Patents

Literature

35results about How to "Taste flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing functional type food containing persimmon

The invention relates to a method for preparing a functional type food containing persimmon. The technical scheme provided by the invention is as follows: the method comprises the following steps of: carrying out re-acerbity resistant treatment on persimmons: softening mature persimmons, cleaning, removing bases, pulping, and embedding by adding a compound debitterizing agent containing 2-5% of beta-cyclodextrin and maltodextrin to prevent re-acerbity; adding the prepared substances into ingredients; and deeply processing: stirring, mixing, rubber grinding, refining, slicing, drying, uncovering slices, overlapping slices, and slicing, wherein the embedding time is 50-70 min; and the embedding temperature is 35-45 DEG C. By adopting the technical scheme, the method disclosed by the invention has the benefits that: persimmons are processed into serial fruit paste type leisure foods which have the advantages of being good in mouth feel, easy for storage and applicable to being eaten by men and women of all ages; a condition is created for persimmon industrialization; unlike other foods containing persimmons, the produced foods can avoid re-acerbity phenomenon, taste good and tenacious and are suitable for being stored for a long time; and the technical problem which is expected to solve for a long time but not solved is solved.

Owner:陕西恒康生物科技有限公司

Method for preparing papaya cake

InactiveCN1883297APrevent crystallizationTaste flexibleFood preparationPapaya familyAdditive ingredient

Disclosed is a process for preparing papaya cakes from papaya fruit as the principal raw material through charging gelling agent, cane sugar and lemon acid, heating and moulding, and drying at a changed temperature.

Owner:SOUTH CHINA AGRI UNIV

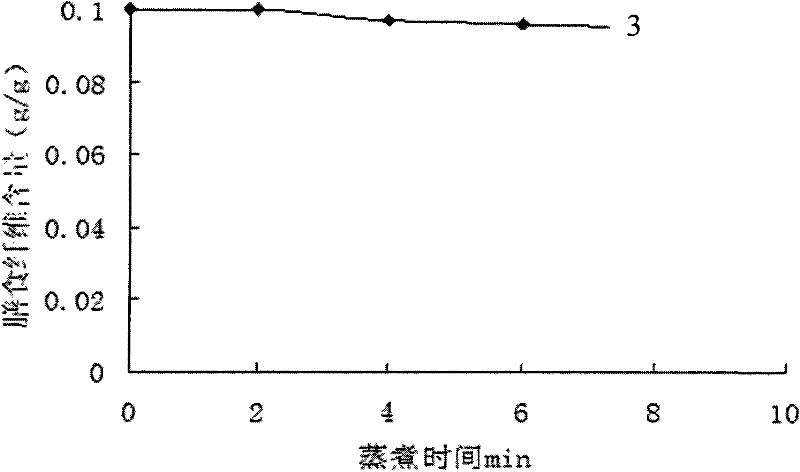

Method for producing water chestnut sheet jelly

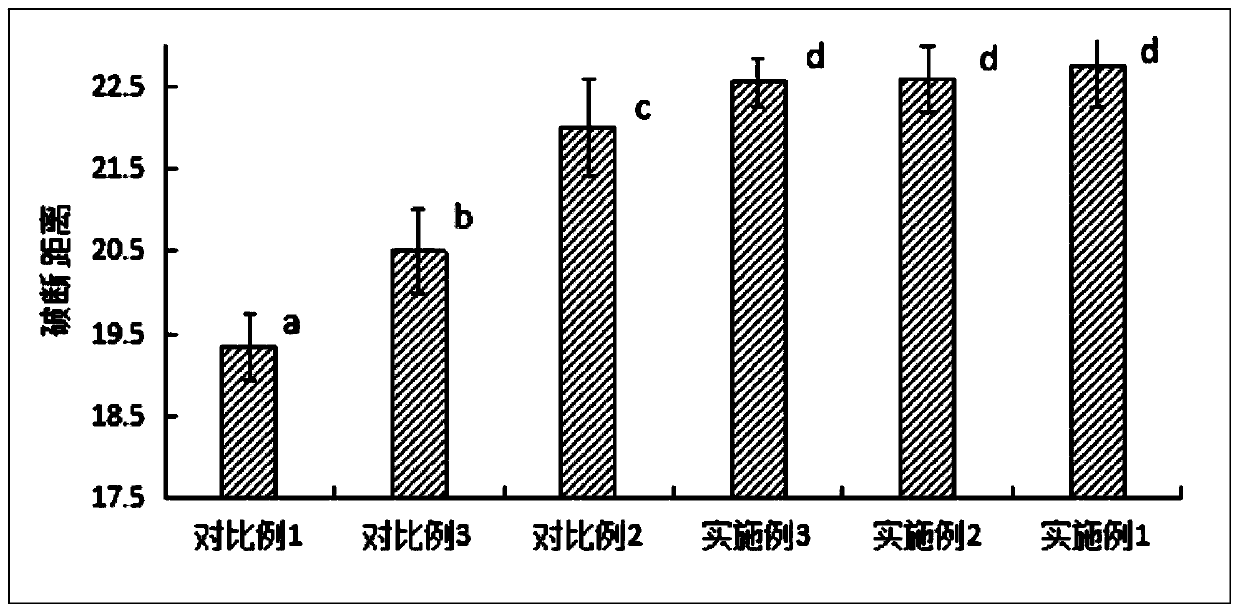

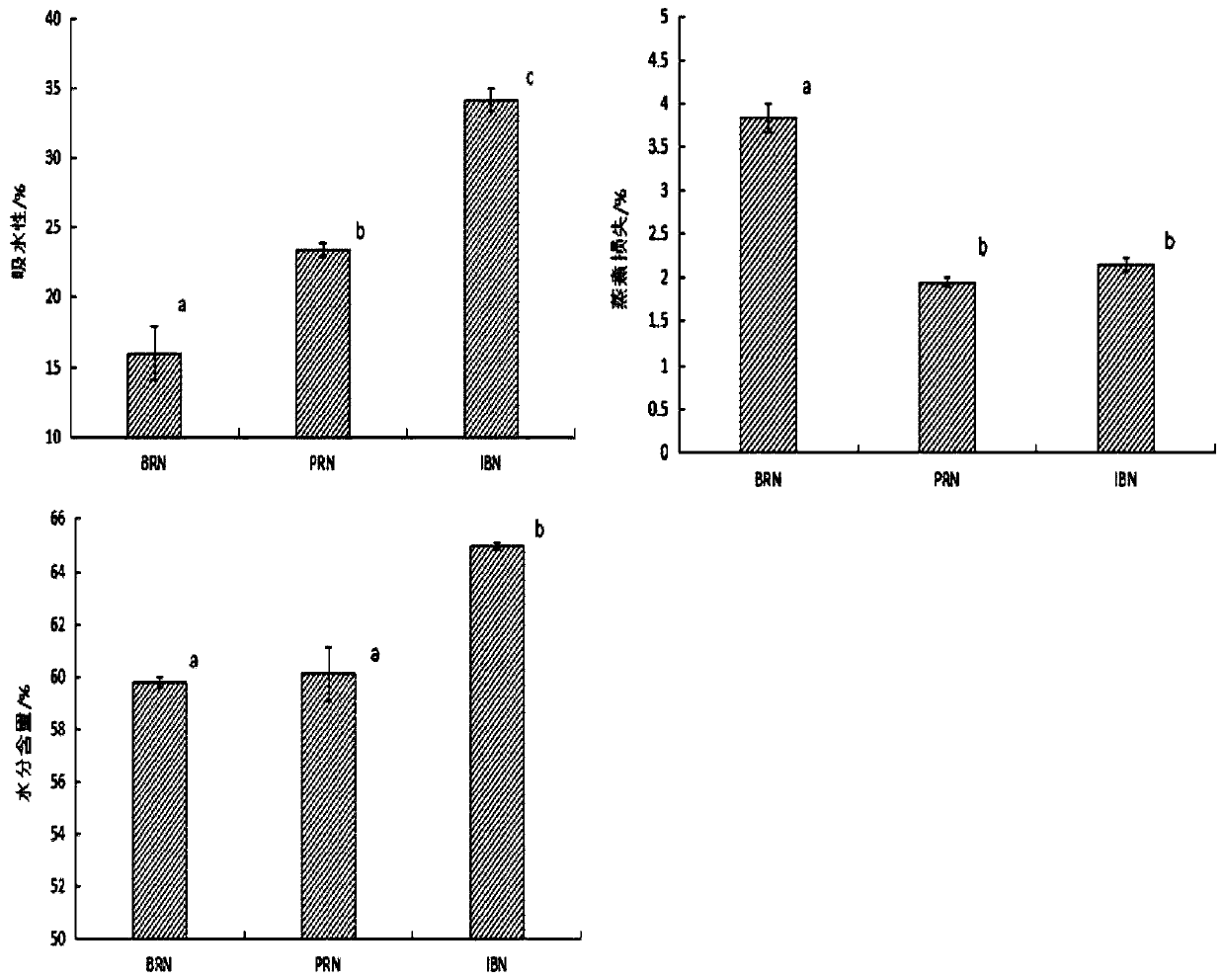

The invention discloses a method for producing water chestnut sheet jelly, which comprises the following steps: adding flavone substances and dietary fiber separated and extracted from waste of water chestnut processing into water chestnut starch, corn starch, potato starch and sweet potato starch; stirring the mixture to obtain slurry; and preparing to obtain the water chestnut sheet jelly. The method extracts water chestnut flavones and the dietary fiber from mass processing waste caused by the current water chestnut production to realize waste utilization, and reduces the production cost of the water chestnut sheet jelly by adding accessories such as the corn starch, the potato starch and the sweet potato starch, does not influence the quality of the water chestnut sheet jelly, the content of functional ingredients of the sheet jelly is improved obviously, the stretching force of the water chestnut sheet jelly is increased by 11.5 percent, the boiling loss rate is increased by 25.0 percent, the swelling capacity is reduced by 8.0 percent, the content of flavone compounds is increased by 40mg / 500g, the dietary fiber is increased by 0.1g / g, and the water chestnut sheet jelly has high nutrition and health care values.

Owner:华农(潮州)食品研究院有限公司

Convenient additive-free five-cereal nutritional noodles and processing method thereof

ActiveCN104256361AElastic footIncrease elasticityFood ingredient functionsFood preparationNutritive valuesQuality optimization

The invention relates to convenient additive-free five-cereal nutritional noodles and a processing method thereof, and belongs to the field of food processing. The processing method comprises the following steps: performing quality optimization treatment on corns and black beans, grinding together with wheat, polished round-grained rice and yellow millets, blending, and performing curing forming to obtain the convenient five-cereal nutritional noodles. The obtained five-cereal nutritional noodles give full play to complementary nutrition advantages of rice, flour and beans, are endowed with relatively high nutritional value, are good in elasticity, toughness and reconstitution properties, do not need to be digested, can be eaten after being soaked with boiling water, and are convenient and quick; the process conditions are mild, no chemical and biosynthetic technologies are adopted, no pollution, waste residue, waste steam, waste water or harmful substance is generated, green production is realized, no gluten fortifier, thickening colloid, enzyme preparation or preservative is added, and no chemical reagent is used, so that the noodles are safe to eat.

