Completely degradable high shock resistance composite, and preparation method and application thereof

A high-impact, composite material technology, applied in textiles and papermaking, telephone structure, non-woven fabrics, etc., can solve the problems of poor impact performance, easy to brittle fracture, etc., achieve excellent impact resistance performance, low environmental hazards , to meet the effect of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

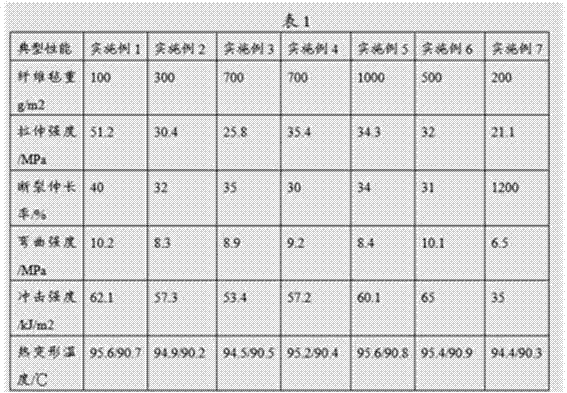

[0039] Open 45 parts of hemp fibers with a length of 50 mm, and open 55 parts of PBAT fibers with a length of 70 mm. After the opening, the two fibers are pre-mixed, and the fibers are formed into a net. Lay the netted natural fibers and PBAT fibers. layer; the fiber mat will not scatter after being punched by a needle punching machine; the obtained fiber mat is properly cut, layered, and hot-pressed. The relevant performance tests are shown in Table 1.

Embodiment 2

[0041] Open 30 parts of silk fibers with a length of 70 mm, and open 70 parts of PBAT fibers with a length of 100 mm. After the opening, the two fibers are premixed, and the fibers are formed into a web. layer; the fiber mat will not scatter after being punched by a needle punching machine; the obtained fiber mat is cut, layered, and hot-pressed. The relevant performance tests are shown in Table 1.

Embodiment 3

[0043] Open 20 parts of ramie fibers with a length of 100 mm, and open 80 parts of PBAT fibers with a length of 100 mm. After the opening, the two fibers are premixed, and the fibers are formed into a net. Lay the netted natural fibers and PBAT fibers. layer; the fiber mat will not scatter after being punched by a needle punching machine; the obtained fiber mat is cut, layered, and hot-pressed. The relevant performance tests are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com