Patents

Literature

49results about How to "Prevents enzymatic browning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for tea extract

The invention discloses a preparation method for a tea extract, belonging to the technical field of extraction of effective components of tea leaves. The preparation method comprises the following steps: firstly, carrying out low-temperature rapid freezing treatment on high-quality commercial tea leaves; then immediately crushing; then combining a high-voltage pulsed electric field (PEF for short) technology, an ultrasonic treatment technology and a low-temperature enzymolysis technology; and carrying out low-temperature extraction in a whole process. According to the preparation method for the tea extract, the loss of effective components, caused by high-temperature processing, is avoided, and the extraction rate of the effective components of the tea leaves is also improved. The process is simple and low in cost; the introduction amount of extraneous food additives, processing auxiliary agents and chemical substances is reduced; the natural nutritional ingredient and the flavor of the tea leaves are kept to the greatest extent, the low-carbon production is realized and the environment is protected.

Owner:LVJIN DEV FUJIAN

Method for preparing watermelon juice

The invention provides a method for preparing watermelon juice. The method comprises the following steps of: pulping watermelon flesh to prepare an initial product of the watermelon juice under an anaerobic environment, carrying out ultrahigh pressure processing on the initial product of the watermelon juice, and then arranging the processed product at 0-10 DEG C for storing, wherein the anaerobic environment means that the oxygen content of an environment is not higher than 3%. The invention further provides the watermelon juice. According to the method disclosed by the invention, elements in the watermelon juice, such as original small molecular flavor matters, soluble solid matters, organic acid, amino acid and the like, are greatly preserved, thus damages on main color rendering materials and thermo-sensitive flavor substances in the watermelon due to temperature and oxygen are avoided, and fresh taste watermelon juice with original cleaning flavor of a fresh watermelon is obtained.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