Owner:吉林省正源食品有限责任公司

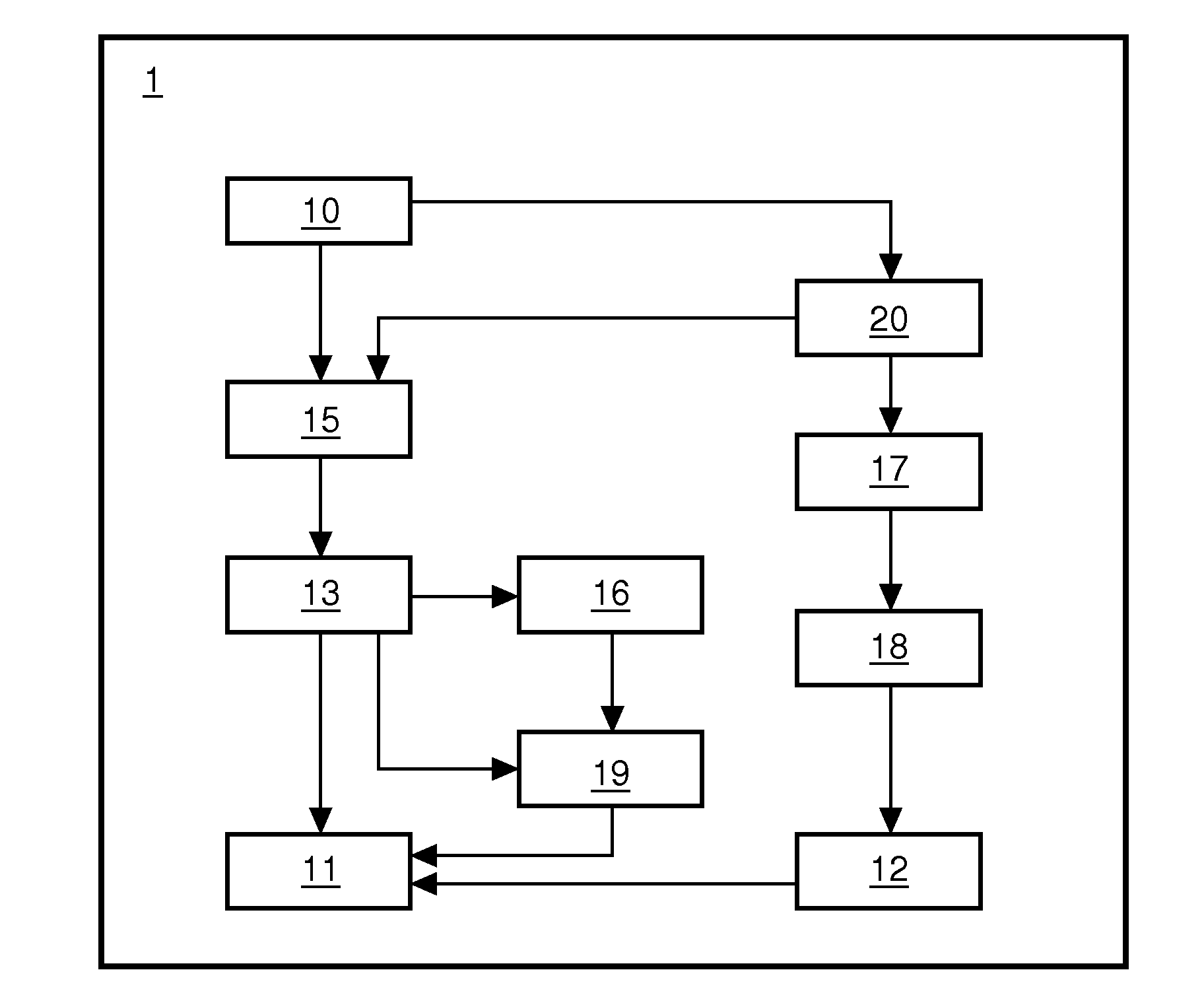

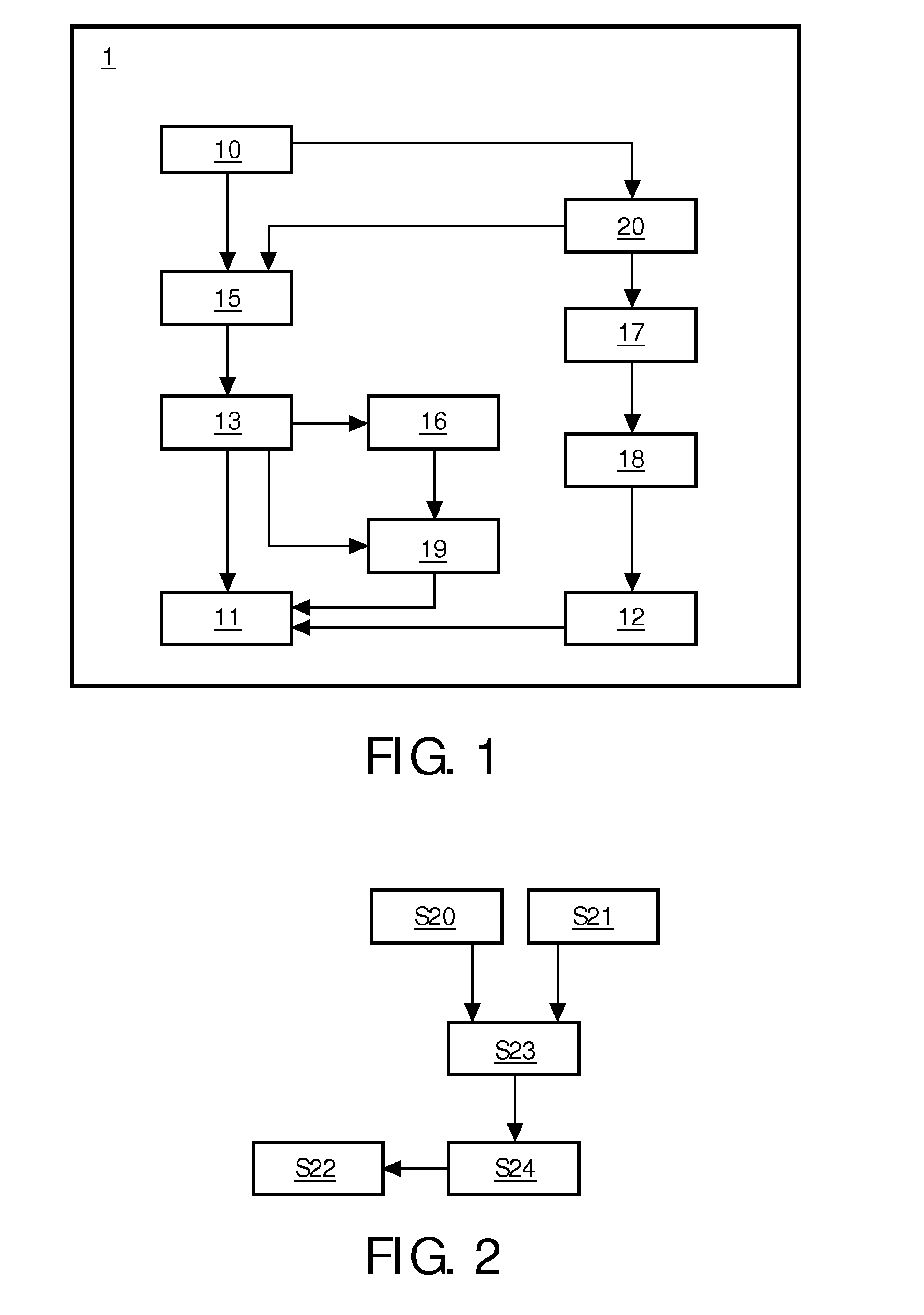

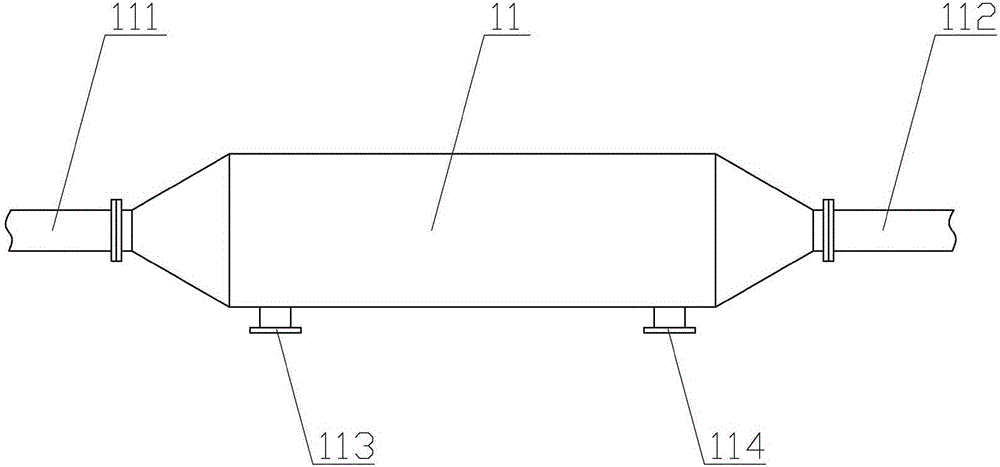

Methods and devices for cooking rice

The invention proposes a method and a device for cooking rice. The device comprises a first container (110) for containing the rice together with water; a first heater (120, 121 and 122) for heating the rice and the water in the container (110); and a regulator (130, 31, 132, 133 and 134) for, during the heating, regulating the amount of water.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

