Patents

Literature

101results about How to "Reduce the probability of burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

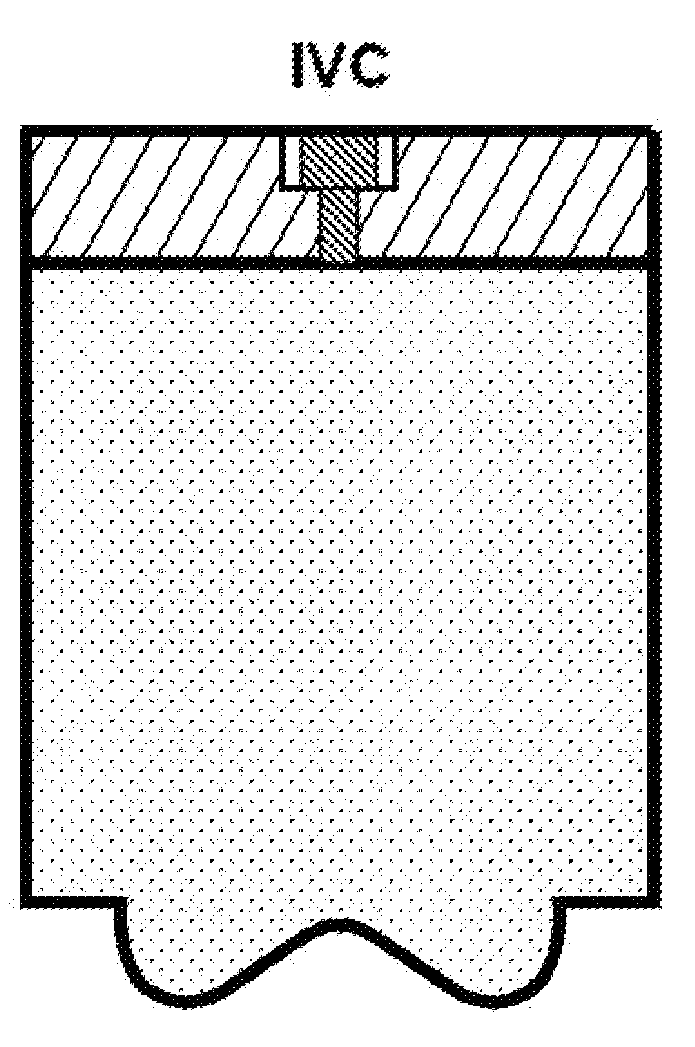

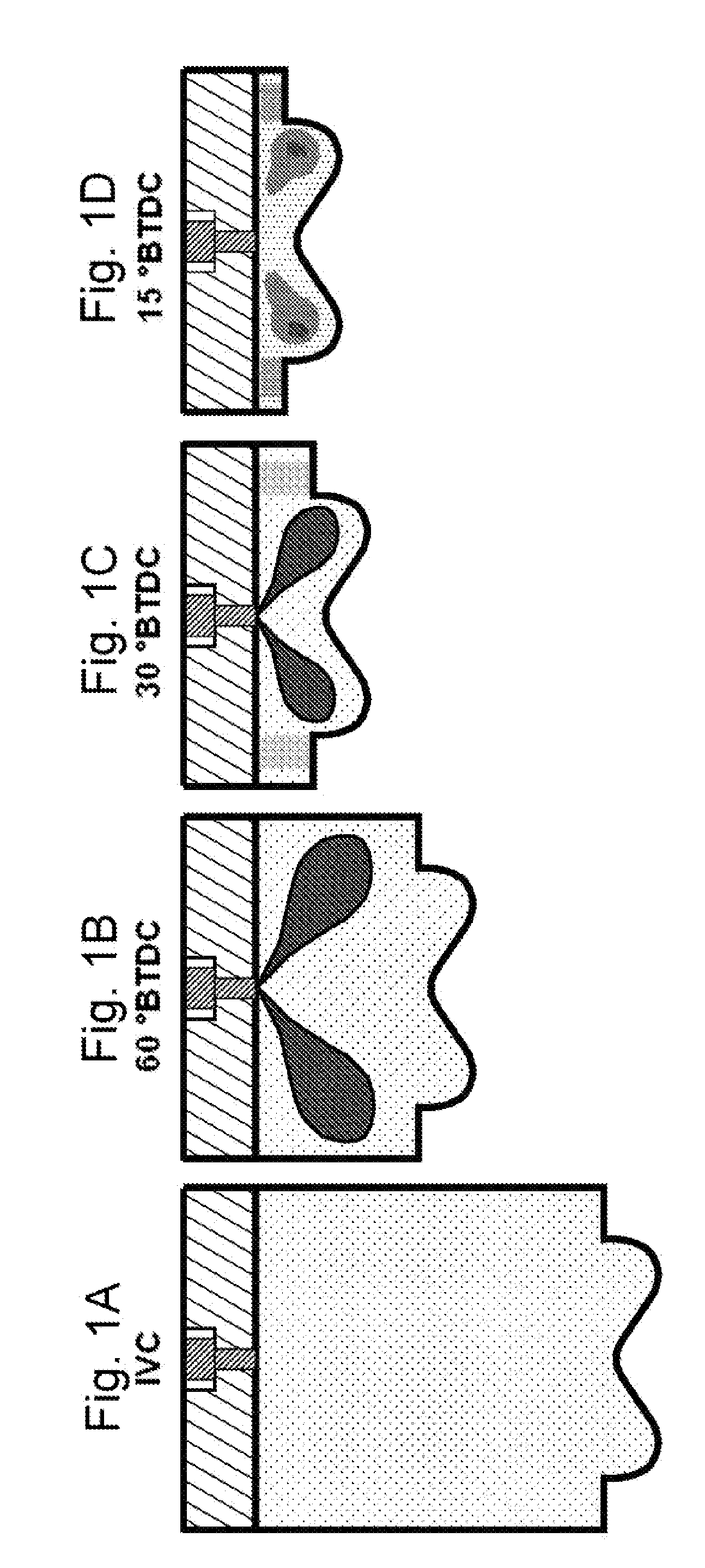

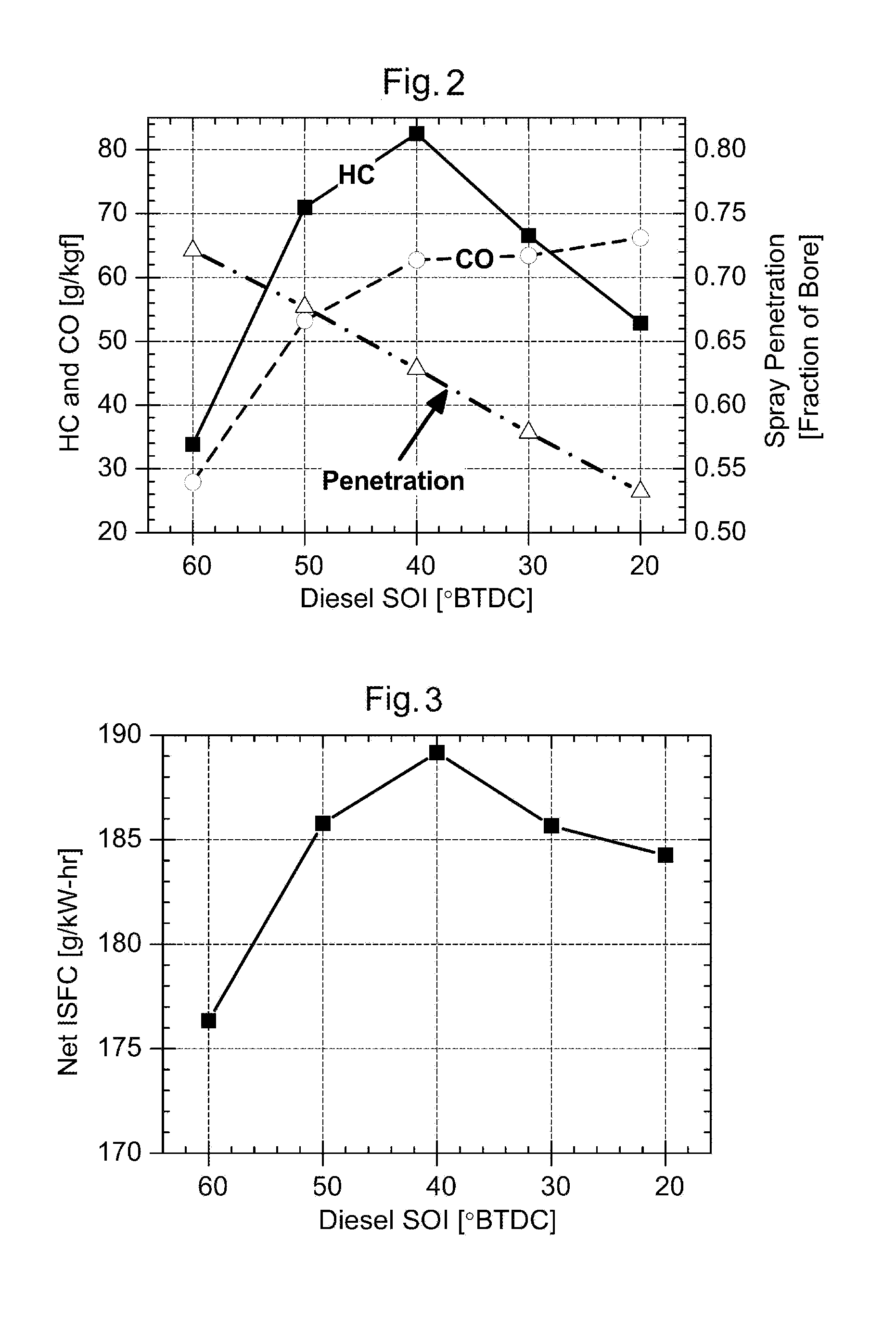

Engine combustion control via fuel reactivity stratification

ActiveUS20110192367A1High and low reactivityConvenience to workElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

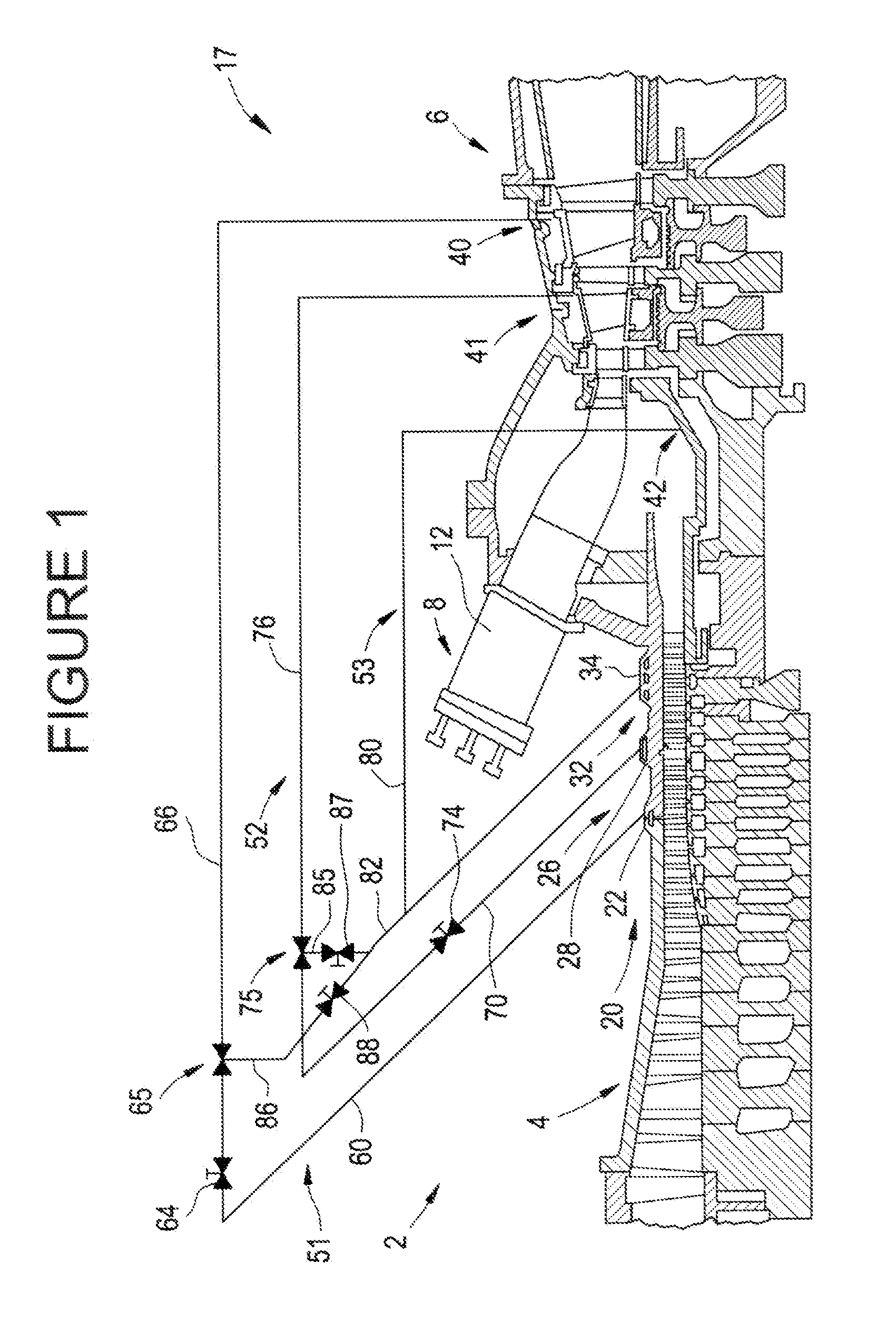

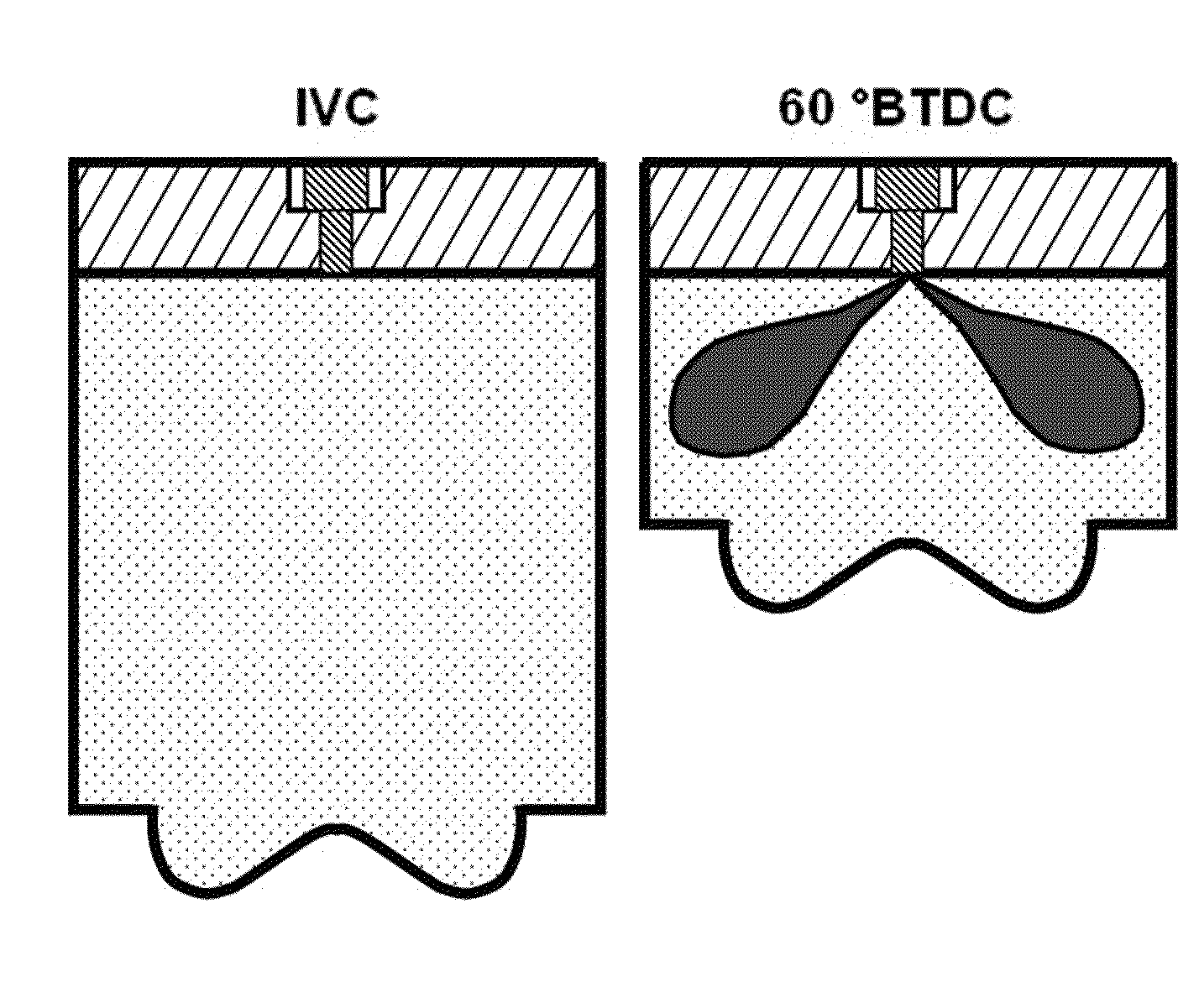

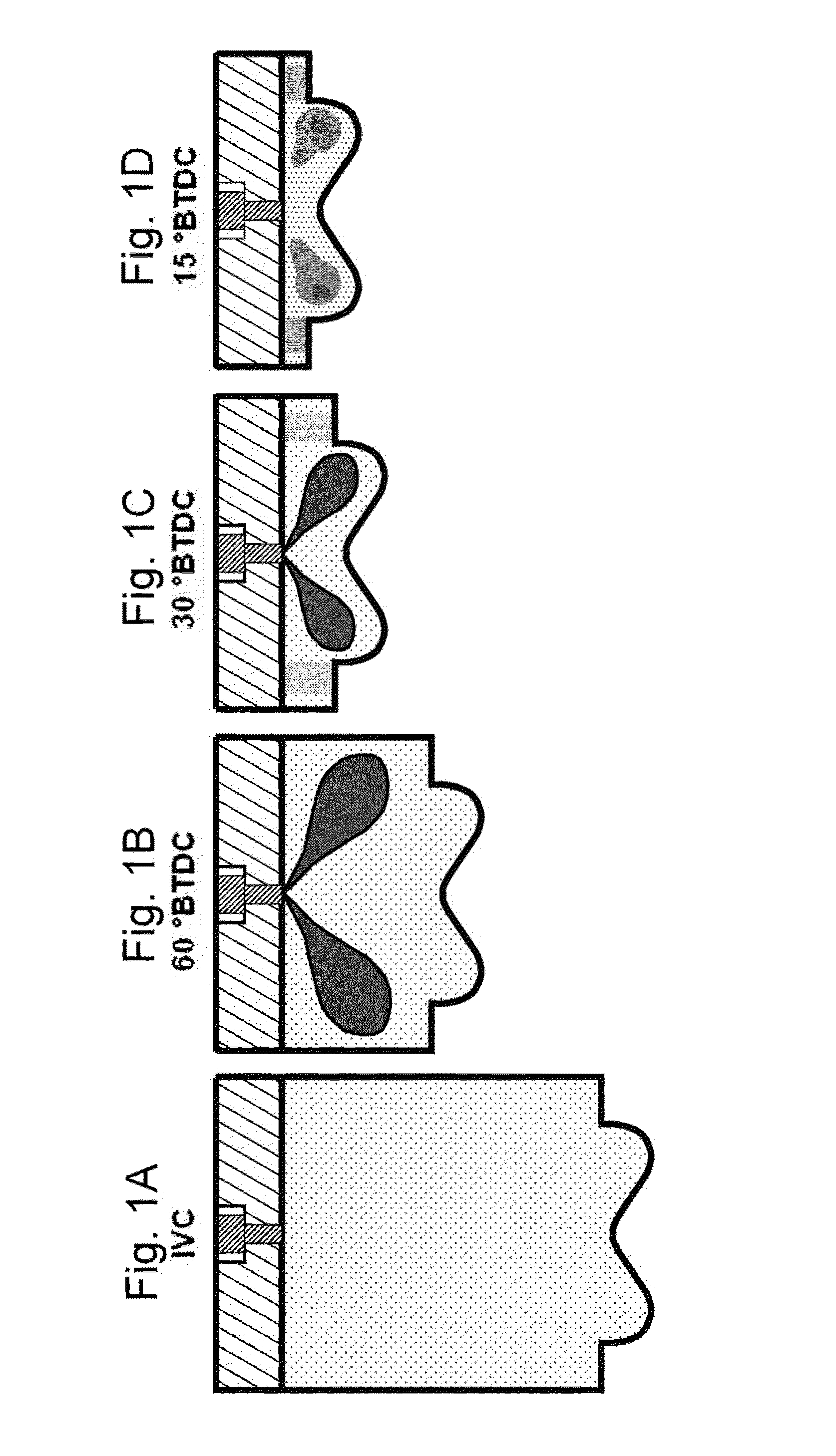

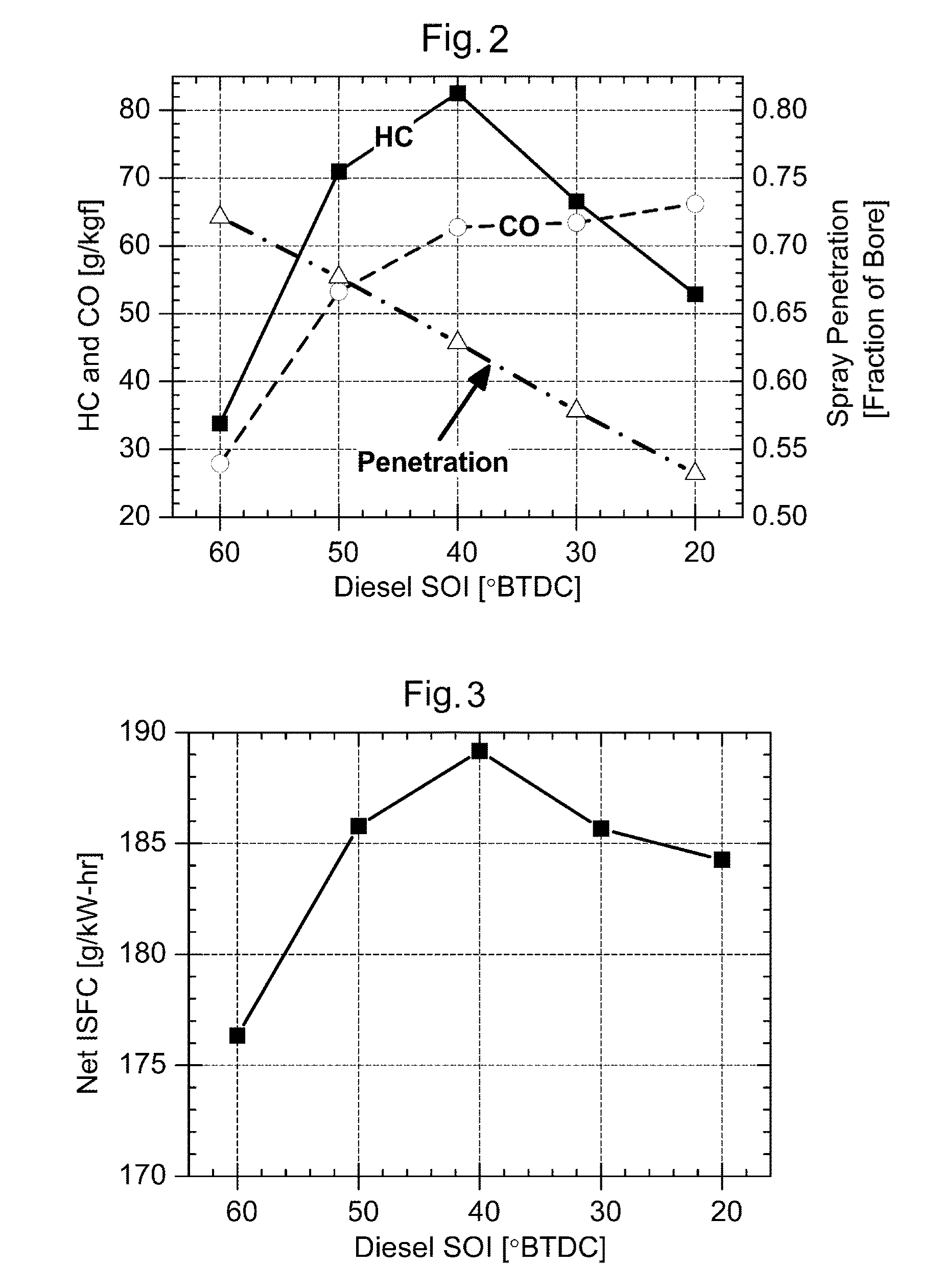

A compression ignition engine uses two or more fuel charges having two or more reactivities to control the timing and duration of combustion. In a preferred implementation, a lower-reactivity fuel charge is injected or otherwise introduced into the combustion chamber, preferably sufficiently early that it becomes at least substantially homogeneously dispersed within the chamber before a subsequent injection is made. One or more subsequent injections of higher-reactivity fuel charges are then made, and these preferably distribute the higher-reactivity matter within the lower-reactivity chamber space such that combustion begins in the higher-reactivity regions, and with the lower-reactivity regions following thereafter. By appropriately choosing the reactivities of the charges, their relative amounts, and their timing, combustion can be tailored to achieve optimal power output (and thus fuel efficiency), at controlled temperatures (and thus controlled NOx), and with controlled equivalence ratios (and thus controlled soot).