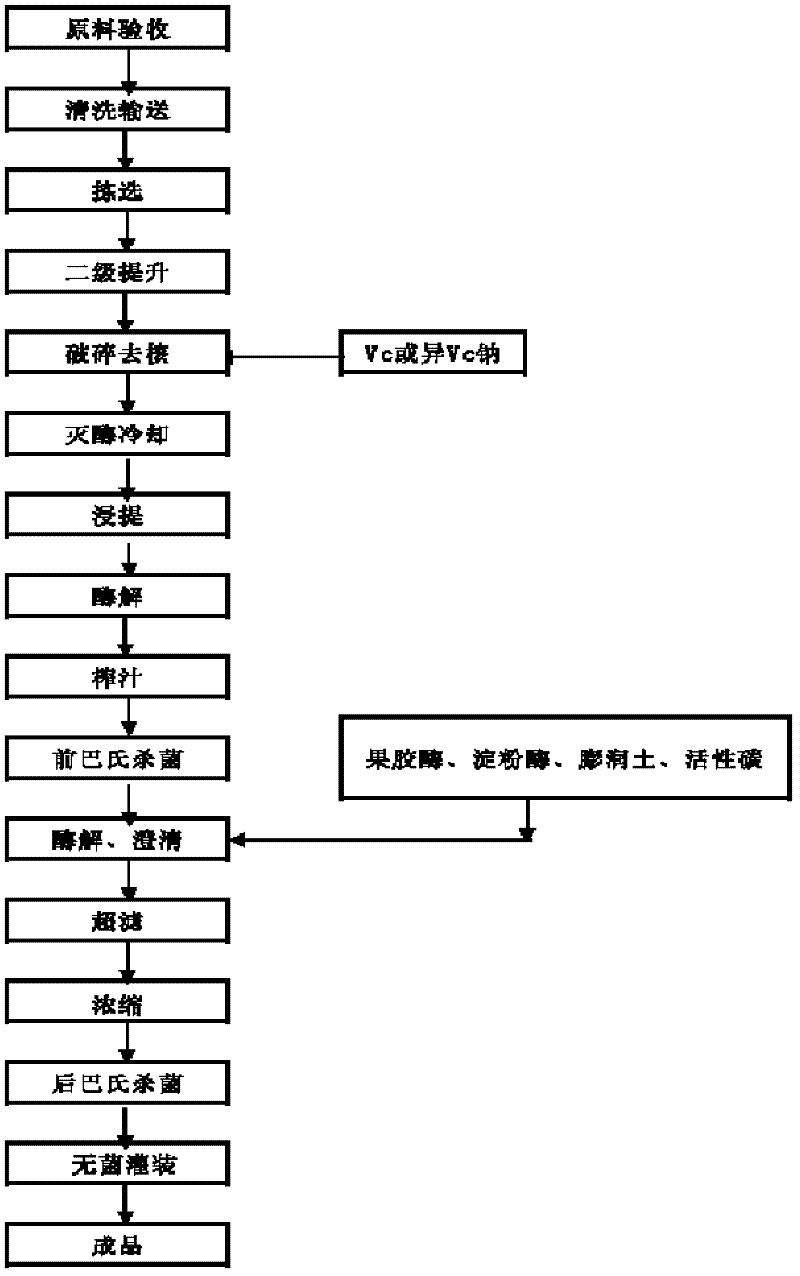

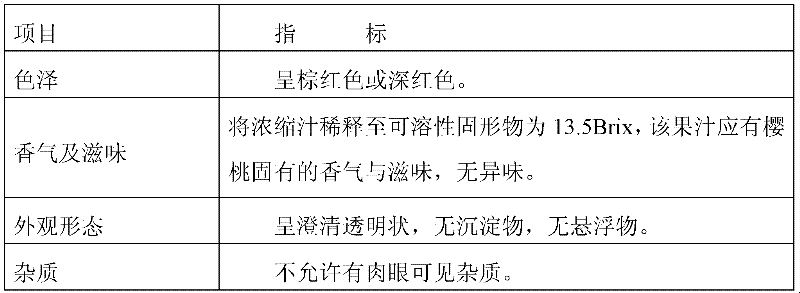

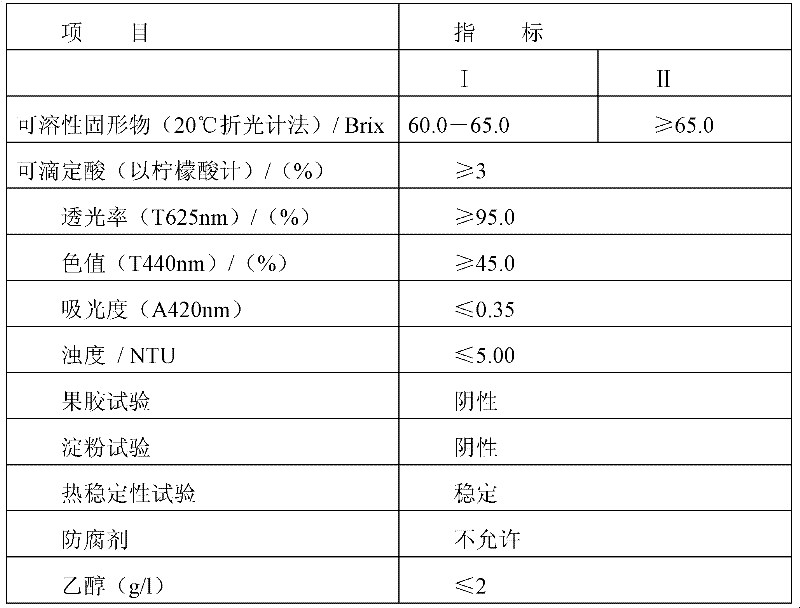

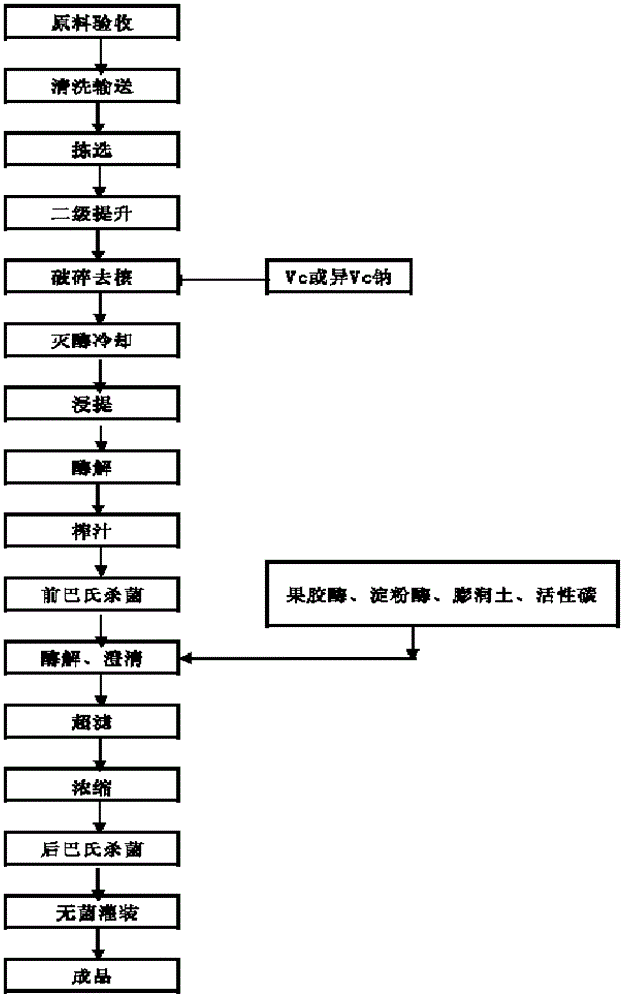

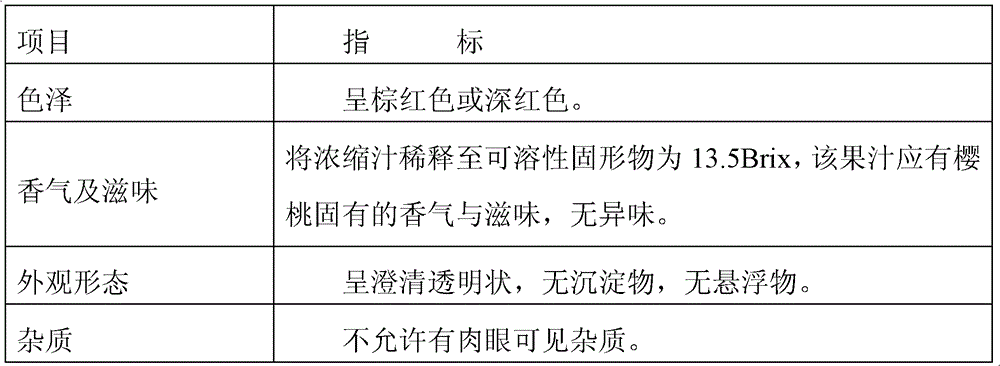

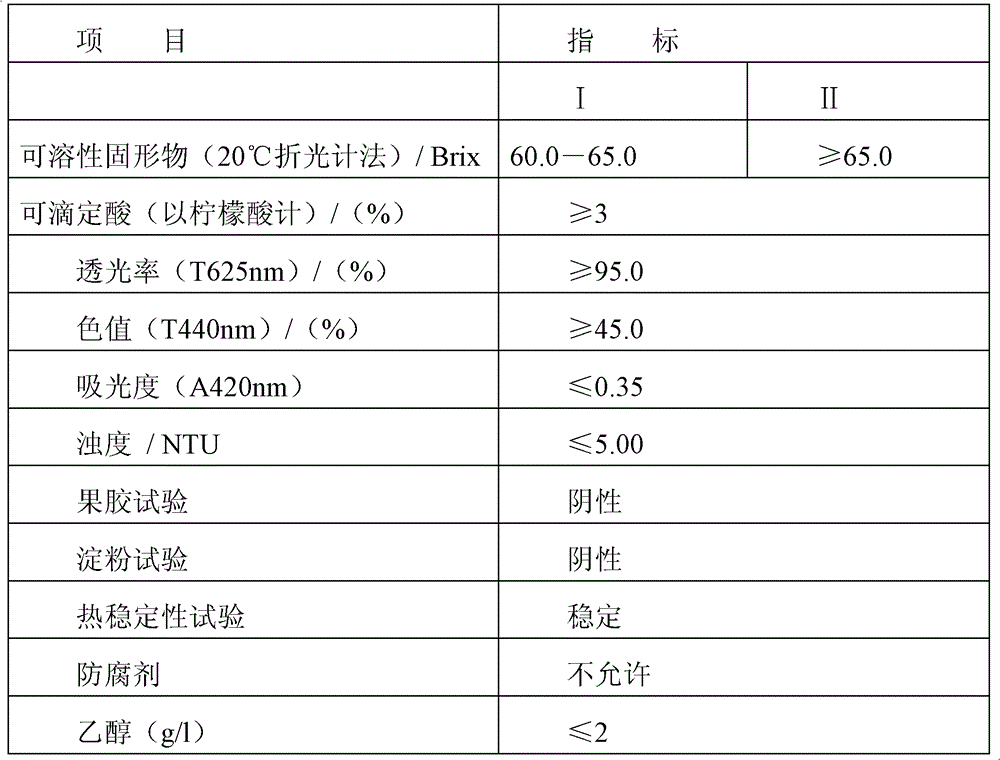

Process for producing cherry juice concentrate

The invention discloses a process for producing a cherry juice concentrate. The process comprises the steps as follows: washing cherries, crushing, removing stones, inactivating enzymes, cooling, leaching, cooling, performing enzymolysis, juicing, performing pasteurization, clarifying enzymatic hydrolysates, performing ultrafiltration, concentrating, performing pasteurization again, and packaging. The process improves the quality of the cherry juice concentrate. The cherry juice concentrate has a red brown or scarlet color, and is clear and free of sediments or suspended substances. The content of soluble solids is more than 60.0 Brix. When diluted until the content of soluble solids is 13.5 Brix, the cherry juice concentrate maintains the fragrance and flavor of cherries and smells good.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

Quick-frozen fresh-kept gastrodia elata blume and technology for preparing same

InactiveCN102860354AGood quality and good priceFacilitate the thawing processFruit and vegetables preservationAdditive ingredientGastrodia elata

The invention relates to a quick-frozen fresh-kept gastrodia elata blume and a technology for preparing the same. The technology comprises the following steps of cleaning and grading fresh gastrodia elata blume, quick-freezing at the temperature of -20 DEG C, subpackaging and performing freezing storage to obtain the finished product, namely the quick-frozen gastrodia elata blume. After being unfrozen, the gastrodia elata blume can be used as fresh gastrodia elata blume for processing or cooking. The quick-frozen fresh-kept gastrodia elata blume provided by the invention has the advantages of high fresh-keeping effect, small loss of functional compositions such as nutritional ingredients, long shelf life and the like, and can meet perennial demands of enterprise production and markets.

Owner:陈朝银

Processing technology for efficiently increasing gastrodin content in gastrodia elata blume

InactiveCN102894241AMaintain shape and compositionShort duration of actionNervous disorderAntipyreticNutritionEngineering

The present invention discloses a processing technology for efficiently increasing gastrodin content in gastrodia elata blume. The processing technology is characterized by adopting high strength and low strength microwave segmenting processing, wherein per kg of a gastrodia elata blume raw material is subjected to a 1000-10000 W microwave treatment for 1-10 min at a high strength stage, and per kg of the gastrodia elata blume raw material is subjected to a 100-1000 W microwave treatment for 3-30 min at a low strength stage, such that gastrodin content in the fresh gastrodia elata blume can be substantially increased, advantages of short processing time, high gastrodin content, low loss of nutrition and other functional components, and the like are provided, and the processed gastrodia elata blume can be adopted as a gastrodin-rich gastrodia elata blume raw material to be further processed into other gastrodia elata blume products, and has better medical care values and commodity values compared with the conventionally-processed gastrodia elata blume.

Owner:陈朝银

Low-sugar large hawthorn fruit preserves processing method

InactiveCN106900966APrevents enzymatic browningBright colorConfectionerySweetmeatsNutritive valuesFlavor

The invention discloses a low-sugar large hawthorn fruit preserves processing method, belongs to the technical field of food processing, and aims to provide a low-sugar large hawthorn fruit preserves processing method which is characterized in that fresh large hawthorn fruits are selected and processed, food preservatives and coloring agents are omitted, flavor and nutrition values of the large hawthorn fruits are kept, and the processed large hawthorn fruits has the advantages of bright color, sour and sweet taste and the like. The method includes the steps: selecting; cleaning; peeling; stripping and slicing; protecting color; boiling sugar; filtering sugar; drying, packaging. The colors of large hawthorn fruit blocks are protected by the aid of sodium chloride solution, and sugar filtering is performed by the aid of microwave technique. The processing method is used for making large hawthorn fruit preserves.

Owner:HEZHOU UNIV

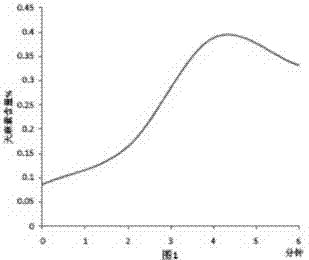

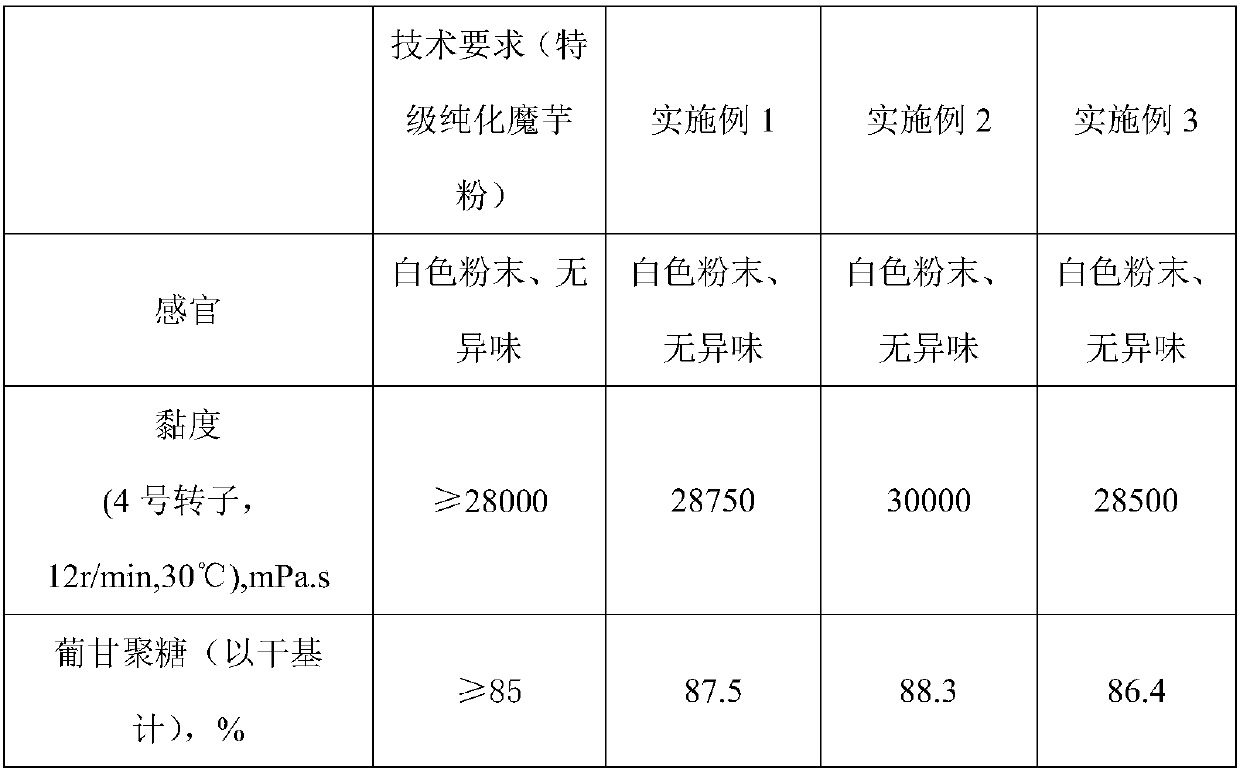

Preparation method of konjac flour

The invention discloses a preparation method of konjac flour. The preparation method comprises the following steps of adding a color fixative for preventing konjac from generating brown strains for four times in the process of crushing fresh konjac. The preparation method of the konjac flour provided by the invention can be used for directly processing the fresh konjac, few processing flows and low processing cost are used, and purified konjac micro powder being high in stickiness, high in viscosity stability, high in glucomannan content and good in color is obtained. According to the method,the defects that a conventional method for producing the purified konjac micro powder is multiple in steps, high in cost and high in energy consumption are overcome, the preparation technology is simple and easy to operate, the production cost is low, and the energy consumption is low. The prepared konjac flour is white in color, high in product quality, high in glucomannan content, high in stickiness and good in stability, and is low in sulfur dioxide residues. The method is suitable for industrialized production.

Owner:阮华桂

Preparation method of high-nutrition pet instant food, and pet instant can

InactiveCN109393189AImprove nutritional balanceReduce weightAnimal feeding stuffFood gradeRaw material

The invention discloses a preparation method of a high-nutrition pet instant food, and a pet instant can. The high-nutrition pet instant food disclosed by the invention has higher nutrition balance, and is extremely light in weight and convenient to carry. In feeding, the pet instant food can which is used for feeding pets can be obtained only by just mixing the high-nutrition pet instant food with carry-on water, so that the nutrition and the portability of the pet instant food are greatly improved. Meanwhile, the pet instant food adopts food-grade raw materials, and the eating safety is higher. Besides, the product is uniform in texture, unified in color, beautiful in appearance and high in consistency, presents a mixed state of thick soup and particles after rehydration, and the particles are strong in meat feeling and good in palatability.

