Patents

Literature

160results about How to "Reduce thermal decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solution containing cellulose dissolved in n-methylmorpholine-n-oxide and high tenacity lyocell multifilament using the same

ActiveUS20050154093A1Solidifying temperatureIncrease flexibilityNon-fibrous pulp additionMonocomponent cellulose artificial filamentLiquid stateLyocell

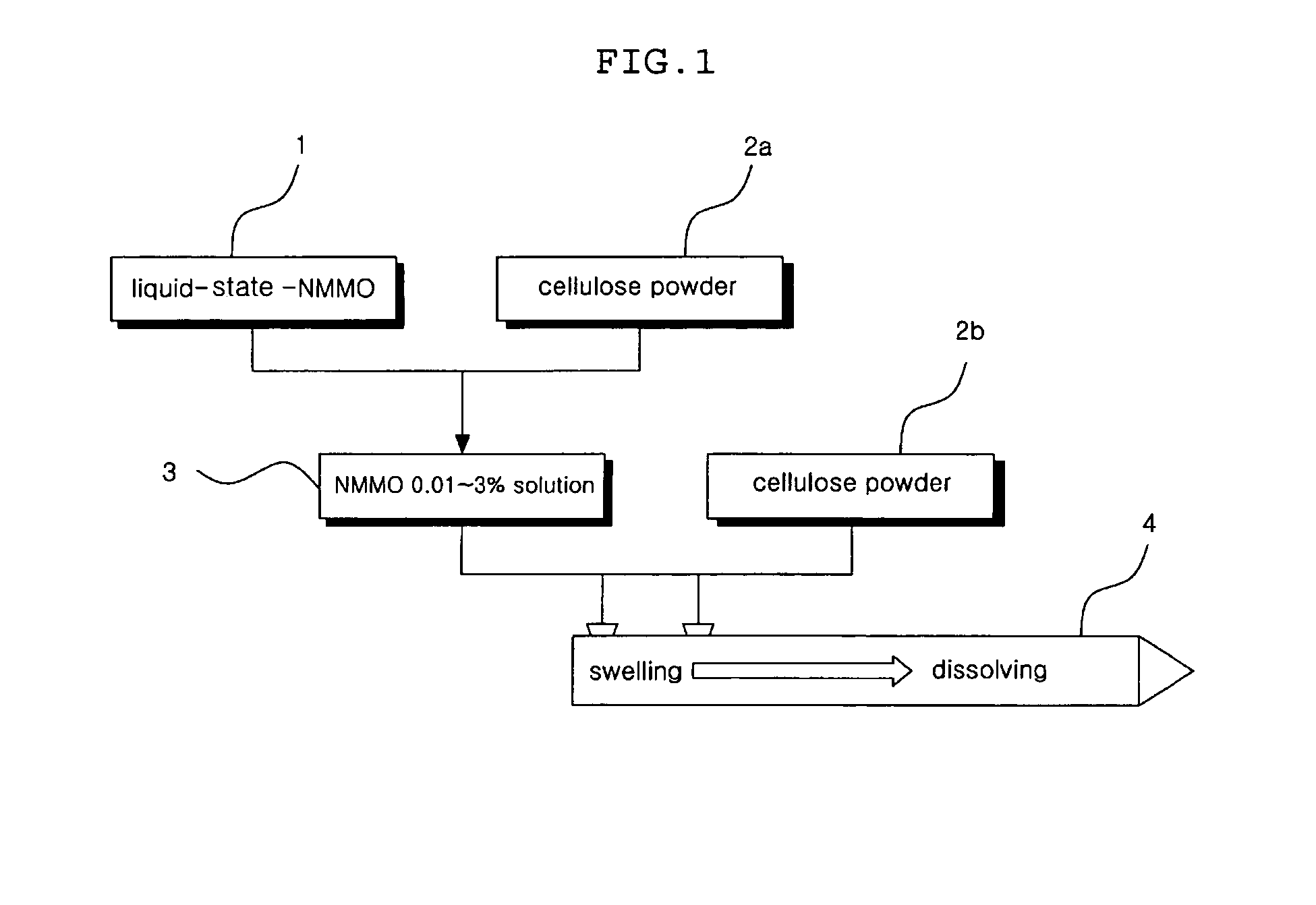

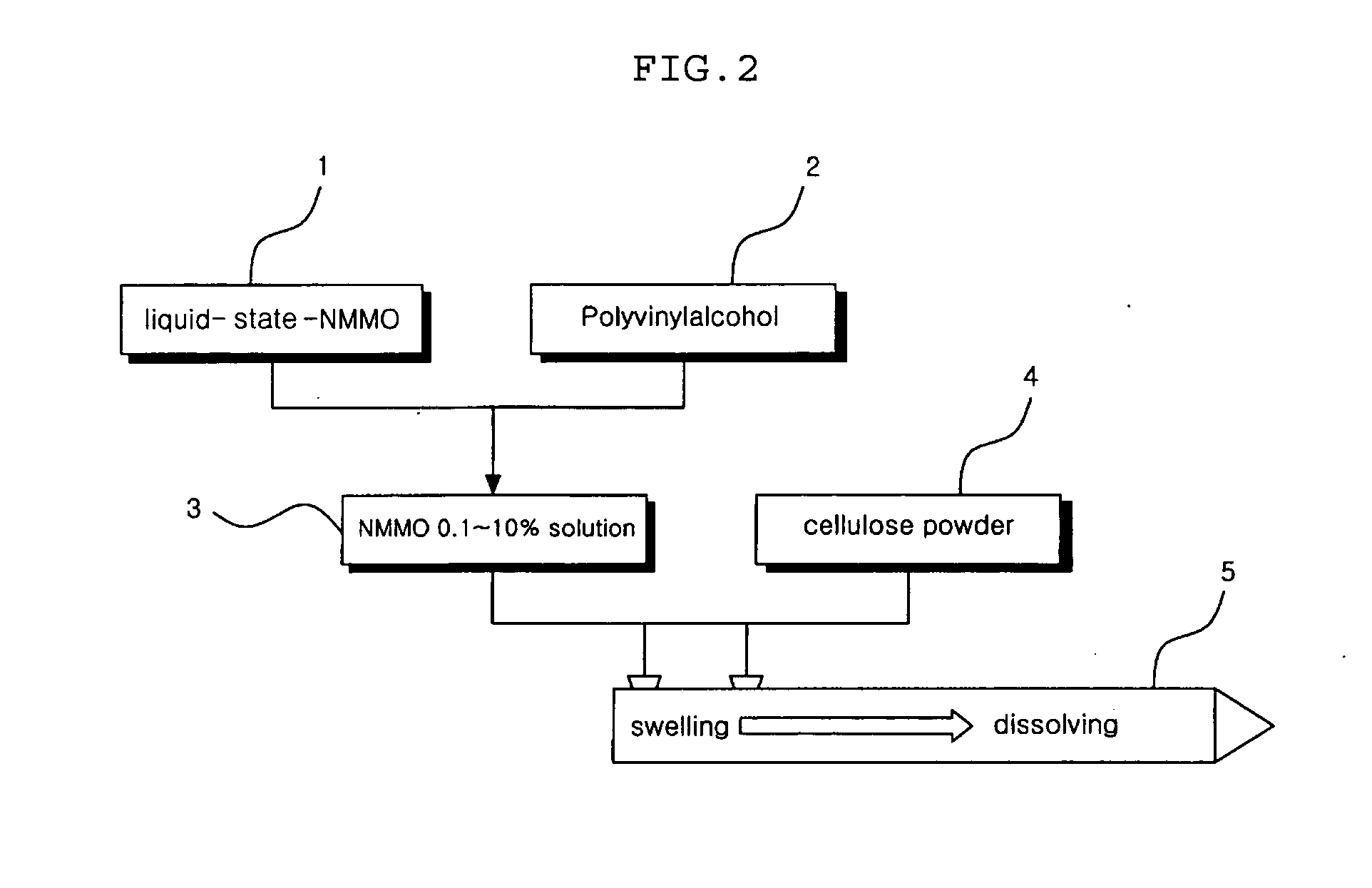

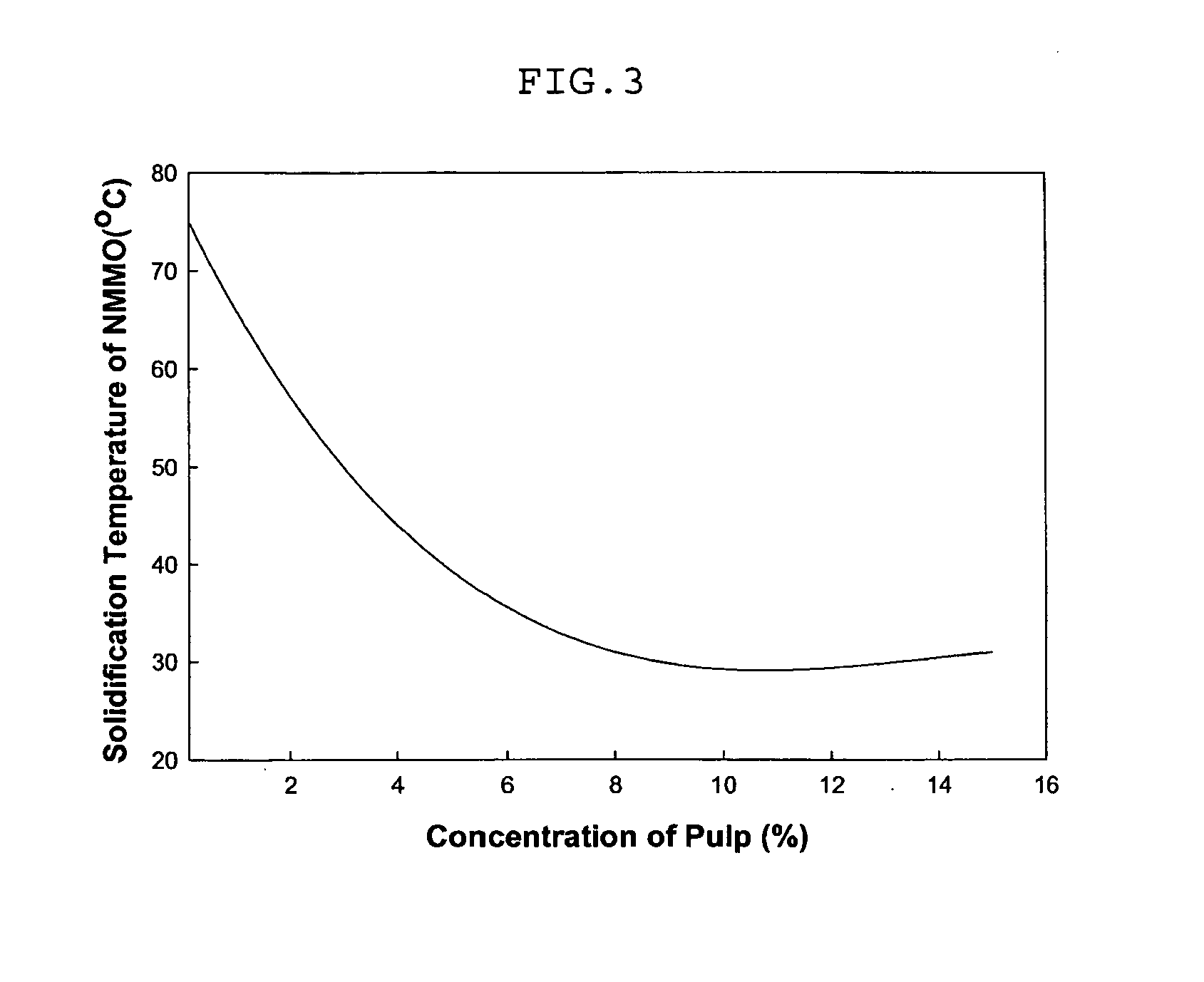

This invention relates to a method of preparing cellulose solution which is homogeneous at relatively low temperature, in which a small amount of cellulose powder or polyvinylalcohol is dissolved in the liquid-state, concentrated N-methylmorpholine-N-oxide (hereinafter, referred to as ‘NMMO’) so as to lower the solidifying temperature of NMMO, and then, the resulting solution and cellulose powder are fed into an extruder so as to be mixed, swollen and melted in the extruder.