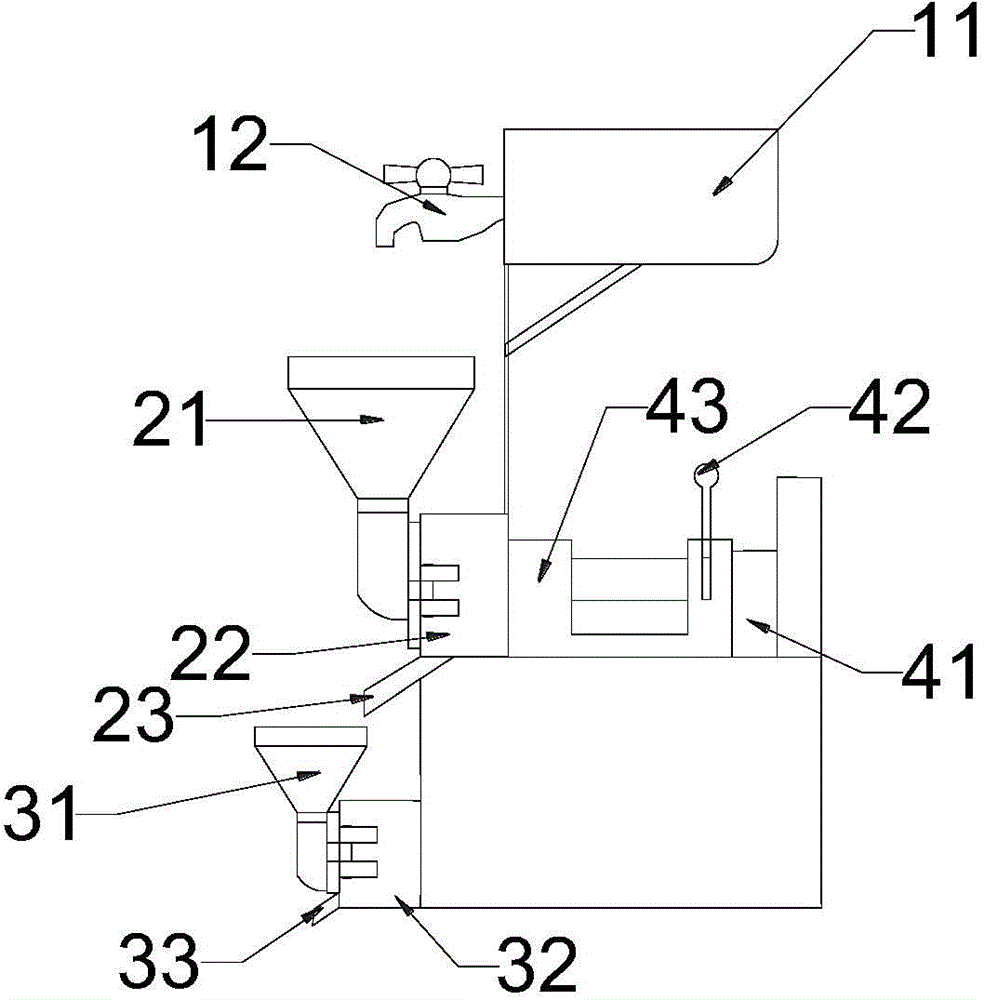

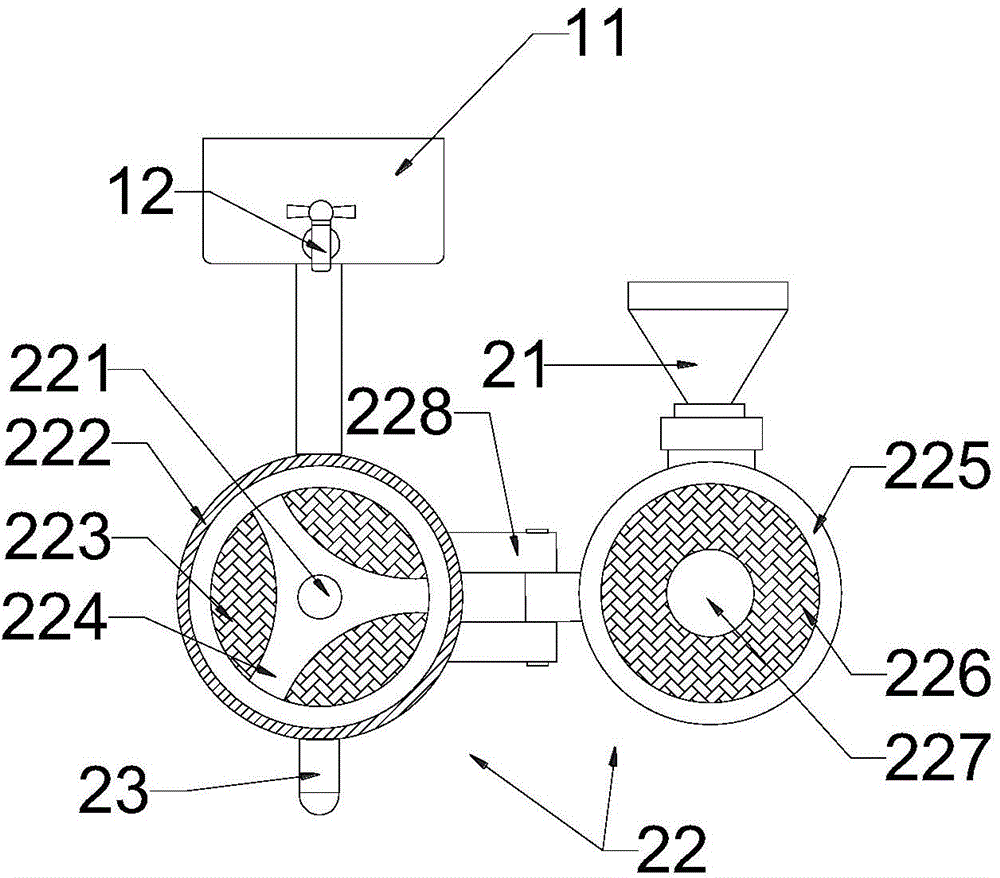

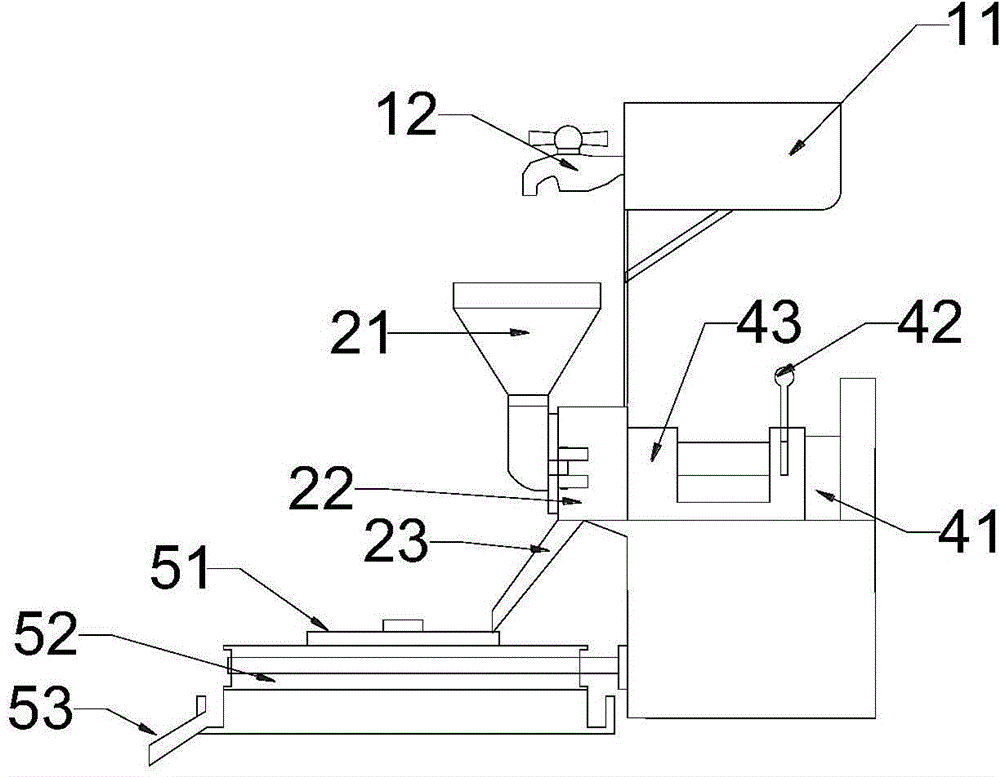

Steamed vermicelli roll manufacturing method and low-temperature fine rice milk grinding machine

The invention provides a steamed vermicelli roll manufacturing method and a low-temperature fine rice milk grinding machine. The steamed vermicelli roll manufacturing method includes the steps that rice is washed clean; the rice is soaked in a low-temperature environment; rice milk is generated through rice grinding in the low-temperature environment; starch is added into the rice milk, the starch and the rice milk are stirred to form mixed rice milk; water is added into the mixed rice milk for dilution to form pre-made rice milk; the pre-made rice milk is placed in a steamer to be heated till the rice milk is fully steamed, and steamed vermicelli rolls are formed; by means of a forming technology, the steamed vermicelli rolls are shaped into expected shapes. The method is characterized in that during rice milk grinding, crushed ice and / or ice cakes and / or ice water are / is added into a millstone. By means of the low-temperature rice milk grinding mode, the situation that temperature is too high and accordingly the rice milk is heated when the rice is ground is avoided, the situation that rice milk precursors become early steamed is prevented, and the taste of the steamed vermicelli rolls is better.

Owner:黄越通

Kelp sweety rich in fibre and method of preparing the same

A kelp candy is rich in fiber; the formed candy block contains kelp paste element and embedded blocks and grains of melon, fruit and vegetable besides the sugar and flavoring agent; the raw materials comprise kelp raw material (2.00 to 40.00 percent), sugar (8.00 to 50.00 percent), xylitol (0.30 to 2.00 percent), salt (0.08 to 1.00 percent), citric acid (0.02 to 0.20 percent), melon, fruit and vegetable (0.30 to 5.00 percent) and water; the kelp is ground with water and condensed after sugar, xylitol and salt are added; and then the mixture is condensed again after the blocks and grains of melon, fruit and vegetable are added; the candy is manufactured after the processes of injection molding, drying, compressing, cutting, second drying and packing. The present invention combines the kelp which is rich in nutrition but has no good taste and candy which people loves together; fruit and vegetable are added to process the combination into candies with different flavors, novel patterns, natural cluster and flexible taste; the candy is a leisure food with rich nutrition.

Owner:DALIAN POLYTECHNIC UNIVERSITY +1

Purple rice row-shaped rice noodles and preparation method thereof

InactiveCN107484945ASoft tasteTaste flexibleFood ingredient as colourFood dryingOff-flavourProcess engineering

The invention discloses purple rice row-shaped rice noodles and a preparation method thereof. Milled long grain nonglutinous rice and purple rice are mixed in the weight ratio of the milled long grain nonglutinous rice to the purple rice being (6-8) to (1.5-2.5) to be used as raw materials, and the row-shaped rice noodles are made through technological flows of selecting materials, performing soaking, performing grinding to obtain pulp, performing dehydration, steaming flour, performing extrusion to obtain rice noodle strips, performing strip squeezing, performing cooling, performing cutting, performing steaming once again, performing baking, performing shaping and the like. Compared with a method for making ordinary row-shaped rice noodles, the preparation method disclosed by the invention has the advantages that the purple rice (brown rice) is added in the respect of selection of the raw materials, so that certain specialty is obtained during making, the processing technology is complex, the technical requirements are high, and the made row-shaped rice noodles are light purple, moistening and transparent in noodle strips, in bar-shaped side-by-side arrangement, rich in rice fragrance, free from acid smell, moldy smell and other peculiar smell, uniform in thickness of rice noodle strips, and free from strip drawing; after the rice noodles are cooked and rehydrated, the soup is not pasty, the rice noodles seldom break, and the rice noodles have the characteristics of being soft, smooth, pliable, tough and refreshing in mouth feel, free from sticking to teeth and the like, and also have the advantages of being rich in nutrition, unique and attractive in appearance, good in mouth feel and the like.

Owner:新兴县微丰农业科技有限公司

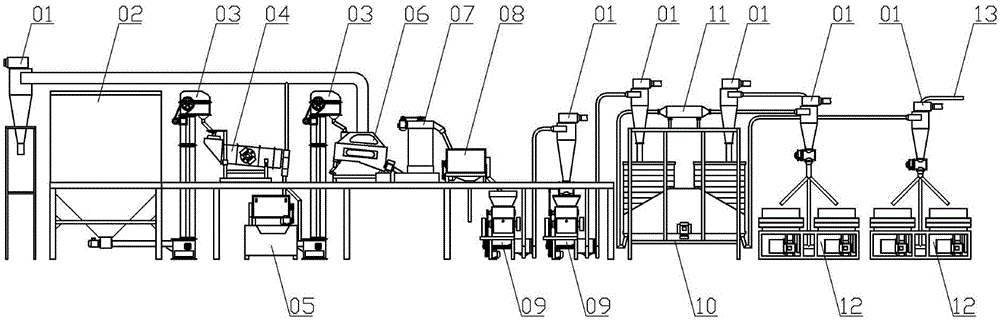

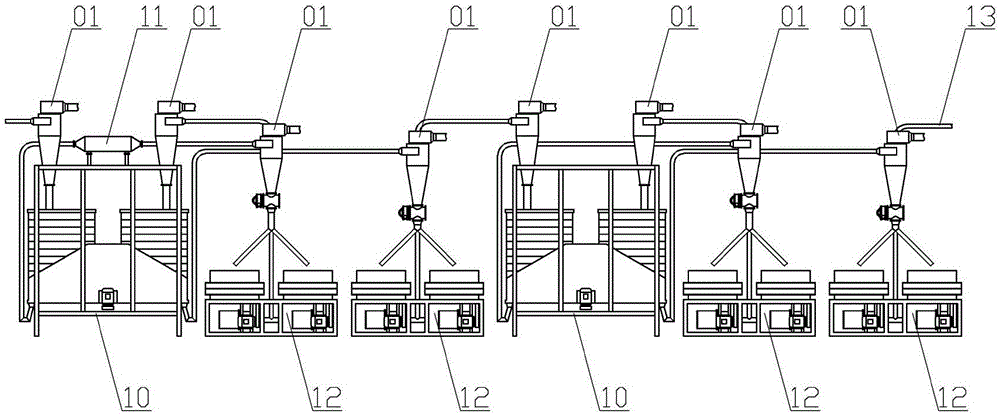

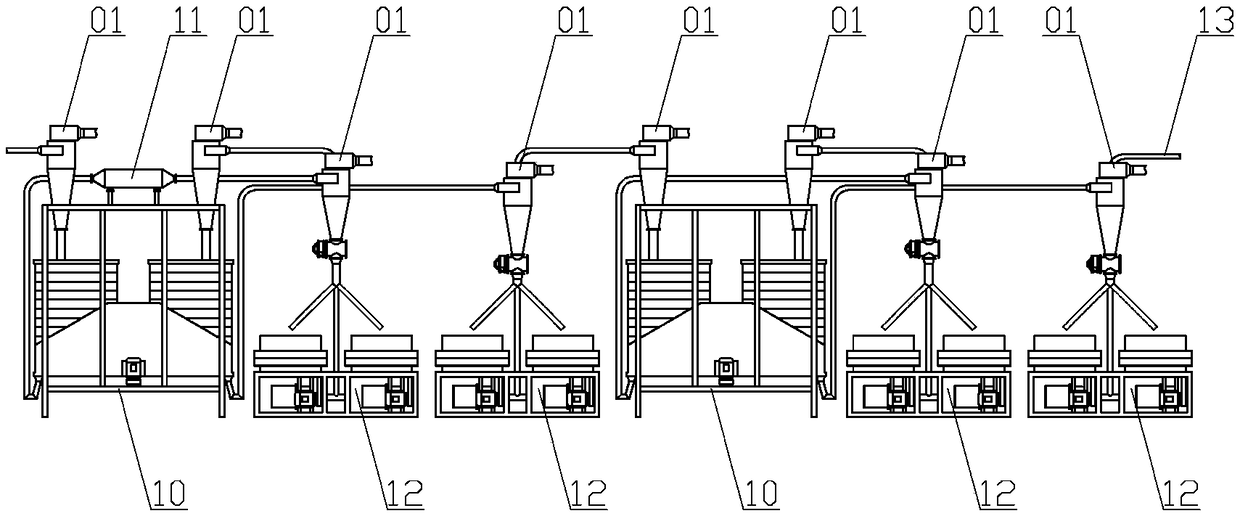

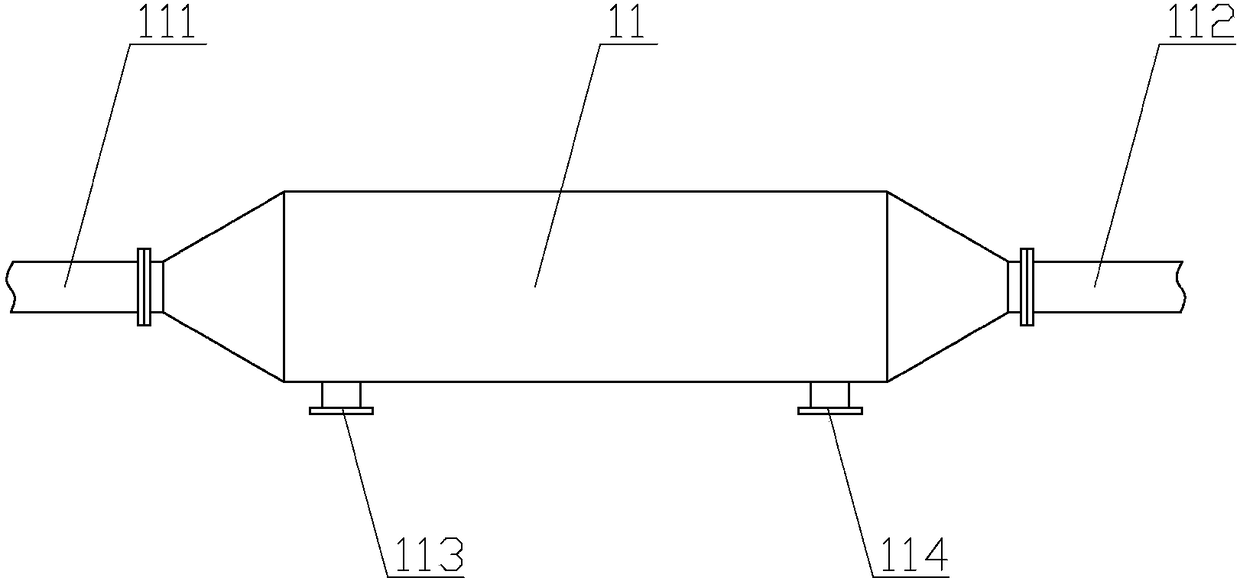

Low-temperature wheat flour processing method, system device adopting method and application

