Patents

Literature

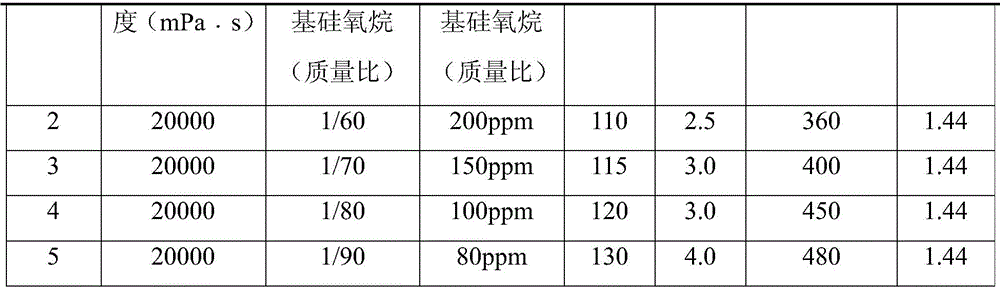

74results about How to "High capping rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

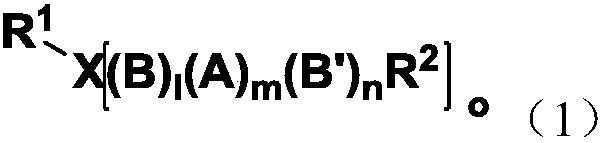

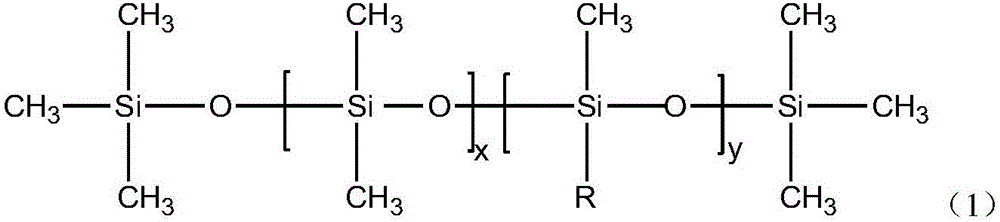

Silicone compound, a process for the preparation thereof and a process for the preparation of an ophthalmic device therefrom

ActiveUS8168735B2High purityHigh capping rateSilicon organic compoundsOptical elementsHydrogen atomMethyl group

