Patents

Literature

356results about How to "Reduced flame retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

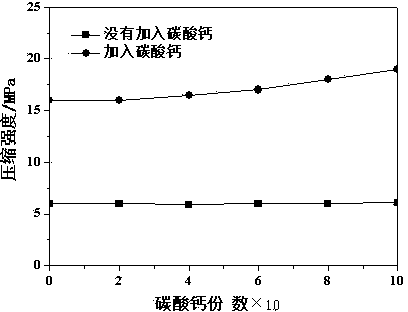

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

Ion conducting polymers and polymer blends for alkali metal ion batteries

ActiveUS20150288028A1Reduced flame retardancyLower glass transition temperatureSolid electrolytesFuel and secondary cellsPolyethylene oxideLithium–air battery

Electrolyte compositions for batteries such as lithium ion and lithium air batteries are described. In some embodiments the compositions are liquid compositions comprising (a) a homogeneous solvent system, said solvent system comprising a perfluropolyether (PFPE) and polyethylene oxide (PEO); and (b) an alkali metal salt dissolved in said solvent system. In other embodiments the compositions are solid electrolyte compositions comprising: (a) a solid polymer, said polymer comprising a crosslinked product of a crosslinkable perfluropolyether (PFPE) and a crosslinkable polyethylene oxide (PEO); and (b) an alkali metal ion salt dissolved in said polymer. Batteries containing such compositions as electrolytes are also described.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Halogen-free Tg resin composite and presoaked material and laminated board made by adopting same

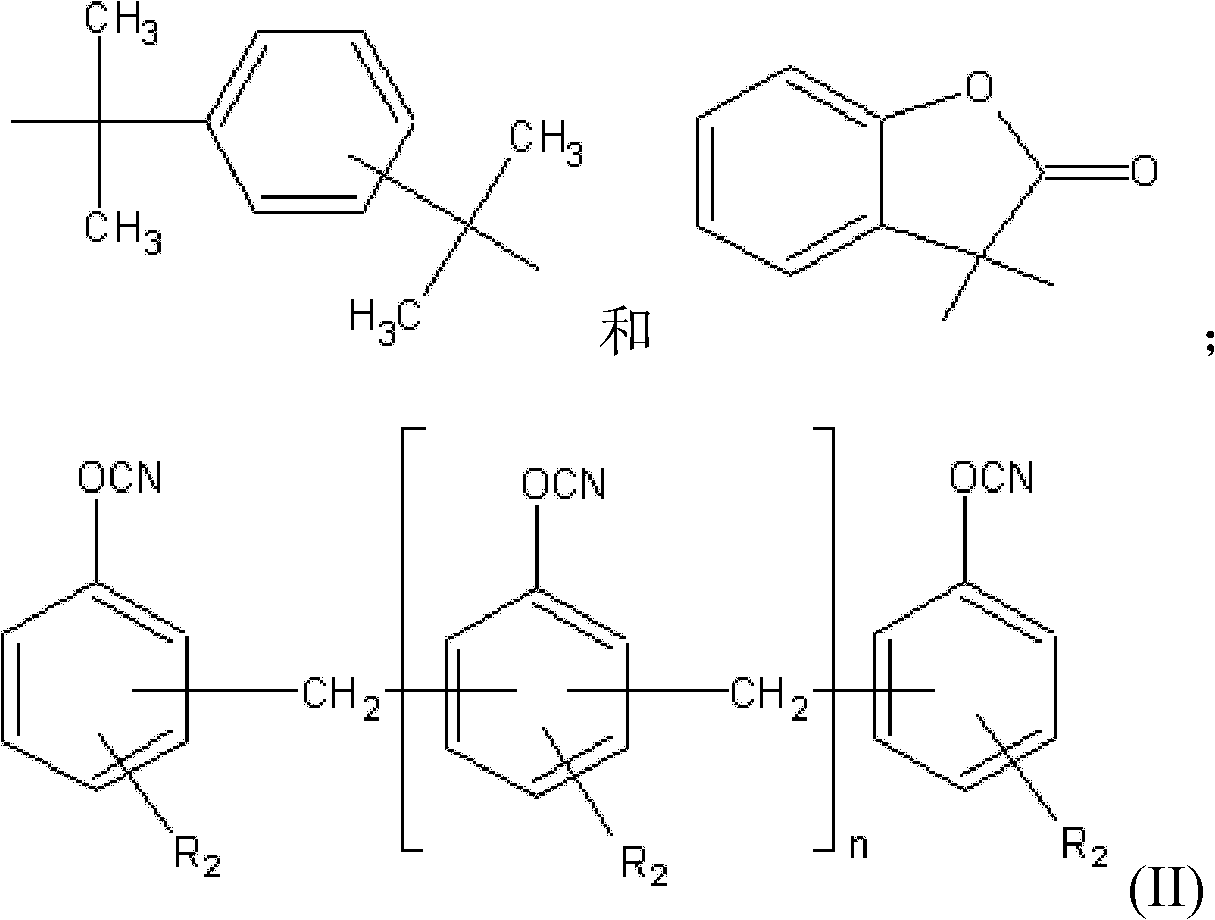

ActiveCN102134375AExcellent dielectric propertiesLow dielectric propertiesPrinted circuit aspectsSynthetic resin layered productsVitrificationPhosphonium

The invention relates to a halogen-free Tg resin composite and a presoaked material and a laminated board made by adopting the composite. Counted by part by weight of organic solid matters, the halogen-free high-Tg resin composite contains the following components according to part by weight: (A) 10 to 50 parts by weight of cyanate resin; (B) 10 to 50 parts by weight of at least one compound withdihydro-benzoxazine ring; (C) 10 to 50 parts by weight of at least one kind of bismaleimides resin; (D) 10 to 50 parts by weight of at least one kind of poly-epoxy compound; and (E) 5 to 30 parts by weight of at least one kind phosphonium flame retardant. The halogen-free high-Tg resin composite has the performances of low water absorption, low CTE (coefficient of thermal expansion), high Tg, good dielectric property and the like, and the presoaked material and laminated board made by adopting the composite has the characteristics of high vitrification transition temperature, low CTE, low dielectric constant, low water absorption, high thermal resistance and the like, thus being application to multi-layer circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

Phase-change energy-storage polyurethane foam and preparation method thereof

The invention discloses a phase-change polyurethane foam and a preparation method thereof. The foam is prepared by subjecting a polyurethane foam raw material to processes of reacting, foaming, and curing; wherein the polyurethane foam raw material comprises polyether, polymethylene polyphenyl isocyanate, silicone oil, and methyl chloride; the reactions are carrier out after the mixing of a phase-change energy-storage microcapsule and the polyurethane foam raw material, the phase-change energy-storage microcapsule is composed of a capsule wall made of polyurethane-polysiloxane and a capsule core made of an organic phase-change material, and polycarbodiimide is taken as the cross-linking agent. The phase-change energy-storage microcapsule integrates the advantages of organic materials and inorganic materials together, namely has the organic materials' advantages of flexibility and elasticity, also has the inorganic materials' advantages of excellent mechanical performance and fire-retardant performance, and overcomes the shortage of easy separation between the conventional microcapsule and the foam substrate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Durable anti-flaming anti-microbial mould-proof fabric, preparation method and application thereof

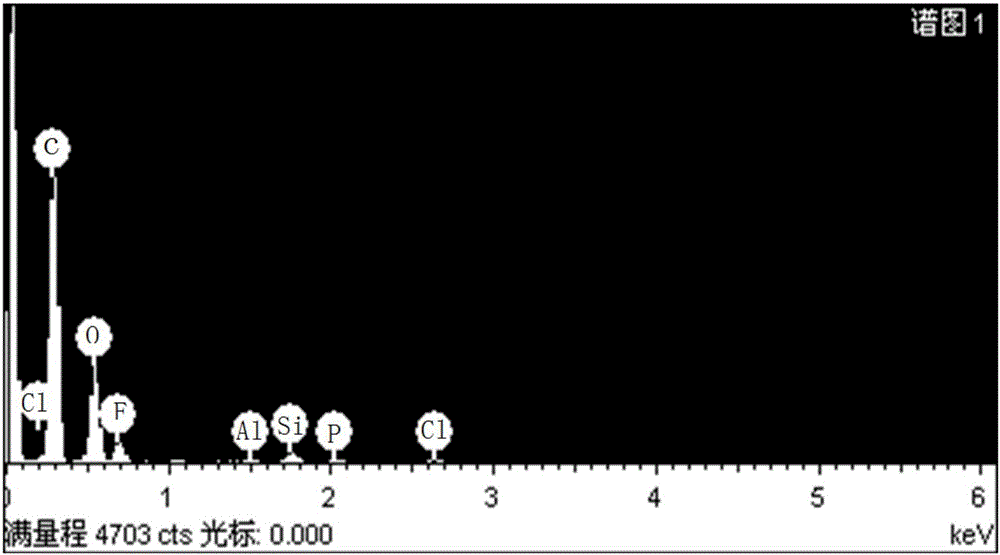

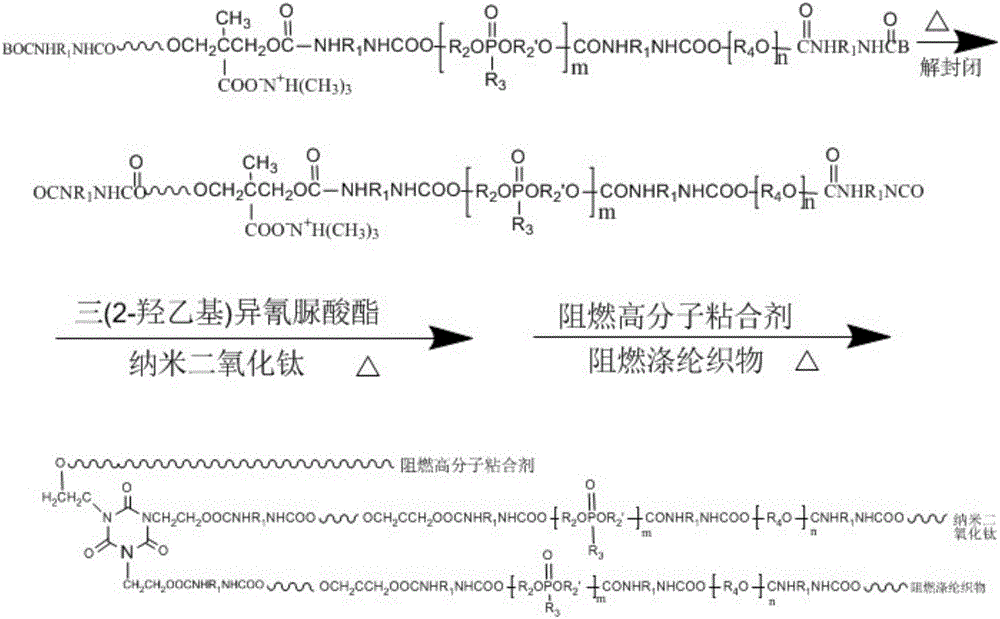

ActiveCN106192370AGuaranteed flame retardant performanceHas antibacterial and antifungal effectsFibre treatmentAdhesivePrepolymer

The invention discloses a durable anti-flaming anti-microbial mould-proof fabric. The durable anti-flaming anti-microbial mould-proof fabric contains an anti-flaming dacron fabric and an anti-microbial agent, a mould-proof agent, an anti-flaming synergist, a photocatalyst and a penetrating agent which are combined with the anti-flaming dacron fabric in a physical manner and chemical manner, wherein the physical manner is to combine through the cementing action of the anti-flaming macromolecule adhesive and the chemical manner is to bond through the crosslinking by generating NCO by de-blocking the phosphorus containing blocking type polyurethane prepolymer at high temperature. The durable anti-flaming anti-microbial mould-proof fabric provided by the invention still has excellent anti-microbial mould-proof performances after being washed for 40 times with water, and formaldehyde can be removed. The anti-flaming performance after the fabric is washed for 50 times with water still can meet the GB8624-2012 B1 level and GB20286-2006 anti-flaming level 1 requirements.

Owner:杭州中隽科技有限公司

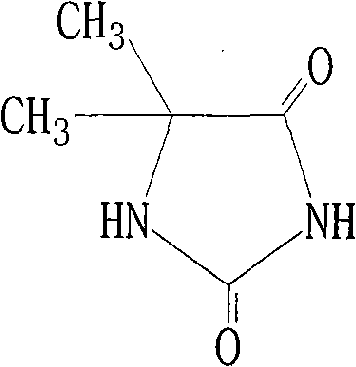

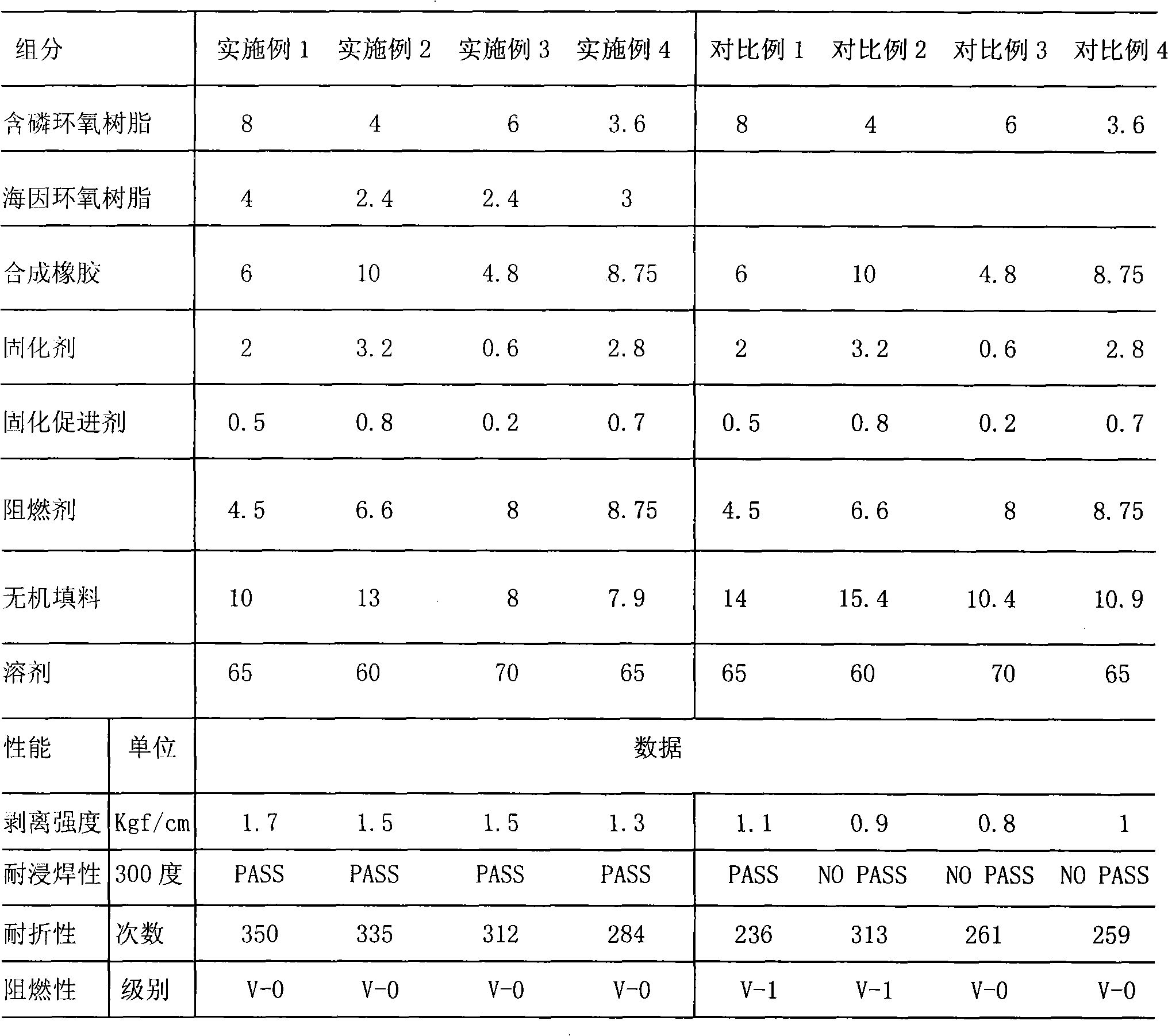

Halogen-free flame retardant epoxy resin composite and flexible copper clad laminate prepared with same

ActiveCN101633770ALow viscosityGood workmanshipInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentWeather resistanceChemistry

The invention discloses a halogen-free flame retardant epoxy resin composite and a flexible copper clad laminate prepared from same. The invention is characterized that hydantoin epoxy resin is added in the existing composite and the hydantoin epoxy resin has the advantage that the viscosity is low, the manufacturability is good; the thermal stability is good, the thermostability is high; the weather resistance is good, the hydantoin epoxy resin can be shined by sunlight and ultraviolet light without yellowing and chalking; the hydantoin epoxy resin can be is resistant to salt fog, the corrosion resistance is outstanding, the product has low toxicity and good flame retardant and the like. Therefore the hydantoin epoxy resin is very applicable to being used to prepare the halogen-free flame retardant epoxy resin composite. In addition, the invention also provides a polyimide copper clad laminate prepared by adopting the composite as adhesive, and the prepared copper clad laminate has the advantage of good flame retardant performance, high peel strength, good folding endurance and the like and can increase the electrical property of the copper clad laminate.