Owner:SHANDONG HAICHUANG IND & TRADE CO LTD

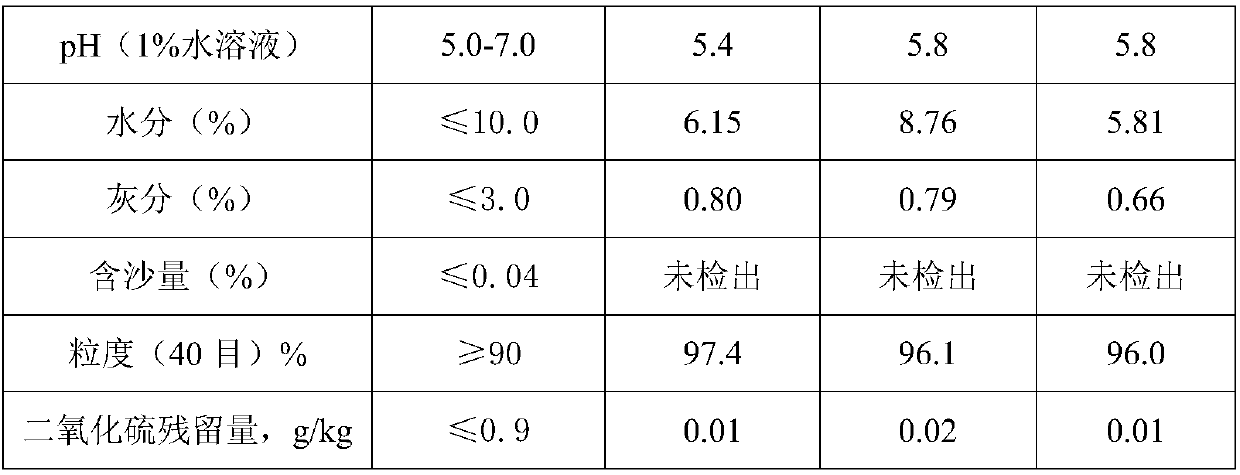

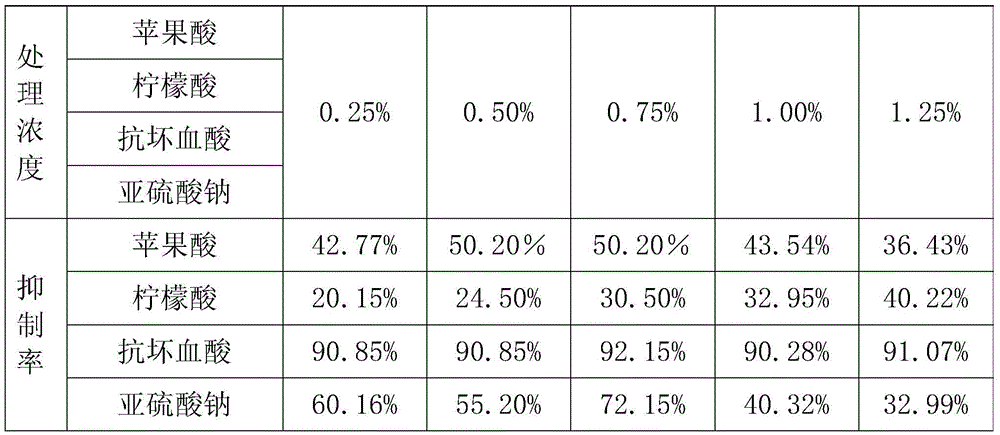

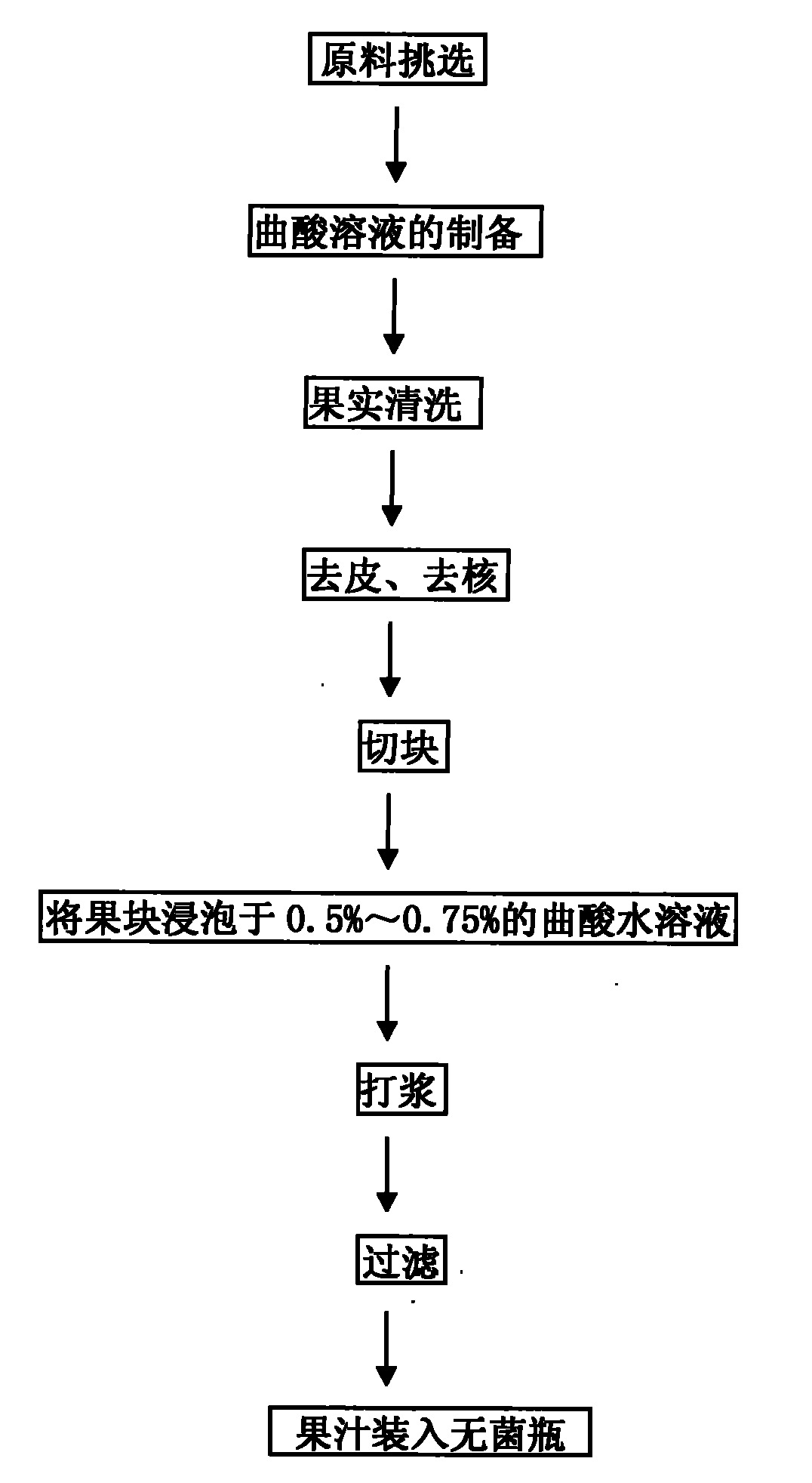

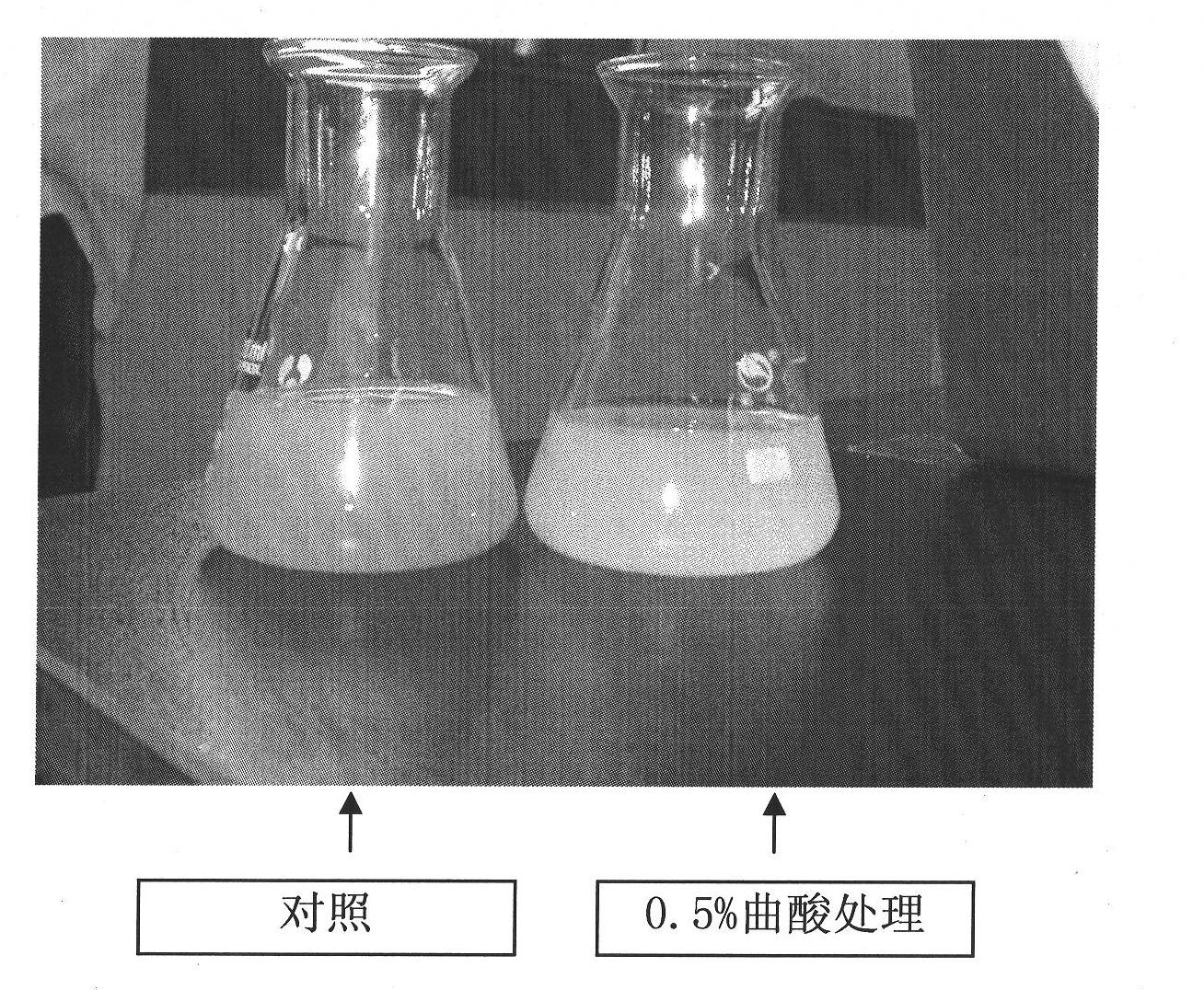

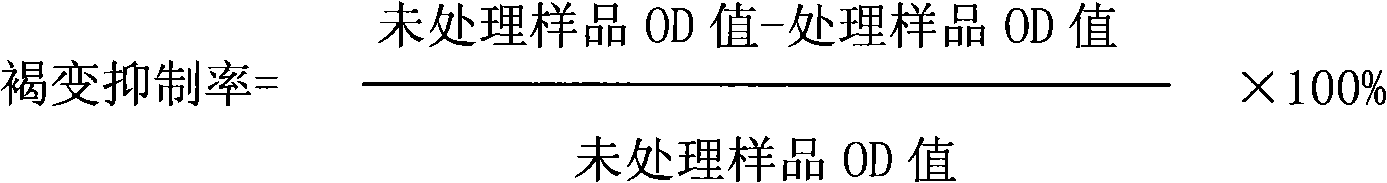

Method for inhibiting browning of fruit juice

The invention belongs to the technical field of juice processing, and particularly relates to a method for inhibiting the browning of fruit juice; the characteristic that kojic acid has strong inhibition effect on polyphenol oxidase is utilized, and treatment is conducted before the beating and crushing of fruits in order to achieve a significant effect of inhibiting the browning of fruit juice. The method comprises the steps that after the fruits are cut into pieces, and soaked for 30 seconds by utilizing 0.5%-0.75% of kojic acid and then beaten to prepare juice, the prepared juice is significant in inhibiting the browning, and losses of the nutritional quality and flavor are less. Because the kojic acid is a natural substance, compared with traditional browning inhibition additives, the produced juice is easily soluble in water, is not invaded by bacteria, the antibacterial effect is less affected by the PH value, and the juice is good in thermal stability, completely toxic-free and odor-free, and the method has very good potential on preventing the browning of juice. The method for inhibition of the browning of juice is simple in use process, low in cost, very suitable for applications in juice processing, and has good application value and industrialization prospect.

Owner:启东市惠鹤蔬果农地股份专业合作社

Method for inhibiting apple juice browning through malic acid

The invention discloses a method for inhibiting apple juice browning through malic acid and belongs to the technical field of fruit processing. A malic acid aqueous solution with the concentration being 0.5-0.75% is used, apple flesh is diced, soaked, pulped and smashed, and the browning inhibition rate can reach 50.20%. Malic acid is used for preventing browning of apple juice, and malic acid is the original component in apples and low in addition concentration, so that original taste of apples is kept to the largest extent; the apples are processed before being pulped so that floccule cannot occur and the quality of the juice can be high.

Owner:刘世东

Needle mushroom fresh-keeping agent and preparation method thereof

InactiveCN109105479AInhibition of respirationInhibit growthFruit and vegetables preservationNatural extract food ingredientsBudMushroom

The invention belongs to the field of edible fungus fresh keeping, and particularly relates to a needle mushroom fresh-keeping agent and a preparation method thereof. The needle mushroom fresh-keepingagent is prepared from the following raw materials in parts by weight: 3 to 6 parts of folium artemisiae argyi, 10 to 15 parts of yellow cinnamon leaves, 3 to 6 parts of lotus leaves, 6 to 10 parts of fructus chebulae, 3 to 6 parts of rhizoma polygoni cuspidati, 3 to 6 parts of radix paeoniae rubra, 2 to 4 parts of rhizoma anemarrhenae, 3 to 6 parts of green tea, 6 to 10 parts of radix arnebiae seu lithospermi, 3 to 6 parts of herba andrographitis, 8 to 12 parts of Ilex pur-purea buds, 3 to 6 parts of herba arabidopsis thalianae, and 2 to 4 parts of pears. The raw materials are classified into three types according to the effect of raw materials and are extracted by separately utilizing a water decoction extraction method, a methanol extraction method, and an ethanol reflux method, and then the obtained extraction solutions are mixed and fermented, thus obtaining the needle mushroom fresh-keeping agent. By adopting the needle mushroom fresh-keeping agent provided by the invention, the growth proliferation of microorganisms can be inhibited, the breathing and metabolism effect of the needle mushrooms can be alleviated, the needle mushrooms can be effectively kept fresh, and the fresh-keeping period can be 40 days or more; and moreover, the needle mushroom fresh-keeping agent is wide in raw material source, simple in preparation method and low in cost.

Owner:印江自治县板溪镇印龙食用菌专业合作社

Compound burdock and kiwifruit crisp slices and preparation method thereof

The present invention discloses compound burdock and kiwifruit crisp slices and a preparation method thereof, and belongs to the technical field of food processing. The compound burdock and kiwifruitcrisp slices comprise the following raw materials in parts by weight: 55 parts of burdock roots, 35 parts of kiwifruits, 8.9 parts of water, 0.05 part of xanthan gum, 0.05 part of sodium carboxymethylcellulose and 1 part of sucrose. The natural compound burdock crisp slices belong to dried fruit crisp slices, The compound burdock and kiwifruit crisp slices contain inulin, proteins, phenolic substances, pectin and other nutritional functional ingredients, and have characteristics of being "natural, green, nutritious and healthy". The compound fruit and vegetable functional crisp slices have avariety of physiological effects of lowering blood sugar, lowering blood lipids, enhancing immunity, preventing tumors, preventing cancers, preventing aging, clearing intestines and dispelling toxins,etc., are suitable for people at all ages, can be eaten by any populations, and are especially suitable for sub-healthy populations with chronic diseases.

Owner:JIANGSU TIANYUAN ZHONGKE BIOTECHNOLOGY CO LTD

Method for suppressing brown stain of early crisp pear juice by using kojic acid