Owner:WISCONSIN ALUMNI RES FOUND

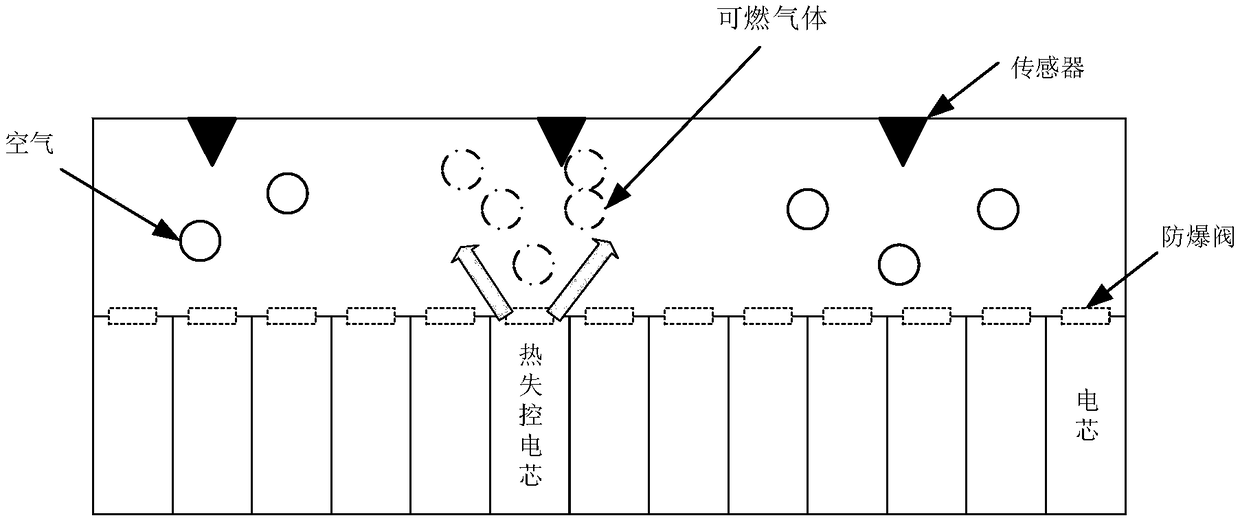

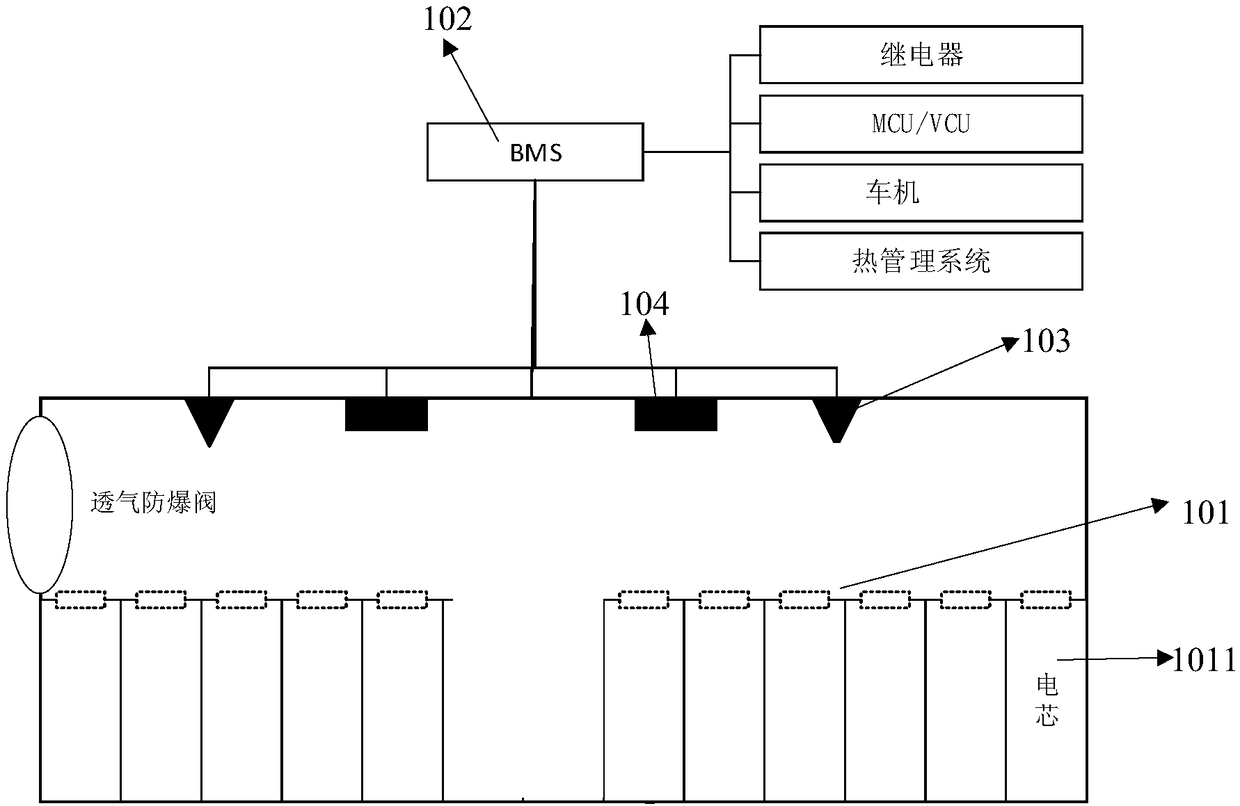

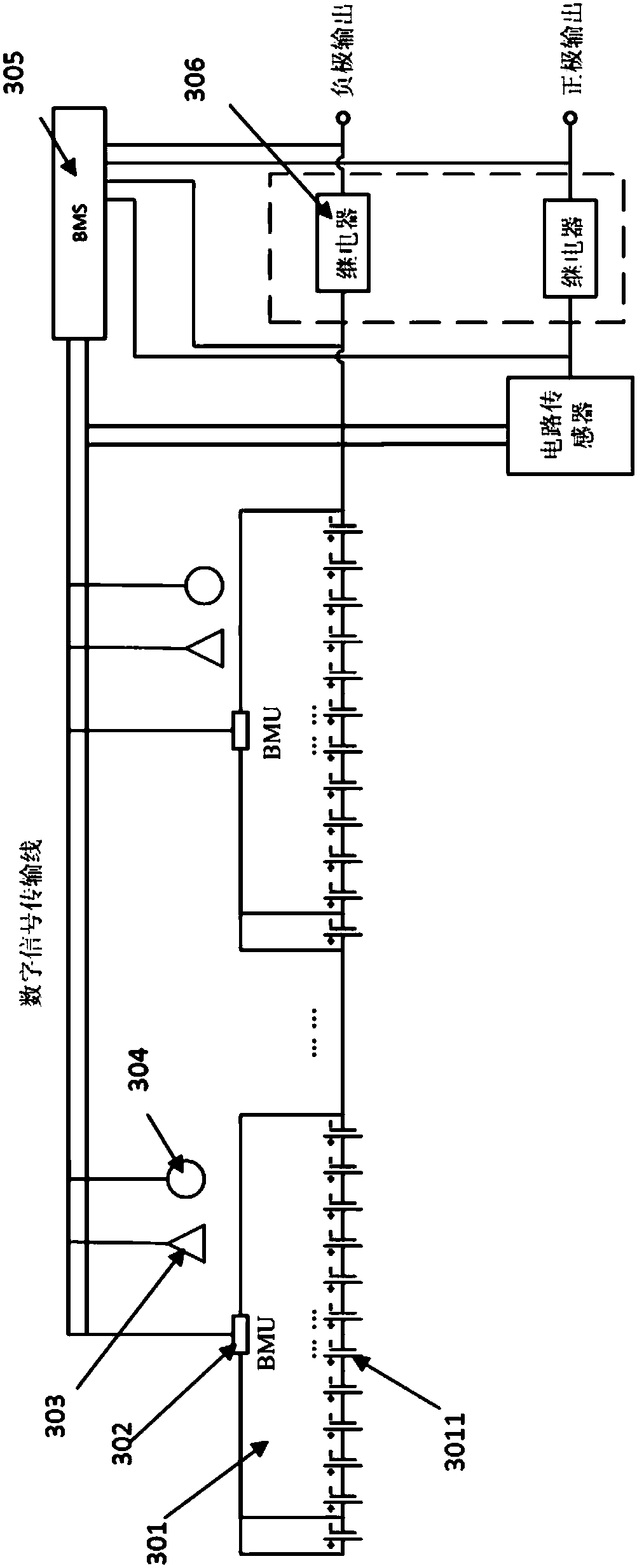

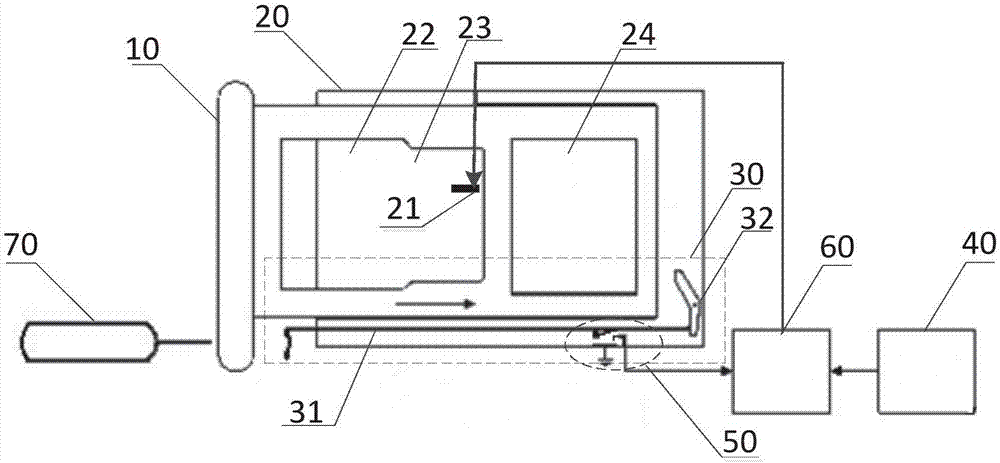

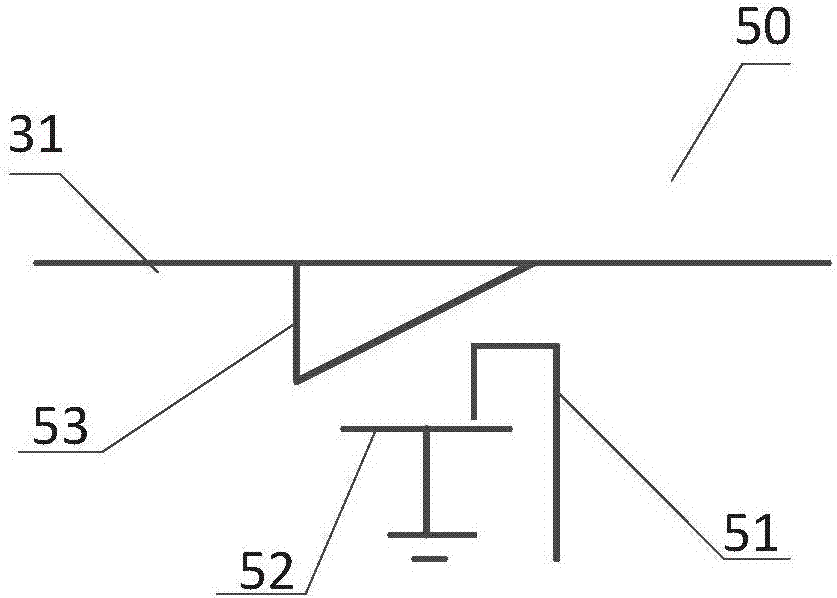

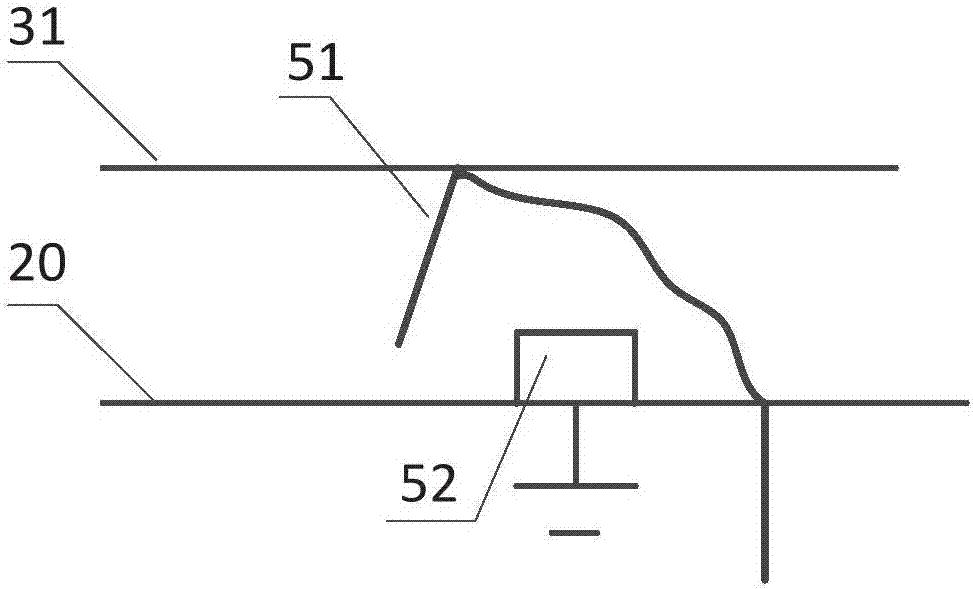

Fire extinguishing method of battery system and battery system

ActiveCN109316687AReduce damage hazardImprove securityElectrical testingCells structural combinationRisk levelCombustible gas

The invention discloses a fire extinguishing method of a battery system and the battery system. With adoption of the fire extinguishing method, the safety of the battery system can be improved. The battery system comprises a battery management system (BMS), a battery module, a gas sensor and a fire extinguishing device. BMS receives the concentration value of flammable and combustible gas collected by the gas sensor from the gas sensor, determines a target gas sensor with a security risk and the risk level of the target gas sensor according to the concentration value of the flammable and combustible gas, starts the fire extinguishing device corresponding to the target gas sensor when the risk level of the target gas sensor exceeds the first risk alarm value, and sprays fire extinguishing gas to the battery module corresponding to the target gas sensor through the fire extinguishing device. According to the fire extinguishing method, the gas sensor is adopted to monitor the flammable and combustible gas, fire is extinguished through the fire extinguishing gas, the early warning time can be prolonged, the best fire extinguishing opportunity can be grasped, and the combustion probability of a system is reduced to improve the safety of the battery system.

Owner:HUAWEI TECH CO LTD

Tubular cigarette device comprising cerium oxide

InactiveUS7624739B2Reduce the probability of burningMinimizing cigarette sidestream smokeTobacco treatmentCigar manufactureBurn cigaretteEffective length

A device for minimizing cigarette sidestream smoke and reducing free-burn rate of a burning cigarette is disclosed. The device comprises a non-combustible tubular element encasing an effective length of a tobacco charge of a cigarette located in the tubular element. The tubular element minimizes sidestream smoke emission from a burning tobacco charge and reduces free-burn rate of such burning tobacco charge to increase the number of puffs from the burning tobacco charge.

Owner:ROTHMANS

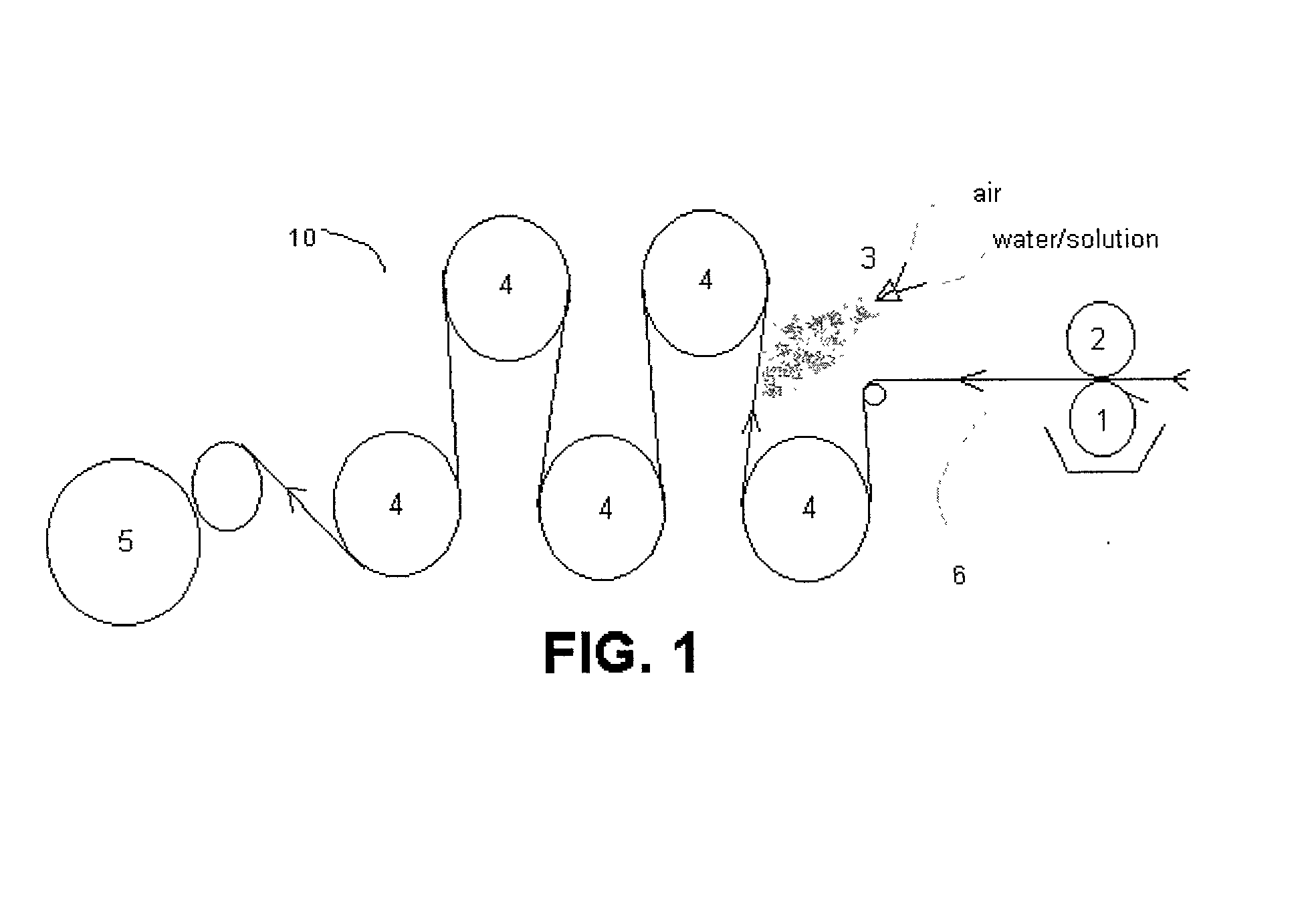

Novel materials and method of making same for low ignition propensity products

InactiveUS20020129824A1Reduce porositySufficient paper porosity closureNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceBurning chemicals

Novel materials for making low ignition propensity products are disclosed. Specifically, a treated cigarette paper for making low ignition propensity cigarettes are disclosed. The cigarette base paper containing a thermoplastic polymer aqueous suspension coated regions on a surface of the base paper so as to obtain coresta porosities of less than 15 is provided. This cigarette paper is further treated with a conditioning medium which is either water alone or water with a burning chemical such as an alkali metal containing organic salt either on the same surface bearing the thermoplastic polymer or on the opposite surface. The self-extinction characteristics of the cigarettes with the treated paper are improved. A method for making a cigarette paper for low ignition propensity cigarettes comprising a plurality of regions of a thermoplastic polymer aqueous suspension printed on to a surface of a base paper is also provided.

Owner:RF & SON

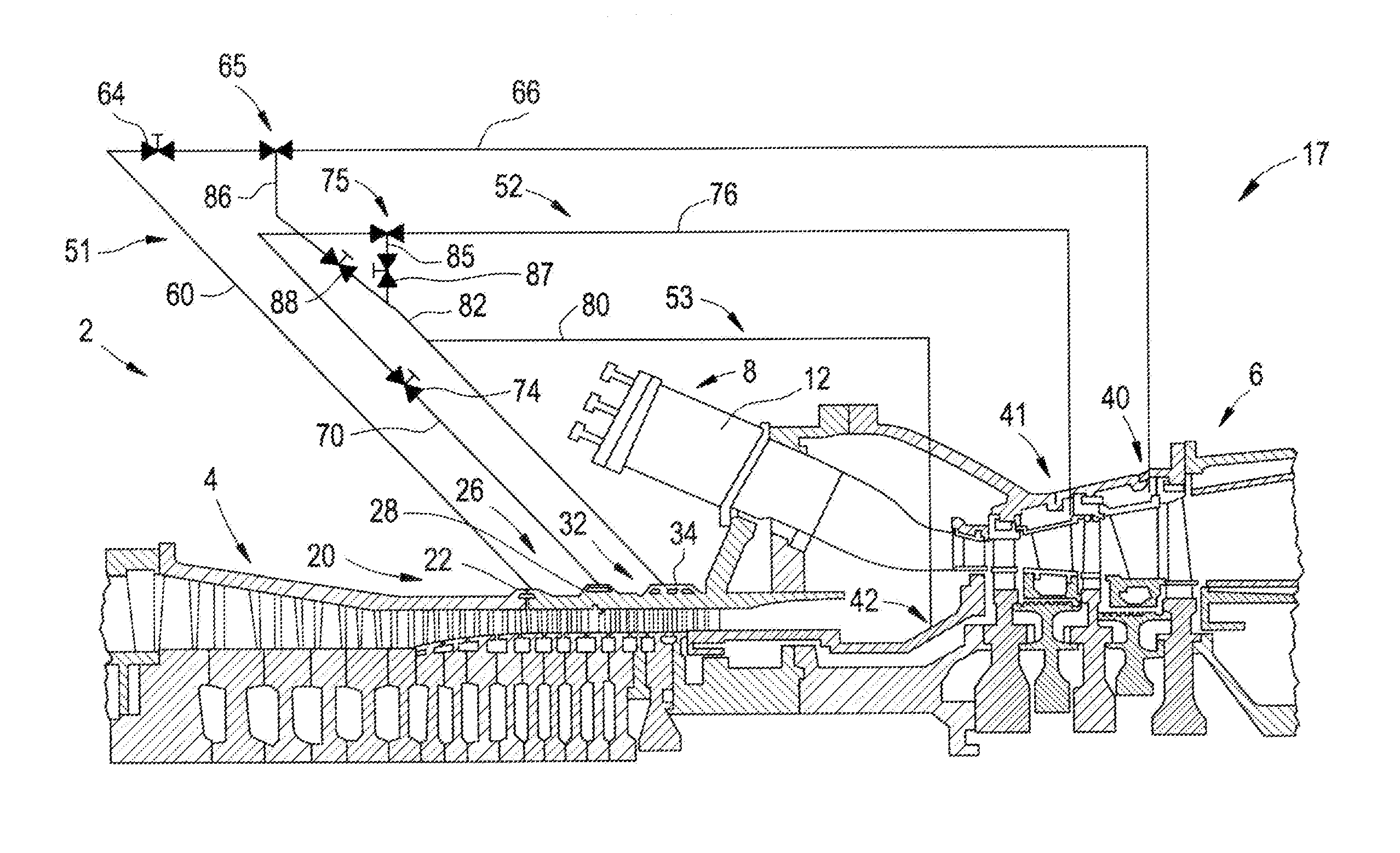

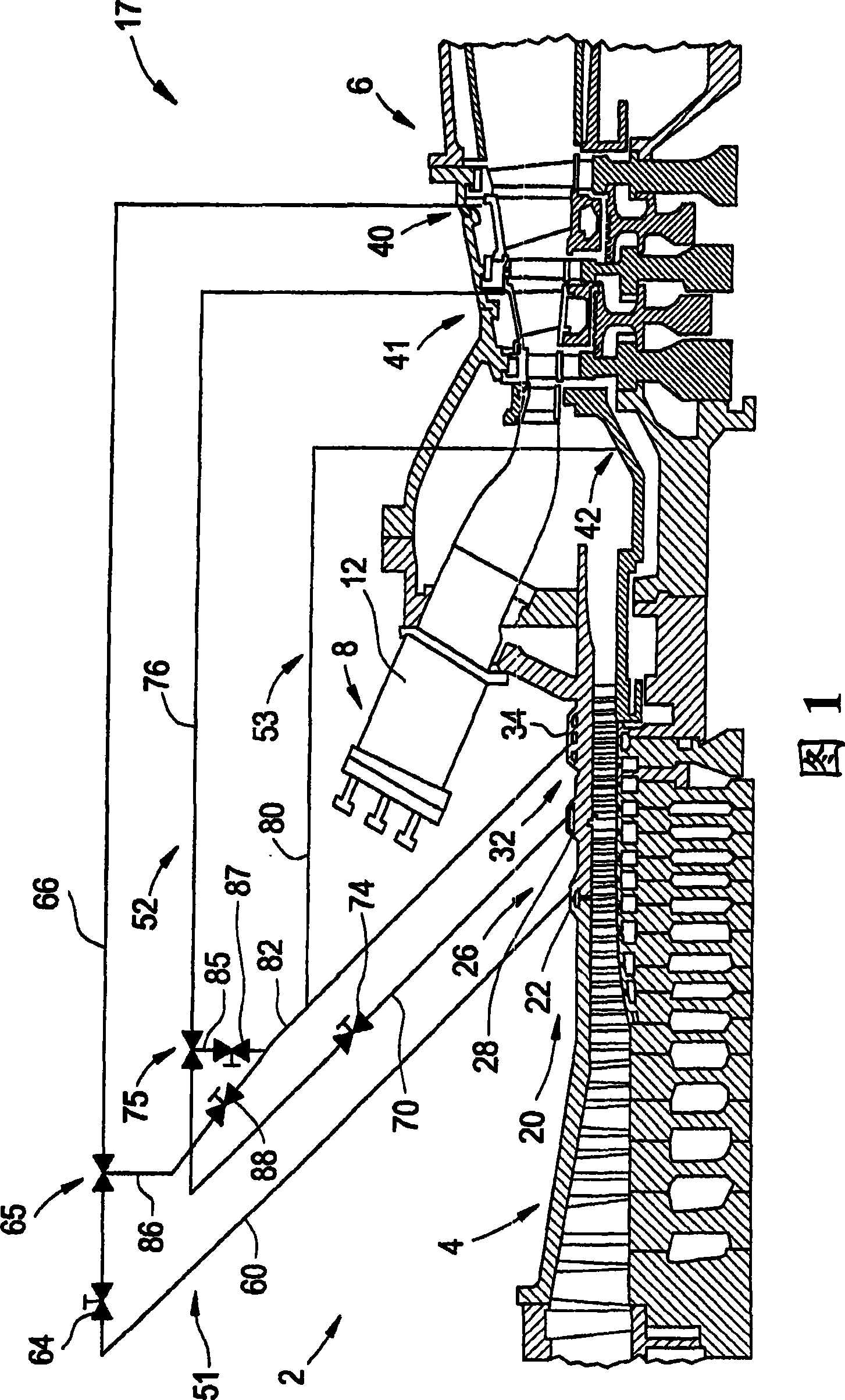

System for delivering air from a multi-stage compressor to a turbine portion of a gas turbine engine

ActiveUS8057157B2Improve performanceLow turn downPropellersWind motor controlGas compressorHigh pressure

A system for providing air from a multi-stage to a turbine includes a turbine having a high pressure input port and a low pressure input port. The system also includes a compressor having at least one high pressure extraction air output and at least one low pressure extraction air output. A valve is fluidly connected to the at least one high pressure extraction air output, at least one low pressure extraction air output and low pressure input port of the turbine. The valve is selectively operated to fluidly connect the at least one low pressure extraction air output with the low pressure input port during normal operating conditions and fluidly connect the at least one high pressure extraction air output and the low pressure input port during a turn down condition or below design temperature operation to enhance turbine engine performance.

Owner:GENERAL ELECTRIC CO

Engine combustion control via fuel reactivity stratification

ActiveUS8616177B2High and low reactivityConvenience to workElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

A compression ignition engine uses two or more fuel charges having two or more reactivities to control the timing and duration of combustion. In a preferred implementation, a lower-reactivity fuel charge is injected or otherwise introduced into the combustion chamber, preferably sufficiently early that it becomes at least substantially homogeneously dispersed within the chamber before a subsequent injection is made. One or more subsequent injections of higher-reactivity fuel charges are then made, and these preferably distribute the higher-reactivity matter within the lower-reactivity chamber space such that combustion begins in the higher-reactivity regions, and with the lower-reactivity regions following thereafter. By appropriately choosing the reactivities of the charges, their relative amounts, and their timing, combustion can be tailored to achieve optimal power output (and thus fuel efficiency), at controlled temperatures (and thus controlled NOx), and with controlled equivalence ratios (and thus controlled soot).