InactiveCN106423398AIncrease productivityReduce high temperatureGrain treatmentsPrimary screeningMoisture

The invention discloses a low-temperature wheat flour processing method, a system device adopting the method and application. Wheat is stored in a dry environment of 15-20 DEG C, the wheat is processed by using the wheat processing device, primary screening, stone removal and wheat wetting are performed for 10-12 hours, the wheat wetting temperature is 18-25 DEG C, 6-12 KGy gamma ray irradiation sterilization, secondary roughening, twice breaking, flat-screen screening and cooling are performed, the rotation speed is 38 r / min-40 r / min after the first time of stone-mill grinding, and then wheat flour is produced through three times of flat-screen screening and stone-mill grinding. The method is high in production efficiency and free of additives, a cooler is added to reduce high material temperature caused by a flour mill, meanwhile the rotation speed of a stone mill is improved from 20 r / min to 40 r / min, the powder yield can be up to 87%, it is detected that the moisture content of the produced wheat flour is below 4.5%, the ash content is below 0.8%, the magnetic metal content is below 0.00015%, and gluten quality is up to 28%.

Owner:XINJIANG DETIANLI AGRI DEV CO LTD

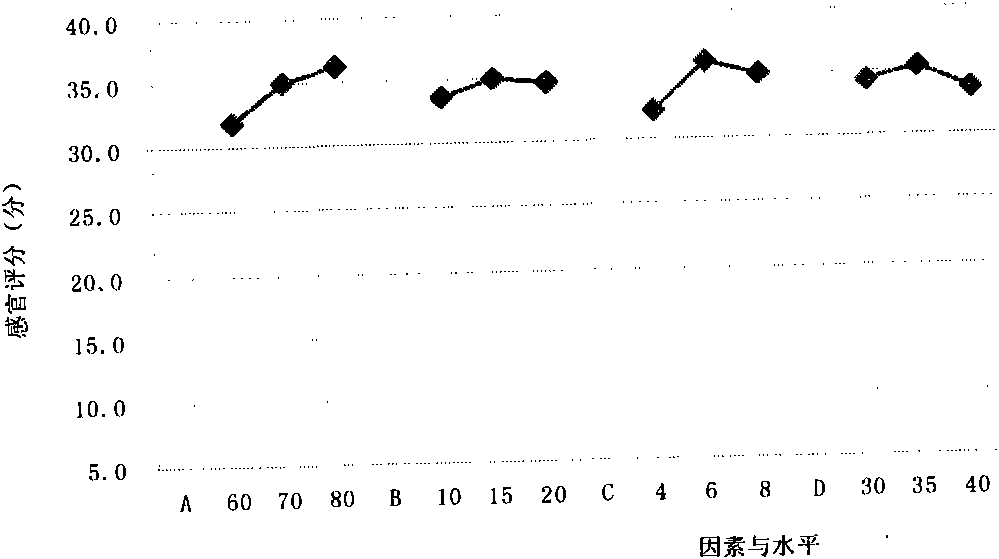

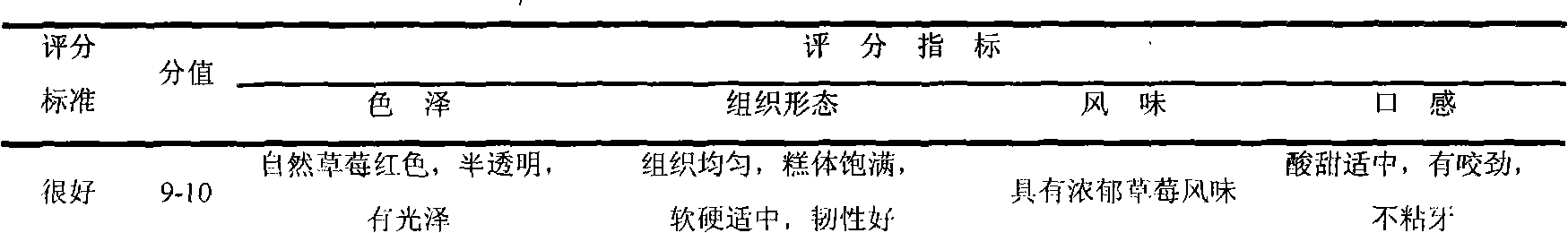

Strawberry cake and preparation method thereof

InactiveCN101953424AStrong aromaTaste flexibleConfectionerySweetmeatsCarrageenanHigh-fructose corn syrup

The invention relates to a strawberry cake and a preparation method thereof, belonging to the technical field of food processing. The strawberry cake are prepared from the following components in parts by weight: 80 parts of strawberry pulp, 15 parts of rice flour, 6 parts of gelatinizing agent and 35 parts of sugar by the steps of blending, concentrating, molding and drying. In the invention, the crudely prepared strawberry pulp is used as a main material, the rice flour and glutinous rice flour by a proper proportion are matched, and components such as carrageenan, konjac glucomannan, and the like are added; barley maltsyrup or high fructose corn syrup is used for partially replacing cane sugar; and far infrared vacuum drying equipment is adopted to dry to prepare the strawberry cake. The prepared strawberry cake has pleasant sweetness and sourness, strong fragrance and flexile mouthfeel and maintains the flesh texture and the flavor of strawberries.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Microgranule purple laver noodle and its making method

InactiveCN100356862CImprove qualityIncreased cooking strengthDough treatmentFood preparationSurface moisturePorphyra

Owner:NINGBO UNIV

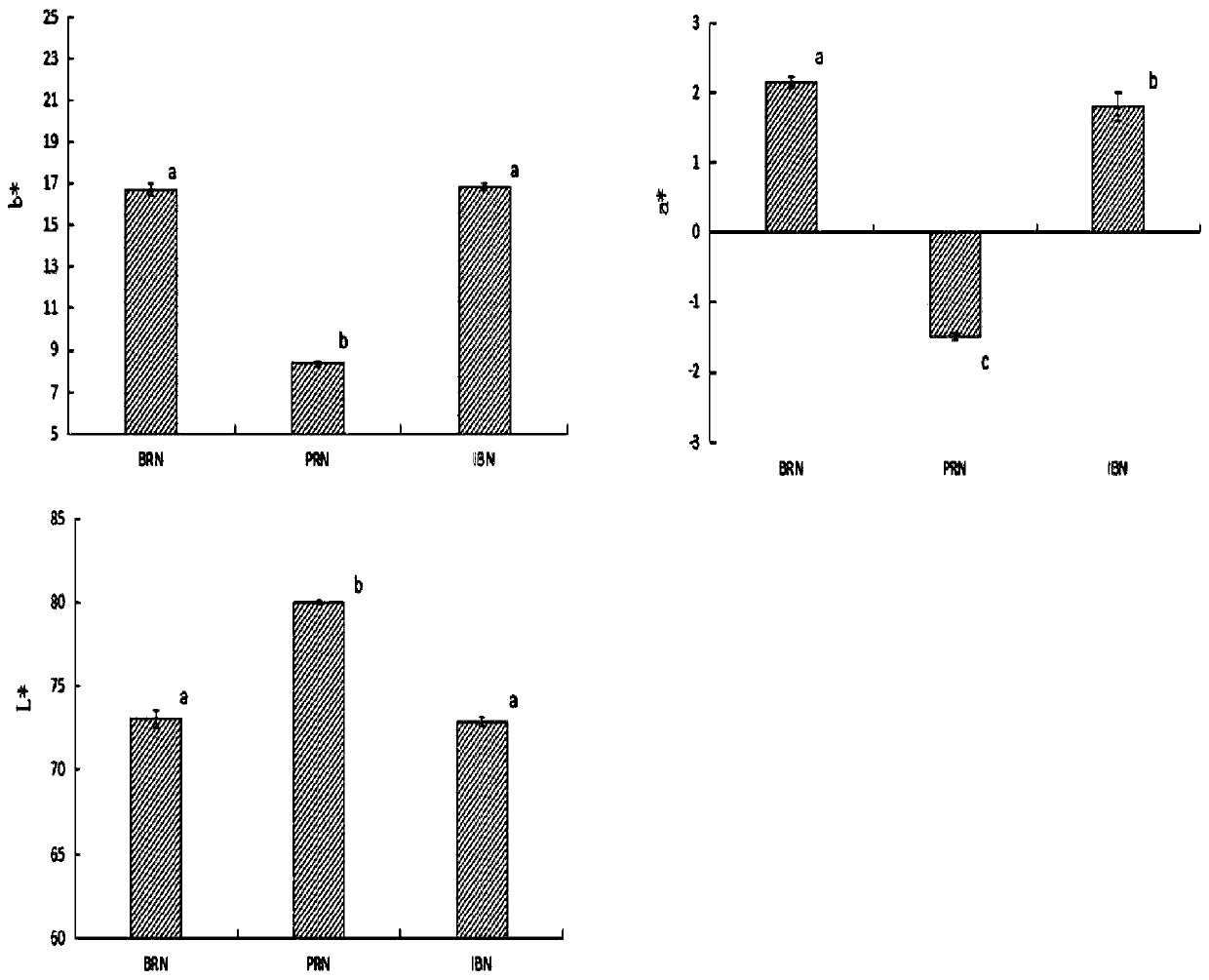

Making method of whole-grain rice noodles (cut noodles)

The invention discloses a making method of whole-grain rice noodles (cut noodles), which is applied to the field of food producing and processing. The making method is characterized by comprising thefollowing steps of step I, selecting materials: selecting 30-45 parts of carefully-selected brown rice, and performing screening with a 50-70-mesh sieve; step II, performing brown rice milling: milling off bran from the carefully-selected brown rice; step III, performing distribution: for two processed products of polished rice and the bran produced in the step II, loading the bran with a dry storage vessel, performing storage at 4 DEG C, and independently preserving the polished rice; step IV, soaking rice: flushing and soaking the polished rice obtained in the step III; step V, performing backfilling and pulp grinding: performing pulp grinding on the soaked rice, besides, filling back the bran obtained in the step III to rice pulp, and performing milling and mixing; step VI, performing blending and stirring; step VII, performing slice steaming; and step VIII, performing strip cutting and performing shaping. The rice noodles have nutrient value of whole grains, and the mouth feel andthe texture are close to those of ordinary rice and flour.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production method for easily-soaked boilproof cured nutritive fresh corn

The invention provides a production method for easily-soaked boilproof cured nutritive fresh corn, which comprises the following steps: firstly, ripe corns and boxthorns are grinded down, and fresh corns are hulled, threshed and grinded in a superfine manner; secondly, after secondary curing, the product obtained in the first step is extruded, cut, cooked, refrigerated in vacuum, stored for six months, and can be eaten after being rehydrated in boiling water for three minutes; and the product obtained in the second step is dried in a controlled temperature between 50 to 52 DEG C for 120 minutes, moisture is reduced to about 8 to 9 %, the corn is cooked into pliable and delicious corn food after being rehydrated and boiled in boiling water for 5 minutes, and can be stored for 12 months in an ordinary temperature. By using the method provided by the invention, the shortcomings that the mouthfeel of corn food produced by directly boiling and grinding corn seeds is bad, and the rehydration time in boiling water is short are overcome, the status quo that the fresh corns can be only produced into food with short freshness date such as cans and quick-freeze corncobs is changed, and a novel food processing method for the fresh corn is created.