Owner:HYOSUNG ADVANCED MATERIALS CORP

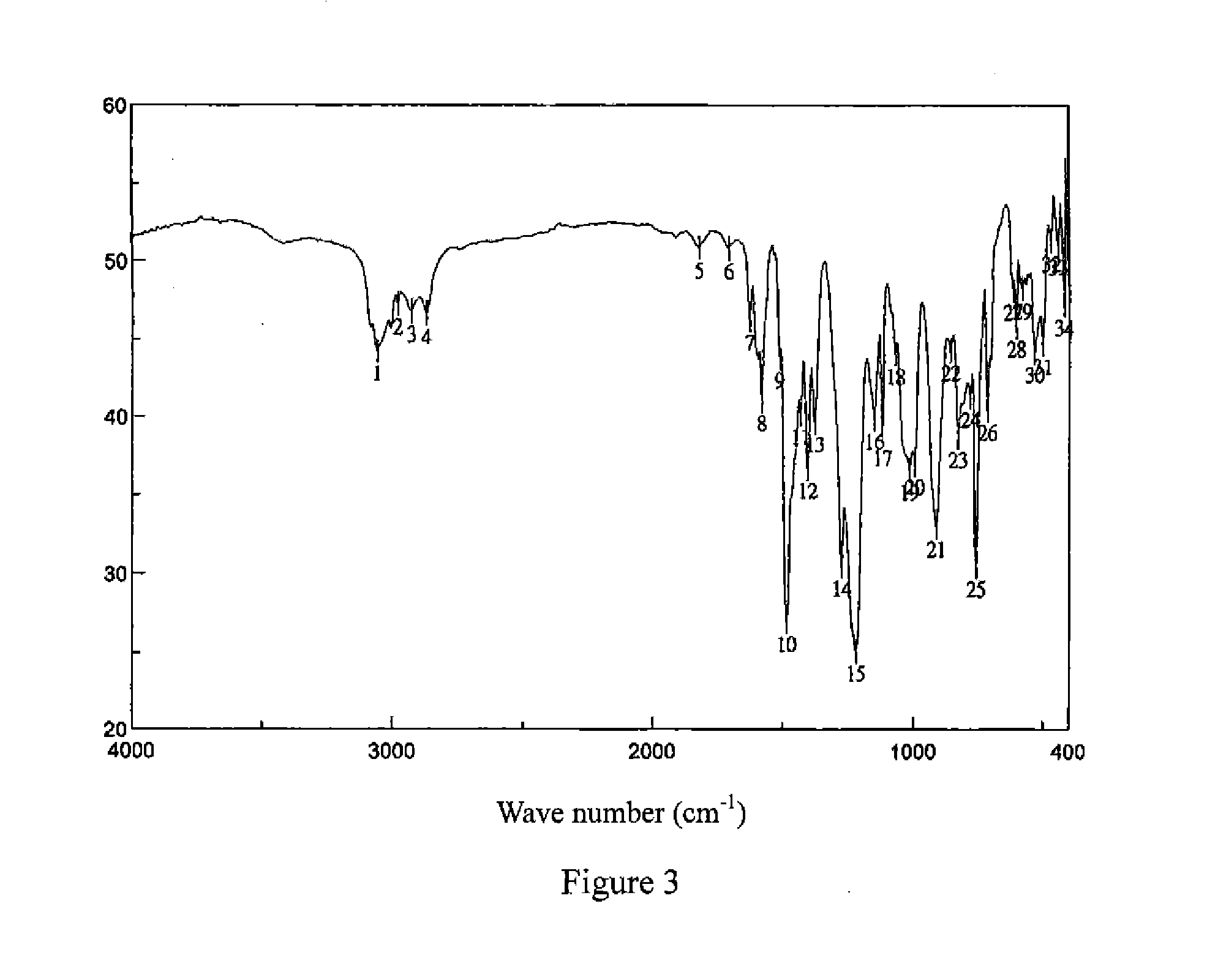

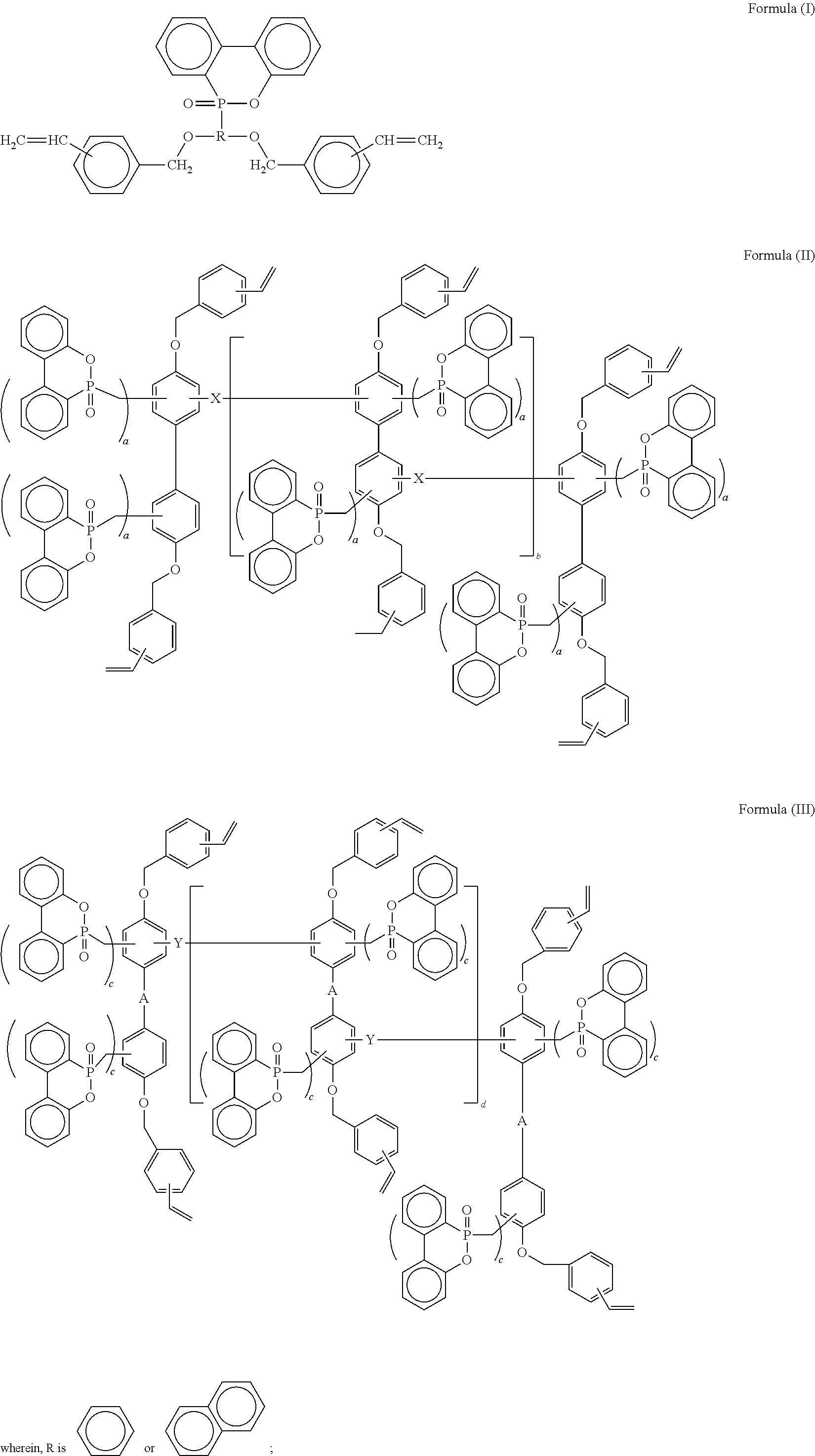

Vinylbenzyl-etherified-dopo compound resin composition and preparation and application thereof

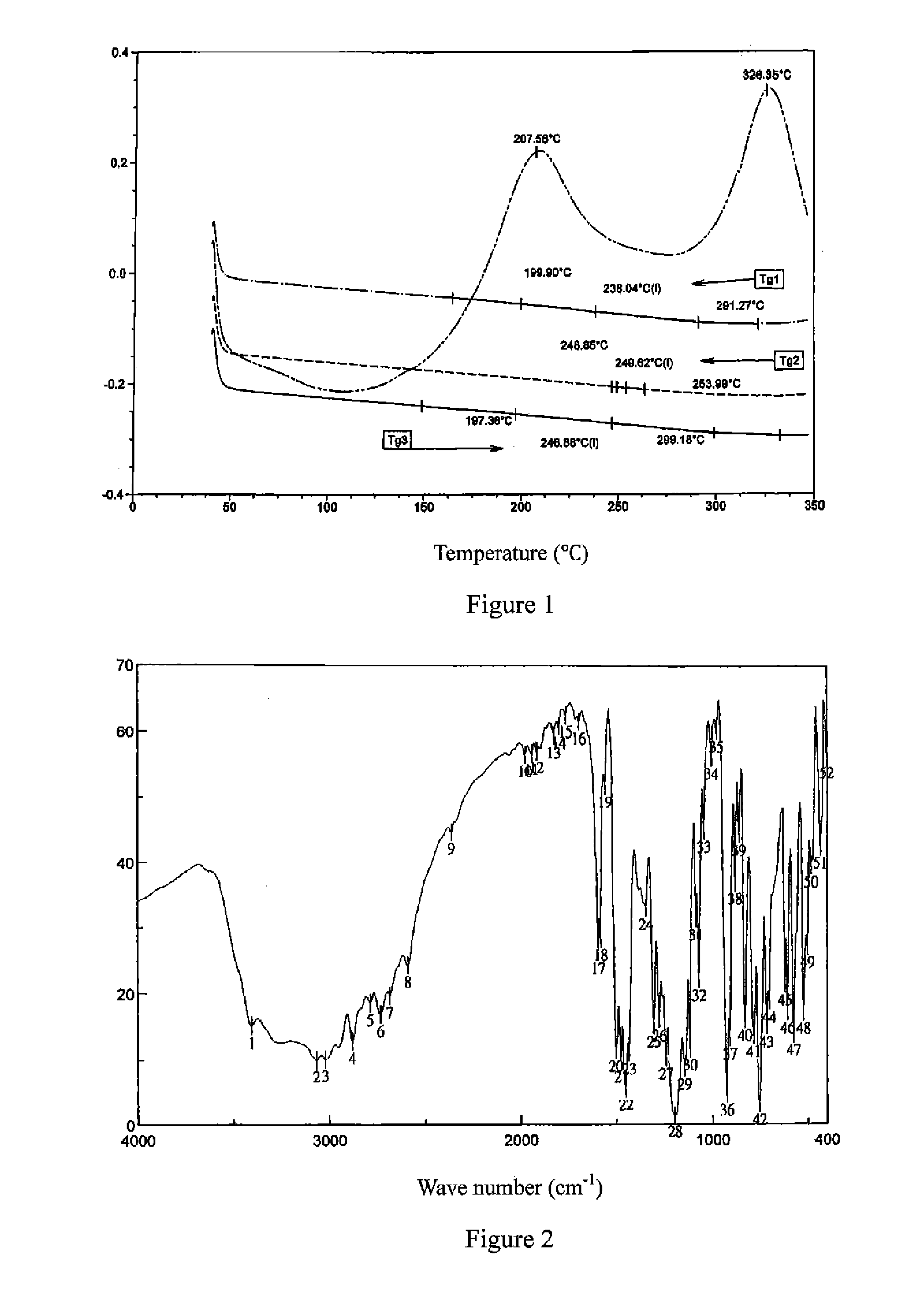

The present invention belongs to the technical field of a resin having low dielectric properties, and presents a vinylbenzyl-etherified-DOPO compound resin composition and a preparation method and application thereof. The composition includes a vinylbenzyl-etherified-DOPO compound resin and a vinyl-terminated polyphenylene ether resin. The DOPO resin is vinylbenzyl etherified in the present invention, thus obtaining a vinylbenzyl-etherified-DOPO compound resin having low dielectric properties, and there are no hydroxyl group on itself, no hydroxyl function group will be generated during the cross-linking reaction; and the vinylbenzyl-etherified-DOPO compound resin contains phosphorus atoms, and has flame retardancy. The prepared vinylbenzyl-etherified-DOPO compound resin and the hydroxyl-free, low dielectric vinyl-terminated polyphenylene ether resin are combined in the present invention, thus obtaining a resin composition having low dielectric constant and low dielectric loss tangent, which can achieve excellent dielectric properties and flame retardancy when applying to the metal laminates and printed circuit boards.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

Composite cathode material for thermal battery and preparation method of composite cathode material

ActiveCN105140485AImprove electronic conductivityImprove ionic conductivityDeferred-action cellsCell electrodesLithium oxideComposite cathode

The invention discloses a composite cathode material for a thermal battery and a preparation method of the composite cathode material. The composite cathode material for the thermal battery disclosed by the invention comprises the following raw materials in percentage by mass: 25%-55% of FeS2, 35%-65% of CoS2, 1%-5% of lithium oxide and 5%-10% of superfine conductive powder. The composite cathode material disclosed by the invention is high in conductivity and high in service efficiency.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

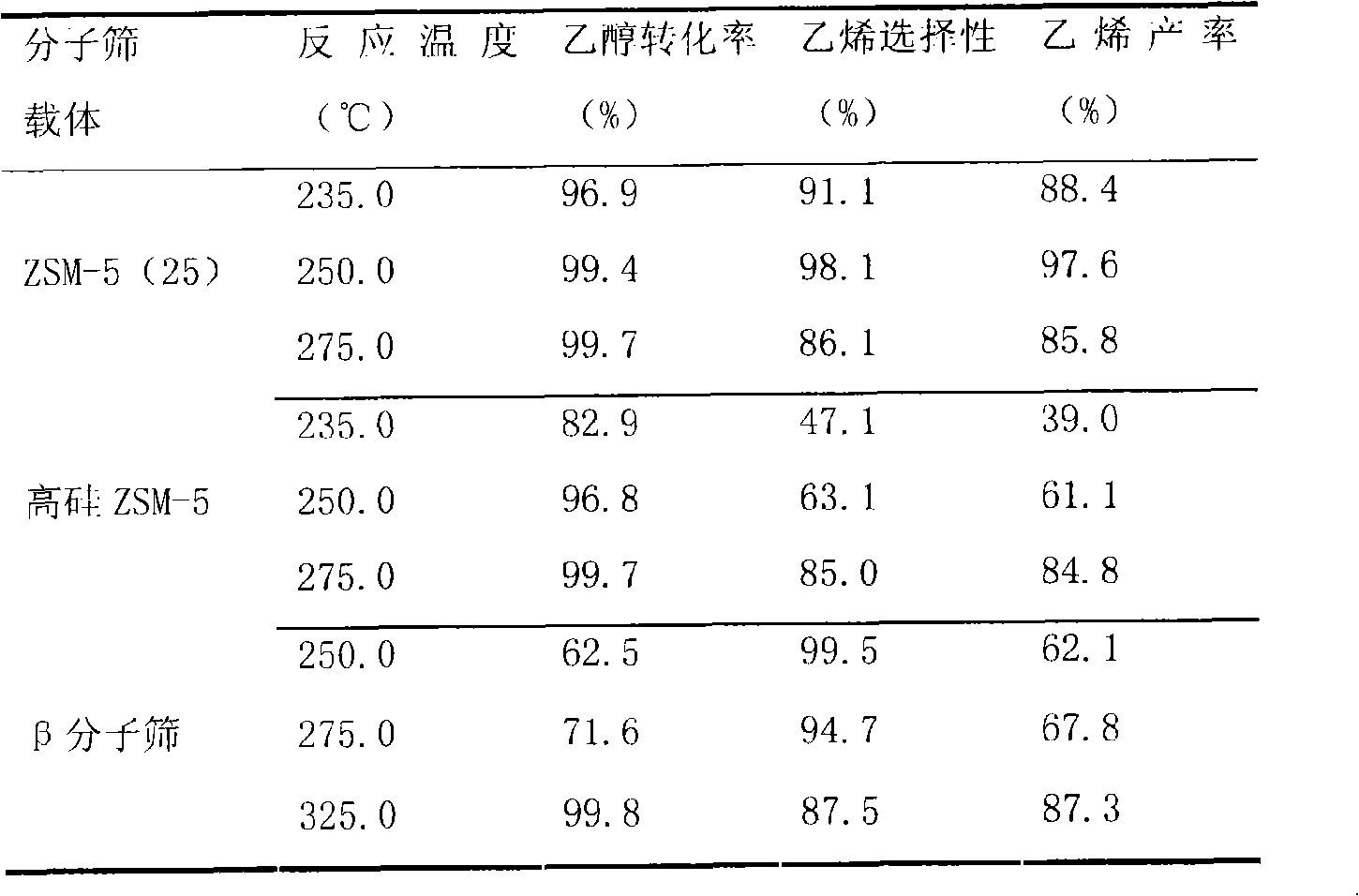

Method for preparing molecular sieve solid acid catalyst used for preparing ethylene by ethanol dehydration

InactiveCN101579637ARaw materials are cheap and easy to getSimple processMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention discloses a method for preparing a molecular sieve super solid acid catalyst used for preparing ethylene by ethanol dehydration, belonging to the technical field of chemical product preparation, wherein the method comprises immersion method and hydro-thermal method, and the molecular sieve solid acid catalyst is prepared with ZSM-5 hydrogen as a carrier by loading Fe3 metallic ion. The invention also provides a technical process that ethanol is dehydrated and converted into ethylene at a low temperature under the action of molecular sieve solid acid catalyst. In the invention, the catalyst used for preparing ethylene by ethanol dehydration can dehydrate the ethanol with different concentrations at a temperature of 220 DEG C to prepare the ethylene, and the conversion rate can reach 98.4%. The catalyst has high activity at a low temperature, thus solving the technical problems of high temperature and low airspeed existed in the present industrial production.

