Crystal grape storage and preservation method

A technology for storage and preservation of grapes, applied in the field of storage and preservation of agricultural products, can solve the problems of microbial infection, easy browning of fruits, shedding and other problems, and achieve the effects of reducing sulfur dioxide residue, inhibiting fruit senescence, and reducing the dosage used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

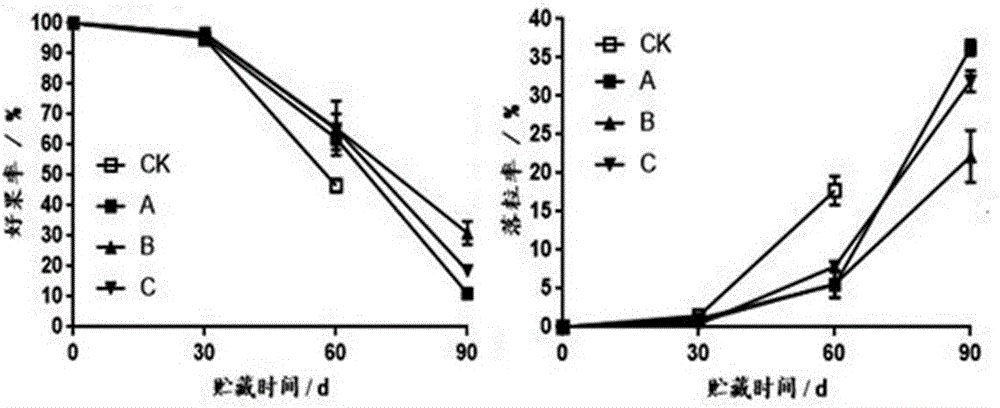

[0033] Crystal grapes are sprayed with fungicides for disease prevention and control before bagging. 7. Harvest when they are ripe, dissipate the heat in the field, remove bagging, mechanical damage and pests and diseases, wax the fruit pedicles, and pack them in 3kg / bag Put them in a 0.02mm PE fresh-keeping bag, transfer them to a 1.5±0.5°C cold storage for 24 hours, and use ultraviolet light to sterilize the cold storage and crystal grapes during the pre-cooling period. The following treatments are carried out: CK: direct storage in bags is used as a control treatment; A: Add 1-MCP preservative at 1.0 μL / L and store in bags; B: Add 1 bag of CT-2 / kg and 1.0 μL / L 1-MCP and store in bags; C: Press 2 bags of CT-2 / kg 2 / kg and 1.0μL / L 1-MCP were put into bags and stored at low temperature.

[0034] Statistics of different treatment groups stored good fruit rate and seed drop rate, the results are shown in figure 1 .

Embodiment 2

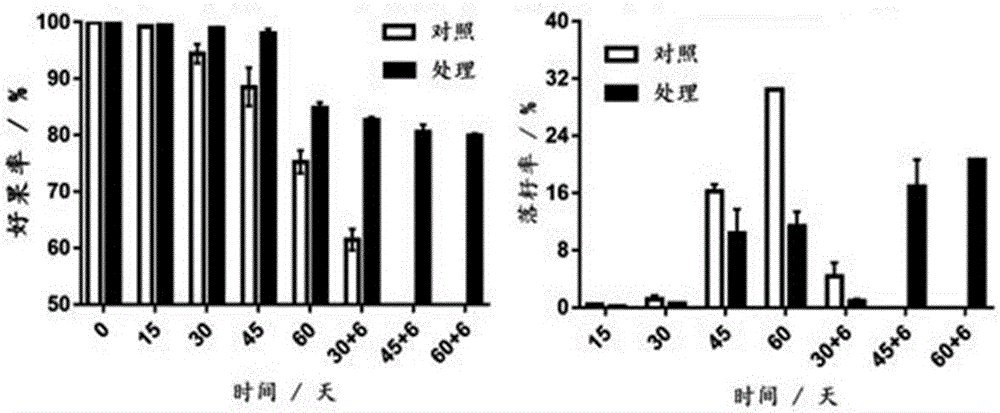

[0036] Crystal grapes are sprayed with fungicides before bagging for disease prevention and control. Harvest when they are ripe, dissipate the heat in the field, remove bagging, mechanical injuries, and fruits that have been damaged by diseases and insect pests. Apply wax to the fruit pedicles and pack them in 3kg / bag Put it in a 0.04mm PE fresh-keeping bag, transfer it to a cold storage at 1.5±0.5°C for 24 hours, and use 10mg / m2 during the pre-cooling period 3 Ozone was used to sterilize cold storage and crystal grapes, and the following treatments were carried out: storage in bags without preservatives was used as a control treatment; 1 bag of CT-2 / kg and 1.0 μL / L 1-MCP was put in preservatives and stored in bags for the treatment group.

[0037] The good fruit rate and seed drop rate of different treatment groups during storage and shelf life were counted, and the results are shown in figure 2 .

[0038] From the above results, it can be seen that the crystal grape stora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com