Owner:PANYU NANSHA YAN TIN CHEM

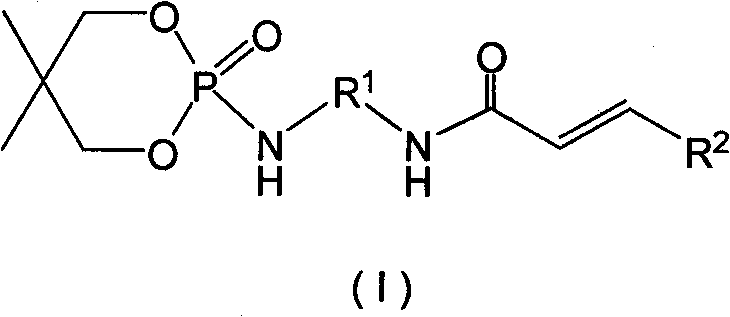

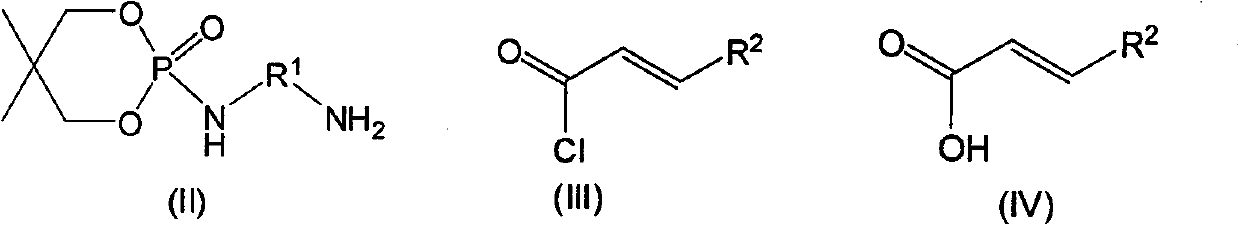

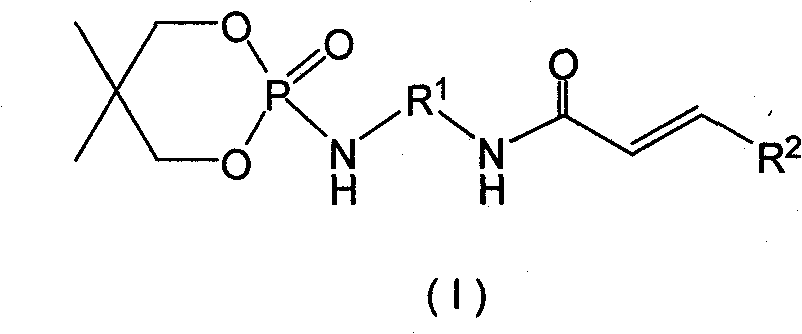

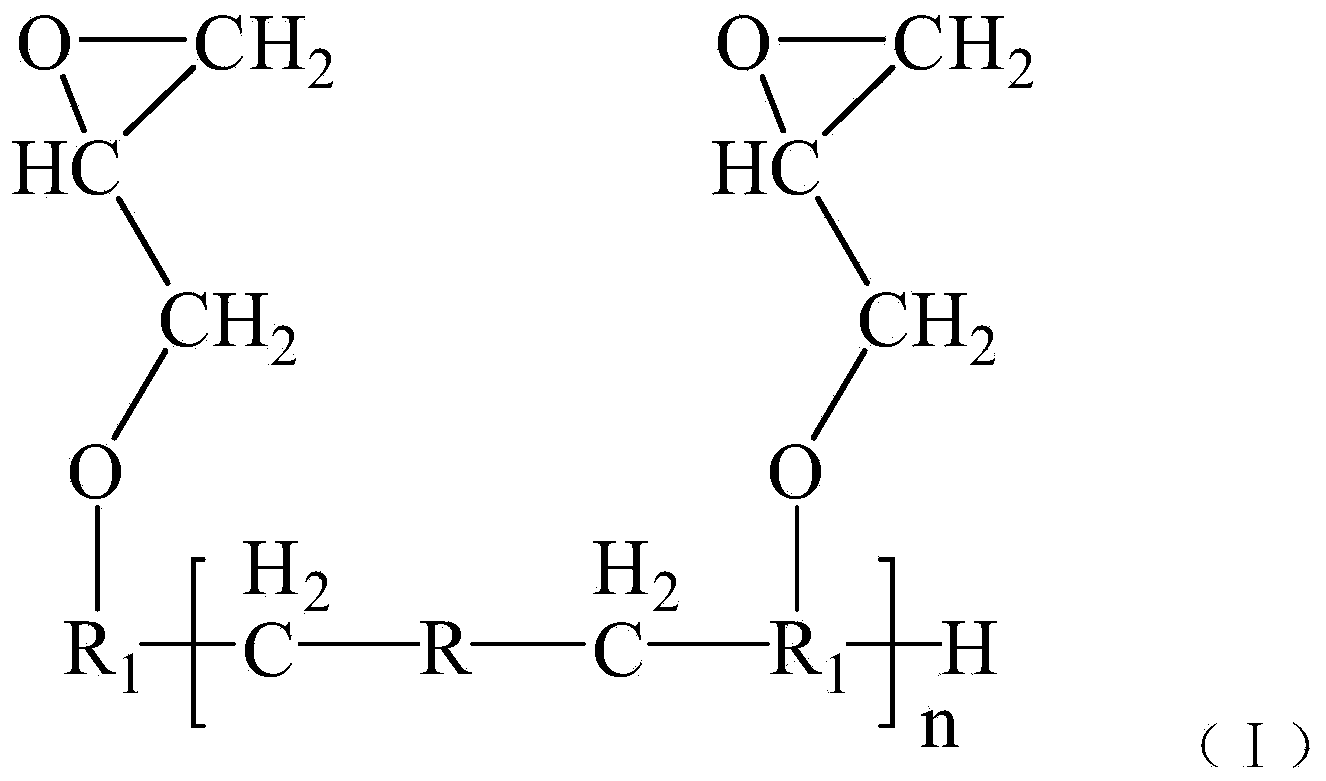

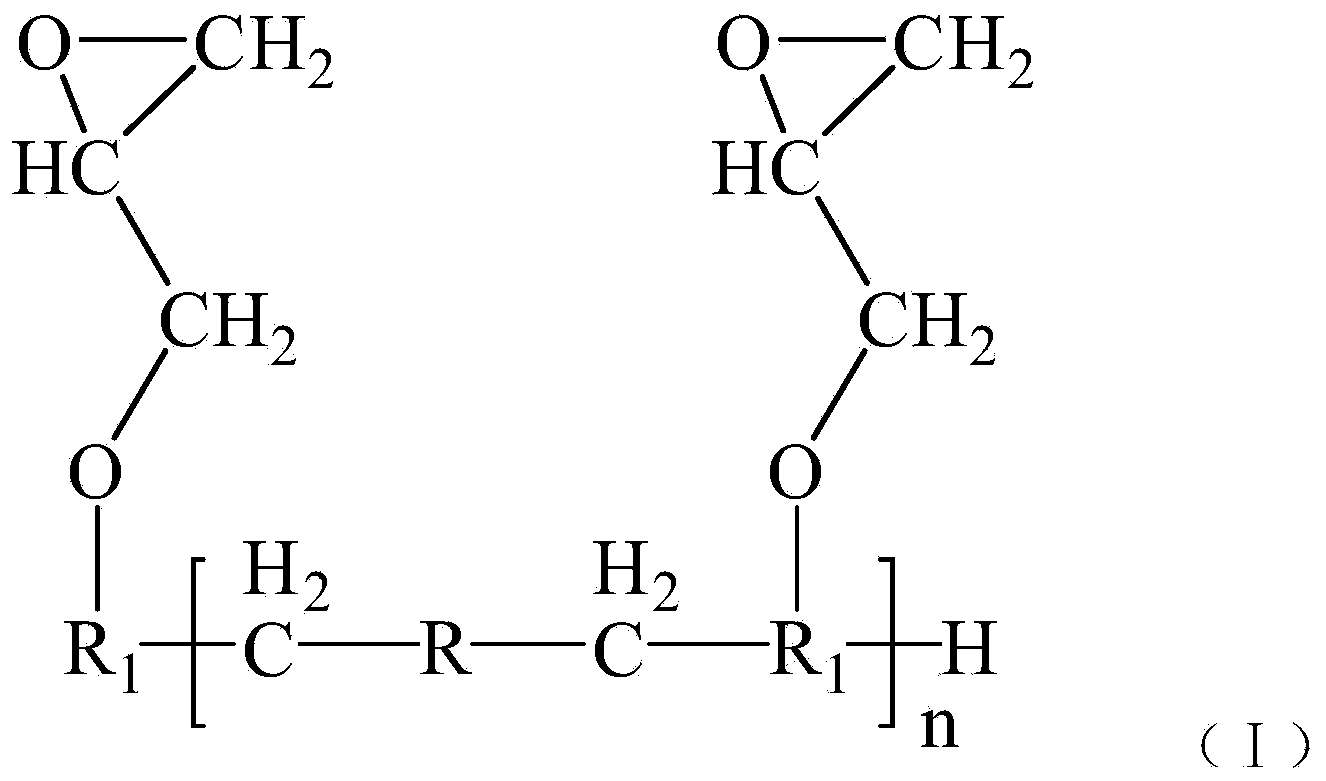

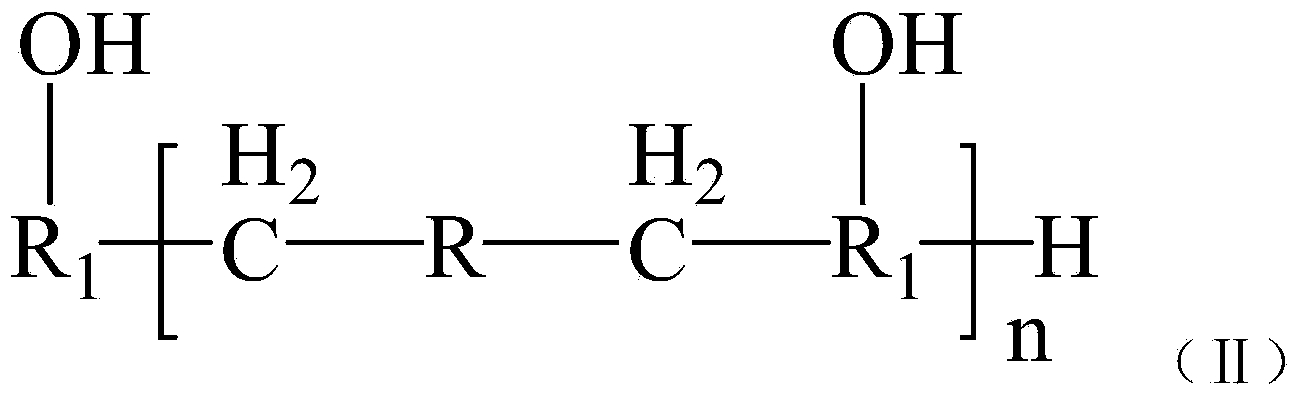

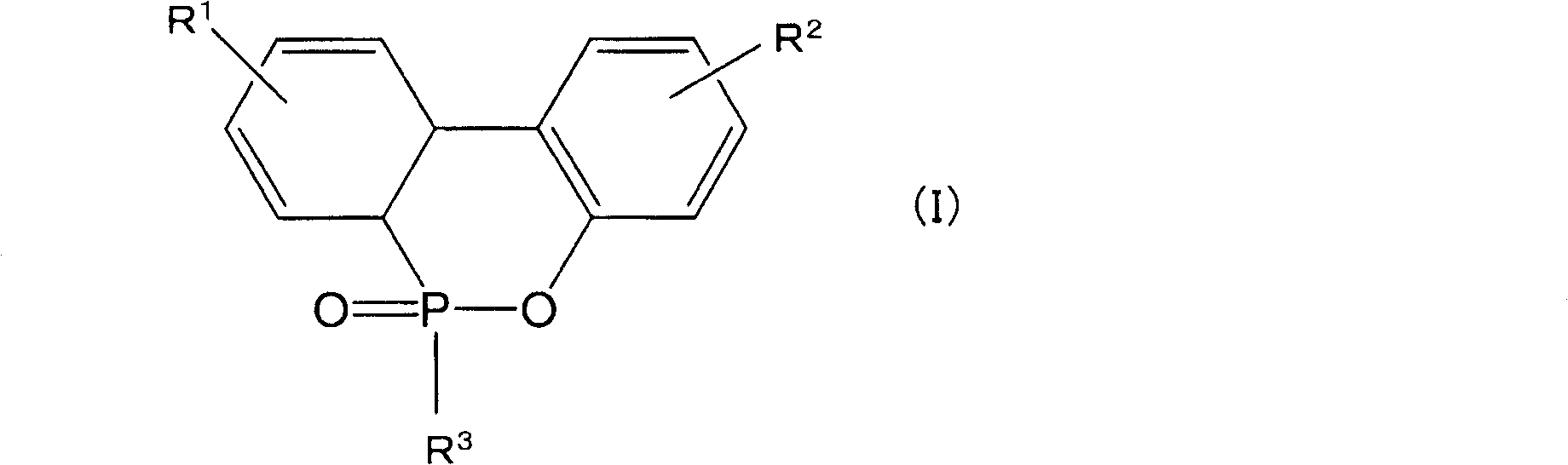

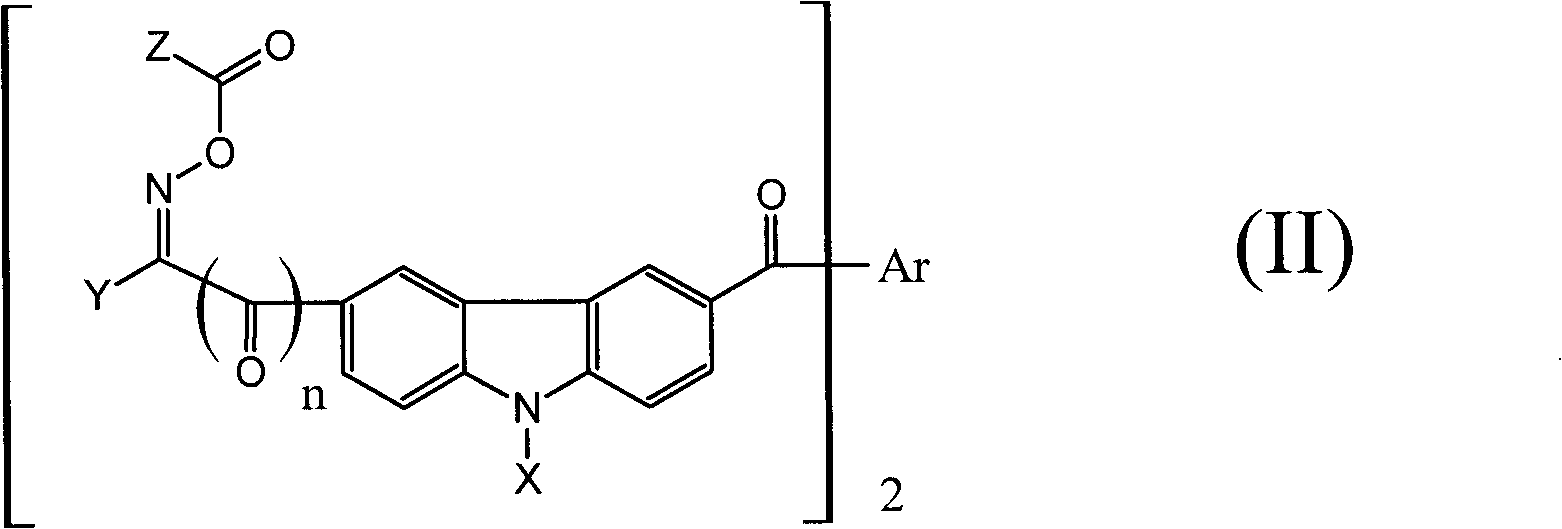

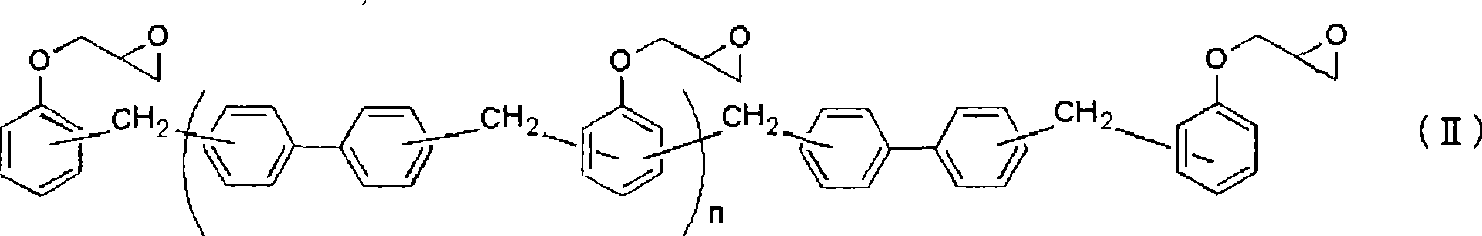

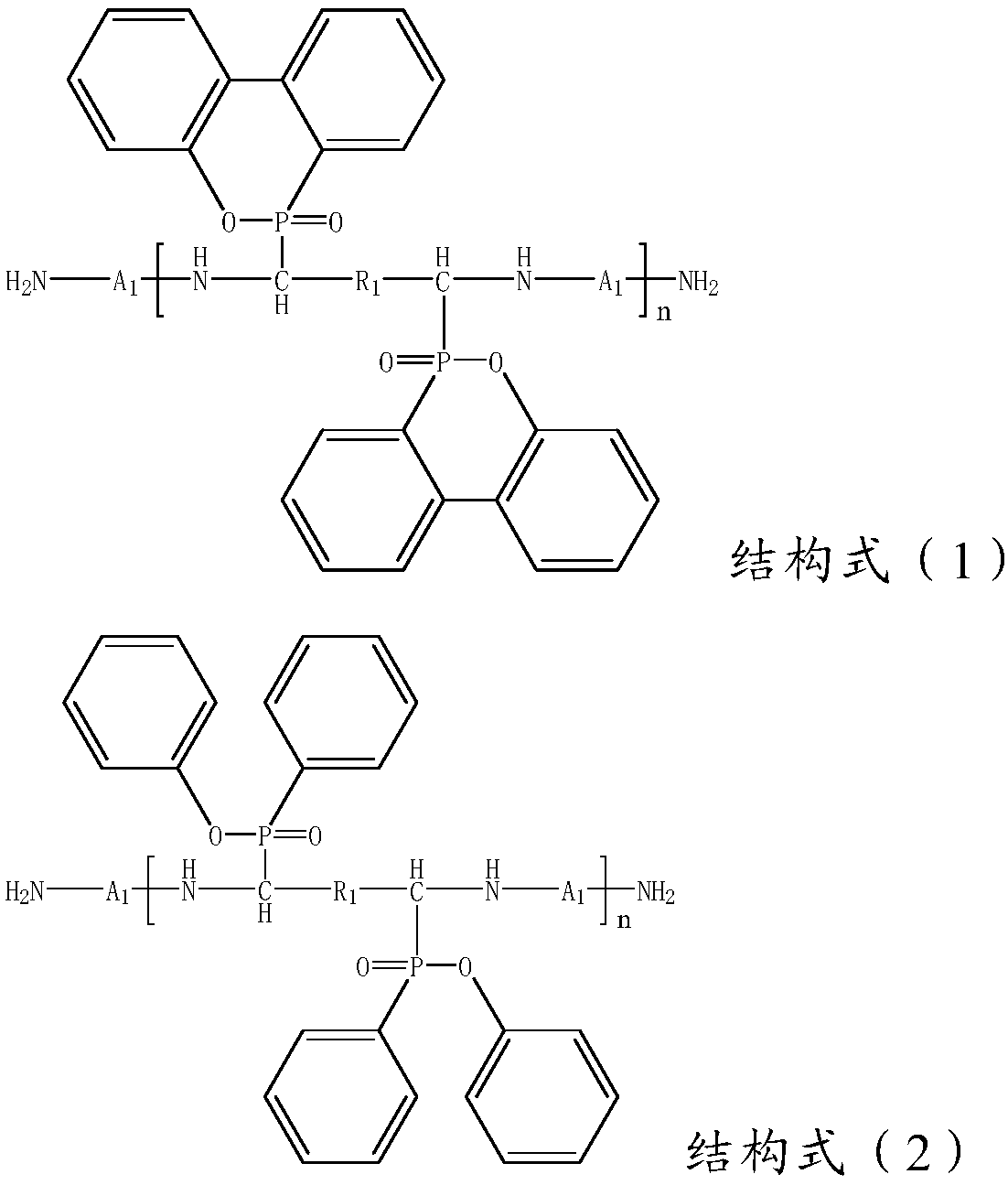

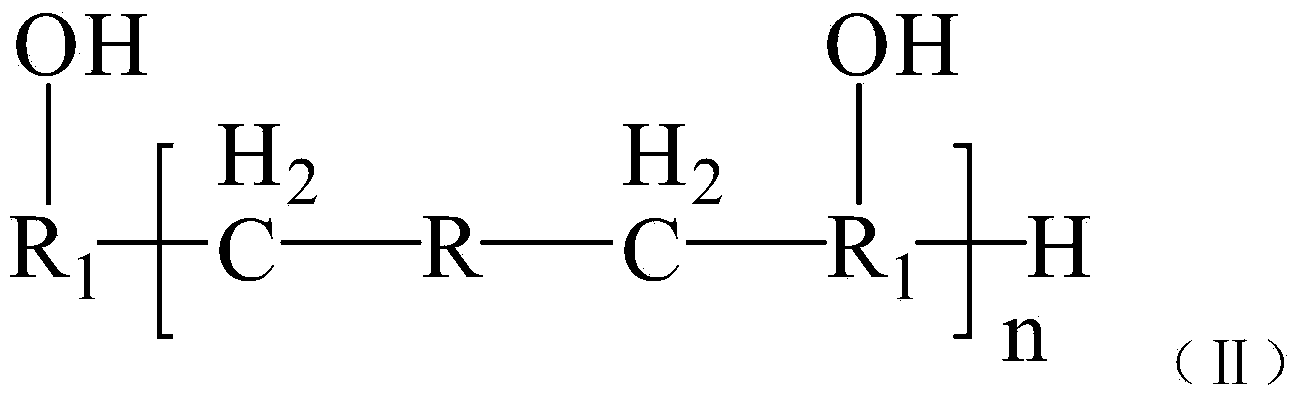

Reaction type phosphorus/nitrogen flame retardant, and its preparation method and application

ActiveCN102225953AImprove flame retardant performanceReduced flame retardancyGroup 5/15 element organic compoundsMolecular materialsNitrogen

The invention discloses a reaction type phosphorus / nitrogen flame retardant, and its preparation method and application. A structure of the reaction type phosphorus / nitrogen flame retardant is shown in the formula (I). The preparation method of the reaction type phosphorus / nitrogen flame retardant comprises the following steps that: a phosphaspiro-containing amine compound shown in the formula (II) and a carboxylic acid halide shown in the formula (III) undergo a reaction or the phosphaspiro-containing amine compound shown in the formula (II) and a carboxylic acid shown in the formula (IV) undergo a reaction to obtain the reaction type phosphorus / nitrogen flame retardant. In the invention, a copolymer is produced from a reaction type phosphorus / nitrogen flame retardant and monomers and is utilized for modifying high-molecular materials in a fire retardant characteristic, and through synergistic effects of nitrogen and phosphorus elements in the phosphorus / nitrogen flame retardant, flame retardant effects of high-molecular materials adopting the phosphorus / nitrogen flame retardant can be improved, thus a usage amount of the phosphorus / nitrogen flame retardant in the high-molecular materials is decreased and a cost of the high-molecular materials with a flame retardant characteristic is reduced.

Owner:浙江通力新材料科技股份有限公司

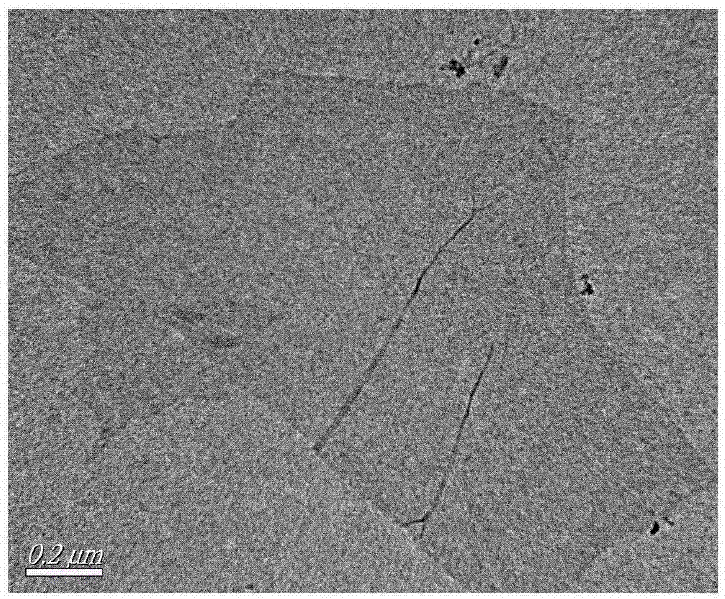

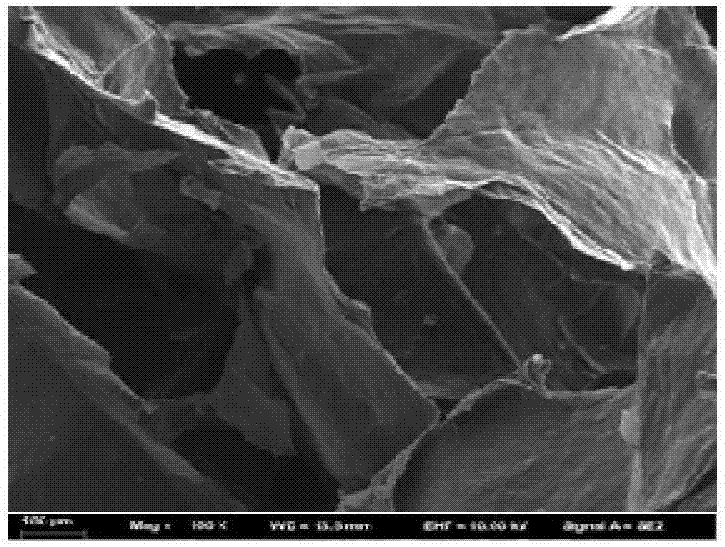

Preparation method of bamboo nanocellulose/reduced graphene oxide composite carbon aerogel and application of preparation method

InactiveCN107265434AImprove mechanical propertiesReduce manufacturing costCarbon preparation/purificationEthylenediaminePretreatment method