Owner:TSINGHUA UNIV

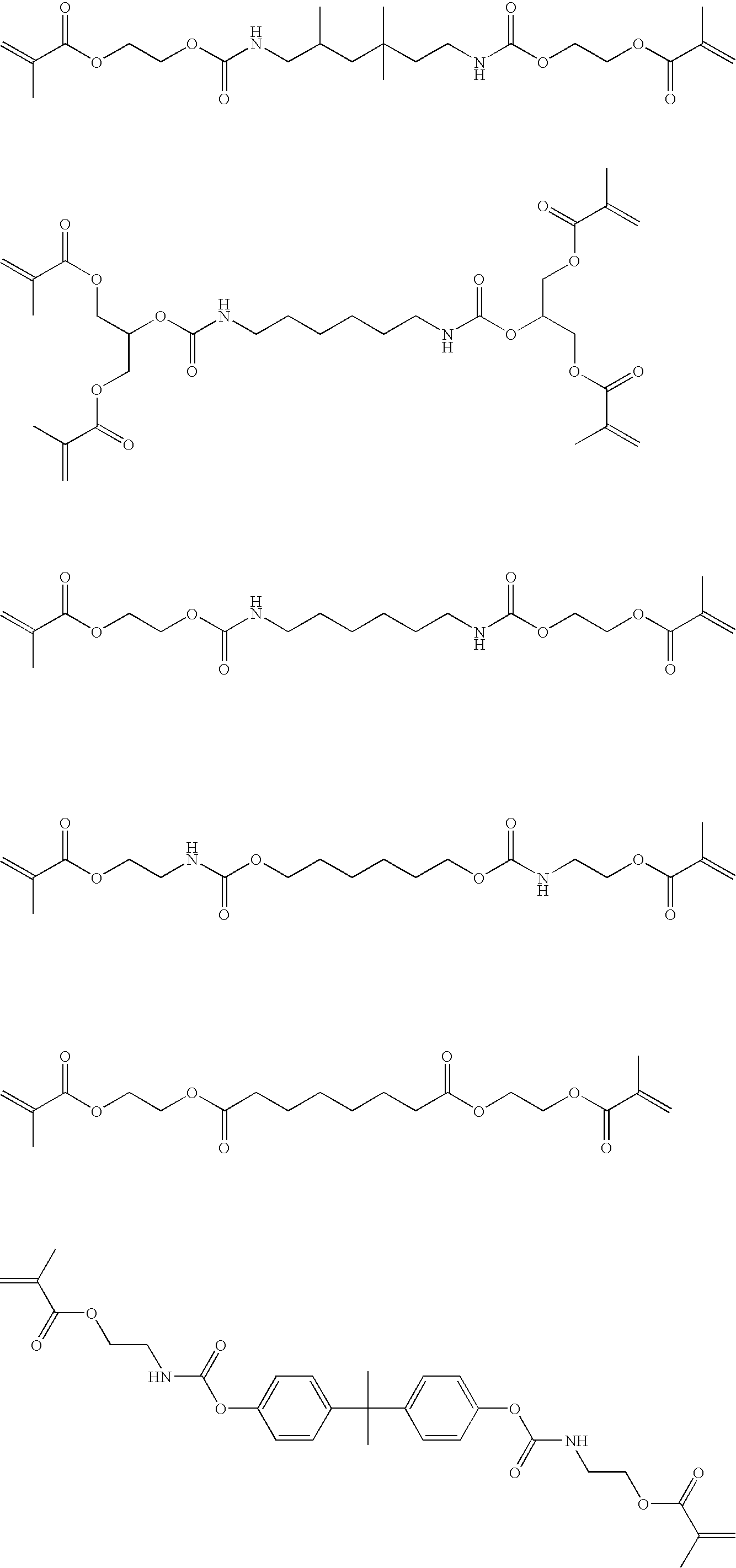

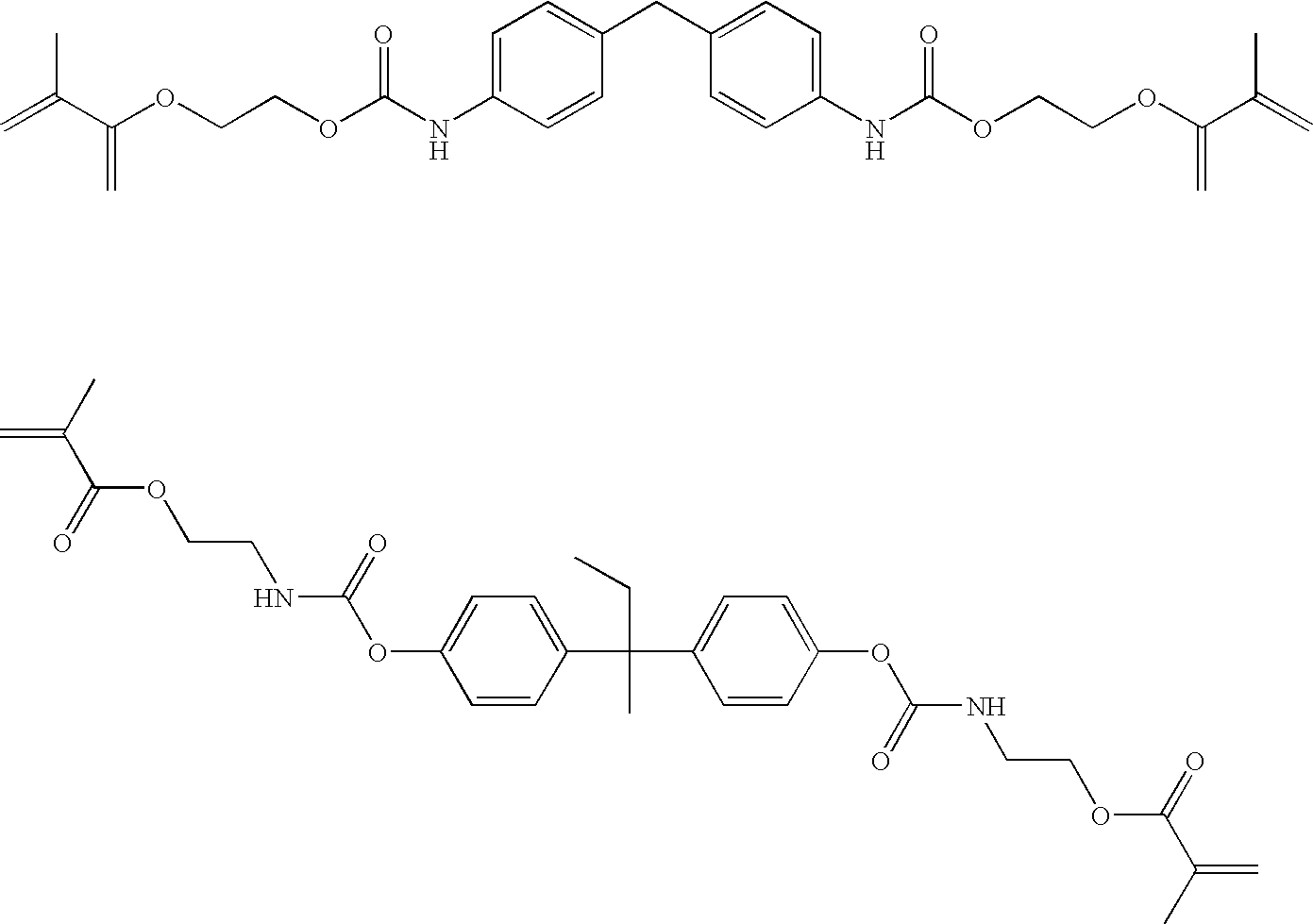

Resin composition for laser engraving, resin printing plate precursor for laser engraving, relief printing plate and method for production of relief printing plate

InactiveUS20090220753A1High engraving sensitivityHigh sensitivityPhotosensitive materialsDecorative surface effectsPolyesterLaser engraving

Owner:FUJIFILM CORP

Graphene modified silicone rubber cable sheath material

InactiveCN106280475AAvoid attackReduce attackInsulated cablesInsulated conductorsPolymer scienceFumed silica

The invention discloses a graphene modified silicone rubber cable sheath material. The material is prepared from raw materials as follows: phenyl siloxane rubber, methyl vinyl silicone rubber, fluororubber, polybutadiene rubber, polyurethane, ethylene-acrylate rubber, zinc oxide, stearic acid, 2,4-dichlorobenzoyl peroxide, an assistant crosslinker TAIC, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, cerium oxide, fumed silica, carbon black, nano calcium carbonate, stearic acid modified magnesium hydroxide, ammonium polyphosphate, modified graphene oxide, nano silicon carbide, magnesium stearate, triphenyl phosphate, tributyl citrate, an accelerator, an anti-aging agent and silane modified cellulose. The graphene modified silicone rubber cable sheath material is high in strength, excellent in heat resistance and flame retardation, good in aging resistance and long in service life.

Owner:ANHUI LAND GRP

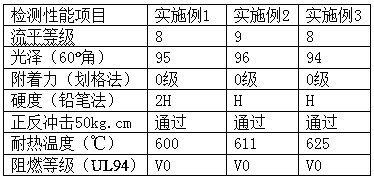

High-temperature-resistant flame-retardant powder paint and production method thereof

InactiveCN110643280AImprove stabilityImprove insulation performanceFireproof paintsPowdery paintsEpoxyPowder coating

The invention discloses high-temperature-resistant flame-retardant powder paint and a production method thereof. The powder paint is produced from the following raw materials in parts by weight: 30-60parts of organic silicon resin, 30-60 parts of epoxy resin, 3.4-6.8 parts of modified dicyandiamide, 0.2-0.4 part of dimethylimidazole, 10-20 parts of silica powder, 10-20 parts of mica powder, 0.3-0.6 part of a sand textured agent, 30-60 parts of a flame retardant and 1.2-2.4 parts of carbon black. A film, which is formed after the produced powder paint is subjected to spraying and curing, has excellent high-temperature-resistant performance, fireproof performance and flame-retardant performance in the premise that the mechanical performance, including the levelling performance and the anti-impact performance, of the film is not affected; and according to the powder paint, the production method is simple, and industrial production can be conducted.

Owner:广西南宁维一防腐科技有限公司

Stable polymer compositions and methods of making same

InactiveUS20050159536A1Increase entropyImprove stabilityEmulsion paintsPolymer sciencePolymer coatings

The present invention comprises a polymer composition which is comprised of subcompositions which are separately stable within the polymer composition and methods of making the polymer compositions. These polymer compositions may be useful as coatings for paper, food packaging, vinyl, plastics, man-made substrates, wood and metal. An advantage of these polymer composition is that they are aqueous non-fluorocarbon polymers, which are less pollutive than state of the art polymer coatings.

Owner:SMITH MARVIN MCCLINTON

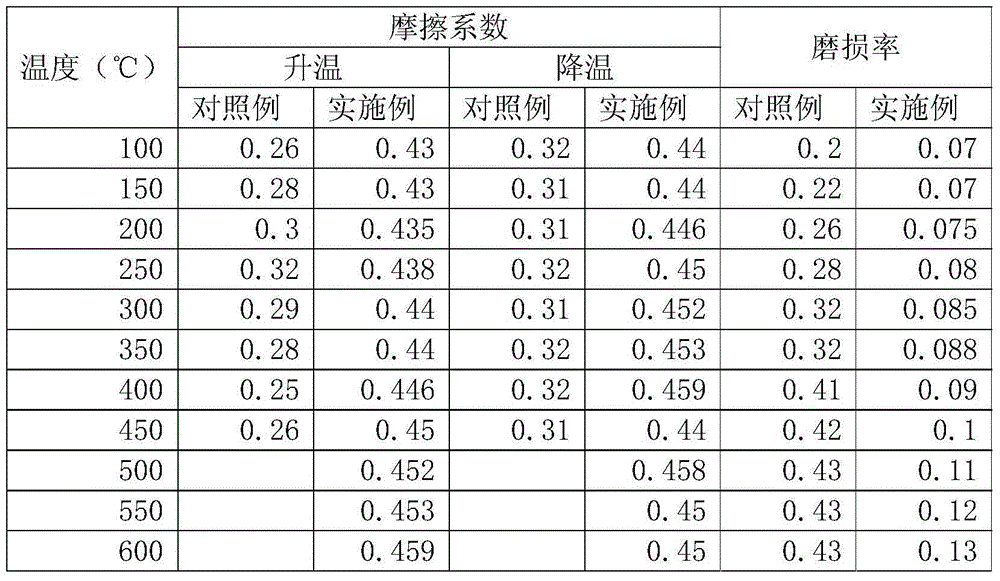

High-performance composite brake disc material

InactiveCN104893256AImprove thermal conductivityEnhanced interface bindingFriction liningMicrosphereWear resistant

The invention discloses a high-performance composite brake disc material, the wear resistant material comprises the following raw materials: bisphenol a novolac epoxy resin, diaminodiphenyl sulfone, hollow microspheres, a lubricant, a silane coupling agent, diamine, an imidazoles compound, an anti-oxidant, chloroprene rubber powder, alumina and reinforced fibers. The reinforced fibers can be a mixture of zylonite fiber, aramid fiber, cotton fiber and ramie fiber; the interface combination of fiber and particles in the materials is good, and the fiber and particles in the materials enable synergistic interaction with antimonony oxide and graphite, generation of thermal decomposition, heat attenuation and heat cracks phenomena can be effectively reduced, thermal conductivity of the materials is good, heat generated when brake friction is carried out can be timely radiated, brake disc surface temperature can be rapidly reduced, high temperature heat attenuation is reduced, hollow microspheres, the lubricant, the silane coupling agent and the enhance fiber are specific, friction coefficient of the wear resistant materials can be enhanced by intermolecular cooperation of the substances, and stability of the friction coefficient can be improved simultaneously.

Owner:CHONGQING JIAOTONG UNIVERSITY

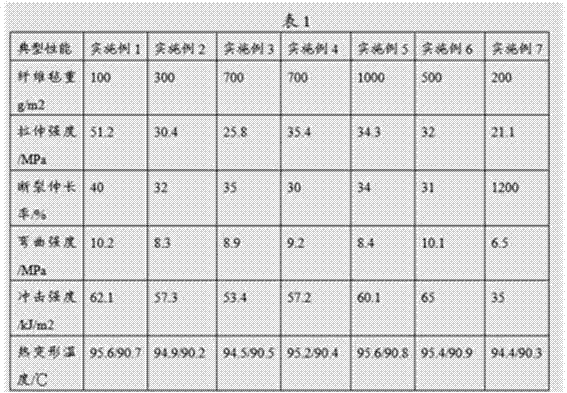

Completely degradable high shock resistance composite, and preparation method and application thereof

InactiveCN103361880AStrong impact resistanceAvoid breakingNon-woven fabricsTelephone set constructionsShock resistanceNatural fiber

The invention discloses a completely degradable high shock resistance composite which comprises the following components in parts by weight: 20-80 parts of natural fiber and 20-80 parts of poly(butyleneadipate-co-terephthalate) (PBAT) fiber. The invention further discloses a preparation method and an application of the completely degradable high shock resistance composite. The composite adopts the PBAT fiber as a base material, so that the composite has very excellent shock resistance and is not easy to break. In addition, a reinforcing phase and a base body of the composite are degradable materials, so that the composite is less harmful to an environment, cannot result in white pollution, and meets a requirement of sustainable development.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

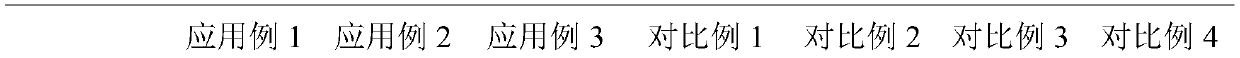

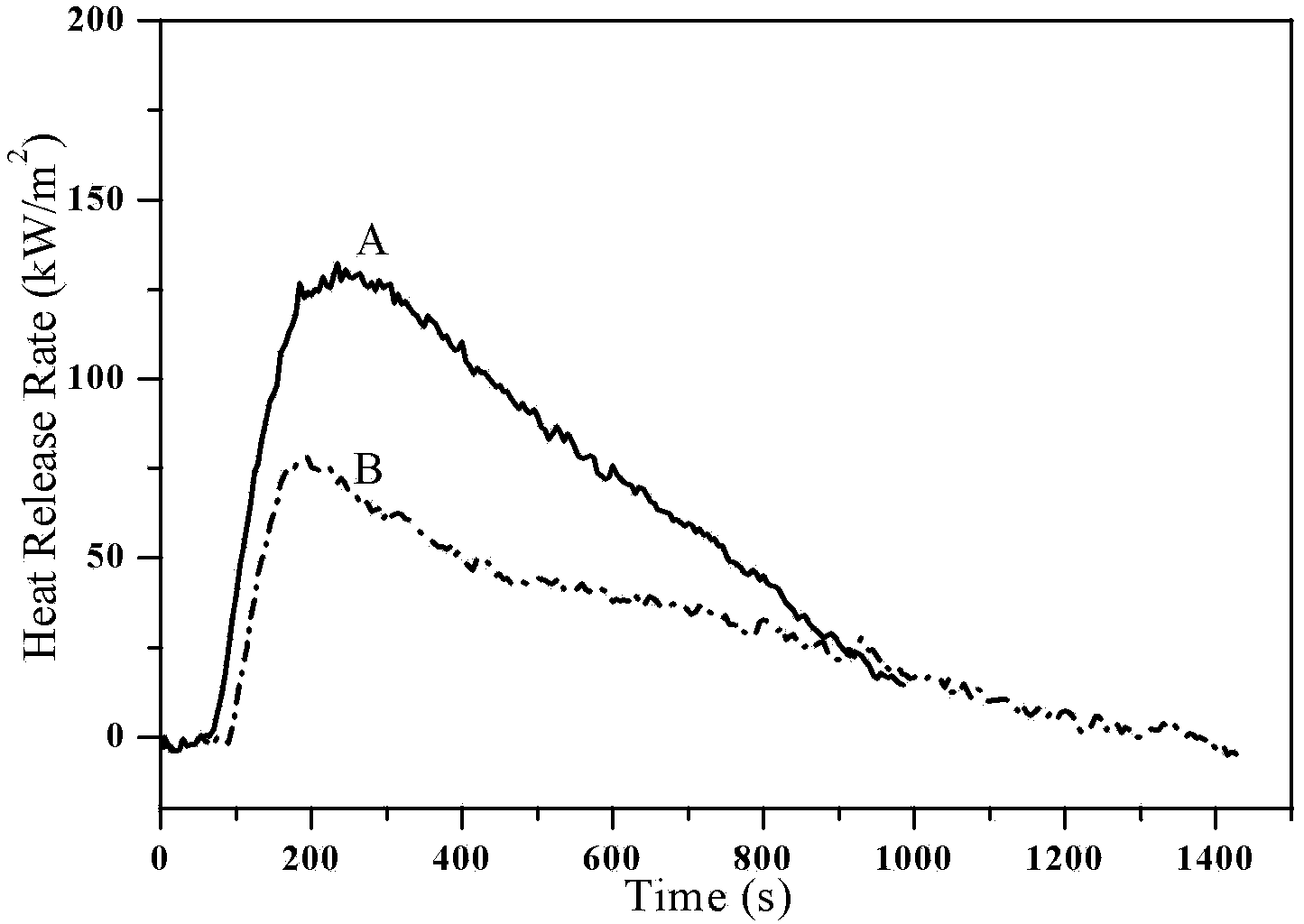

Environment-friendly flame retardant and intumescent fireproof coating prepared therefrom

ActiveCN111234564AHigh degree of graphitizationHigh strengthFireproof paintsPigment flushingCarbon layerFurfurylamine

The invention discloses an environment-friendly flame retardant. The flame retardant is prepared by firstly utilizing tetrabutyl ammonium hydroxide and phosphoric acid to peel zirconium phosphate andthen utilizing furfuryl amine to coat zirconium phosphate. The flame retardant can effectively solve the problems that zirconium phosphate is easy to agglomerate and the like, and can play a synergistic flame-retardant role with an intumescent flame-retardant system in a fireproof coating. When the flame retardant is used to prepare an intumescent fire retardant coating, the film-forming property,the fire resistance, the durability and the like of the obtained fire retardant coating can be remarkably improved. The obtained flame retardant integrates flame retardance, smoke suppression and enhancement functions and is low in halogen-free cost, good in char forming property, high in carbon layer strength, environmentally friendly and wide in applicability, and the related preparation methodis simple in process, mild in reaction conditions and suitable for application and popularization.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for extracting hovenia dulcis thunb total flavones by cooperation of surfactant and microwave-ultrasonic extraction process

