Preparation method of butyl-terminated allyl polyether

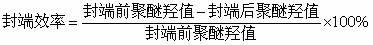

A technology of allyl polyether and butyl polyether, which is applied in the field of preparation of butyl-terminated allyl polyether, can solve the problems of by-products, low butyl-terminated rate, poor reactivity, etc. The effect of fast speed, high end capping rate and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 1000 grams of butanol polyoxypropylene ether (m=0, n=80, molecular weight about 4700) and 16.1 grams of solid sodium methoxide into a 2L reactor, and stir vigorously. The temperature is 100-110°C, under vacuum conditions (pressure -0.09--0.1MPa) and demethanol is reacted at the same time, and the reaction is 3 hours. Cool down to 60-70°C, slowly introduce 24.4 g of allyl chloride, maintain the pressure at 0.3 MPa, and continue the reaction for 5 hours. Excess allyl chloride is recovered by distillation under reduced pressure, and the end-capped polyether product is obtained after filtering to remove solid impurities.

Embodiment 2

[0026] Add 1,000 grams of butanol block polyether (m=40, n=40, polyether propylene oxide end, molecular weight about 4150), 18.2 grams of sodium methoxide into a 2L reactor, and stir vigorously. The temperature is 100-110°C, the reaction is under vacuum conditions (pressure -0.09--0.1MPa) and the methanol is released at the same time, and the reaction is 3 hours. The temperature was lowered to 60-70° C., and 27.7 g of allyl chloride was slowly added dropwise under normal pressure, and the reaction was continued for 4 hours. Excess allyl chloride is recovered by distillation under reduced pressure, and the end-capped polyether product is obtained after filtering to remove solid impurities.

Embodiment 3

[0028] Add 1000 grams of butanol random polyether (m=20, n=20, molecular weight about 2120) and 30.6 grams of solid sodium methoxide into a 2L reactor, and stir vigorously. The temperature is 100-110°C, under vacuum conditions (pressure -0.09--0.1MPa) and demethanol is reacted at the same time, and the reaction is 2 hours. The temperature was lowered to 60-70° C., and 46.9 g of allyl chloride was slowly added dropwise under normal pressure, and the reaction was continued for 4 hours. Excess allyl chloride is recovered by distillation under reduced pressure, and the end-capped polyether product is obtained after filtering to remove solid impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com