The invention belongs to the field of environmental function material preparation and pollutant treatment and relates to a preparation method of bamboo nanocellulose / reduced graphene oxide composite carbon aerogel. The preparation method comprises the steps of firstly adopting bamboo as a raw material, preparing the nanocellulose through a peroxide pretreatment method and an ultrasonic stripping method; inducing nanocellulose and graphene oxide solution gelatinization through ethylenediamine to prepare the bamboo nanocellulose / graphene oxide aerogel; and washing to remove residual ethylenediamine and obtaining low-density, hydrophobic, porous and flame-retardant bamboo nanocellulose / reduced graphene oxide composite carbon aerogel by combining a freeze drying method and a high-temperature pyrolysis method. The material has high adsorption capacity on oil and organic solvent pollutants. By adopting cheap and renewable bamboo as the raw material, the prepared composite carbon aerogel material is excellent in performance and suitable for large-scale production.

Owner:JIANGSU UNIV

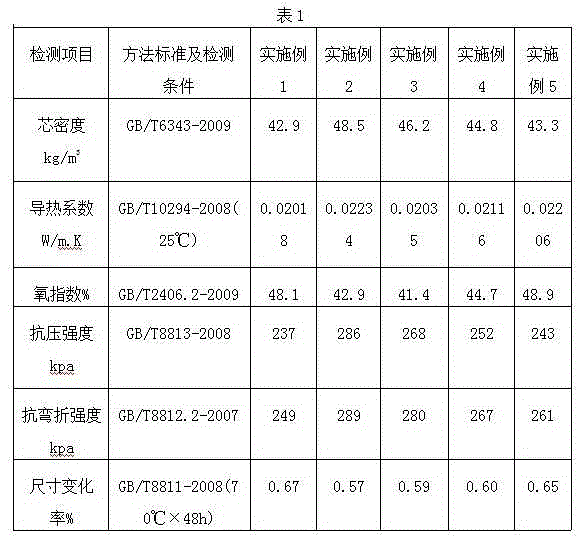

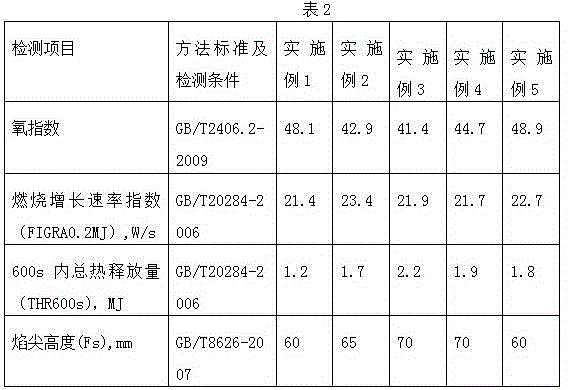

Flame-retardant rigid polyurethane foam heat insulation plate

The invention relates to a flame-retardant rigid polyurethane foam heat insulation plate. The flame-retardant rigid polyurethane foam heat insulation plate comprises a component A and a component B, wherein the component A is formed by mixing flame-retardant polyether or flame-retardant polyether polyol, amidogen ether polyol, common polyether polyol, a foam stabilizer, a catalyst, a reactive flame retardant, modified expandable graphite and a foaming agent according to a certain proportion. The component B is isocyanate. The component A and the component B are mixed, and then are subjected to compression molding to obtain the flame-retardant heat insulation plate. According to the prepared flame-retardant rapid polyurethane foam heat insulation plate, flame-retardant testing data exceed a GB8624-2012B1-grade flame-retardant standard, the oxygen index is up to 48.9, and the heat conduction coefficient is about 0.02W / m.k. The flame-retardant rigid polyurethane foam heat insulation plate has excellent compressive strength and bending resistance strength. The flame-retardant rigid polyurethane foam heat insulation plate is suitable for being applied to the fields of flame retardance and heat insulation of building walls, refrigeration houses, refrigerators, solar water heaters and the like.