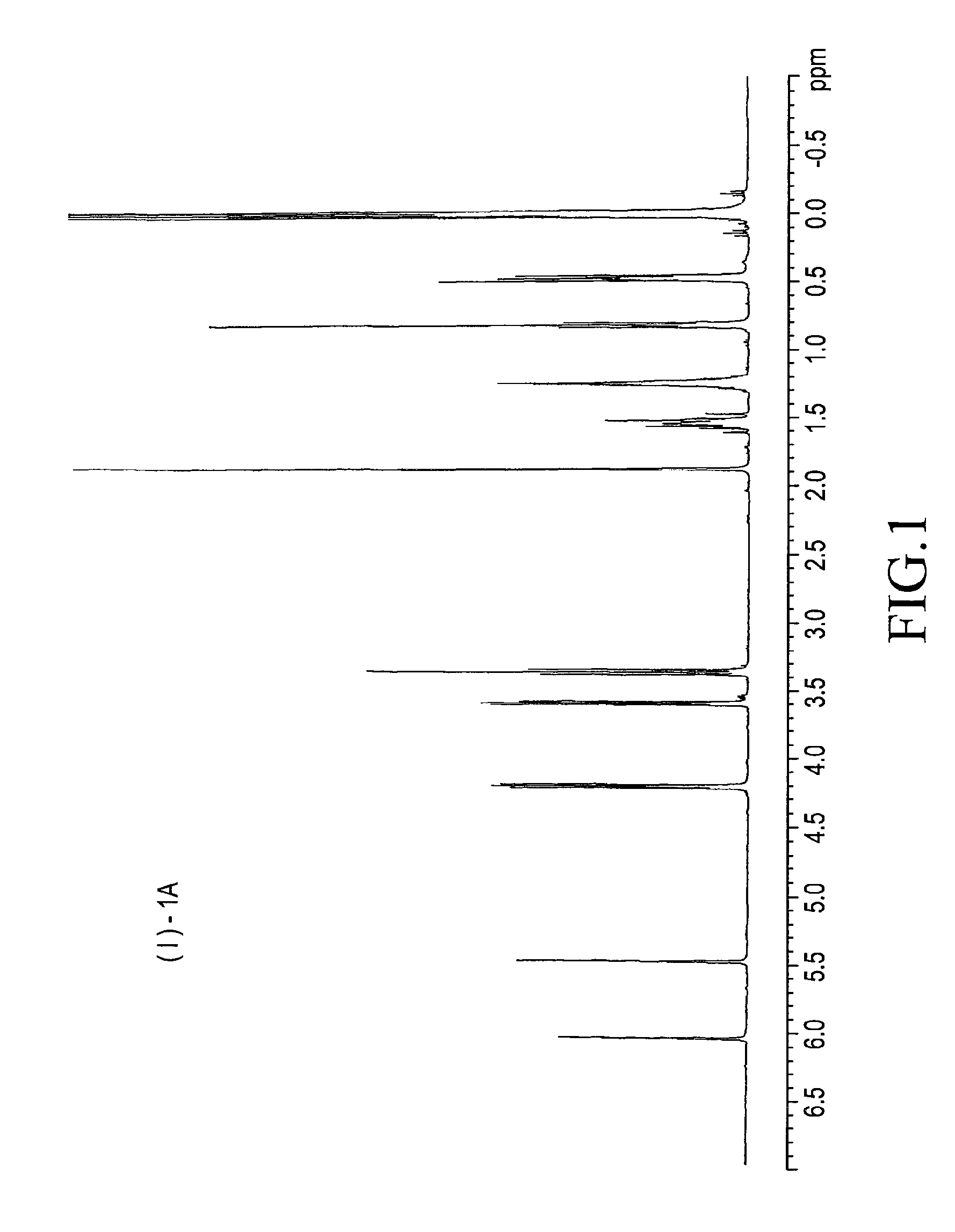

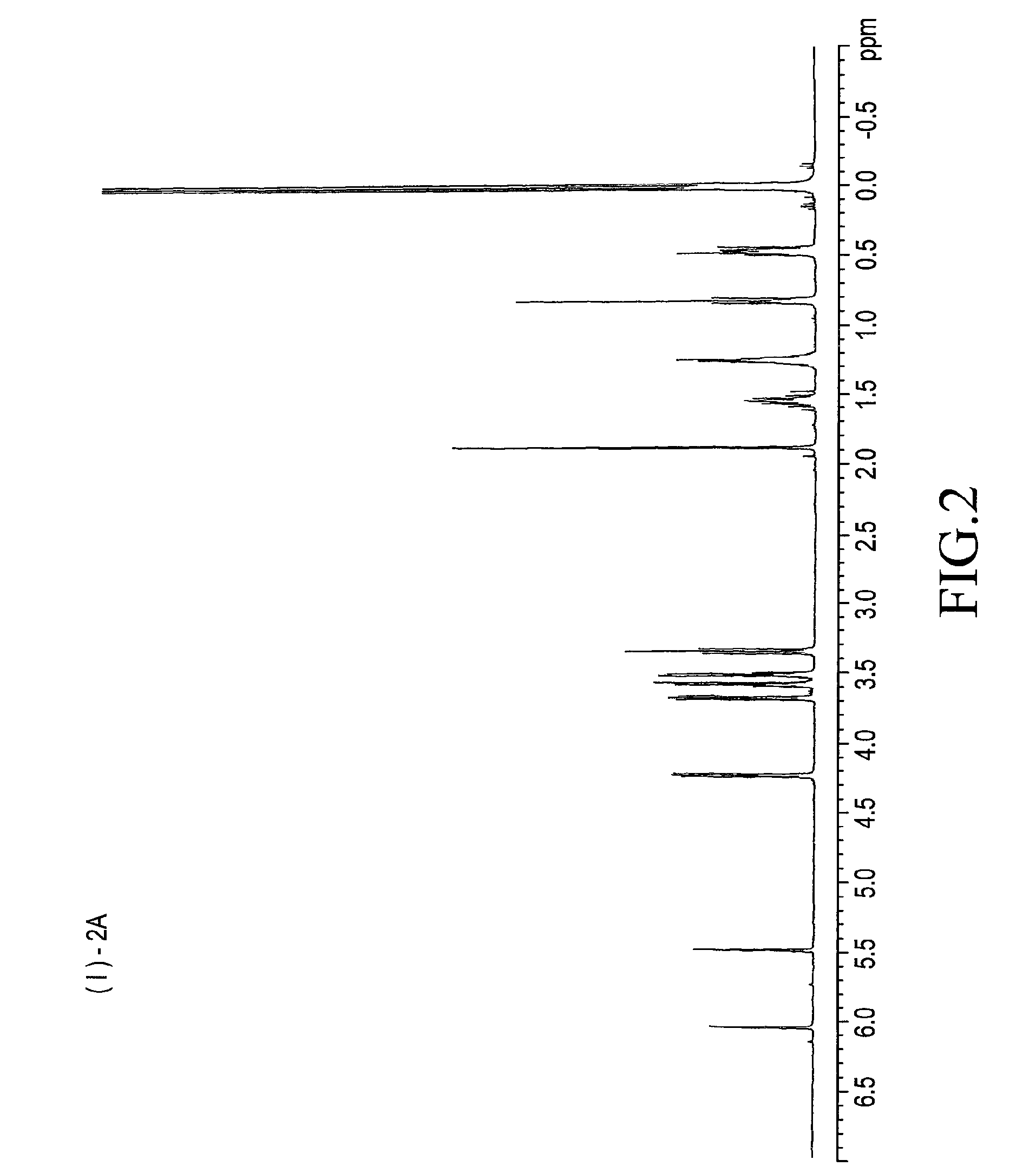

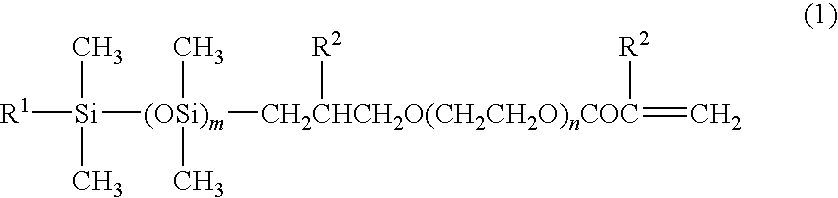

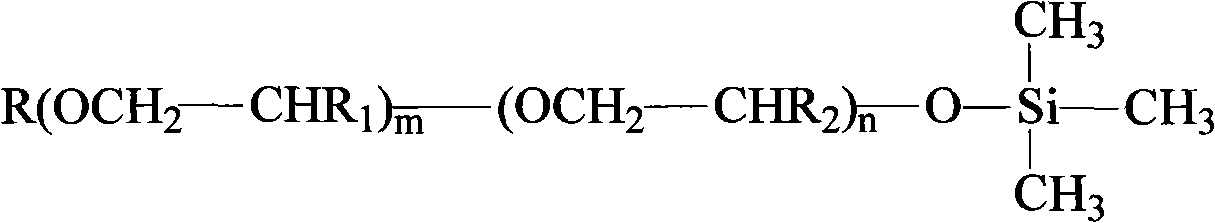

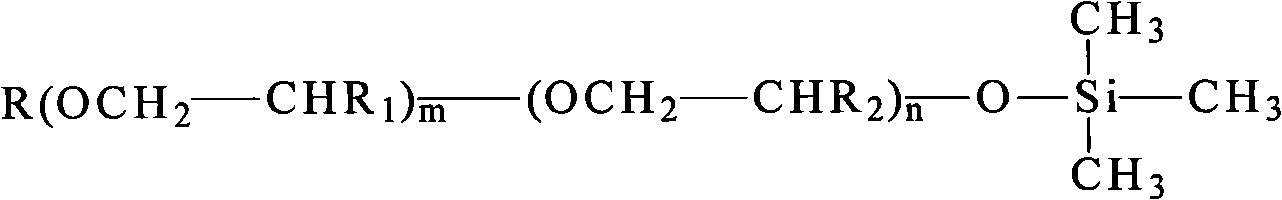

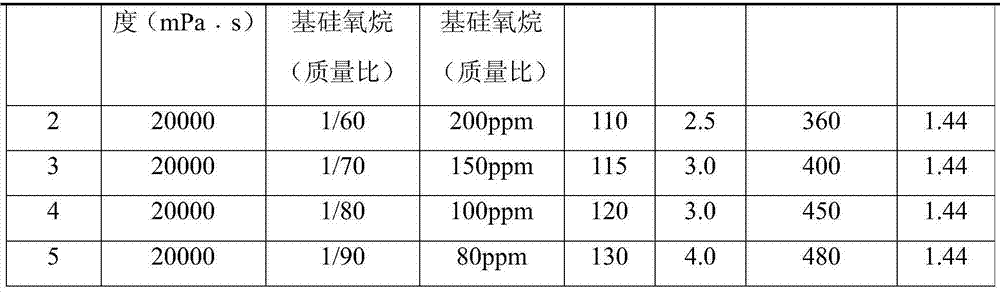

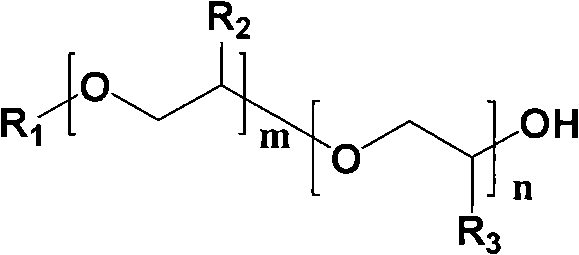

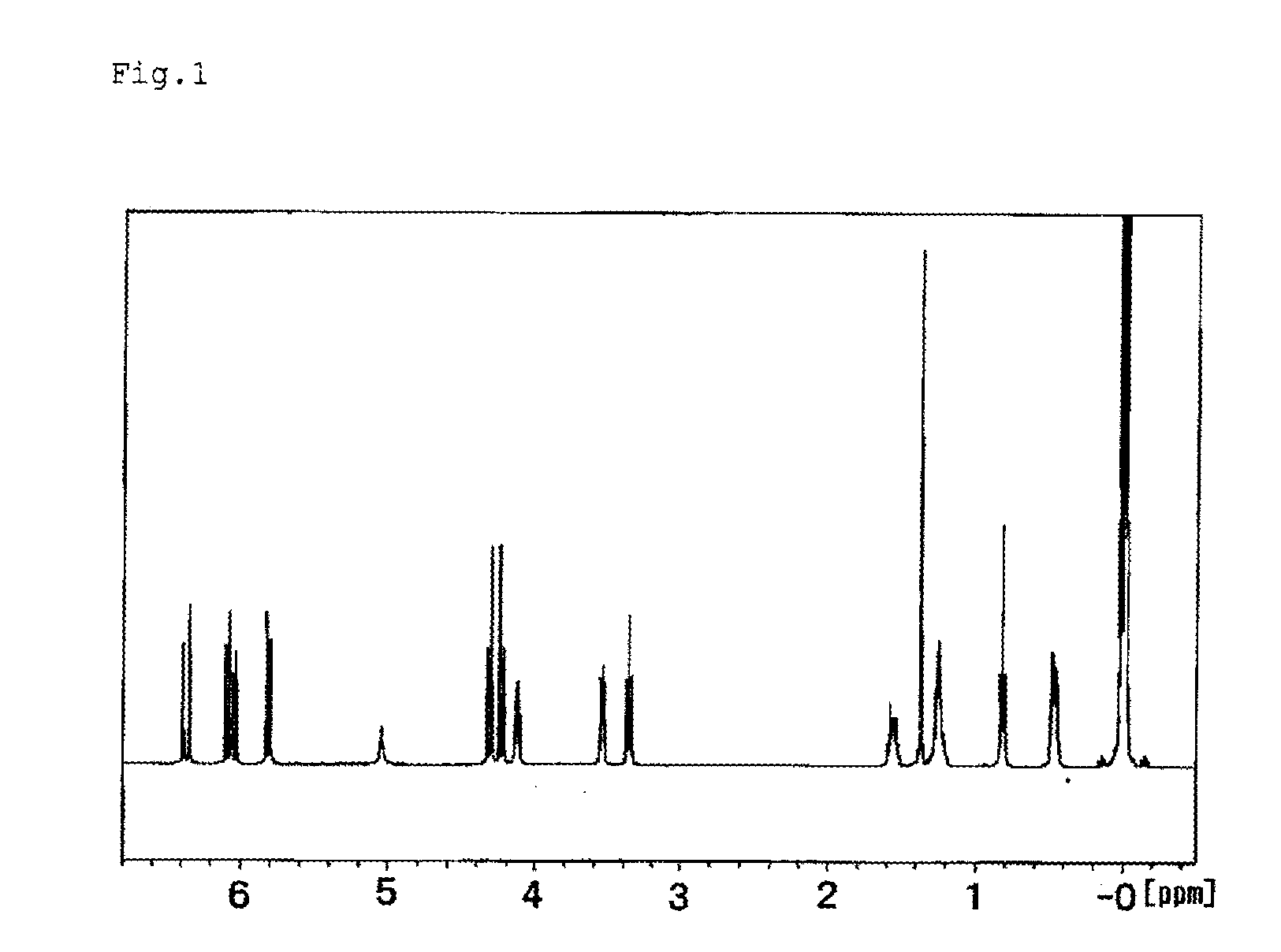

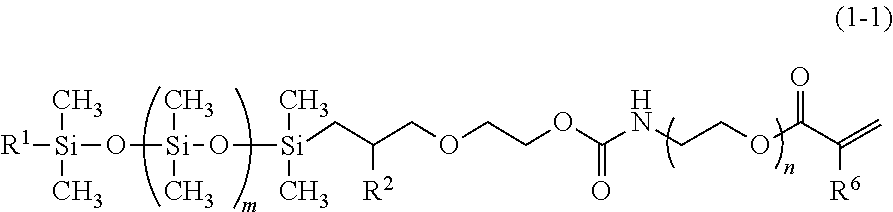

The present invention provides a hydrophilic silicone which has a predetermined number of silicon atoms and a high purity and is suitable for producing an ophthalmic device and a process for preparing the same.The silicone compound is represented by formula (1) with a purity of 95% by weight or higher,wherein m is one value out of the integers of from 3 to 10, n is one value out of the integers of from 1 to 10, R1 is one out of alkyl groups having 1 to 4 carbon atoms, and R2 is one out of a hydrogen atom and a methyl group.

