Halogen-free flame-retardant polypropylene fiber and preparation method thereof

A polypropylene fiber and polypropylene technology, applied in the manufacture of fire-resistant and flame-retardant filaments, fiber chemical characteristics, single-component polyolefin artificial filaments, etc., can solve the problem of increased broken filaments, poor compatibility, and unsustainable flame-retardant performance and other problems, to achieve the effect of simplifying the processing technology, good flame retardant effect, and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

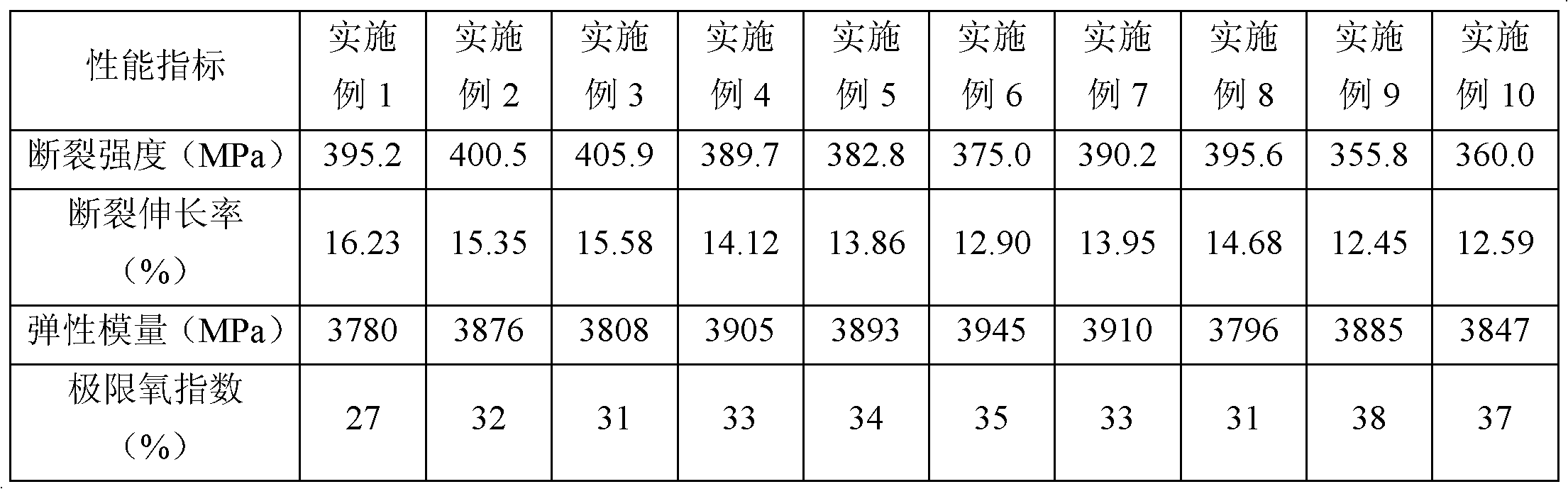

Examples

Embodiment 1

[0041] Take the raw material according to the following parts by weight:

[0042] Polypropylene (PP) (Sinopec) 100 parts,

[0043]Ammonium polyphosphate (APP) (Zhenjiang Star Flame Retardant Material Factory) 12 parts,

[0044] Pentaerythritol (PER) (Jinan Taixing Fine Chemical Co., Ltd.) 4 parts,

[0045] 2 parts of silicone oil (GE company of the United States),

[0046] Maleic anhydride grafted polypropylene (PP-g-MAH) (Huangshan Beinuo Technology Co., Ltd.) 2.5 parts,

[0047] Antioxidant 1010 (Beijing Extremely Easy Chemical Co., Ltd.) 0.5 parts.

[0048] (1) Weigh various raw materials according to the above ratio, mix them uniformly in a high-speed mixer, and then pass through a twin-screw extruder, melt extrusion and granulate to obtain a halogen-free flame-retardant polypropylene (PP) masterbatch, and extrude The temperature is 200-220°C;

[0049] (2) Cut the halogen-free flame-retardant polypropylene (PP) masterbatch into slices, vacuum-dry it at 80-120°C for 1-...

Embodiment 2

[0052] Take the raw material according to the following parts by weight:

[0053] Polypropylene (PP) (Sinopec) 100 parts,

[0054] Modified ammonium polyphosphate (APP) (wherein, APP is purchased from Zhenjiang Star Flame Retardant Material Factory) 12 parts, (the surfactant of modified ammonium polyphosphate is calcium stearate)

[0055] Pentaerythritol (PER) (Jinan Taixing Fine Chemical Co., Ltd.) 4 parts,

[0056] 2 parts of silicone oil (GE company of the United States),

[0057] Maleic anhydride grafted polypropylene (PP-g-MAH) (Huangshan Beinuo Technology Co., Ltd.) 2.5 parts,

[0058] Antioxidant 1010 (Beijing Extremely Easy Chemical Co., Ltd.) 0.5 parts.

[0059] (1) Weigh various raw materials according to the above ratio, mix them uniformly in a high-speed mixer, and then pass through a twin-screw extruder, melt extrusion and granulate to obtain a halogen-free flame-retardant polypropylene (PP) masterbatch, and extrude The temperature is 200-220°C;

[0060] (2) ...

Embodiment 3

[0063] Take the raw material according to the following parts by weight:

[0064] Polypropylene (PP) (Sinopec) 100 parts,

[0065] Modified ammonium polyphosphate (APP) (wherein, APP is purchased from Zhenjiang Star Flame Retardant Material Factory) 12 parts, (the surfactant of modified ammonium polyphosphate is magnesium stearate)

[0066] Sorbitol (Shouguang Huatian Sugar Alcohol Co., Ltd.) 4 parts,

[0067] 1 part of silicone oil (GE company of the United States),

[0068] Maleic anhydride grafted polypropylene (PP-g-MAH) (Huangshan Beinuo Technology Co., Ltd.) 1 part,

[0069] Antioxidant 168 (Beijing Extremely Easy Chemical Co., Ltd.) 0.5 parts.

[0070] (1) Weigh various raw materials according to the above ratio, mix them uniformly in a high-speed mixer, and then pass through a twin-screw extruder, melt extrusion and granulate to obtain a halogen-free flame-retardant polypropylene (PP) masterbatch, and extrude The temperature is 200-220°C;

[0071] (2) Cut the halo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com