Preparation method of konjac flour

A konjac flour and konjac technology, applied in the field of food processing, can solve the problems of low quality, high difficulty and high energy consumption of konjac flour, and achieve the effects of low residual sulfur dioxide, prevention of browning and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

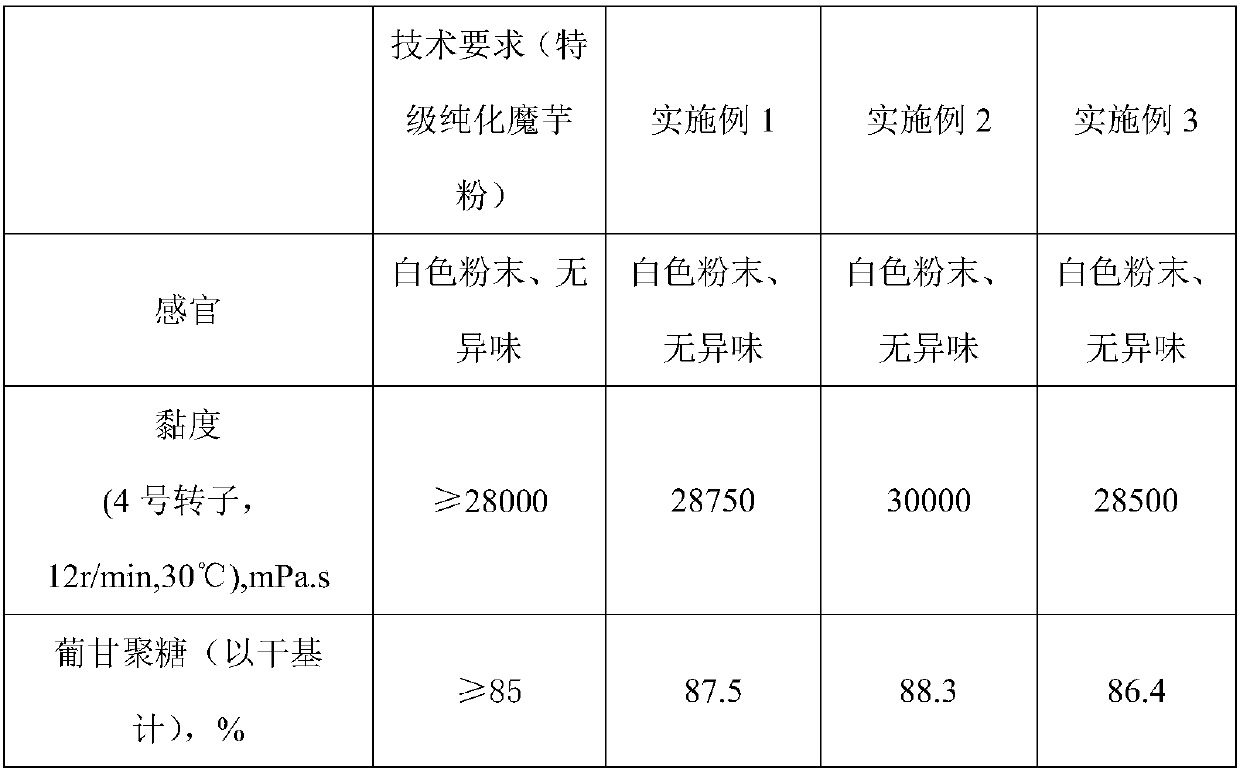

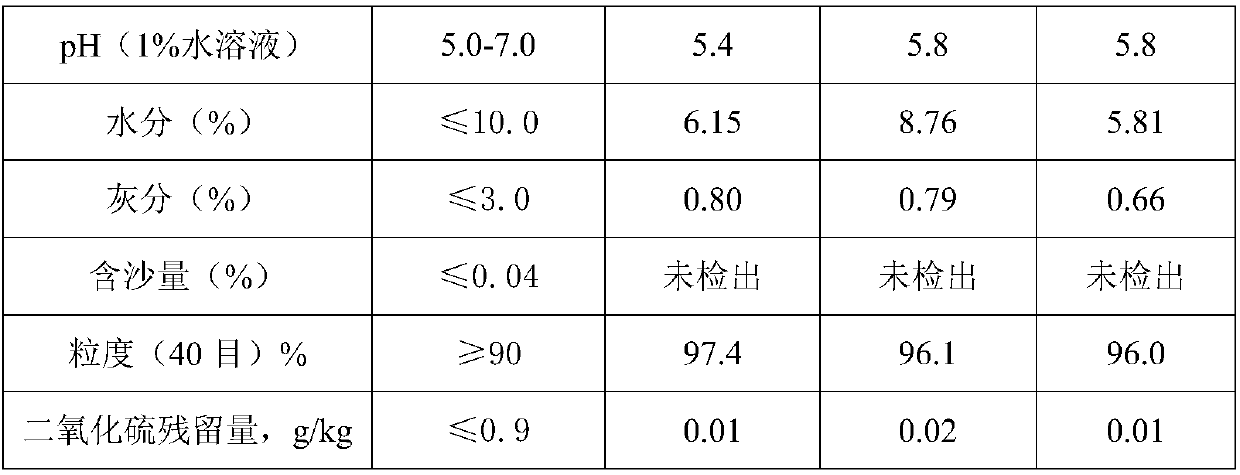

Embodiment 1

[0081] 1. Prepare color protectant

[0082] 1-1) Color protectant A

[0083] Mix NaCl, citric acid and water, stir and dissolve evenly to prepare color-protecting agent A, wherein the mass percent concentration of NaCl in color-protecting agent A is 1%; the mass percent concentration of citric acid is 0.15%.

[0084] 1-2) Color protectant B

[0085] Mix sodium sulfite, citric acid, absolute ethanol and water, stir and dissolve evenly, and make color-protecting agent B, wherein the concentration of sodium sulfite in color-protecting agent B is 50ppm; the mass percent concentration of citric acid is 0.15%; The mass percentage concentration is 70%.

[0086] 1-3) Color protectant C

[0087] Mix sodium sulfite, citric acid, absolute ethanol and water, stir and dissolve evenly, and make color-protecting agent C, wherein the concentration of sodium sulfite in color-protecting agent C is 50ppm; the mass percent concentration of citric acid is 0.15%; The mass percentage concentrati...

Embodiment 2

[0122] 1. Prepare color protectant

[0123] 1-1) Color protectant A

[0124] Mix NaCl, citric acid and water, stir and dissolve evenly to prepare color-protecting agent A, wherein the mass percent concentration of NaCl in color-protecting agent A is 0.5%; the mass percent concentration of citric acid is 0.25%.