InactiveCN103751317AReduce extraction timeImprove extraction efficiencyPlant ingredientsHovenia dulcisActive agent

The invention particularly relates to a method for extracting hovenia dulcis thunb total flavones by cooperation of a surfactant and a microwave-ultrasonic extraction process. The method comprises the following steps: (1) grinding hovenia dulcis thunb, and performing Soxhlet extraction by petroleum ether to remove fat so as to obtain fully defatted ground hovenia dulcis thunb; (2) uniformly mixing the ground hovenia dulcis thunb, distilled water and the surfactant to obtain a mixed solution; (3) performing microwave-ultrasonic extraction on the mixed solution at the microwave power of 200-600 W and the ultrasonic power of 100-500 W for 5-20 minutes; (4) after the extraction, performing alcohol precipitation on the extracted filtrate to remove alcohol supernatant, and concentrating and drying to obtain a hovenia dulcis thunb total flavones extract. Due to the adoption of the method for extracting hovenia dulcis thunb total flavones, the extraction time is greatly shortened, the extraction efficiency is improved, the cost is reduced, and the energy consumption is low; meanwhile, a distilled water solution in which a small amount of the surfactant is dissolved is taken as an extraction solution, so that the problem of toxic organic solvent residues is solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method for halogen-free flame-retardant high-density polyethylene/ethylene-vinyl acetate polymer

InactiveCN103554598AImprove interfacial adhesionImprove mechanical propertiesPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a preparation method for a halogen-free flame-retardant high-density polyethylene / ethylene-vinyl acetate polymer. The preparation method specifically comprises the following steps: I, adding 2 to 4 parts by weight of silane coupling agent into 180 to 220 parts by weight of anhydrous alcohol, mixing the silane coupling agent and the anhydrous alcohol uniformly, heating the mixture to 70 to 90 DEG C, adding 100 parts by weight of dried expandable graphite into the solution, and stirring to obtain modified expandable graphite; II, uniformly mixing 5 to 15 parts by weight of modified expandable graphite, 70 parts by weight of high-density polyethylene, 30 parts by weight of ethylene-vinyl acetate polymer, 2.5 to 7.5 parts by weight of ammonium polyphosphate and 2.5 to 7.5 parts by weight of red phosphorus flame retardant master batch in a mixer to obtain a mixture; III, mixing and granulating the mixer by using a screw extruder, drying the extruded granules and performing injection molding on the dried granules. The prepared composite material has high flame retardant property and high mechanical property.

Owner:SOUTHWEST JIAOTONG UNIV

Wear-resistant material for brake block of heavy duty automobile

InactiveCN104788906ASolve the real problemLong processOther chemical processesCross-linkCarbon fibers

The invention discloses a wear-resistant material for a brake block of a heavy duty automobile. The wear-resistant material comprises raw materials as follows: bisphenol A novolac epoxy resin, diaminodiphenyl sulfone, mineral powder, a lubricant, a cross-linking agent, chloroprene rubber powder, aluminum oxide, cotton fiber, carbon fiber, aramid fiber, sisal fiber, antimonous oxide, graphite and calcium lignosulfonate. The components are compatible, so that the overall performance of the wear-resistant material is effectively guaranteed, the components can make up for defects in performance mutually and can have high performance due to mutual restriction functions, problems of existing brake blocks are solved, high-speed decline and high-temperature decline can be well prevented, and the wear-resistant material has advantages of better stability and long service life.

Owner:CHONGQING JIAOTONG UNIVERSITY

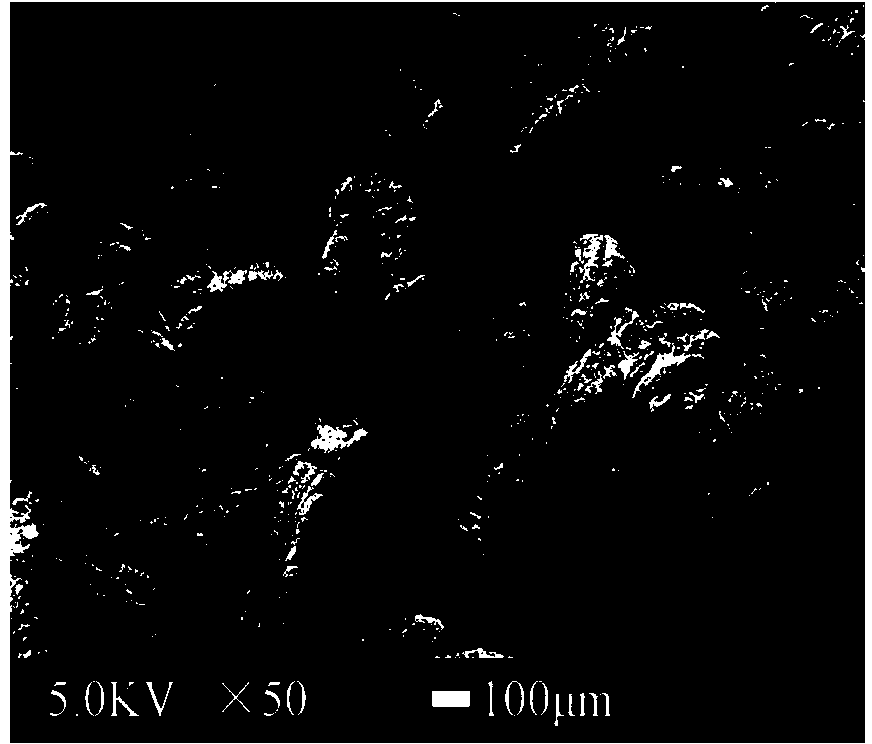

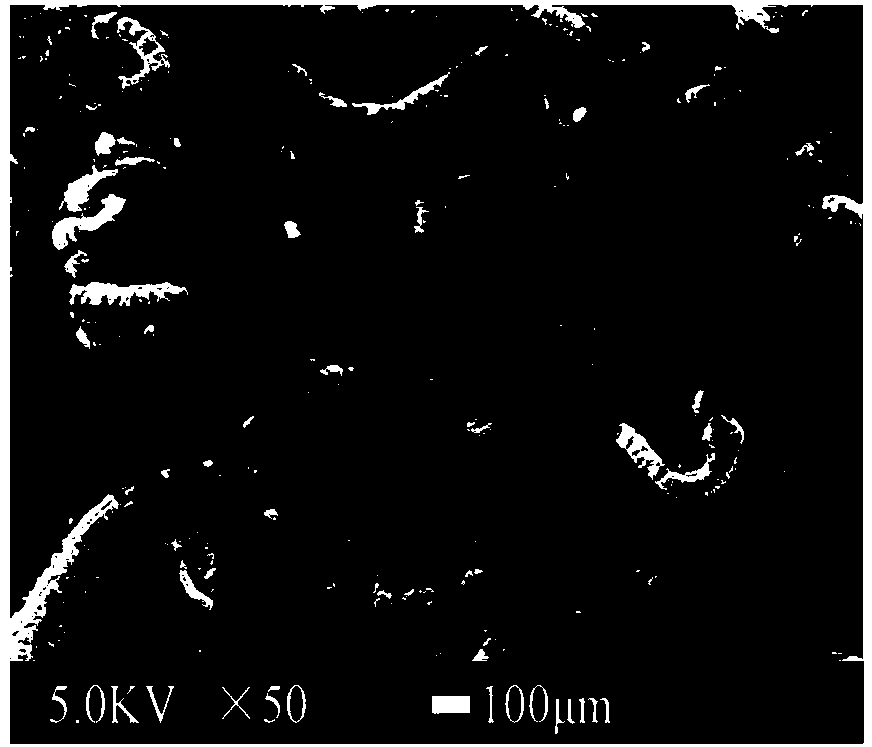

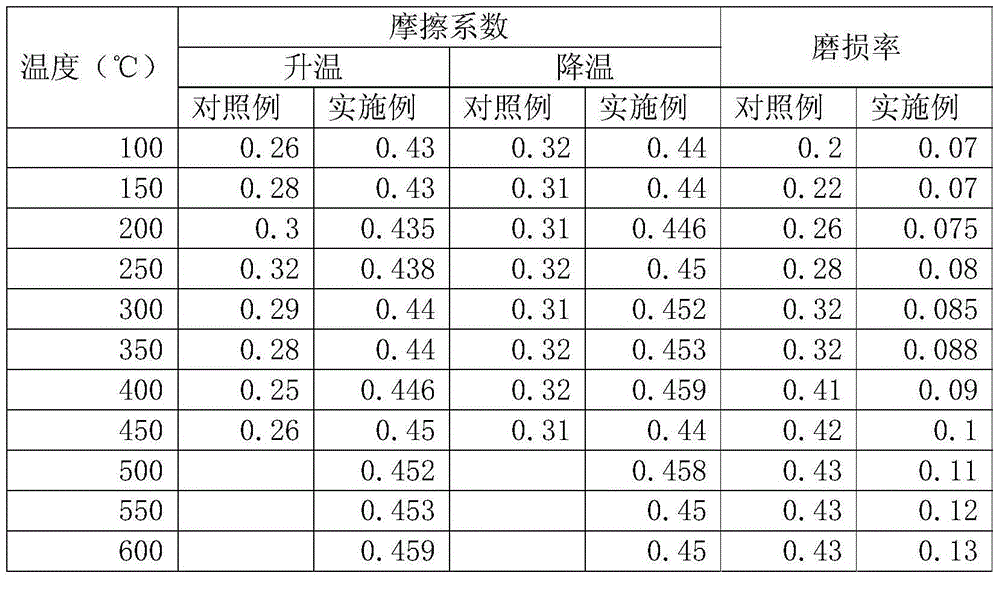

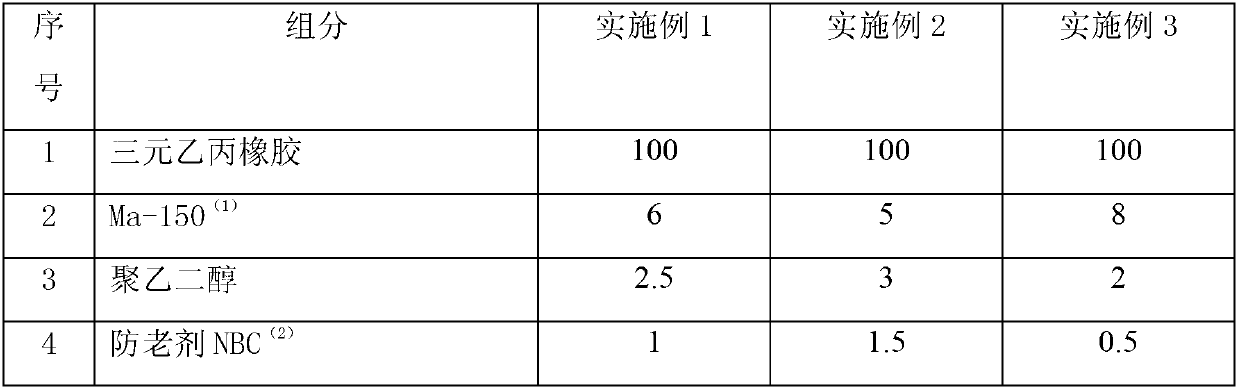

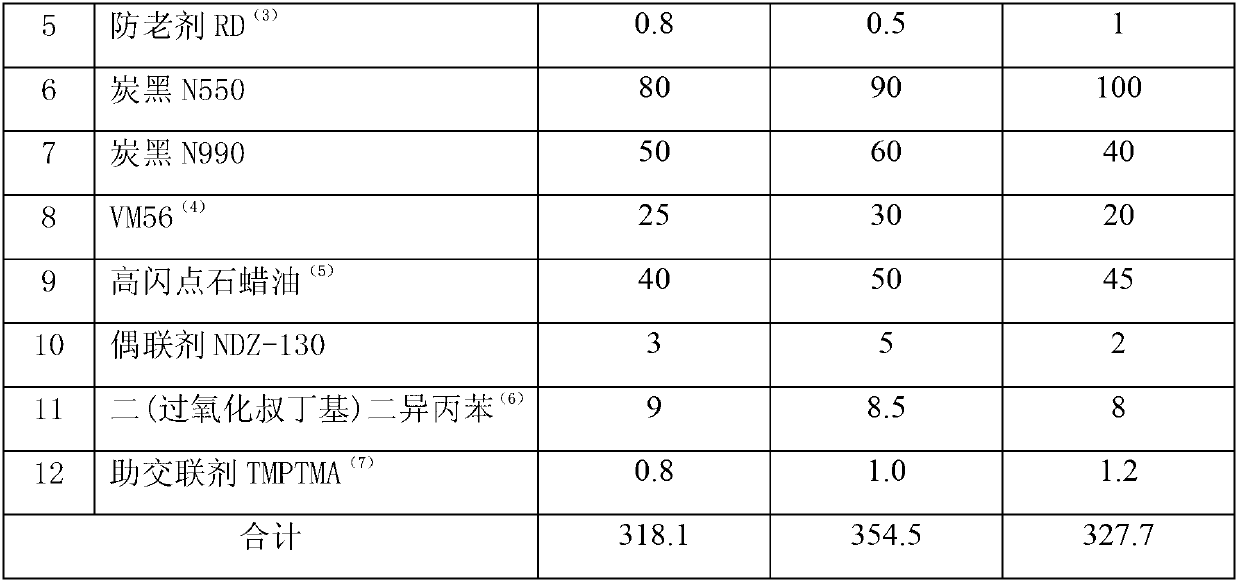

Ethylene-propylene-diene monomer composition with limiting temperature of 175 DEG C for vehicle rubber pipe

InactiveCN102875906AImprove resistance to oxidative degradationLow resistance to oxidative degradationFlexible pipesPolymer sciencePolyethylene glycol

The invention relates to an ethylene-propylene-diene monomer composition with a limiting temperature of 175 DEG C for a vehicle rubber pipe. The ethylene-propylene-diene monomer composition comprises ethylene-propylene-diene monomer rubber, methyl acrylate (Ma)-150, polyethylene glycol, anti-aging agents, carbon black, VM56, high flash point paraffin oil, coupling agent NDZ-130, di(tert-butylperoxy) diisopropyl benzene and assistant crosslinker trimethylopropane trimethacrylate (TMPTMA). According to the formula of the composition, the high temperature resistance is excellent, the performance is slightly reduced after 72 hours under the high temperature of 175 DEG C, the variation in hardness is maintained within 10, the compression set after high temperature resistance is low, simultaneously the performance retention rate after oil resistance is good, the volume change is maintained within 100%, the low temperature resistance is good, the ethylene-propylene-diene monomer composition can be used at the low temperature of 45 DEG C below zero, the ozone resistance is excellent, and the formula can meet requirements of heating system and air intake and exhaust system rubber pipes and intercooler air outlet and radiator flexible pipes which are used at short time under the limiting condition of high temperature of 175 DEG C.