Owner:WISCONSIN ALUMNI RES FOUND

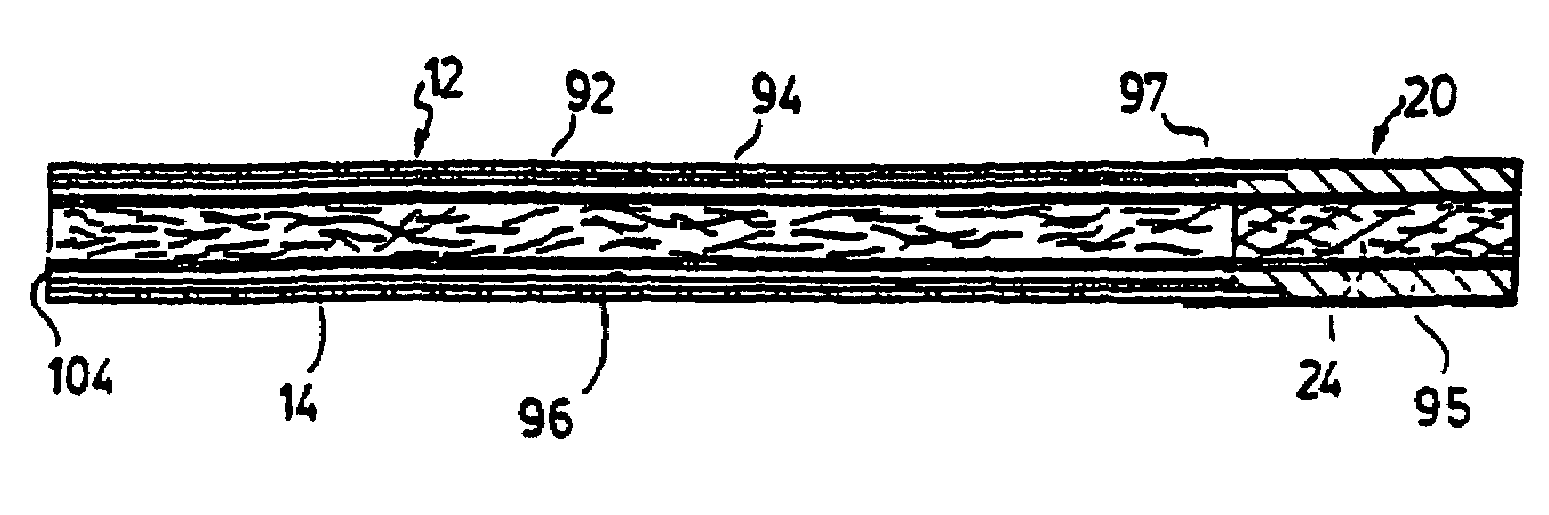

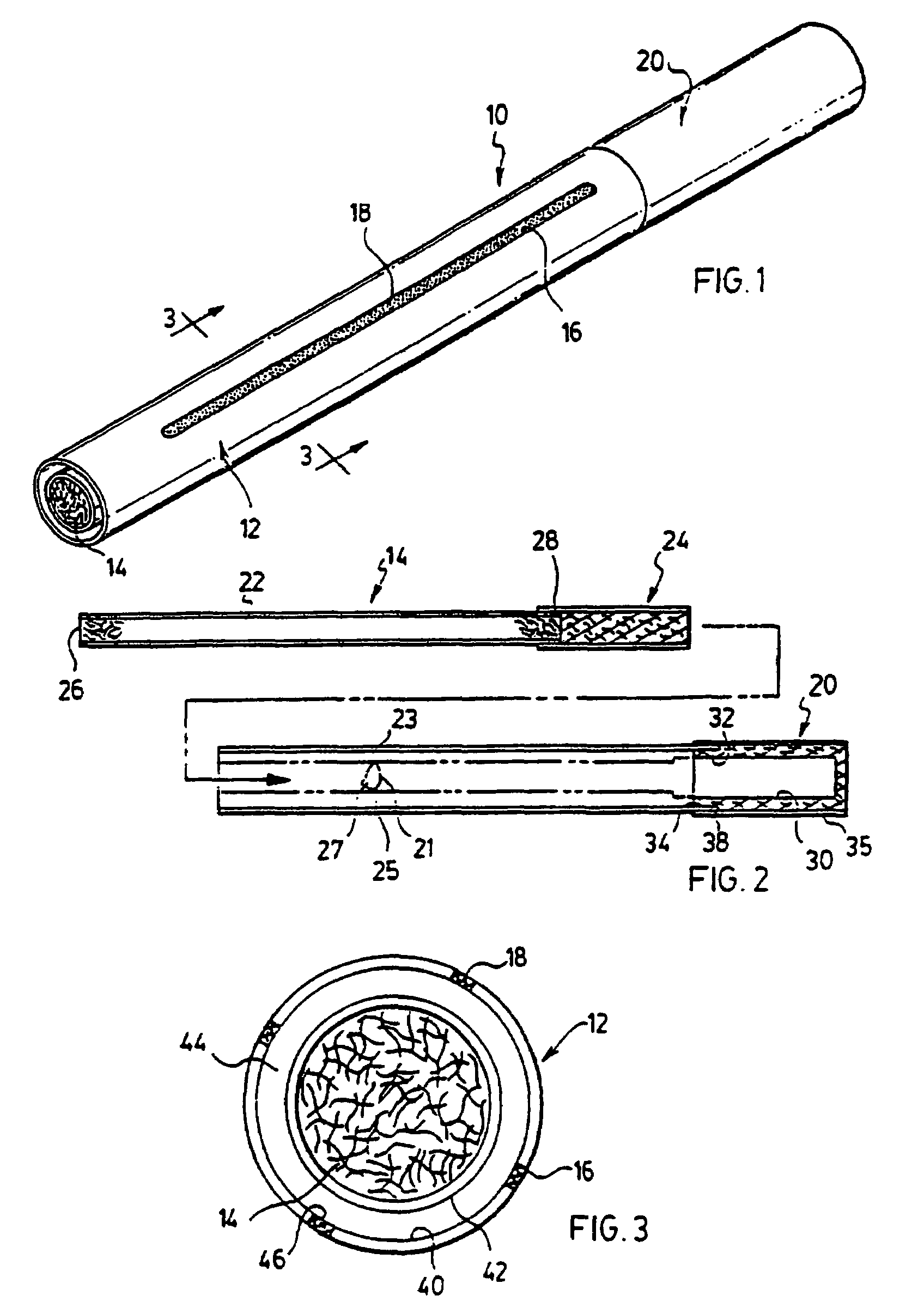

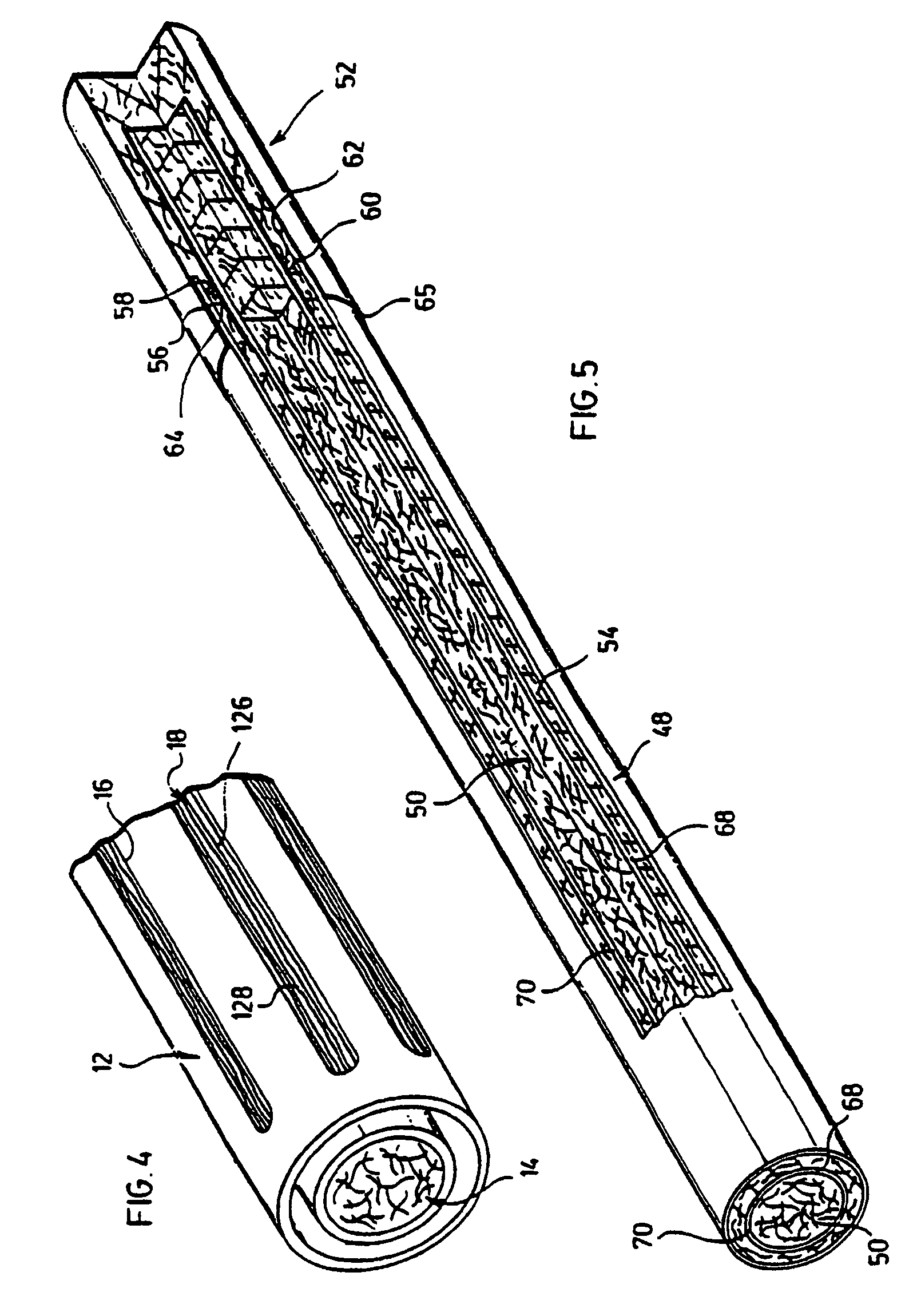

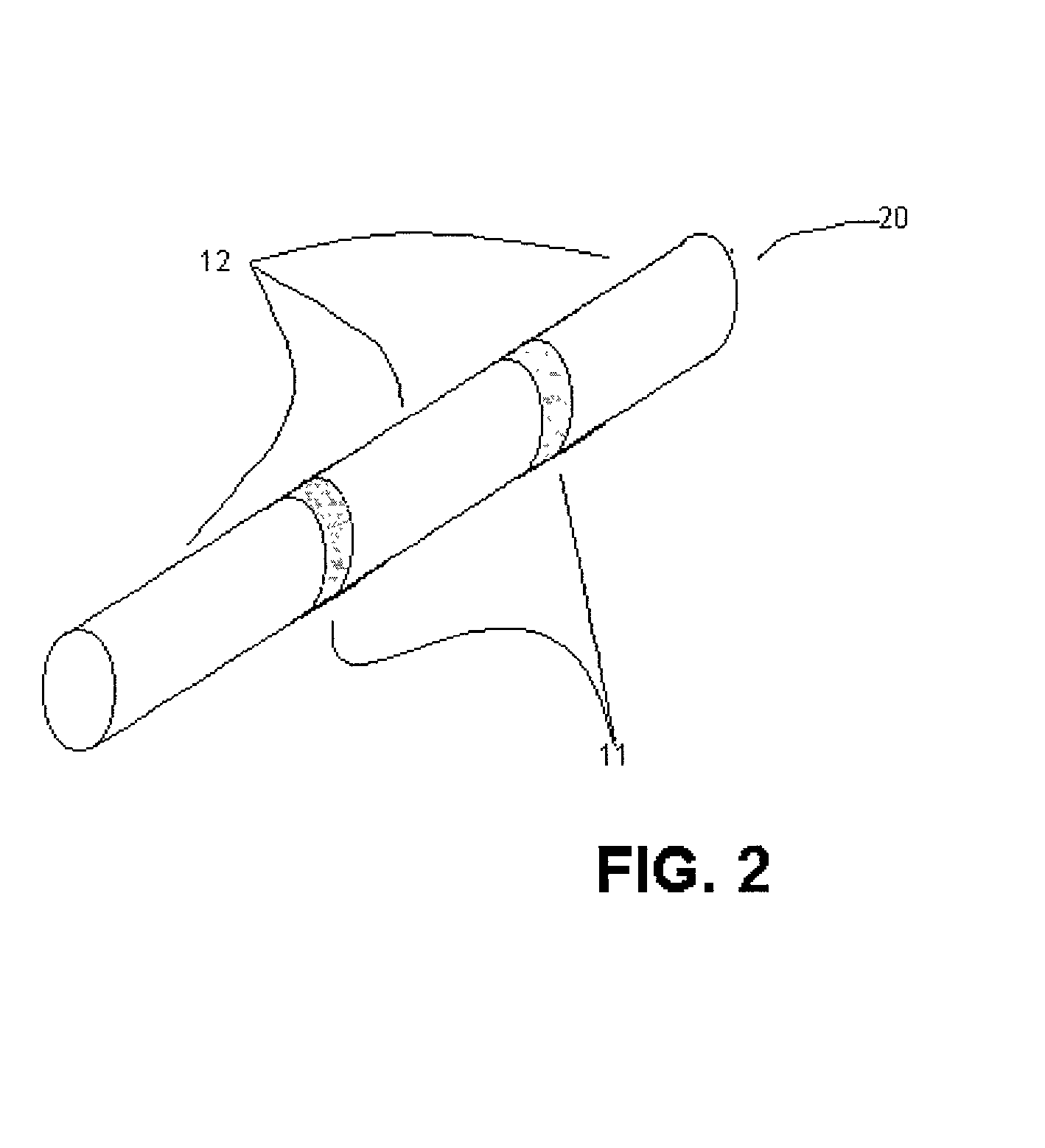

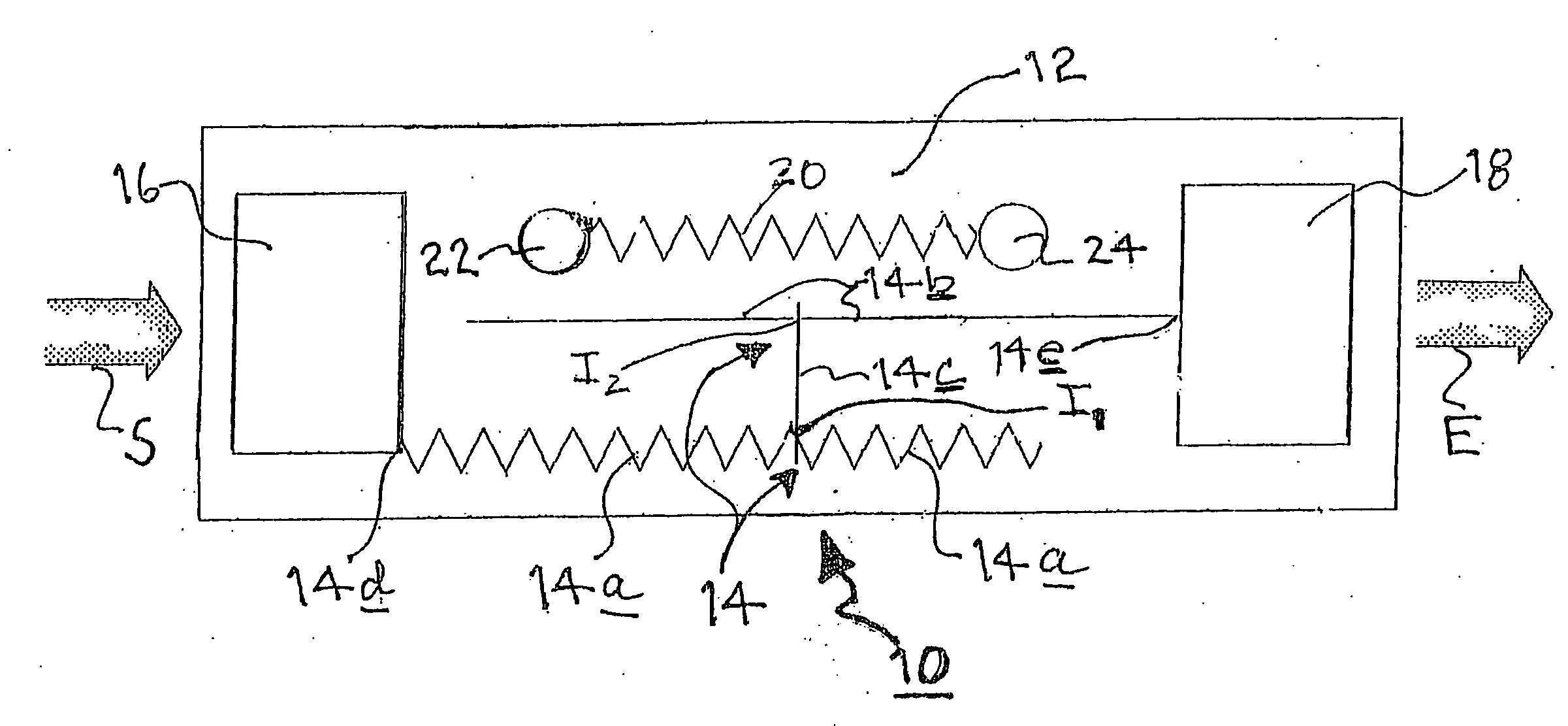

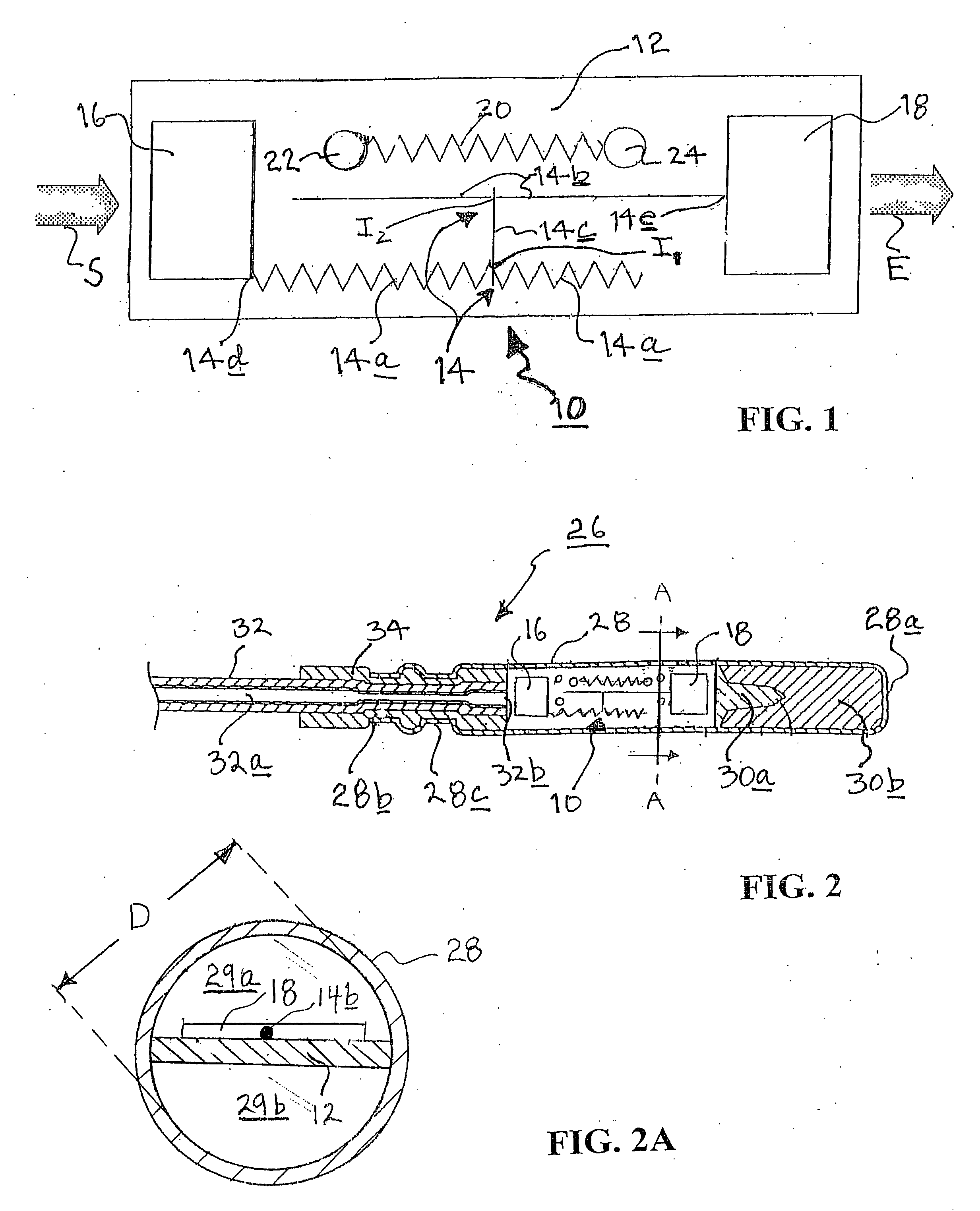

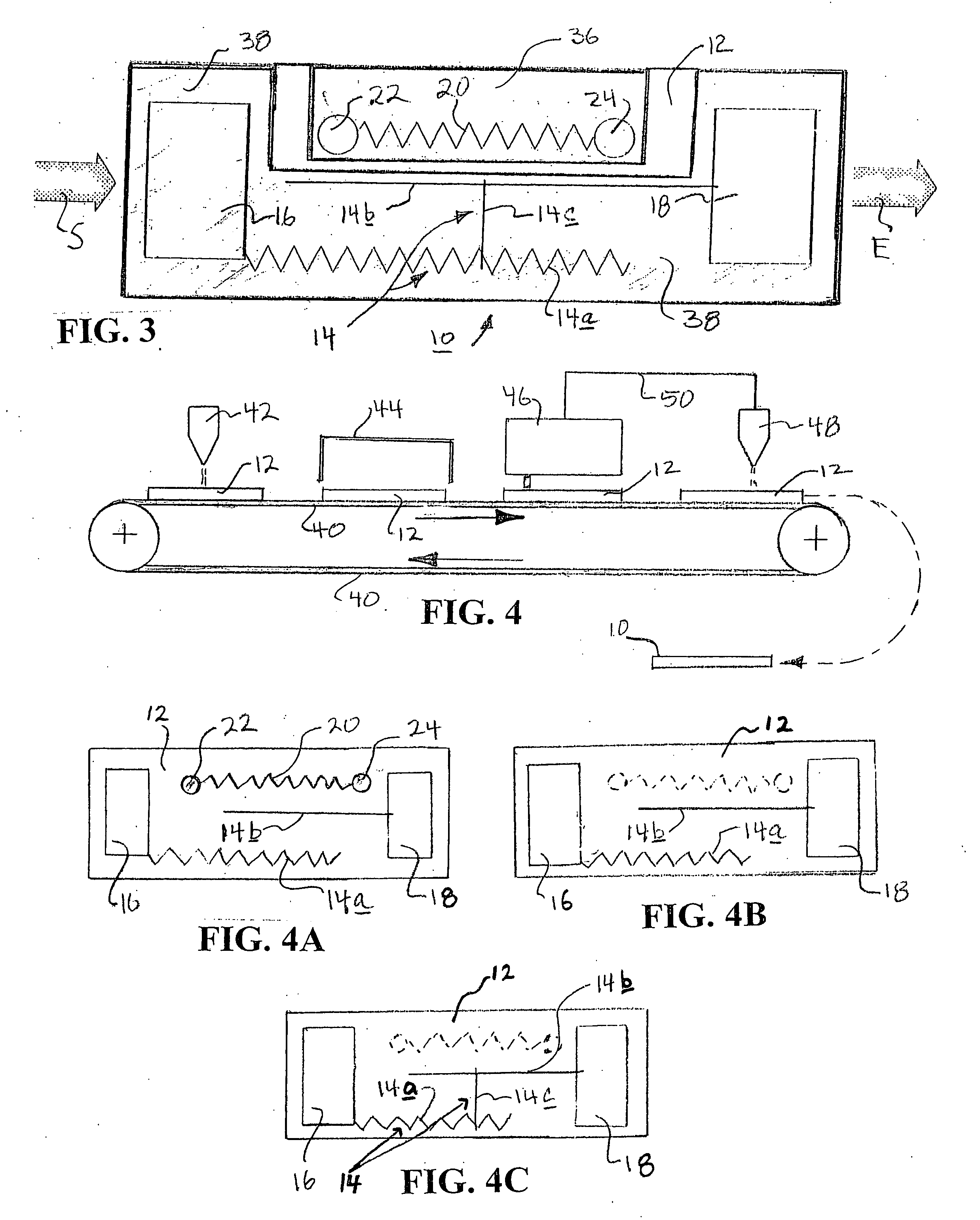

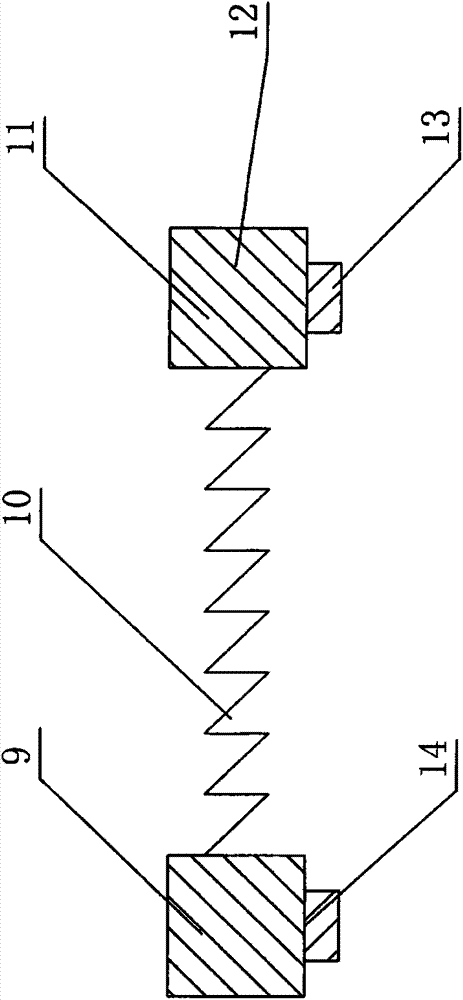

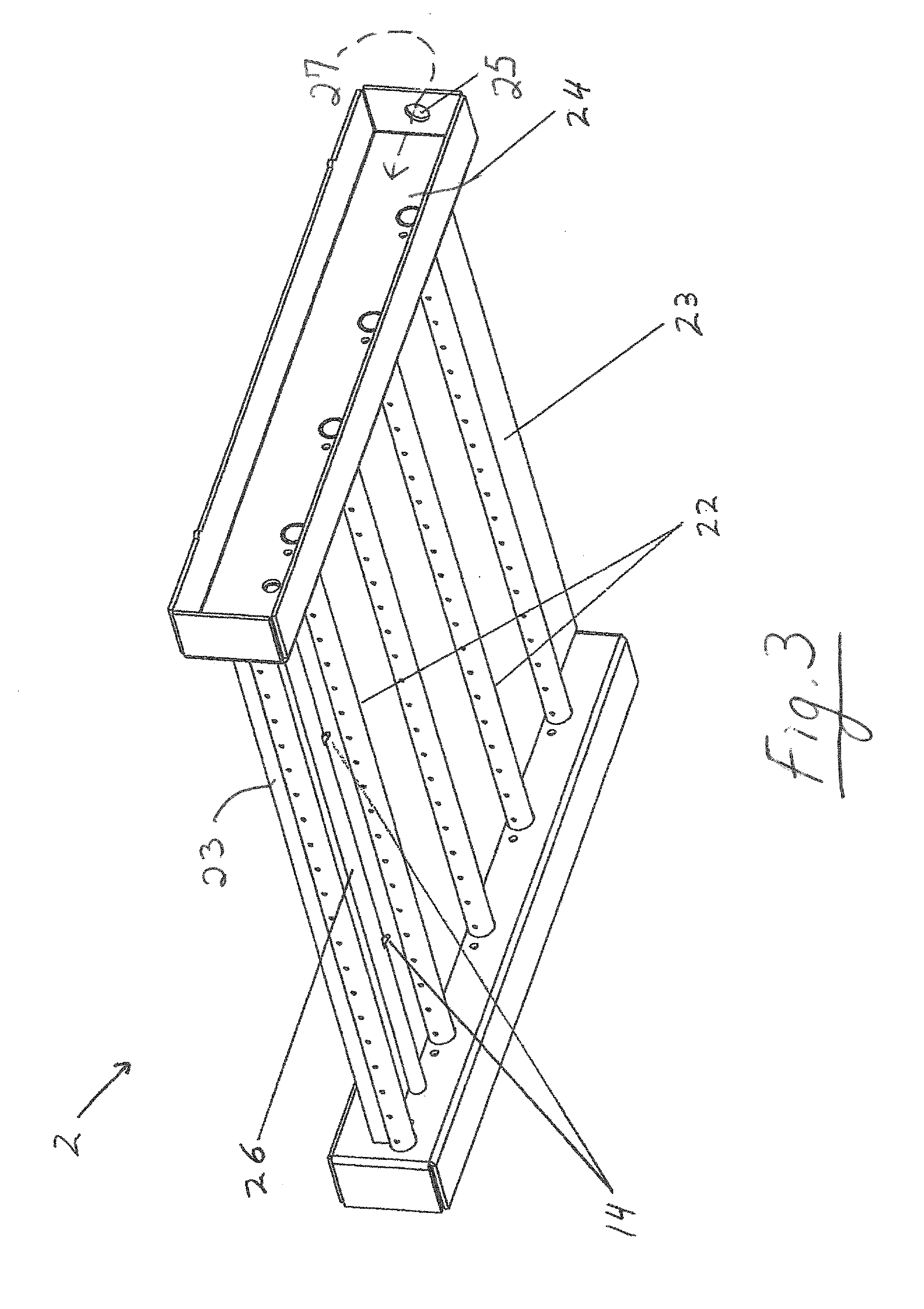

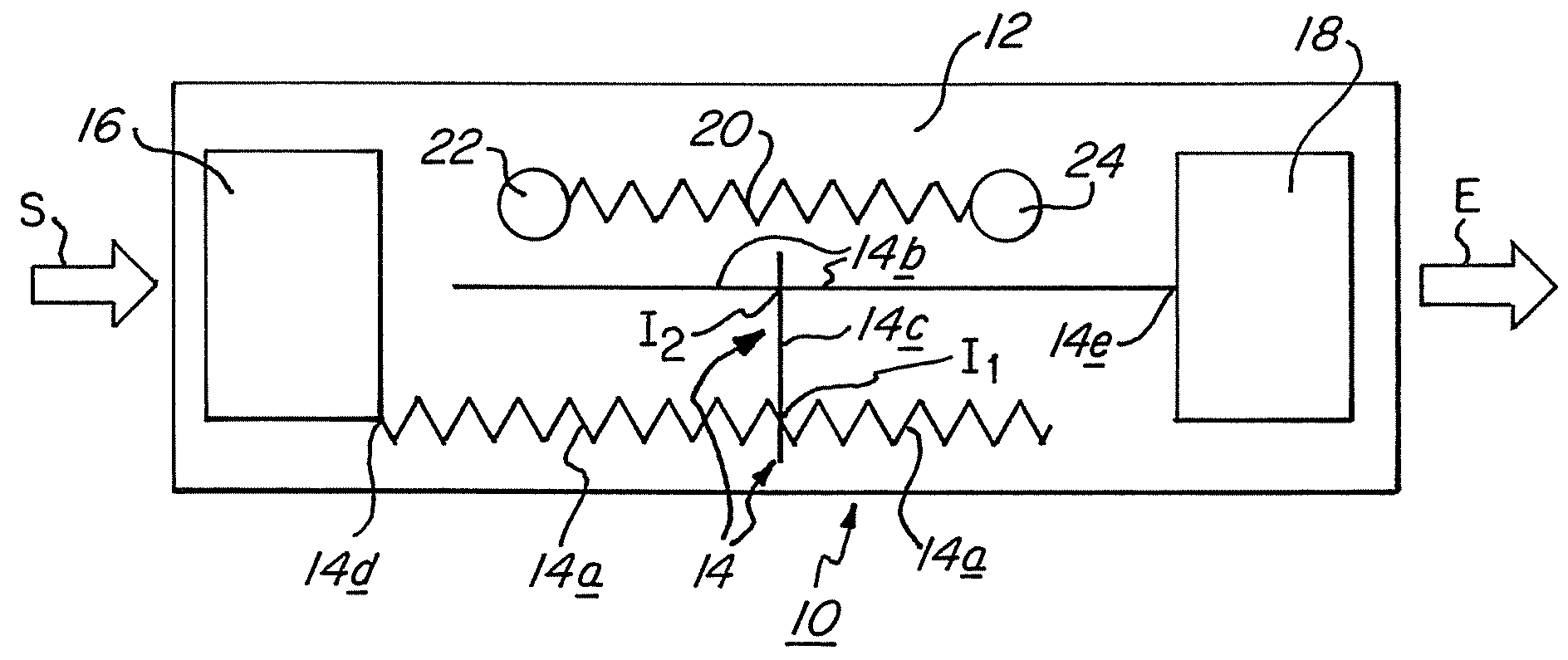

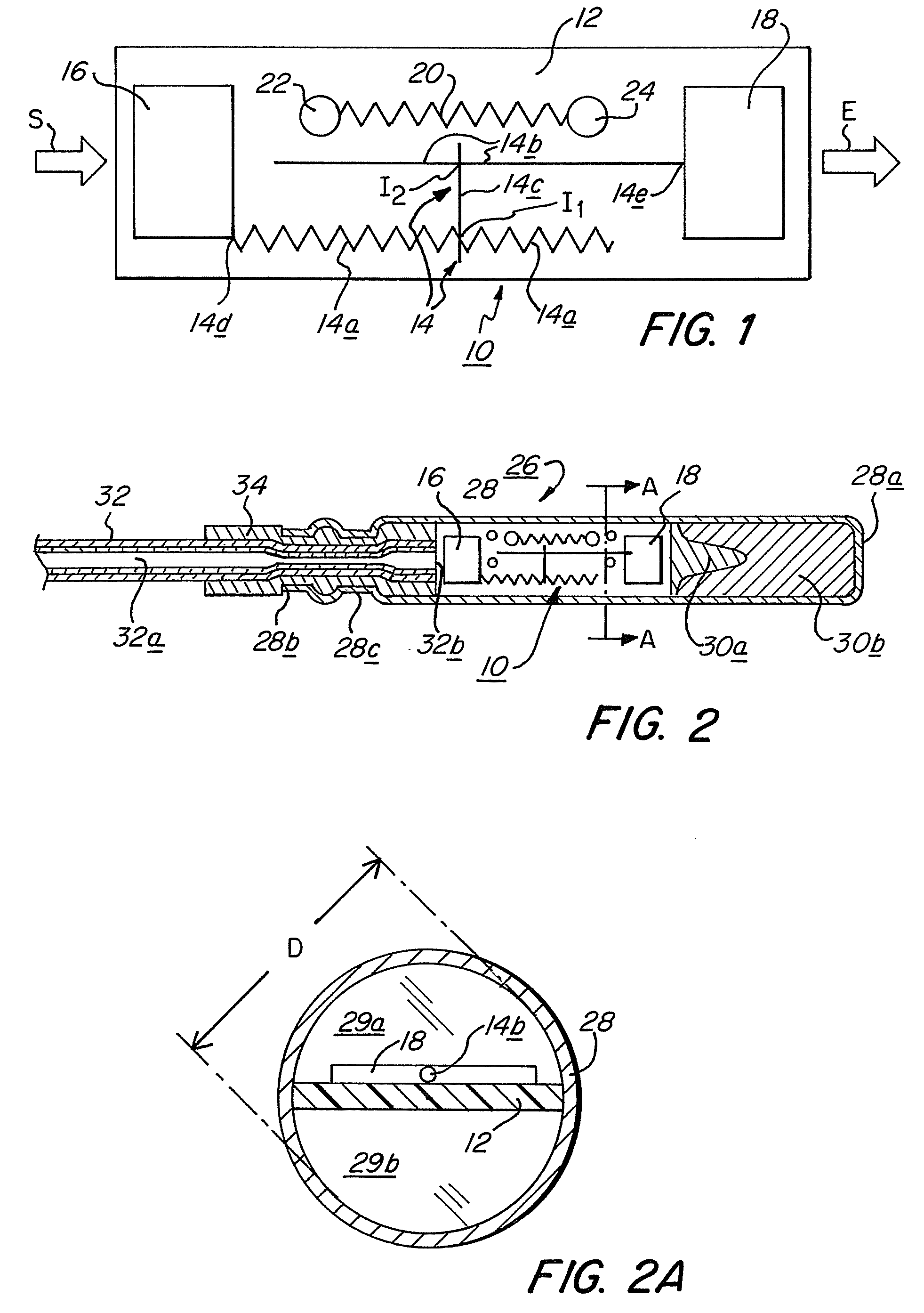

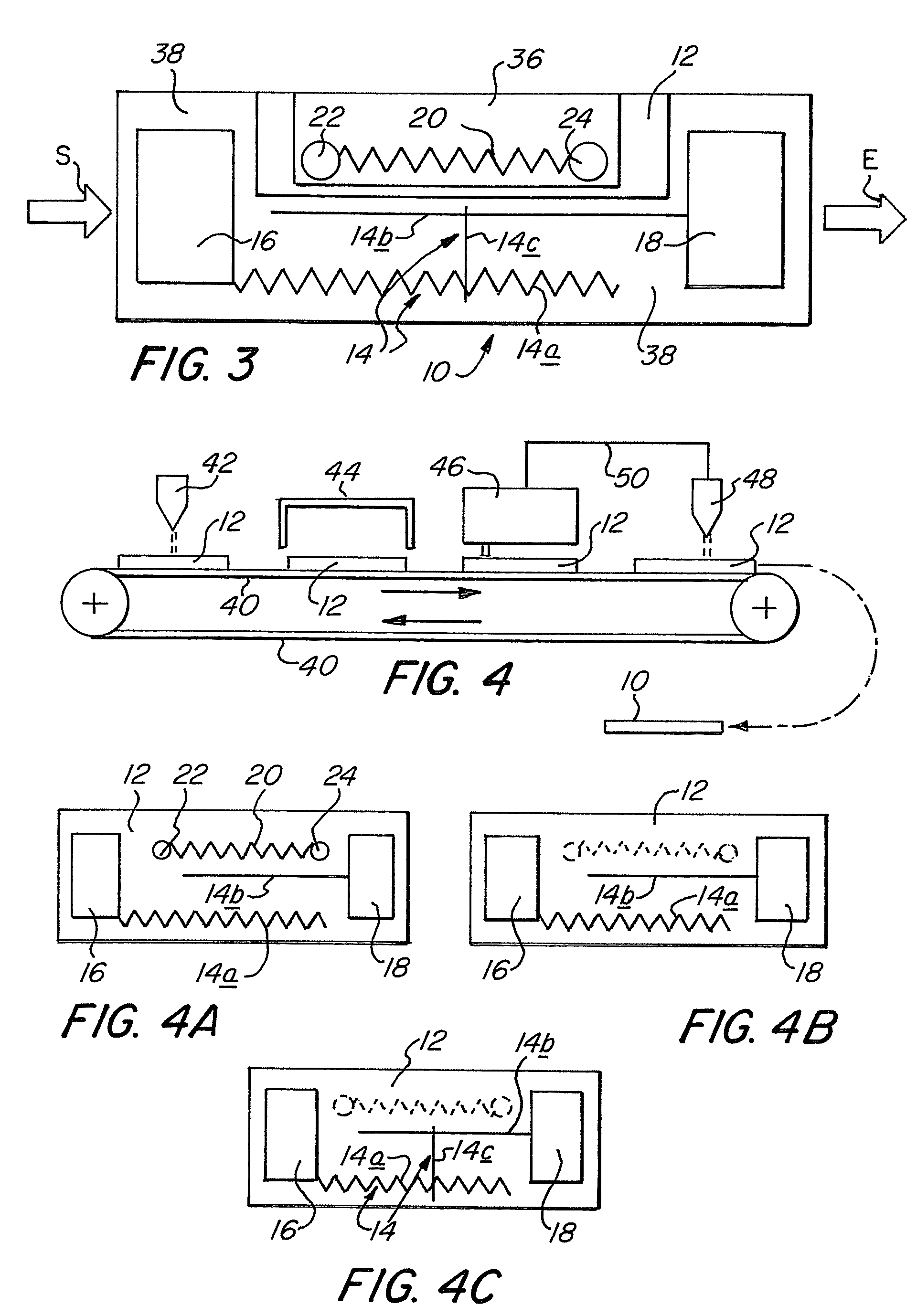

Delay units and methods of making the same

InactiveUS20060236887A1Increase and decrease burn rateReduce burning rateBlasting cartridgesImpact fuzesDelayed periodsEffective length

A delay unit (10) comprises a timing strip (14) and, optionally, a calibration strip (20) deposited on a substrate (12). The timing and calibration strips comprise energetic materials which optionally may comprise particles of nanosize materials, e.g., a fuel and an oxidizer, optionally applied as separate layers. A method of making the delay units comprises depositing onto a substrate (12) a timing strip (14) having a starting point (14d) and a discharge point (14e) and depositing onto the same or another substrate a calibration strip (20). Timing strip (14) and calibration strip (20) are of identical composition and are otherwise configured, e.g., thickness of the strips, to have identical burn rates. The calibration strip (20) is ignited and its burn rate is ascertained. The timing strip (14) is adjusted by an adjustment structure to attain a desired delay period, preferably on the basis that the burn rate of the timing strip (14) is substantially identical to that of the calibration strip (20) and ascertaining the burn rate of the calibration strip. The adjustment may be attained by one or more of providing the timing strip with jump gaps (164), an accelerant or retardant (166a, 166b), completing the timing strip with a bridging strip (14c), or establishing a selected effective length of the timing strip by positioning one or both of a pick-up charge (16) and relay charge (18) over a portion of the timing strip.