The invention relates to a method for suppressing brown stain of early crisp pear juice by using kojic acid, belonging to the technical field of fruit processing. The forceful characteristic of the kojic acid in suppressing polyphenol oxidase is adopted, and suppression is carried out before the fruit is pulped and broken so as to achieve the effect of noticeably suppressing brown stain of the early crisp pear juice. The method comprises the following steps: the early crisp pears are diced; then the diced pears are soaked in the kojic acid with concentration of 0.5%-0.75% for 30s; afterwards, and the soaked pears are pulped and prepared into the juice, thus the brown stain of the obtained fruit juice is notably suppressed and nutritional quality and flavour of the fruit juice are slightly lost. Being a natural substance, compared with the traditional additives for suppressing the brown stain, the kojic acid is easily soluble in water and free from utilization of bacteria; in addition, antibiosis capacity of the kojic acid is slightly effected by the pH value and the kojic acid features good thermal stability, complete innocuity and no objectional odor, thus enjoying very good potential for application in preventing the fruit juice from the brown stain. The method of the invention features simple use steps, low cost and good application in the field of the fruit juice processing, thus enjoying good application value and industrialized prospect.

Owner:NANJING AGRICULTURAL UNIVERSITY

Kiwifruit NFC juice and preparation method thereof

The invention discloses a kiwifruit NFC juice and a preparation method thereof, and belongs to the technical field of food processing. The kiwifruit NFC juice is obtained by selecting, washing, soaking, color protection, pulping, adjusting the ratio of sugar to acid and adding natural antibacterial substance nisin in combination with the ultra-high pressure sterilization technology. The juice aimsto overcome the defects caused by the heat sterilization technology and retain the original fresh characteristics and nutritional characteristics of the kiwifruit NFC juice to the utmost extent. Themethod has the advantages of being simple and efficient, nutritious, healthy and low in production cost. The prepared kiwi NFC juice has taste, flavor and nutritional value closer to those of fresh fruit, and is rich in flesh and unique in flavor.

Owner:SHAANXI UNIV OF SCI & TECH

Processing method of barley leaf, konjac and coix seed powder

InactiveCN107853549AGood gelImprove water retentionNatural extract food ingredientsFood ingredient functionsBARLEY GRASSPolyphenol oxidase

The invention relates to a processing method of barley leaf, konjac and coix seed powder. The processing method is characterized in that short-time fixation is conducted with high temperature stream for passivating the activities of polyphenol oxidase and peroxidase, thereby inhibiting occurrence of enzymatic browning, preventing color distortion and oxidation, optimizing flavor and improving thepermeability of the tissue cells of barley grass; and different temperatures and wind speeds are set for each stage in a drying process, thereby achieving the effects of conducting drying uniformly and reducing browning and nutrient loss. The nutritional powder prepared by the processing method contains rich protein and dietary fibers and relatively low fat content and sodium element content, canmeet the demand of a human body on nutrients, conforms to the health concepts of people pursuing food containing high protein, high dietary fibers, low fat and low sodium and has higher nutritional value.

Owner:安徽华健生物科技有限公司

Process for producing cherry juice concentrate

The invention discloses a process for producing a cherry juice concentrate. The process comprises the steps as follows: washing cherries, crushing, removing stones, inactivating enzymes, cooling, leaching, cooling, performing enzymolysis, juicing, performing pasteurization, clarifying enzymatic hydrolysates, performing ultrafiltration, concentrating, performing pasteurization again, and packaging. The process improves the quality of the cherry juice concentrate. The cherry juice concentrate has a red brown or scarlet color, and is clear and free of sediments or suspended substances. The content of soluble solids is more than 60.0 Brix. When diluted until the content of soluble solids is 13.5 Brix, the cherry juice concentrate maintains the fragrance and flavor of cherries and smells good.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

Processing method of konjac refined powder

The invention provides a technology for processing konjac refined powder through combination of microwave vacuum drying, inert-gas protection microwave heating for inactivating enzyme activity, and adry-wet method. The technology comprises the processing flows of preparing konjac, performing cutting, performing color protection, performing microwave vacuum drying, stopping inflating inert gas ina vacuumizing sealing container, performing microwave heating, performing heat insulating, stopping microwave heating vacuumizing for quick cooling, performing crushing, performing filtering separation, performing washing and performing drying to obtain products. The advantages of microwave and vacuum drying are sufficiently used, the konjac is quickly and uniformly pre-dried under anoxia and non-high-temperature state, and the dosage of alcohol during subsequent wet-method processing can be reduced doubly; and the measures of adopting inert-gas protection and microwave heating for rapidly inactivating the enzyme activity of polyphenols in the konjac, so that the generation of enzymatic browning in the subsequent processing is avoided. When the konjac is processed according to the technology, low-sulfur or sulfur-free high-viscosity konjac refined powder can be prepared, and besides, the processing cost can be substantially reduced.