Owner:TIANJIN PENGYI GRP CO LTD

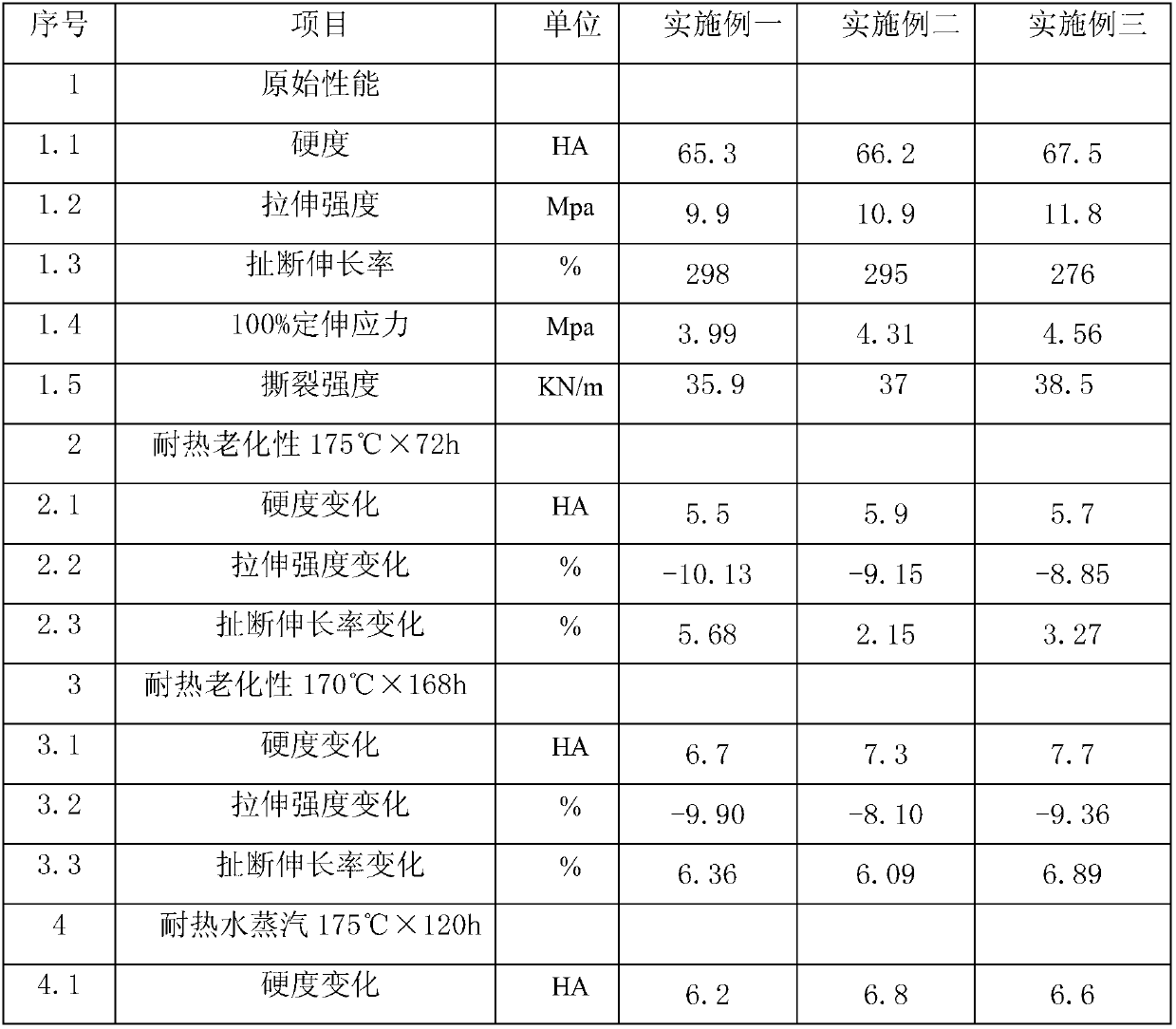

Continuous production process of high purity trimellitic anhydride with trimellitic acid

The continuous production process of high purity trimellitic anhydride with trimellitic acid includes the following steps: smelting trimellitic acid and eliminating acetic acid and water in the first kettle, and eliminating water inside trimellitic acid molecule in the second kettle to form trimellitic anhydride; eliminating heavy components in crude trimellitic anhydride product in one heavy component eliminating evaporator; eliminating light components in the evaporator of one light component eliminating tower; and rectifying through condensing trimellitic anhydride in the condenser on the top of the light component eliminating tower to obtain trimellitic anhydride product fed to the product tank. The present invention has stable product quality, high product purity, high product yield, low power consumption and other advantages.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

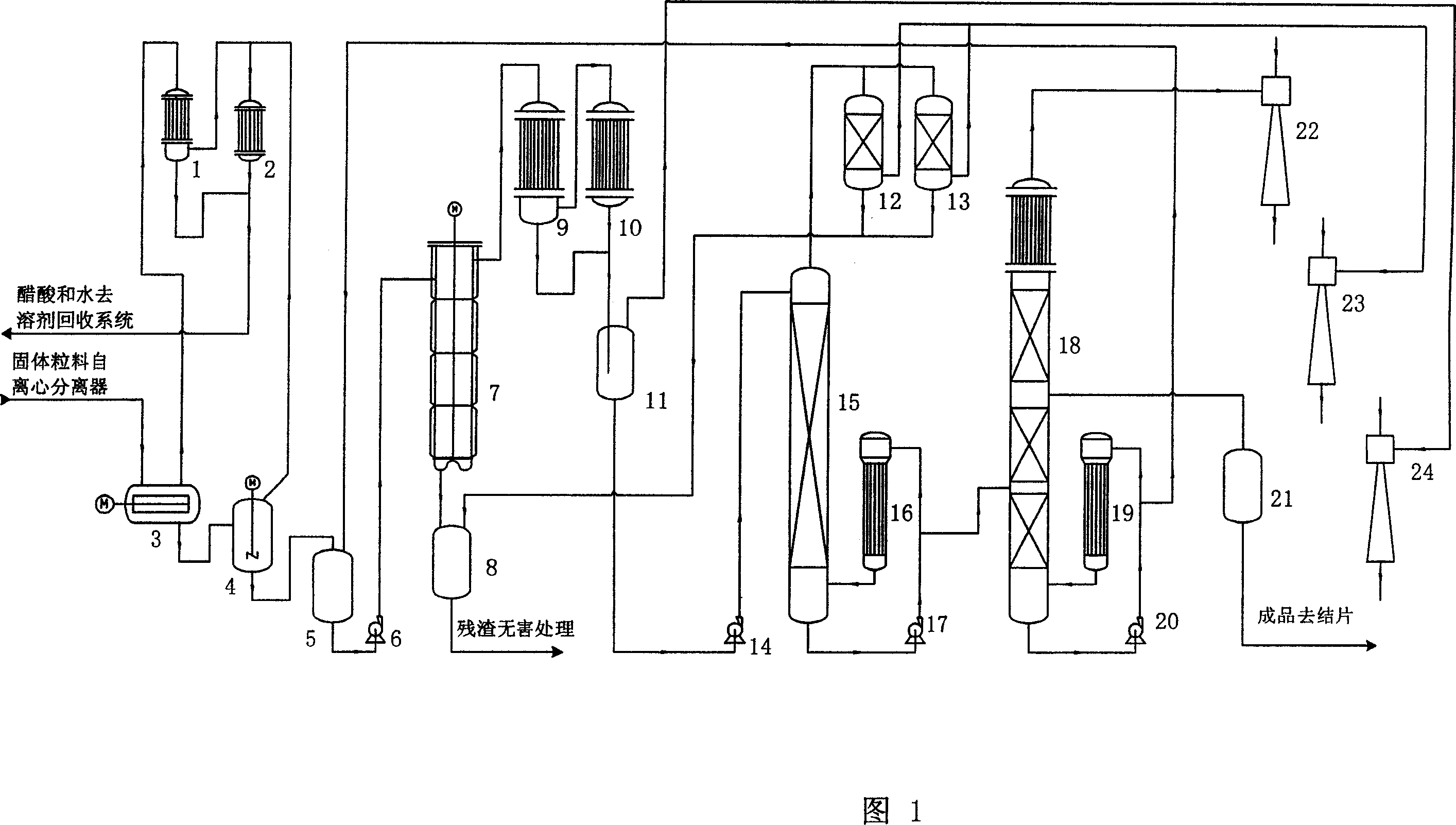

OLED display and manufacturing method thereof

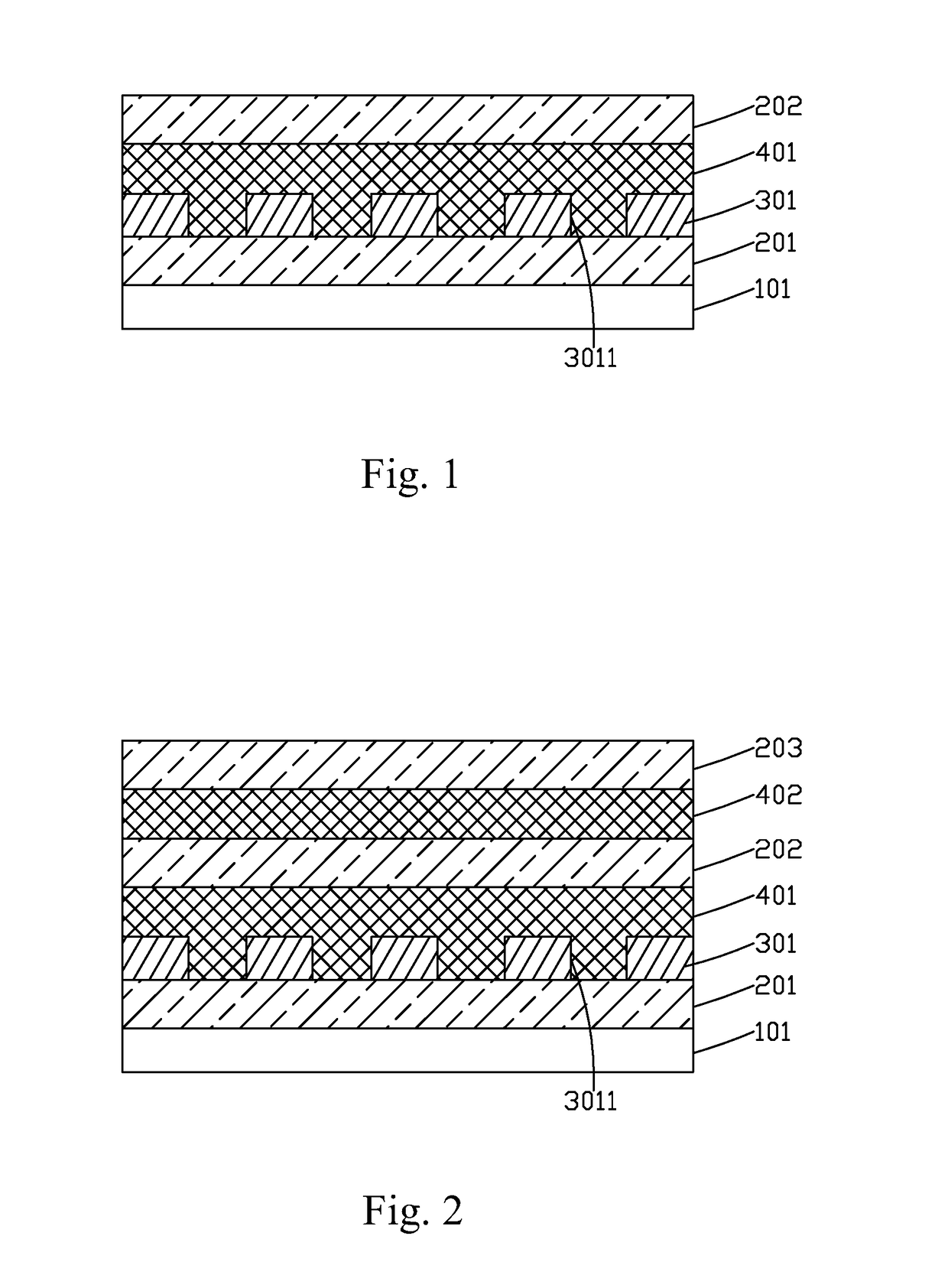

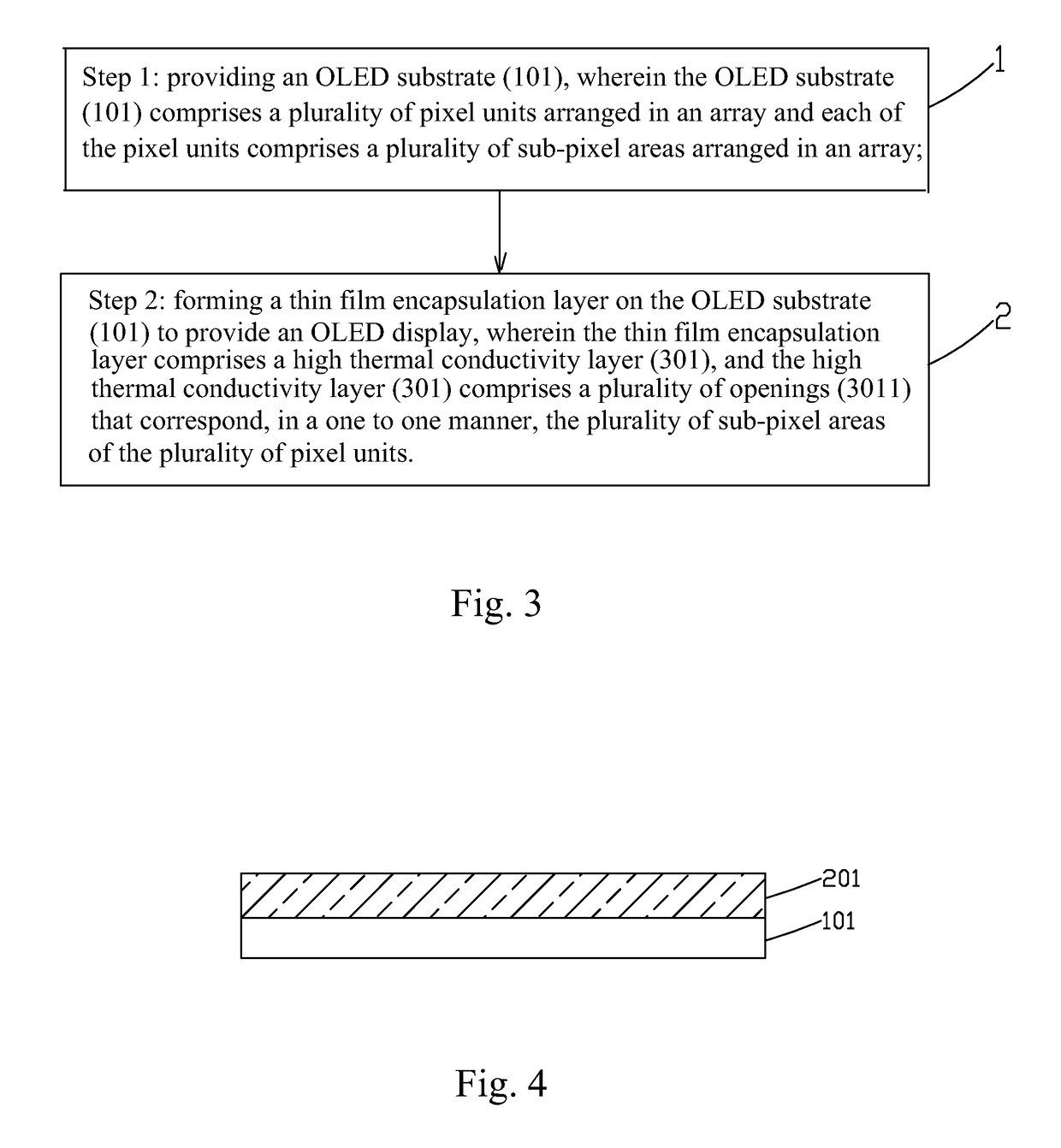

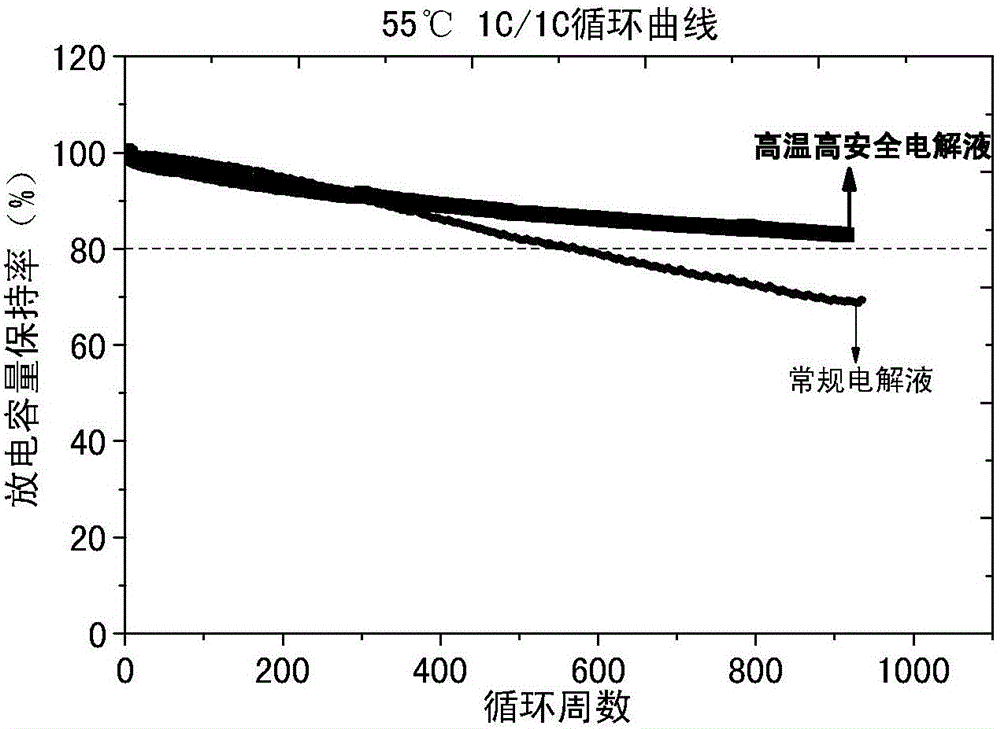

ActiveUS20180212191A1Reduce thermal decompositionExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceDisplay device