Owner:SHIN ETSU CHEM IND CO LTD

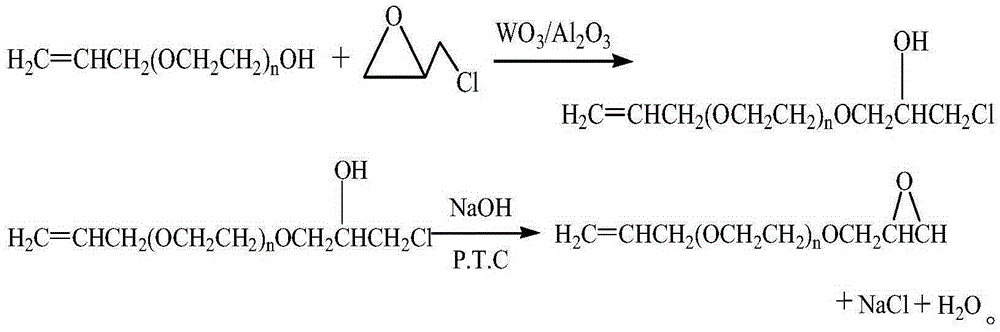

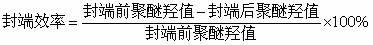

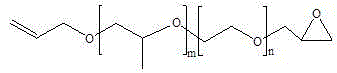

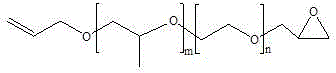

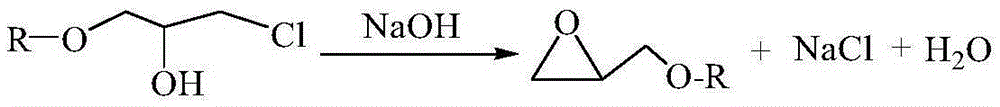

Method for preparing glycidol ether terminated propenol polyoxyethylene ether

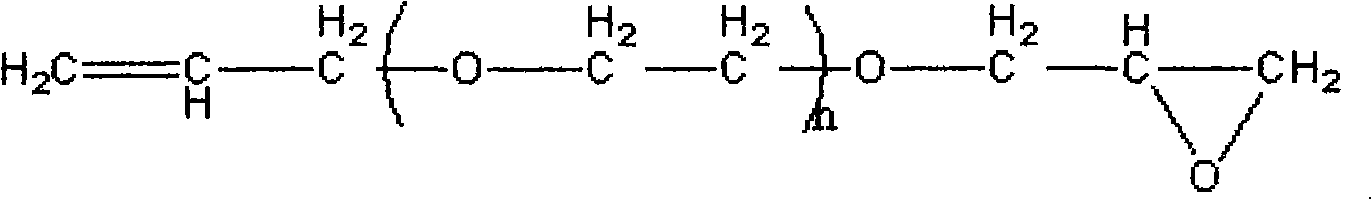

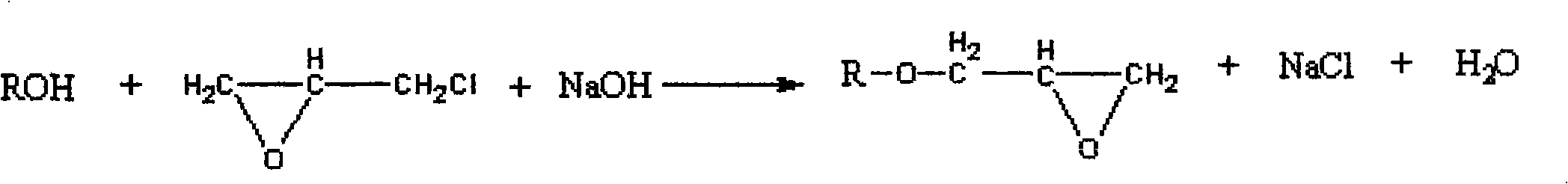

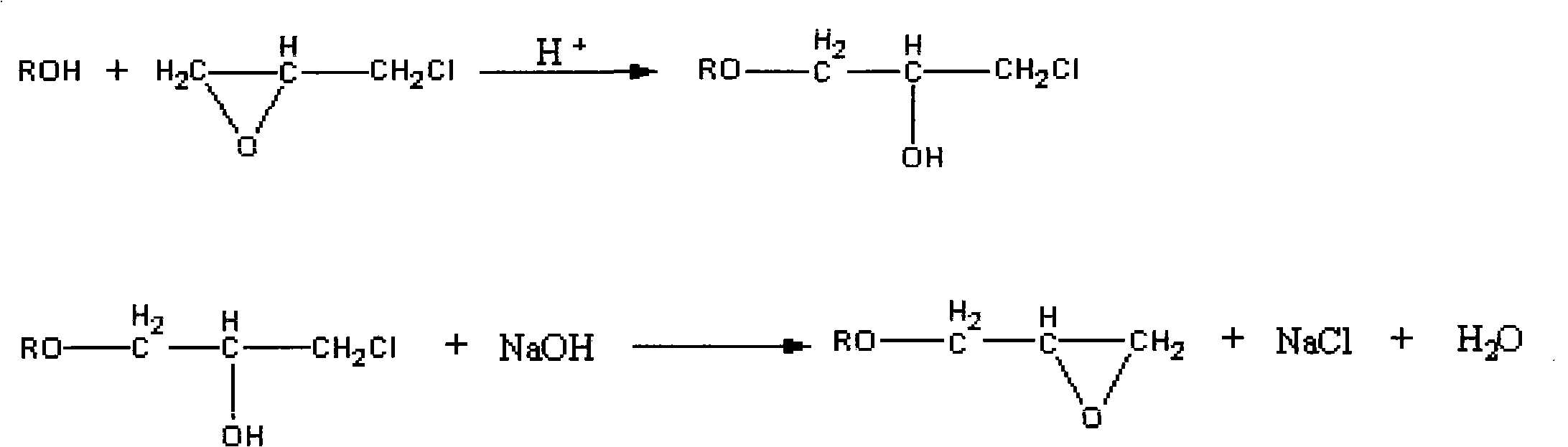

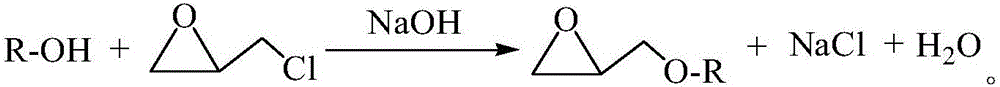

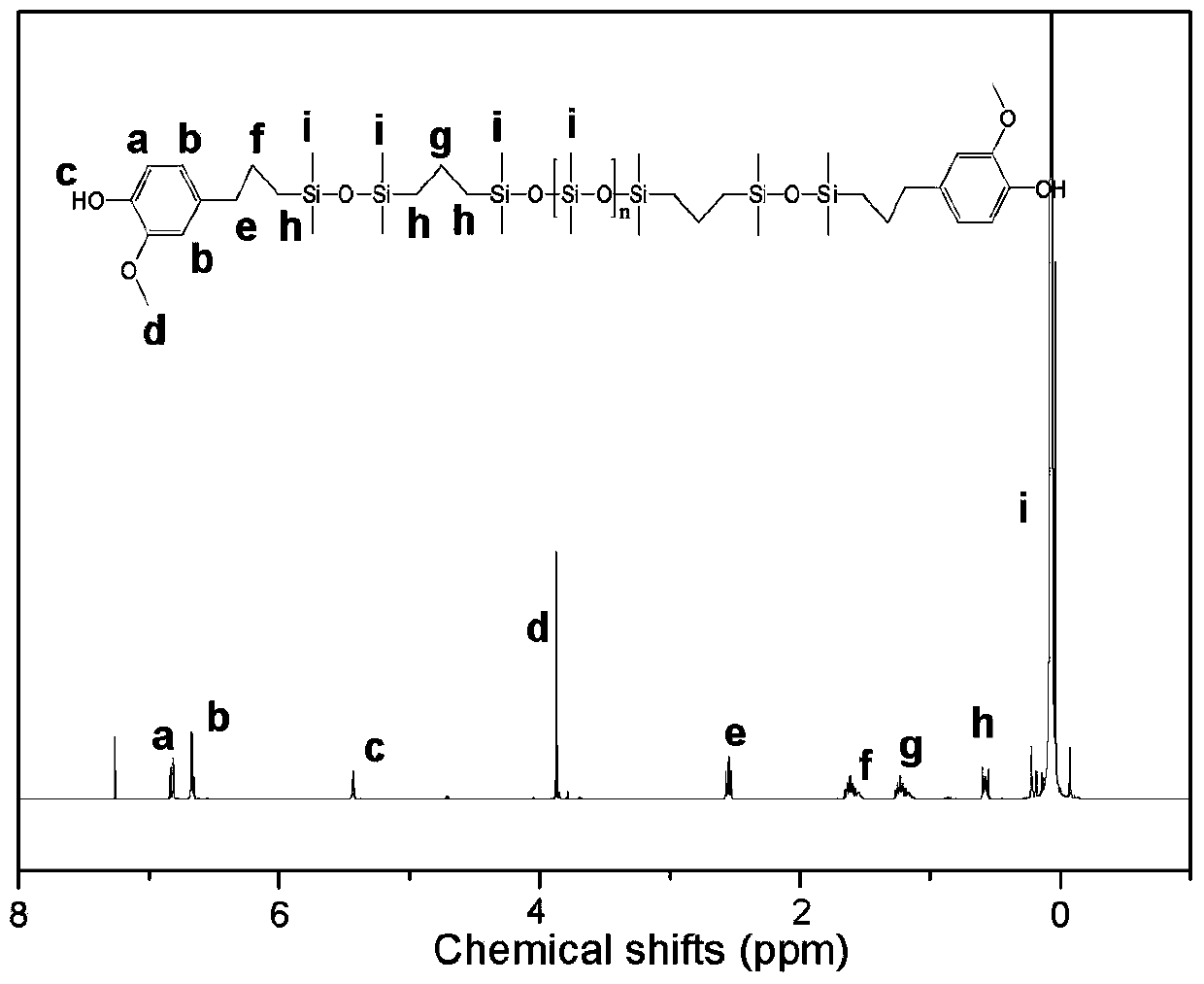

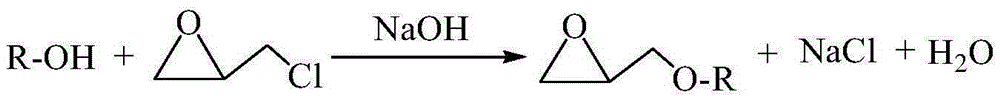

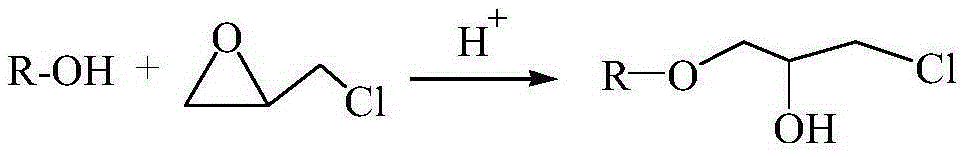

The invention discloses a method for preparing glycidol ether terminated propenol polyoxyethylene ether, which comprises the following steps of: mixing commercial allyl polyoxyethylene ether and epoxy chloropropane serving as raw materials, performing ring opening reaction on the mixture by adopting NaH as a catalyst to generate an allyl polyoxyethylene chlorohydrine ether intermediate, then removing redundant epoxy chloropropane with reduced pressure, adding inorganic alkali into the allyl polyoxyethylene chlorohydrine ether intermediate, and performing ring closing reaction to prepare the glycidol ether terminated propenol polyoxyethylene ether. The method has the characteristics of high reaction speed and high termination efficiency.

Owner:ZHEJIANG HUANGMA TECH

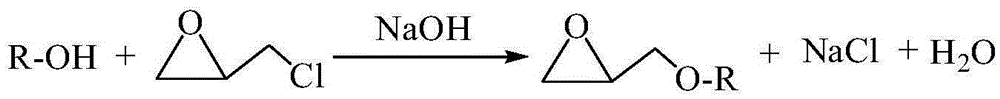

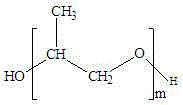

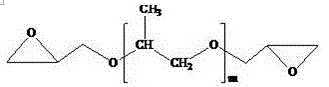

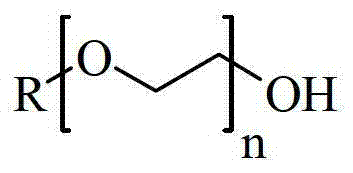

End capping polyether prepared with end hydroxyl radical polyether and preparation thereof

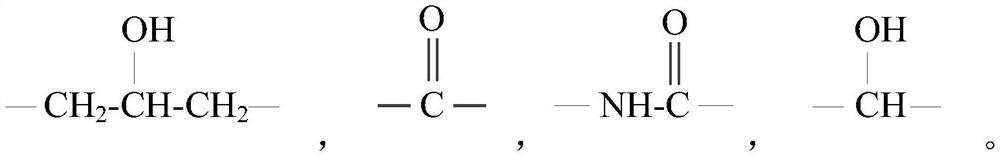

ActiveCN101343358AHigh capping rateMild reaction conditionsGroup 4/14 element organic compoundsEndcappingCarbon chain

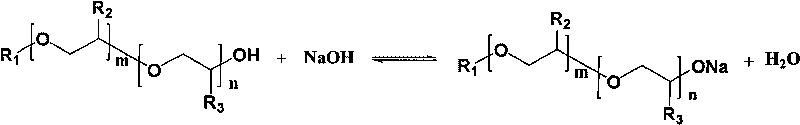

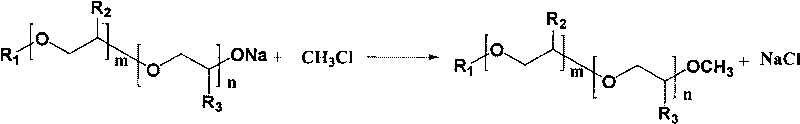

The invention discloses end capping polyether which is prepared by hydroxyl-terminated polyether and the preparation method thereof. The reaction condition is mild, and the end capping rate can achieve higher than 95 percent. The end capping polyether prepared by the hydroxyl-terminated polyether is provided with the structure that R is C1-C20 carbon chain group, R1 is-H, -CH3 or -CH2CH3, R2 is -H, -CH3 or -CH2CH3, m and n are respectively the number of the chain segment of OCH2-CHR1 and OCH2-CHR2 in the chain segment of the polyether, m is 0 to 45, m plus n is 1 to 210, and the chain segments of n and m are respectively homopolymerized, segmented or randomly copolymerized.

Owner:JIANGSU MAYSTA CHEM

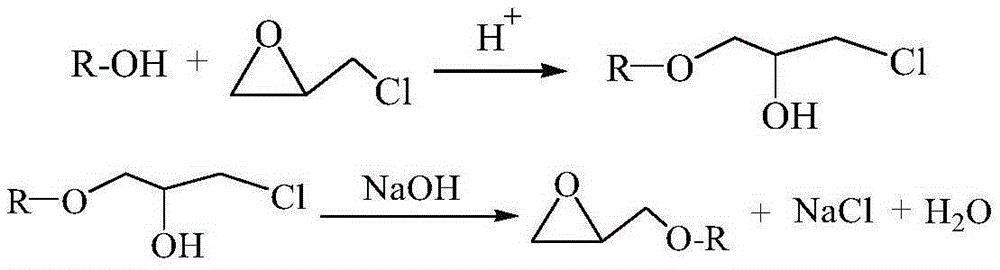

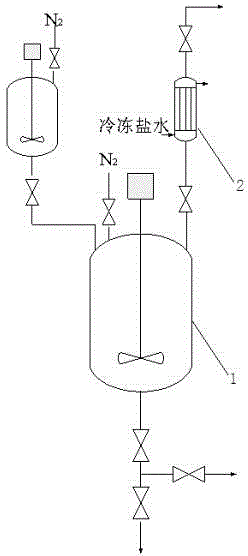

Method for compounding epoxy-terminated allyl alcohol polyoxyethylene ethers

The invention relates to a method for compounding epoxy-terminated allyl alcohol polyoxyethylene ethers, which belongs to the synthesis technology field of organic compounds, and uses allyl alcohol polyoxyethylene ethers and epichlorohydrin as raw materials, adds catalysts into the allyl alcohol polyoxyethylene ethers, is slowly added with epichlorohydrin drop by drop under the protection of nitrogen, filters and recycles the catalysts after finishing a reaction, distills and recycles the epichlorohydrin by reducing pressure, adds solid alkali and quaternary ammonium salt catalyst into a chlorohydrin ether intermediate, reacts for a period of time under the protection of the nitrogen, is added with a neutralizer to neutralize after being filtered to discharge salt, and then is added with an adsorbent to prepare finished products by refining. The method for compounding the epoxy-terminated allyl alcohol polyoxyethylene ethers is applied to compound the epoxy-terminated allyl alcohol polyoxyethylene ethers, effectively recycles the catalysts above 15 times, prevents strongly acidic catalysts from affecting equipment and operation environment, further achieves balance of ending ratio and color, gives high reaction activities for products simultaneously, and also guarantees quality indicators of finished products.

Owner:ZHEJIANG HUANGMA TECH

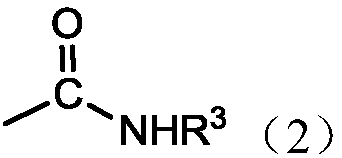

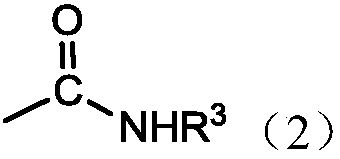

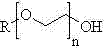

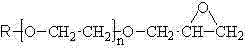

Preparation method of butyl-terminated allyl polyether

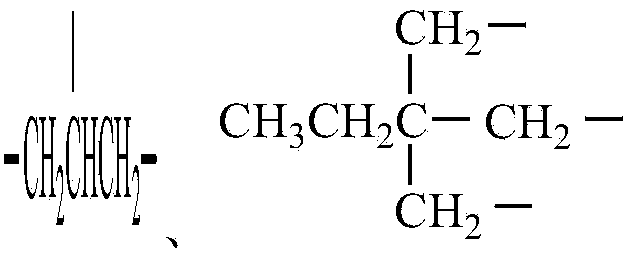

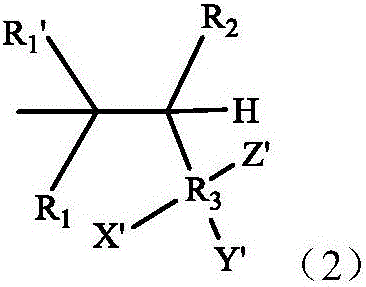

The invention discloses a preparation method of butyl-terminated allyl polyether. The method is characterized in that: butyl polyether and halogenated propylene are employed as the raw materials for reaction, and the butyl polyether has the following general formula (1), wherein, m+n is less than 80; the prepared alkyl-terminated polyether has the following general formula (2), wherein, m+n is less than 80; an alkoxidation reagent is added into the butyl polyether for reaction, with the butyl polyether and the alkoxidation reagent in a feeding mole ratio of 1:1-1.5; then allyl chloride is introduced for reaction continuously so as to obtain butyl-terminated allyl polyether, with the butyl polyether and allyl chloride in a feeding ratio of 1:1-1.5. The method of the invention can prepare butyl-terminated allyl polyether products of high termination efficiency which is higher than that of butyl-terminiated polyether prepared by existing preparation methods.

Owner:ZHEJIANG HUANGMA TECH

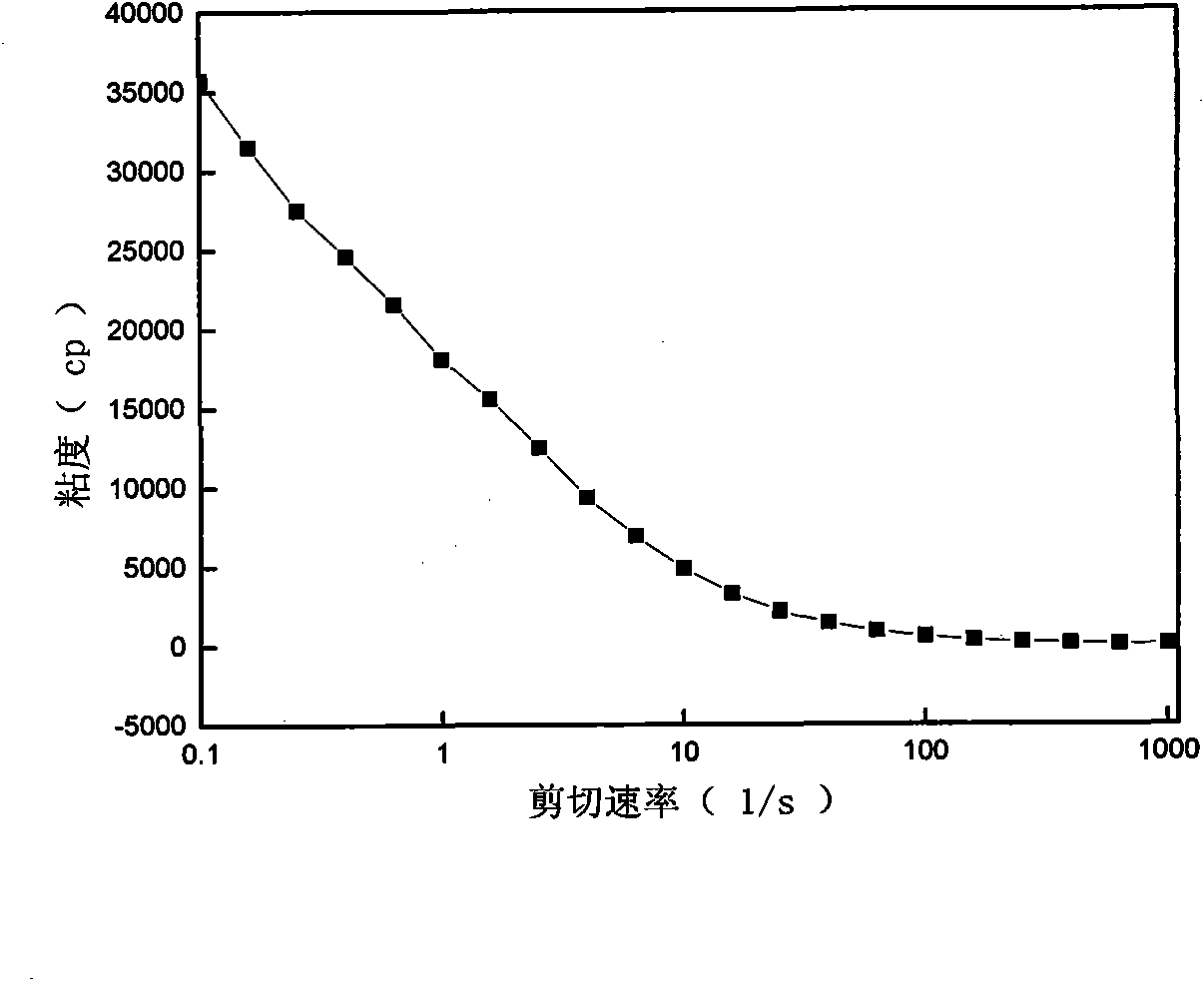

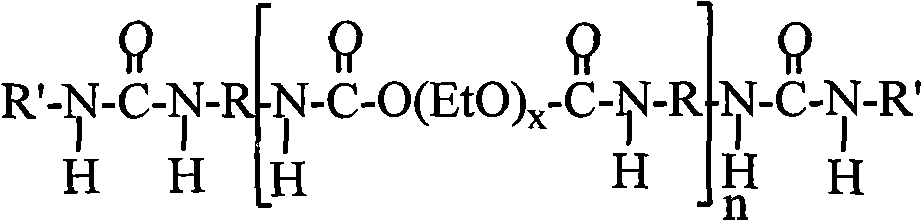

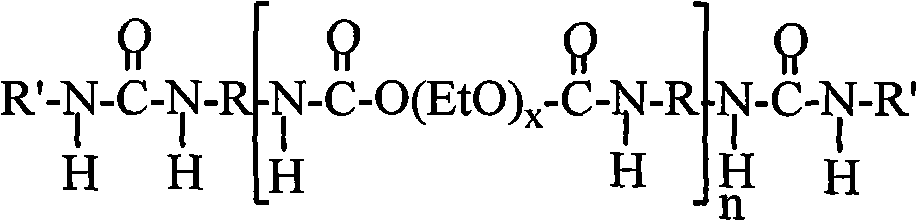

Poly(urethane-urea) associative thickener and preparation method and application thereof