Owner:镇安县雪樱花魔芋制品有限公司

Preparation method of fresh jujube and apple juice

The invention discloses a preparation method of fresh jujube and apple juice, which comprises the following steps of: 1, cleaning fresh jujubes and apples, soaking in water with the temperature of 40-60 DEG C for 30-60min, then denucleating and stripping and slicing; 2, placing 10-20 parts by weight of fresh jujubes, 30-60 parts by weight of apples and 5-10 parts by weight of water into a refiner for crushing to obtain a mixture; and 3, preserving the temperature of the mixture under the condition of a water bath of 40-50 DEG C for 15-20min, homogenizing, centrifuging, degassing, sterilizing and cooling to room temperature to obtain the fresh jujube and apple juice. The mixture of the fresh jujubes and the fresh apples is subjected to temperature preservation for 15-20min under the condition of the water bath of 40-50 DEG C, thus endogenous pectinase in the applies and the jujubes can be activated, initial turbidity and suspension stability of the juice are remarkably improved, and the endogenous pectin methylesterase in the apples and the fresh jujubes can act on apple pectin to ensure that negative charges are carried in the apple pectin, thus the repulsive force among particles is increased and the stability is increased.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Method for prolonging shelf life of fresh-cut fruits and vegetables by treatment of medium-pressure mixed inert gases

ActiveCN102077859BPrevents enzymatic browningDelay aging deteriorationFruit and vegetables preservationBiotechnologyBrowning

The invention relates to a method for prolonging the shelf life of fresh-cut fruits and vegetables by treatment of medium-pressure mixed inert gases, and belongs to the technical field of refreshing and storage of fruits and vegetables. Aiming at the characteristics of moisture loss, browning, microbial contamination and difficulty in quality maintenance in the fresh-cut fruits and vegetables, the invention provides a method for prolonging the shelf life by pressurization of the mixed inert gases. The fresh-cut fruits and vegetables are pressurized by the mixed inert gases (argon, nitrogen and xenon) to reach the pressure of between 20 and 25 MPa and are processed for 30 to 60 minutes, and water molecules on fresh-cut surfaces form gas hydrates, so the activity of the water molecules in the fruits and vegetables and the activity of enzymes are inhibited, and 15 to 20 percent of inert gas-containing micro air holes are formed in tissue to achieve the better subsequent refreshing effect. By the method, the metabolic loss and microbial contamination during the storage of the fresh-cut fruits and vegetables are reduced, the enzymatic browning and tissue softening of the fresh-cut fruits and vegetables are inhibited, the organoleptic quality and nutritive value of the fresh-cut fruits and vegetables are better kept, the shelf life of the fresh-cut fruits and vegetables is prolongedby 10 to 15 days under the condition of cold storage, and the shelf storage life of the fresh-cut fruits and vegetables is prolonged by 7 to 8 days at room temperature.

Owner:JIANGNAN UNIV

Wall hanging type empaistic picture preparation process

InactiveCN1634714BAvoid exposureSolve high temperature resistanceDecorative surface effectsSpecial ornamental structuresUltravioletPulp and paper industry

Owner:NORTHEAST FORESTRY UNIVERSITY +3

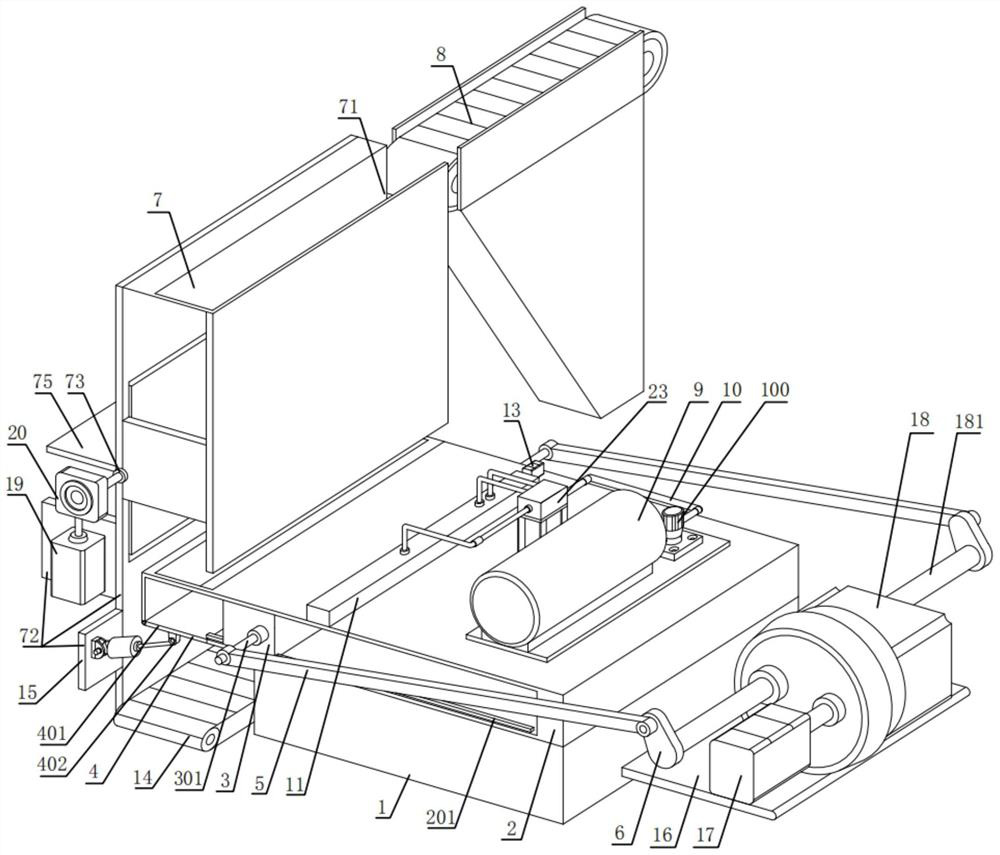

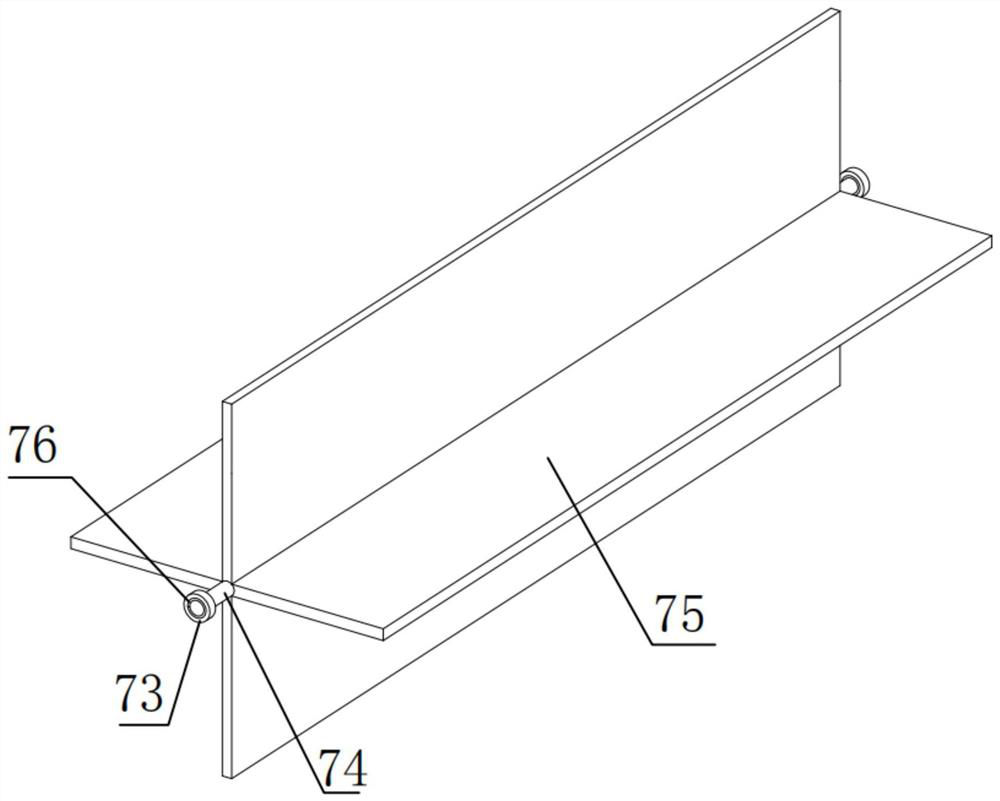

Konjak slicing machine and konjak fine powder processing technology

ActiveCN113001598AImprove slicing efficiencyReduce labor costsFood ingredient functionsMetal working apparatusEngineeringPower unit

The invention discloses a konjak slicing machine and a konjak fine powder processing technology. The konjak slicing machine comprises a base, a slicing shell, a slicing knife holder, slicing knives, a slicing cavity, a material storage box, a conveying belt, an acid storage tank, a containing cavity, a semicircular groove, a conveying chain belt and a cylinder. Guide rails are arranged in the slicing shell. Push rods are arranged at the two ends of the slicing tool holder. A transmission rod is connected to each push rod in a rotating mode, and an eccentric wheel is connected to the other end of each transmission rod in a rotating mode and fixedly connected with a power unit. A motor pump is arranged on a conveying pipeline. The semicircular groove is formed in the containing cavity. The bottom of the slicing cavity is connected with a discharging plate in a rotating mode, and a transmission base is fixedly arranged at the bottom of the discharging plate. The cylinder is connected with the transmission base in a rotating mode. The konjak slicing machine is high in slicing efficiency, and color protection can be immediately carried out on konjak slices after slicing. Konjak fine powder manufactured through the konjak fine powder processing technology is low in sulfur content and high in viscosity, and has a very good color and very high quality.