Owner:吉林省全鑫科技有限公司

Chili sauce and making method thereof

InactiveCN108157930AReduce salt consumptionBright red colorFood scienceMonosodium glutamateChilli con carne

The invention discloses a chili sauce and a making method thereof. The chili sauce is made from the following raw materials in parts by weight of 20-30 parts of broken dried chilies, 20-30 parts of edible oil, 0.8-1.5 parts of mushroom dry powder, 1-1.5 parts of table salt, 5-7 parts of a light soy sauce, 3-5 parts of a thick broad-bean sauce, 3-5 parts of oyster sauce, 2-4 parts of star anise powder, 6-9 parts of dried pineapple granules and 4-7 parts of deep-fried green beans. The chili sauce is moderate in pepperiness, fresh and delicious in taste without addition of monosodium glutamate, light in fruity flavor, light in sour and sweet taste, and suitable for taste of common people.

Owner:袁俊

A kind of production method of water chestnut powder skin

The invention discloses a method for producing water chestnut sheet jelly, which comprises the following steps: adding flavone substances and dietary fiber separated and extracted from waste of water chestnut processing into water chestnut starch, corn starch, potato starch and sweet potato starch; stirring the mixture to obtain slurry; and preparing to obtain the water chestnut sheet jelly. The method extracts water chestnut flavones and the dietary fiber from mass processing waste caused by the current water chestnut production to realize waste utilization, and reduces the production cost of the water chestnut sheet jelly by adding accessories such as the corn starch, the potato starch and the sweet potato starch, does not influence the quality of the water chestnut sheet jelly, the content of functional ingredients of the sheet jelly is improved obviously, the stretching force of the water chestnut sheet jelly is increased by 11.5 percent, the boiling loss rate is increased by 25.0 percent, the swelling capacity is reduced by 8.0 percent, the content of flavone compounds is increased by 40mg / 500g, the dietary fiber is increased by 0.1g / g, and the water chestnut sheet jelly has high nutrition and health care values.

Owner:华农(潮州)食品研究院有限公司

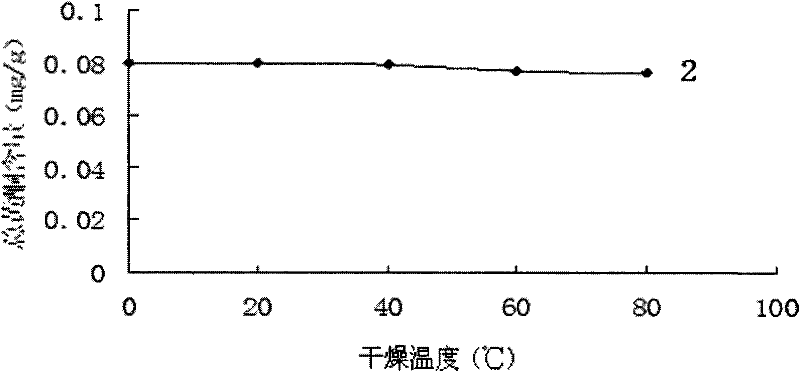

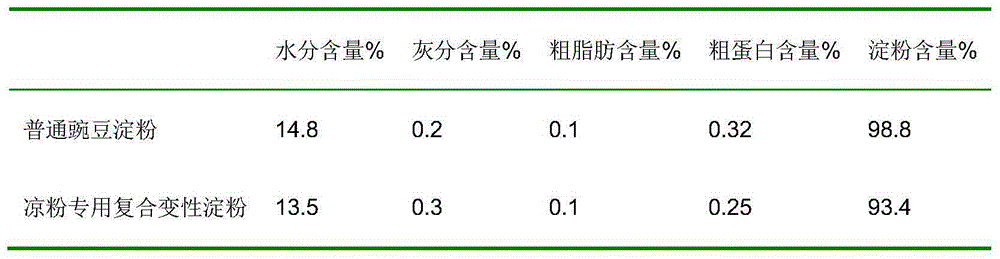

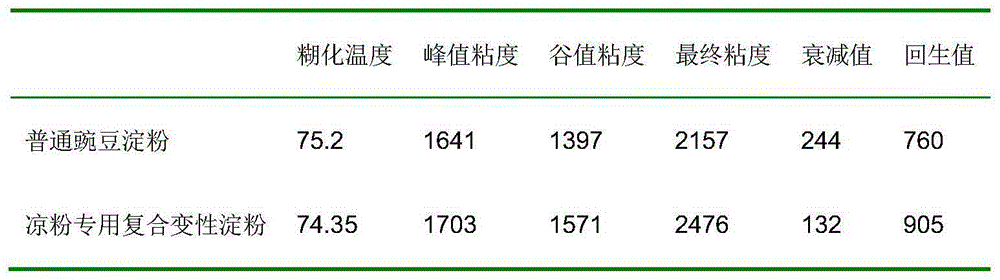

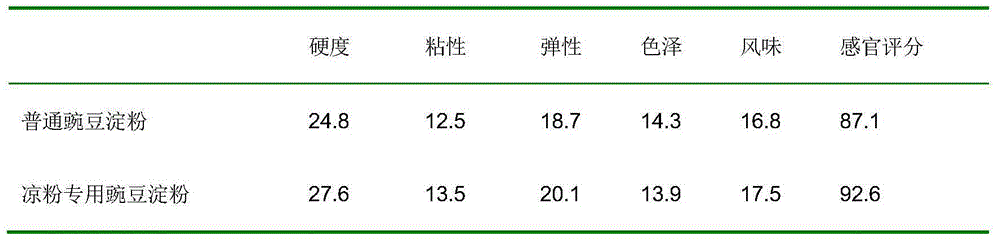

Compound modified starch specially used for bean jelly

InactiveCN105146264AExtended shelf lifeImprove hardness and elasticityFood preservationFood preparationOrganic acidHardness

The present invention discloses a compound modified starch specially used for bean jelly. The compound modified starch mainly comprises 95.95-99.05 parts of pea starch, 0.2-0.9 part of carrageenan, 0.1-0.8 part of potassium chloride, 0.15-0.85 part of rivier giant arum tuber powder and 0.5 to 1.5 parts of an organic acid, wherein the organic acid is citric acid, malic acid or tartaric acid. In the present invention, non-fermentation method is used to produce the pea starch, the organic acid is used to modify the starch in the process of starch production, and a compound colloid of carrageenan and rivier giant arum tuber powder is used to embed the modified starch particles. The starch disclosed by the invention is a special pea starch suitable for producing pea jelly, the pea jelly produced from the starch has a significantly increased shelf life, and the hardness and elasticity of the pea jelly are effectively improved, so that the pea jelly is not easy to crack and has delicate and flexible mouthfeel. The pea jelly has a very broad market prospect, and the production method is beneficial to jelly producers for large-scale production and long-distance sales.

