Modified engineering plastic and preparation method thereof

A technology of engineering plastics and modification, which is applied in the field of engineering plastics and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

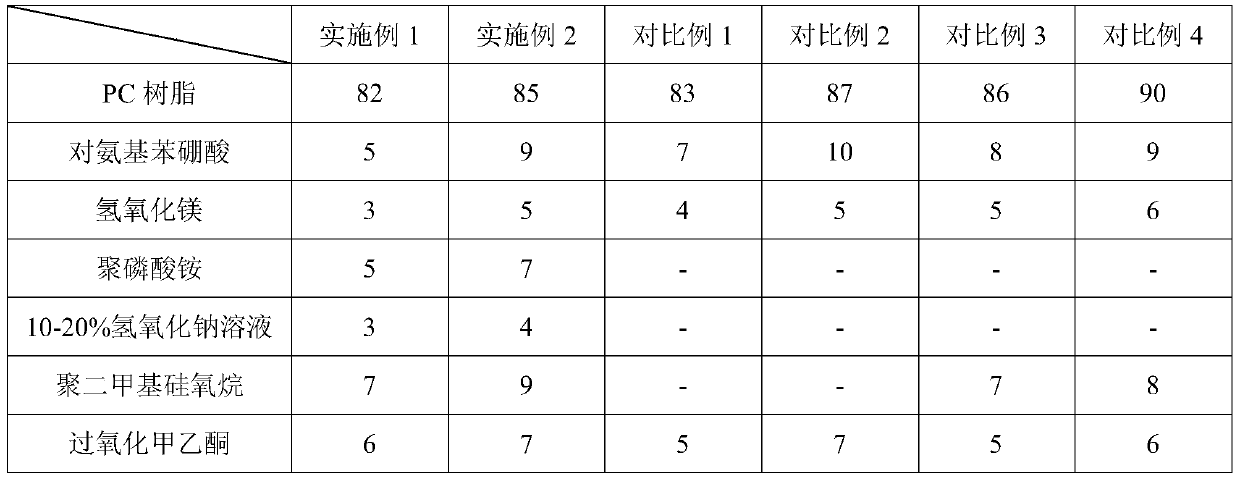

[0038] The components of modified engineering plastics are shown in Table 1-1, and the preparation method of modified engineering plastics includes the following steps:

[0039] S1, take each raw material according to weight part;

[0040] S2. Add PC resin, magnesium hydroxide and p-aminophenylboronic acid to the mixer, mix at 75°C for 21 minutes, and the mixing speed of the mixer is 680r / min, cool to room temperature, and obtain a premix;

[0041] S3. Add ammonium polyphosphate, 12% sodium hydroxide solution, polydimethylsiloxane and methyl ethyl ketone peroxide to the premix obtained in step S2, stir at 50°C for 10min, and stir at a speed of 400r / min, and then at a speed of 650r / min and stirred for 38min, the temperature rose to 81°C during the stirring process, and the heating rate was 4°C / min to obtain a mixture, which was cooled to room temperature;

[0042] S4. Add stabilizers, toughening agents, lubricants, antioxidants and fillers to the mixture obtained in step S3, ...

Embodiment 2

[0044] The difference from Example 1 is that, in parts by weight, the components of the modified engineering plastics are shown in Table 1-1, and the preparation method of the modified engineering plastics comprises the following steps:

[0045] S1, take each raw material according to weight part;

[0046] S2. Add PC resin, magnesium hydroxide and p-aminophenylboronic acid to the mixer, mix at 77°C for 25 minutes, and the mixing speed of the mixer is 700r / min, and cool to room temperature to obtain a premix;

[0047] S3. Add ammonium polyphosphate, 15% sodium hydroxide solution, polydimethylsiloxane and methyl ethyl ketone peroxide to the premix obtained in step S2, stir at 50°C for 13min, stirring at a speed of 420r / min, and then at a speed of 700r / min and stirred for 40min, the temperature rose to 85°C during the stirring process, and the heating rate was 4°C / min to obtain the mixture, which was cooled to room temperature;

[0048] S4. Add stabilizers, tougheners, lubrican...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com