The present invention provides an OLED display and a manufacturing method thereof. The OLED display of the present invention includes an OLED substrate and a thin film encapsulation layer disposed on the OLED substrate. The thin film encapsulation layer includes a patterned the high thermal conductivity layer and the high thermal conductivity layer is provided with a plurality of openings formed therein to correspond, in a one to one manner, to a plurality of sub-pixel areas of the OLED substrate so as to prevent the high thermal conductivity layer from absorbing light and also help eliminate the constraint that a top emission device is only allowed to use a material having a high transmission rate, thereby allowing for effective transfer of heat generated during an operation of an OLED device without deteriorating light emission efficiency of the device, reducing thermal decomposition of a material of the OLED device, and ensuring the device possesses sufficiency capability of blocking external moisture and oxygen to thus extend the service life of the device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

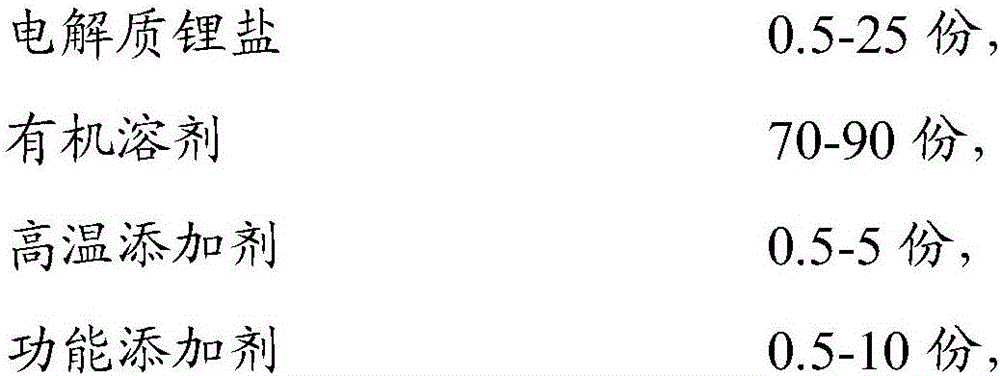

High-temperature and high-safety non-water electrolyte

InactiveCN106025354AReduce thermal decomposition abilityImprove thermal stabilitySecondary cells servicing/maintenanceOrganic electrolytesVinylene carbonateLithium electrode

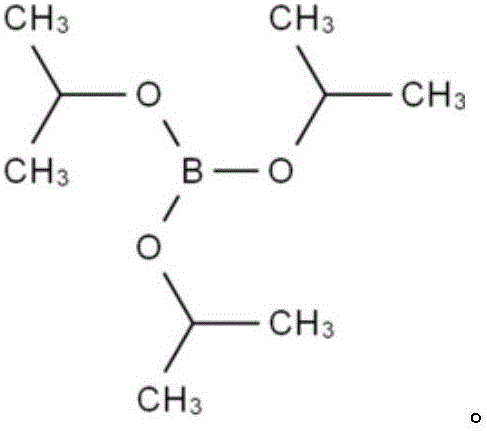

The invention relates to the field of chemical engineering and relates to a high-temperature and high-safety non-water electrolyte for a lithium ion battery. The high-temperature and high-safety non-water electrolyte is prepared from substances in parts by weight as follows: an organic solvent, lithium salt, a high-temperature additive and an additive, wherein the organic solvent adopts high-purity carbonic ester type organic solvents; the lithium salt is one or a mixture of lithium hexafluorophosphate, lithium tetrafluoroborate, lithium bis(oxalate) borate, lithium bis(trifluoromethanesulfonyl)imide, lithium difluoro(oxalato) borate, lithium bis(fluorosulfonyl)imide and the like; the high-temperature additive is triisopropyl borate; the additive is at least one of vinylene carbonate, methylene methanedisulfonate, 1,3-(1-propene) sultone, 1,3-propane sultone, cyclohexylbenzene, methyl 2,2-difluoro-2-(fluorosulfonyl)acetate and the like. At the high temperature, the high-temperature additive, namely, triisopropyl borate, lacks an electron structure and easily interacts with PF6<->, the thermal decomposition capability of LiPF6 is reduced, the thermal stability of the electrolyte is improved, the cycle life of the battery is further prolonged, the safety performance of the battery is further improved, and the high-temperature use demands of the battery cell can be met.

Owner:SHANDONG HIRONG POWER SUPPLY MATERIAL

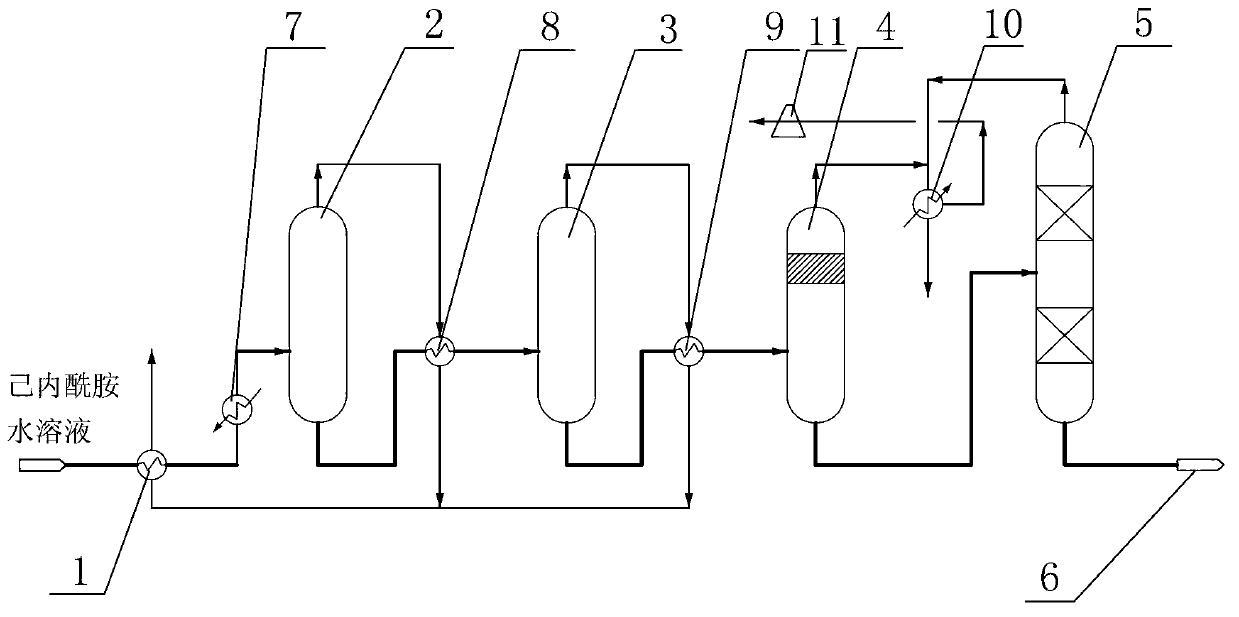

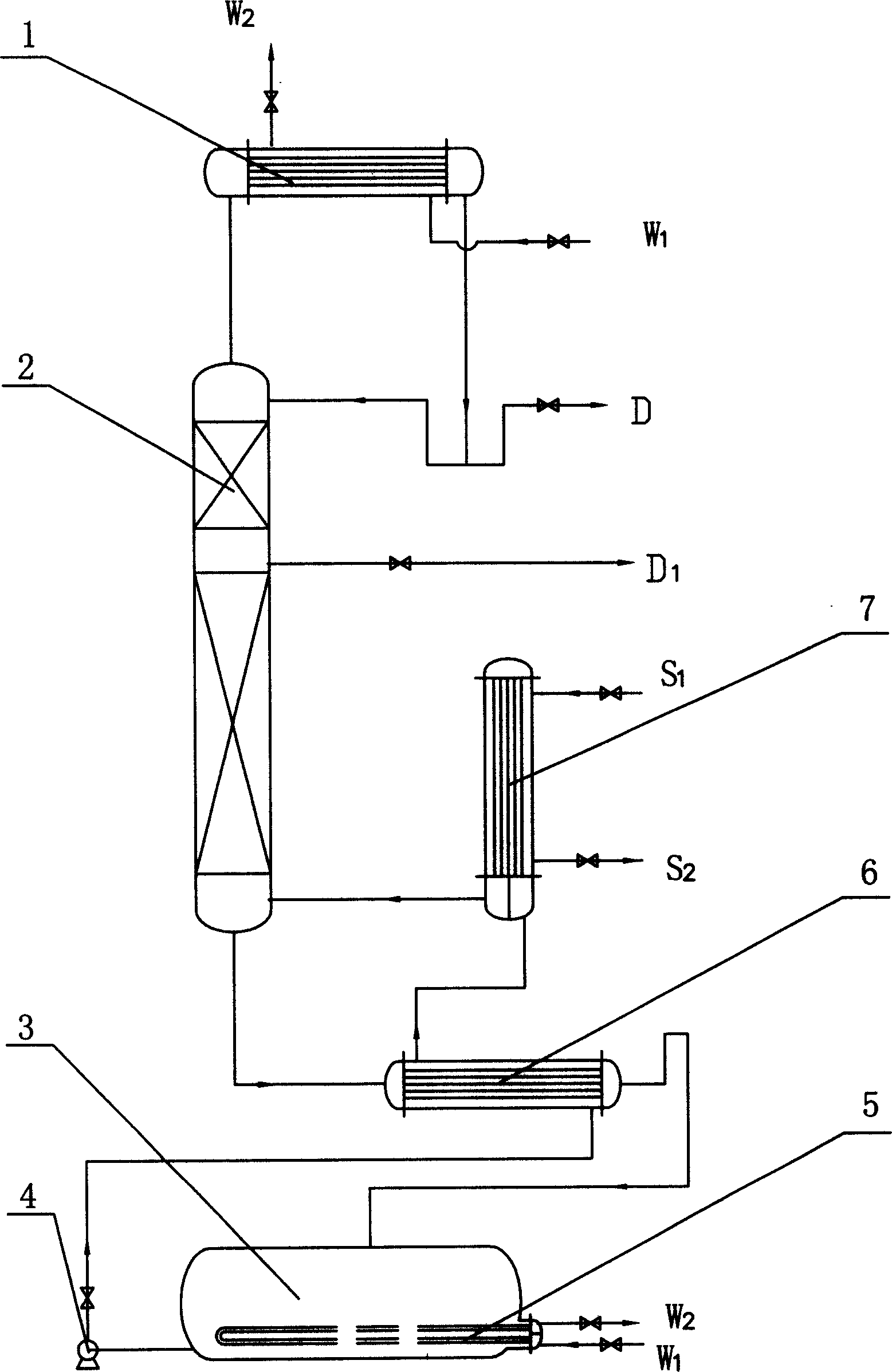

Production system of dehydrated caprolactam and method thereof

ActiveCN102989185AReduce consumptionLow operating pressureEvaporator accessoriesLactams separation/purificationEvaporationEngineering

The invention discloses a production system of dehydrated caprolactam and a method thereof. The system is characterized by comprising a first-efficiency heat exchanger, a first-efficiency evaporator, a second-efficiency heat exchanger, a second-efficiency evaporator, a third-efficiency heat exchanger and a third-efficiency evaporator which are sequentially connected and then connected with a rectifying tower. The production method comprises the following steps of: pre-heating the materials and then sending the materials to the first-efficiency evaporator for evaporation under the conditions of a temperature of 115-125 DEG C and a pressure range from 0.2 to 0.35MPaG; heating the materials and sending the materials to the second-efficiency evaporator for evaporation under the conditions of a temperature of 105-110 DEG C and a pressure range from 0.05 to 0.1MPaG; heating the materials and sending the materials to the third-efficiency evaporator for evaporation under the conditions of a temperature of 85-95 DEG C and a pressure range from 0.05 to 0.08MPaG; and sending the materials to the rectifying tower for rectification under the conditions of a temperature of 90 DEG C and a pressure range from 0.05 to 0.08MPaG, wherein the dehydrated caprolactam with less than 0.001% of water is obtained at the bottom of the rectifying tower. The invention has the advantages that multiple effective and gradient utilization of steam is realized through rational control of pressure and temperature, a large amount of cold and heat are saved, and the thermal decomposition of the caprolactam is reduced at a lower operating temperature.

Owner:SEDIN NINGBO ENG

Preparation method of high-performance fluoride rubber/silicone rubber cable sheath material

InactiveCN105802090AGood weather resistanceAccelerated corrosionRubber insulatorsInsulated cablesElastomerCalcium silicate

The invention discloses a preparation method of a high-performance fluoride rubber / silicone rubber cable sheath material. The preparation method comprises the following steps of performing primary mixing on fluoride rubber, silicone rubber, epoxy acrylate elastomer, hydrogenated butadiene-acrylonitrile rubber, maleic anhydride grafted polyethylene and methyl vinyl silicone rubber grafted methacrylic acid-2,2,2-trifluoroethyl to obtain a primary rubber compound; adding carbon nanotubes, stearic acid modified diatomite, calcium silicate, polyaniline nanofibers, sepiolite fibers and calcium hydroxide, and mixing for 1 to 5 minutes; adding 2,6-di-tert-butyl paraaminophenol, 2,5-di-tert-butylhydroquinone, nitrosodiphenylamine, butylmercaptooxo stannane, 5,5'- dimethyl-5,10-dihydracridine, and mixing for 3 to 8 minutes; adding stearic acid, inositol hexaphosphate, epoxidized linseed oil, active magnesium oxide, bisphenol AF, benzyl triphenyl phosphorus chloride, N,N'-meta phenylene bismaleimide, phenolic resin and an accelerator, mixing for 5 to 10 minutes and then vulcanizing for two times.