Owner:YANTAI ORIENTAL PROTEIN TECH

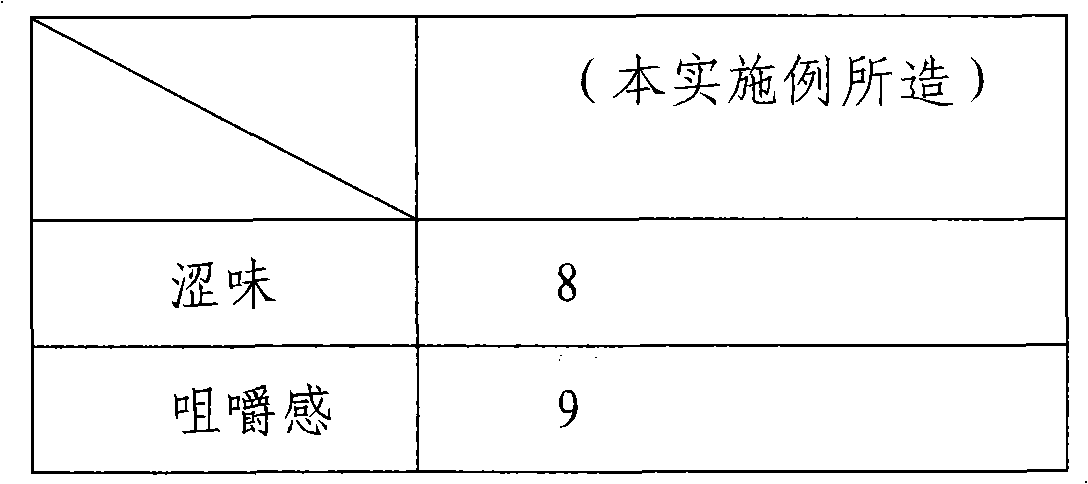

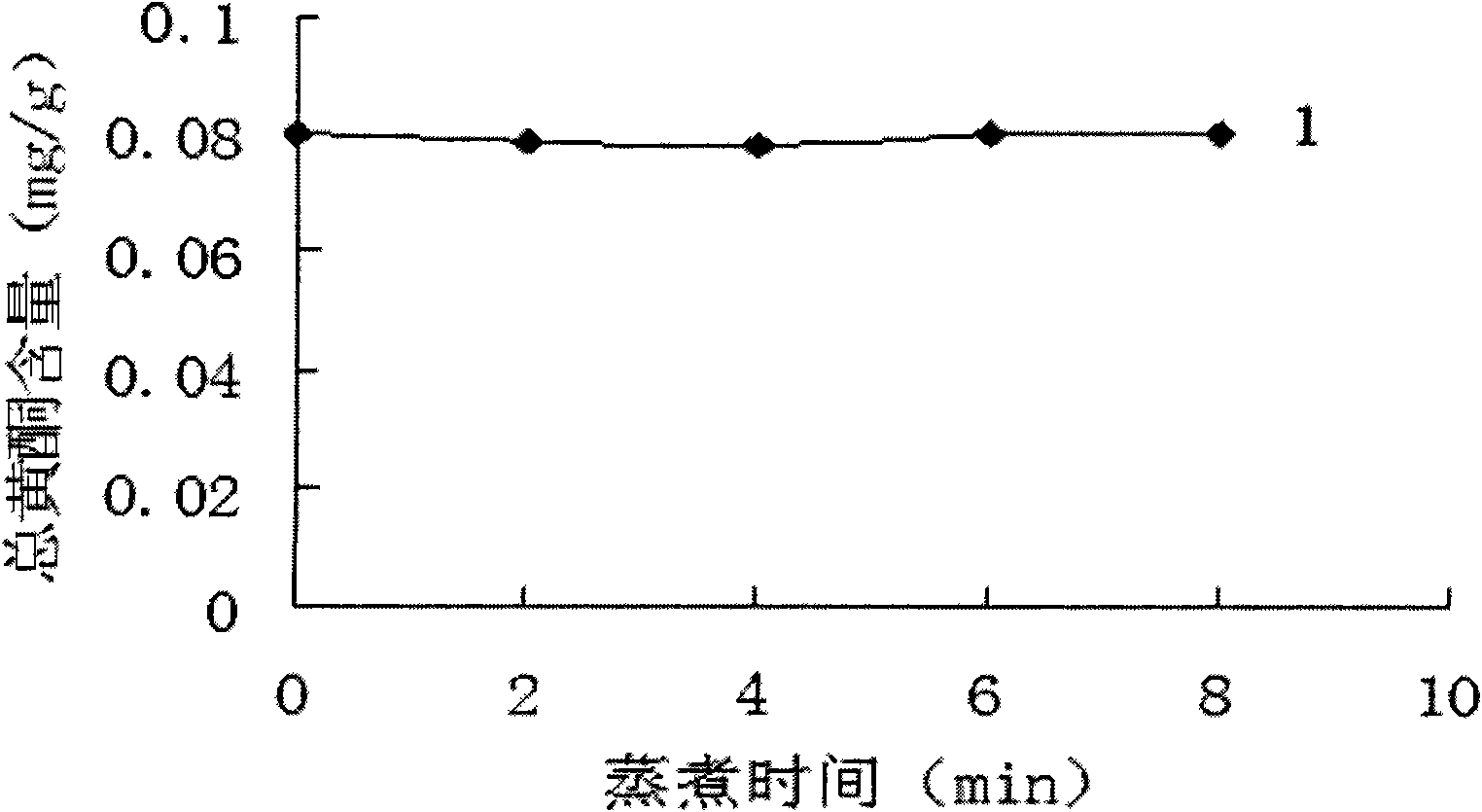

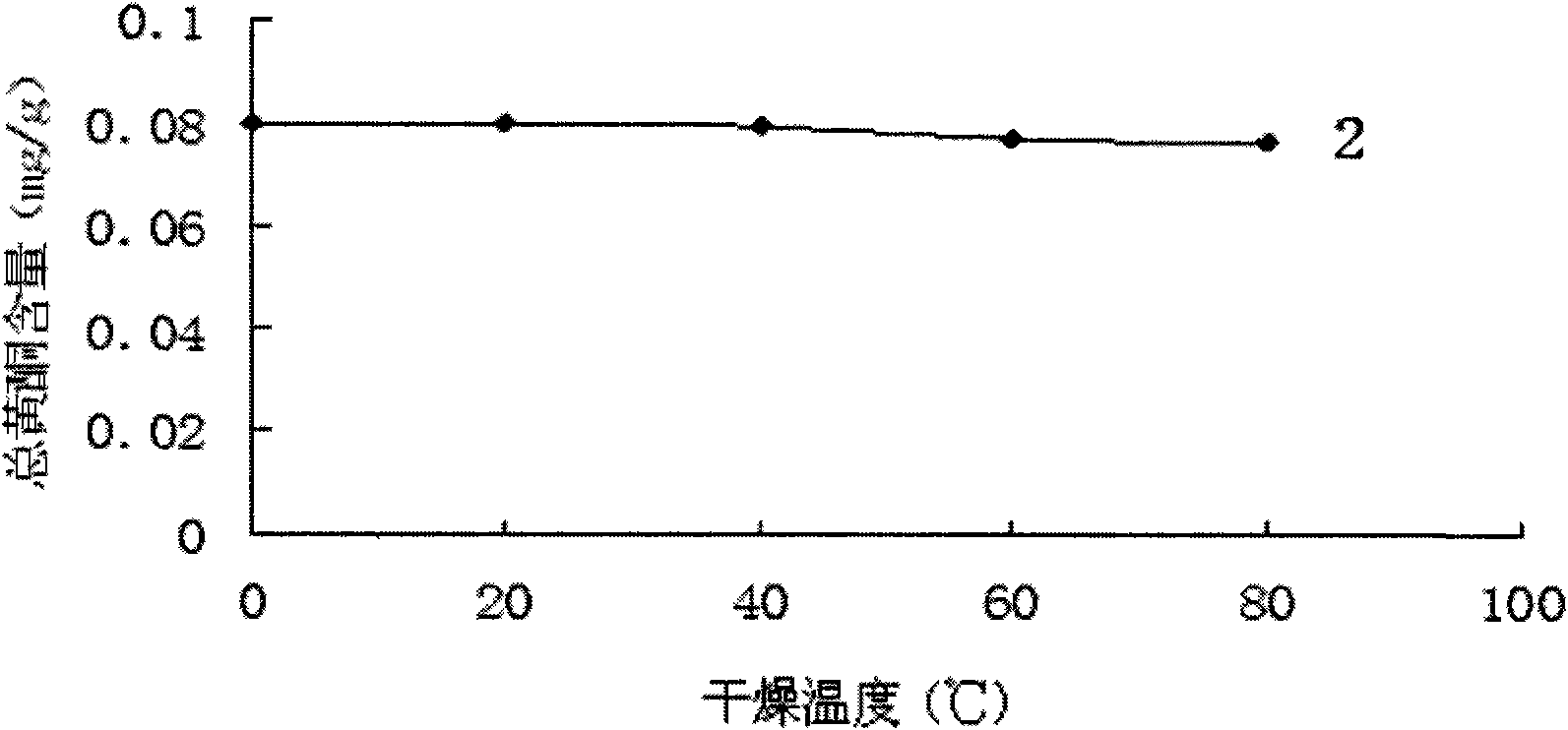

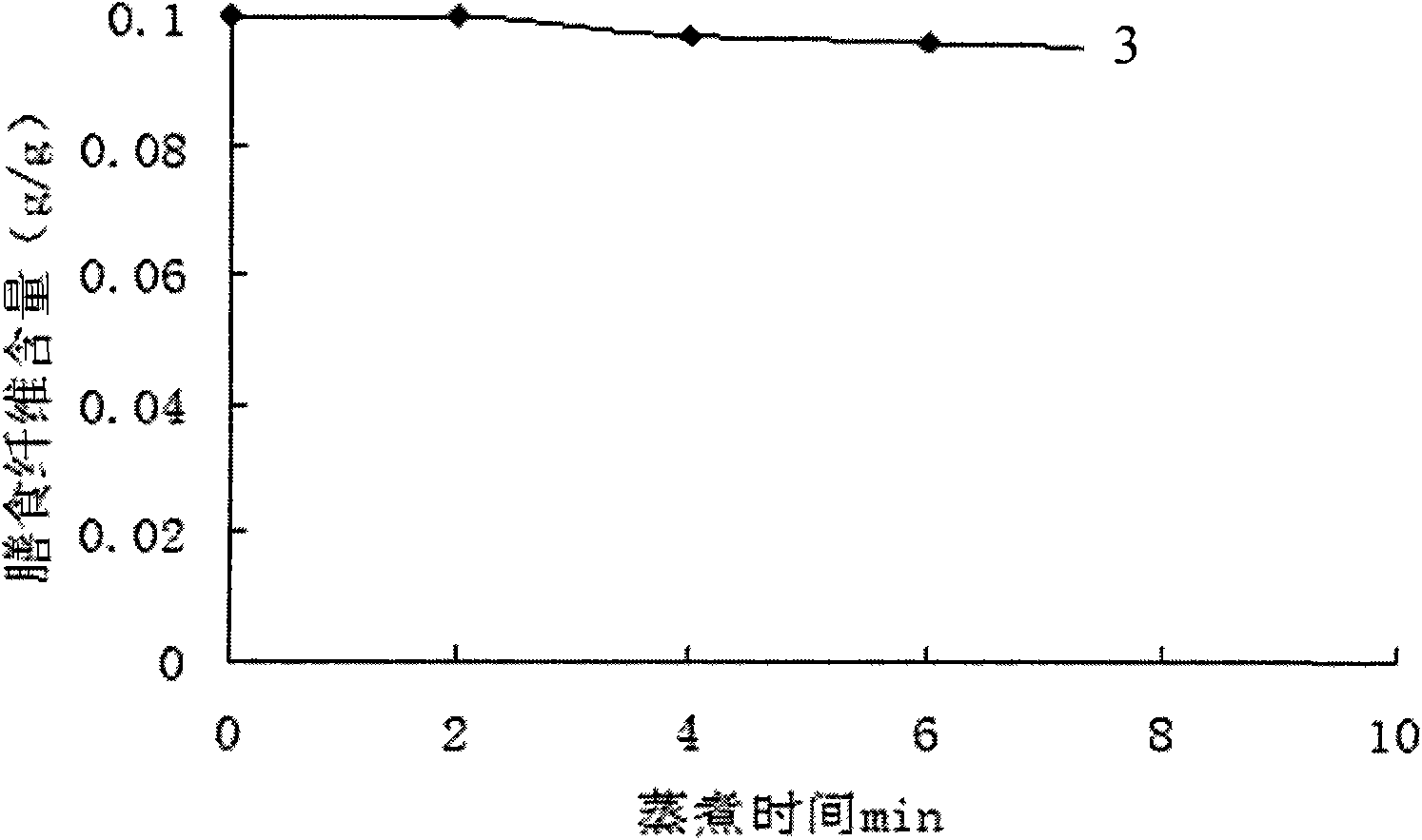

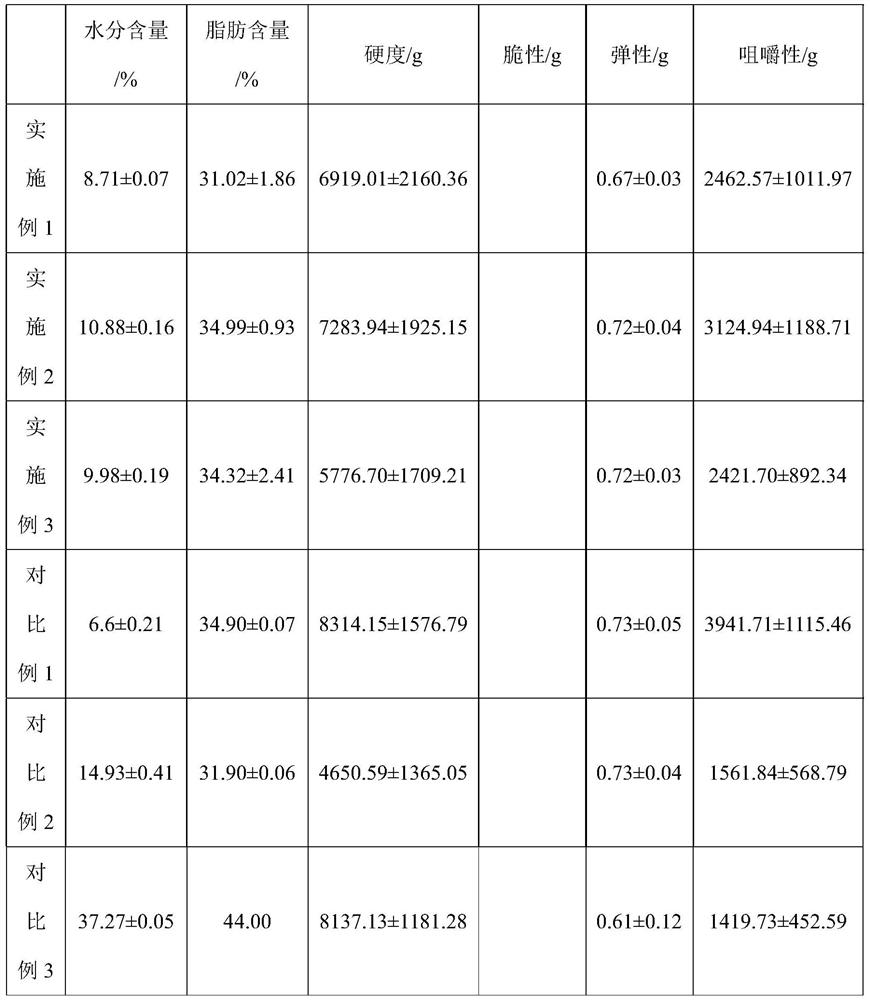

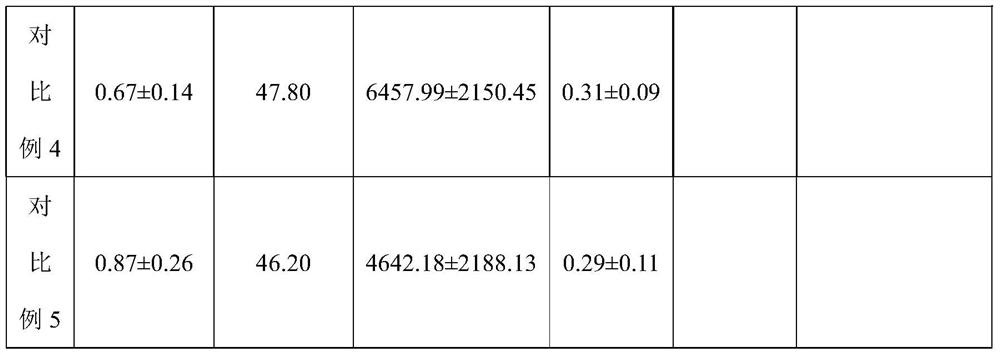

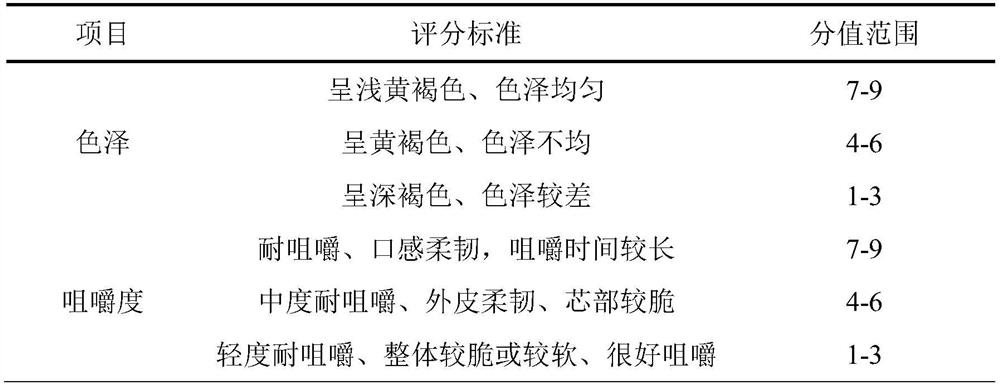

Chewing-resistant semi-degreased leisure peanuts and preparation method thereof

The invention relates to chewing-resistant semi-degreased leisure peanuts and a preparation method thereof. The preparation method of the leisure peanuts comprises the following steps: providing peanut kernels with the fat content of 25wt%-45wt%; pre-cooking the peanut kernels to obtain complex peanut kernels with the water content of 30wt%-45wt%; and drying the complex peanut kernels to prepare the leisure peanuts. The water content of the leisure peanuts is 8wt%-13wt%, and the fat content of the leisure peanuts is 20wt%-40wt%. The prepared leisure peanuts are flexible in taste, elastic, palatable and chewy.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