Owner:WEIHAI YUNSHAN TECH +1

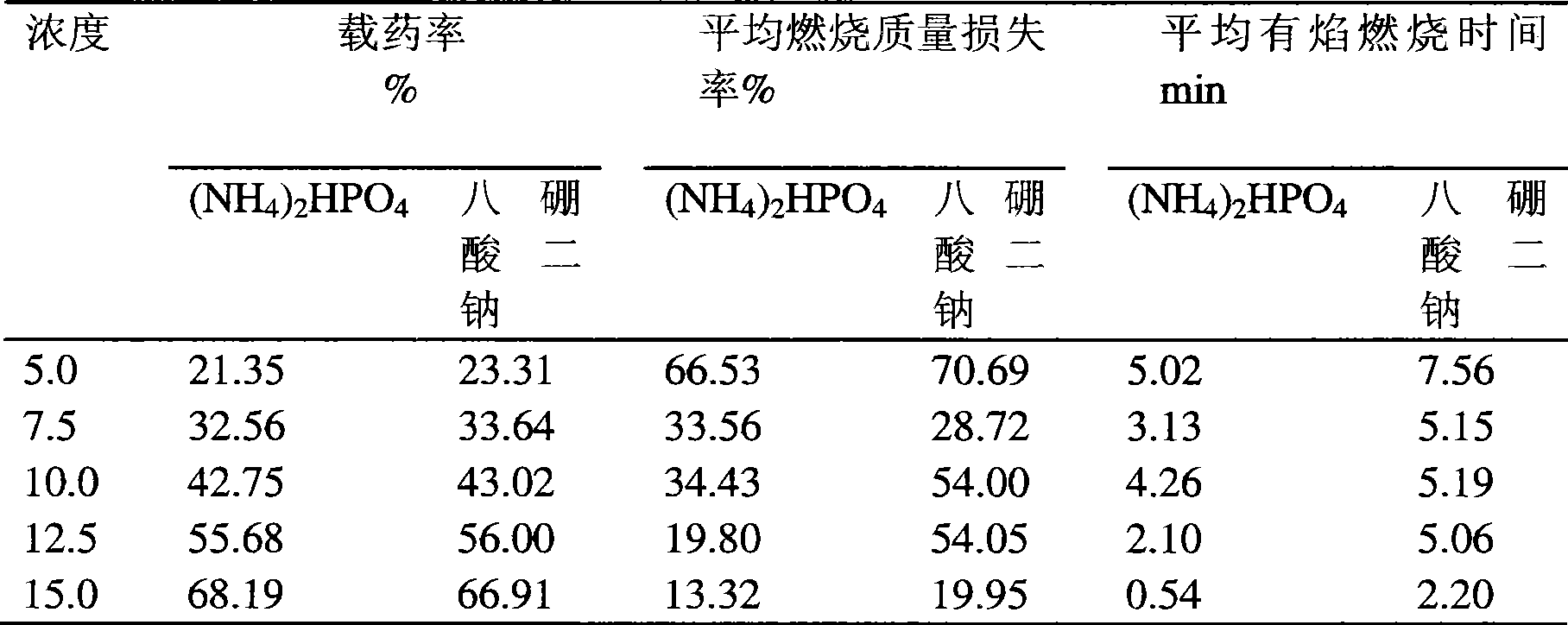

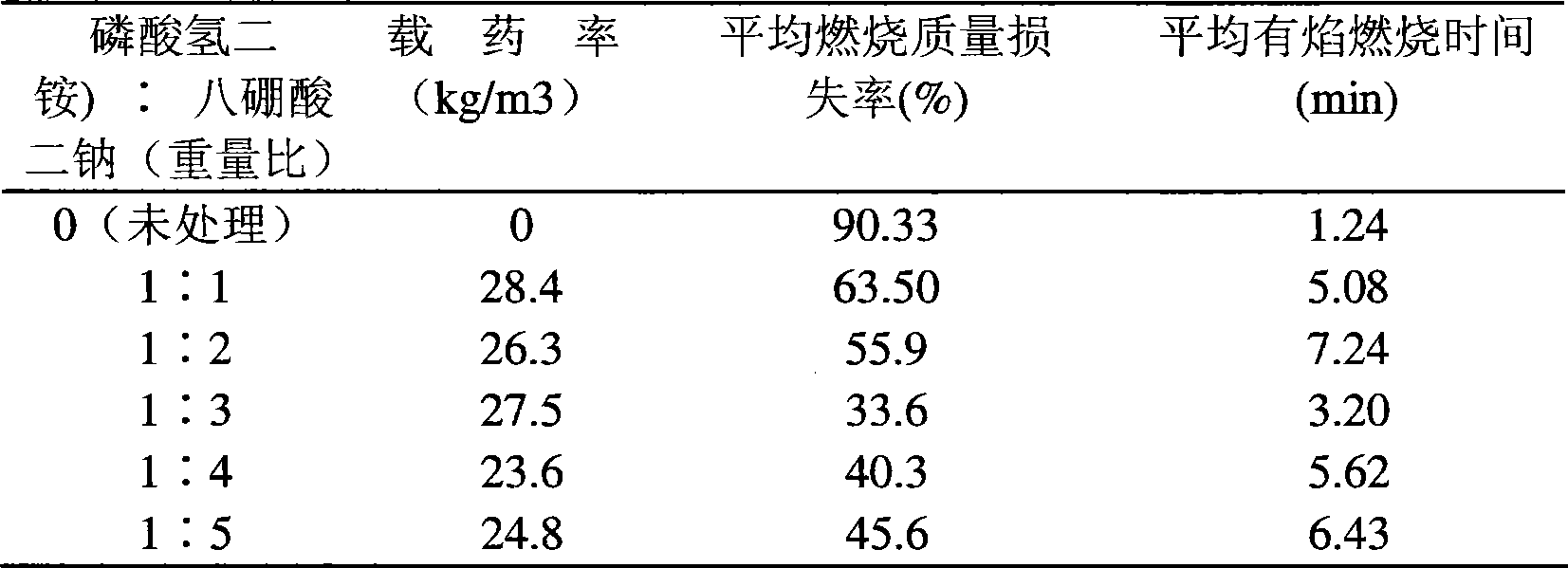

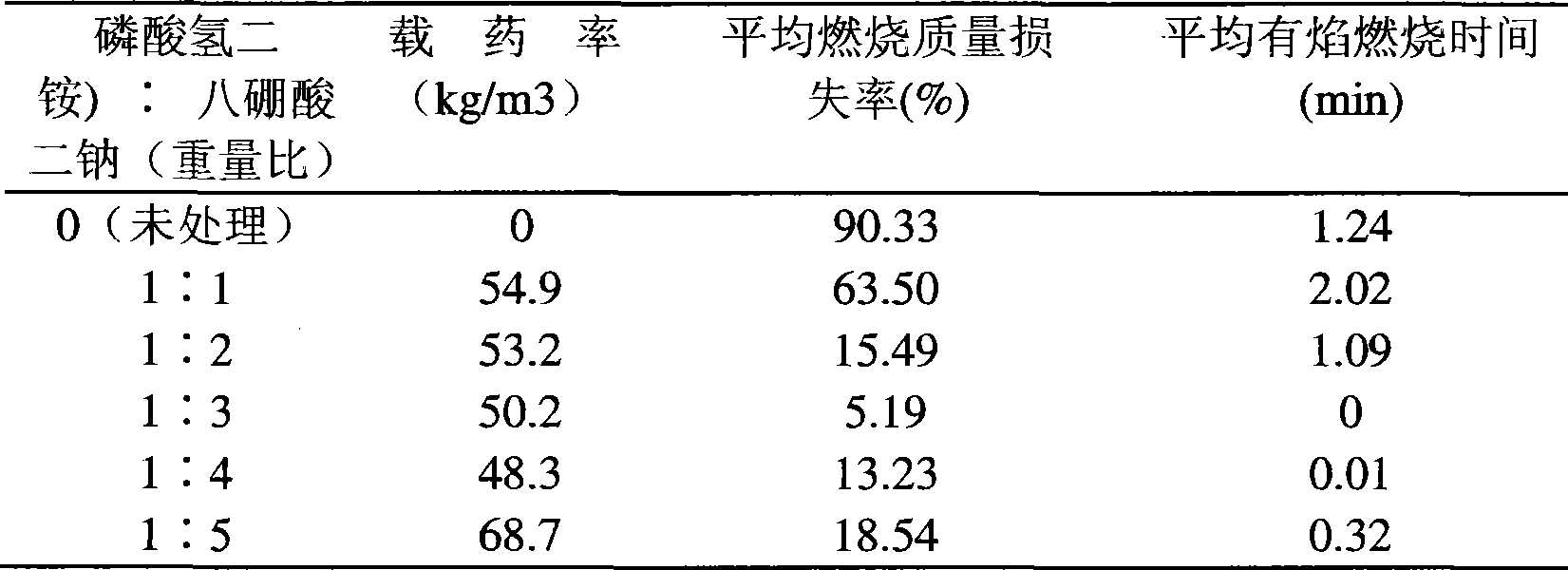

Phosphorus nitrogen boron lumber combustion inhibitor

The invention relates to a phosphorus-nitrogen-boron wood flame retardant, which is characterized in that the range of each component name and weight percentage of the compositions comprises: 70 to 80 percent of 8-sodium diborate and 18 to 30 percent of one or two of inorganic phosphorus-nitrogen compound and water soluble ammonium polyphosphate, wherein the inorganic phosphorus-nitrogen compound is one or more of ammonium phosphate, diammonium phosphate and monoammonium phosphate. A germicide with the weight percentage of between 0.7 and 3 percent or / and a staining agent with the weight percentage of between 0.7 and 7 percent can be added to the phosphorus-nitrogen-boron wood flame retardant, wherein the germicide is one or more of chlorothalonil, sanmate and tebuconazol; and the staining agent is one or more of malachite green, alkali red, alkali blue, alkali yellow and alkali black. The phosphorus-nitrogen-boron wood flame retardant can be dissolved in water and the concentration of the wood flame retardant is less than or equal to 20 percent. Wood subjected to treatment through the phosphorus-nitrogen-boron wood flame retardant has the effects of good flame retardant effect, small hygroscopicity, corrosion resistance, insect prevention, mildew prevention, more color change and so on. The phosphorus-nitrogen-boron wood flame retardant has the advantages of low toxicity, no chlorine and lower cost.

Owner:GUANGDONG ACAD OF FORESTRY +1

Low smoke zero halogen flame retardant sheath layer for optical cable

ActiveCN102977451ASolve the technical problem of outer diameter fluctuationReduced filling capacityFibre mechanical structuresAluminium hydroxideCarvacryl acetate

The invention discloses a low smoke zero halogen flame retardant sheath layer for an optical cable, wherein the optical cable comprises an optical cable core and a low smoke zero halogen flame retardant sheath layer covering the outer surface of the optical cable, and the low smoke zero halogen flame retardant sheath layer is composed of the following components in parts by weight: 65-75 parts of ethylene-vinyl acetate copolymer, 20-30 parts of high-pressure metallocene polyethylene, 10-20 parts of special modified polyethylene, 70-110 parts of aluminium hydroxide, 20-30 parts of magnesium hydroxide, 2-5 parts of silicone master batch, 1-3 parts of polyethylene wax, 30-50 parts of flowable agent, 0.15-0.45 parts of antioxidant and 2-5 parts of black master batch. The low smoke zero halogen flame retardant sheath layer for the optical cable enables the outer diameter of the optical cable to be even, thereby guaranteeing the shrinkage integrity of the optical cable core; as a result, signals can not be greatly attenuated in the transmission process in the cable; and simultaneously, the tensile strength of the cable is greater than or equal to 13 MPa, while the elongation at break is greater than or equal to 250% and the oxygen index is greater than or equal to 34%; and the cable has excellent mechanical properties.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

Aqueous-oily low-viscosity environment-friendly two-component adhesive and preparation method thereof

PendingCN107488431ACritical volume reductionReduced flame retardancyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNano siliconOrganic solvent

The invention relates to an aqueous-oily low-viscosity environment-friendly two-component adhesive and a preparation method thereof. The objective of the invention is to provide the environment-friendly polyurethane two-component adhesive which is good in bonding strength, wettability, fire resistance and weatherability, stable in performance and easy to coat. The adhesive is characterized in that the adhesive comprises a component A including water glass and a component B including a mixture of a polyurethane prepolymer and polyisocyanate; the component A contains no or little filler; and in the component B, the content of NCO is 8.5 to 25%, and the content of an organic solvent is 8% to 19.9%. Because the component A contains no or little filler and the component B contains an appropriate amount of an organic solvent, hydroxylated nano-silicon in the water glass and a part of reactive groups wrapped and concealed in the prepolymer are fully activated, so a unique dense interpenetrating polymer network is formed, thereby overcoming the problem of burr formation caused by small amounts of filler and solvents and the problems of poor compatibility and difficult coating caused by multiple solvents and producing unexpected technical effects.

Owner:CHONGQING LIERDA SCI & TECH DEV

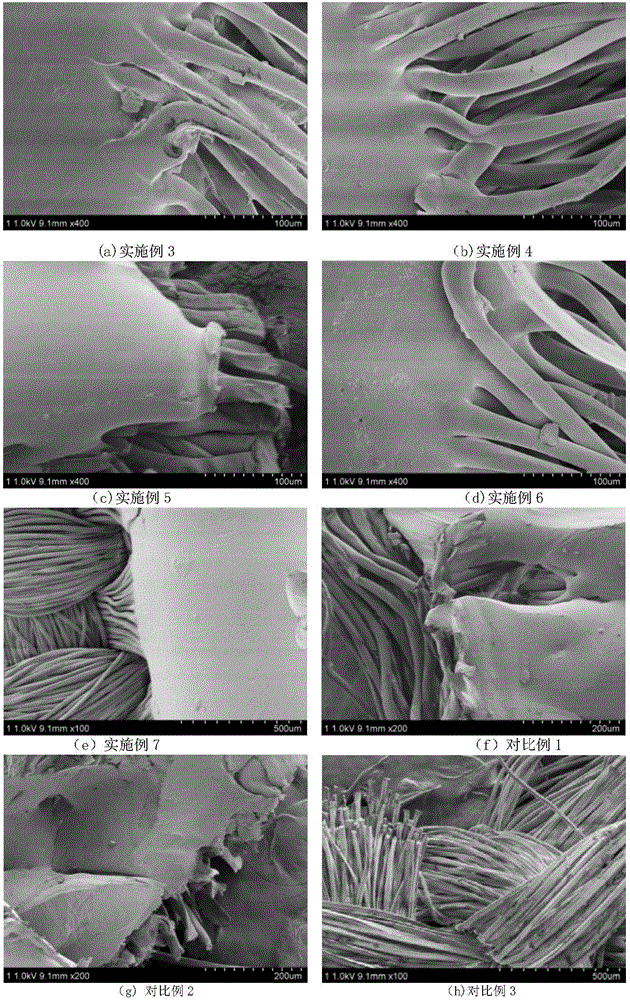

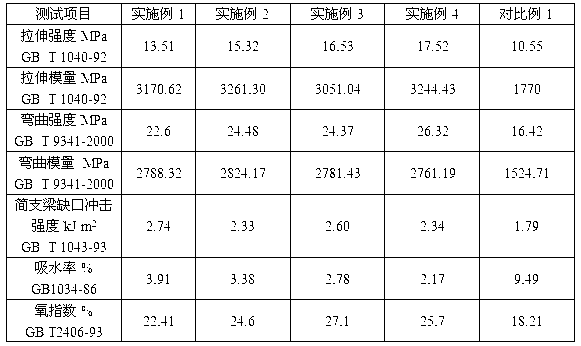

Preparation method of silica sol surface modified straw wood-plastic composite material

The invention discloses a preparation method of a silica sol surface modified straw wood-plastic composite material. The preparation method includes crushing and drying crop straws to obtain straw powders, using silica sol to soak the straw powders, drying the straw powders to obtain surface modified straw powders, mixing the surface modified straw powders, recycled plastics and other processing auxiliaries at a high speed, and then performing extrusion and granulation to obtain granules of the silica sol surface modified straw wood-plastic composite material. The prepared silica sol surface modified straw wood-plastic composite material is lower in water absorption rate and higher in strength, modulus, size stability and antiflaming performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Compression molding fibre-reinforced straw plastic combined cabinet slab and preparation method thereof

The invention discloses a compression molding fibre-reinforced straw plastic combined cabinet slab which is prepared from the following raw materials according to parts by weight: 0.2-0.6 part of modified crop straw fibre or straw fibre wood powder thereof, 0.1-0.2 part of PET or nylon waste silk, 0.05-0.2 part of melamine, 0.05-0.2 part of modified talcum powder, 0.01-0.05 part of chemical assistant and 0.3-0.6 part of polyolefin thermoplastic resin. The invention also discloses a preparation method thereof. The cabinet slab of the invention is formaldehyde-free environment-protection material and has wood texture and handling characteristics, and the machinery mechanics strength thereof exceeds that of good-quality solid-wood slabs; and in addition, the cabinet slab does not adsorb water and has the functions of low coefficient of thermal expansion, moisture prevention, mildew prevention, aging prevention, combustion prevention, reuse and the like and is an ideal cabinet slab wood replacing material.

