Rust-proof fluorocarbon powder coating

A technology for powder coatings and anti-rust pigments, applied in the field of fluorocarbon anti-rust powder coatings and anti-rust coatings, can solve the problems of a single type of water-soluble fluorocarbon coatings, unsuitable for on-site construction, and unsatisfactory film-forming effects, and achieve surface Smooth and non-staining, excellent comprehensive physical and chemical properties, great thermoplastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

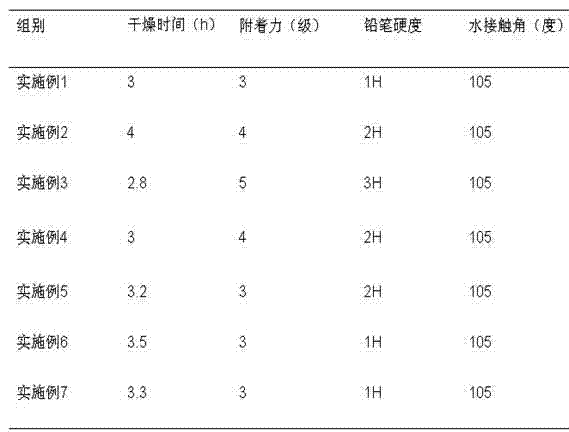

Examples

Embodiment 1

[0018] A fluorocarbon antirust powder coating, comprising the following raw materials in parts by weight: 50 parts of chlorotrifluoroethylene-ethylene copolymer, 1.2 parts of aluminum polyphosphate, 0.6 part of aluminum zinc phosphate, 0.2 part of magnesium zinc phosphate, organic zinc complex 1 part, 0.2 parts of sodium molybdate, 12 parts of silicon dioxide, 5 parts of diatomaceous earth, 3 parts of ceramic microbeads, 15 parts of polyamide resin, 3 parts of calcium stearate, and 5 parts of ethylene glycol.

Embodiment 2

[0020] A fluorocarbon antirust powder coating, comprising the following raw materials in parts by weight: 80 parts of chlorotrifluoroethylene-ethylene copolymer, 5 parts of aluminum polyphosphate, 2.5 parts of aluminum zinc phosphate, 0.5 part of magnesium zinc phosphate, organic zinc complex 4 parts, 0.8 parts of sodium molybdate, 15 parts of silicon dioxide, 8 parts of diatomaceous earth, 7 parts of ceramic beads, 30 parts of polyamide resin, 10 parts of calcium stearate, and 15 parts of ethylene glycol.

Embodiment 3

[0022] A fluorocarbon antirust powder coating, comprising the following raw materials in parts by weight: 65 parts of chlorotrifluoroethylene-ethylene copolymer, 2.5 parts of aluminum polyphosphate, 2 parts of aluminum zinc phosphate, 0.5 part of magnesium zinc phosphate, organic zinc complex 2.5 parts, 0.5 parts of sodium molybdate, 13 parts of silicon dioxide, 5 parts of diatomaceous earth, 5 parts of ceramic beads, 22 parts of polyamide resin, 6 parts of calcium stearate, and 10 parts of ethylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com