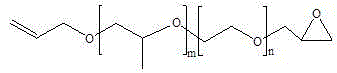

Preparation method of glycidol ether base end-capped allyl alcohol random polyether

A glycidyl ether-based, random polyether technology, applied in the chemical industry, can solve the problems of troublesome solvents, poor product color, low conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

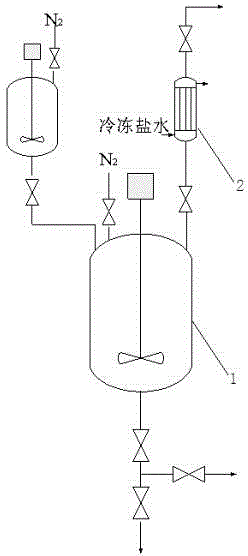

[0052]Put 56.47g (2.353moL) of NaH and 239.46g (2.588moL) of epichlorohydrin into the dripping reaction kettle with nitrogen, stir for 30min and fill with nitrogen to 0.4 MPa; Add 1000g (2.353moL) allyl alcohol atactic polyether (molecular weight=425, m=2.62, n=4.63), 0.782g (0.002353moL) tetra-n-butylammonium bromide, set nitrogen under vacuum, and open the nitrogen valve and the outlet valve of the reflux condensing device, continuously feed nitrogen gas to the end-capping kettle (nitrogen flows through the capping kettle to the reflux condensing device, and finally enters the tail gas device through the outlet valve); open the connecting valve, and press the dropping addition kettle into the end-capping kettle. About 1h; after the dropwise addition, the temperature was raised to 40°C, and the reaction was carried out at this temperature for 5h. After the reaction is completed, the temperature is lowered to 30°C, and the crude product is obtained so far; the crude product is...

Embodiment 2

[0055] Put 29.27g (1.22moL) of NaH and 117.34g (1.27moL) of epichlorohydrin into the dripping reactor with nitrogen, stir for 30min and then fill with nitrogen to 0.4 MPa; Add 1000g (0.976moL) allyl alcohol random polyether (molecular weight = 1025, m = 15.4, n = 5.0), 0.808g (0.00488moL) tetraethylammonium chloride, after vacuum nitrogen, open the nitrogen valve and The outlet valve of the reflux condensing device continuously feeds nitrogen gas to the end-capping kettle (nitrogen flows through the capping kettle to the reflux condensing device, and finally enters the tail gas device through the outlet valve); open the connecting valve, and the dripping kettle presses the material into the capping kettle for about 1h; after the dropwise addition, the temperature was raised to 60°C, and the reaction was carried out at this temperature for 8h. After the reaction was completed, the temperature was lowered to 30°C, and the crude product was obtained; after the crude product was f...

Embodiment 3

[0057] Put 17.78g (0.74moL) of NaH and 68.53g (0.74moL) of epichlorohydrin into the dripping reaction kettle with nitrogen, stir for 30min and fill with nitrogen to 0.4 MPa; Add 1000g (0.494moL) allyl alcohol random polyether (molecular weight = 2025, m = 22.35, n = 16.96), 1.372g (0.00494moL) tetrabutylammonium chloride, after vacuum nitrogen, open the nitrogen valve and The outlet valve of the reflux condensing device continuously feeds nitrogen gas to the end-capping kettle (nitrogen flows through the capping kettle to the reflux condensing device, and finally enters the tail gas device through the outlet valve); open the connecting valve, and the dripping kettle presses the material into the capping kettle for about 1h; after the dropwise addition, the temperature was raised to 80°C, and the reaction was carried out at this temperature for 10h. After the reaction is completed, the temperature is lowered to 30°C, and the crude product is obtained so far; the crude product i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com