Owner:绍兴一普塑业有限公司

Liquid silicone rubber composition having low permanent compression deformation and preparation method thereof

The invention discloses a liquid silicone rubber composition having low permanent compression deformation, which comprises the following components in parts by mass: 100 parts of vinyl polydimethylsiloxane, 1-50 parts of inorganic filler, 1-30 parts of structurized control agent, 0.01-10 parts of crosslinking agent, 0.01-2 parts of platinum catalyst, 0.001-1 part of inhibitor, 0.1-20 parts of magnesium oxide and 0.01-10 parts of compression deformation improver. The invention also discloses a preparation method of the liquid silicone rubber composition having low permanent compression deformation. According to the invention, after the compression deformation improver is introduced into the vinyl polydimethylsiloxane, the permanent compression deformation performance can be obviously reduced; and the liquid silicone rubber composition still has very good processability and is suitable for being used as liquid silicone rubber of a spark plug sheath of an automobile.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

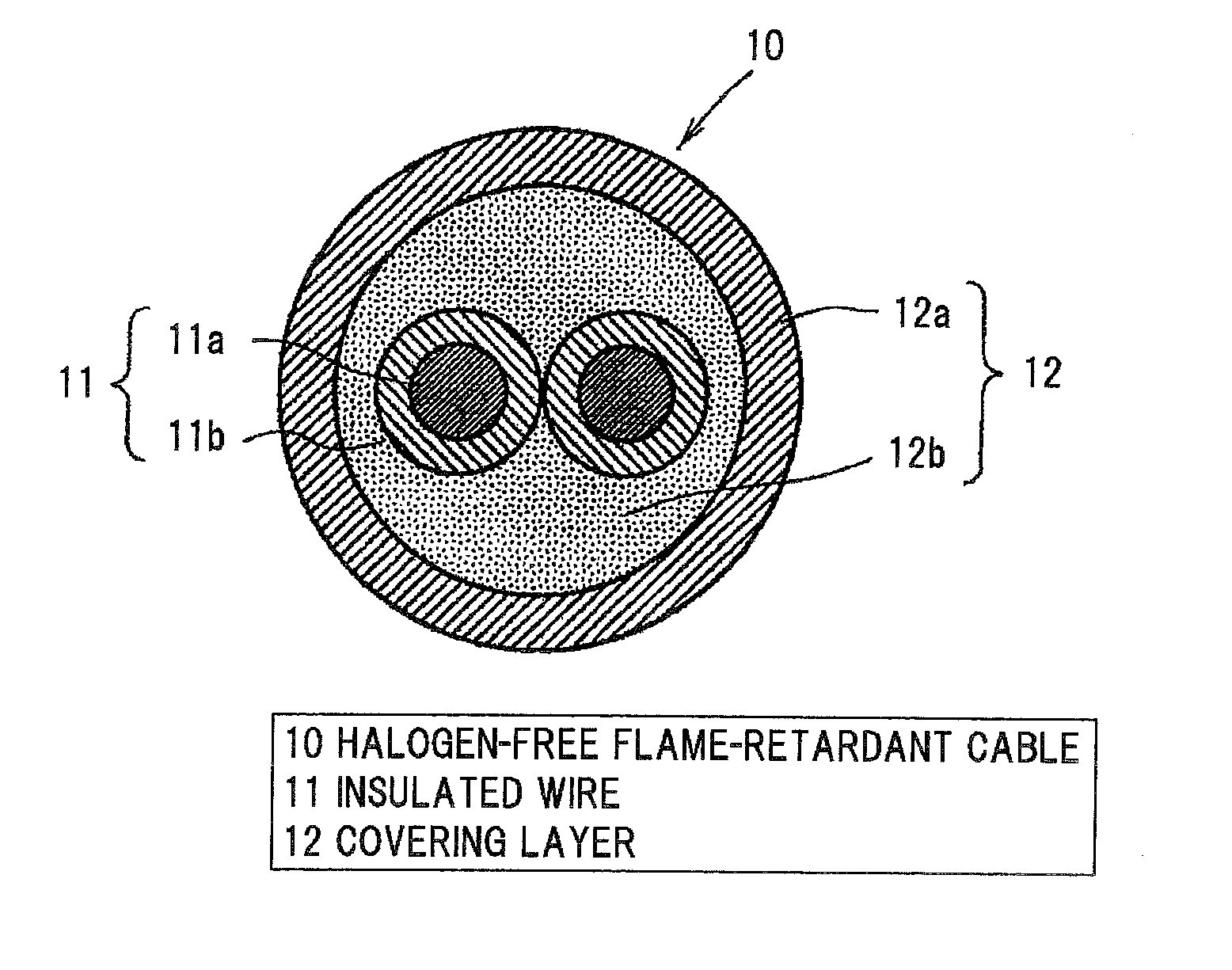

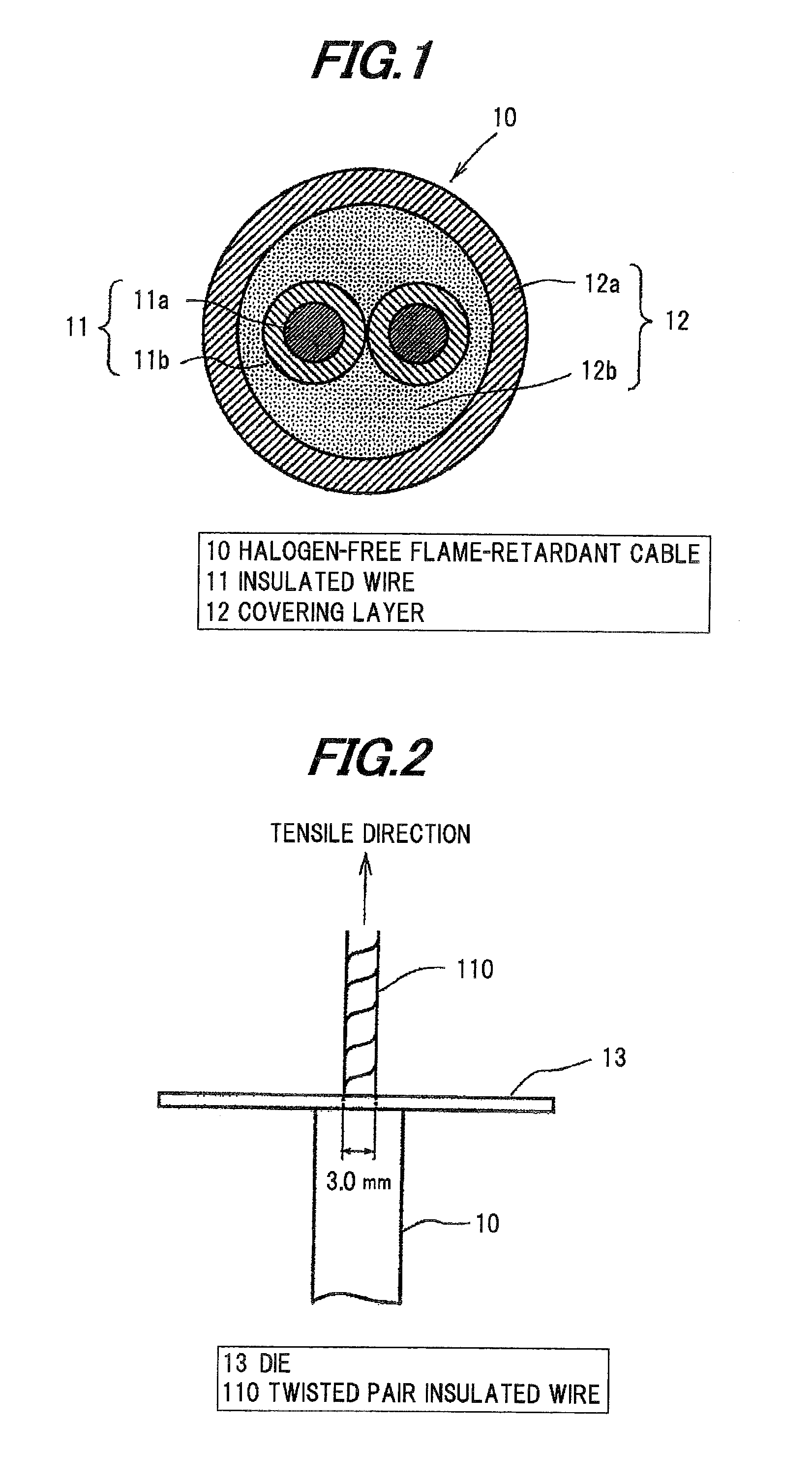

Halogen-free flame-retardant cable

ActiveUS20110174518A1Suppression gapReduce bond strengthInsulated cablesInsulatorsCross-linkInsulation layer

A halogen-free flame-retardant cable includes a multi-core twisted wire including a plurality of insulated wires twisted together, the plurality of insulated wires each including a conductor and an insulation layer on an outer periphery of the conductor, an inner layer formed on an outer surface of the multi-core twisted wire, and an outer layer formed on the inner layer. The outer layer includes a resin composition including not less than 30 parts by mass of a flame retardant with respect to 100 parts by mass of thermoplastic polyurethane (TPU). The inner layer includes a resin composition comprising an ethylene-vinyl acetate copolymer (EVA) with a vinyl acetate (VA) content of not less than 33%, and the outer layer is subjected to cross-linking treatment.