Owner:DYNO NOBEL INC

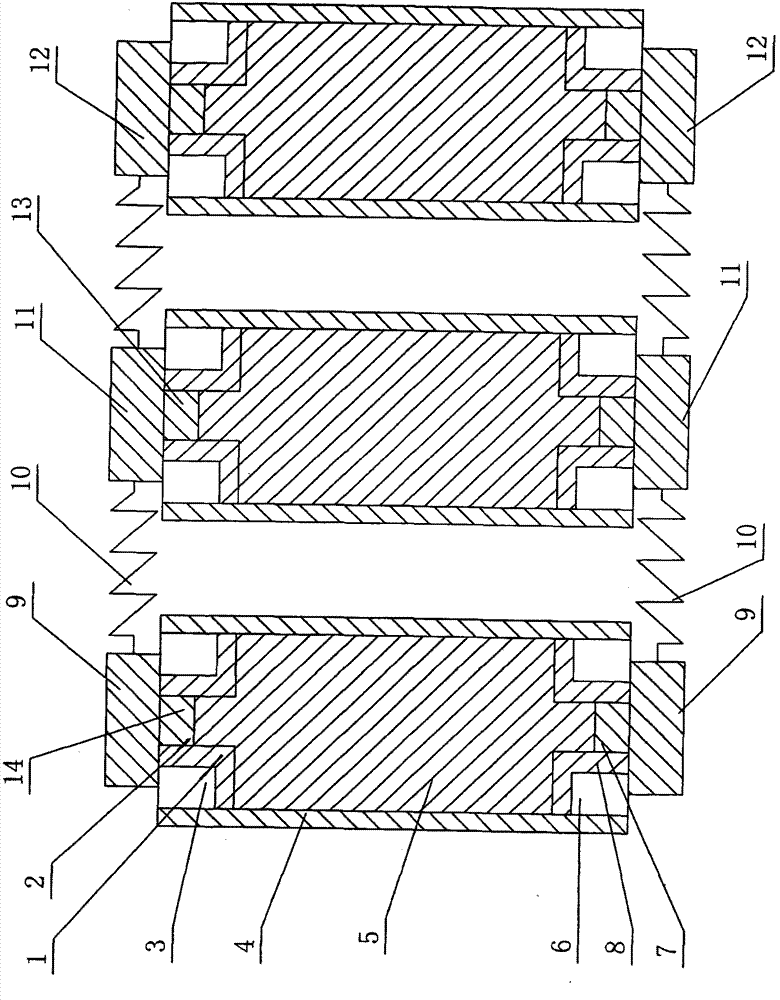

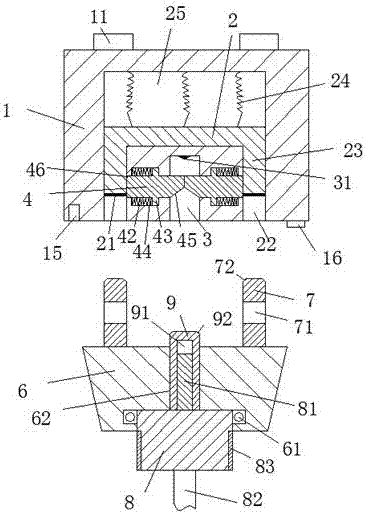

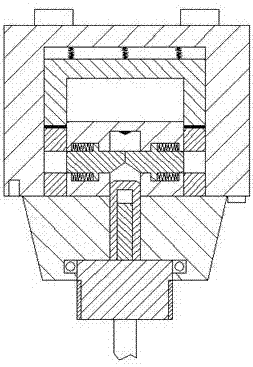

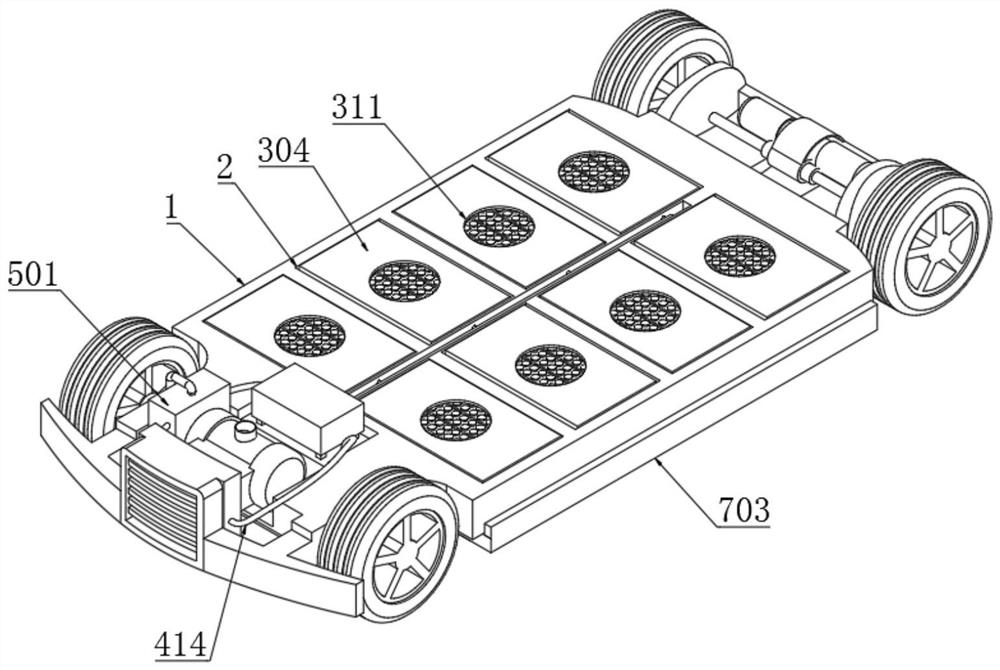

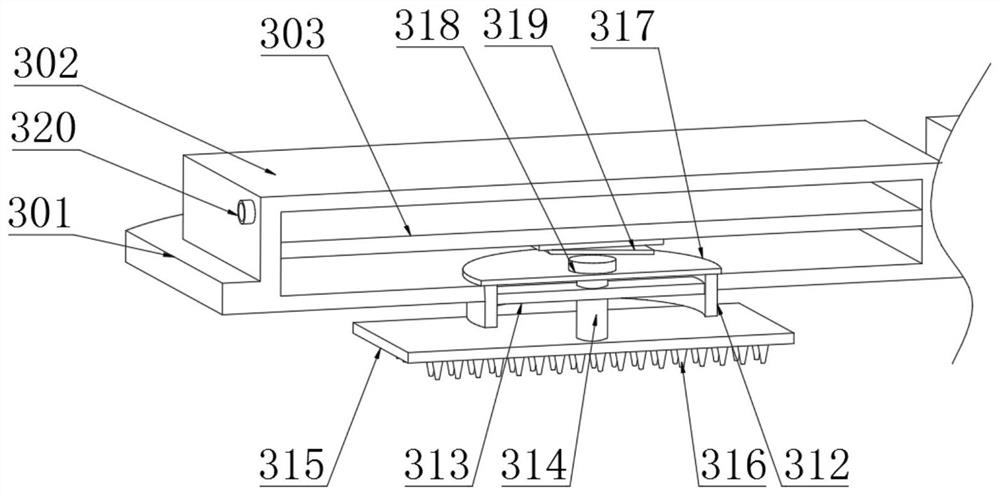

Battery pack power supply system for reducing burning probability of battery packs of electric vehicles

ActiveCN104723855AReduce the probability of burningAvoid harmElectric propulsion mountingElectric/fluid circuitPower switchingElectric vehicle

Disclosed is a battery pack power supply system for reducing burning probability of battery packs of electric vehicles. Two battery pack boxes of the system can be automatically replaced, power source surge protectors of the battery pack boxes are connected with the battery pack boxes and capable of discharging leak current on the battery pack boxes, and power cords of the power source surge protectors are serially or parallelly connected with an input current power cord and an output current power cord in a filtering manner, so as to prevent burning of the battery packs caused by high-current attack during short circuit and charging. When the first battery pack's temperature still rises after up to 150 degrees Centigrade, a switch of the power source can be pressed to separate a front bracket of an electric jack from the battery pack boxes, and the first battery pack box is abandoned, similarly when the second battery box' temperature is out of control, temperature of the two battery packs is out of control and the two battery pack boxes can be abandoned and the electric vehicles can be pulled over nearby by means of freewheeling.

Owner:岳秀兰

Catalyst in oxychlorination reaction as well as its preparation method and application

InactiveCN1446627AIncrease catalyst loadingHigh selectivityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsDichloroethaneOxychlorination

A catalyst for oxychlorination reaction is prepared from Cu-contained alumina microspheres, RE metal chosen from La, Nd, Ce, Pr and Y, and at least one alkali metal through preparing the Cu-containedalumina microspheres and adding active components by impregnation method. Its advantages are high conversion rate of hydrogen chloride (99.75%), high purity of dichloroethane (99.6%), high output rate of dichloroethane (22 g / hr), high selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Control system for monitoring and adjusting combustion performance in a cordwood-fired heating appliance

InactiveUS20140311477A1Easy to operateImprove featuresCombustion-air/flue-gas circulation for stovesWater heatersThermostatActuator

A system including temperature measuring devices, a controller, and an actuator, maintains a desired gas temperature range in the secondary combustor by proportionally making adjustments to the primary air orifice or other primary air valve of a cordwood burning appliance. Heat output of the appliance is directly related to the temperature of the gases in the secondary combustor, and sufficient engagement of the second combustor during off-gassing of volatiles from the wood will control emissions from the appliance. The operator can select a desired room temperature via the thermostat and the controller will use different secondary gas temperature target ranges in order to meet the desired room temperature as commanded by the thermostat throughout the burn event. The controller also controls the start-up phase of combustion and charcoal phase of combustion.

Owner:DNR ENG LLC A WASHINGTON STATE LIMITED LIABILITY

System for delivering air from a multi-stage compressor to a turbine portion of a gas turbine engine

ActiveCN101418724ANot cost effectiveHigh outputGas turbine plantsEngine componentsGas compressorHigh pressure

A system for providing air from a multi-stage to a turbine includes a turbine having a high pressure input port and a low pressure input port. The system also includes a compressor having at least one high pressure extraction air output and at least one low pressure extraction air output. A valve is fluidly connected to the at least one high pressure extraction air output, at least one low pressure extraction air output and low pressure input port of the turbine. The valve is selectively operated to fluidly connect the at least one low pressure extraction air output with the low pressure input port during normal operating conditions and fluidly connect the at least one high pressure extraction air output and the low pressure input port during a turn down condition or below design temperature operation to enhance turbine engine performance.