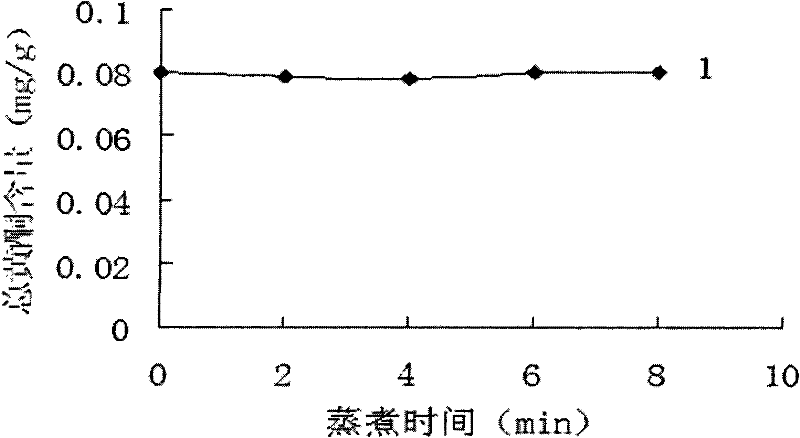

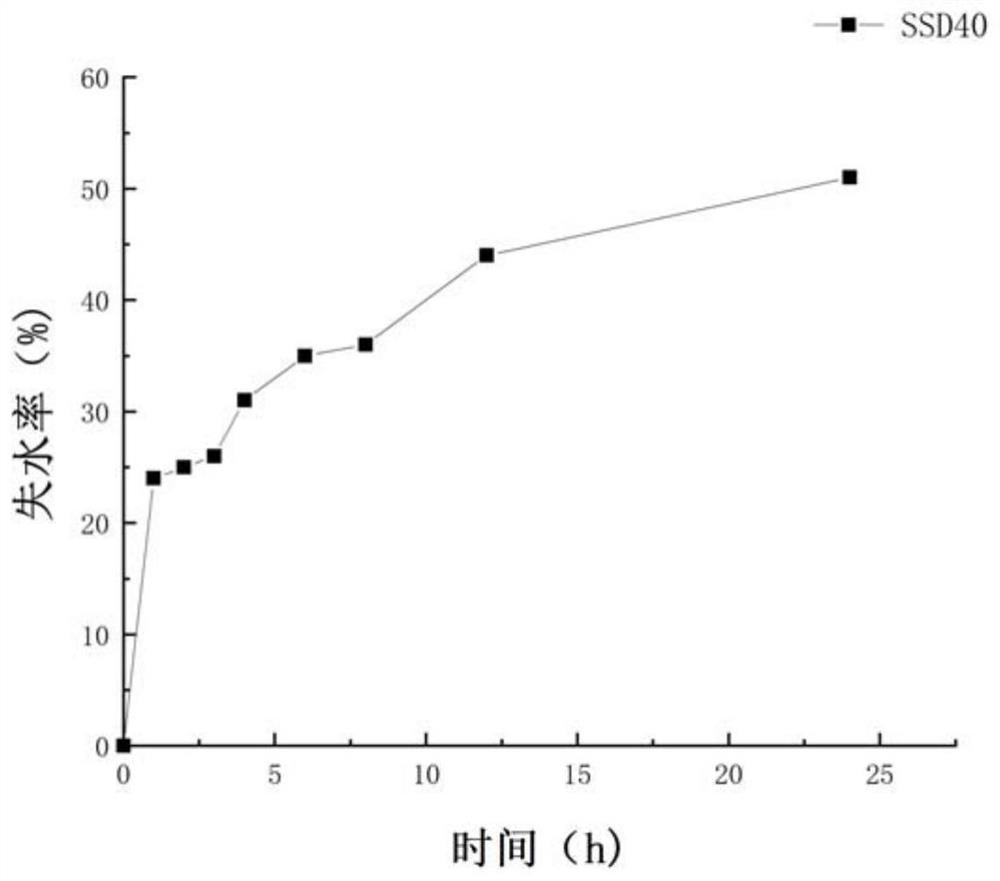

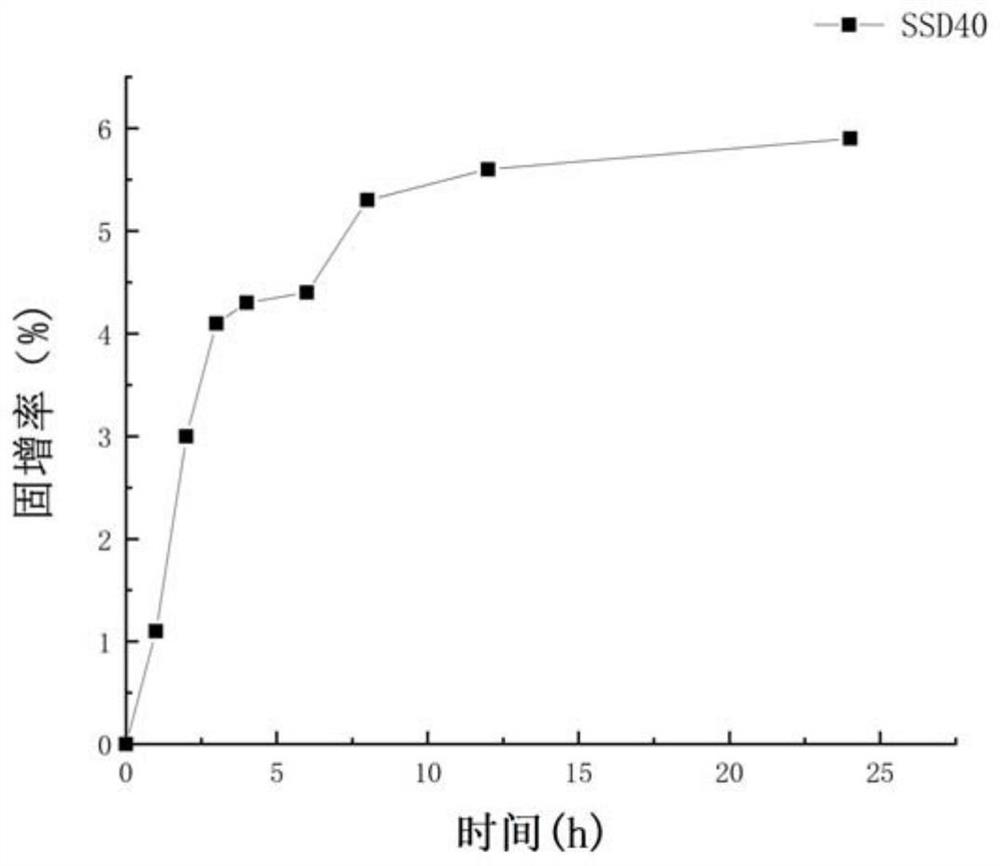

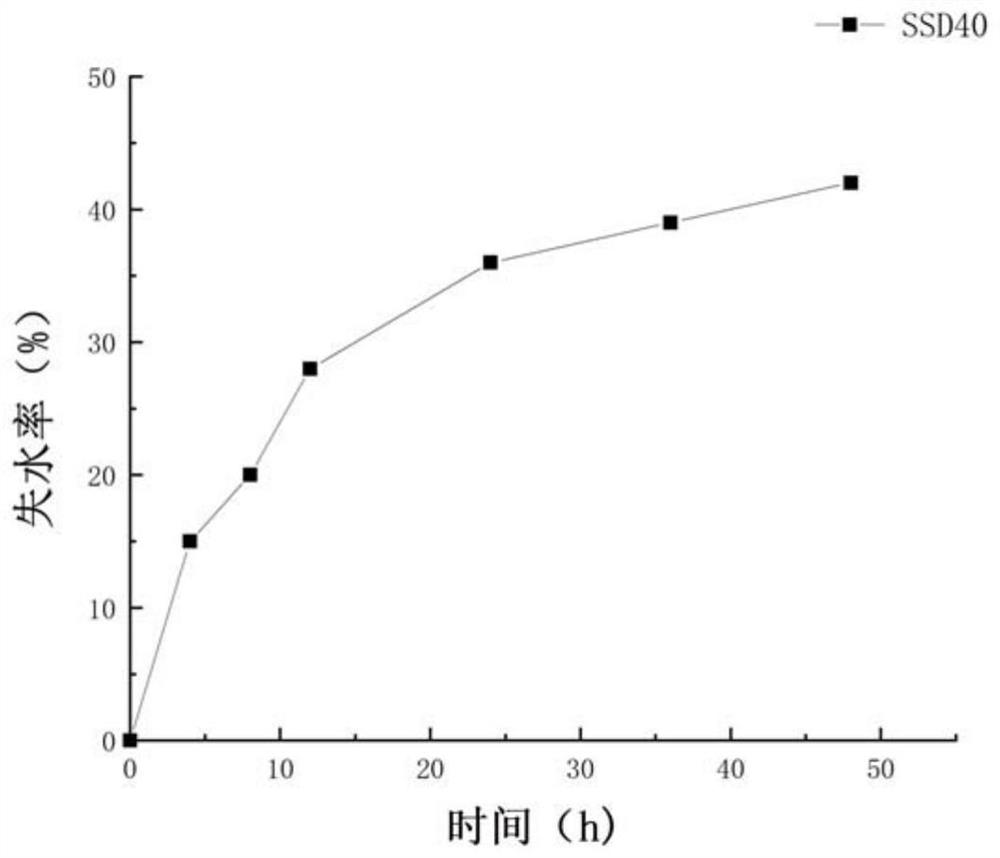

Method for improving quality of dried mangoes through intermittent solid sugar permeation

PendingCN113142374AReduce degradationAvoid looseFood thermal treatmentConfectioneryBiotechnologySucrose

The invention provides a method for improving the quality of dried mangoes through intermittent solid-state sugar permeation. The method comprises the following steps: firstly, carrying out primary solid-state sugar permeation on mango blocks; intermittent treatment; performing ultrasonic blanching; performing secondary solid sugar permeation, and finally drying; according to the method, sucrose is used as a solid penetrant for the first time, so that pressure difference is generated inside and outside cells, free water in the cells is rapidly removed, then intermittent treatment is carried out, three-state water in mango cell tissues is mutually converted and redistributed, the cell tissues are fully trimmed, and ultrasonic blanching is used for promoting the cell tissues to form micro-channels and second solid sugar permeation is performed, and in the whole process, cell tissue damage is small, nutrient substance loss is little, the technology is simple, industrialized production is facilitated, and the produced dried mangoes have good toughness and elasticity and high nutritive value.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS +1

Additive-free five-grain nutritious instant noodles and production method thereof

ActiveCN104256361BElastic footIncrease elasticityFood ingredient functionsPreservativeQuality optimization

The invention relates to convenient additive-free five-cereal nutritional noodles and a processing method thereof, and belongs to the field of food processing. The processing method comprises the following steps: performing quality optimization treatment on corns and black beans, grinding together with wheat, polished round-grained rice and yellow millets, blending, and performing curing forming to obtain the convenient five-cereal nutritional noodles. The obtained five-cereal nutritional noodles give full play to complementary nutrition advantages of rice, flour and beans, are endowed with relatively high nutritional value, are good in elasticity, toughness and reconstitution properties, do not need to be digested, can be eaten after being soaked with boiling water, and are convenient and quick; the process conditions are mild, no chemical and biosynthetic technologies are adopted, no pollution, waste residue, waste steam, waste water or harmful substance is generated, green production is realized, no gluten fortifier, thickening colloid, enzyme preparation or preservative is added, and no chemical reagent is used, so that the noodles are safe to eat.

Owner:吉林省正源食品有限责任公司

Konjac noodles and preparation method thereof

PendingCN112056545AGood film formingImprove toughnessFood preservationFood ingredient as solidifying agentBiotechnologyCellulose

The invention belongs to the field of konjac food processing. Konjac noodles are prepared from the following components in percentage by mass: 4-5% of konjac fine powder, 15-17% of modified starch, 0.1-0.3% of sodium carbonate, 0.05-0.1% of citric acid, 0.05-0.1% of D-sorbitol solution, 0.05-0.1% of carrot pigment, 0.04-0.06% of titanium dioxide, 0.04-0.06% of locust bean gum, 0.01-0.03% of xanthan gum, 0.01-0.03% of carboxymethyl cellulose, 0.01-0.03% of corn gum, 0.01-0.03% of carrageenan, 0.005-0.015% of ethyl maltol, 0.005-0.015% of vitamin E and the balance of pure water. The konjac noodles have good palatability and chewiness, high expansion rate, are similar to noodles in shape, are not easy to be burnt when being cooked, and have soft and tough taste and high resilience.