Owner:HITACHI CABLE

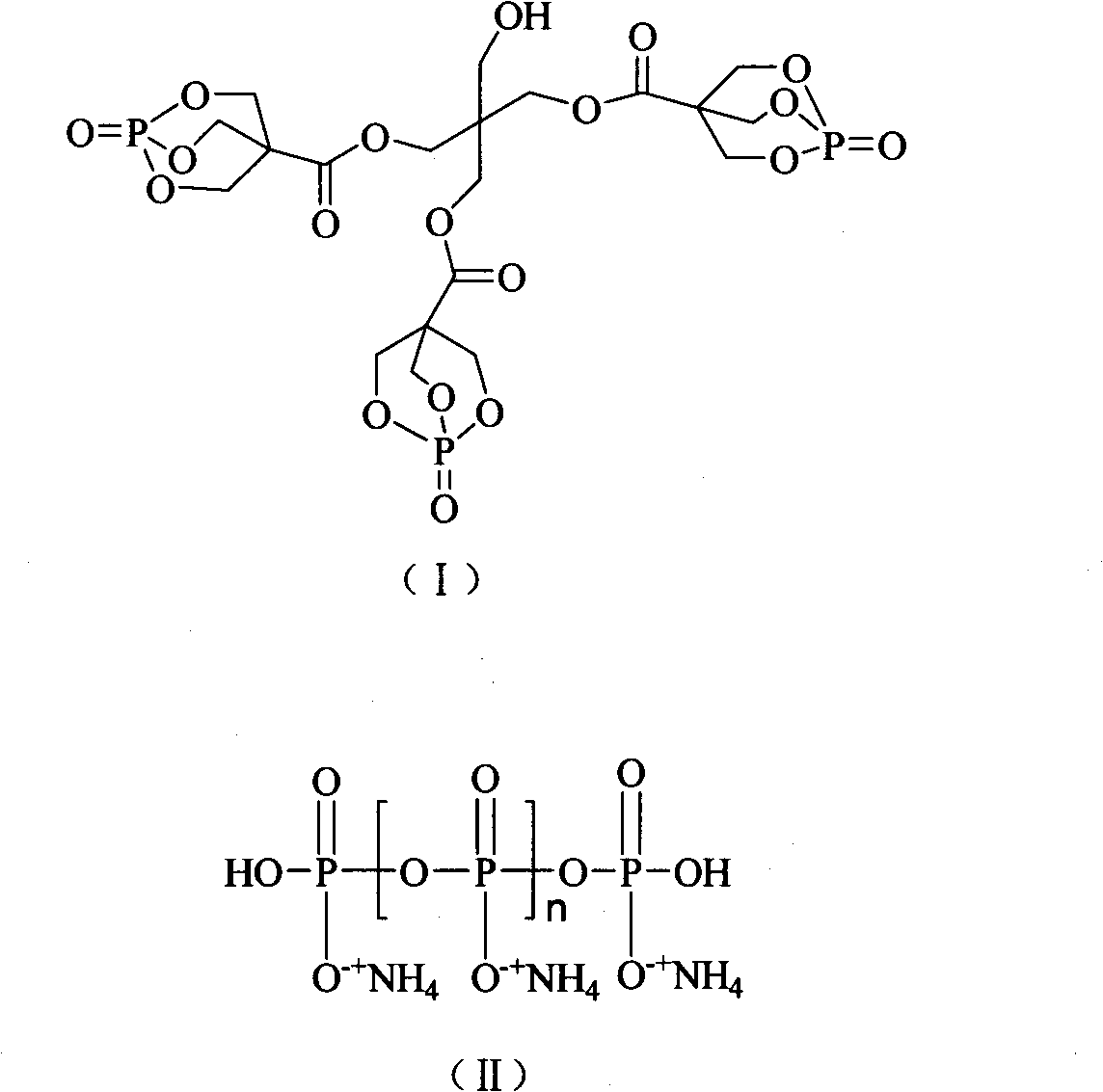

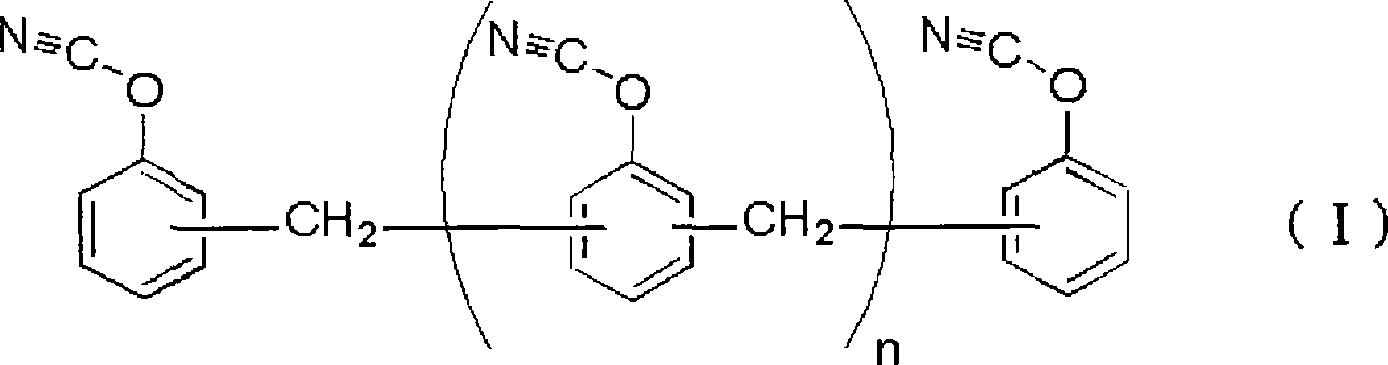

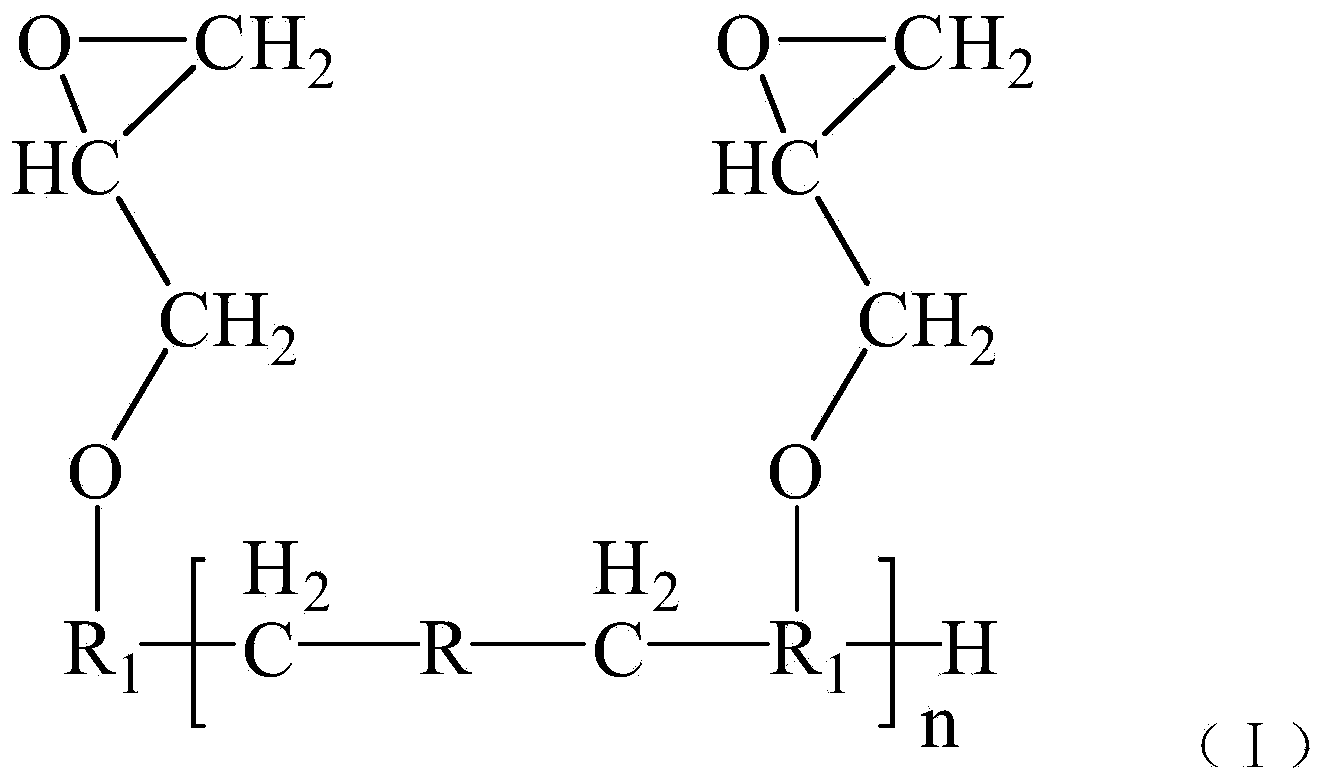

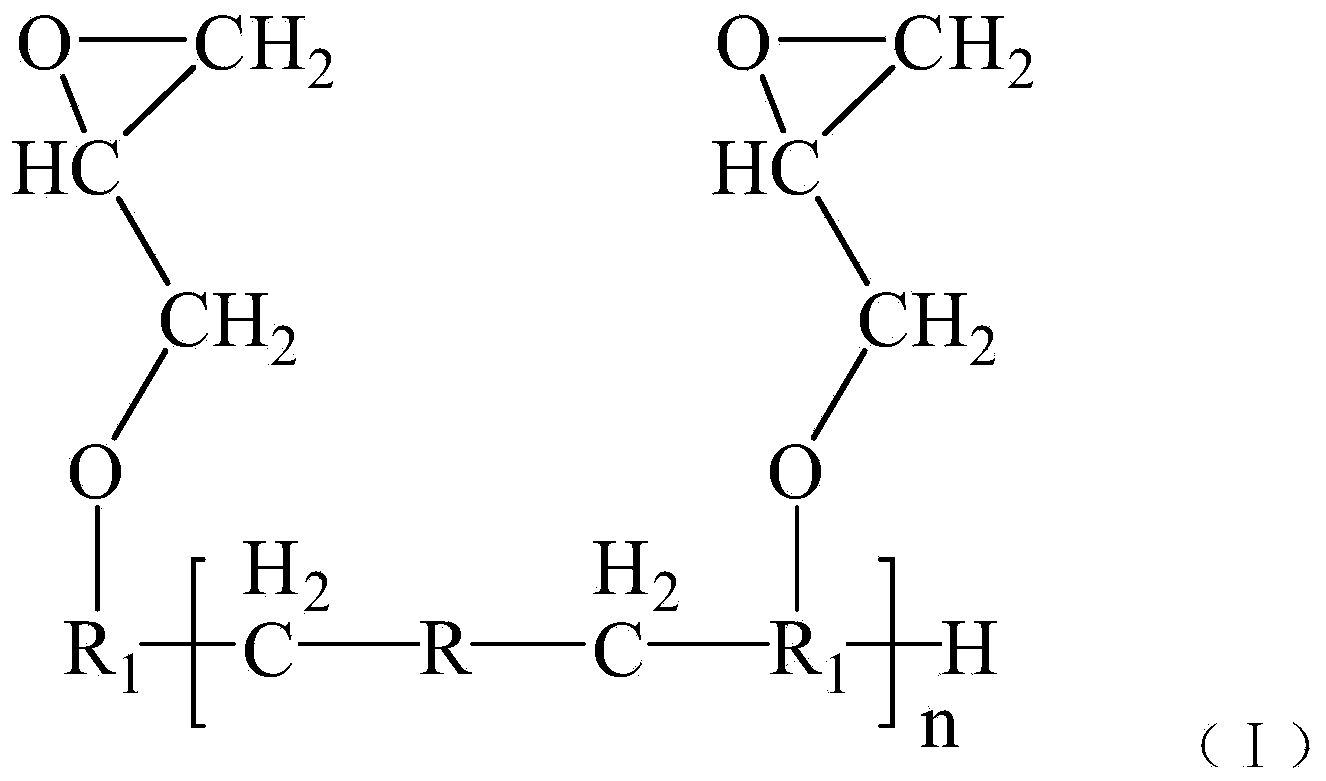

Cyanate resin composition and application thereof

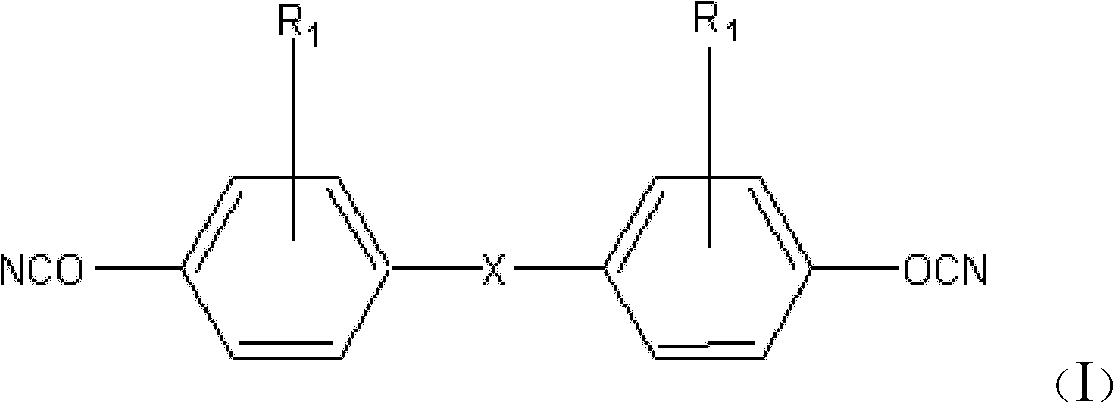

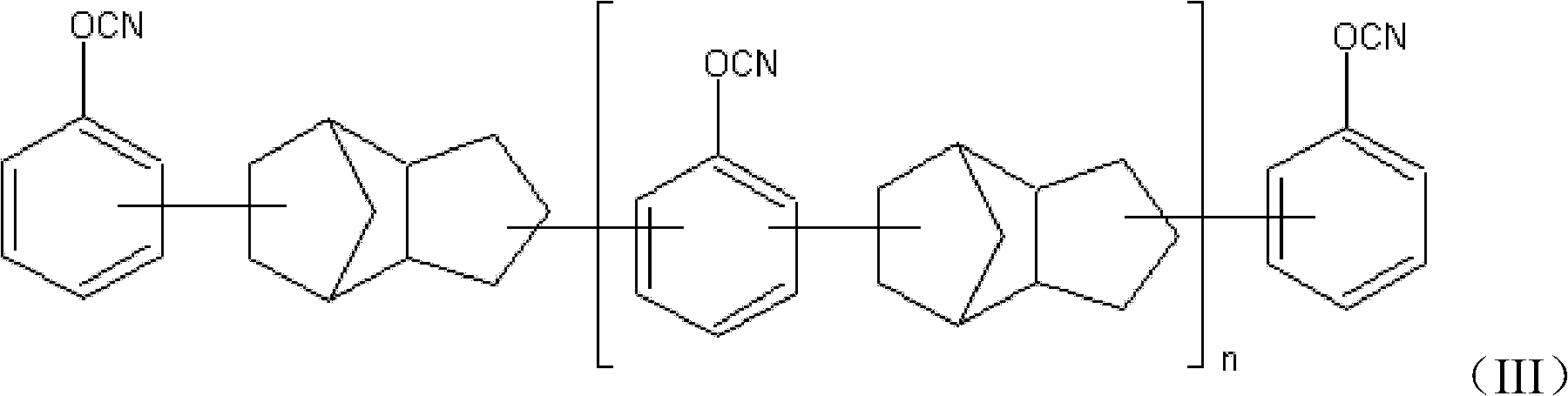

InactiveCN103724999AImprove moisture resistanceImprove heat resistanceSynthetic resin layered productsElectrical equipmentEpoxyHigh density

The invention relates to a cyanate resin composition, and a prepreg, laminated board, metal foil clad laminated board and printed circuit board prepared from the same. The cyanate resin composition comprises a cyanate resin (A), an epoxy resin disclosed as Formula (I) and a maleimide compound (C). The cyanate resin composition, and the prepreg, laminated board, metal foil clad laminated board and printed circuit board prepared from the cyanate resin composition have the advantages of favorable moisture resistance, favorable heat resistance, high flame retardancy, high reliability and low planar thermal expansion coefficient, and is suitable for substrate materials for manufacturing high-density printed circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

Low temperature resistant environment-friendly inflaming retarding PC/PET alloy and method for preparing same

InactiveCN101712793AImprove liquidityGood solvent resistanceHeat deflection temperatureThermal deformation

The invention provides a low temperature resistant environment-friendly inflaming retarding PC / PET alloy and a method for preparing the same. The alloy is prepared by drying and stirring components of PC, PET, a compatilizer, a toughening agent, a phosphorus burning agent, a synergetic flame retardant, a low-temperature modifier and an antioxidant, melt-extruding the components in a double-screw extruder and granulating. The low temperature resistant environment-friendly inflaming retarding PC / PET alloy has the advantages of excellent low temperature resistance, strong impact, high thermal deformation temperature, good flame resistance, mechanical property and size stability, and wide application in fields such as household appliances, electronic devices, building materials and automobiles.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

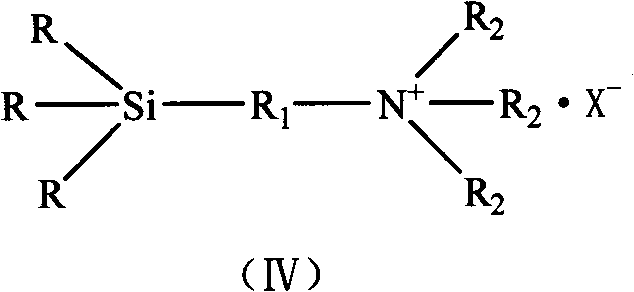

Intumescent flame retardant polyethylene containing organosilicon compound

ActiveCN101948581AImprove efficiencyAdd lessGroup 4/14 element organic compoundsGroup 5/15 element organic compoundsPolyolefinMetal

The invention belongs to the technical field of polyolefin flame retardant products and particularly relates to intumescent flame retardant polyethylene containing an organosilicon compound, which simultaneously contains intumescent compounded flame retardant and the organosilicon compound and has higher flame retardant efficiency. The intumescent flame retardant polyethylene containing the organosilicon compound also contains a metal oxide hydrate containing an organosilicon flame retardant synergist and comprises the following compositions in percentage by weight: 70-80 percent of polyethylene, 17-29.5 percent of compounded intumescent flame retardant and 0.5-3 percent of the metal oxide hydrate containing the organosilicon flame retardant synergist.

Owner:HANGZHOU GAOXIN RUBBER & PLASTIC MATERIALS CO LTD

Halogen-free flame-retardant polypropylene fiber and preparation method thereof

ActiveCN103173884AGood flame retardant effectSimple processing technologyFlame-proof filament manufactureMelt spinning methodsAmmonium polyphosphateMaleic anhydride

The invention belongs to the technical field of high polymer materials and relates to a polypropylene fiber and a preparation method of the polypropylene fiber. The material comprises the following components in parts by weight: 100 parts of polypropylene, 12-28 parts of ammonium polyphosphate, 2-12 parts of polyol compound, 1-10 parts of organic silicone resin, 1-5 parts of maleic anhydride grafted polypropylene and 0.5-2 parts of an antioxidant. The polypropylene fiber prepared by the invention adopts an expansion type composite synergistic halogen-free and flame-retardant system so as to become a halogen-free, low-smoke, low-toxicity and environment-friendly flame-retardant system and realize a good flame-retardant effect. Compared with the existing expansion type flame-retardant system, the polypropylene fiber disclosed by the invention adopts the ammonium polyphosphate as a main composition part, and the ammonium polyphosphate can be simultaneously used as an acid source and a gas source in an expansion type flame retardant, so that the independent gas source is removed, the reaction of the acidic or the alkaline gas source during the processing process can be avoided, the flame-retardant effect can be prevented from being lowered, and the processing technology is further simplified.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

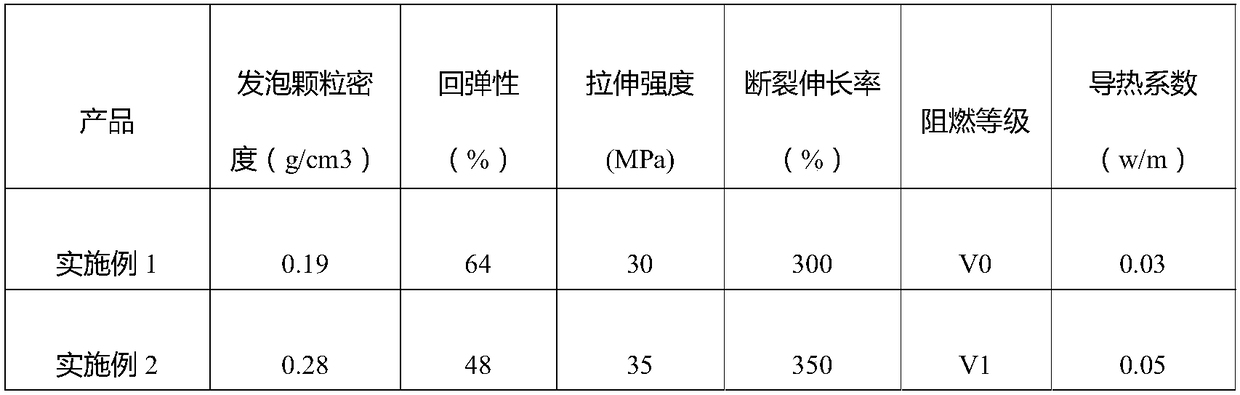

Ultra-light high-resilience low-thermal-conductivity composite foam material and preparation method thereof

InactiveCN108440939AIncrease elasticityLow thermal conductivityIndustrial equipmentVolumetric Mass Density

The invention discloses an ultra-light high-resilience low-thermal-conductivity composite foam material and a preparation method thereof. The preparation method comprises the following steps of: (1) mixing thermoplastic elastomer particles, a low-thermal-conductivity material and flame retardant, and performing synthesis and granulation to obtain to-be-foamed composite particles; (2) placing the to-be-foamed composite particles in a high pressure reaction kettle, introducing carbon dioxide gas into the high pressure reaction kettle, regulating the pressure and temperature of the high pressurereaction kettle so as to make the carbon dioxide in a supercritical state, performing pressure maintaining and penetration, releasing the pressure rapidly, and performing heating and foaming to prepare composite foamed particles; and (3) performing compression molding on the omposite foamed particles through steam so as to prepare the ultra-light high-resilience low-thermal-conductivity compositefoam material. The composite foam material has the characteristics of low density, high elastic resilience, strong mechanical strength, flame retardancy, low thermal conductivity and the like, and thecomposite foam material can be widely applied to buildings and industrial equipment and fields which have special requirements for mechanical properties, resilience and flame retardancy of materials.

