Process for producing cherry juice concentrate

A production process and technology for concentrated juice, applied in the field of cherry juice concentrate production process, can solve the problems of easy loss of nutrients and unstable color of cherry juice, and achieve the effect of color protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

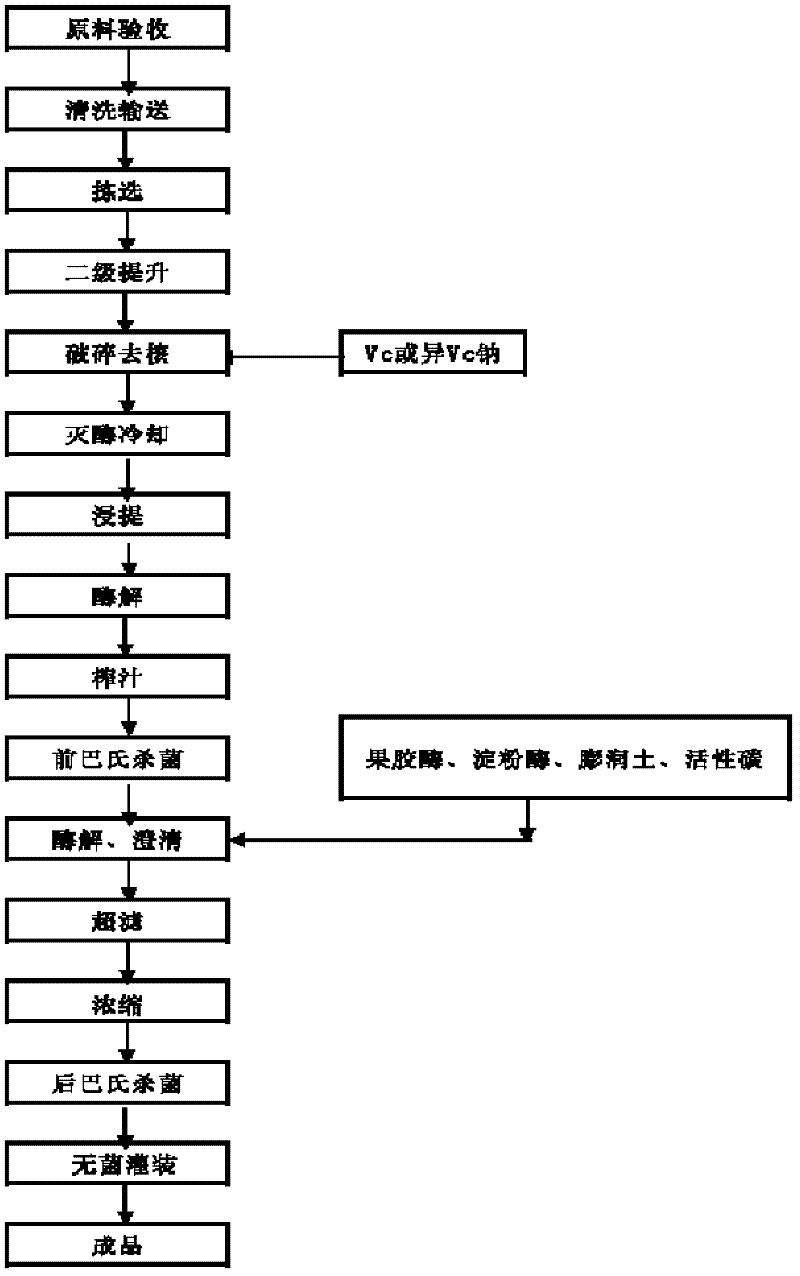

[0035] see figure 1 , cherry juice concentrate production process, comprises the following steps:

[0036] 1) Use at least eight mature cherries as raw materials, and clean the raw materials:

[0037] Pour the eight-ripe cherries into the bubbling floating washing machine for cleaning. The cleaning water is clean tap water or condensed water, and it is replaced once after four hours of use; the cleaned cherries are lifted to the mesh belt fruit sorter by the elevator, and picked manually. Remove impurities such as rotten fruit, miscellaneous fruit, leaves, etc., and control the unqualified fruit rate to less than 2%; the selected cherries enter the secondary floating washing machine for secondary cleaning;

[0038] After cleaning and removing impurities, transport the cherries to the rotary crusher for crushing through the elevator. Add 0.1% Vc of cherry quality (specifically added by aqueous solution) to prevent browning;

[0039] Collect the crushed cherry pulp and send i...

Embodiment 2

[0052] see figure 1 , cherry juice concentrate production process, comprises the following steps:

[0053] 1) Use at least eight mature cherries as raw materials, and clean the raw materials:

[0054] Pour the eight-ripe cherries into the bubbling floating washing machine for cleaning. The cleaning water is clean tap water or condensed water, and it is replaced once after four hours of use; the cleaned cherries are lifted to the mesh belt fruit sorter by the elevator, and picked manually. Remove impurities such as rotten fruit, miscellaneous fruit, leaves, etc., and control the unqualified fruit rate to less than 2%; the selected cherries enter the secondary floating washing machine for secondary cleaning;

[0055] After cleaning and removing impurities, convey the cherries to the rotary crusher for crushing through the elevator. Add 0.15% iso-Vc sodium (in the form of a specific solution) of cherry quality to prevent browning;

[0056] Collect the crushed cherry pulp and s...

Embodiment 3

[0069] see figure 1 , cherry juice concentrate production process, comprises the following steps:

[0070] 1) Use at least eight mature cherries as raw materials, and clean the raw materials:

[0071] Pour the eight-ripe cherries into the bubbling floating washing machine for cleaning. The cleaning water is clean tap water or condensed water, and it is replaced once after four hours of use; the cleaned cherries are lifted to the mesh belt fruit sorter by the elevator, and picked manually. Remove impurities such as rotten fruit, miscellaneous fruit, leaves, etc., and control the unqualified fruit rate to less than 2%; the selected cherries enter the secondary floating washing machine for secondary cleaning;

[0072] After cleaning and removing impurities, convey the cherries to the rotary crusher for crushing through the elevator. Add 0.15% iso-Vc sodium (in the form of a specific solution) of cherry quality to prevent browning;

[0073] Collect the crushed cherry pulp and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com