Owner:四川惠渠农业科技有限公司

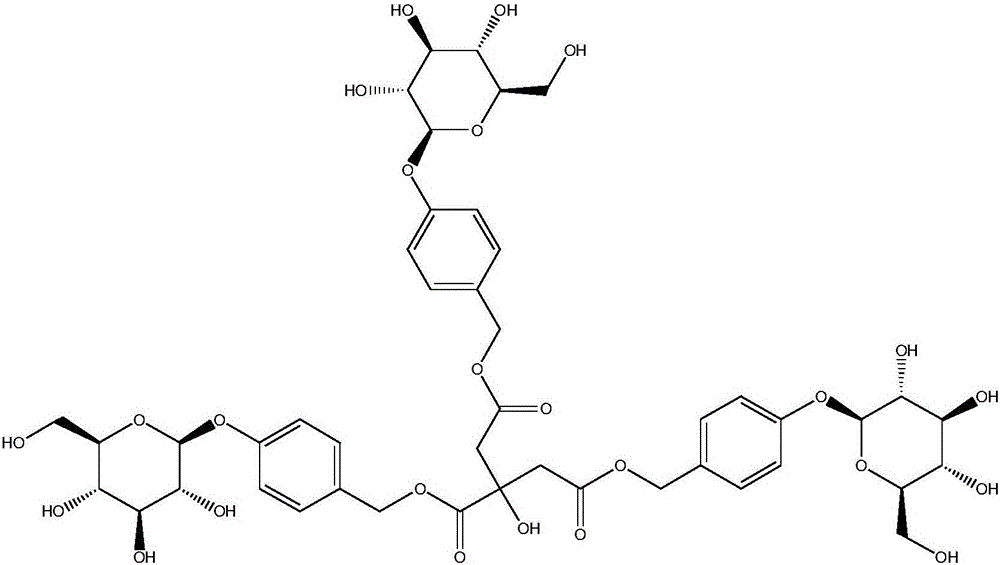

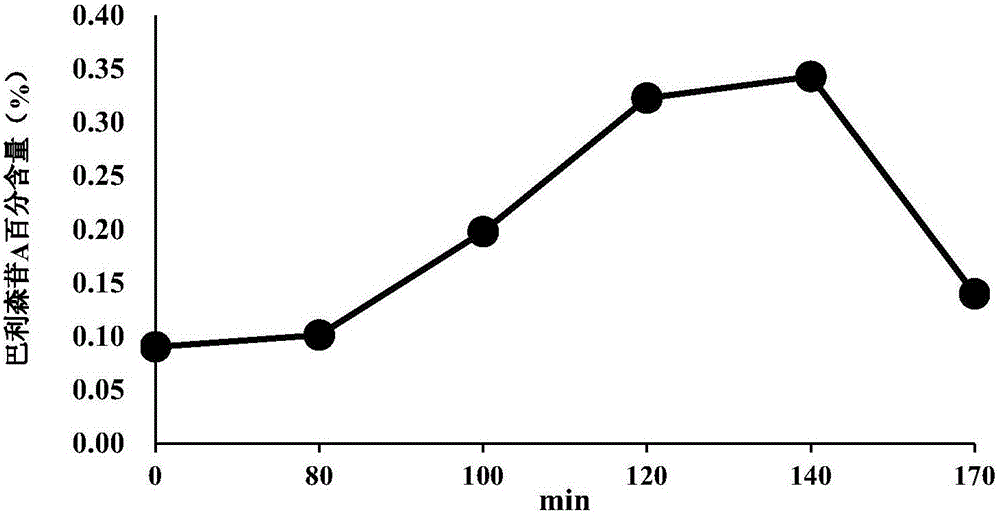

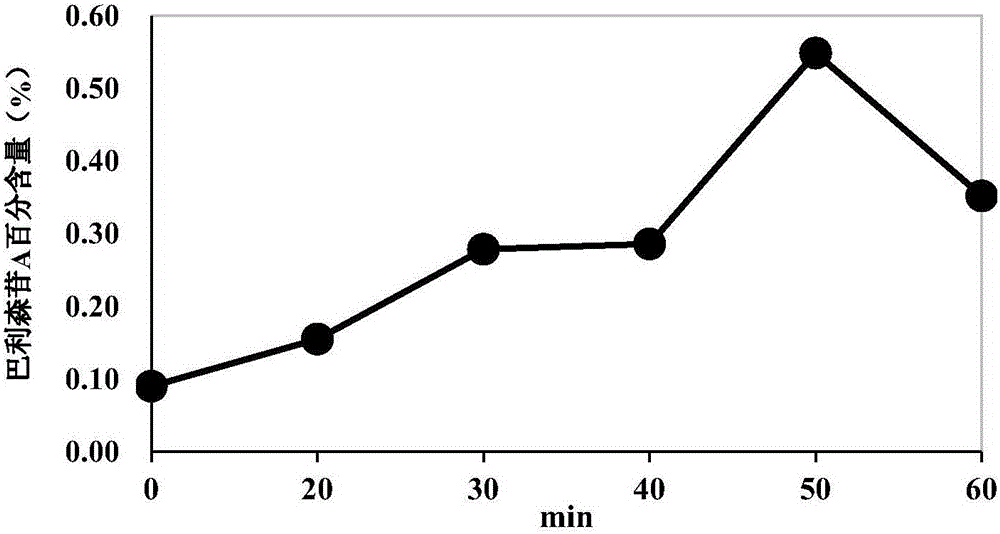

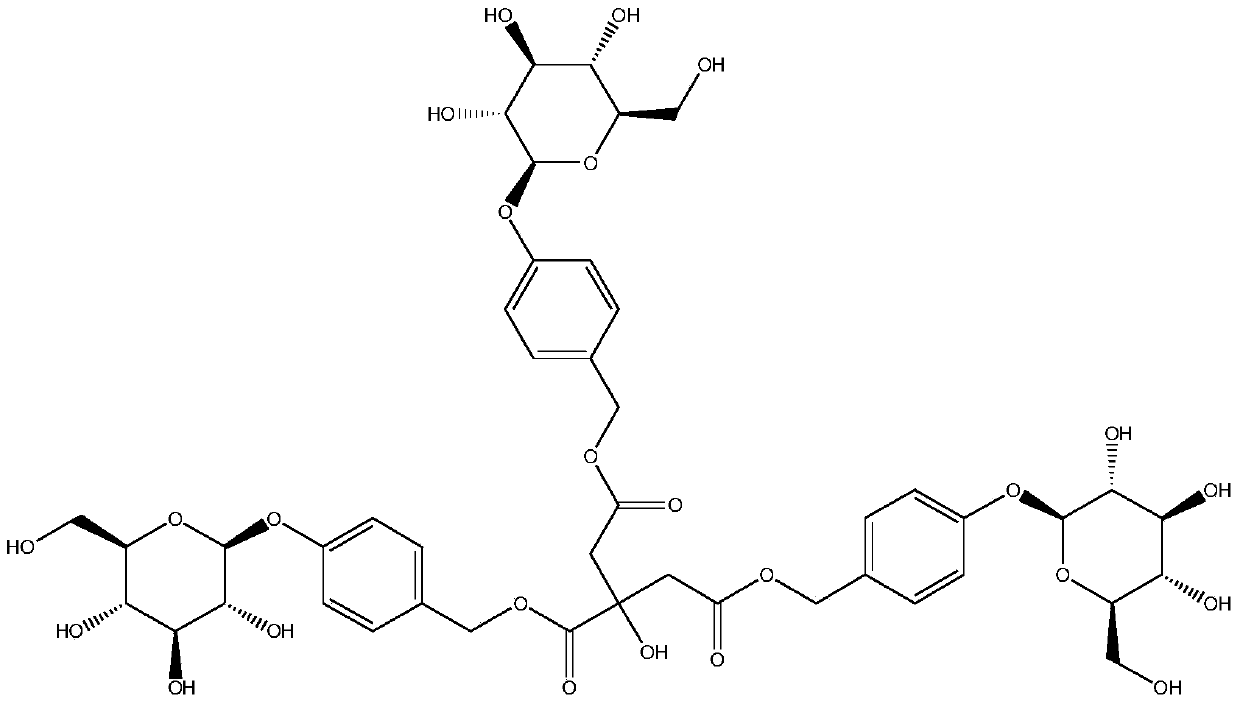

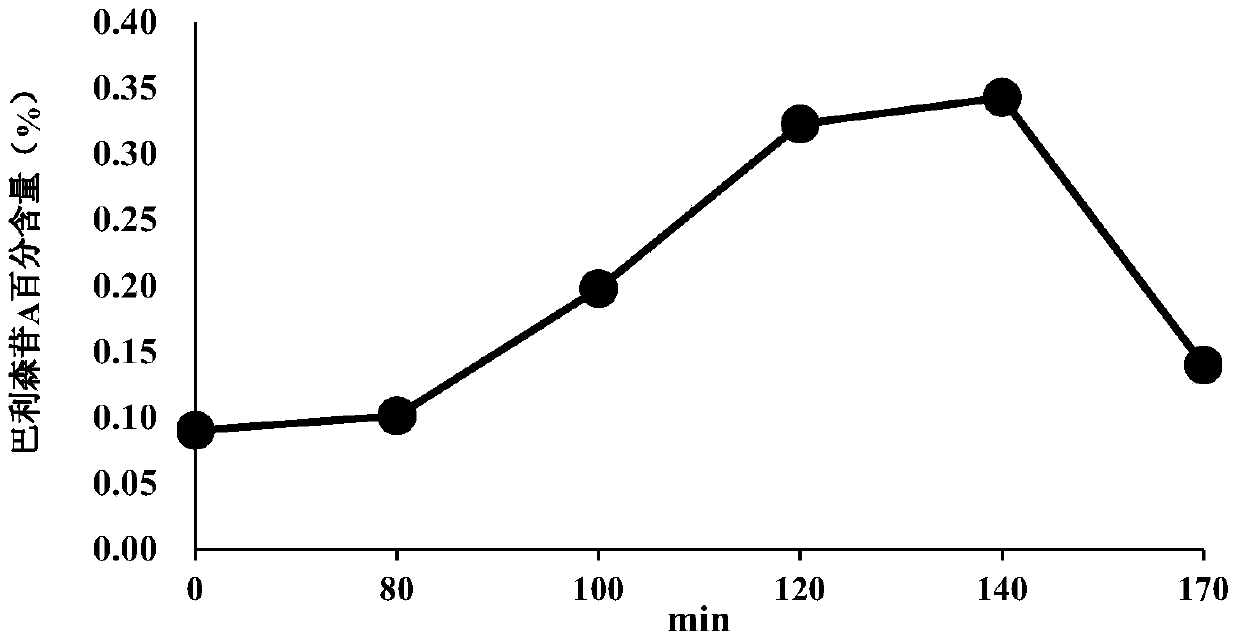

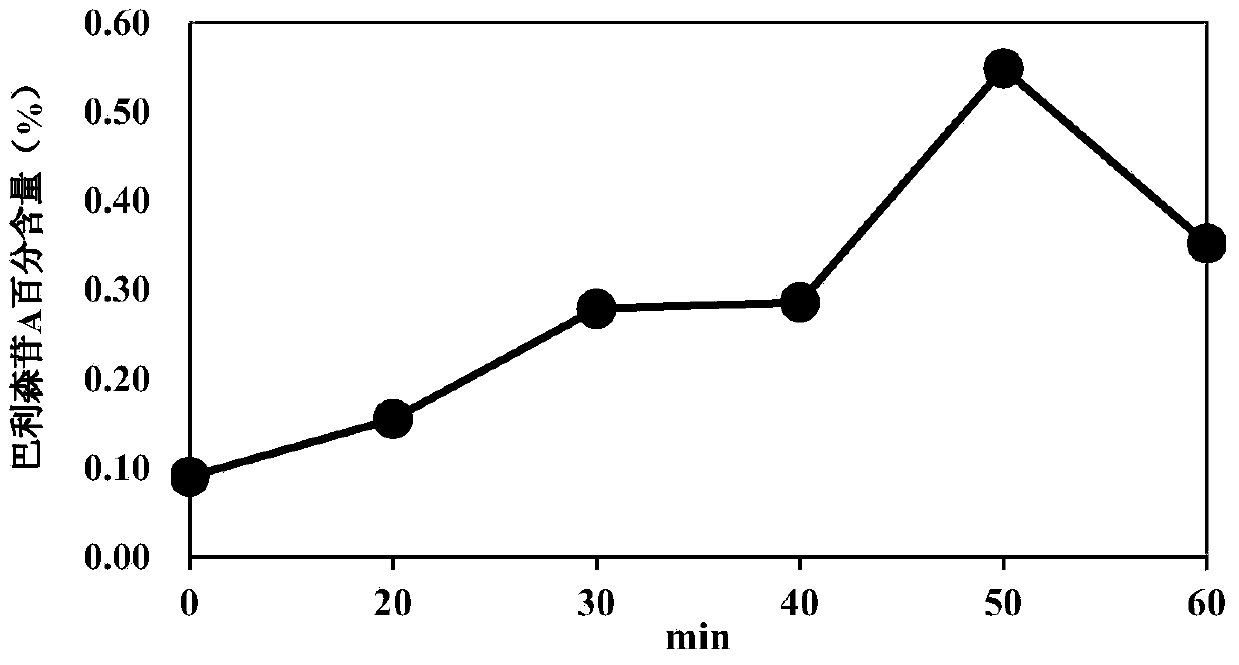

Method for efficiently improving Parishin A content in gastrodia elata

ActiveCN105770489AFast heatingIncrease internal temperatureOrganic active ingredientsNervous disorderAmbient pressureComputer science

The invention discloses a method for efficiently improving the Parishin A content in gastrodia elata.The method comprises the following steps that the gastrodia elata is put into a microwave device, is processed by using microwave irradiation and then is dried under ambient pressure.The method has the advantages of being is simple in operation, low in cost, short in processing time and capable of increasing the Parishin A content in the gastrodia elata by 1.67-16 times.