Owner:GENERAL ELECTRIC TECH GMBH

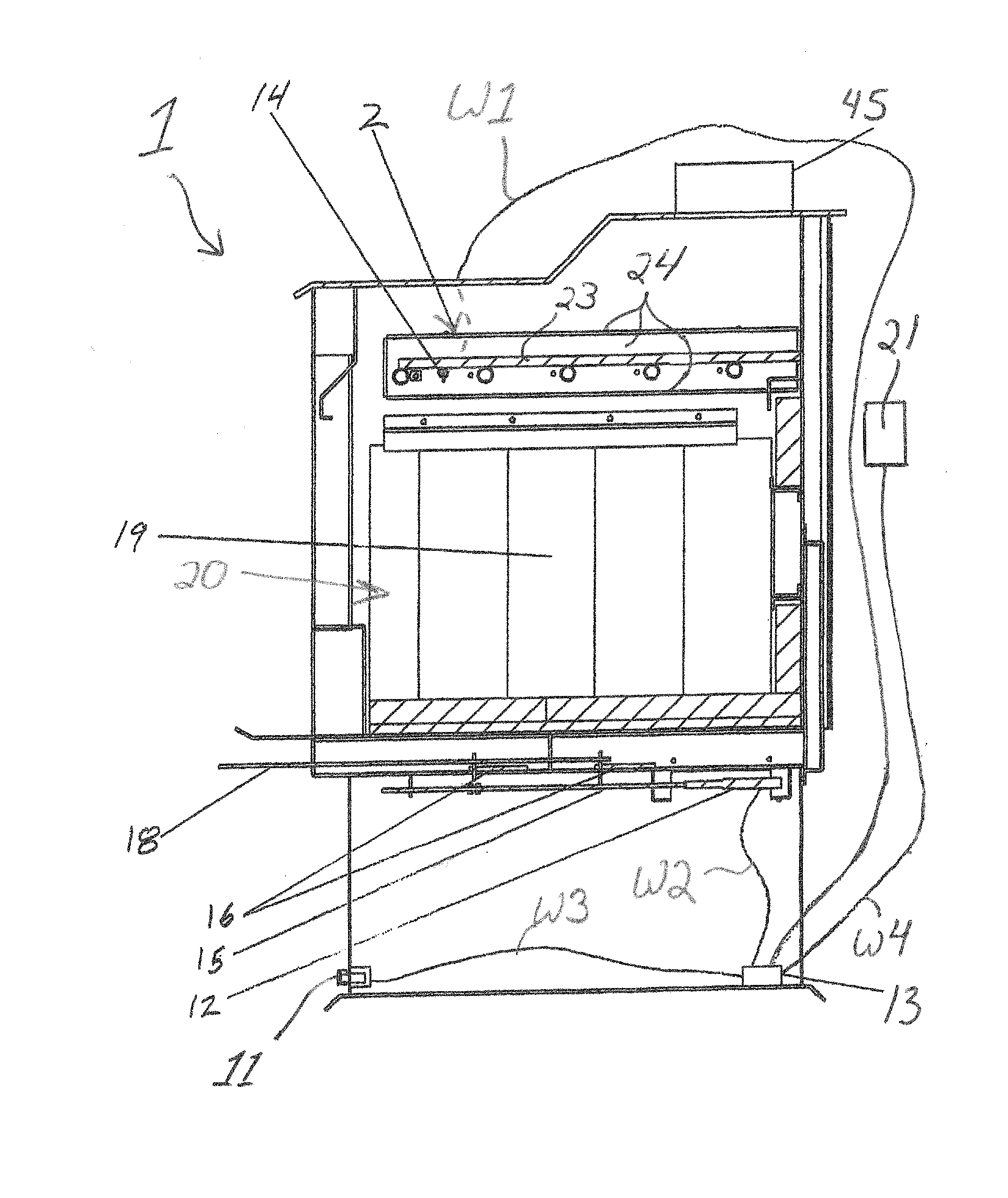

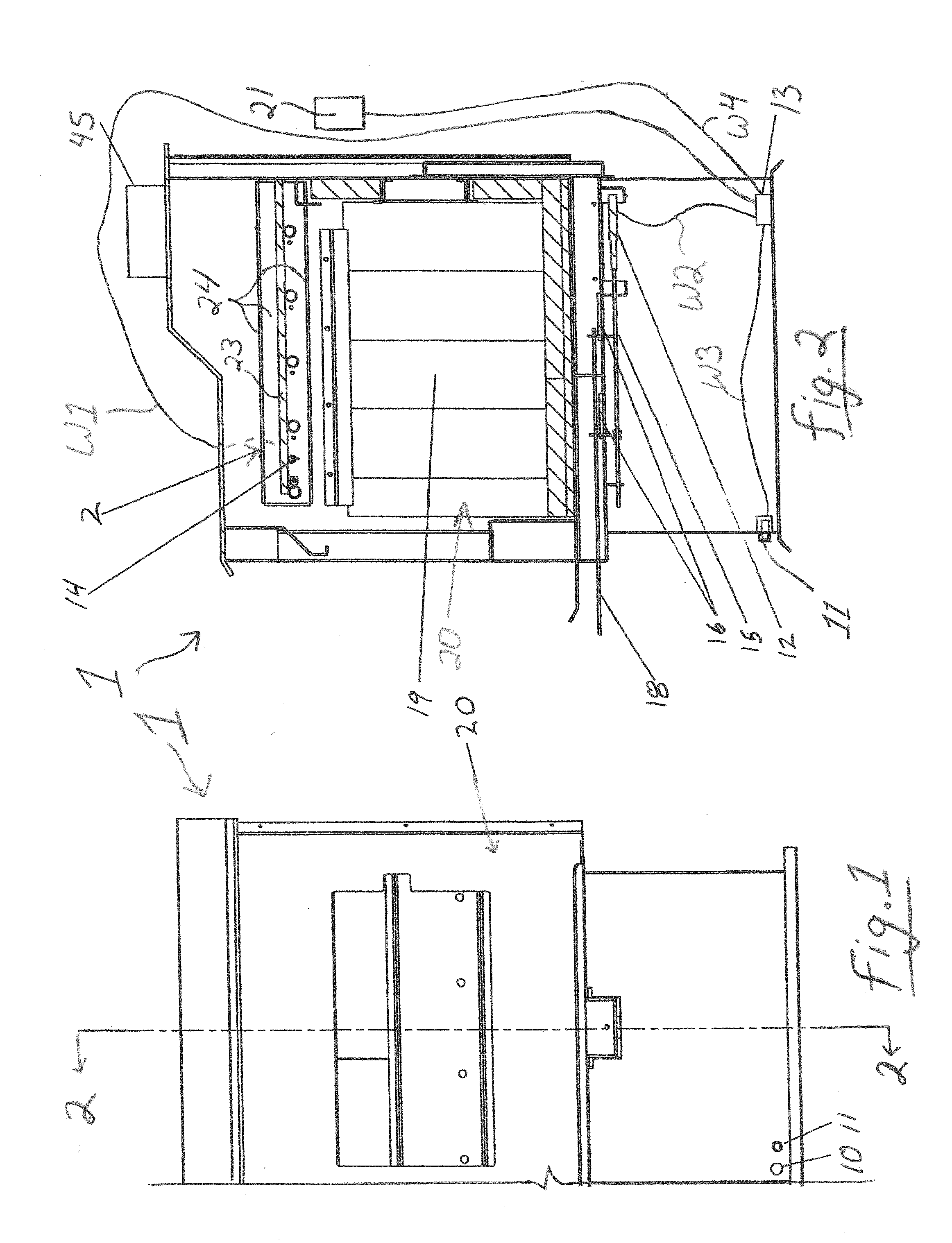

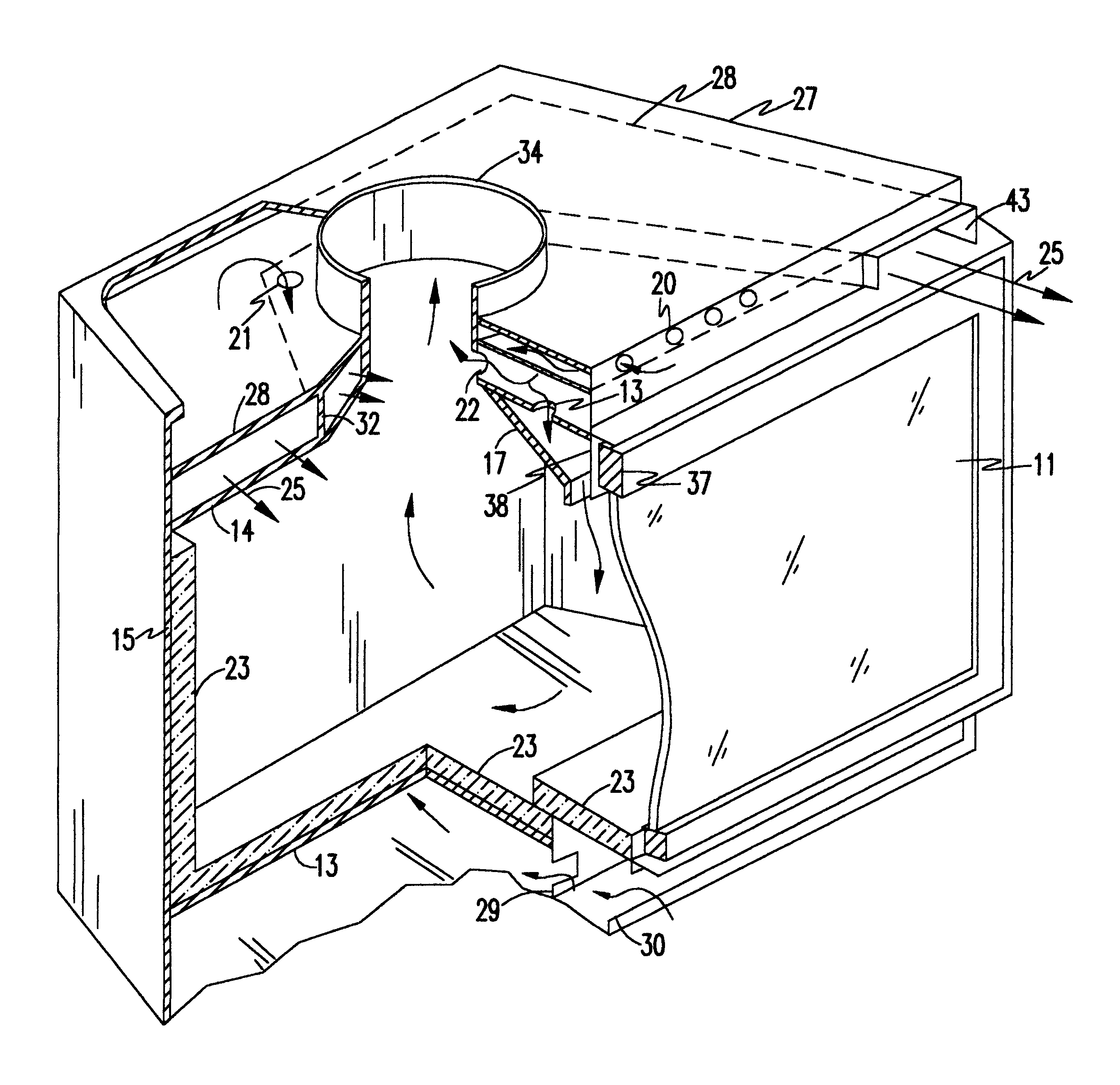

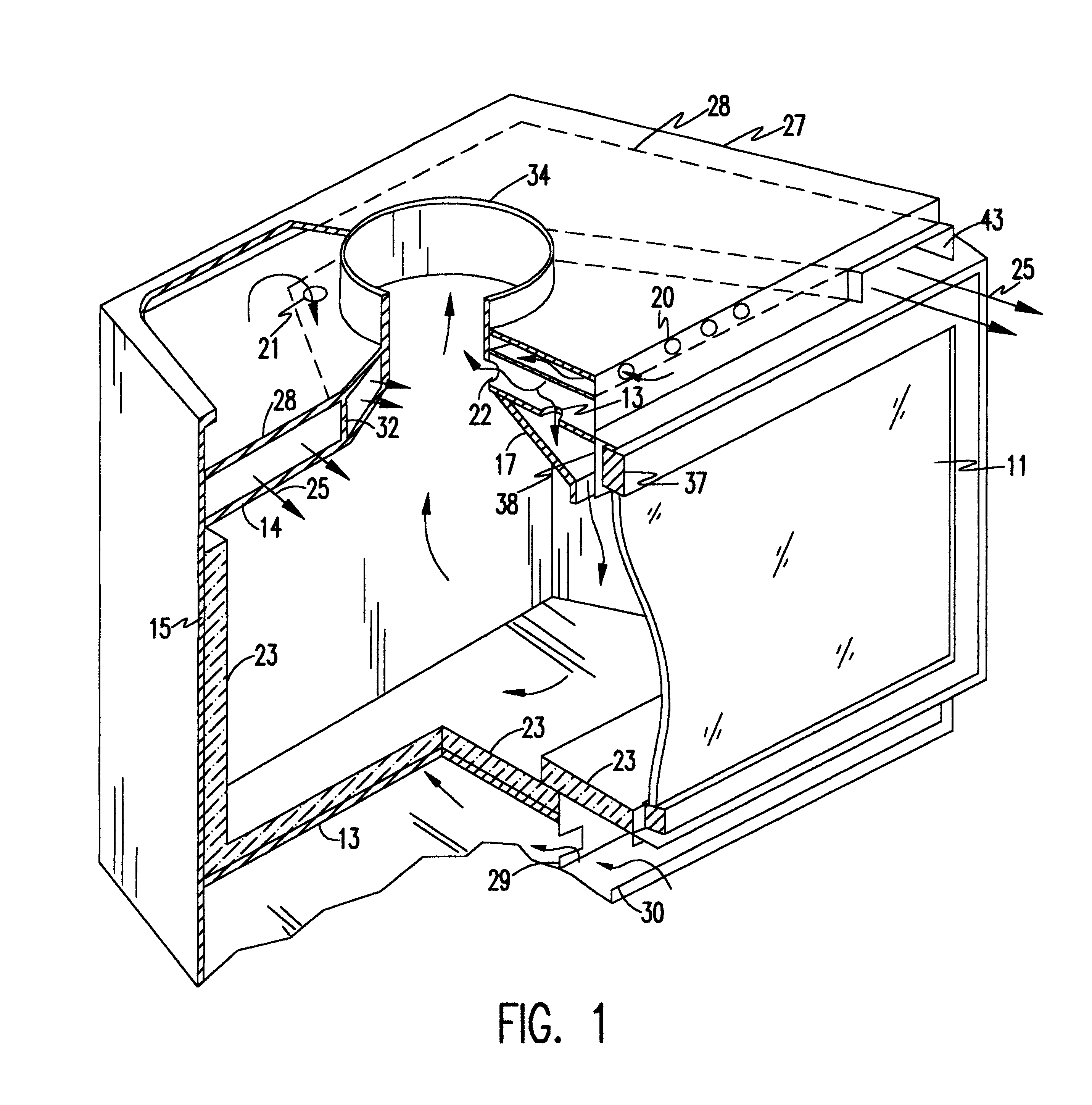

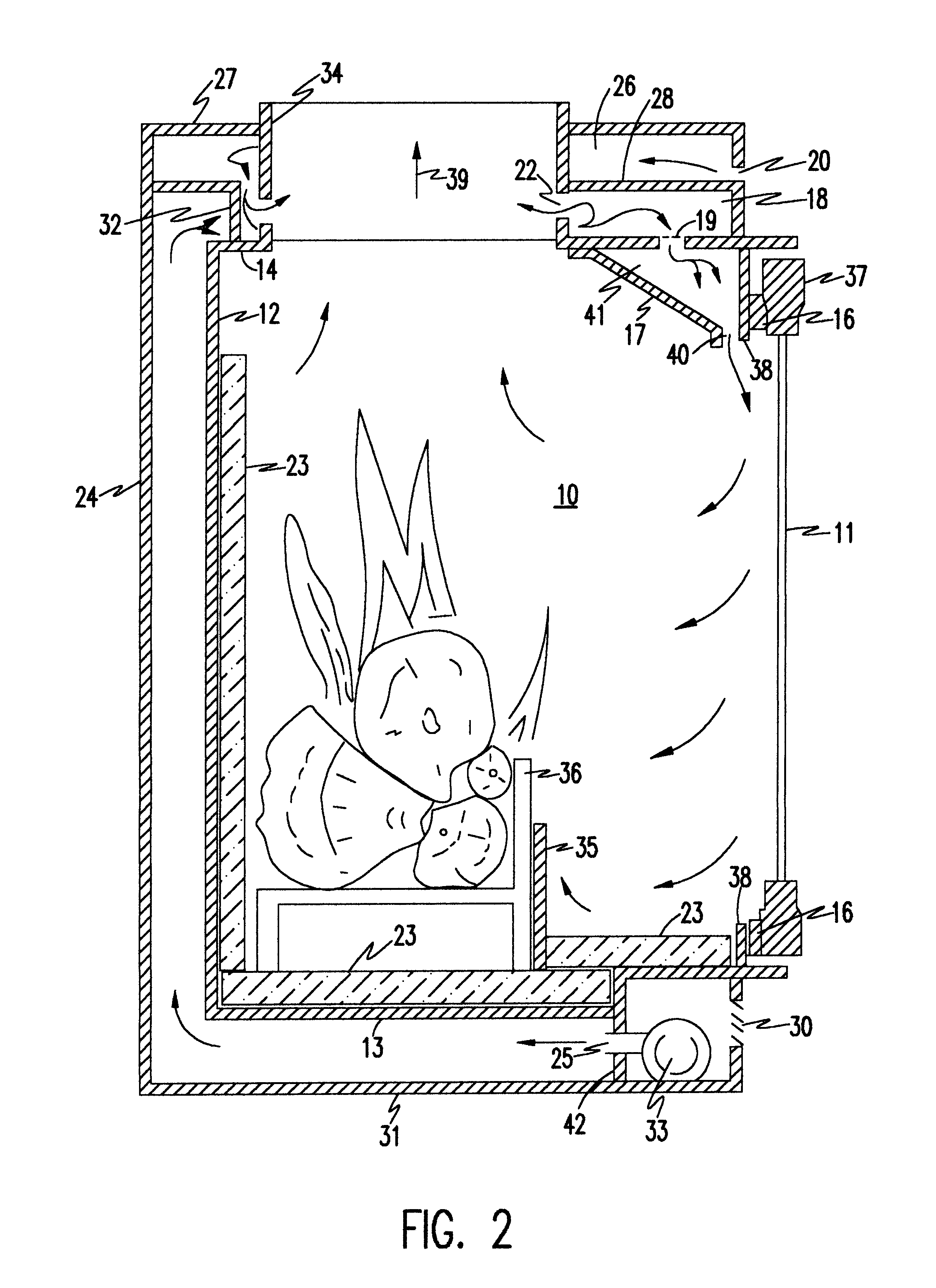

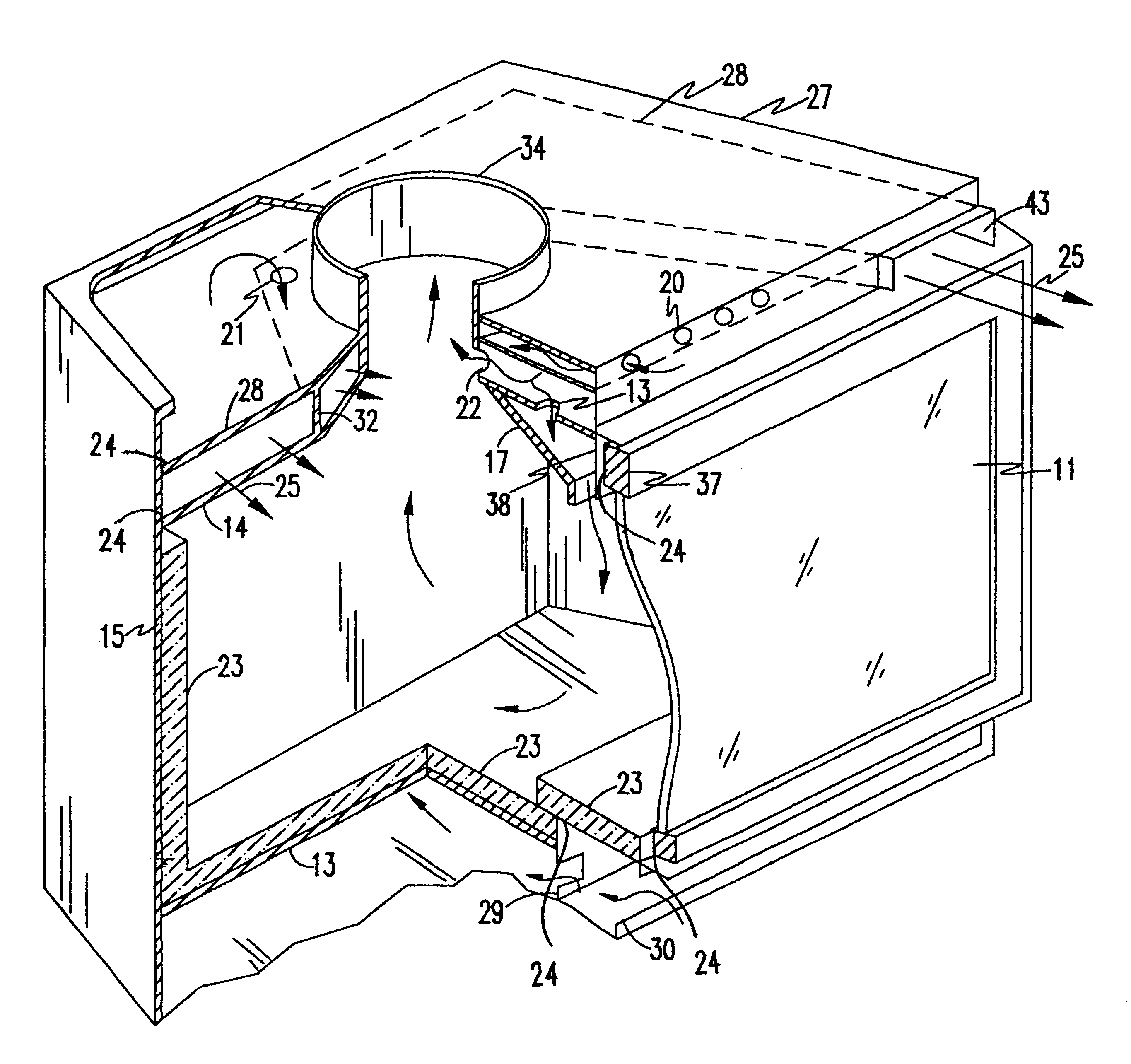

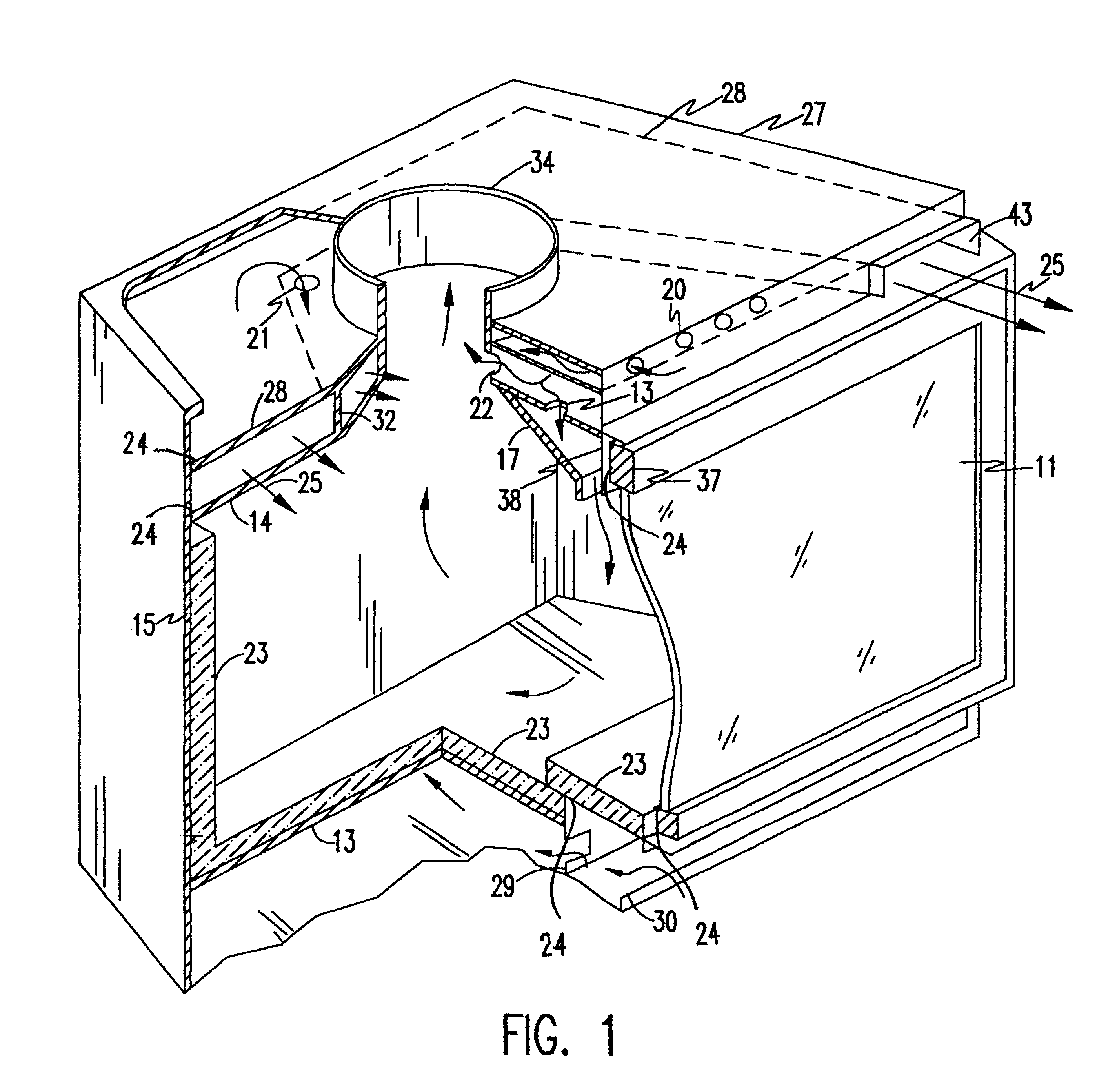

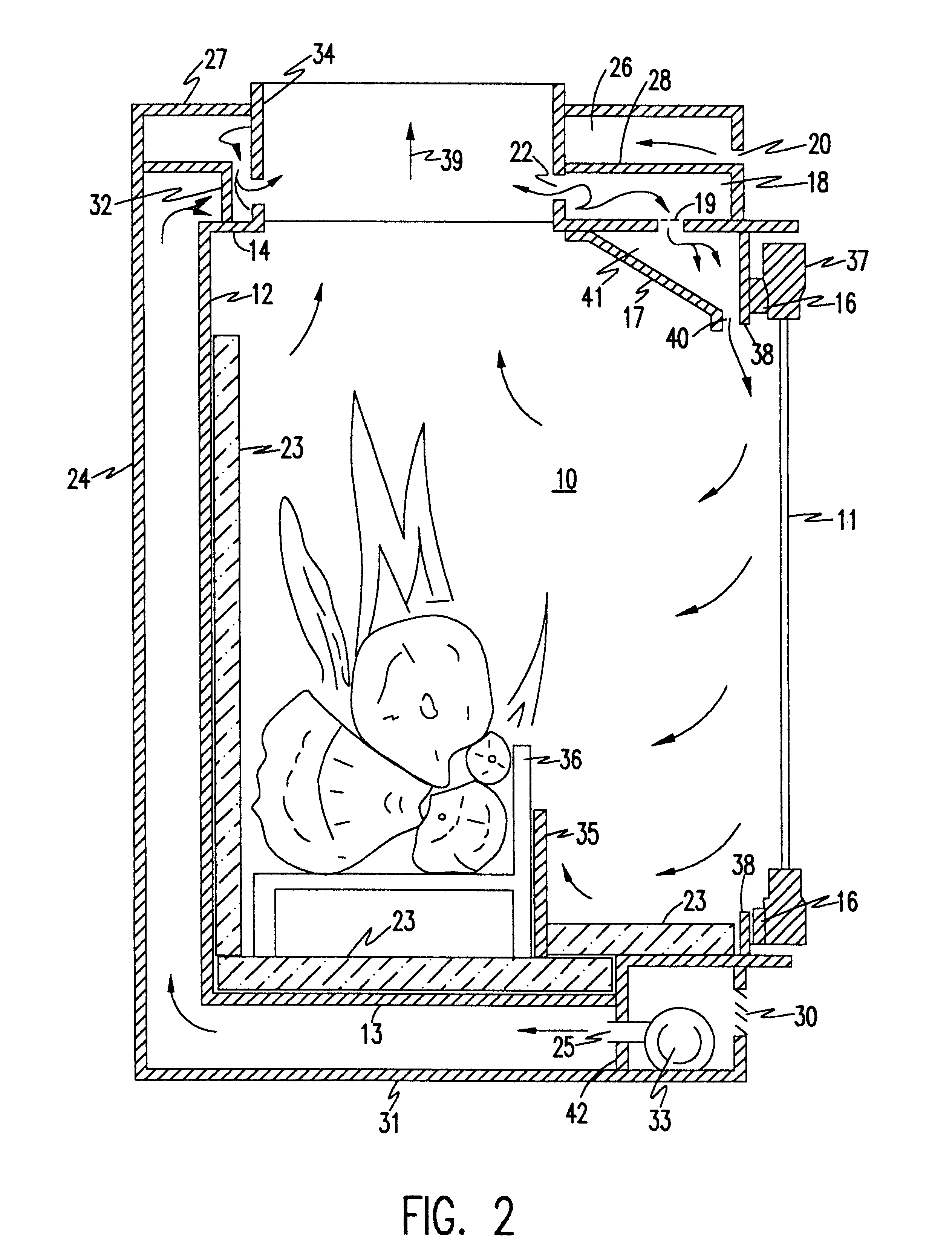

Wood heater

InactiveUS6216684B1Low efficiencyReduce pollutionDoors for stoves/rangesCombustion-air/flue-gas circulation for stovesCombustion systemFirewood

A combustion system for burning firewood including a combustion chamber defined by front, rear and side walls, a ceiling and a bottom. An access door is provided for addition of fuel into the combustion chamber. A substantial amount of combustion air enters the combustion chamber near the top of the fueling doors via apertures and is directed down the face of the fueling doors providing cooling. A geometry of the air metering orifice is either fixed or of limited adjustability such that the minimum flow of combustion air required for flaming combustion of a full load of fuel is maintained at all times. The combustion air flow cannot be reduced beyond a certain point and thus smoldering and very low air / fuel ratios are avoided. Since the air metering is tuned for proper flaming combustion with the largest expected fuel load and cannot be reduced further, fuel loads smaller than the design fuel load will result in higher air / fuel ratios, thus further ensuring that sufficient combustion air is present for sustained flaming. Furthermore, the minimum combustion air setting limits the amount of combustion air entering the combustion chamber such that too much air is not introduced resulting in inefficiency due to sensible heat loss, chemical loss (pollution), quenching of the flames, and undesirably high burn rates. Ideally, the burning rate of a full load of fuel is below 5 kg / hr, however, the maximum bum rate when burning a full load of fuel may be reduced to as low as 2 kg / hr depending on the size of the firebox and the desired maximum heating capacity of the appliance. Heat output is adjustable primarily by the amount of fuel added at each fuel loading.

Owner:CHAMPION MARK

Wood heater

InactiveUS6488024B2Low efficiencyReduce pollutionDoors for stoves/rangesCombustion-air/flue-gas circulation for stovesCombustion systemFirewood

A combustion system for burning firewood including a combustion chamber defined by front, rear and side walls, a ceiling and a bottom. An access door is provided for addition of fuel into the combustion chamber. A substantial amount of combustion air enters the combustion chamber near the top of the fueling doors via apertures and is directed down the face of the fueling doors providing cooling. A geometry of the air metering orifice is either fixed or of limited adjustability such that the minimum flow of combustion air required for flaming combustion of a full load of fuel is maintained at all times. The combustion air flow cannot be reduced beyond a certain point and thus smoldering and very low air / fuel ratios are avoided. Since the air metering is tuned for proper flaming combustion with the largest expected fuel load and cannot be reduced further, fuel loads smaller than the design fuel load will result in higher air / fuel ratios, thus further ensuring that sufficient combustion air is present for sustained flaming. Furthermore, the minimum combustion air setting limits the amount of combustion air entering the combustion chamber such that too much air is not introduced resulting in inefficiency due to sensible heat loss, chemical loss (pollution), quenching of the flames, and undesirably high burn rates. Ideally, the burning rate of a full load of fuel is below 5 kg / hr, however, the maximum burn rate when burning a full load of fuel may be reduced to as low as 2 kg / hr depending on the size of the firebox and the desired maximum heating capacity of the appliance. Heat output is adjustable primarily by the amount of fuel added at each fuel loading.

Owner:CHAMPION MARK

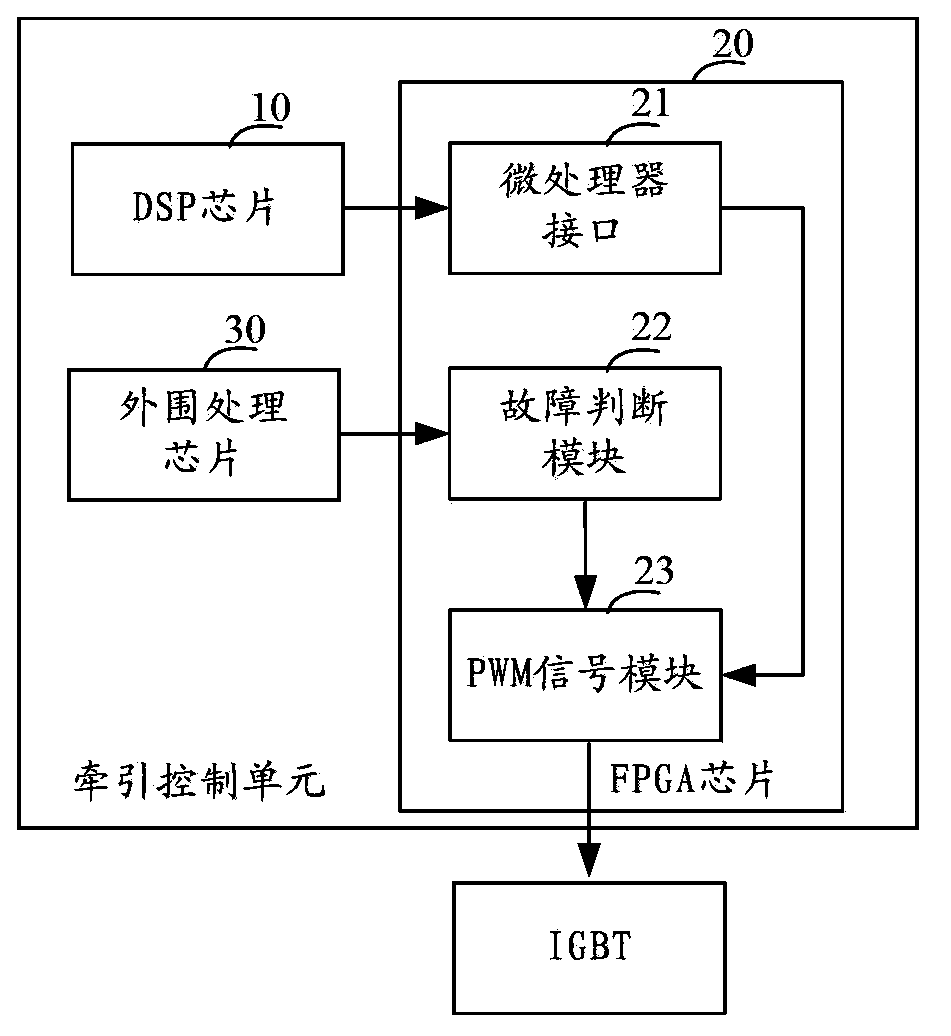

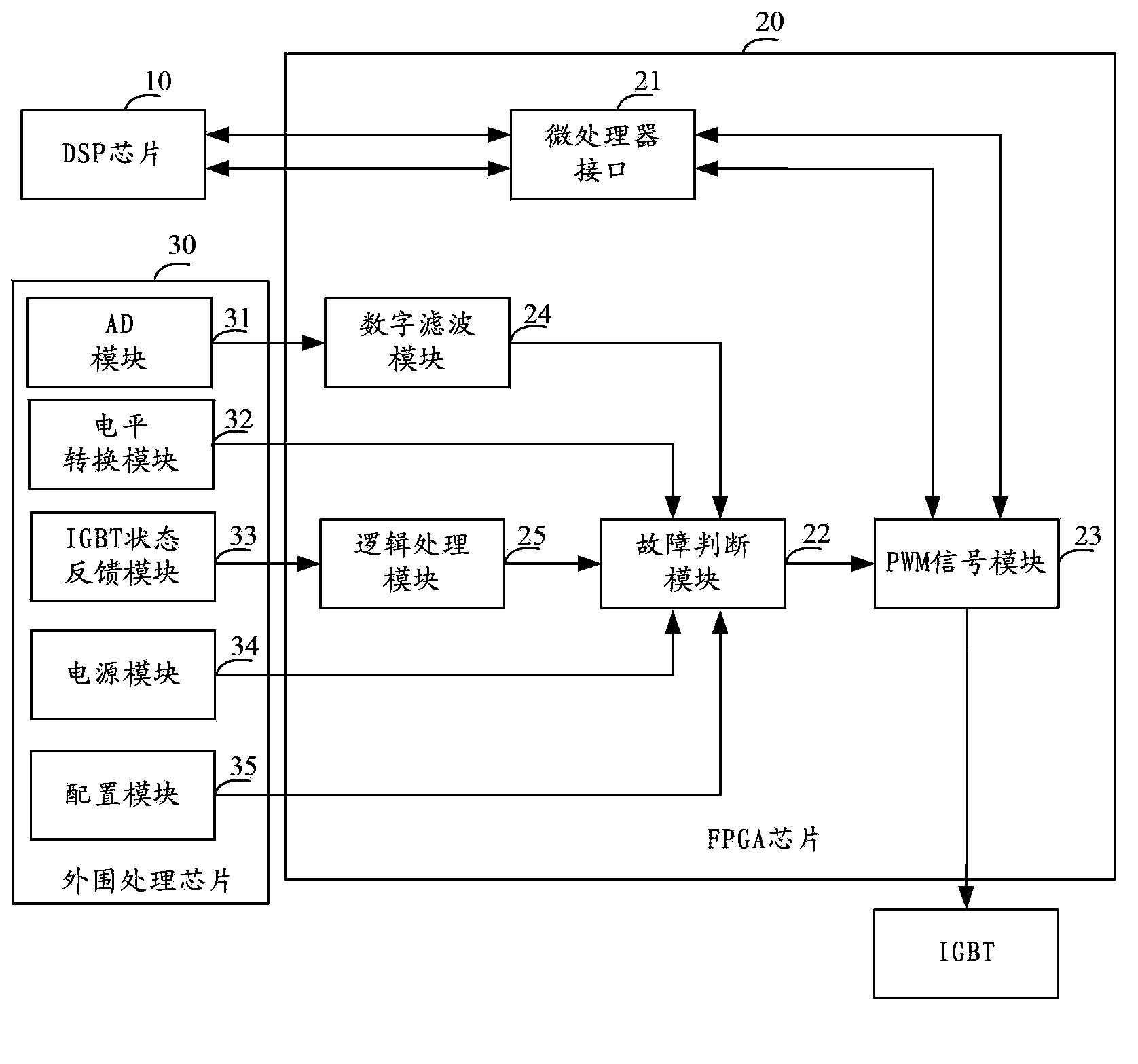

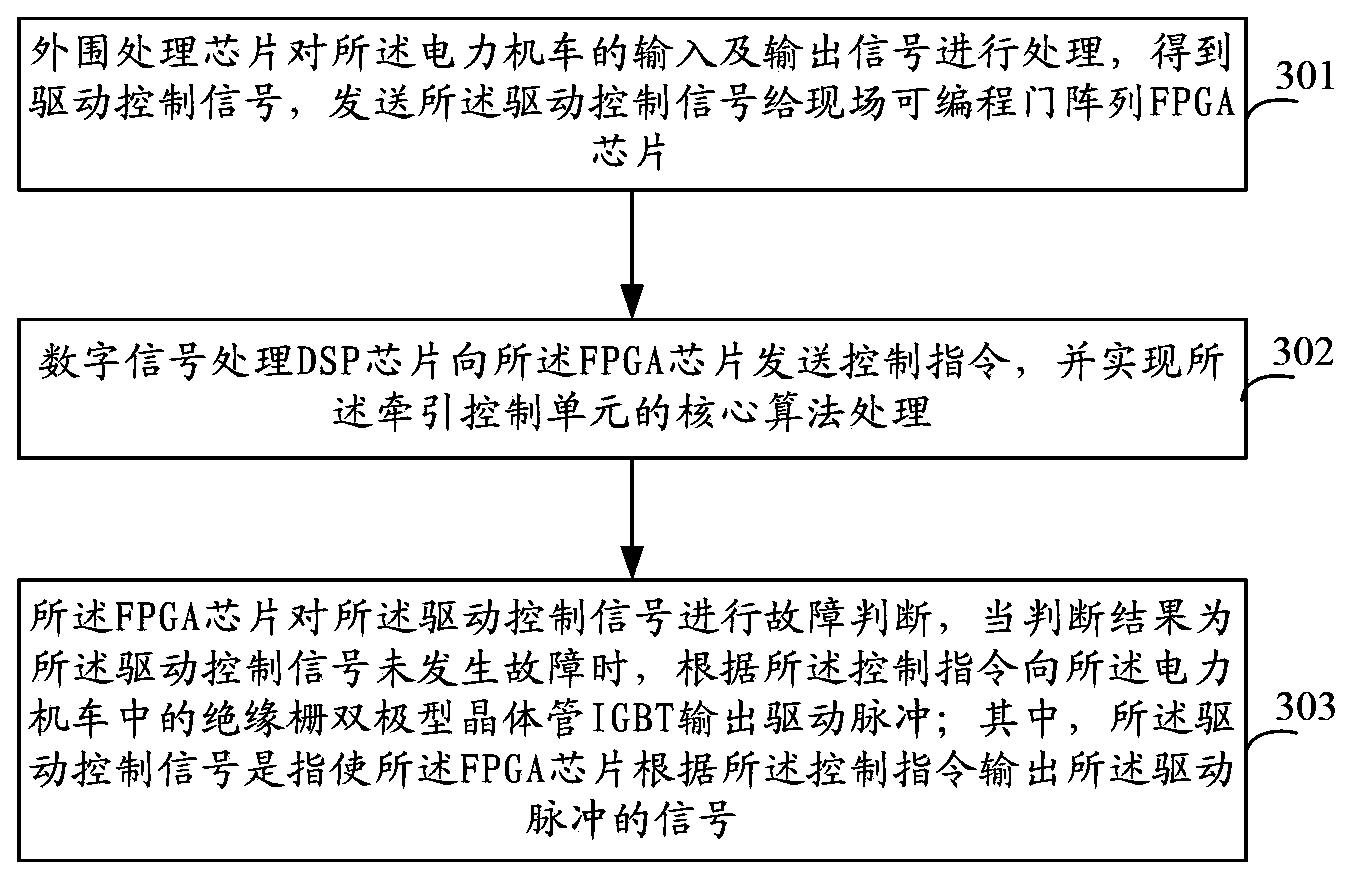

Electric locomotive traction control unit and control method

ActiveCN103802841AAvoid destructionReduce the probability of burningProgramme control in sequence/logic controllersLocomotivesEngineeringFpga chip

The invention provides an electric locomotive traction control unit and a control method. A peripheral processing chip processes input and output signals of an electric locomotive to acquire a drive control signal. The drive control signal is sent to an FPGA chip. The FPGA chip simultaneously receives a control command sent by a DSP chip used as a main processing chip. The FPGA chip carries out fault judgment on the drive control signal. If a judgment result is that the drive control signal does not have a fault, drive pulse is output to an IGBT in the electric locomotive according to the control command. According to the invention, the FPGA chip judges the drive control signal sent by the control drive pulse; if the FPGA chip judges that the drive control signal does not have a fault, the FPGA chip sends the drive pulse to the IGBT to drive the IGBT to work; if the FPGA chip judges that the drive control signal has a fault, the FPGA stops sending the drive pulse, so as to prevent the IGBT from damage under the condition of a burst fault of the electric locomotive; and the burning rate of the IGBT can be reduced.