The invention discloses a poly(urethane-urea) associative thickener and a preparation method and application thereof. The thickener comprises poly(urethane-urea) polymer, deionized water and an organic solvent. The preparation method comprises the following steps of: in the presence of a catalyst, reacting polyether glycol subjected to methylbenzenea zeotropic water removal with diisocyanate for 2 to 6 hours to generate polyurethane prepolymer; adding primary amine and a catalyst, reacting for 2 to 8 hours, precipitating a product by using a precipitator, and drying the precipitate to obtain poly(urethane-urea) polymer; and preparing the prepared polymer, the deionized water and the organic solvent into solution to obtain the poly(urethane-urea) associative thickener. The prepared thickener has good thickening effect on styrene-acrylate emulsion and pure acrylic emulsion, so that the emulsion has the characteristics of high viscosity at a low shear rate and low viscosity at a high shear rate. The poly(urethane-urea) associative thickener also can be applied to other aqueous systems, such as the fields of coatings, cosmetics, papermaking, leather and the like.

Owner:DONGHUA UNIV

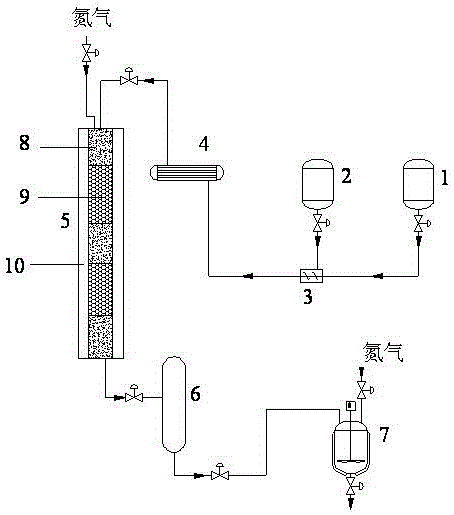

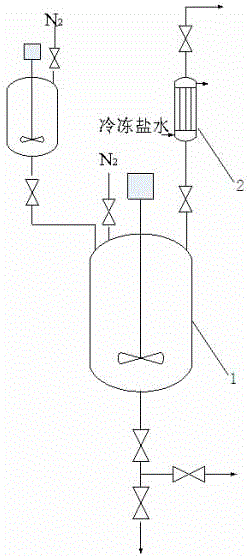

A continuous ring-opening production process for epoxy-terminated polyether

The invention relates to a continuous ring-opening production process for epoxy-terminated polyether and belongs to the technical field of organic polymer compounds. Allyl alcohol polyoxyethylene ether and epichlorohydrin are adopted as raw materials. The process includes mixing the allyl alcohol polyoxyethylene ether and the epichlorohydrin, heating, continuously feeding the mixture to a two-stage fixed bed reactor, performing a ring-opening reaction under catalysis of a solid superacid, adding a product collected by a collecting tank at the lower end of the reactor to a reaction kettle through a metering pump every 2-4 h, adding an alkali and a quaternary ammonium salt catalyst, stirring for 1-4 h while maintaining the temperature, filtering to obtain a crude product, performing vacuum distillation to recover the epichlorohydrin, and purifying to obtain a qualified product. The process is applied for producing the epoxy-terminated polyether, and has advantages of a high equipment utilization rate, a high production efficiency, and the like.

Owner:ZHEJIANG HUANGMA TECH

Polyamide recovery process and polyamide obtained by recovery process

ActiveCN111892743AImprove precipitation efficiencyHigh crystallinityLayered productsPlastic recyclingEndcappingPolyamide

The invention discloses a polyamide waste recovery process, which comprises the following steps: adding polyamide waste into a compound solvent, heating to 50 DEG C to a solution reflux temperature, stirring until the polyamide waste is dissolved, carrying out decolorization treatment, and filtering to obtain a polyamide solution; adding the polyamide solution into water, precipitating polyamide in deionized water to separate out a solid, and separating to obtain recycled polyamide; wherein the compound solvent is prepared from the following components in parts by weight: 10 to 30 parts of phenol and 15 to 40 parts of methylbenzene. According to the invention, the solvent system mainly comprising phenol / toluene has the following advantages: 1, the solvent phenol can carry out secondary endcapping on polyamide, so the end capping rate is improved, and the hydrolysis resistance, alcoholysis resistance and aging resistance are improved; 2, polyamide can be fully separated out when the polyamide solution is added into deionized water, and the obtained polyamide is good in crystallization property; and 3, the phenol / toluene solvent system is low in volatility and irritation, relativelylow in damage to equipment under a high-temperature condition, green, environment-friendly and pollution-free.

Owner:KINGFA SCI & TECH CO LTD

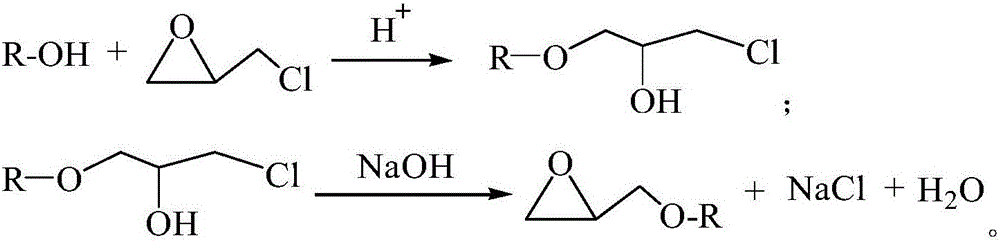

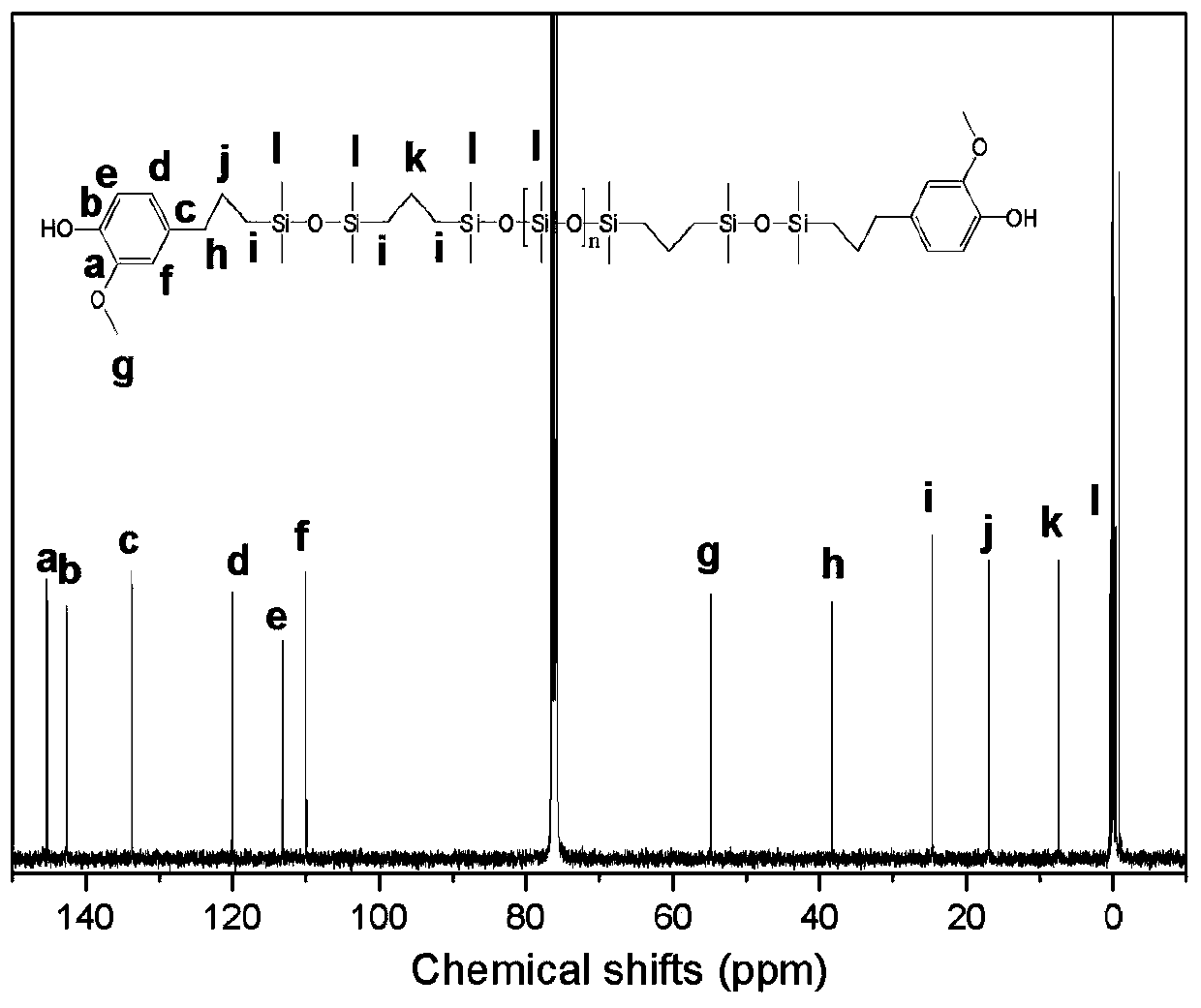

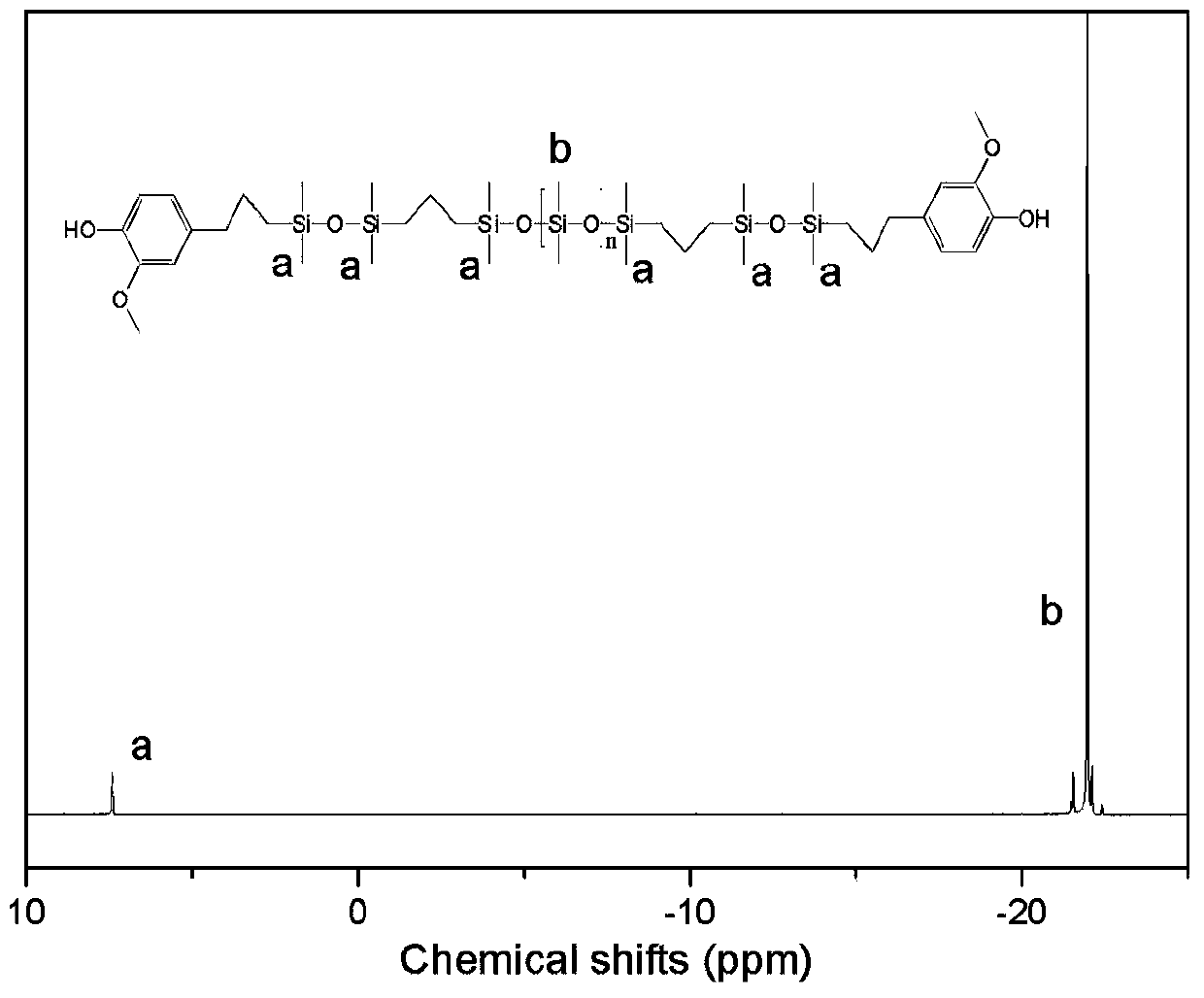

Phenol-terminated polysiloxane, preparation method thereof, and polysiloxane-polycarbonate copolymer