Owner:惠州旺嘉食品有限公司

Method for preparing candied persimmon

The invention provides a method for preparing candied persimmons. The method comprises the following steps: selecting millstone-shaped persimmons in Ji County in Tianjin, performing early astringent taste removal treatment and disinfection treatment on the selected persimmons, preparing a blank, pouring the persimmons into a basin, drying in a drying room, forming, and carrying out sugar adhering and packaging, thereby obtaining the candied persimmons. The candied persimmons are saffron yellow, bright in color and chewable and pliable in taste and have strong persimmon flavor.

Owner:TIANJIN QINGLIAN SHANSHUI FOOD

Production process of nutrient-rich Yangzhou quick-boiled shredded dried bean curd

The invention relates to a production process of nutrient-rich Yangzhou quick-boiled shredded dried bean curd and belongs to the technical field of bean products. The shredded dried bean curd are boiled with edible salt, kept fresh and shredded, then primary quick-boiling, soaking and secondary quick-boiling are carried out, flavoring liquid, shredded ginger, shredded red pepper, chopped coriander, dried shrimps and the liked are added, mixed and stirred, and then the shredded dried bean curd can be eaten. According to the quick-boiled shredded dried bean curd provided by the invention, undersoaking of the flavoring liquid, the shredded dried bean curd tastes flexible, delicious and mellow and is enriched in flavor, thereby wining much love of people. The quick-boiled shredded dried beancurd provided by the invention can be eaten immediately after being prepared and can also be packed to be carried for long distance. The Yangzhou quick-boiled shredded dried bean curd prepared by theproduction technology provided by the invention is a healthy and hygienic food suitable for and loved by people of all ages, is rich in nutrient, convenient to prepare and delicious.

Owner:胡应明

A kind of manufacture method of candied mushroom

A manufacturing method of a mushroom conserved fruit relates to a mushroom, in particular to a conserved fruit adopting the mushroom, in particular a mushroom stem as raw materials. The invention provides the manufacturing method of the mushroom conserved fruit. The impurities of mushroom raw materials are removed, a hard and rotten mildew part is cut down; the mushroom raw materials after being picked out and cleaned is dipped by water, so that the mushroom condensates; the mushroom after condensation is cleaned, mud and other feculences stuck on the mushroom are scoured off; the cleaned mushroom is boiled in boiling water, thereby reaching the effects of slaking and sterilizing; the mushroom after being boiled is dehydrated; the dehydrated mushroom is seasoned and fried; the mushroom after being seasoned and fried is performed; the mushroom which is performed is dried; the dried mushroom is cooled; and the cooled mushroom is packaged. The mushroom is rich in nutritive materials, such as lentinan, etc., in particular the mushroom stem is rich in over sized fibres, and therefore, after being processed into the conserved fruit, the mushroom has the health care functions of promotion of stomach creepage, assimilation promotion, cancer and diabetes mellitus prevention.

Owner:周冰冰

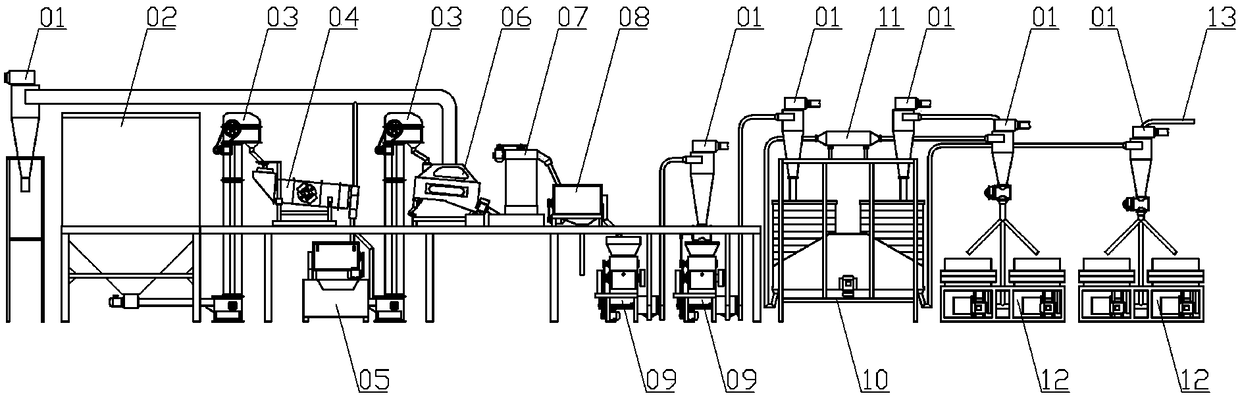

A low-temperature processing method of wheat flour and the system device and application thereof

InactiveCN106423398BIncrease productivityReduce high temperatureGrain treatmentsPrimary screeningMoisture

The invention discloses a low-temperature wheat flour processing method, a system device adopting the method and application. Wheat is stored in a dry environment of 15-20 DEG C, the wheat is processed by using the wheat processing device, primary screening, stone removal and wheat wetting are performed for 10-12 hours, the wheat wetting temperature is 18-25 DEG C, 6-12 KGy gamma ray irradiation sterilization, secondary roughening, twice breaking, flat-screen screening and cooling are performed, the rotation speed is 38 r / min-40 r / min after the first time of stone-mill grinding, and then wheat flour is produced through three times of flat-screen screening and stone-mill grinding. The method is high in production efficiency and free of additives, a cooler is added to reduce high material temperature caused by a flour mill, meanwhile the rotation speed of a stone mill is improved from 20 r / min to 40 r / min, the powder yield can be up to 87%, it is detected that the moisture content of the produced wheat flour is below 4.5%, the ash content is below 0.8%, the magnetic metal content is below 0.00015%, and gluten quality is up to 28%.

Owner:XINJIANG DETIANLI AGRI DEV CO LTD

Method for preparing papaya cake

InactiveCN100420386CPrevent crystallizationTaste flexibleFood preparationPapaya familyAdditive ingredient

Disclosed is a process for preparing papaya cakes from papaya fruit as the principal raw material through charging gelling agent, cane sugar and lemon acid, heating and moulding, and drying at a changed temperature.

Owner:SOUTH CHINA AGRI UNIV

Buckwheat vermicelli and preparation method thereof

InactiveCN108685013AImprove tasteTaste flexibleFood dryingFood ultrasonic treatmentChemistryUltrasonic technology

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Production method for easily-soaked boilproof cured nutritive fresh corn

The invention provides a production method for easily-soaked boilproof cured nutritive fresh corn, which comprises the following steps: firstly, ripe corns and boxthorns are grinded down, and fresh corns are hulled, threshed and grinded in a superfine manner; secondly, after secondary curing, the product obtained in the first step is extruded, cut, cooked, refrigerated in vacuum, stored for six months, and can be eaten after being rehydrated in boiling water for three minutes; and the product obtained in the second step is dried in a controlled temperature between 50 to 52 DEG C for 120 minutes, moisture is reduced to about 8 to 9 %, the corn is cooked into pliable and delicious corn food after being rehydrated and boiled in boiling water for 5 minutes, and can be stored for 12 months in an ordinary temperature. By using the method provided by the invention, the shortcomings that the mouthfeel of corn food produced by directly boiling and grinding corn seeds is bad, and the rehydration time in boiling water is short are overcome, the status quo that the fresh corns can be only produced into food with short freshness date such as cans and quick-freeze corncobs is changed, and a novel food processing method for the fresh corn is created.

Owner:吉林省全鑫科技有限公司

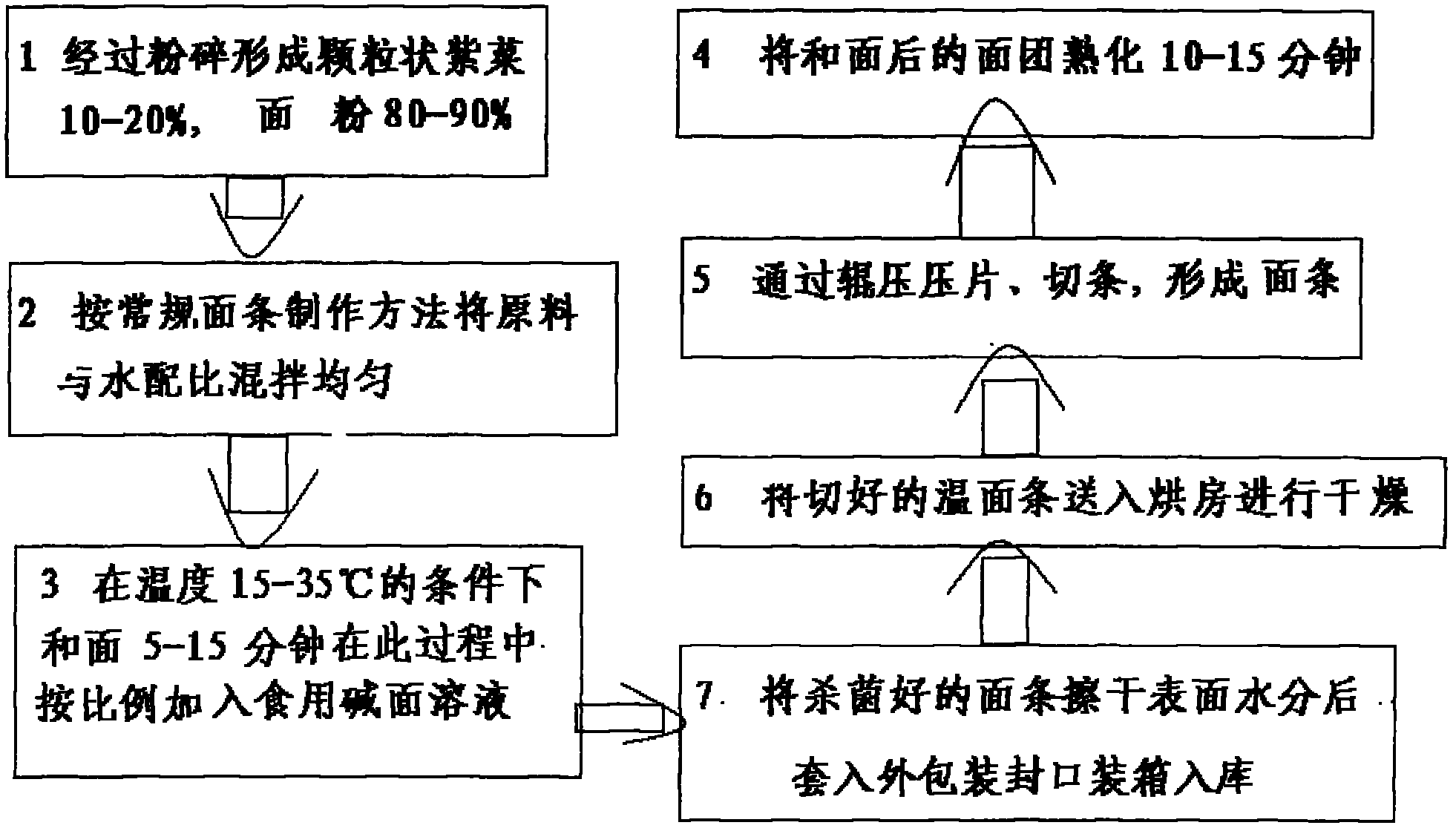

Black noodles and processing method thereof

InactiveCN103125835AImprove qualitySatisfied disorderly distributionFood preparationMicronizationRaw material

The invention discloses black noodles and a processing method of the black noodles. The black noodles and the processing method of the black noodles comprise the following technique steps: 1 the raw materials of the black noodles comprise, by weight, 10% to 20% of micronization agar, 80% to 90% of flour, 5% to 8% of water of the micronization agar, and 10% to 90% of ultrafine particles, wherein the particle size of the ultrafine particles is between 60 meshes to 120 meshes; 2 the raw materials and water are matched, stirred and mixed evenly according to a conventional noodle production method; 3 dough making is conducted for 5 minutes to 15 minutes under the temperature of 15 DEG C to 35 DEG C, and edible sodium carbonate solution is added in the process of dough making; 4 the dough is cured for 10 minutes to 15 minutes after the dough making; 5 sheet rolling and slitting are conducted so that the noodles are made; 6 cut wet noodles are placed in a drying room to be dried; and 7 the water on the surface of the noodles are wiped after drying sterilization, and then the noodles are sleeved by an outer packing, sealed, enchased and put in storage. The black noodles and the processing method of the black noodles have the advantages that processed micronization agar noodles are delicious in taste, convenient to eat, rich in nutriments, smooth in surface and easy to store.

Owner:侯和平

Dry-type three-segment mature method rice-flour production technique

Owner:湖南省天龙米业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com