Owner:CHINA CNR CORPORATION

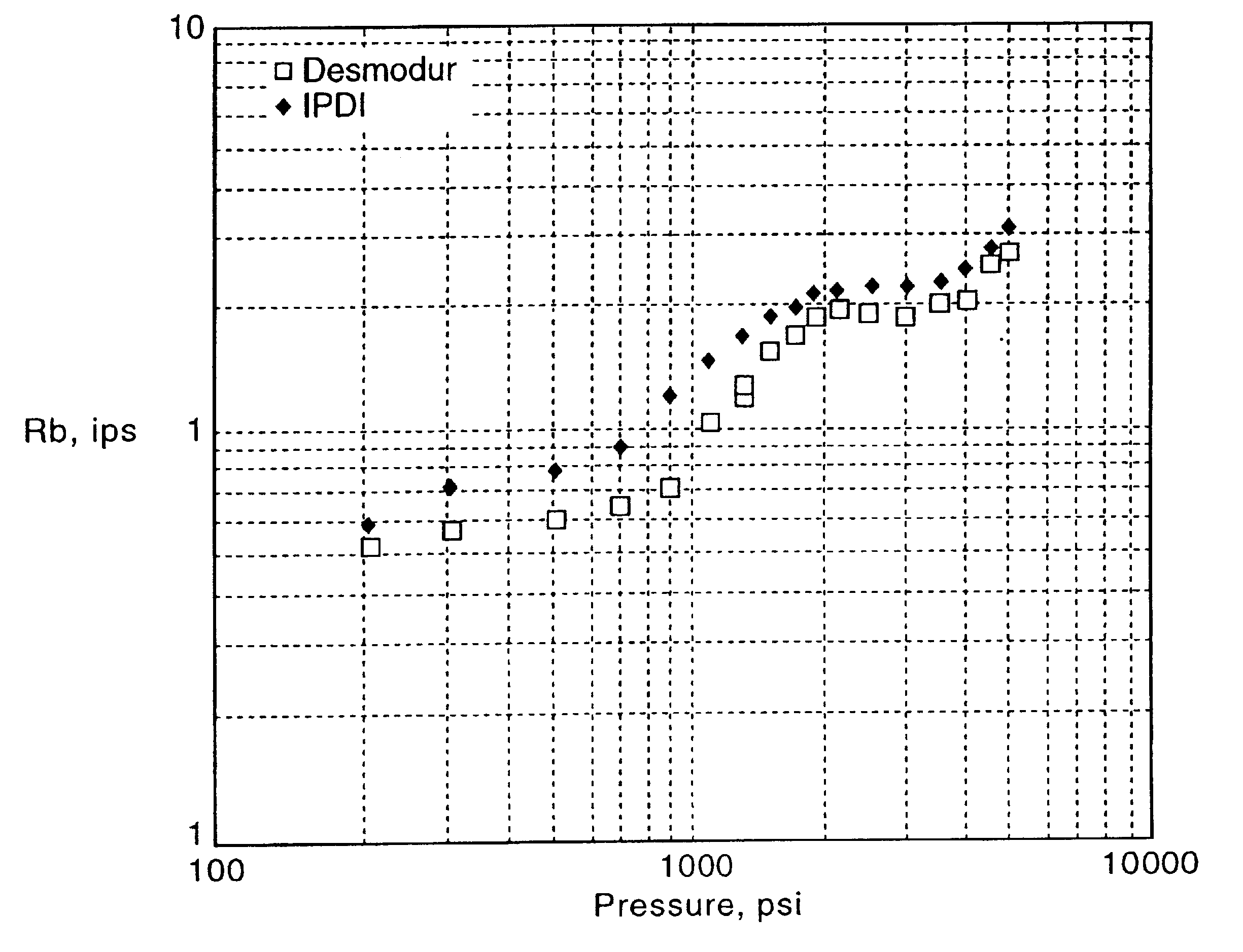

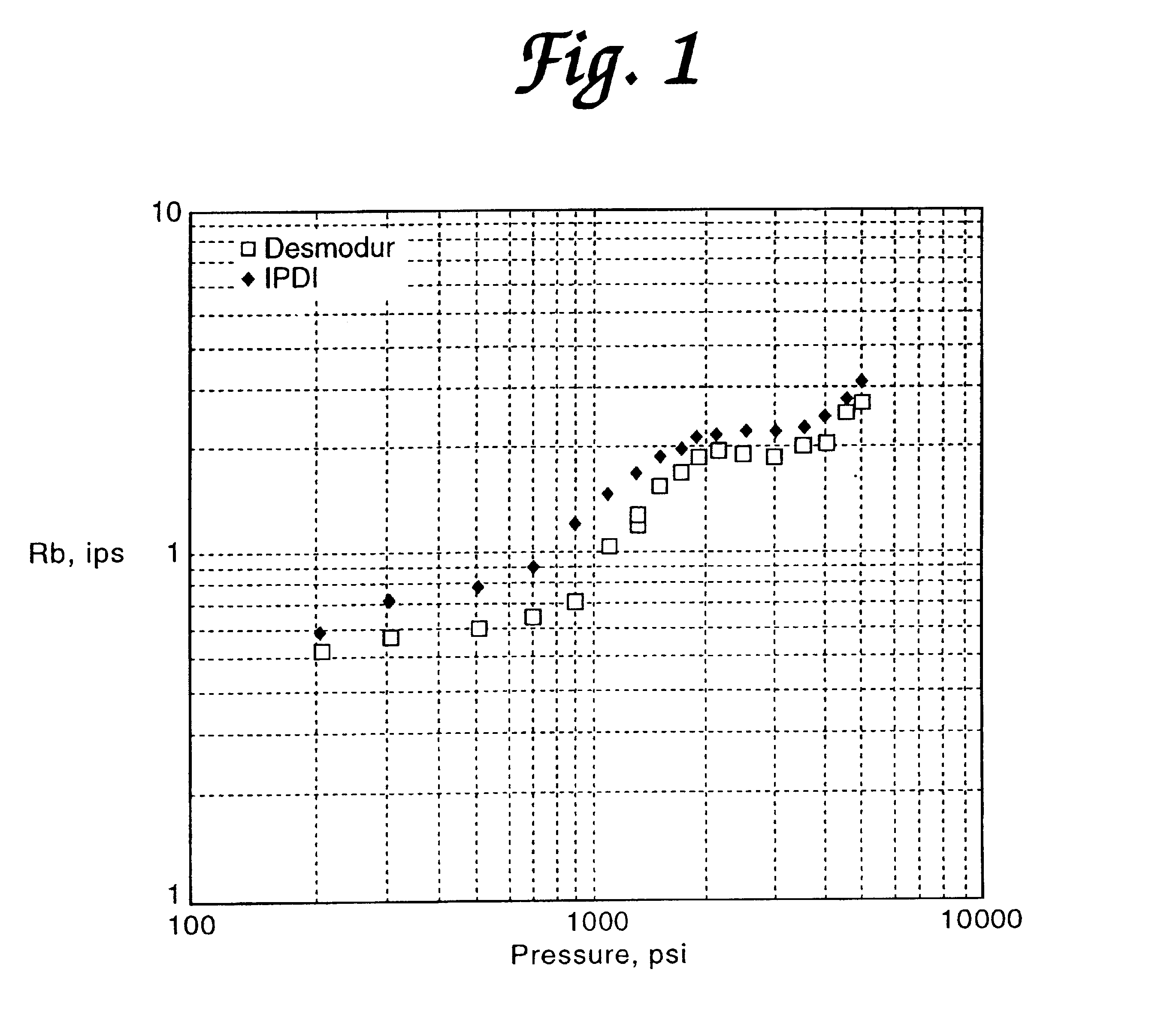

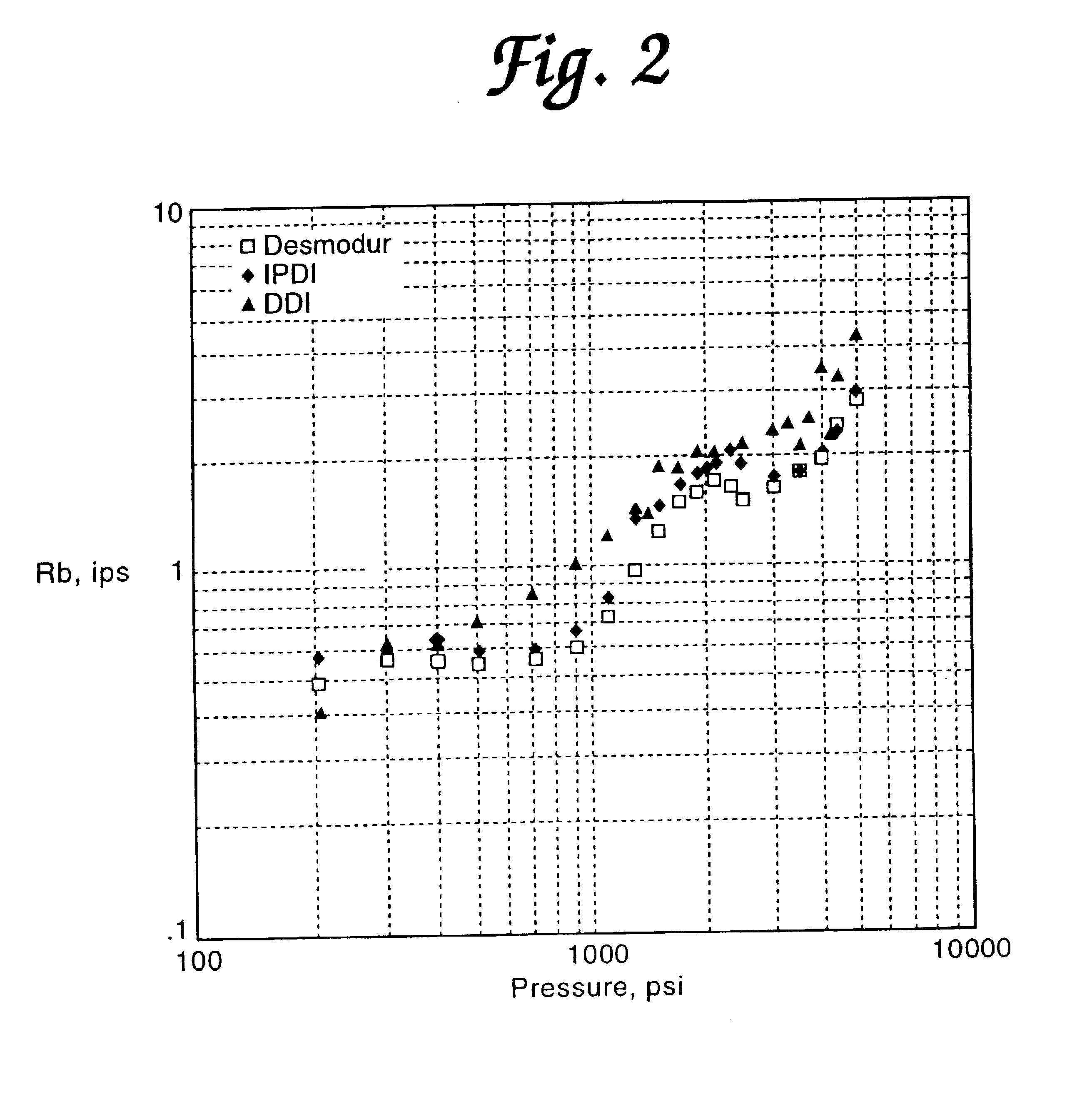

Energetic oxetane propellants

InactiveUS6217682B1Increase burn rateImproved plateau definitionNon-explosive/non-thermic compositionsPressure gas generationPlasticizerOxetane

An energetic solid rocket motor propellant having one or more plateau regions of low operating pressure exponent is disclosed. The propellant is formulated from ingredients including an energetic polyoxetane, an effective amount of a plasticizer, an inorganic oxidizer in at least two discrete particle size ranges, and a refractory oxide burn rate modifier.

Owner:NORTHROP GRUMMAN SYST CORP

Bridge facility

InactiveCN107171103AImprove stability and securityThe overall structure is simpleLive contact access preventionEngineeringElectric shock

The invention discloses a facility for a bridge, which includes a frame body and an electrical connector mated with the frame body. Between the electrical connection slots with the port facing forward, the rear end of the electrical connection slot is provided with an electrical contact piece connected to the external power, and the rear ends of the two slots are connected with sliding slots. A sliding block that can be slid back and forth is provided in the sliding joint groove. The overall structure of the present invention is simple, the production cost is low, the power supply is safe and stable, and the operation steps of power on and off are relatively simple, which effectively reduces the electric shock accidents in the existing life. , to ensure the safety of people's lives, and to avoid the occurrence of bridge equipment power failure accidents caused by accidental kicking and collision, and reduce the burnout rate of bridge equipment, which is suitable for popularization and use.

Owner:周一戈

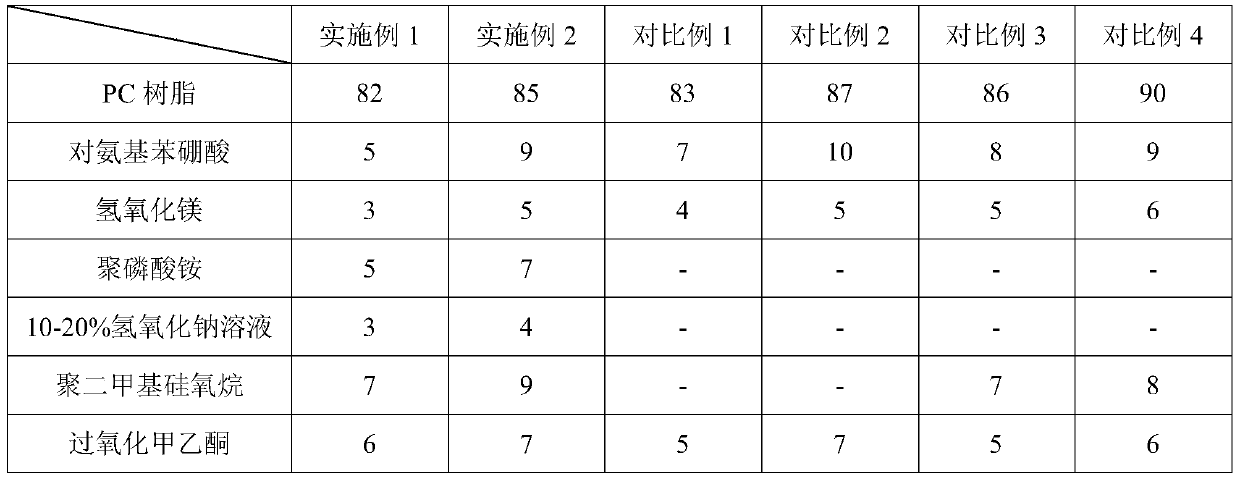

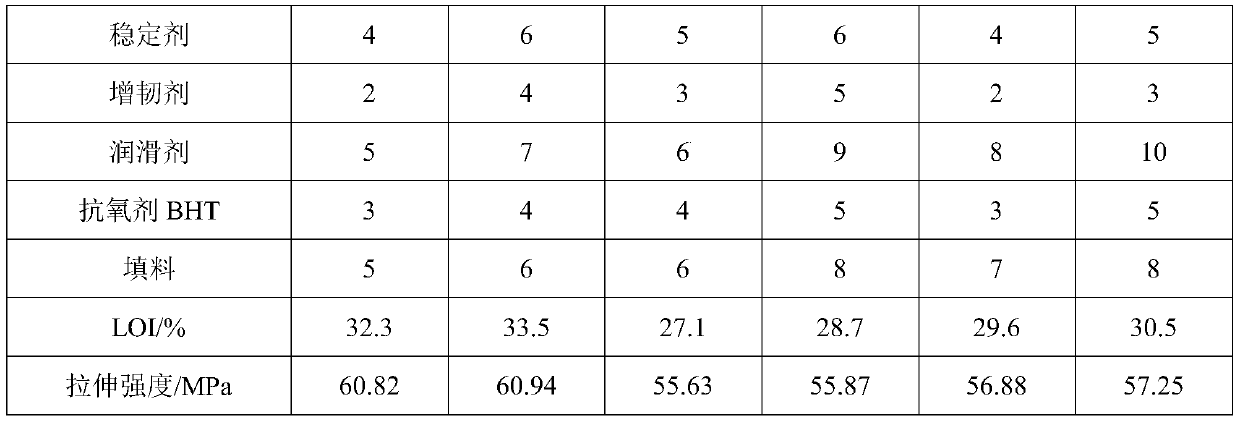

Modified engineering plastic and preparation method thereof

The invention relates to the technical field of engineering plastics, and discloses modified engineering plastic and a preparation method thereof. The engineering plastic comprises the following components: in parts by weight, 80-90 parts of PC resin, 4-6 parts of a stabilizer, 2-5 parts of a toughening agent, 5-10 parts of a lubricant and 3-5 parts of an antioxidant BHT, and a halogen-free flameretardant is also included, and comprises 7-10 parts of p-aminophenyl boronic acid and 3-6 parts of magnesium hydroxide. The modified engineering plastic has the following advantages that a synergistic flame retardant effect is achieved by magnesium hydroxide and p-aminophenyl boronic acid, on the one hand, the amount of magnesium hydroxide can be reduced, and on the other hand, a double-layer flame retardant structure is formed through a magnesium oxide protective film and a B-O-C carbon layer, so that a better flame retardant effect is achieved.

Owner:WENZHOU CITY FANHUA ENG PLASTIC

Catalyst in oxychlorination reaction as well as its preparation method and application

InactiveCN1164363CEasy loadingHigh selectivityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMicrosphere

A catalyst for oxychlorination reaction is prepared from Cu-contained alumina microspheres, RE metal chosen from La, Nd, Ce, Pr and Y, and at least one alkali metal through preparing the Cu-contained alumina microspheres and adding active components by impregnation method. Its advantages are high conversion rate of hydrogen chloride (99.75%), high purity of dichloroethane (99.6%), high output rate of dichloroethane (22 g / hr), high selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

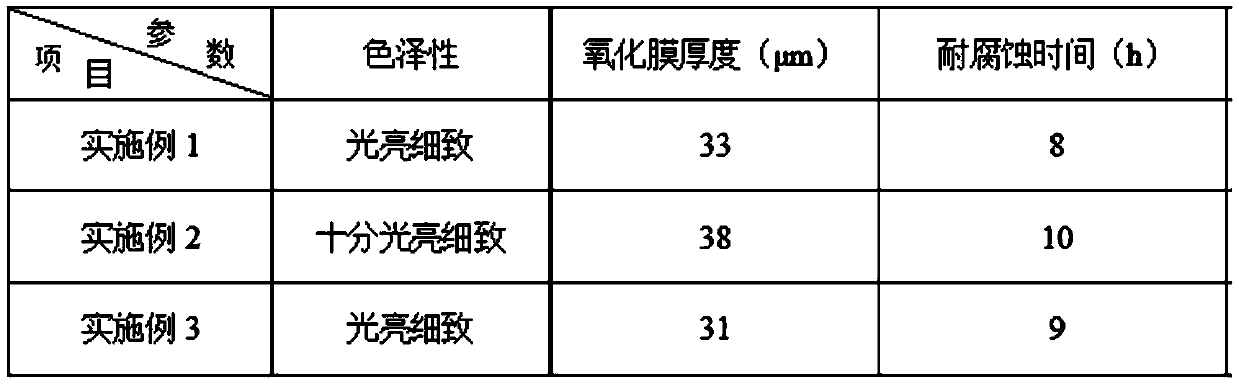

Aluminum profile anode oxidizing electrolyte, preparation method thereof and aluminum profile anode oxidizing process

ActiveCN110306228AStrong complexing abilityStrong surface adsorptionSurface reaction electrolytic coatingAluminum IonElectrolysis

The invention discloses aluminum profile anode oxidizing electrolyte, a preparation method thereof and an aluminum profile anode oxidizing process and belongs to the technical field of electrolysis orelectrophoretic processes. The electrolyte is composed of phytic acid, fulvic acid, a PH conditioning agent and water, the concentration of the phytic acid in the electrolyte is 70-90 g / L, the concentration of the fulvic acid in the electrolyte is 35-55 g / L, and the PH value of the electrolyte is 2.0-2.8. On the one hand, the phytic acid of the electrolyte is mainly sourced from root trunks, stems and seeds of plants, the fulvic acid can be used for a medical purpose, and therefore, the electrolyte mainly composed of the phytic acid and the fulvic acid is completely poisonous and harmless andis environmentally friendly; and on the other hand, aluminum ions dispersed into a solution and a complex formed by the phytic acid and the aluminum ions can be adsorbed to a position nearby an aluminum profile, a complex of phytic acid and Al<3+> is also formed on the surface of aluminum oxide while hole sealing is assisted, a layer of compact hydrophobic protective film is produced, a chemicaldissolution effect of the electrolyte on the oxidation film is retarded, the performance of the film is improved, and the corrosion resistance of the oxidation film is enhanced.

Owner:ANHUI LANT ALUMINUM

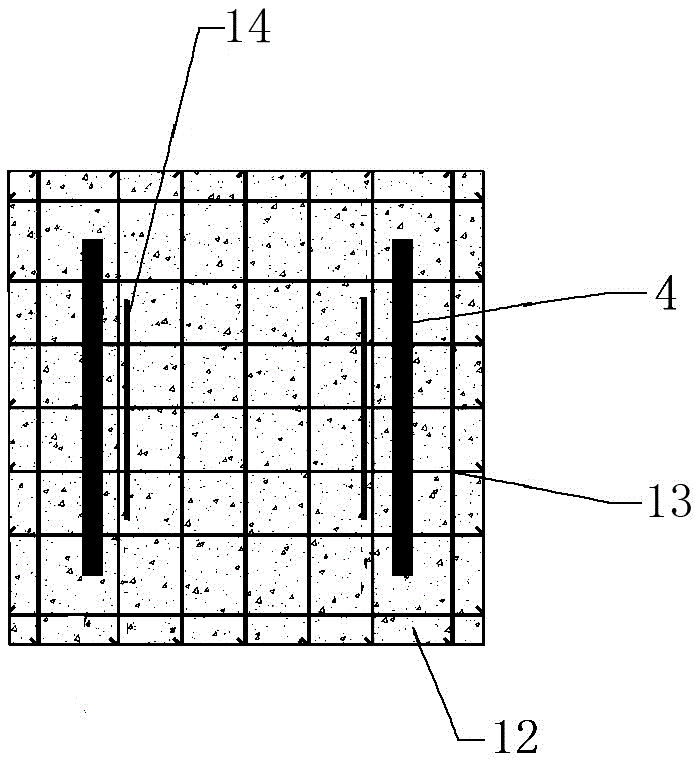

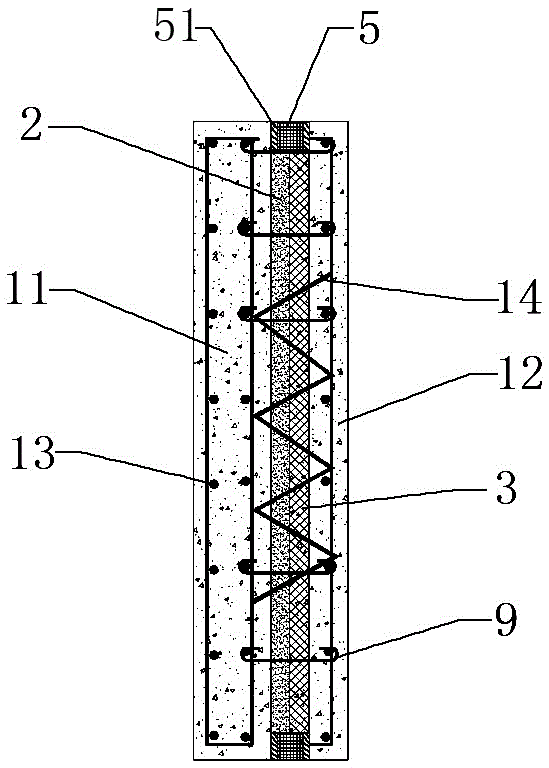

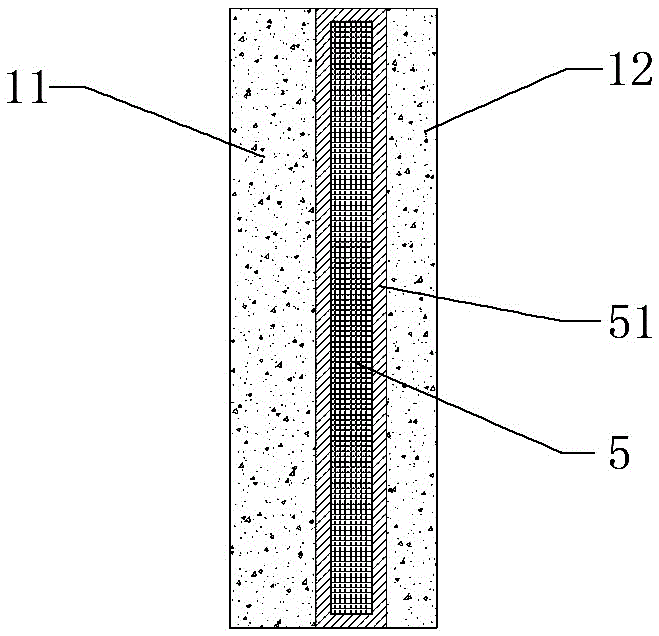

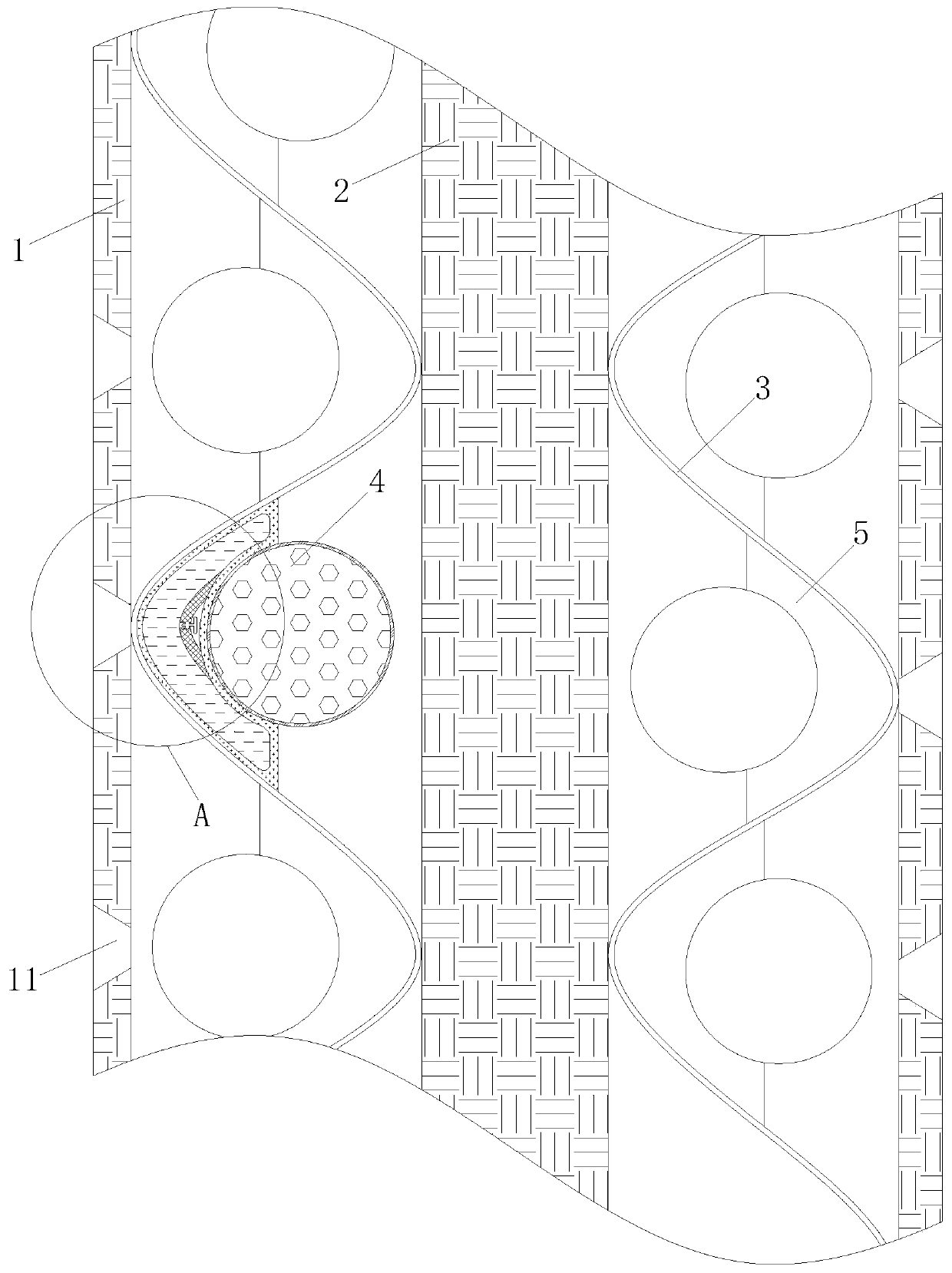

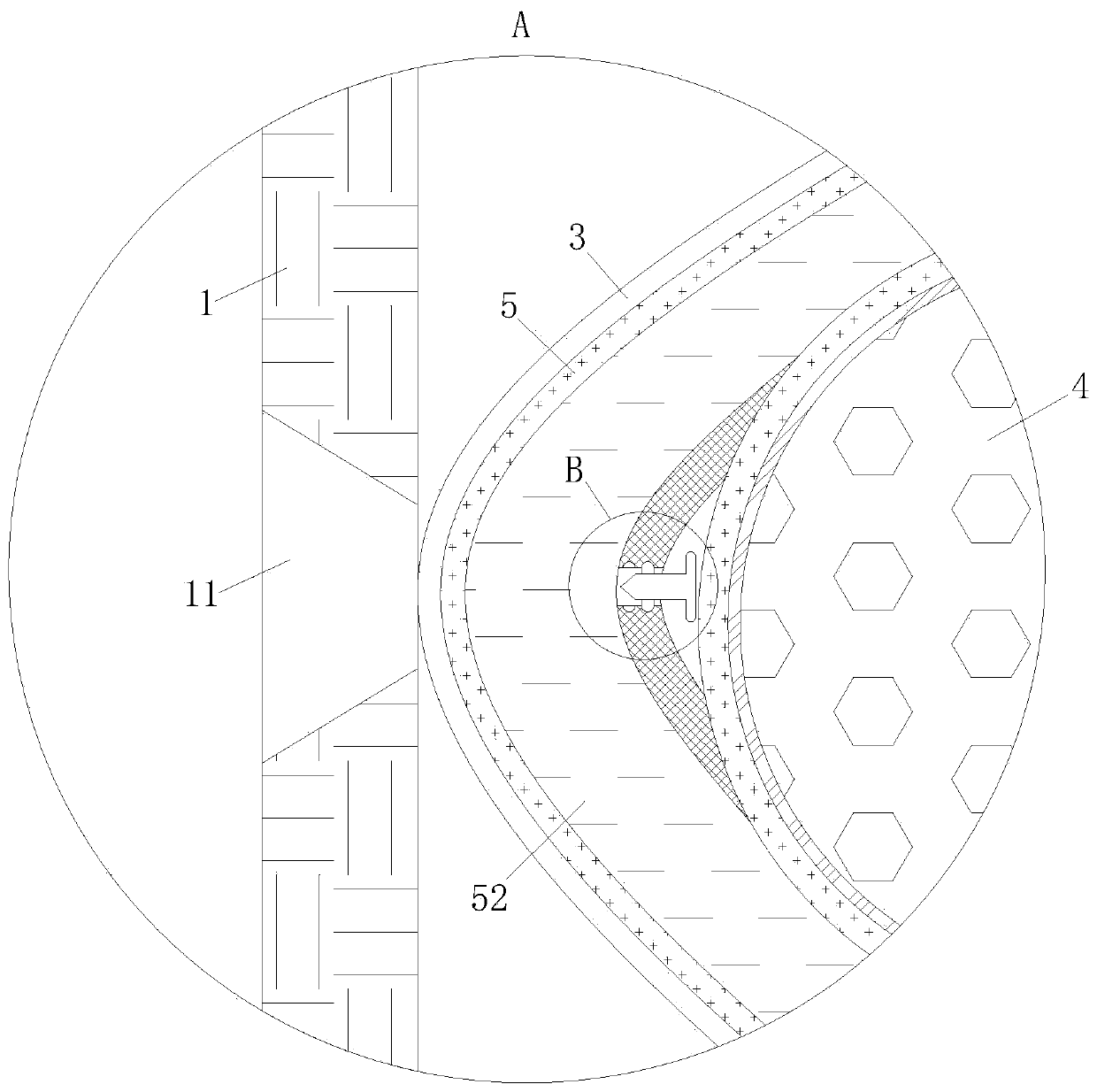

Flexibly-connected high fireproof and heat-preservation wall board and construction method thereof

PendingCN107524248AReduce the probability of burningReduce supplyWallsHeat proofingReinforced concreteRebar

The invention relates to the technical field of fireproof and heat-preservation wall boards and discloses a flexibly-connected high fireproof and heat-preservation wall board and a construction method thereof. The flexibly-connected high fireproof and heat-preservation wall board comprises a reinforced concrete wall body which comprises an inner wall surface and an outer wall surface; the inner wall surface and the outer wall surface are internally paved with reinforcement cages, and the ends of the peripheries of the inner wall surface and the outer wall surface are provided with closing plates; fireproof layers and heat-preservation layers are arranged between the inner wall surface and the outer wall surface, and connecting pieces are connected between the reinforcement cages inside the inner wall surface and the outer wall surface; and the fireproof layers are arranged on one side or the two sides of the heat-preservation layers. The flexibly-connected high fireproof and heat-preservation wall board is provided with closed cavities, has good heat-preservation and fireproof property and is good in durability, high in anti-shearing strength and anti-bending strength, convenient to construct, fast in construction and efficient.