The invention discloses phenol-terminated polysiloxane, a preparation method thereof, and a polysiloxane-polycarbonate copolymer. The method includes the following steps: a) catalyzing a reaction of tetramethyldisiloxane and an allyl-containing phenolic compound by using a transition metal catalyst A to prepare phenol-modified hydrogen-containing silane having a phenol group at one end and a silicon-hydrogen bond at one end; b) performing separation by using reduced-pressure rectification to obtain phenol-modified hydrogen-containing silane with purity of >=99%; and c) catalyzing B by using atransition metal catalyst, performing a hydrosilylation reaction on the pure phenol-modified hydrogen-containing silane and polysiloxane with a vinyl end group to obtain the polysiloxane containing aphenol group at the end group. The content of the free allyl-containing phenol compound in the phenol-terminated polysiloxane is 100 ppm or less, the phenol group capping rate is 98% or more, and theresidual metal platinum content is <= 5 ppm. The phenol-terminated polysiloxane is used for preparing the modified polycarbonate, and the obtained polysiloxane-polycarbonate copolymer has a high polysiloxane content, and excellent heat resistance and yellowing resistance.

Owner:WANHUA CHEM GRP CO LTD +1

Preparation method of double-epoxy blocked polypropylene glycol

The invention belongs to the technical field of chemical industry, and particularly relates to a preparation method of double-epoxy blocked polypropylene glycol. The preparation method comprises the following steps: (1) dropwise adding a certain amount of NaH into a dripping reaction kettle, stirring, starting a condenser, vacuumizing to slowly suck epoxy chloropropane into the kettle, and then introducing nitrogen until the pressure is 0.4MPa for later use; (2) adding a certain amount of polypropylene glycol and a phase transfer catalyst into a blocking reaction kettle provided with a reflux condensing device, replacing the nitrogen in the kettle, slowly introducing nitrogen, slowly adding a mixture of NaH and epoxy chloropropane obtained in the step (1), and then heating for a certain time to obtain a crude product; and (3) filtering and desalting the crude product obtained in the step (2), adding a neutralizing agent for neutralization, subsequently vacuumizing for recycling epoxy chloropropane, then adding an adsorbent and refining to obtain a qualified finished product. The double-epoxy blocked polypropylene glycol prepared by the method disclosed by the invention has the advantages of light color (smaller than or equal to 40, platinum-cobalt colorimetric method) and high blocking rate (larger than or equal to 95%).

Owner:ZHEJIANG HUANGMA TECH

Preparation method of glycidol ether base end-capped allyl alcohol random polyether

The invention relates to a preparation method of glycidol ether base end-capped allyl alcohol random polyether, which comprises the following steps: (1) adding NaH into a dropwise addition reaction kettle, starting a stirrer and a condenser, vacuumizing to slowly suck epoxy chloropropane into the kettle, and then charging nitrogen gas to 0.4 MPa for later use; (2) adding allyl alcohol random polyether and a phase-transfer catalyst into an end-capping reaction kettle with a reflux condensing device, performing in-kettle nitrogen replacement, then slowly introducing nitrogen gas, slowly adding the NaH and epoxy chloropropane mixture in the step (1), and then performing temperature reaction for a period of time to obtain a crude product; and (3) filtering the crude product to remove salt, neutralizing with neutralizer, then vacuumizing to recover the epoxy chloropropane, adding adsorbent, and refining to obtain the qualified finished end-capped product. The preparation method can satisfy the requirements of high-end products for end-capping rate and color, and is easy to realize industrial application.

Owner:ZHEJIANG HUANGMA TECH

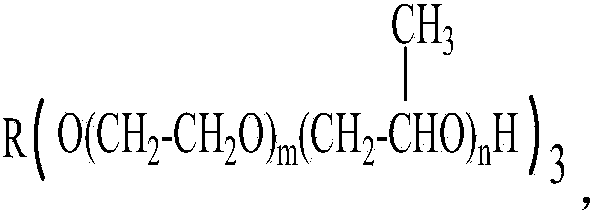

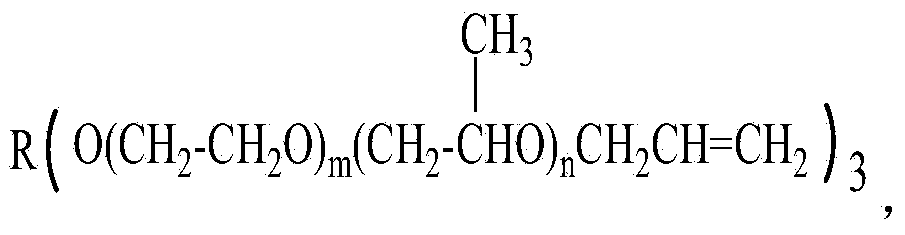

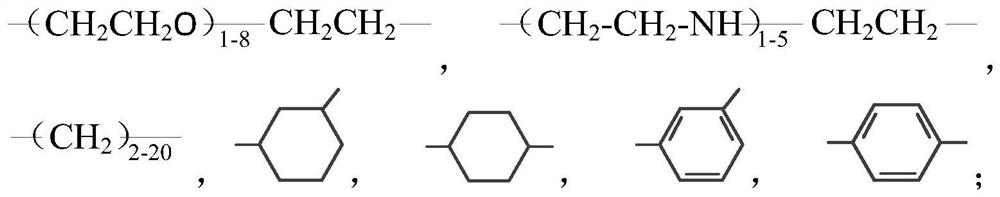

Low-foam nonionic surfactant, preparation method therefor and application of low-foam nonionic surfactant

ActiveCN108654512AGood emulsificationLess foamPolymeric surface-active compoundsTransportation and packagingChemical industryAddition reaction

A low-foam nonionic surfactant and a preparation method therefor. The invention provides a nonionic surfactant represented by a general formula (1) shown in the description, a preparation method therefor and an application of the nonionic surfactant. The invention particularly relates to a method for preparing compositions through alkoxylation and addition reaction in the presence of a catalyst such as alkaline, acidic or bimetallic cyanides and use of the compositions as nonionic surfactants, particularly in textiles, industry, public washing and daily chemical industry.

Owner:联泓(江苏)新材料研究院有限公司

Method for synthesizing epoxy stop end butanol polyoxyethylene polyoxypropylene ether

The invention relates to a method for synthesizing epoxy stop end butanol polyoxyethylene polyoxypropylene ether and belongs to the technical field of organic compound synthesis. A WO3 / ZrO2 catalyst is added into butanol polyoxyethylene polyoxypropylene ether; under the protection of nitrogen, epichlorohydrin is added dropwise slowly; after the reaction is over, the catalyst is filtered and recycled, epichlorohydrin is recycled through reduced pressure distillation, a chlorhydrin ether intermediate product is obtained; solid alkali and quaternary ammonium salt catalysts are added; under the protection of nitrogen, after the reaction and filtering for desalting, a neutralizer is added for neutralization, an adsorbent is added, and the refining is performed. By applying the method to synthesis of epoxy stop end polyoxyethylene polyoxypropylene ether, the catalyst is effectively recycled and reused 15 times or above, and the influence on devices and the operating environment caused by the strong acid catalyst is avoided; moreover, the balance of the stop end rate and color is achieved, and the condition indexes of finished products are also guaranteed.

Owner:ZHEJIANG HUANGMA TECH

Preparation method of glycidyl terminated allyl alcohol polyoxyethylene ether

The invention discloses a preparation method of glycidyl terminated allyl alcohol polyoxyethylene ether. The method comprises the following technical steps: 1) adding solid sodium hydroxide, calcium chloride and water into a pressure reaction kettle, fully stirring and dissolving, and then decompressing and dehydrating till being dried; 2) controlling the temperature, inflating nitrogen to the pressure reaction kettle to constant pressure, then, putting a quaternary ammonium salt phase transfer catalyst and an allyl alcohol polyoxyethylene ether into the pressure reaction kettle, vacuumizing and replacing nitrogen, then dropwise adding epoxy chloropropane without air by vacuumization at a low temperature for synthetic reaction, and after dropwise addition, continuously carrying out reaction; and 3) after reaction, filtering to remove salt, neutralizing by phosphoric acid and degassing to recover excessive epoxy chloropropane to obtain a coarse product, and then, refining the coarse product. The product prepared by the method disclosed by the invention has the characteristics of light color and luster, high terminating rate, high double bond protective rate and simplicity in process.