Owner:NINGBO GMF TECH +1

Preparation method of coal ash-resin composite material suitable for extrusion molding

InactiveCN103172952ASuitable for technology expansion applicationLow requirements for process conditionsLow-density polyethylenePolyvinyl chloride

The invention discloses a preparation method of a coal ash-resin composite material suitable for extrusion molding. The method comprises the following steps of: surface modification of coal ash; preparation of the coal ash-resin composite material; and extrusion molding of the coal ash-resin composite material, wherein the temperatures of three-sectional screws are 165 DEG C, 185 DEG C and 180 DEG C respectively; the temperature of a nozzle is 180 DEG C; the rotating speed of the screw is 10-15rpm (revolutions per minute); and a sample is obtained after being cooled by water. The coal ash-resin composite material suitable for extrusion molding is formed through the following processes: performing surface modification on the coal ash of which the granularity is 200 meshes, and compounding the coal ash subjected to surface modification with resins of polrvinyl chloride (PVC), low-density polyethylene (LDPE) and the like, and assistants such as chlorinated polyethylene (CPE), ethylene-vinyl acetate (EVA), triphenyl phosphate and calcium stearate.

Owner:SHAANXI UNIV OF TECH

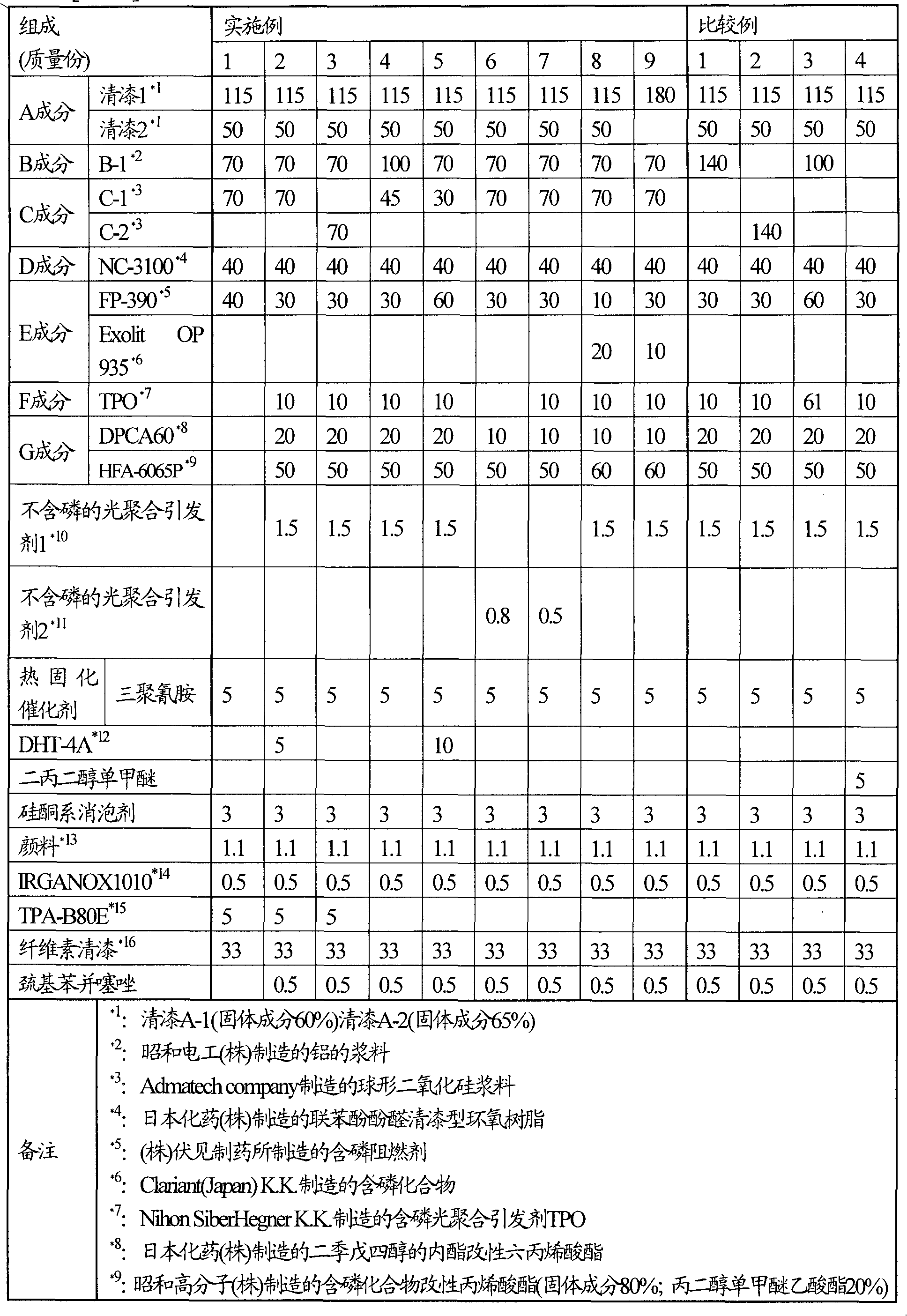

Curable resin composition, dry membrane and printed circuit board using same

ActiveCN101845219AReduce environmental burdenReduced flame retardancyPrinted circuit detailsPhotosensitive materials for photomechanical apparatusAluminium hydroxideEther

The invention provides a curable resin composition, dry membrane and printed circuit board using the same, more particularly, the invention provide a curable resin composition and a dry membrane, as well as a printed circuit board formed by a flame-resistant curable membrane such as a solder resisting membrane and the like formed by using the same, wherein, the curable resin composition has a halogen-free flame retardant, and can form a solder resisting layer with low warpage and excellent flame resistance and bending. The curable resin composition contains (A) carboxyl-contained resin, (B) aluminium hydroxide and (C) spherical silica a thermocuring resin composition comprises the above (A), (B) and (C), and (D) a thermocuring component with more than two ring-shaped ether group and / or ring-shaped sulfide group, and a photocuring thermocuring resin composition comprises the above (A), (B), (C) and (D), and (F) a photopolymerisable initiator and (G) a photopolymerisable monomer, preferably contains (E) a phosphorus-containing compound.

Owner:TAIYO HLDG CO LTD

Resin composition, metal foil with resin, insulating sheet with base material and multilayer printed wiring board

InactiveCN1938358AIncrease the coefficient of linear expansionReduced flame retardancyPrinted circuit aspectsSynthetic resin layered productsCrazingHalogen

Owner:SUMITOMO BAKELITE CO LTD

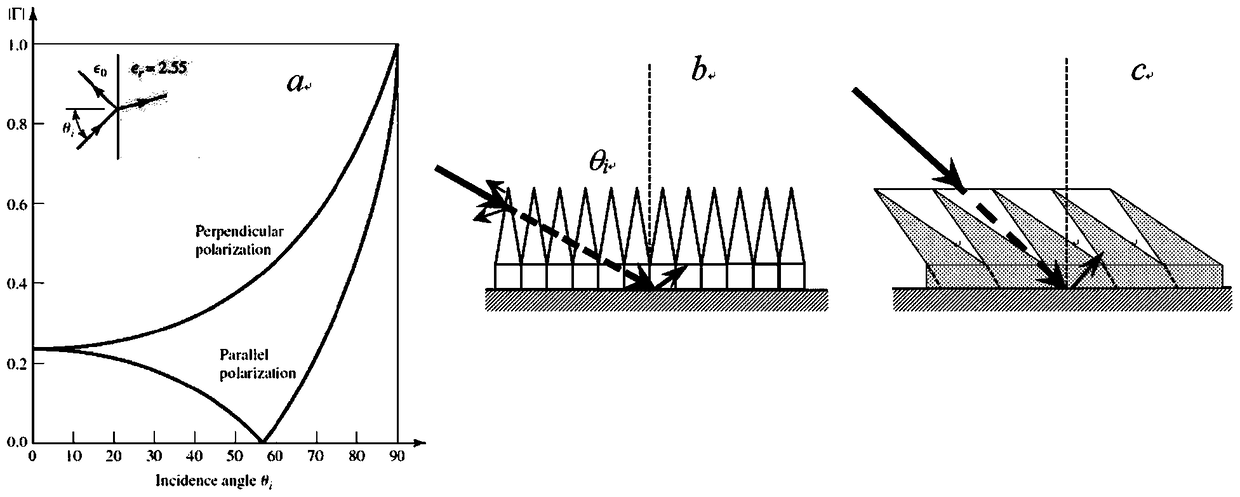

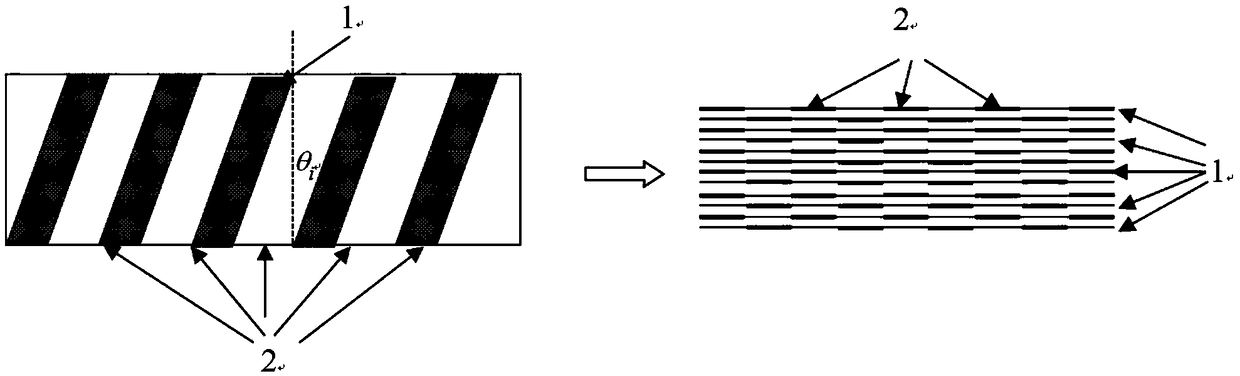

Super-wide incidence angle microwave absorbing materials and a production method thereof

InactiveCN108966622AHigh temperature resistanceFlame retardantMagnetic/electric field screeningElectrically-conductive paintsAngle of incidenceTemperature resistance

The invention belongs to the technical field of microwave absorbing materials. The invention discloses a kind of super-wide incidence angle microwave absorbing materials which are composed of a slanted irregular honeycomb structure made of a flexible substrate and a graphene conductive coating coated on the flexible substrate. The invention also discloses a production method of the super-wide incidence angle microwave absorbing materials. The method comprises the steps of the structural design of the super-wide incidence angle microwave absorbing materials, generation of surface resistance distribution through printing the graphene conductive coating on the flexible materials, manufacturing of the slanted irregular honeycomb structure, etc. The super-wide incidence angle microwave absorbing materials have the microwave absorbing frequencies ranging from millimeter wave to microwaves and incidence angles ranging from normal incidence angles to high incidence angles. Meanwhile, the material has the advantages such as low cost, a high technique, being environment-friendly, high mechanical strength, low density, a long service life, high temperature resistance and flame retardancy. Furthermore, the super-wide incidence angle microwave absorbing materials of the invention can be contracted to keep, can reduce cost for transport and collection and is in favor of construction and usage of secret test external fields.