[0125] 1-2) Color protectant B

[0126] Mix sodium sulfite, citric acid, absolute ethanol and water, stir and dissolve evenly, and make color-protecting agent B, wherein the concentration of sodium sulfite in color-protecting agent B is 40ppm; the mass percent concentration of citric acid is 0.25%; The mass percentage concentration is 80%.

[0127] 1-3) Color protectant C

[0128] Mix sodium sulfite, citric acid, absolute ethanol and water, stir and dissolve evenly, and make color-protecting agent C, wherein the concentration of sodium sulfite in color-protecting agent C is 70ppm; the mass percent concentration of citric acid is 0.1%; The mass percentage concentrat...

Embodiment 3

[0154] 1. Prepare color protectant

[0155] 1-1) Color protectant A

[0156] Mix NaCl, citric acid and water, stir and dissolve evenly to prepare color-protecting agent A, wherein the mass percent concentration of NaCl in color-protecting agent A is 2%; the mass percent concentration of citric acid is 0.1%.

[0157] 1-2) Color protectant B

[0158] Mix sodium sulfite, citric acid, absolute ethanol and water, stir and dissolve evenly, and make color-protecting agent B, wherein the concentration of sodium sulfite in color-protecting agent B is 70ppm; the mass percent concentration of citric acid is 0.1%; The mass percentage concentration is 50%.

[0159] 1-3) Color protectant C

[0160] Mix sodium sulfite, citric acid, absolute ethanol and water, stir and dissolve evenly, and make color-protecting agent C, wherein the concentration of sodium sulfite in color-protecting agent C is 40ppm; the mass percent concentration of citric acid is 0.25%; The mass percent concentration is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com