Owner:ZHEJIANG LYUKEAN CHEM

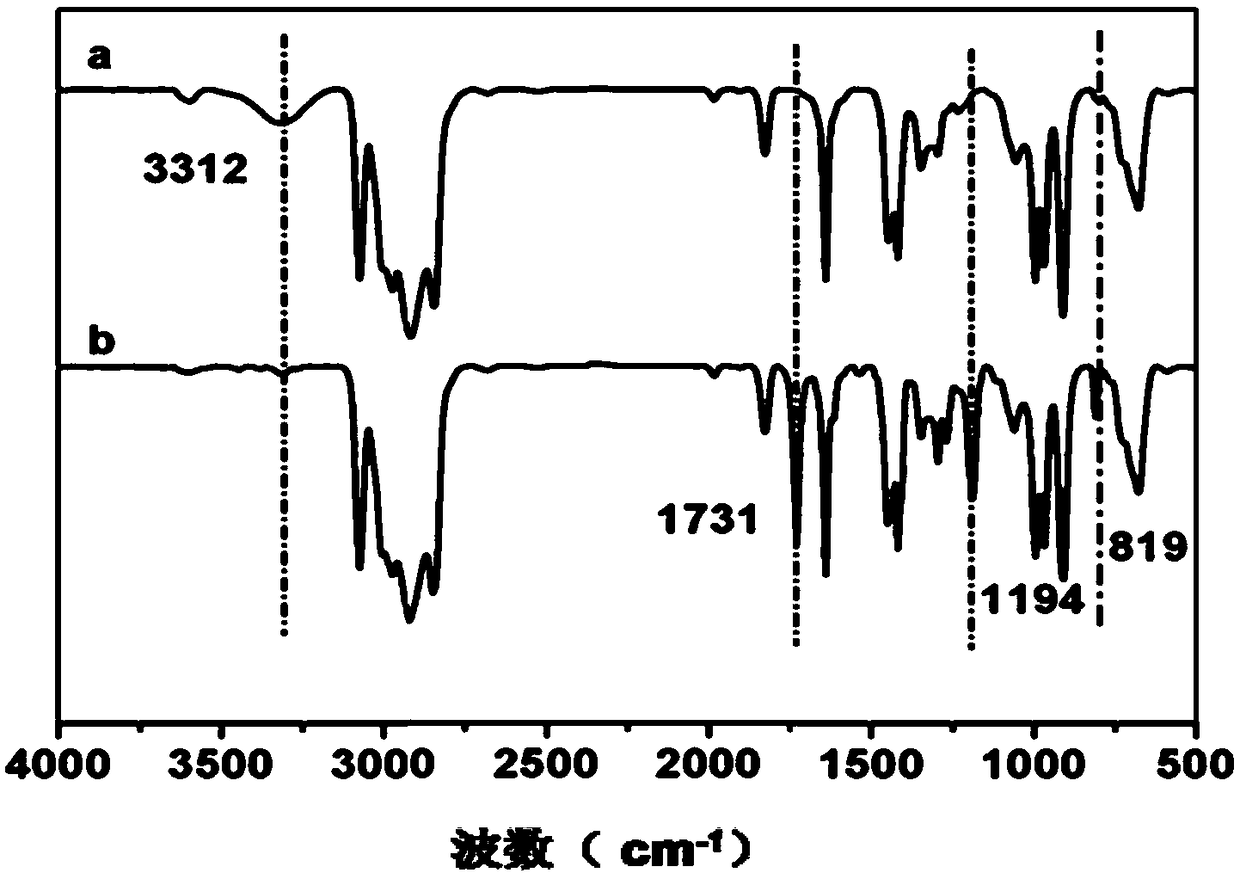

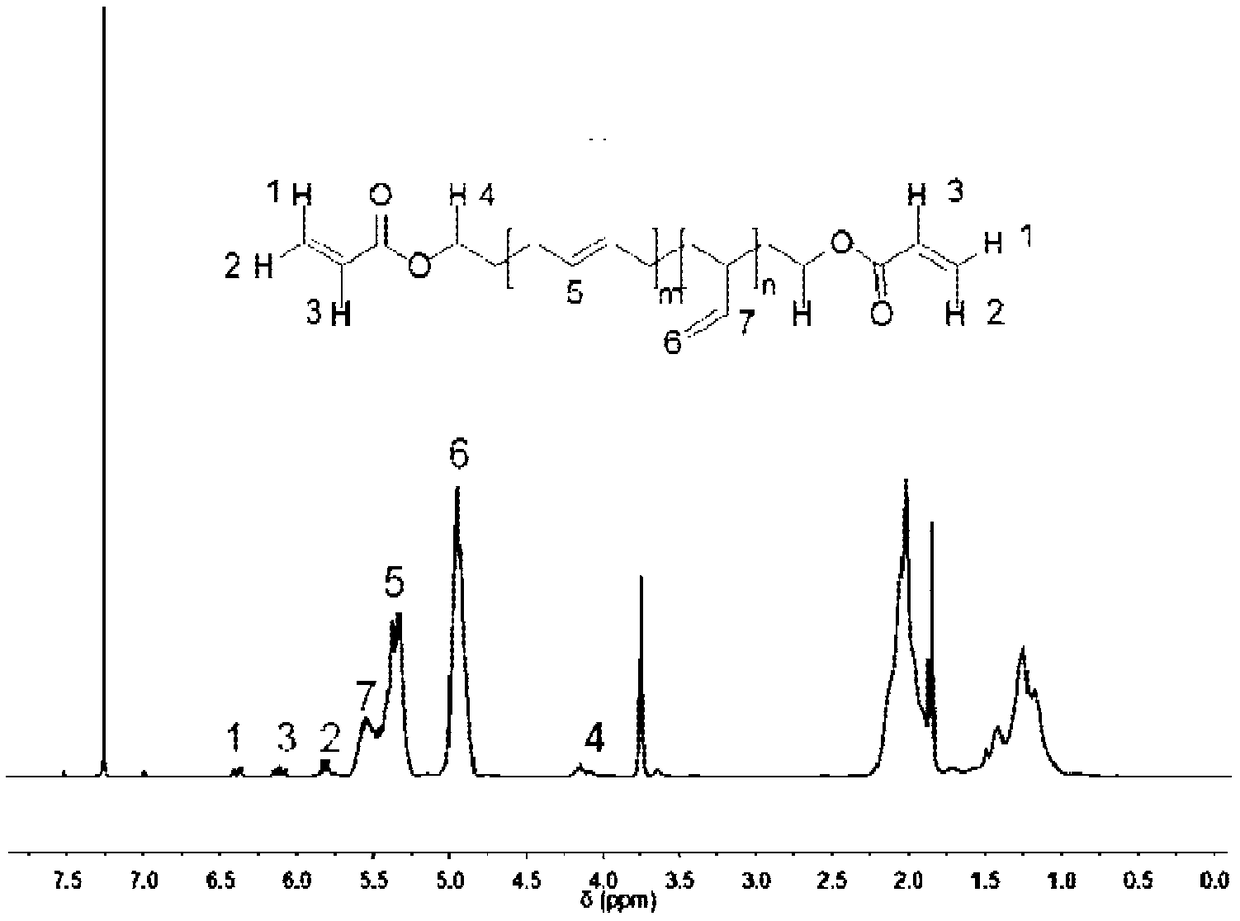

Yellowing-resistant UV-curing liquid-state optical transparent adhesive and preparation method thereof

ActiveCN109294460AEasy to storeHigh capping rateOrganic non-macromolecular adhesiveCross-linkPolymer science

The invention relates to a yellowing-resistant UV-curing liquid-state optical transparent adhesive and a preparation method thereof, wherein the raw materials comprise, by mass, 20-70% of a liquid rubber acrylate macromonomer, 20-60% of an active dilution monomer, 3-20% of a cross-linking monomer, 5-20% of a polybutadiene resin, and 2-20% of a photoinitiator. According to the present invention, the new synthetic route is provided, wherein a hydroxyl-terminated liquid rubber reacts with naphthalene potassium to form a liquid rubber potassium alkoxide, and the liquid rubber potassium alkoxide reacts with an acryloyl chloride compound to form a liquid rubber acrylate macromonomer; with the method, the problems of macromonomer yellowing caused by the direct esterification reaction of the hydroxyl-terminated liquid rubber and the acryloyl chloride compound under the catalysis of the organic alkali and the low end capping rate of the inorganic alkali catalysis can be overcome; and the UV curing film has a light transmittance of up to 99%, a refractive index of 1.50-1.52, and a yellowing index of 0.3.

Owner:山东慕尔斯新材料科技有限公司

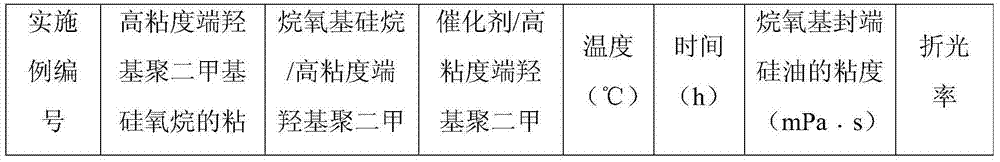

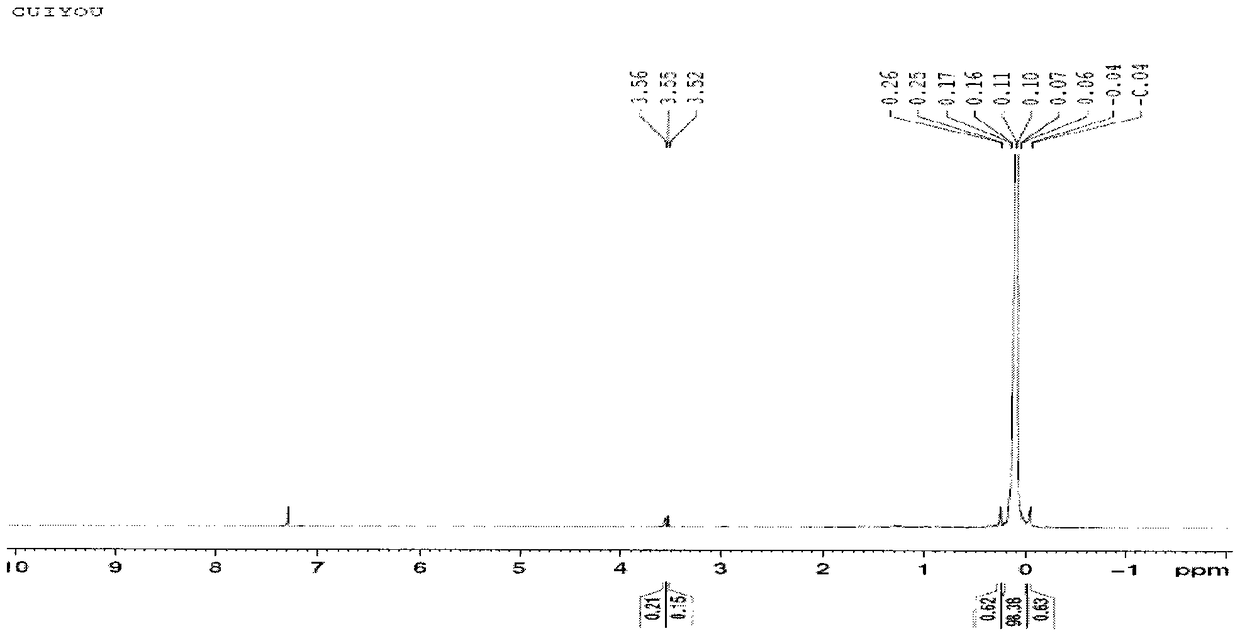

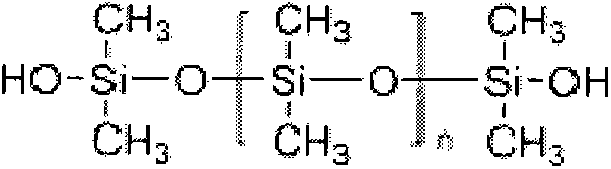

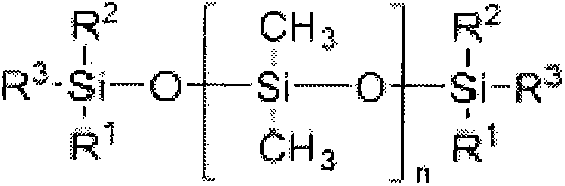

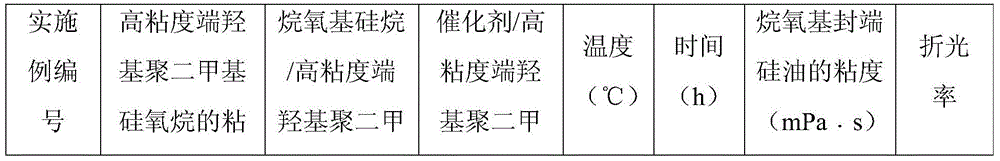

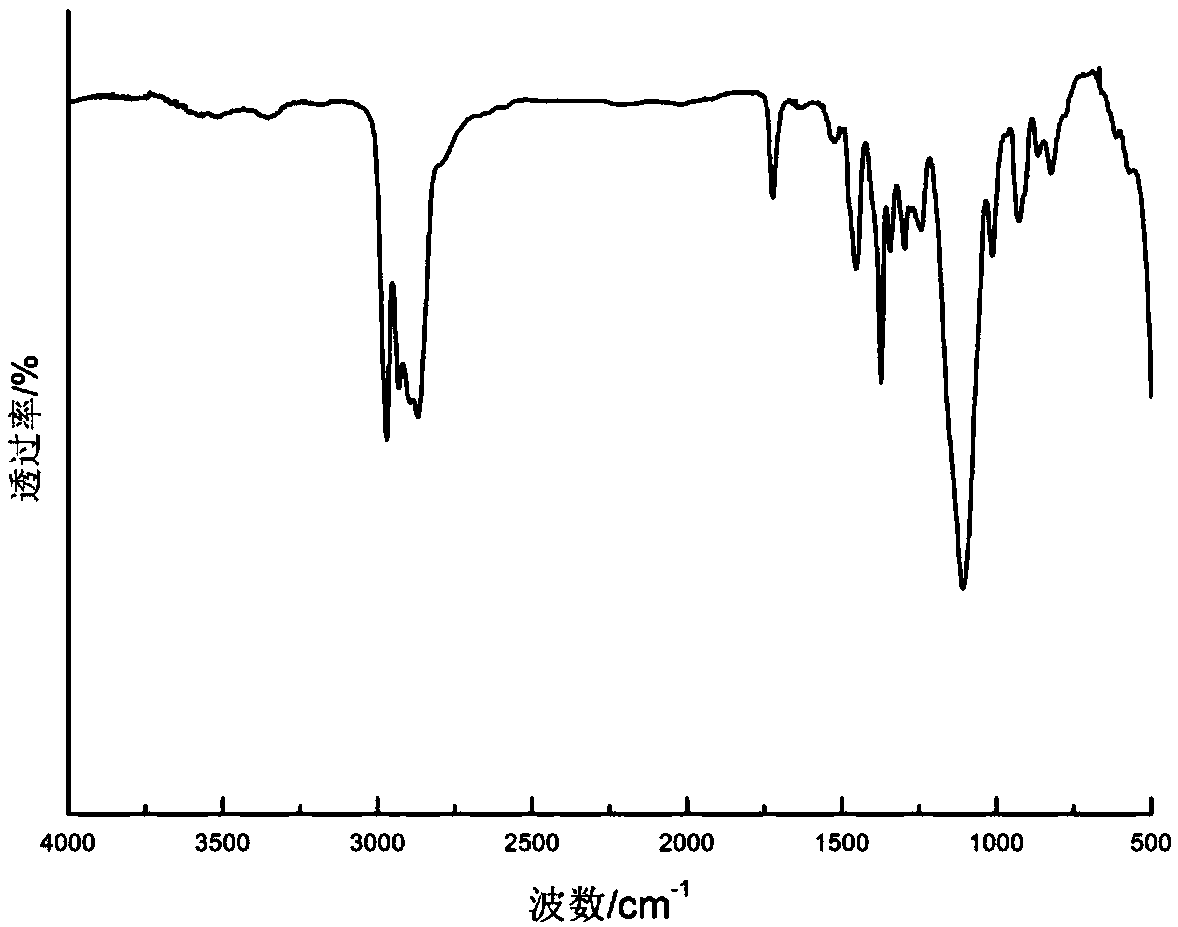

Preparation method of alkoxy end capping silicone oil

The invention belongs to the field of modified silicone oil, specifically relates to a preparation method of alkoxy end capping silicone oil, and aims at solving the technical problems of the existing preparation that the process is complex because of starting from chlorosilane monomer, hydrogen chloride produced by hydrolyzing is difficult to remove, and therefore, the storage stability of a product is poor. The preparation method of the alkoxy end capping silicone oil comprises the following steps: adding a catalyst to high-viscosity-end hydroxyl polydimethylsiloxane and alkoxy silane under the protection of nitrogen, heating to be 80 to 130 DEG C, and reacting for 1 to 6 hours; b, neutralizing to be neutral after the reaction is done; c, filtering to obtain the filtrate that is the crude alkoxy end capping silicone oil product; d, distilling the crude product under a temperature of 120 to 170 DEG C and at a pressure of -0.06 to -0.09Mpa to obtain the alkoxy end capping silicone oil. According to the preparation method of the alkoxy end capping silicone oil, the reaction line is simple, the alkoxy end capping silicone oil is high in stability and high in end capping rate, and a new method is provided to the preparation of the alkoxy end capping silicone oil.

Owner:江苏科幸新材料有限公司

Secondary terminating method for synthesizing methoxy-terminated polyether with high terminating rate

The invention relates to a secondary terminating method for synthesizing methoxy-terminated polyether with high terminating rate, characterized in that terminating is continuously carried out twice in an autoclave. The method comprises the following steps: (1) adding single-hydroxy polyether and alkali to a reaction container; (2) stirring, increasing the temperature and reducing pressure to remove small molecular compounds; (3) leading chloromethane in to finish an etherification reaction under a certain pressure and temperature; (4) adding sodium hydride; (5) stirring, increasing the temperature and reducing pressure to remove hydrogen; (6) leading chloromethane in to finish the etherification reaction under a certain pressure and temperature; and (7) refining and post processing to obtain a qualified product. Polyether with high terminating rate higher than 99% is obtained after post processing the product. The invention overcomes the defects of a traditional process, obviously improves the terminating rate, lowers the post processing difficulty and avoids using carcinogens (such as dimethyl sulfate, and the like) by a traditional method.