Owner:YUNNAN UNIV OF TRADITIONAL CHINESE MEDICINE

Processing method of sweet and sour tomato juice

The invention belongs to the technical field of tomato juice processing, and in particular relates to a processing method of sweet and sour tomato juice: the invention utilizes kojic acid, which has a strong property of inhibiting polyphenol oxidase, and processes the fruit before beating and crushing to achieve significant sweet and sour Processing effect of tomato juice. In the method, the fruit is cut into pieces, soaked in 0.5% to 0.75% kojic acid for 30 seconds, and then beaten to make juice. The browning of the prepared tomato juice is significantly inhibited, and the loss of nutritional quality and flavor is less. Since kojic acid is a natural substance, compared with traditional browning inhibitor additives, it is easily soluble in water, not used by bacteria, the antibacterial power is less affected by the pH value, has good thermal stability, is completely non-toxic, and has no peculiar smell. It has good application potential in juice browning. The invention has simple steps and low cost, is very suitable for application in the field of tomato juice processing, and has good application value and industrialization prospect.

Owner:施红梅

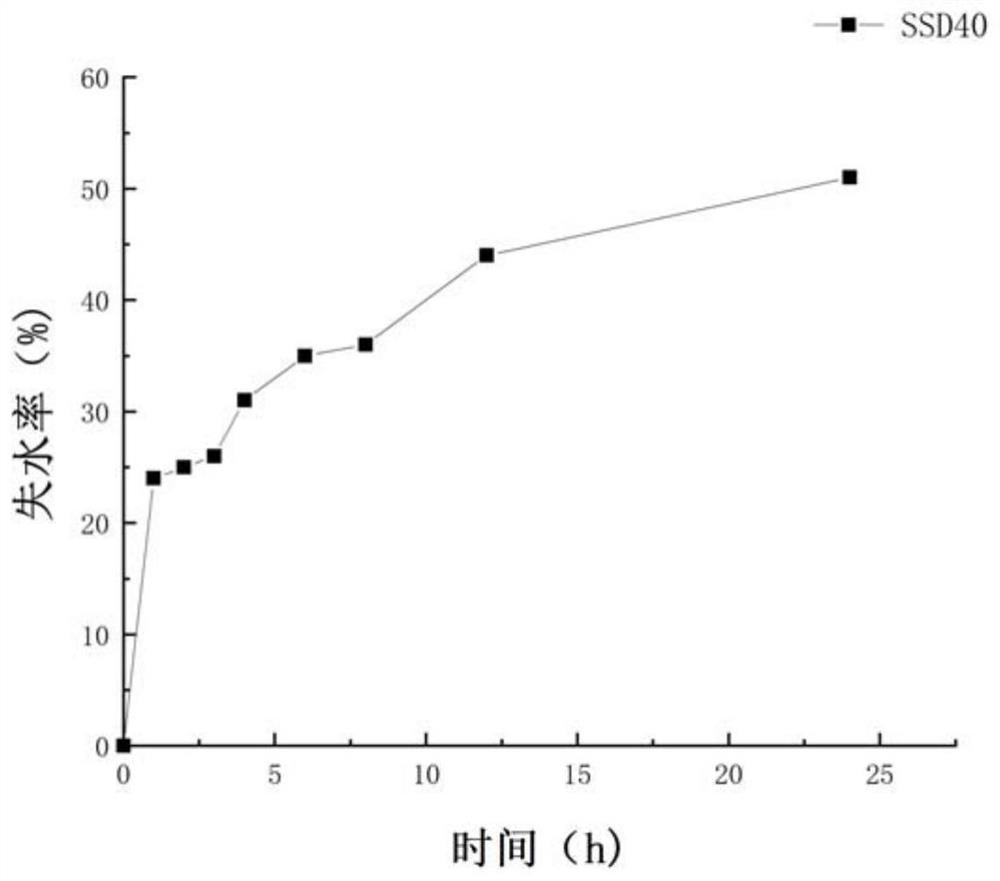

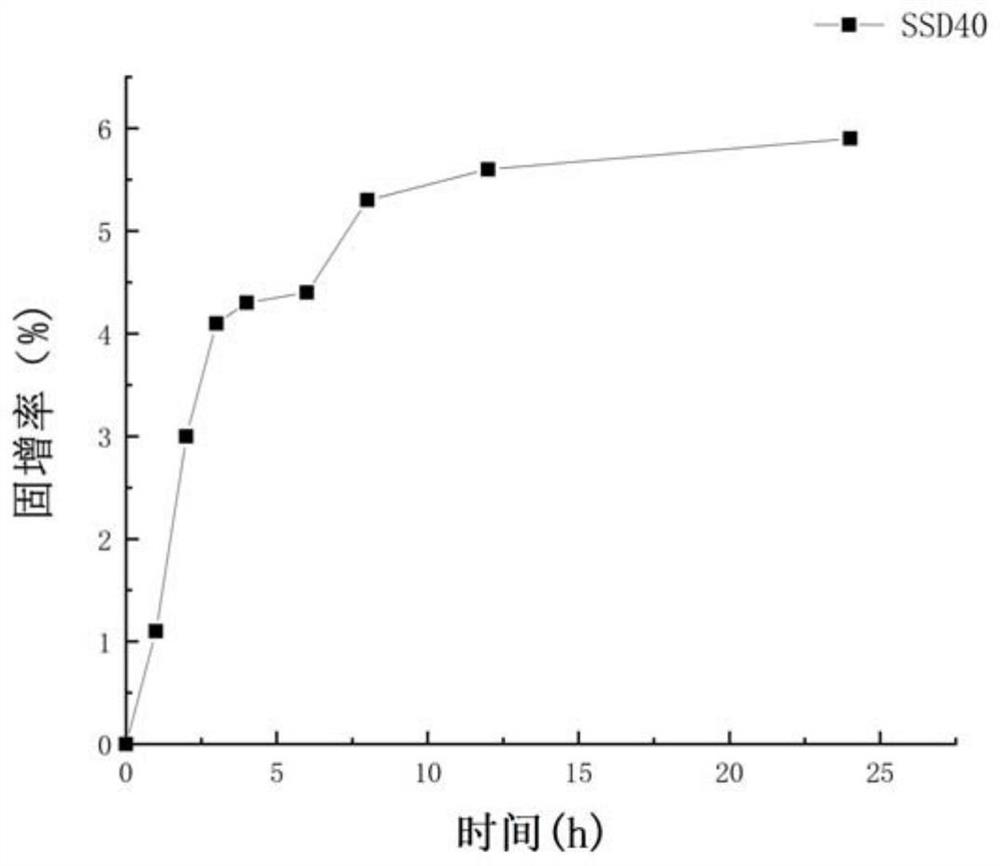

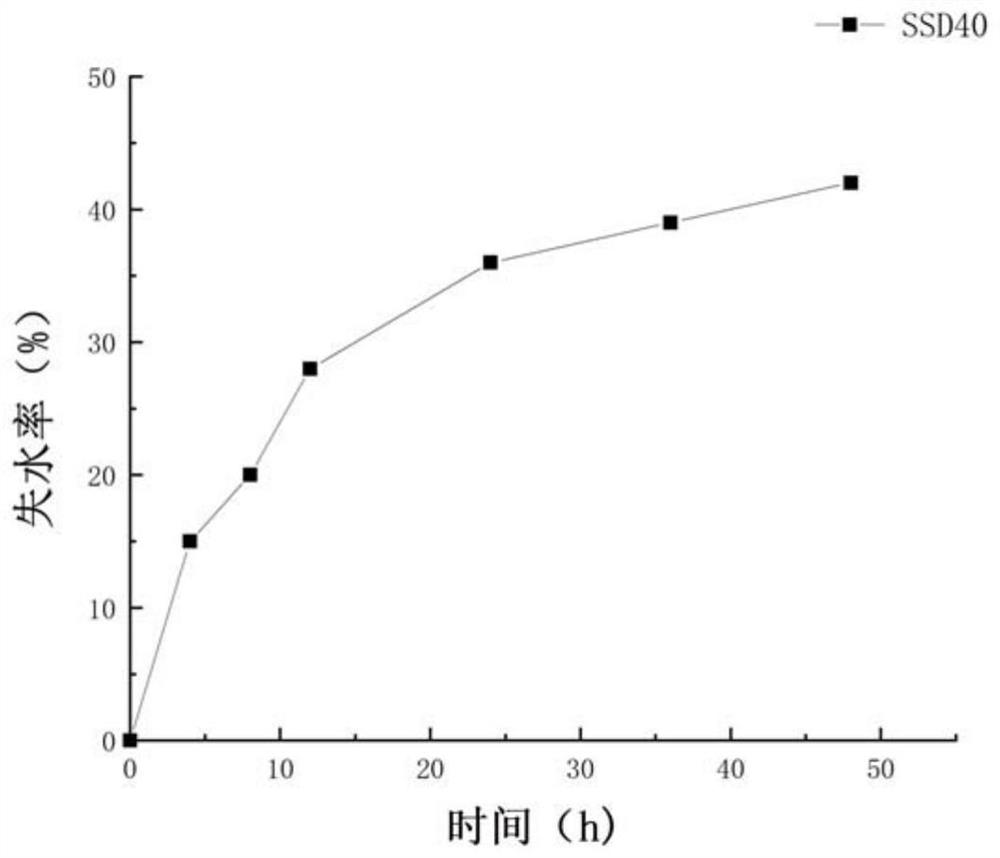

Method for improving quality of dried mangoes through intermittent solid sugar permeation

PendingCN113142374AReduce degradationAvoid looseFood thermal treatmentConfectioneryBiotechnologySucrose

The invention provides a method for improving the quality of dried mangoes through intermittent solid-state sugar permeation. The method comprises the following steps: firstly, carrying out primary solid-state sugar permeation on mango blocks; intermittent treatment; performing ultrasonic blanching; performing secondary solid sugar permeation, and finally drying; according to the method, sucrose is used as a solid penetrant for the first time, so that pressure difference is generated inside and outside cells, free water in the cells is rapidly removed, then intermittent treatment is carried out, three-state water in mango cell tissues is mutually converted and redistributed, the cell tissues are fully trimmed, and ultrasonic blanching is used for promoting the cell tissues to form micro-channels and second solid sugar permeation is performed, and in the whole process, cell tissue damage is small, nutrient substance loss is little, the technology is simple, industrialized production is facilitated, and the produced dried mangoes have good toughness and elasticity and high nutritive value.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS +1

A kind of high-efficiency method for increasing the content of parisonside a in Gastrodia elata

ActiveCN105770489BPrevents enzymatic browningIncrease contentOrganic active ingredientsNervous disorderTraditional medicineMicrowave irradiation

The invention discloses a method for efficiently improving the Parishin A content in gastrodia elata.The method comprises the following steps that the gastrodia elata is put into a microwave device, is processed by using microwave irradiation and then is dried under ambient pressure.The method has the advantages of being is simple in operation, low in cost, short in processing time and capable of increasing the Parishin A content in the gastrodia elata by 1.67-16 times.