Owner:姚攀峰

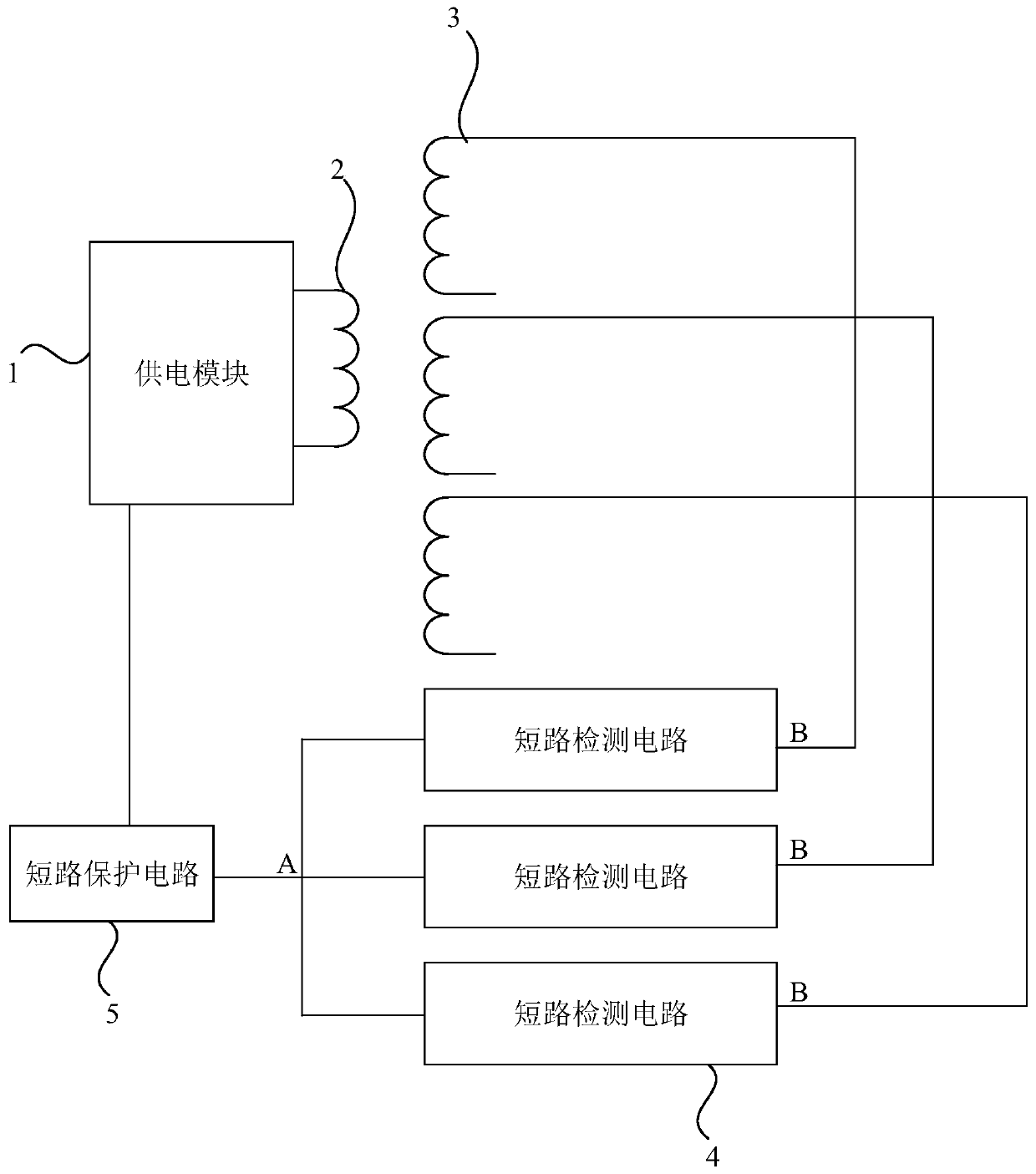

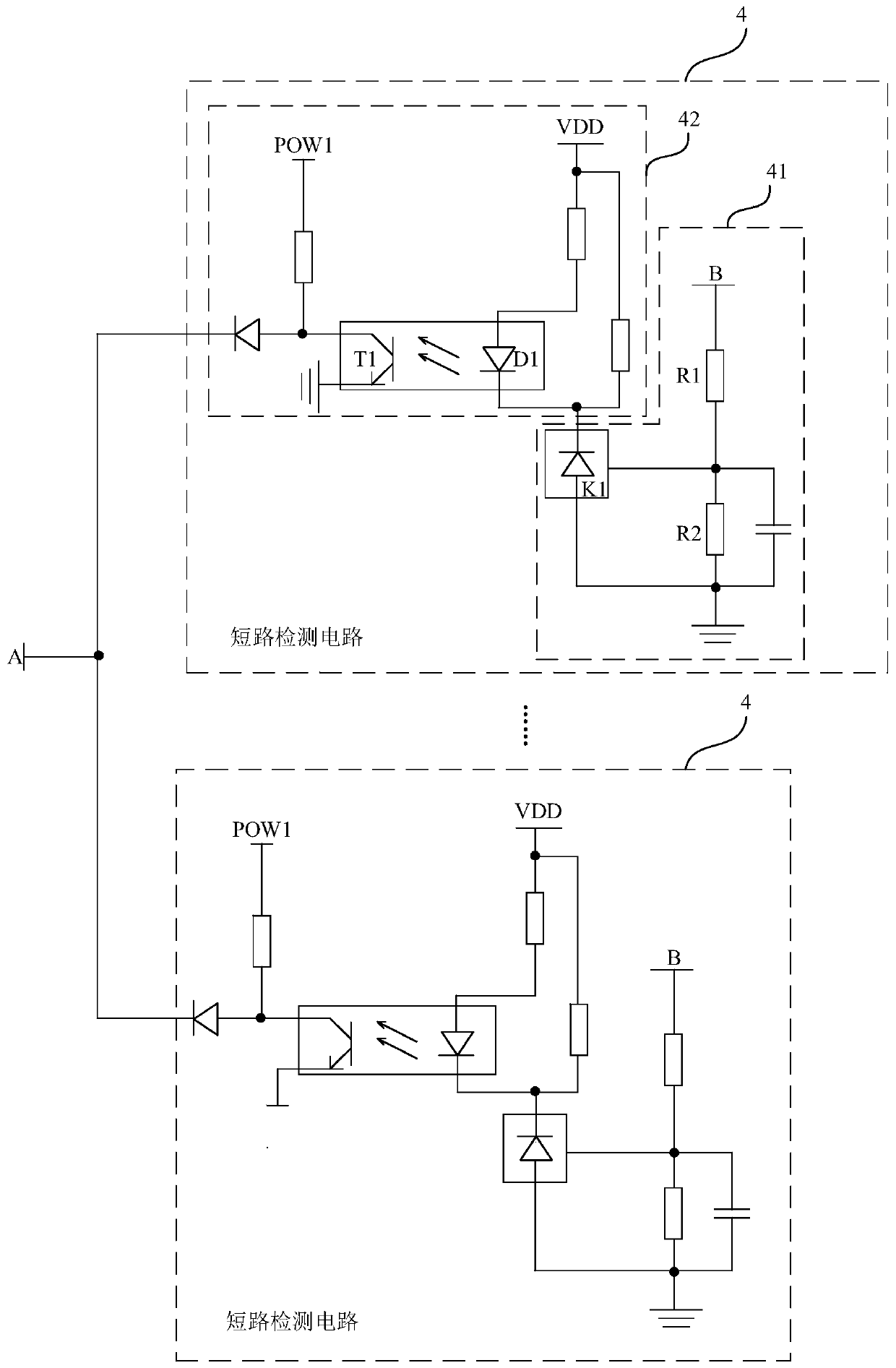

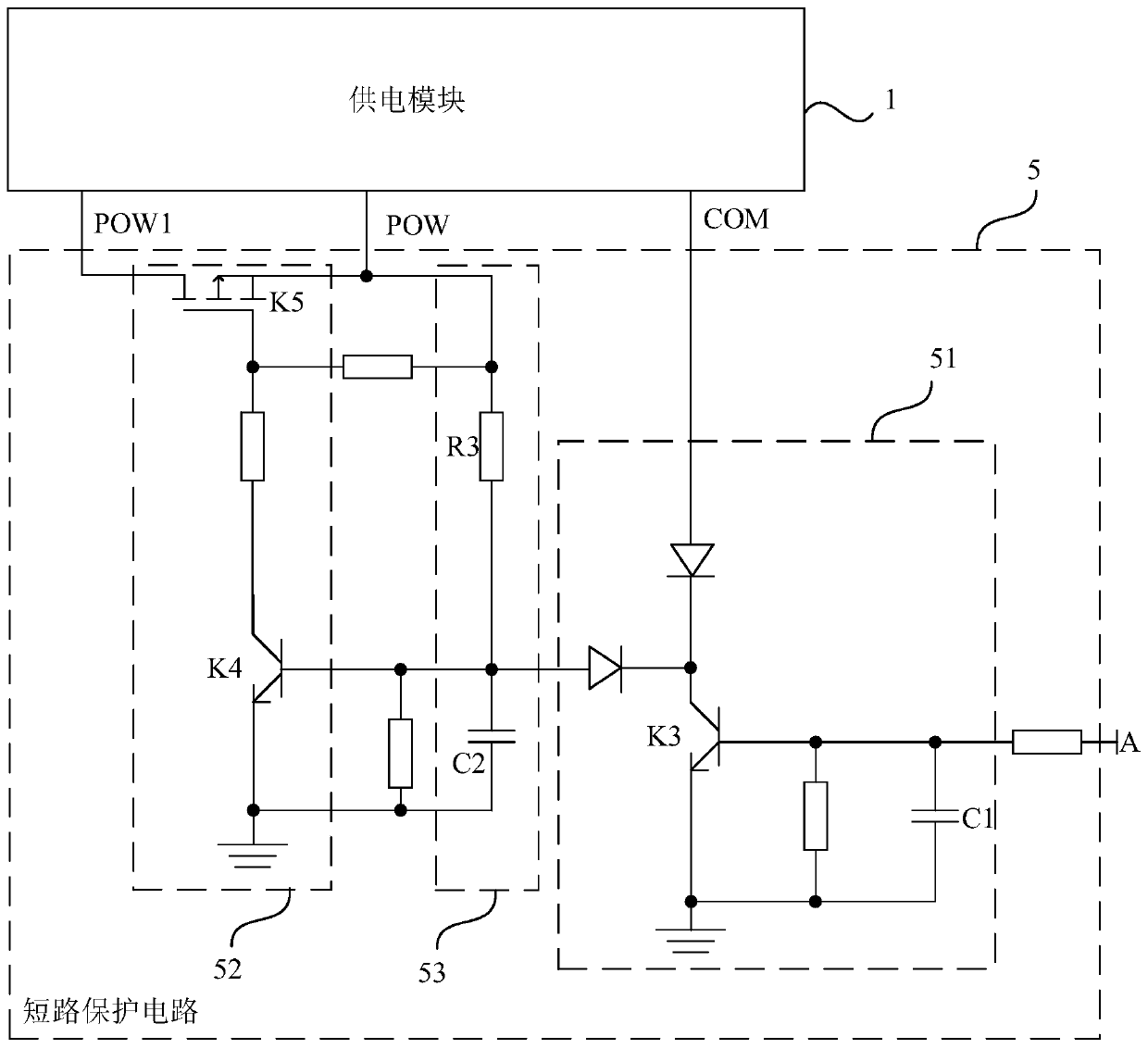

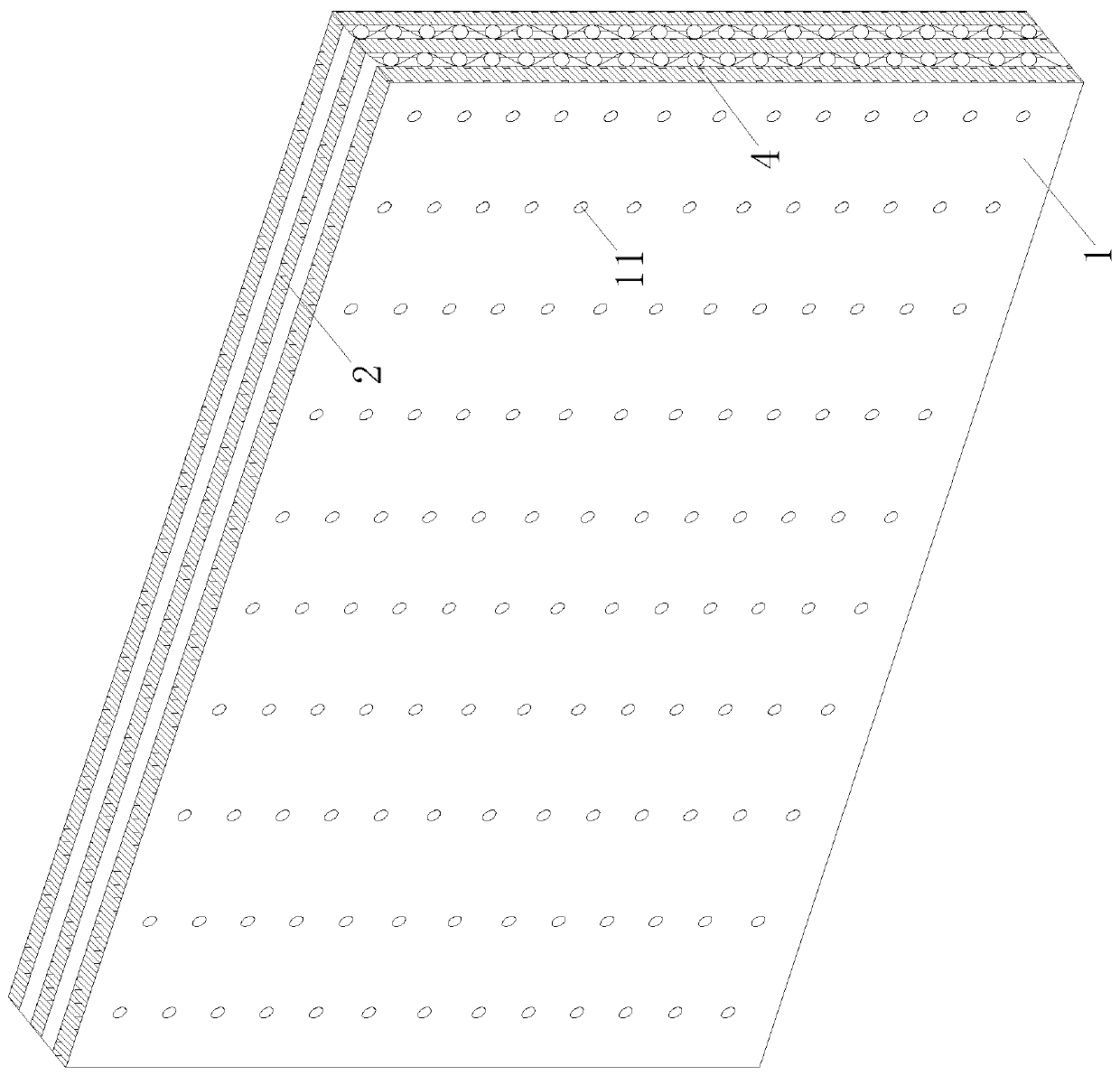

Multipath output short-circuit protection circuit

PendingCN111009878AReduce the probability of burningLow costConversion without intermediate conversion to dcArrangements responsive to excess currentControl signalHemt circuits

The invention discloses a multipath output short-circuit protection circuit which comprises a power supply module, an input winding, a plurality of output windings, a plurality of short circuit detection circuits and a short-circuit protection circuit. The power supply module is used for supplying power to the input winding, and the output windings are used for coupling power supply signals transmitted by the input winding and outputting isolation power supply signals to corresponding loads. A plurality of short circuit detection circuits are used for adjusting output short circuit control signals according to the isolation power supply signals output by the corresponding output windings. A short-circuit protection circuit is used for adjusting power supply control signals output to the power supply module according to the short-circuit control signals output by all the short-circuit detection circuits so as to control a power supply state of the power supply module to the input winding. Through the technical scheme of the invention, cost of outputting multiple paths of isolation power supplies is effectively reduced, short-circuit protection of each path of isolation power supplyoutput branch is realized, and a probability that devices in multiple paths of isolation power supply signal output lines are burnt is reduced.

Owner:SHANGHAI PYLON TECH CO LTD

High-strength flame-retardant corrugated board

ActiveCN111204082AReduce the probability of burningReduced flame retardancySynthetic resin layered productsPaper/cardboard layered productsCorrugated fiberboardEngineering

The invention belongs to the technical field of corrugated boards, and particularly relates to a high-strength flame-retardant corrugated board which comprises outer boards, a clamping board, corrugated core layers and air storage film bags; the corrugated core layers are symmetrically installed on the side walls of the two sides of the clamping board; the outer boards are symmetrically installedon the side walls of the corrugated core layers, the outer side walls of the outer boards are coated with a flame-retardant paint, and a plurality of vent holes are formed in the outer boards; the outer boards, the clamping board, the corrugated core layers and the gas storage film bags are matched, so that the content of carbon dioxide gas around the corrugated board can be increased when the corrugated board encounters high temperature; the oxygen content of the outer side surfaces of the corrugated board is reduced, the combustion probability of the corrugated board is further reduced, theflame retardant effect is achieved, when the gas storage film bag does not explode, the gas storage film bags can play a supporting role between the side walls of the corrugated core layers, and therefore the use strength of the corrugated board is effectively improved.

Owner:浦江红颂包装有限公司

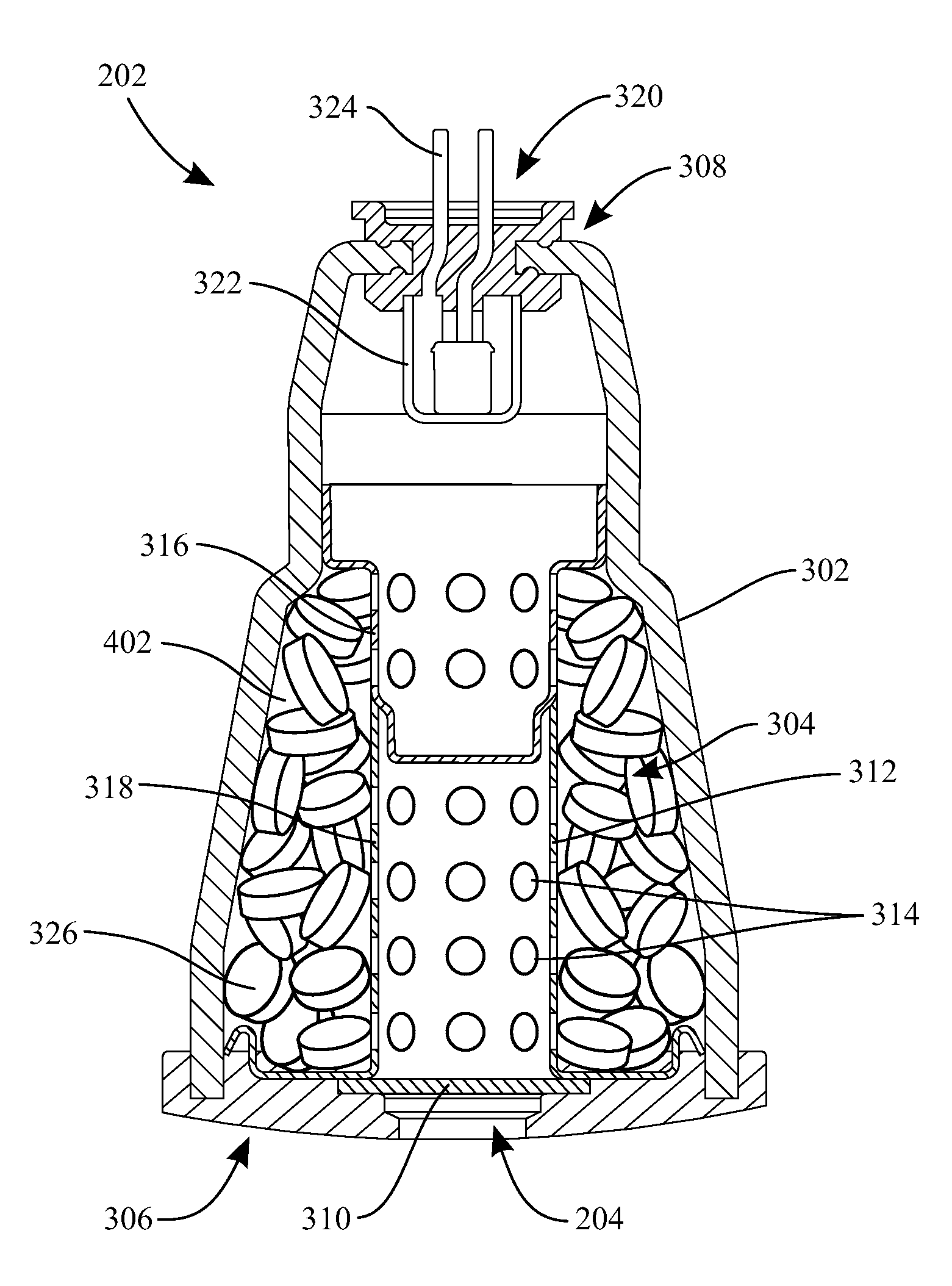

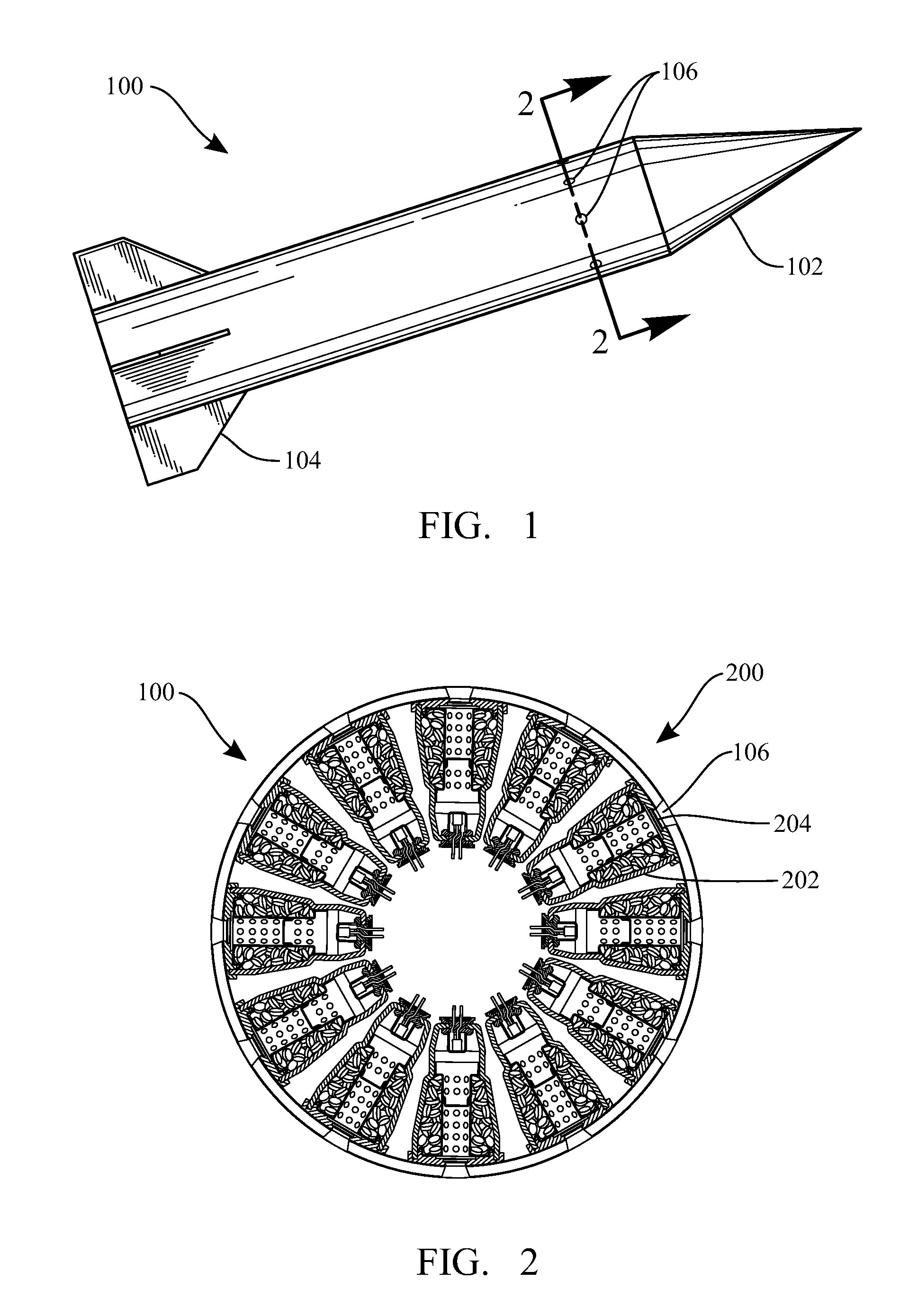

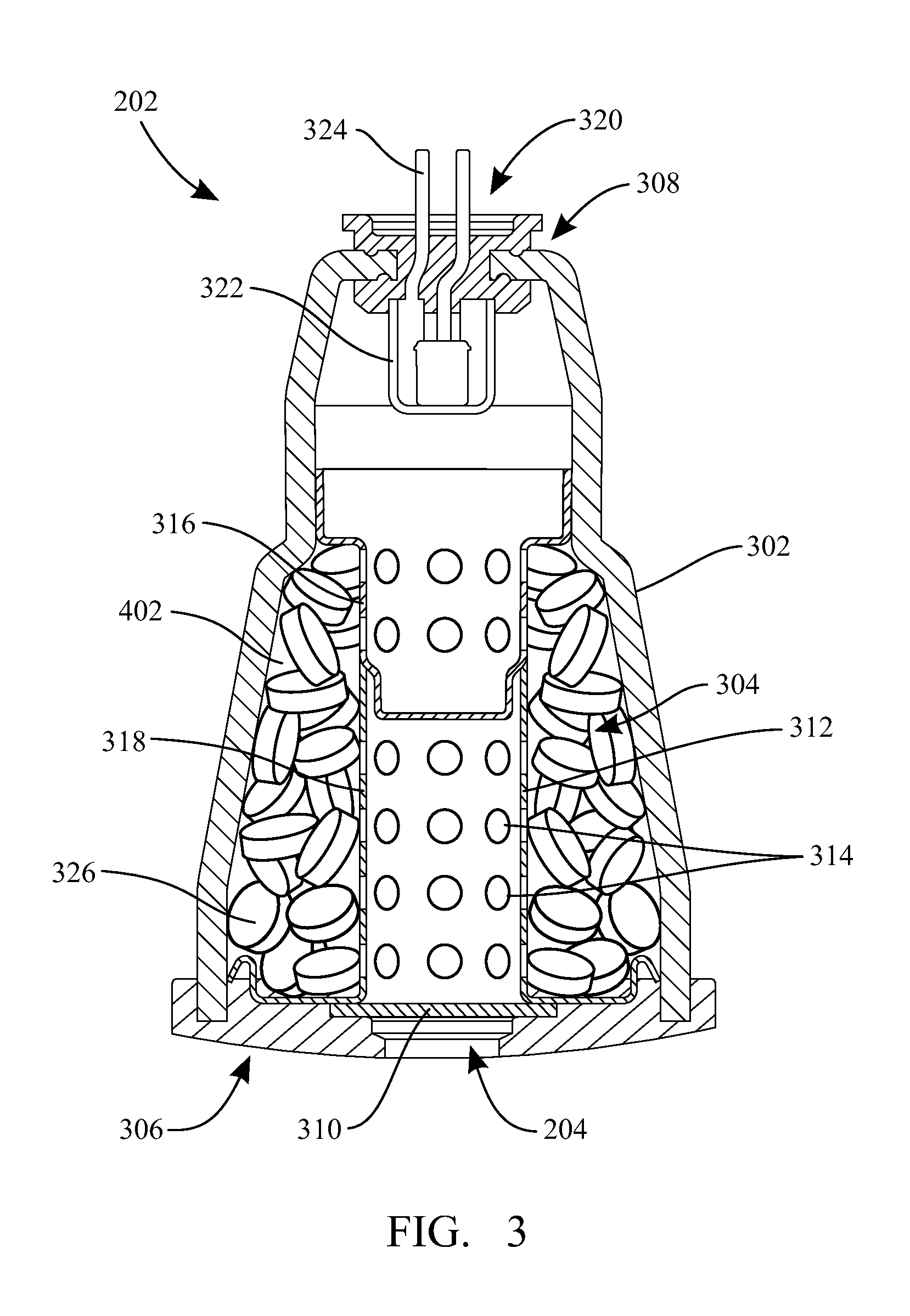

Thruster devices and methods of making thruster devices for use with thrust vector control systems

InactiveUS20130019587A1Easy to useReduce the probability of burningWriting implementsMetal-working apparatusLateral thrustCombustion chamber

Owner:AUTOLIV ASP INC

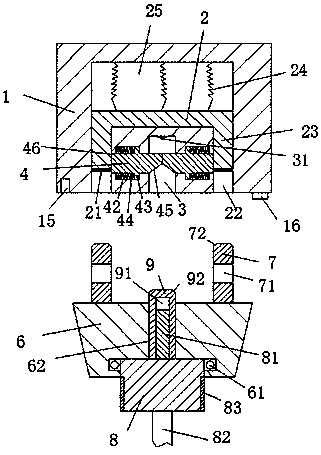

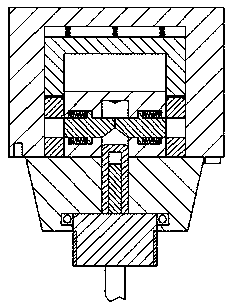

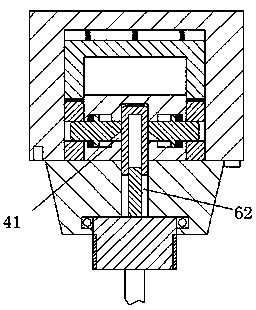

Power supply plug device

InactiveCN107706592AImprove stability and securityAvoid Electric Shock AccidentsCoupling device detailsElectricityElectric shock

The invention discloses a power supply plug-in device, which comprises a power supply body and a plug cooperating with the power supply body. Between the power supply slots with opening forward, the rear end wall of the power supply slots is provided with power supply contacts connected with the power supply, and the rear ends of the two slots are connected with sliding slots, in the sliding slots The sliding block that can slide back and forth is provided, the overall structure of the present invention is simple, the production cost is low, the power supply is safe and stable, and the operation steps of power connection and power off are relatively simple, which effectively reduces the electric shock accidents in the existing life and guarantees the safety of people's lives , It can also avoid the occurrence of power failure accidents of electrical equipment caused by accidental kicking and bumping, and reduce the burnout rate of electrical equipment, which is suitable for popularization and use.