Owner:NANJING WELL BIOCHEM

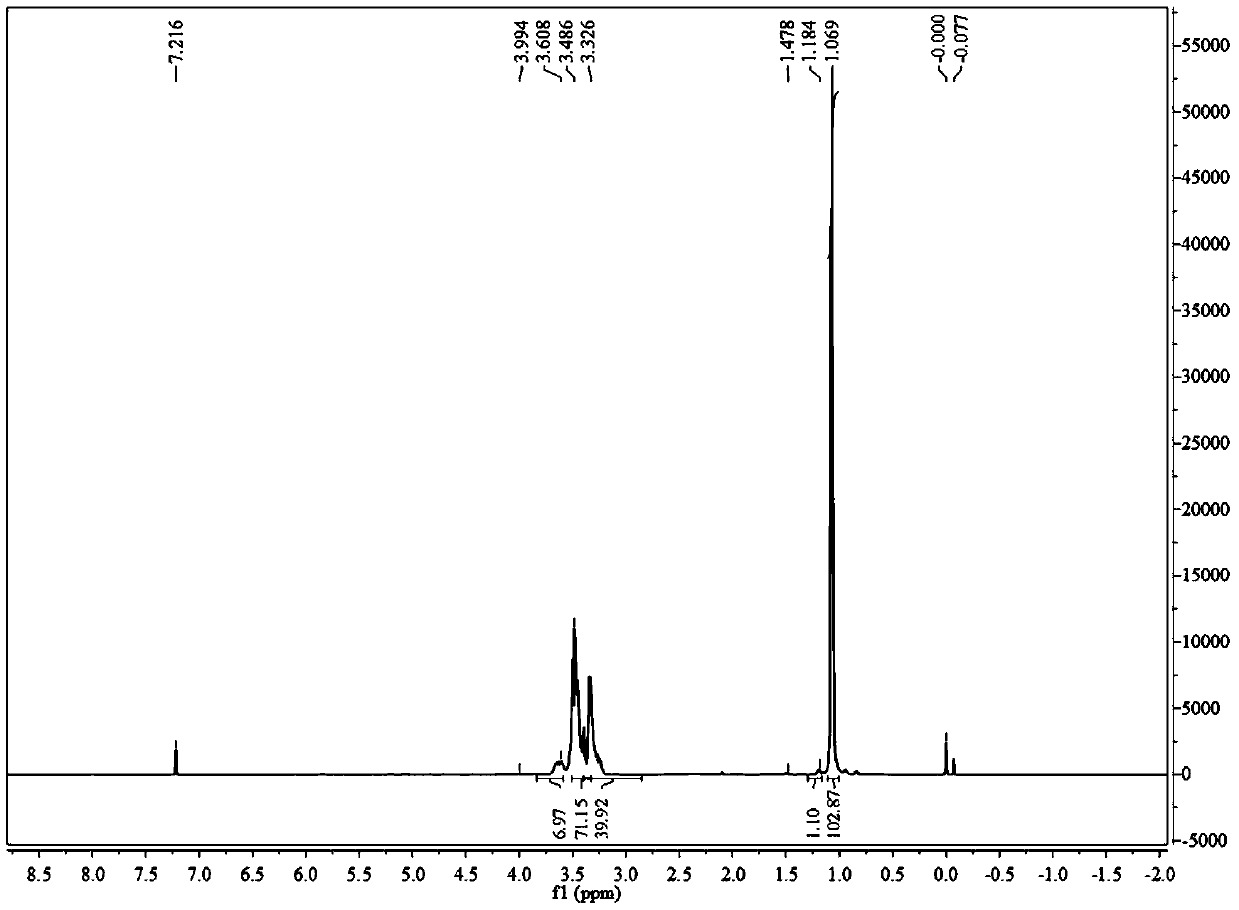

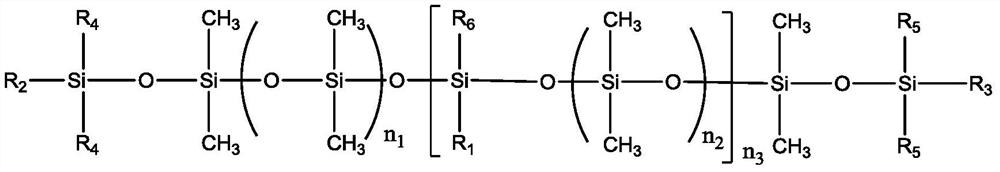

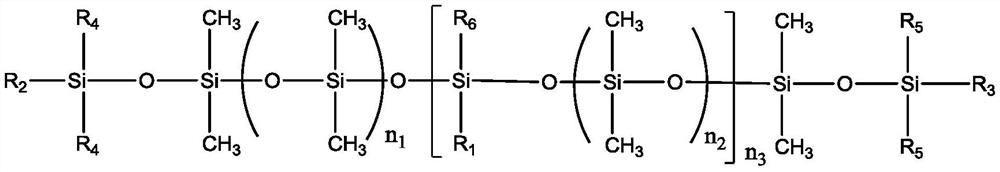

A kind of alkoxy terminated polysiloxane polymer and preparation method thereof

ActiveCN104558612BLow priceSolve problems such as viscosity dropAdhesivesDimethyl siloxanePolydimethylsiloxane

The invention discloses a preparation method of an alkoxy-terminated polysiloxane polymer. According to the method, by adopting organic amine salt as a catalyst for a reaction, the terminating rate of alpha,omega-dihydroxy polydimethylsiloxane is effectively increased and the catalyst and excessive terminating agent can be reacted to obtain amide substances which are harmless to the stability of a product so that the subsequent processing is not needed and the reaction flow is simplified.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Preparation method of alkoxy-terminated silicone oil

The invention belongs to the field of modified silicone oil, specifically relates to a preparation method of alkoxy end capping silicone oil, and aims at solving the technical problems of the existing preparation that the process is complex because of starting from chlorosilane monomer, hydrogen chloride produced by hydrolyzing is difficult to remove, and therefore, the storage stability of a product is poor. The preparation method of the alkoxy end capping silicone oil comprises the following steps: adding a catalyst to high-viscosity-end hydroxyl polydimethylsiloxane and alkoxy silane under the protection of nitrogen, heating to be 80 to 130 DEG C, and reacting for 1 to 6 hours; b, neutralizing to be neutral after the reaction is done; c, filtering to obtain the filtrate that is the crude alkoxy end capping silicone oil product; d, distilling the crude product under a temperature of 120 to 170 DEG C and at a pressure of -0.06 to -0.09Mpa to obtain the alkoxy end capping silicone oil. According to the preparation method of the alkoxy end capping silicone oil, the reaction line is simple, the alkoxy end capping silicone oil is high in stability and high in end capping rate, and a new method is provided to the preparation of the alkoxy end capping silicone oil.

Owner:江苏科幸新材料有限公司

Polylactic acid preparation method

InactiveCN105542154AHigh capping rateEasy to makeTert-Butyloxycarbonyl protecting groupTrifluoroacetic acid

The invention discloses a polylactic acid preparation method, belongs to the field of preparation of polylactic acid, and concretely provides an aminopolylactic acid preparation method with simple preparation process and high amino termination rate. The aminopolylactic acid preparation method comprises the following steps: reacting tert-butoxycarbonyl carbonic anhydride with aminopropanol to synthesize tert-butyloxycarbonyl aminopropanol, initiating ring-opening polymerization of L-lactide with tert-butyloxycarbonyl aminopropanol as an initiator under the catalysis of stannous octoate to synthesize tert-butyloxycarbonylamino-terminated polylactic acid, carrying out trifluoroacetic acid treatment to remove a tert-butyloxycarbonyl group to obtain amino-terminated polylactic acid, and initiating ring-opening polymerization of w-benzyloxycarbonyl-L-lysine-N-carboxylic anhydride with aminopolylactic acid as a macromolecular initiator to synthesize polylactic acid-polylysine. The method has a simple preparation process, and the polylactic acid-polylysine prepared in the invention has a high amino termination rate.

Owner:SHAANXI YUHANG ELECTRONICS

Method for synthesizing trimethyl allyl polyoxypropylene ether

InactiveCN103626990ASolve the problems of poor reactivity and low capping rateAvoid increased side effectsAlcoholEther

The invention relates to a method for synthesizing trimethyl allyl polyoxypropylene ether, belonging to the field of alkyl-terminated polyether preparation technologies. The method comprises an alcohol salinization reaction, a terminating reaction and a refining process, namely adding triol polyoxypropylene ether and an alcohol salinization reagent into a reactor, uniformly stirring, then, controlling the temperature and pressure of alcohol salinization, carrying out the alcohol salinization reaction, removing byproducts after the reaction, then, terminating a remaining product, and refining a terminated crude product so as to remove byproducts, thereby obtaining a final product. By adopting the method disclosed by the invention, the phenomenon of the conventional one-step reaction processes that side reactions are increased due to moisture produced during alcohol salinization reaction is avoided, and the problems that secondary hydroxyl polyether is contained, the reaction activity of high-molecular-weight polyether is poor and the termination rate is low are solved.

Owner:ZHEJIANG HUANGMA TECH

Silicone compound and a use thereof

ActiveUS20150133619A1Improve compatibilityImprove hydrophilicitySilicon organic compoundsPackage sterilisationUltimate tensile strengthSilicon

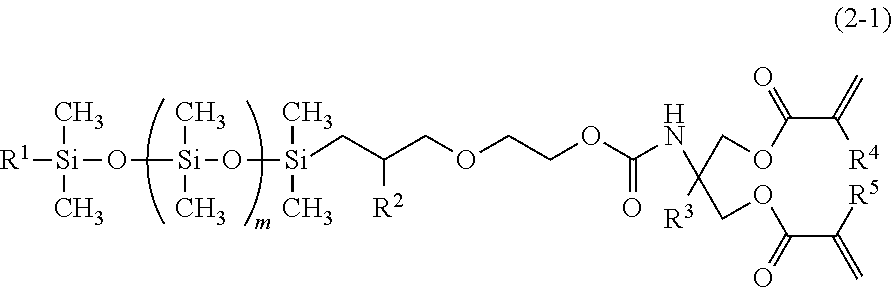

One of the purposes of the present invention is to provide a silicone compound which has a specific number of silicon atoms, is well compatible with (meth)acryl monomers, is suitable as an ophthalmic monomer and provides a polymer having excellent durability of mechanical strength in a buffered phosphate solution. Another purpose of the present invention is to provide a silicone compound which functions well as a crosslinking agent for a polymerizable monomer. Further, another purpose is to provide a method for preparing the silicone compound, in particular the silicone compound having one specific structure at a high ratio. In the first aspect, the present invention provides a compound represented by the following formula (1-1):and a method for preparing the silicone compound. In the second aspect, the present invention provides a compound represented by the following formula (2-1):and a method for preparing the silicone compound.

Owner:SHIN ETSU CHEM IND CO LTD

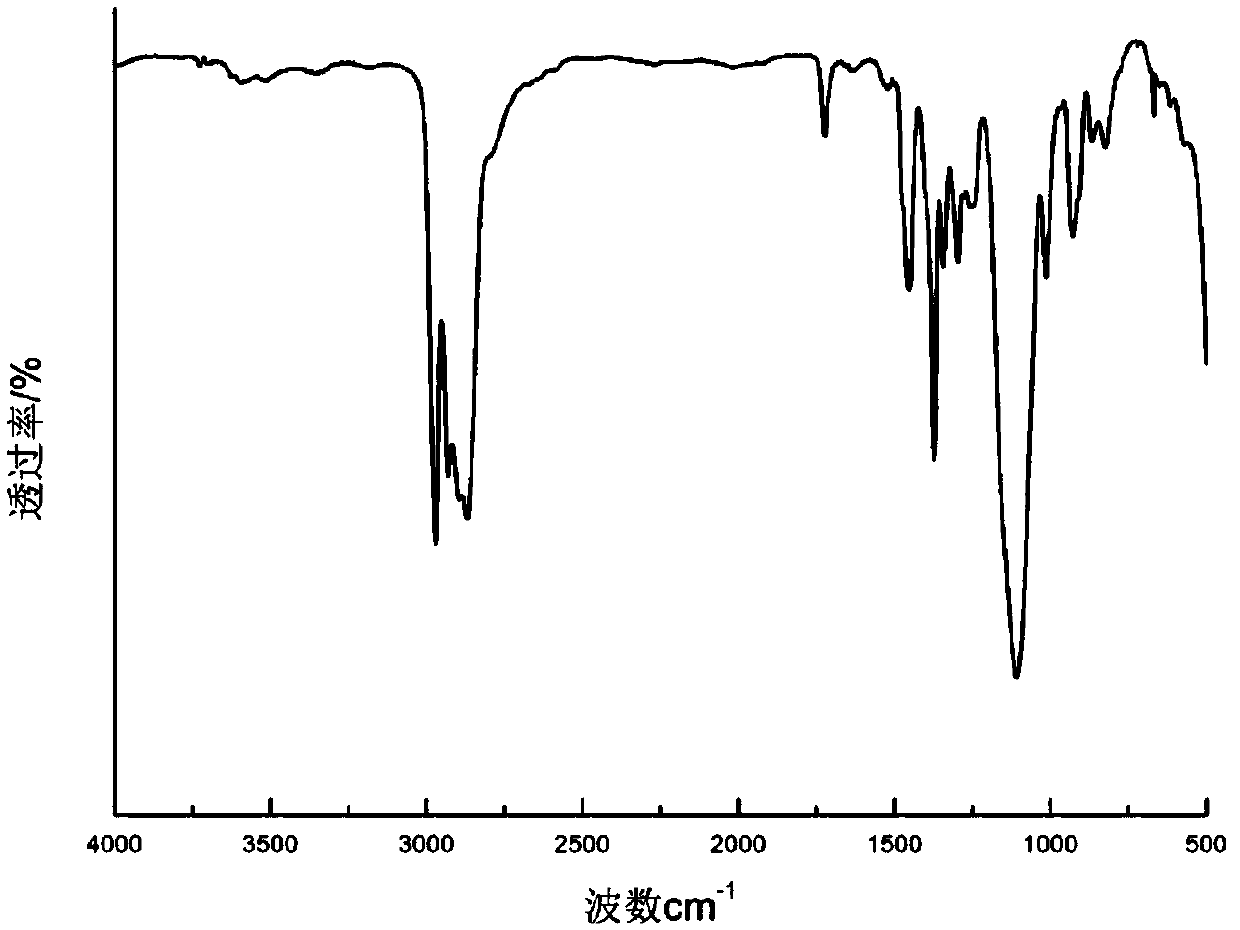

Preparation method of alkoxy-terminated polydimethylsiloxane

ActiveCN113512197AHigh end-capping efficiencySimple production processPhosphoric Acid EstersO-Phosphoric Acid