Owner:YUNNAN UNIV OF TRADITIONAL CHINESE MEDICINE

Method for producing pear syrup by using whole-pear non-enzymatic browning

PendingCN111758941APrevents enzymatic browningReduce foam generationFood electrical treatmentFoam dispersion/preventionPear juiceBrowning

The invention provides a method for producing pear syrup by using whole-pear non-enzymatic browning. Fresh pear fruits are used as raw materials and subjected to juicing, high-voltage pulse electric field treatment, pear residue refinement and compound enzymolysis, microbubble impurity removal treatment, boiling, sterilization and filling to obtain a finished product of the pear syrup. The methodavoids the effects of enzymatic browning on pear juice, makes full use of pear residues at the same time, and realizes production of the pear syrup by using the whole-pear non-enzymatic browning.

Owner:CHAOHU UNIV

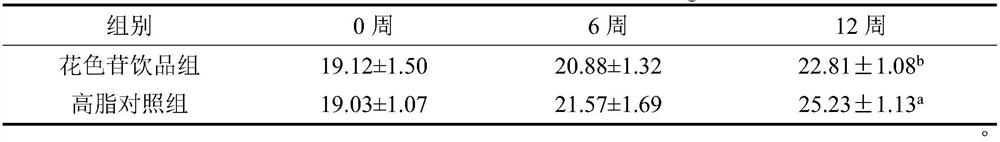

A kind of berry anthocyanin drink with NFC as the main technology and its preparation method

ActiveCN107041495BReduce lossLoss hasNatural extract food ingredientsFood ingredient as mouthfeel improving agentBiotechnologyNutrients substances

The invention relates to a berry anthocyanin drink with NFC as the main technology. Its components and parts by weight are as follows: main raw materials: 60-65 parts of blueberry, 20-25 parts of dragon fruit; auxiliary material: 3-6 parts of xylitol , 0.15-0.25 parts of citric acid, 0.1-0.2 parts of ascorbic acid, 0.4-0.5 parts of thickener, and 0.4-0.5 parts of anthocyanins. Compared with traditional anthocyanin drinks, the beverage of the present invention belongs to the non-concentration process (NFC process) at low temperature, which minimizes the loss of nutrients, ensures the turbidity and stability of the original juice, and has excellent freshness, nutritional components and taste , the technological process is simple, and the cost is low. In addition, the berry anthocyanin drink is rich in anthocyanin, which has certain functions of anti-oxidation, weight loss and lipid reduction.

Owner:TIANJIN UNIV OF SCI & TECH

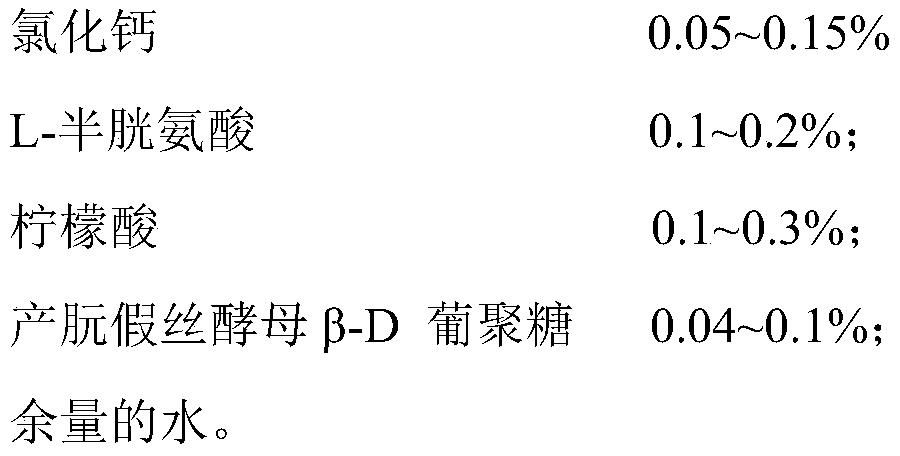

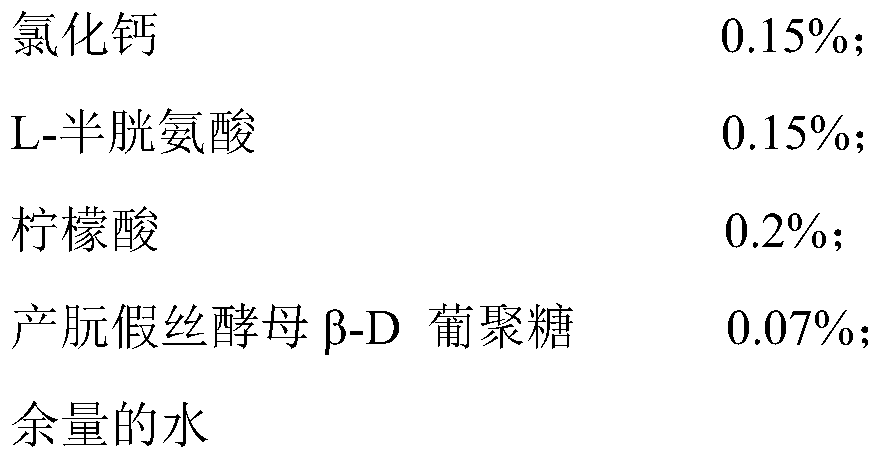

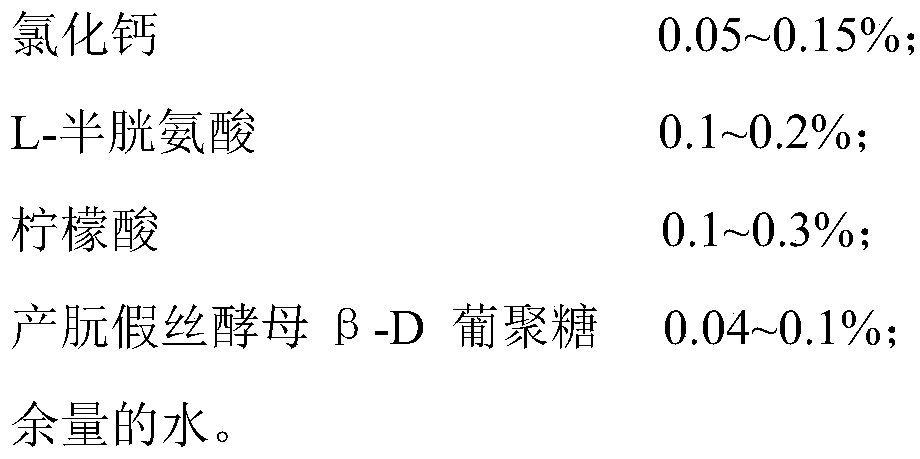

Cabbage composite blanching and color-protecting agent and application thereof

InactiveCN110140859APrevents enzymatic browningImprove product qualityFood ingredient functionsChlorideEnzyme

The present invention discloses a cabbage composite blanching and color-protecting agent and an application thereof. The cabbage composite blanching and color-protecting agent comprises the followingraw materials in mass percentages: 0.05-0.15% of calcium chloride, 0.1-0.2% of L-cysteine, 0.1-0.3% of citric acid, 0.04-0.1% of candida utilis-beta-D glucan and the balance water. The application isas follows: before blanching, cabbages are soaked in the cabbage composite blanching and color-protecting agent, the cabbage composite blanching and color-protecting agent is directly added during thecabbage blanching or the cabbage composite blanching and color-protecting agent is sprayed to prevent cabbage browning after the cabbage blanching. The cabbage composite blanching and color-protecting agent combines an advantages of a single color-protecting agent, suppresses enzymatic browning to an utmost extent, maintains natural color and luster of products, and at the same time, is less in use amount, safe and harmless, and the ideal color-protecting agent during a cabbage bleaching treatment.

Owner:SHANGHAI INST OF TECH +1

Method for inactivating enzyme of longan pulp by steam blanching

InactiveCN101558782BKeep natural colorKeep the flavorFruits/vegetable preservation by heatingFlavorWater soluble

The invention provides a method for inactivating enzyme of longan pulp by steam blanching. The method adopts fresh longan as a raw material, and the longan pulp which can still keep the fresh fragrance and the original color of the longan can be obtained by processing the raw material by the sequential working procedures of cleaning the longan, peeling the shell, removing the core, inactivating the enzyme by steam blanching, cooling, etc. The method avoids the enzymatic browning caused by an endogenous enzyme system, and prevents the longan pulp from directly contacting water, thereby reducingthe loss of water-soluble matters; and the hypobaric hypoxia environment caused by the steam is in favor of the maintenance of the natural color and the flavor of the longan pulp, thereby preventingthe raw and boiling taste from being generated in the operation of processing the longan pulp.

Owner:SOUTH CHINA UNIV OF TECH

A dried apricot processing method

InactiveCN100508786CReduce oxygen contentPrevents enzymatic browningFruit stoningFood preparationInjection airDried apricot

The invention relates to a method for processing dried apricot, wherein it comprises that: washing, removing corn, heating, drying and vacuum packing; the apricot washed and removed corn enters into the air injection heater, impacted by 4. 0-20m / s, 100-200Deg. C and 10-100% humidity air flow for 2-15min, to disinfect enzyme; then enters into the drying box at 50-90Deg. C and 8. 0-15m / s airflow to be dried for 2-15h; then vacuum packing. The inventive dried apricot has high quality, without chemical agent and additive.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com