Owner:西安安聚德纳米科技有限公司

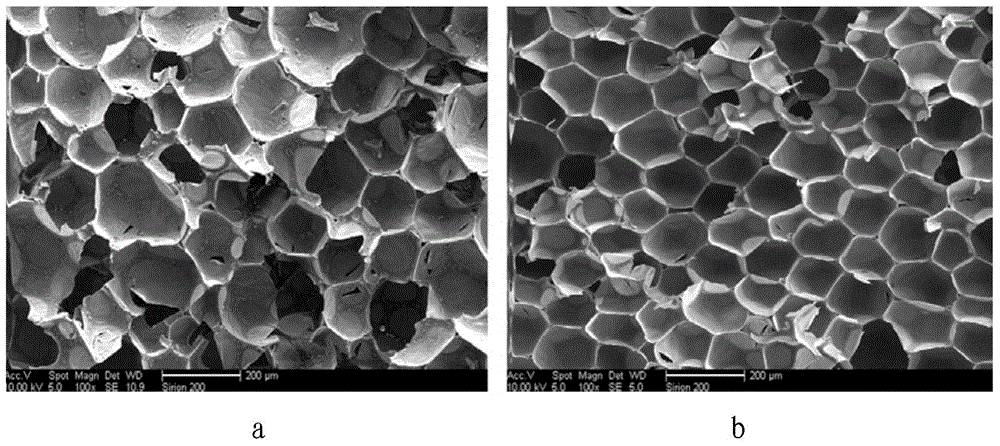

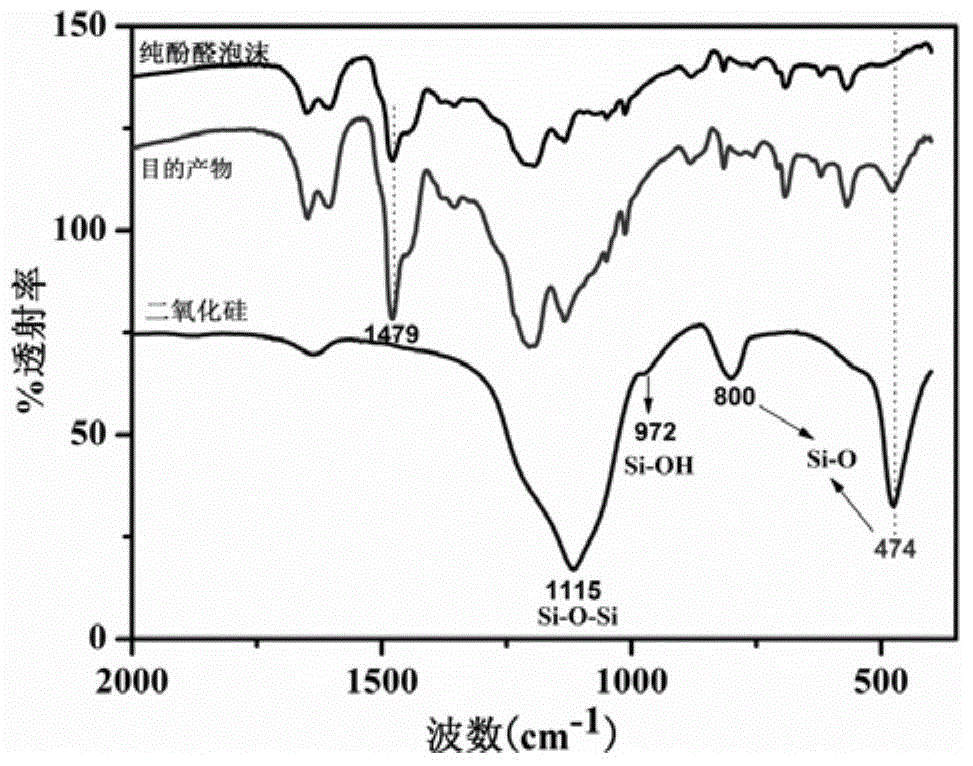

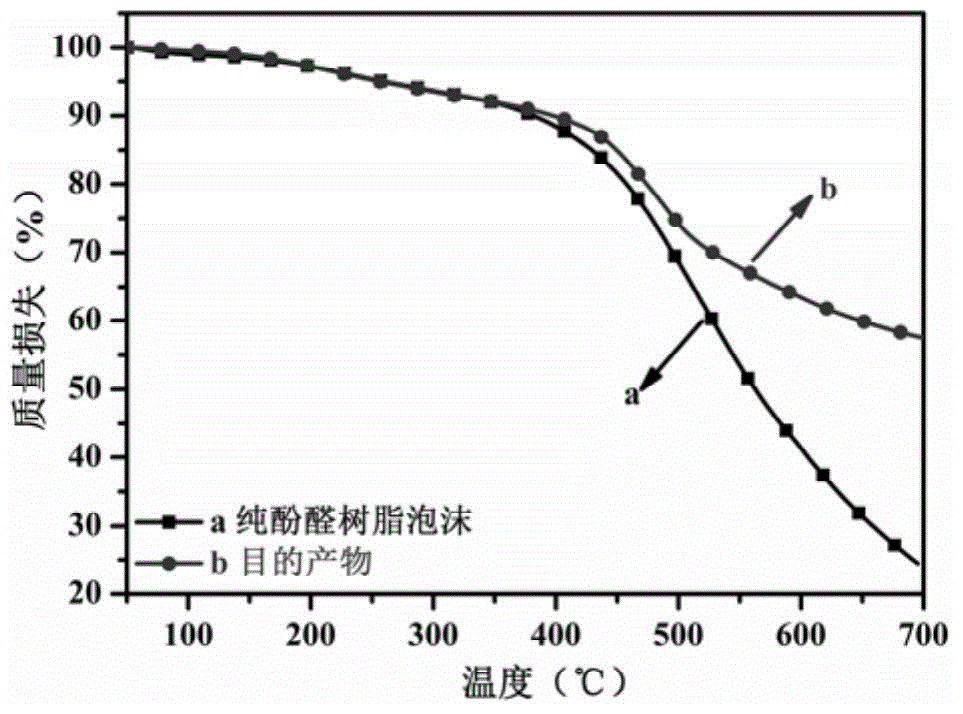

Nano carbon dioxide-phenolic resin composite foam material and preparation method thereof

The invention discloses a nano silicon dioxide-phenolic resin composite foam material and a preparation method thereof. The composite foam material is prepared from silicon dioxide nanoparticles, free phenol, free formaldehyde, a surfactant, a curing agent and sodium chloride as well as phenolic resin, wherein the silicon dioxide nanoparticles are bonded with phenolic resin by virtue of Si-O-C chemical bonds. The method comprises the following steps: firstly, ultrasonically dispersing a SiO2 sol in a formaldehyde solution or a mixed liquid of formaldehyde solution and paraformaldehyde to obtain a mixed solution; then, after mixing the mixed solution, phenol and an alkaline solution, and carrying out polymerization reaction to obtain resol in which the silicon dioxide nanoparticles are uniformly dispersed; then, firstly, carrying out acid neutralization and reduced pressure distillation on the resol; then, mixing and stirring the resol with a foaming agent and the surfactant to obtain mixed resin; and finally, adding the curing agent into the mixed resin and putting into a die to cure and foam to prepare a targeted product. The nano silicon dioxide-phenolic resin composite foam material disclosed by the invention can be widely applied to the fields such as building, aviation, refrigeration and the like commercially.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

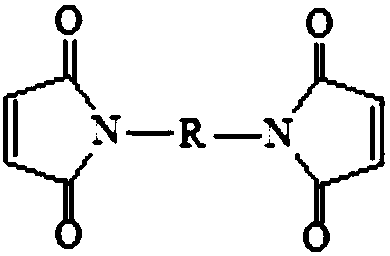

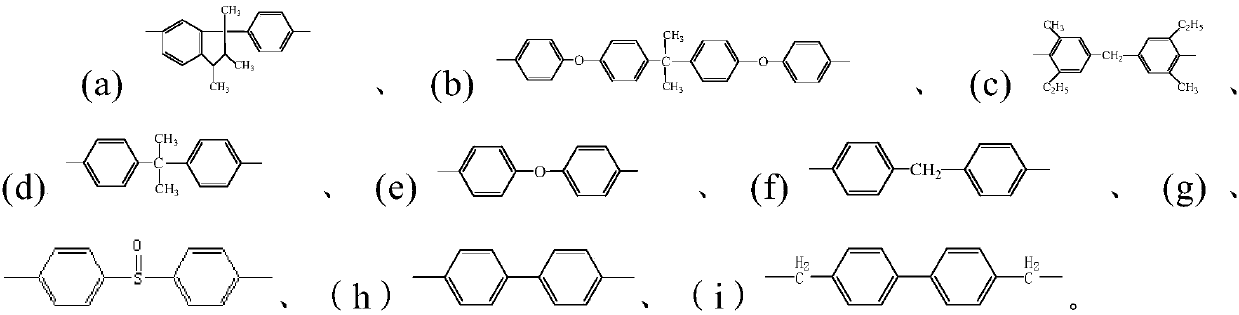

Flame-retardant resin composition and prepreg and laminate prepared using same

ActiveCN109535715AReduced flame retardancyExcellent halogen-free flame retardant performanceSynthetic resin layered productsLaminationEpoxyHydrogen

The invention discloses a flame-retardant resin composition, which comprises the following components by solid weight: 100 parts by weight of a modified bismaleimide prepolymer; 5-30 parts of epoxy resin; 0-20 parts of a curing agent, 0-150 parts of a filler; 0.001-5 parts of a curing accelerator; wherein the modified bismaleimide prepolymer is at least prepolymerized by bismaleimide resin and anamine compound. Compared with the prior art, a DOPO or DPPO-containing amine compound reacts not only with the bismaleimide, but also with the active hydrogen of -NH- in the structure reacts and the epoxy group, so that a small amount of epoxy resin and the curing agent are added to obtain a final cured product having high heat resistance and high modulus, the high-performance print circuit boardrequirements such as HDI multilayer substrates and ultra-thin package substrates can be satisfied, and a small amount of epoxy resin and the curing agent can be added to further improve the adhesion of the resin composition and enhances the anti-stripping intensity of a copper-clad board.

Owner:SHENGYI TECH SUZHOU

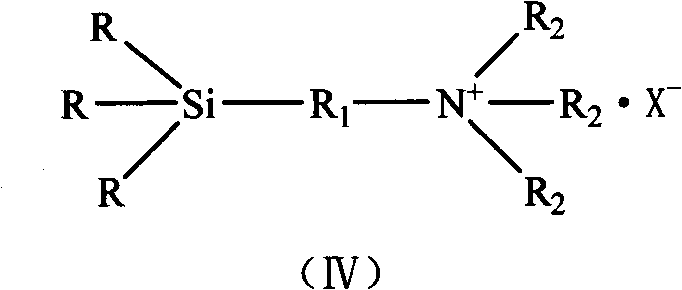

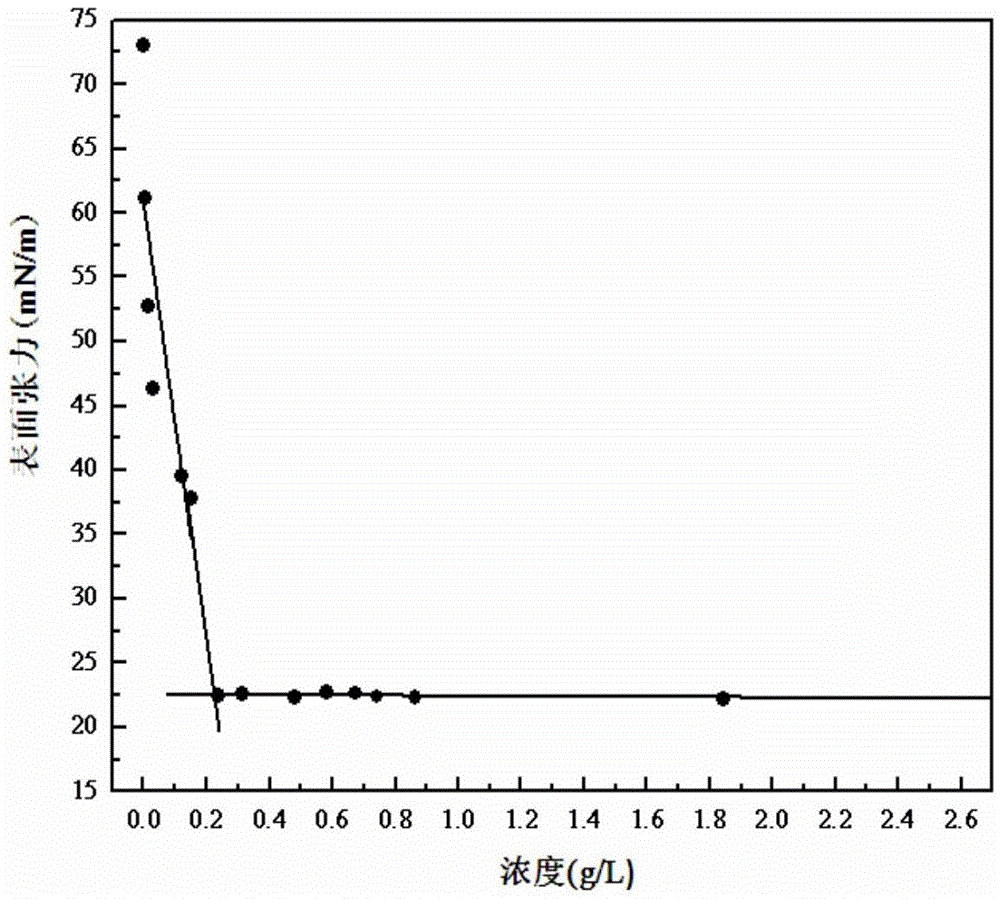

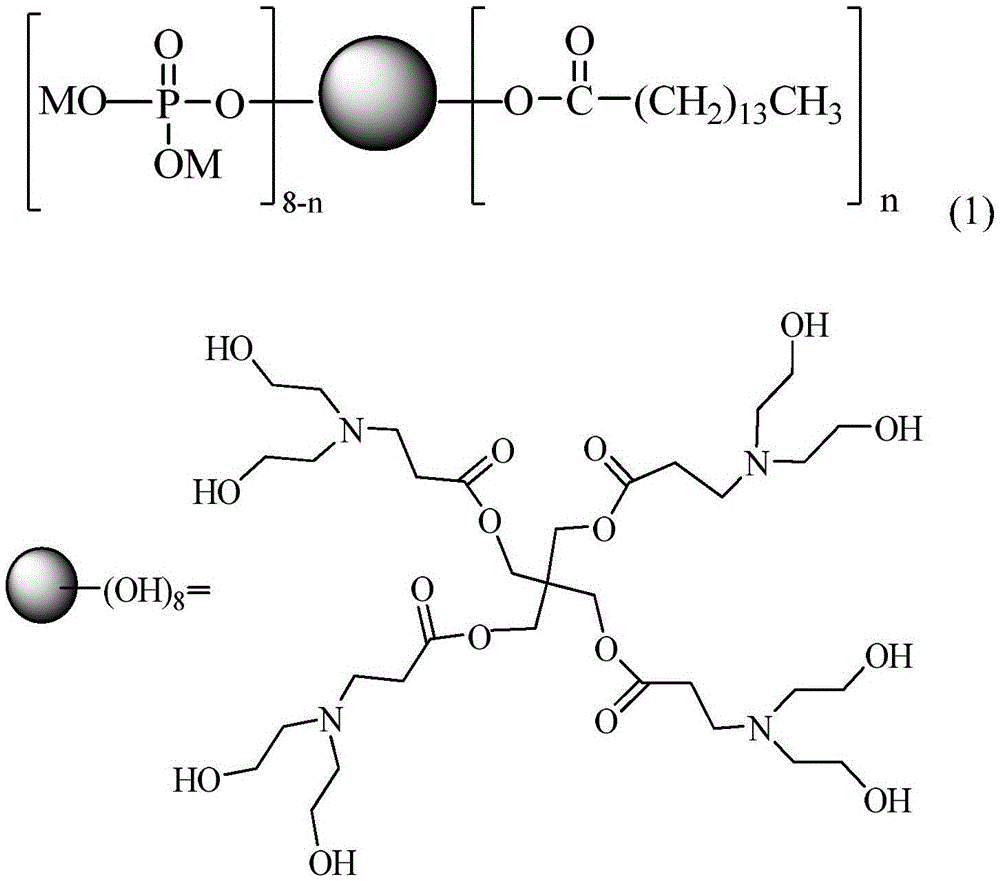

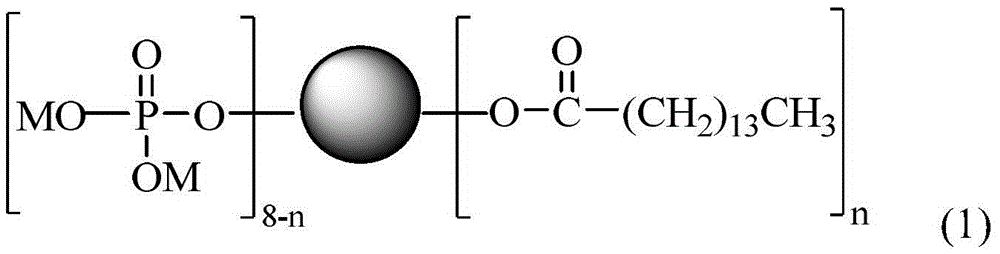

Linear-hyperbranched phosphate salt surface active agent and preparation method thereof

ActiveCN105582850AGood miscibilityGood compatibilityTransportation and packagingMixingSurface-active agentsLipophilicity

The invention discloses a linear-hyperbranched phosphate salt surface active agent and a preparation method thereof. AB2 type monomers are synthesized, then avterminal hydroxyl hyperbranched polymer is synthesized, a long chain is introduced into the middle end of the terminal hydroxyl hyperbranched polymer, unmodified hydroxyl continues to be phosphorylated, and the linear-hyperbranched phosphate salt polymer is synthesized. The hydroxyl long chain is introduced, so that lipophilicity is improved, terminal lipophilicity is modified into a phosphate base, the prepared polymer has multi-terminal hydrophilic groups and hydrophobic groups and can be used as the surface active agent, the dispersity, flame retardance, antibacterial property, antistatic property and other special properties can be given, and excellent surface activity and biocompatibility are achieved.

Owner:广东方中高新材料有限公司

Cyanate resin composition and application thereof

InactiveCN103724998AImprove moisture resistanceImprove heat resistanceSynthetic resin layered productsElectrical equipmentEpoxyHigh density

The invention relates to a cyanate resin composition, and a prepreg, laminated board, metal foil clad laminated board and printed circuit board prepared from the same. The cyanate resin composition comprises a cyanate resin (A) and an epoxy resin disclosed as Formula (I). The cyanate resin composition, and the prepreg, laminated board, metal foil clad laminated board and printed circuit board prepared from the cyanate resin composition have the advantages of favorable moisture resistance, favorable heat resistance, high flame retardancy, high reliability and low planar thermal expansion coefficient, and is suitable for substrate materials for manufacturing high-density printed circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com