The invention discloses a preparation method of alkoxy-terminated polydimethylsiloxane, wherein the preparation method comprises the following steps: (1) mixing DMC and hexamethyldisiloxane, heating to 160-180 DEG C, dropwise adding phosphoric acid, stirring for 6-8 hours, and refluxing to remove water to obtain a silicon phosphate terminator; and (2) heating a linear body to 130-150 DEG C, adding a potassium hydroxide aqueous solution, stirring for condensation polymerization, monitoring the viscosity on line, adding the silicon phosphate terminator obtained in the step (1) before the target viscosity is reached, continuously reacting for 5-50 minutes, vacuumizing, carrying out reduced pressure distillation to remove low-boiling-point substances, and thus obtaining the alpha,omega-dihydroxy polydimethylsiloxane with different viscosities. By adopting the preparation method of the alkoxy-terminated polydimethylsiloxane with the structure, the prepared alkoxy-terminated polydimethylsiloxane has the advantages of high terminating efficiency, convenient production process and good storage stability.

Owner:新纳奇材料科技江苏有限公司

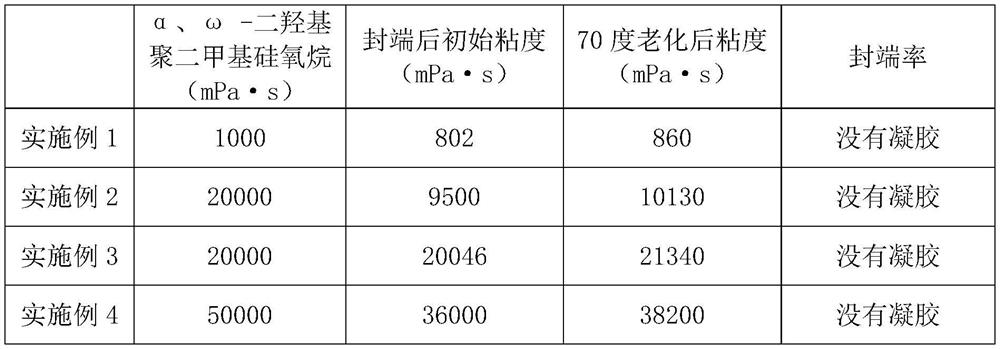

Silanized polymer and preparation method and application thereof

InactiveCN109627411AHigh capping rateHigh reactivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSealantPolymer

The invention provides a silanized polymer with the structure shown in the formula I. The viscosity of the polymer is low, and the polymer is conductive to addition of fillers in a sealant formula toimprove the mechanical properties. The process is easy to control, gelatinization does not easily occur, and the polymer can be applied to sealants and binders. Please see the formula in the description.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Yellowing-resistant polyamide resin, and production raw materials and production method thereof

The invention belongs to the field of resin synthesis preparation, and concretely relates to a yellowing-resistant polyamide resin, and production raw materials and a production method thereof. The production method of the yellowing-resistant polyamide resin comprises the following steps: (1) performing an amidation reaction on a dibasic acid and a diamine under the action of a catalyst, and thengranulating the obtained polyamide resin to obtain polyamide resin particles; and (2) stirring and reacting the polyamide resin particles and a monofunctional isocyanate at 10-120 DEG C for 2-10 h inthe presence of an organic solvent, and performing filtration and drying to obtain the yellowing-resistant polyamide resin. The polyamide resin is produced by the method of the present invention, thepolyamide resin particles are swollen in the organic solvent to make the molecular chain in a nearly freely movable state, the monofunctional isocyanate enters the polyamide resin particles with the organic solvent to carry out an end capping reaction on the tail end of the polyamide molecular chain, the end capping reaction is carried out at a low temperature, and side reactions are very weak, sothat the finally obtained polyamide resin has good yellowing resistance.

Owner:ZHONGLUN PLASTIC IND FUJIAN

A kind of preparation method of alkoxy-terminated polydimethylsiloxane

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

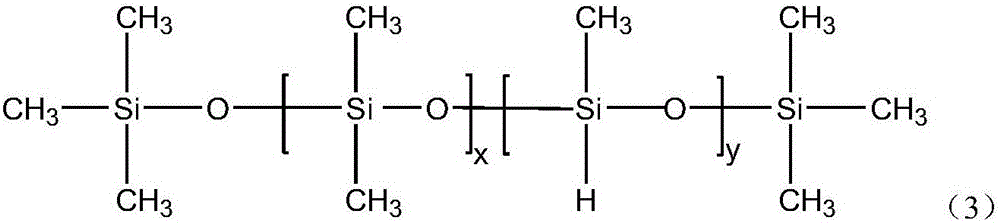

Polyurethane foam stabilizer and preparation method

The invention provides a polyurethane foam stabilizer and a preparation method. The preparation method comprises the following steps of synthesizing of silicone oil with low hydrogen content, synthesizing of unsaturated polyether, synthesizing of isocyanate-terminated unsaturated polyether, and reacting of the silicone oil with low hydrogen content and the isocyanate-terminated unsaturated polyether, so as to obtain the polyurethane foam stabilizer. The preparation method has the advantages that the unsaturated polyether-terminated polyester uses isocyanate as a end-capping reagent, the usage amount is less, the reaction time is short, the waste salt is not produced, the product quality is stable, and the cost is low; the reaction activity is strong, the property is excellent, the problem of existence of terminating in the existing alkyl terminating and unsaturated polyether is solved, and the variety of the existing polyurethane foam stabilizer is enriched by adjusting the type of the isocyanate end-capping reagent.

Owner:联泓(江苏)新材料研究院有限公司

Yellowing-resistant nylon composite material and preparation method thereof

The invention discloses a yellowing-resistant nylon composite material and a preparation method thereof. During preparation, 20-98 parts of dry nylon resin, 0.2-10 parts of an organic solvent, 0-40 parts of a filler, 0.05-0.4 part of an antioxidant and 0.1-0.8 part of a lubricant are added by a main feeder, and the organic solvent reduces the viscosity of a blending system; 0-60 parts of reinforced fiber and 0.02-10 parts of an end capping agent are added by a side feeder, and the organic solvent is favorable for the uniform dispersion and the activity capability of the end capping agent in the system, so that the end capping rate of the end group of the nylon molecular chain is increased, and the amino and carboxyl at the tail end of the nylon molecular chain in the blending system are greatly reduced; in the process of vaporizing and discharging the added organic solvent, oxygen, monomers and oligomers in the blending system are taken away, so that the materials are prevented from being oxidized, decomposed and yellowed due to long-time contact with oxygen in the high-temperature melting and blending processes, and the product with yellowing resistance, heat resistance and thermal stability obviously improved is obtained.

Owner:ZHONGLUN PLASTIC IND FUJIAN

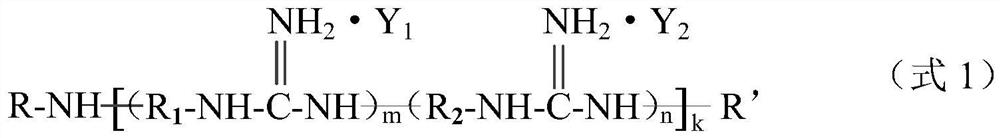

Guanidine salt polymer as well as preparation method and application thereof

The invention discloses a guanidine salt polymer as well as a preparation method and application thereof. The guanidine salt polymer has a characteristic structure as shown in formula 1. The method comprises the following steps: during preparation, adding guanidine salt defining Y1 and Y2 structures respectively into a reaction kettle, then selecting double-end amino diamine with structures of NH2-R1-NH2 and NH2-R2-NH2, respectively subjecting the double-end amino diamine and the guanidinium containing the Y1 and Y2 structures to condensation polymerization, merging the materials, continuing to carry out condensation reaction, cooling to 160 DEG C or below, adding an end-capping reagent of which one end can react with an amino group and the other end is relatively inert, and continuing toreact for 0.2-3 hours to obtain the guanidine salt polymer shown in the formula 1. The guanidine salt polymer can be subjected to grafting reaction with other polymers to obtain a grafted polymer withno cross-linked structure and good processability.

Owner:上海明涌新材料有限公司

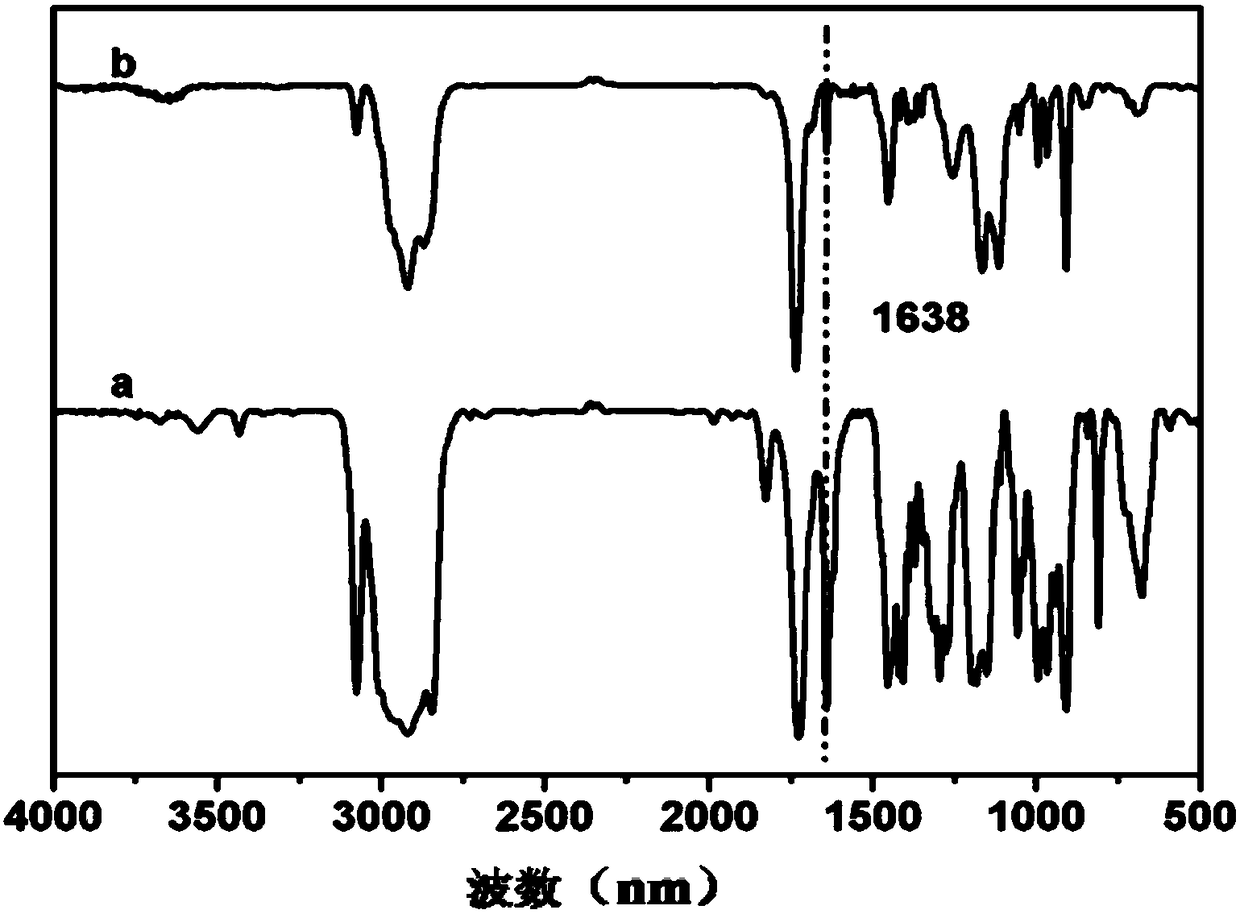

Dual-curable polysiloxane as well as preparation method and application thereof

ActiveCN112442177AHigh capping rateLight curing energy is lowChemical industryCoatingsPolymer scienceEnd-group

The invention discloses double-curable polysiloxane as well as a preparation method and application thereof. Acrylate groups contained in the molecular structure of polysiloxane can be quickly cross-linked and cured under the condition of ultraviolet irradiation, and moisture curing groups are contained in the end group structure, so that the polymer has moisture curing and UV light curing capabilities at the same time. According to a synthetic route provided by the invention, generation of acrylate can be avoided, silicon hydroxyl residue is lower than 1%, energy required by photocuring of the polymer is reduced, and the damp-heat aging resistance of a cured product is improved.

Owner:WANHUA CHEM GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com