Owner:ANHUI HUAYU CABLE GRP

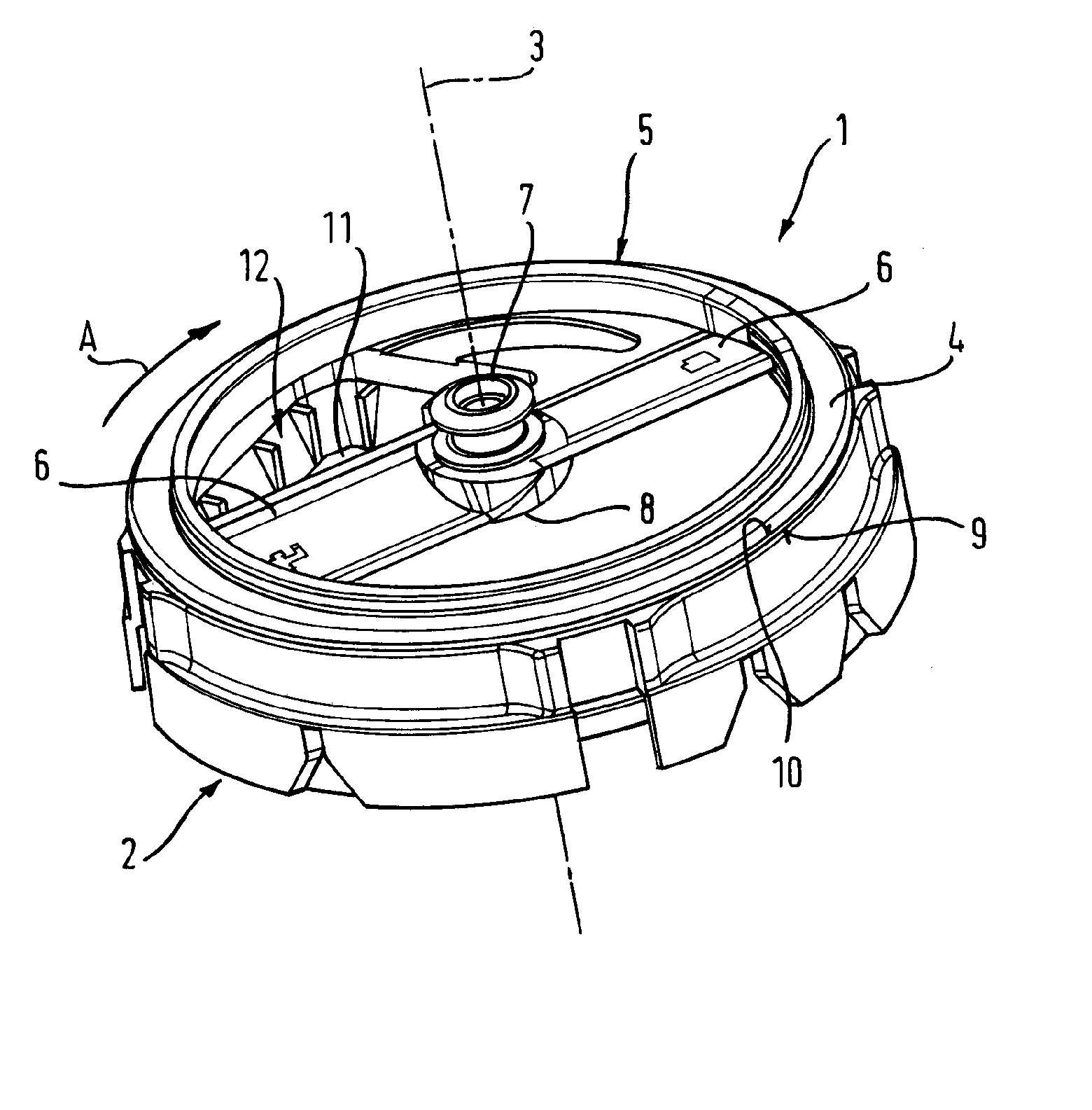

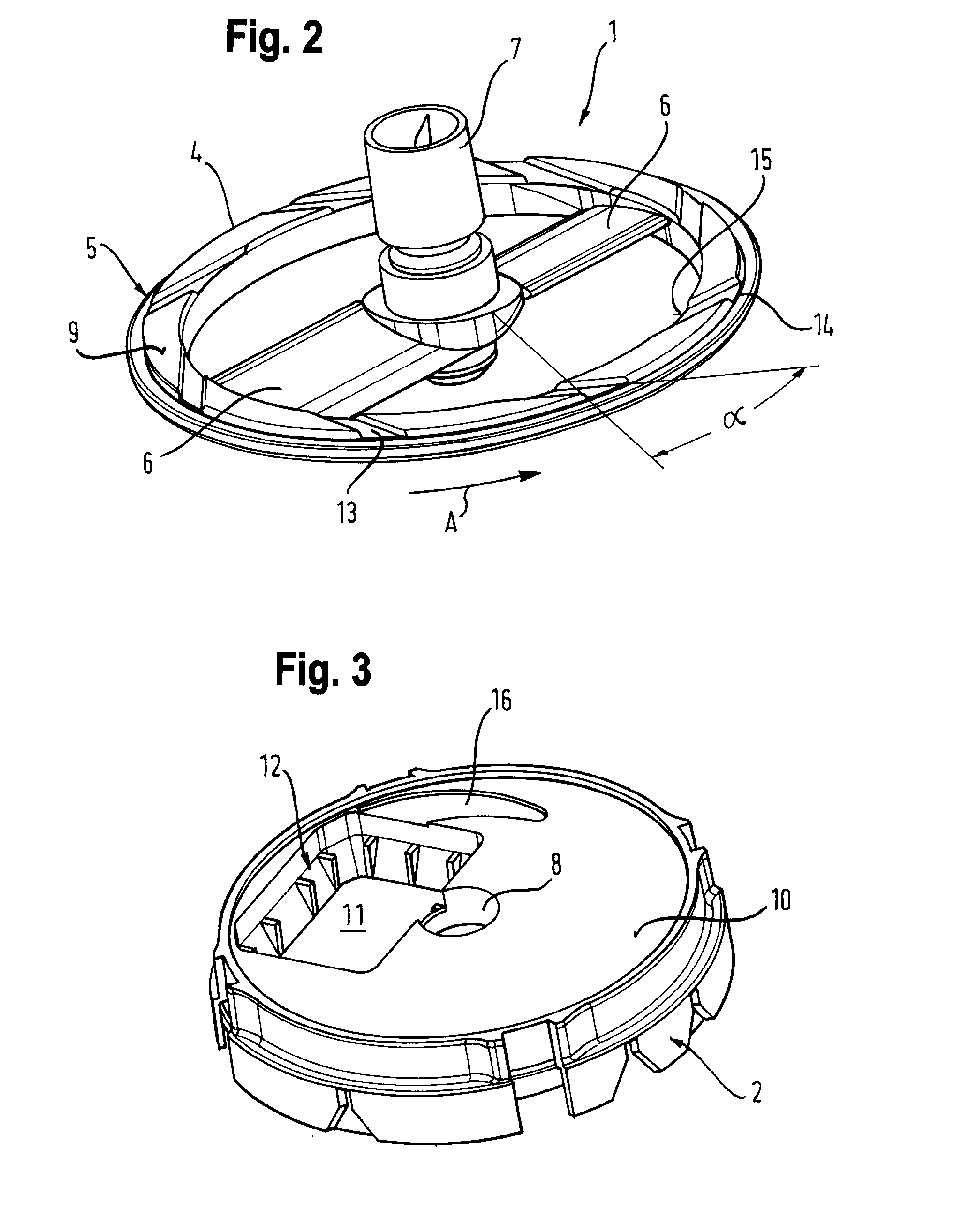

Device for cutting up foodstuffs

ActiveUS20130134247A1Preventing extensive catchingLess thermal stressGrinding machine componentsKitchen equipmentRing elementEngineering

An apparatus for a kitchen appliance for handling items to be processed includes a static housing part having an upper axial face, and a rotating ring element having a lower axial face which rests on the upper axial face of a static housing part in the presence of an annular gap there between. The upper axial face and / or the lower axial face and / or the rotating ring element is hereby constructed such as to effect a radial conveying of items being processed in the annular gap.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Thermosensitive material intermittent rectifying process having side material output and tower kettle cold material storage

An intermittent rectifying system with side discharge and cold storage of material on top for the thermosensitive material is composed of cold storaging tower still, rectifying tower with side discharging, condenser, cooler, shielding pump and evaporator. The thermosensitive material is stored in cold state. Its advantages are short rectifying time, low thermodecomposing rate of raw material, and high purity and output rate of product.

Owner:TIANJIN UNIV

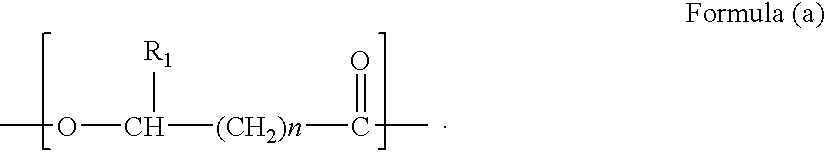

Method for producing aliphatic polyester and the aliphatic polyester

An object of the present invention is to provide an aliphatic polyester with a high polymerization degree having an excellent thermal stability and an industrially advantageous and efficient process for producing the same. In the invention, at the production of a polyester having diol unit(s) and aliphatic dicarboxylic acid unit(s), a metal oxide containing at least one element selected from the group consisting of metal elements belonging to the Groups 3 to 6 of the Periodic Table and at least one element selected from the group consisting of silicon element and metal elements belonging to the Groups 1, 2, 12, 13, and 14 of the Periodic Table is used as a catalyst.

Owner:MITSUBISHI RAYON CO LTD

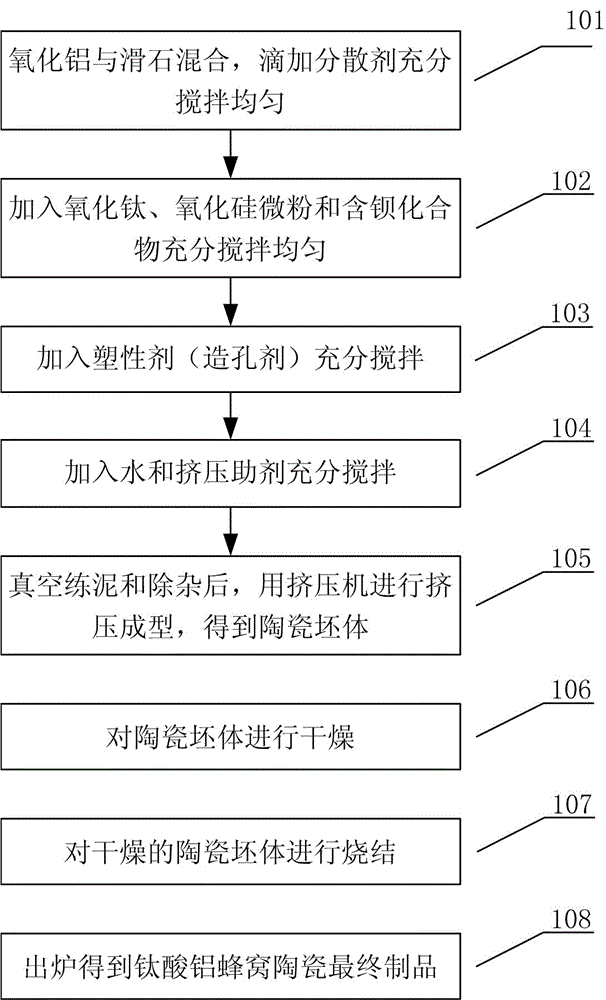

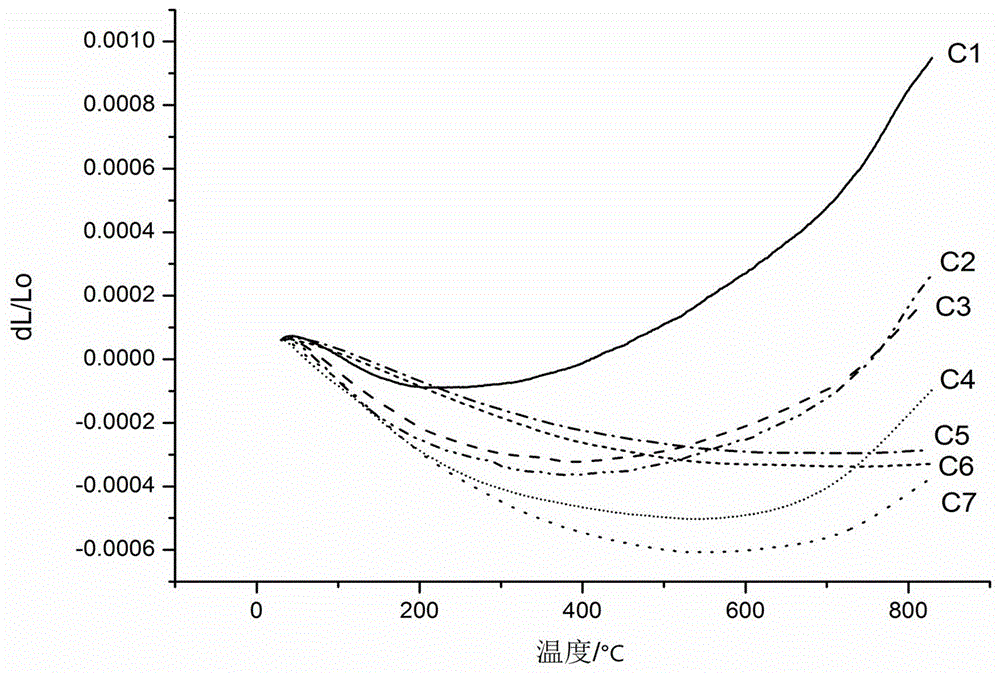

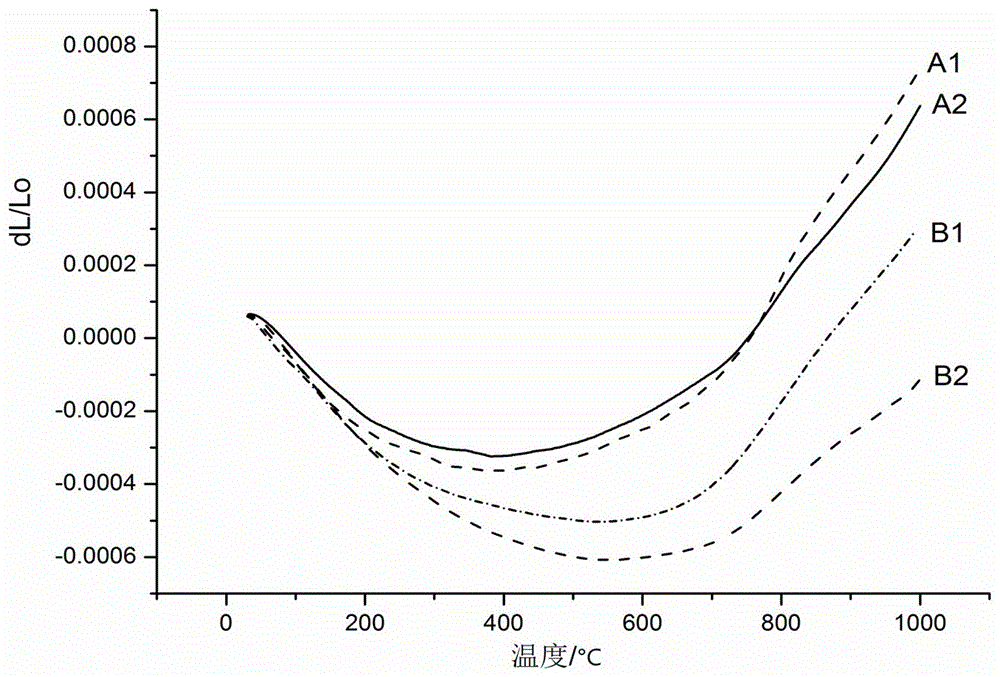

Aluminum titanate honeycomb ceramic material and preparation method thereof

ActiveCN105819851ASolve the strength problemSolve the problem of decomposition of aluminum titanate at 1200°CCeramicwareThermal expansionSilicon dioxide

The invention relates to an aluminum titanate honeycomb ceramic material and a preparation method thereof. The method comprises the following steps: weighing alumina and talcum powder in proportion, and uniformly stirring alumina and the talcum powder; adding titanium oxide, a barium-containing compound and silica which are weighed in proportion; adding a shaping agent and a pore forming agent which are weighed in proportion, and fully stirring; adding pure water and an extrusion aid which are weighed in proportion, and fully stirring; pugging the above obtained pug, removing impurities, and carrying out extrusion molding to obtain a honeycomb ceramic body; and drying the honeycomb ceramic body, and sintering the dried honeycomb ceramic body to obtain the final aluminum titanate honeycomb ceramic product. The honeycomb ceramic material has the advantages of simple and controllable preparation flow, economical raw material cost and high finished product strength. The aluminum titanate honeycomb ceramic prepared through the method, having an extremely low (near zero) thermal expansion coefficient and 1450DEG C or above refractoriness, can meet requirements of use of the engine exhaust gas purifiers for heat intensity and the thermal shock property.

Owner:YUNNAN FILTER ENVIRONMENT PROTECTION S & T

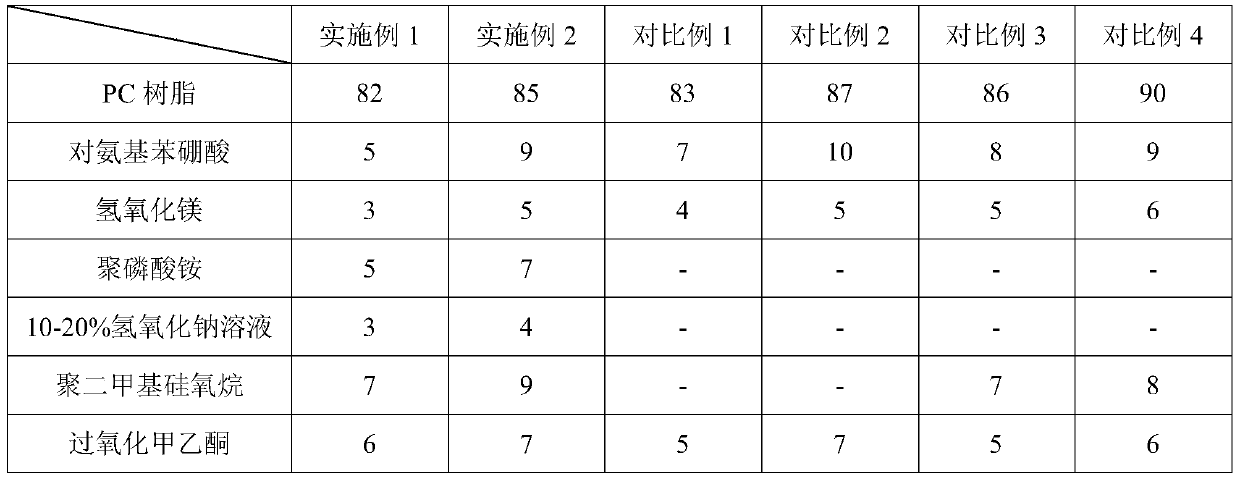

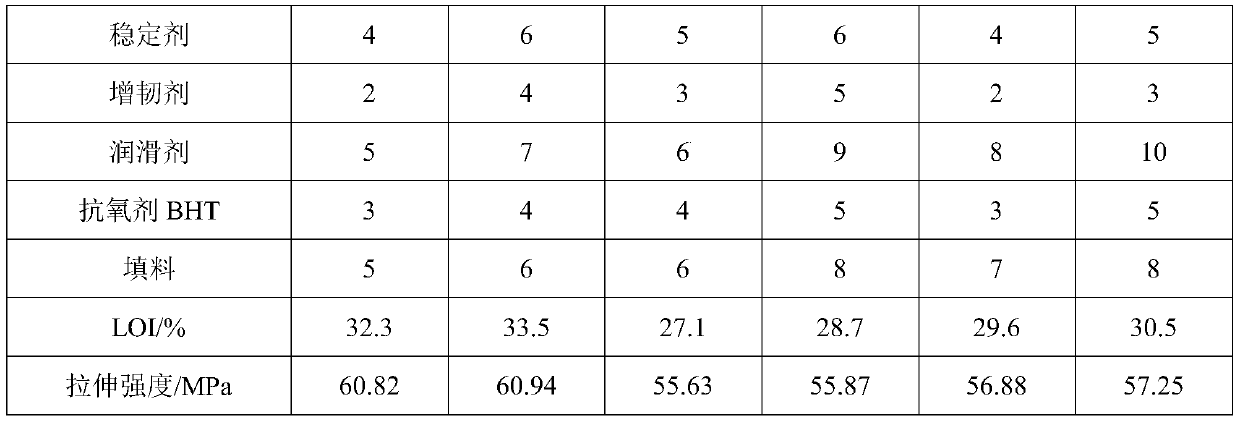

Modified engineering plastic and preparation method thereof

The invention relates to the technical field of engineering plastics, and discloses modified engineering plastic and a preparation method thereof. The engineering plastic comprises the following components: in parts by weight, 80-90 parts of PC resin, 4-6 parts of a stabilizer, 2-5 parts of a toughening agent, 5-10 parts of a lubricant and 3-5 parts of an antioxidant BHT, and a halogen-free flameretardant is also included, and comprises 7-10 parts of p-aminophenyl boronic acid and 3-6 parts of magnesium hydroxide. The modified engineering plastic has the following advantages that a synergistic flame retardant effect is achieved by magnesium hydroxide and p-aminophenyl boronic acid, on the one hand, the amount of magnesium hydroxide can be reduced, and on the other hand, a double-layer flame retardant structure is formed through a magnesium oxide protective film and a B-O-C carbon layer, so that a better flame retardant effect is achieved.

