the rice milk part to realize synchronous grinding and mixing;

[0045] Step 6: Stir the ingredients, add additives to the rice milk in step 5, 2 parts of soybean protein isolate, 2 parts of tapioca starch, 0.5 part of salt, 3 parts of gluten powder, 0.5 part of guar gum, and 54 parts of water , and stir w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com