Method for improving quality of dried mangoes through intermittent solid sugar permeation

A dry and solid mango technology, applied in confectionery, confectionery industry, food drying and other directions, can solve the problems of limited large-scale production of enterprises and complicated technological operation process, and achieves favorable heat and mass transfer and moisture migration, and reduces degradation. , to avoid the effect of enzymatic browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for intermittent solid sugar penetration to improve the quality of dried mangoes, comprising the following steps:

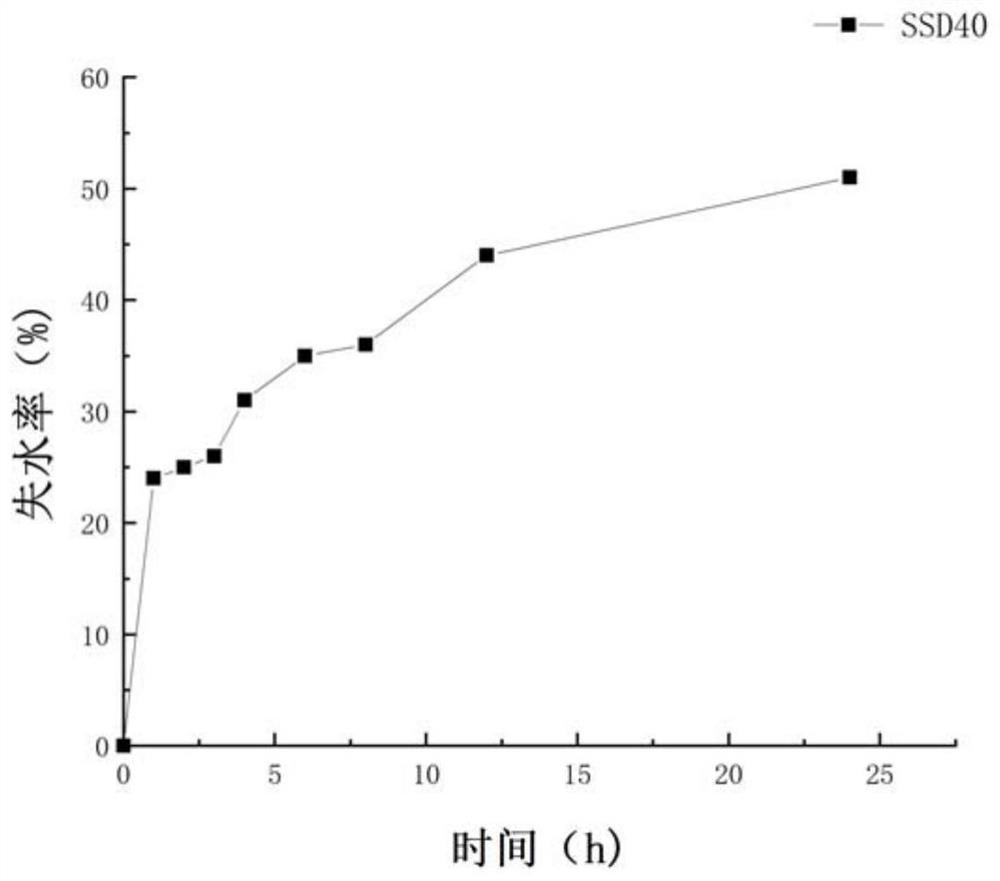

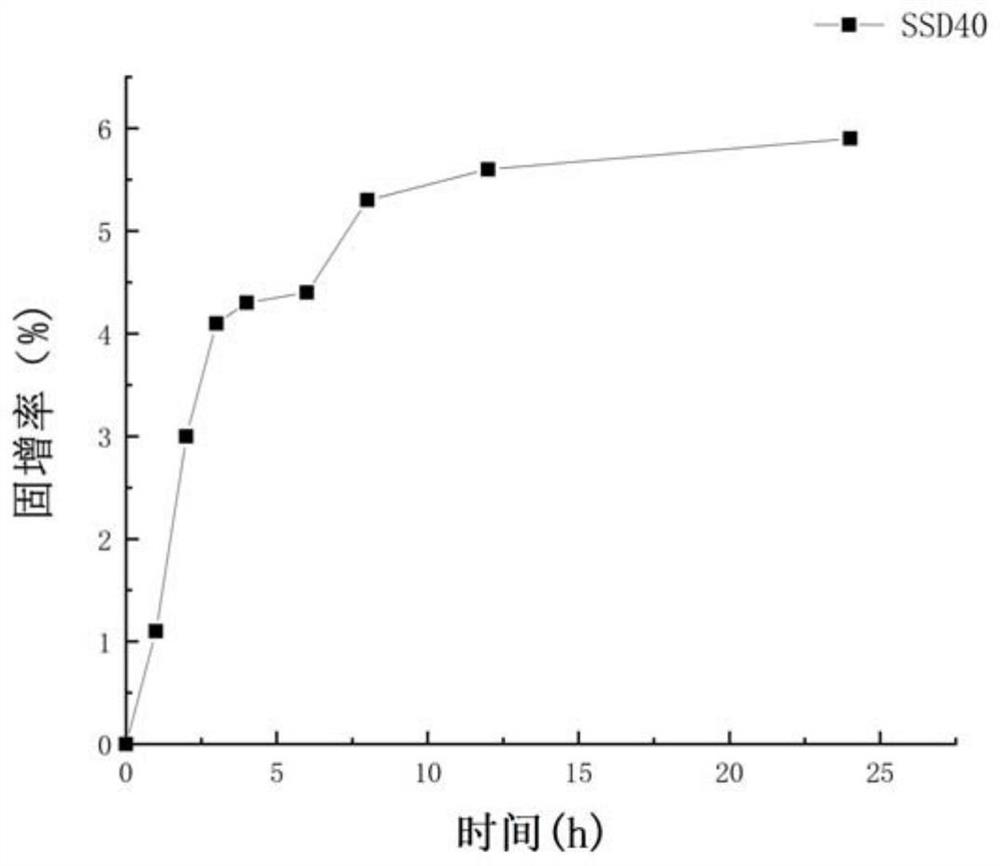

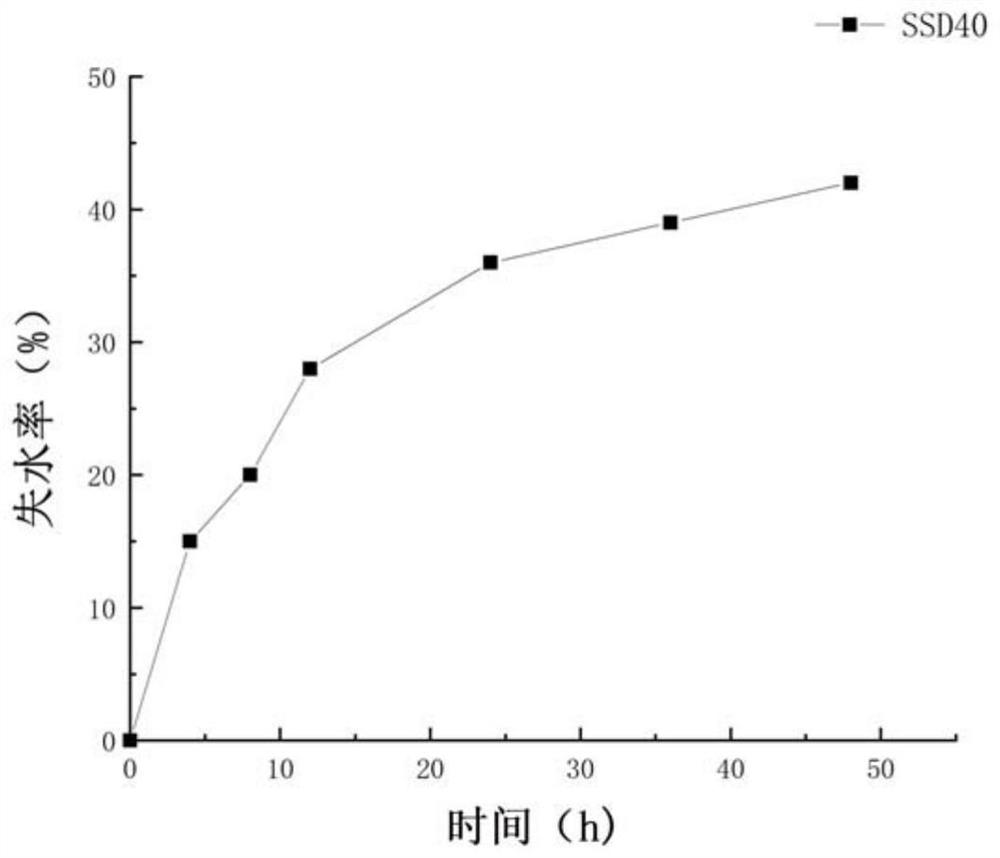

[0032] Choose mangoes with a water content of 80% and a soluble solid content of 12Brix as raw materials, and select mangoes with similar maturity as raw materials. After peeling, cut them into flaky fruit pieces with a thickness of 1cm and a length and width of 3×4cm. Add 100g of good mango pieces, add 40g of sucrose, and carry out solid sugar osmosis treatment, treatment temperature 20℃, treatment time 24h; put the mango pieces after solid sugar osmosis treatment once into the refrigerator at 0-4℃ for 48h; Put the mango pieces into the ultrasonic equipment, and the ultrasonic power density is 0.3W / cm 2 , temperature 70°C, time 1.5min; take 100g of mango pieces after ultrasonic blanching treatment, add 20g of sucrose, and carry out secondary solid sugar infiltration treatment, treatment temperature 20°C, treatment time 48h; After the block is dr...

Embodiment 2

[0044] A method for intermittent solid sugar penetration to improve the quality of dried mangoes, comprising the following steps:

[0045] Choose mangoes with a water content of 85% and a soluble solid content of 13Brix as raw materials, select mangoes with similar maturity as raw materials, peel them and cut them into flaky fruit pieces with a thickness of 1cm and a length and width of 3×4cm. Add 100g of good mango pieces, add 30g of sucrose, and carry out solid sugar osmosis treatment, treatment temperature 30℃, treatment time 24h; put the mango pieces after solid sugar osmosis treatment once into 0-4℃ refrigerator for storage for 48h; Put the mango pieces into the ultrasonic equipment, and the ultrasonic power density is 0.5W / cm 2 , temperature 80°C, time 2min; take 100g of mango pieces after ultrasonic blanching treatment, add 20g of sucrose, and carry out secondary solid sugar infiltration treatment, treatment temperature 30°C, treatment time 48h; After the leach treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com