Owner:WENZHOU CITY FANHUA ENG PLASTIC

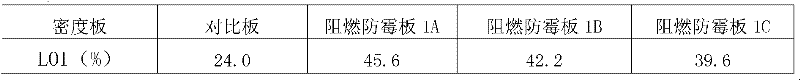

B-P-Mg-Si series density fiber board inflaming-retarding mildewproof agent and preparation and application thereof

The invention relates to a B-P-Mg-Si series density fiber board inflaming-retarding mildewproof agent and a preparation method and application thereof. The density fiber board inflaming-retarding mildewproof agent comprises the raw materials in parts by weight: 30-100 parts of sodium borate, 20-90 parts of polyammonium phosphate, 40-60 parts of magnesium hydroxide and 6-20 parts of organosilicon quaternary ammonium salt. When used for preparing a density fiber board, the B-P-Mg-Si series density fiber board inflaming-retarding mildewproof agent has the addition amount of 4-6 percent of the mass of oven-dry wood as the density fiber board. An inflaming-retarding mildewproof density fiber board prepared by adopting the B-P-Mg-Si series density fiber board inflaming-retarding mildewproof agent has combustion oxygen indexes of exceeding 39.0 percent, can reach the B1-level standard of the combustion performance of building finishing materials, and accords with the requirement of fire service law.

Owner:SHANDONG UNIV

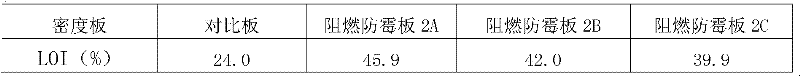

Method for preparing morroniside

ActiveCN104987354AReduce manufacturing costReduce dosageSugar derivativesSugar derivatives preparationCornus officinalisSilica gel

The invention discloses a method for preparing morroniside. The method comprises the following steps: 1) carrying out permeating extraction on cornus officinalis to obtain a cornus officinalis extraction solution; 2) concentrating the cornus officinalis extraction solution obtained in the step 1) to obtain cornus officinalis extract; 3) uniformly mixing the cornus officinalis extract with a silica gel, drying and grinding the mixture, and filling the mixture in a chromatographic column, wherein the chromatographic column is filled with a hollow silica gel for chromatography; and 4) eluting the chromatographic column by using an eluant and collecting a flowing component, then removing the eluant in the flowing component, dissolving residues by methanol, and carrying out recrystallization to obtain morroniside. The purity of the product obtained by the method is greater than 70%, so that the product can be used for further purification and production of high purity morroniside and can be directly used for producing various target products. The method not only is suitable for small-scaled preparation in a lab, but also is suitable for large-scaled industrial production.

Owner:BEIJING INST FOR DRUG CONTROL

Method for preparing PC-PS blend alloy

InactiveCN101531809AFeatures that make up for poor UV resistanceEnsure transparencyInorganic particleWeather resistance

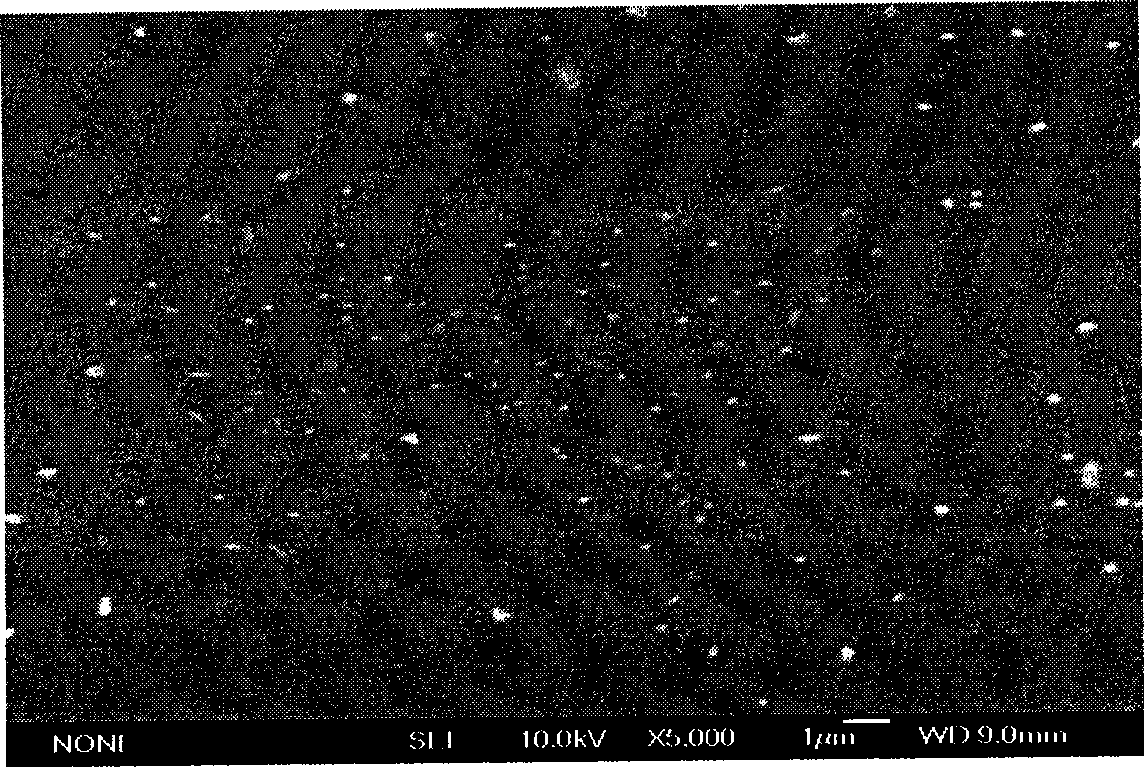

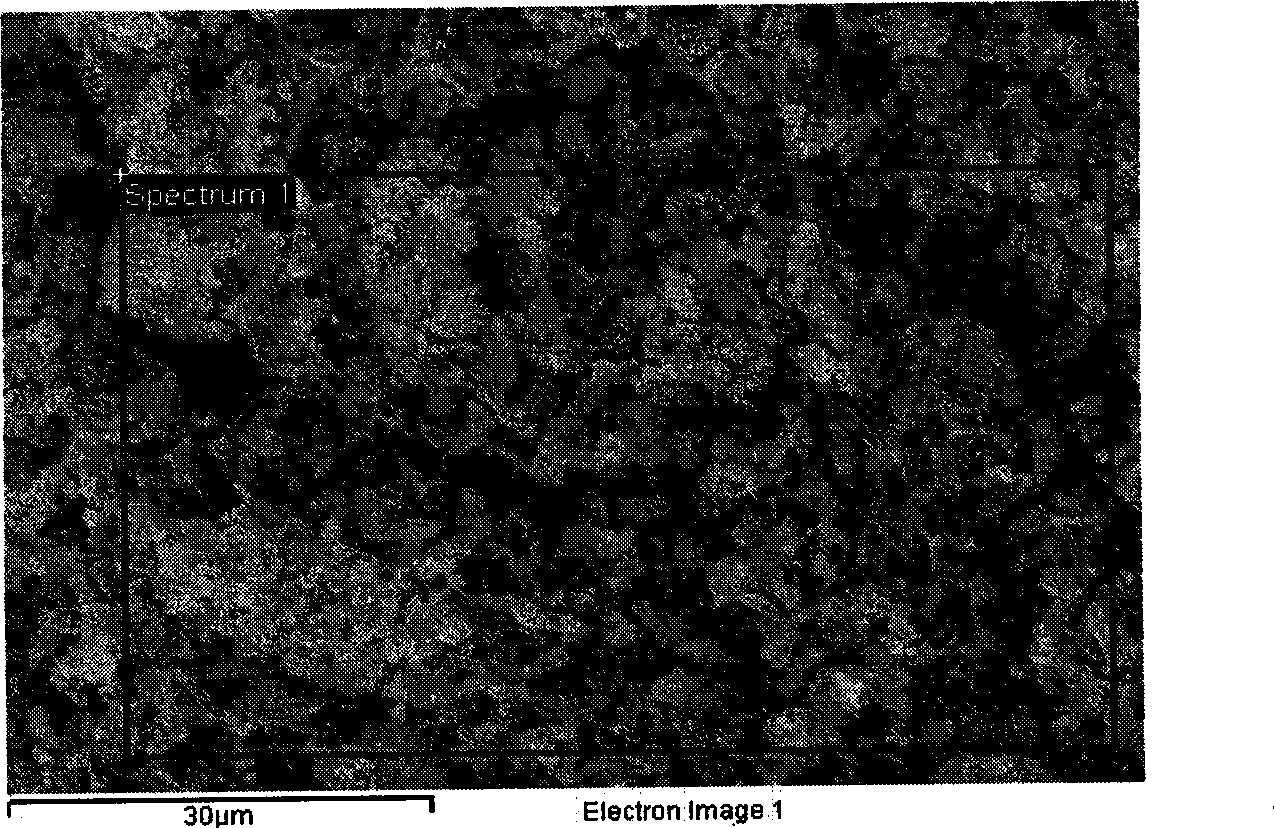

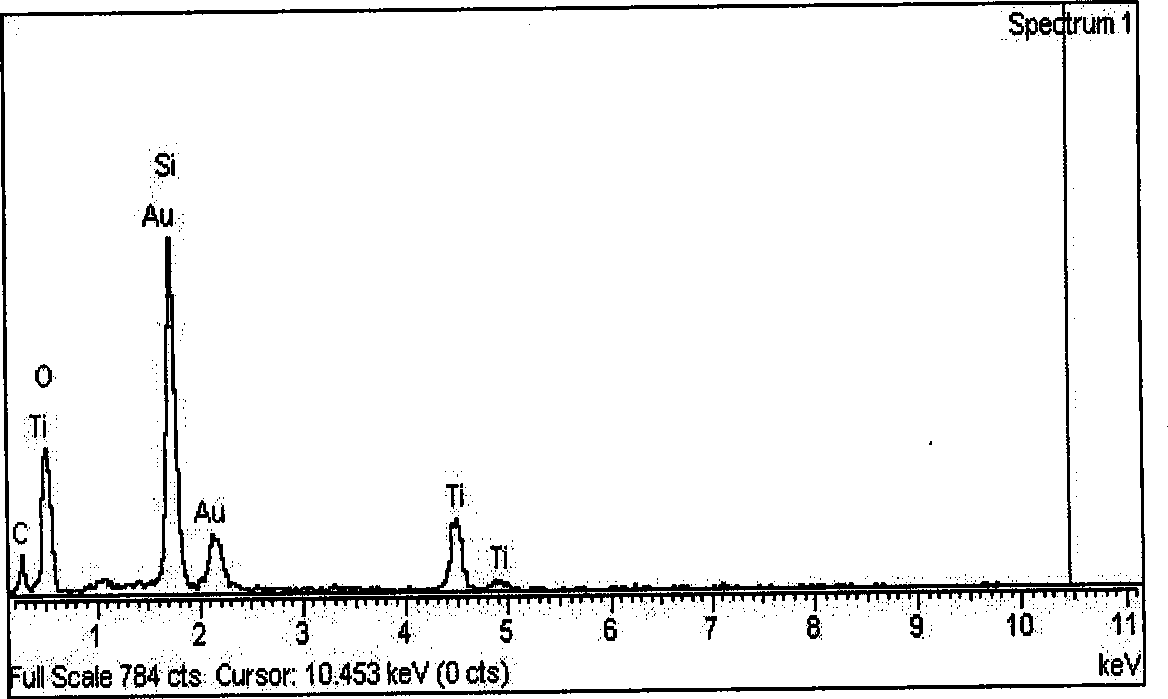

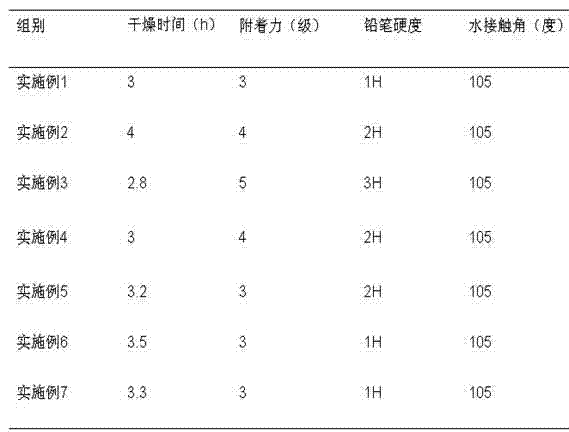

A method for preparing PC-PS blend alloy comprises the following steps: after coating PC, PS and SiO2 to prepare high polymer, coating TiO2 and the SiO2 to obtain inorganic particles, and then melting the high polymer and the inorganic particles again to obtain the blend alloy. The method is simple and convenient, easy to operate and realize and short in period. The prepared blend alloy has better ultraviolet resistance, wearing resistance and weather resistance.

Owner:TAIYUAN UNIV OF TECH

Lubrication plastic for sealing element

The invention discloses lubrication plastic for a sealing element. Firstly, APP (ammonium polyphosphate) is subjected to surface coating with a sol-gel treatment process, surface strength and water resistance are improved, then polyaniline coating is performed, flame resistance and thermolysis are improved, and dispersibility and compatibility of an additive in the plastic are effectively improved.

Owner:HEFEI JIKE NEW MATERIALS

Rust-proof fluorocarbon powder coating

ActiveCN103694811AImprove thermoplasticityHigh chemical resistanceAnti-corrosive paintsPowdery paintsPolyamideFluoboric acid

The invention discloses a rust-proof fluorocarbon powder coating. The rust-proof fluorocarbon powder coating is prepared from the following raw materials in parts by weight: 50-80 parts of chlorotrifluor ethylene-ethylene copolymer, 2-10 parts of rust-proof phosphorus containing pigment, 1-5 parts of flash-rust inhibitor, 20-35 parts of nanoscale filler, 15-30 parts of polyamide resin plasticizer, 3-10 parts of stabilizer, and 5 parts of solvent ethylene glycol. The fluorocarbon powder coating has excellent comprehensive physical and chemical properties and can form even films rapidly; a 0.13-0.18mm thick coating can resist mediums such as hydrochloric acid, fluoboric acid, sulfuric acid, sodium hydroxide and the like; the coating is firmly stuck and even can resist tens of thousands of times of periodic bending; furthermore, the coating of the fluorocarbon coating has no pinhole, has a bright and clean surface with no dirt stuck on, resists flash-rust, does not peel off or foam, and can prevent rust for long time.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com