Owner:罗亚香

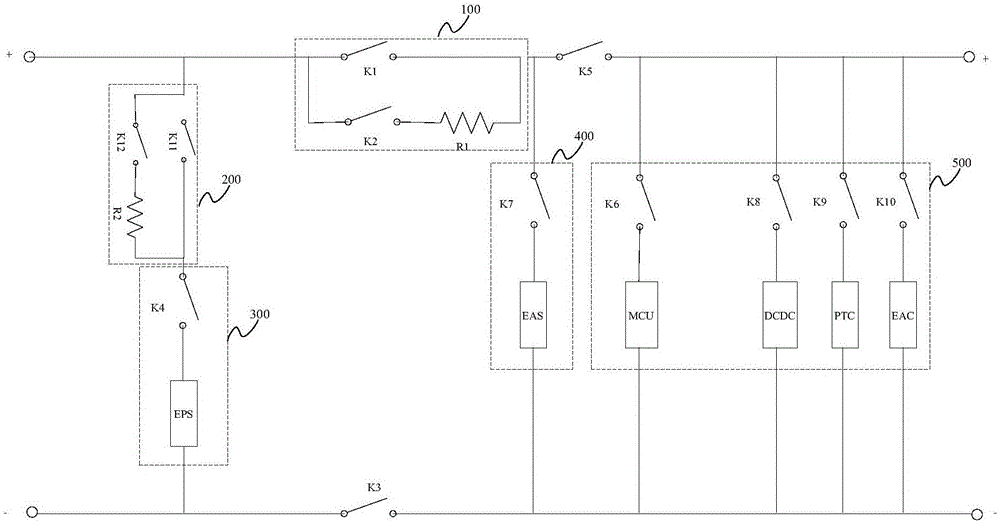

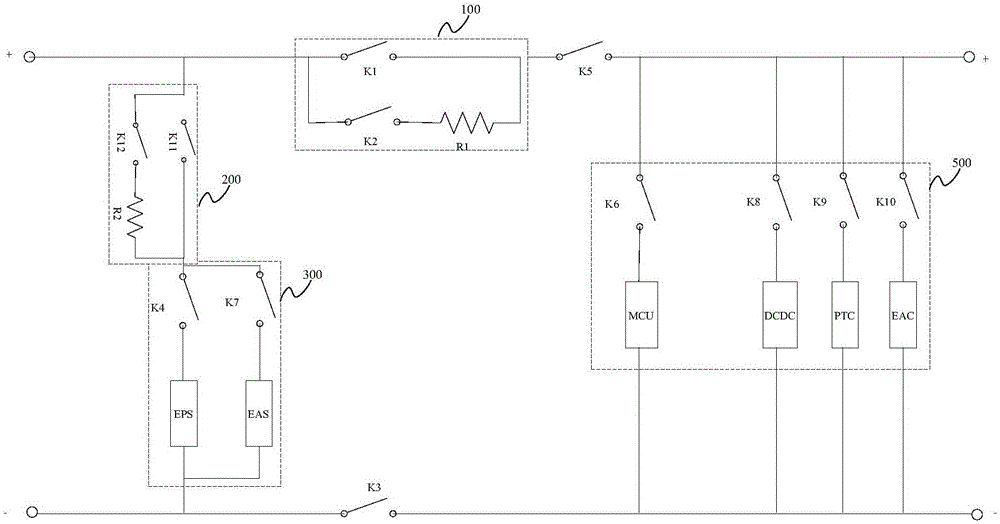

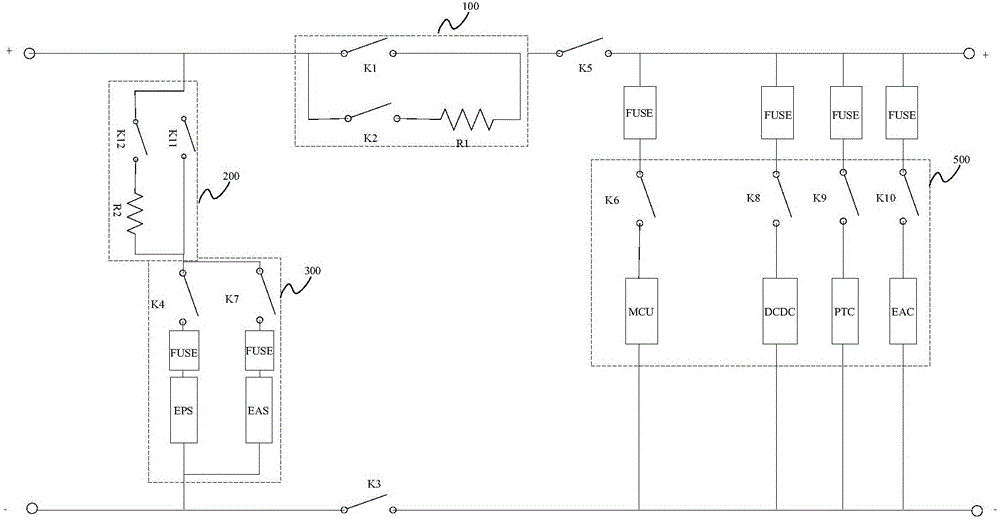

New energy automobile and high-voltage electric system thereof

ActiveCN106740127AReduce the probability of burningImprove job stabilityElectric devicesNew energyEngineering

The invention discloses a new energy automobile and a high-voltage electrical system thereof. According to the high-voltage electrical system of the new energy automobile, a circuit structure and a high-voltage power-off strategy of the high-voltage electrical system are redesigned, and unnecessary high-voltage power failure of a power-assisted steering system is thus avoided; due to the failure of the power-assisted steering system of the new energy automobile, it is difficult for a driver to change the vehicle trajectory and thus an accident may be resulted, however, by the redesign, the probability of such accident is also reduced.

Owner:WEICHAI POWER CO LTD

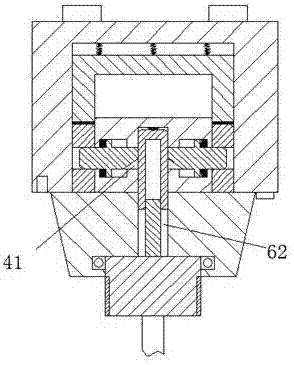

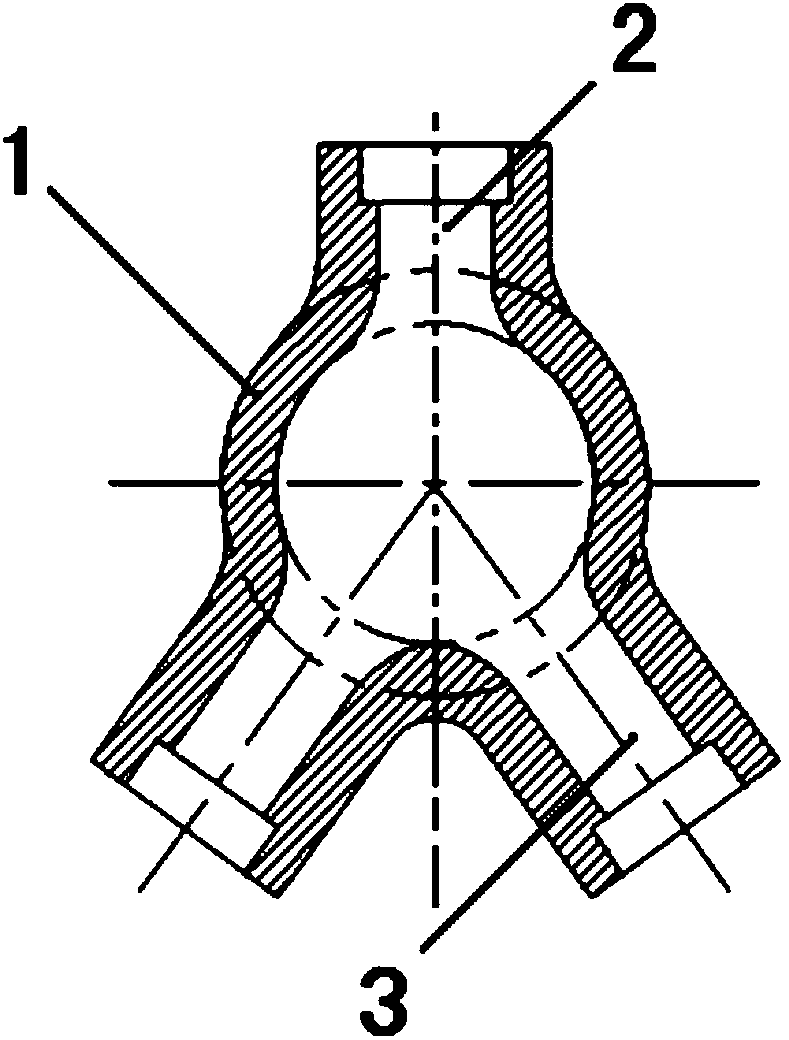

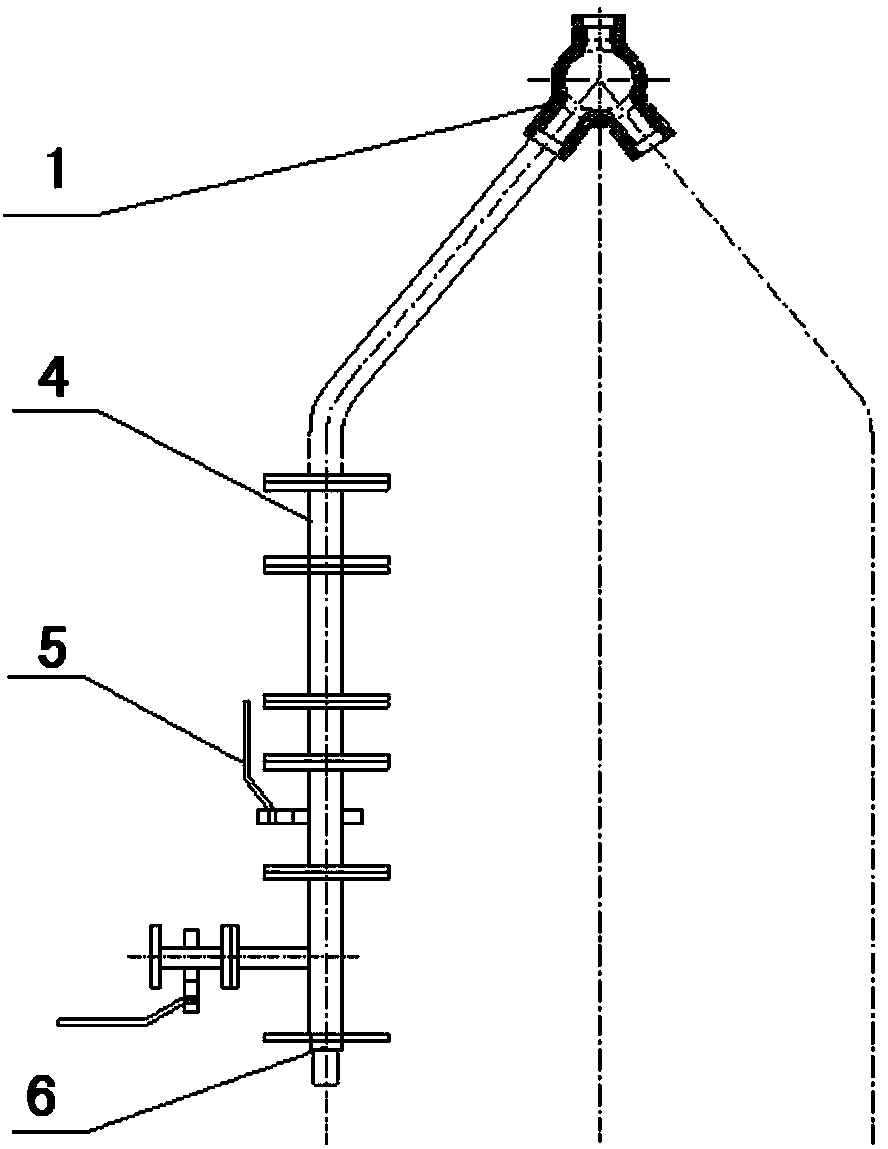

Injection equipment for blast furnace in metallurgical industry

InactiveCN103484583ASolve balance problemsSolve the problem of uneven distribution of pulverized coalBlast furnace componentsBlast furnace detailsCombustionFriction loss

The invention discloses injection equipment for a blast furnace in the metallurgical industry. The injection equipment comprises a distributor, wherein the distributor comprises a header pipe and branch pipes, a spherical cavity is arranged in the intersection between the header pipe and the branch pipes, and the included angle between the header pipe and each branch pipe is larger than 90 degrees. The distributor is provided with the two branch pipes, and the two branch pipes are distributed on two sides of the center line of the header pipe respectively. The injection equipment can resolve the problems that because airflow resistance loss of a bend is high, unbalanced branch pipe airflow and uneven coal powder distribution exist in practical production, tempering phenomena are produced, and safety products are not facilitated; the combustion ratio of coal powder is relatively low, blast furnace coal injection is relatively low, production efficiency is reduced, and production cost is improved. According to the technical scheme, the problems of resistance loss and airflow balancing of the branch pipes are fully considered in design of the novel double-gun distributor, and the requirement of the blast furnace for double-gun injection is met. Meanwhile airflow balancing of the branch pipes is facilitated, and the coal powder is uniformly injected.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Delay units and methods of making the same

InactiveUS7650840B2Increase and decrease burn rateReduce the probability of burningBlasting cartridgesImpact fuzesDelayed periodsEffective length

Owner:DYNO NOBEL INC

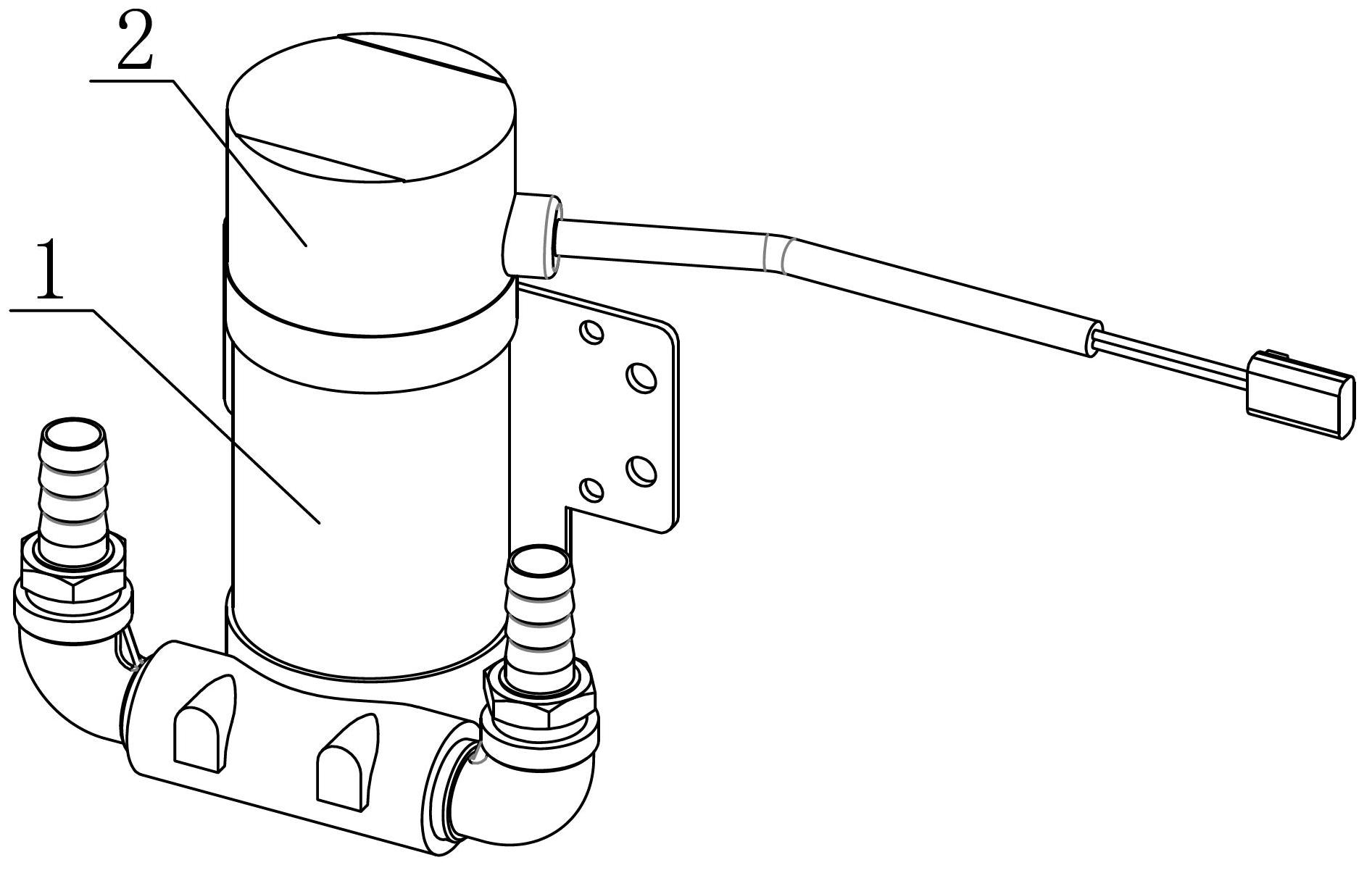

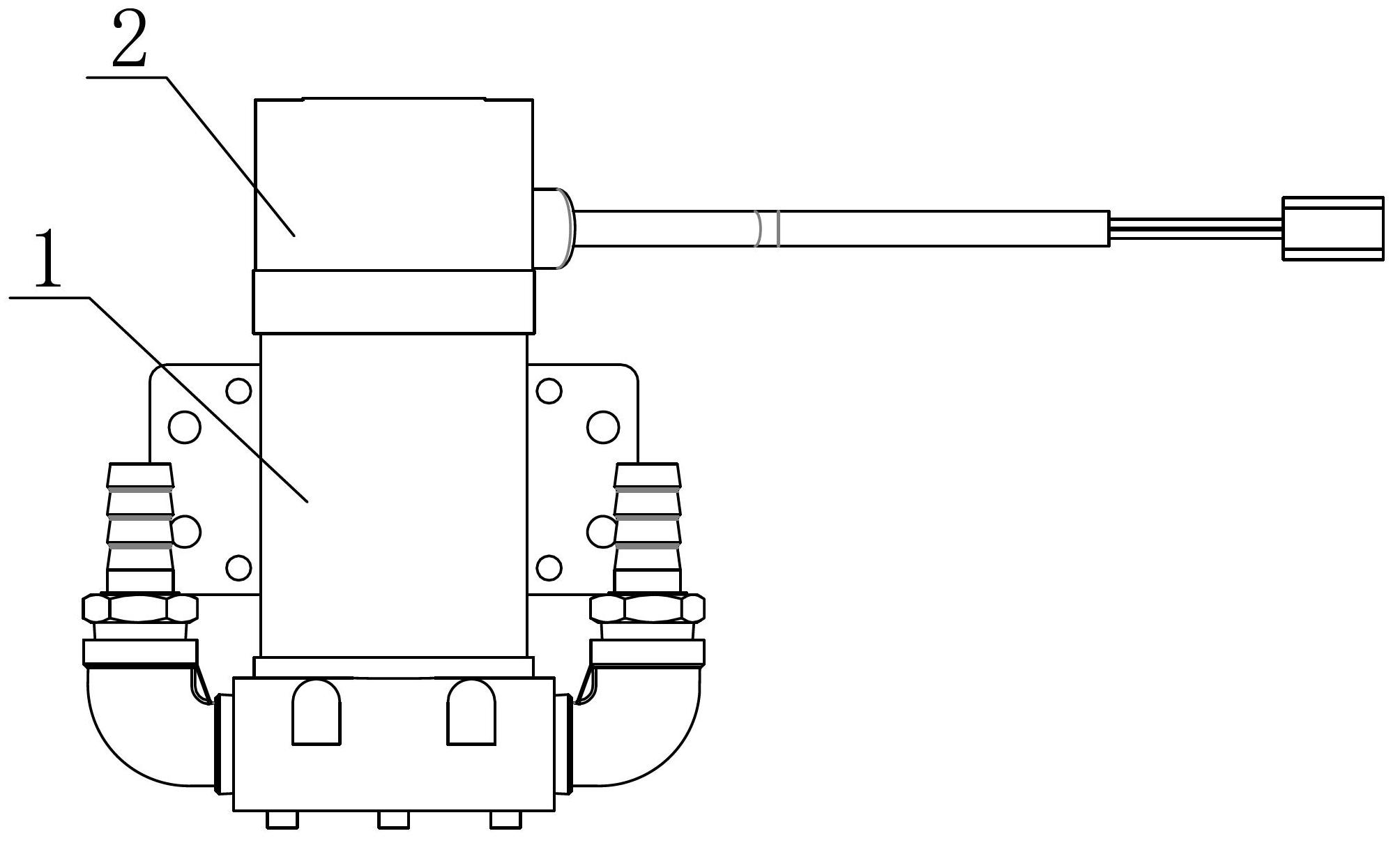

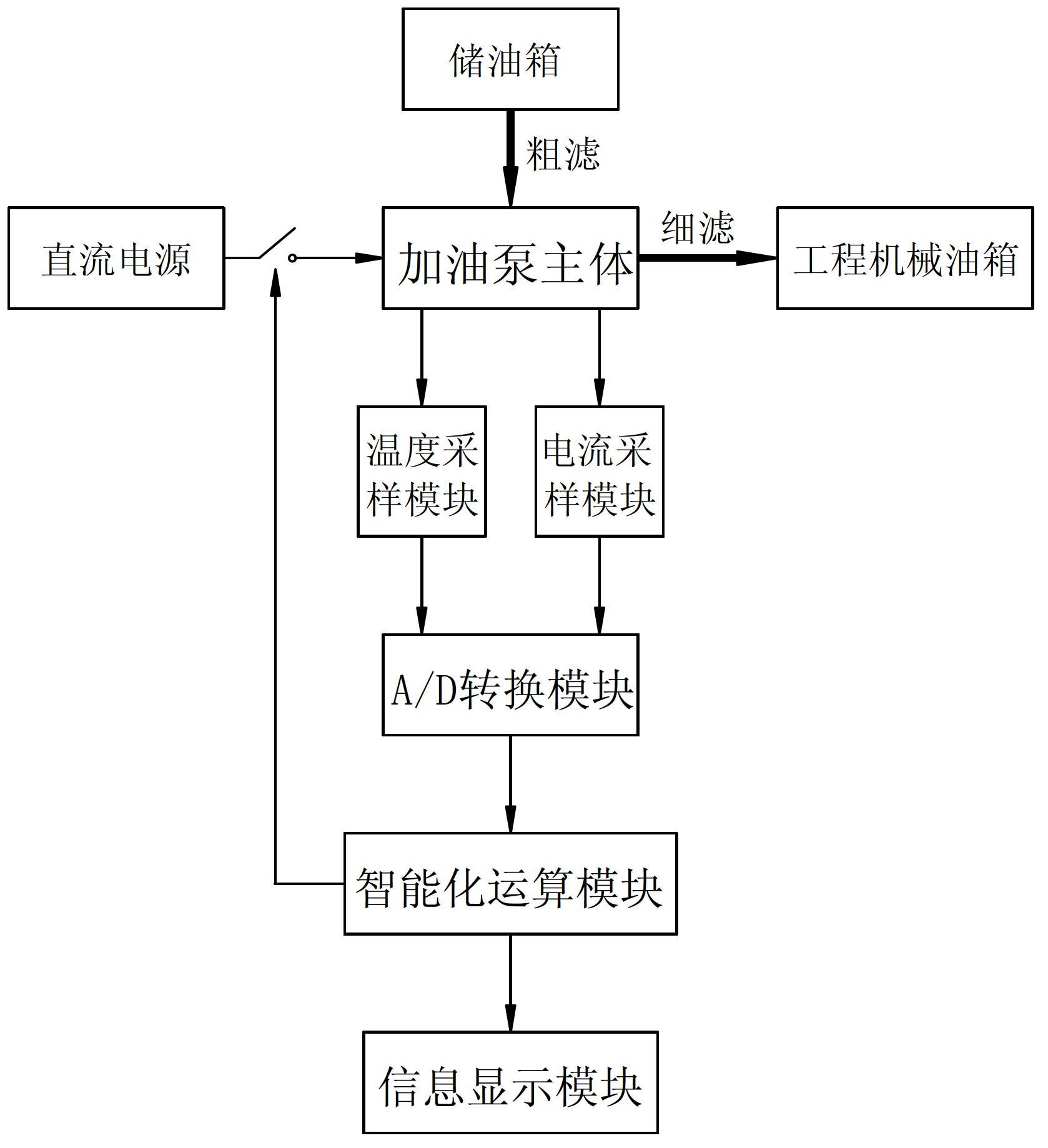

Intelligent DC petrol pump

InactiveCN102691657AReal time monitoringReduce the probability of burningMachines/enginesPump controlPower flowWorking temperature

The invention provides an intelligent DC petrol pump comprising a petrol pump main body, a DC power source for supplying power to the petrol pump main body, and an intelligent control system, wherein the intelligent control system comprises an information sampling module, an A / D conversion module, an intelligent calculation module and a working condition display module; the information sampling module comprises a temperature sampling module and a current sampling module; temperature and current information sampled by the information sampling module is converted by the A / D conversion module, and then input to the intelligent calculation module; and the obtained data are processed by the intelligent calculation module, and then input to the working condition display module. With the intelligent control system, the intelligent DC petrol pump can be monitored in such a manner that when the working temperature of the intelligent DC petrol pump is over-high, the intelligent DC petrol pump is blocked or clamped during work, or an oil storage tank is empty, a technician can carry out corresponding protective measures in advance, so as to reduce the overburning rate of the petrol pump; and due to the level control of the oil tank of a construction machine, oil filling operation can be stopped automatically when the oil tank is fully filled with oil, and the oil filling quantity can be displaced and controlled.

Owner:浙江赛安电气科技有限公司

Terminal card holder and terminal

InactiveCN107317897AReduce the probability of burningImprove experienceTransmissionTelephone set constructionsEngineeringCard holder

The invention discloses a terminal card holder. The terminal card holder comprises a card holder body which is matched with a card tray and provided with a card holder power pin, an ejector mechanism which is arranged in the card holder body and used for ejecting the card tray, and a power management module which is connected with the card holder power pin and is used for cutting off power of the card holder when the card tray exits from the card holder. The terminal card holder is characterized by further comprising a detection switch, wherein the detection switch is connected with the power management module, and cooperates with the ejector mechanism for outputting a card tray ejection trigger signal to the power management module when detecting that the ejector mechanism moves towards a first direction towards which the card tray is ejected, so as to enable the power management module to cut off power of the card holder power pin. The power of the card holder is cut off as a push rod begins to act, that is, the power of the card holder is cut off before the card tray is ejected; when the card tray exists, the card holder is not electrified, so that a card on the card tray is protected from burning down, the probability of card burning-down is lowered, and the user experience is improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

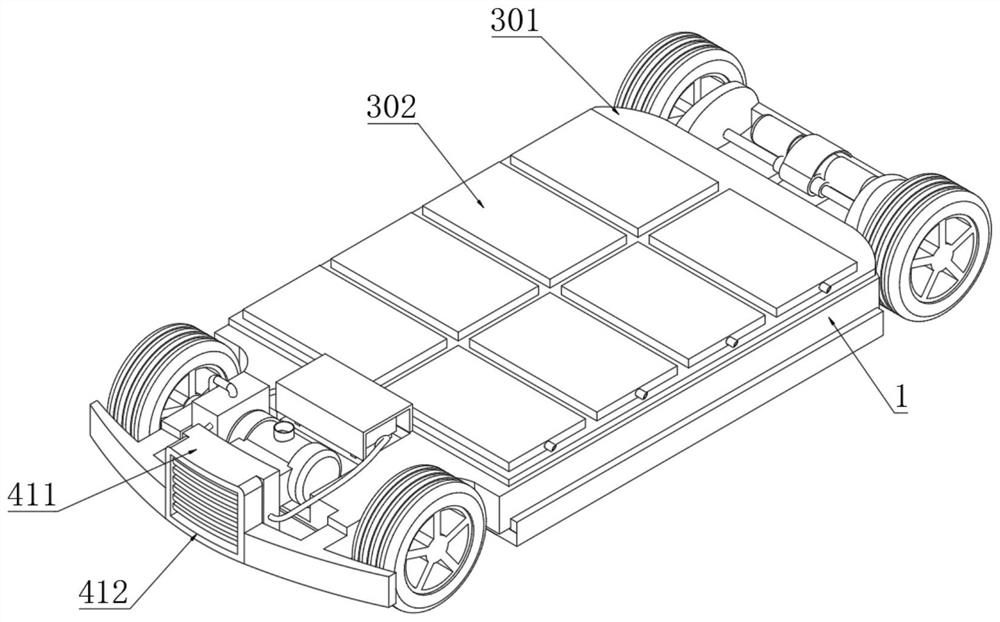

New energy automobile chassis

InactiveCN112060937AScientific and reasonable structureEasy to useAir-treating devicesElectric devicesElectrical batteryNew energy

The invention discloses a new energy automobile chassis. Mounting grooves are equidistantly formed in the top end of the chassis, and battery pack monitoring and protecting mechanisms are movably clamped in the mounting grooves; a heat dissipation and energy utilization mechanism is fixedly connected to one side of the top end of the chassis; a flat cable bundling mechanism is embedded into the middle position of the bottom end of the chassis; and the bottom end of the chassis is fixedly connected with a buffer damping mechanism, and battery boxes are embedded in the mounting grooves. According to the new energy automobile chassis, the battery pack monitoring and protecting mechanisms are arranged, battery packs are separately placed through the battery boxes, and the influence between thebattery packs is avoided, so that when parts of the battery packs are damaged, the other battery packs can still supply power to an automobile, and driving of the automobile is guaranteed; and meanwhile when the interiors of the battery packs swell and swells are formed due to the fact that the temperature of batteries is too high, ejector pins are pushed to be matched with supporting plates to push fixing rods to ascend.

Owner:邹思良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com