Preparation method of silica sol surface modified straw wood-plastic composite material

A wood-plastic composite material and surface modification technology, which is applied in the field of wood-plastic composite materials, can solve the problems that the water absorption characteristics of straw powder are not significantly improved, the use performance, service life impact, and the proportion of straw powder is low. Strength, excellent mechanical properties, the effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

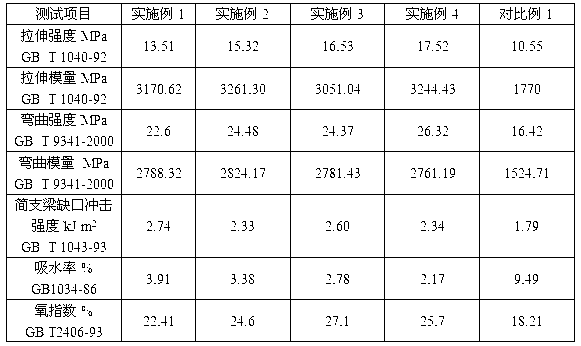

Examples

Embodiment 1

[0022] Put 100 parts of cotton stalk powder with a size of 50 mesh and a water content of 9.0% into a 10-liter reactor, turn on the stirring equipment, and at the same time raise the temperature of the reactor to 50 ° C, and put 20 parts of SiO 2 The mass fraction is 60%, the pH value is 10.0, the viscosity is 10 centipoise, SiO 2 The silica sol with a particle size of 6 nanometers was added to the reaction kettle in a spray form within 1 hour, and the stirring was continued for 2 hours after the addition, and then the temperature was raised to 160°C under stirring conditions, and dried to obtain the surface modified cotton of the silica sol. Rod stalk powder. Take 100 parts of recovered HDPE, 150 parts of the above-mentioned silica sol surface modified straw powder, 10 parts of PE-g-MA, 5 parts of plastic processing aids and 20 parts of activated calcium carbonate, add them to the high-speed mixer, close the feed port of the mixer, Turn on the mixer, raise the temperature to...

Embodiment 2

[0024] Put 100 parts of corn stalk powder with a size of 90 mesh and a water content of 5.6% into a 10-liter reactor, turn on the stirring equipment, and at the same time raise the temperature of the reactor to 70 ° C, and put 120 parts of SiO 2 The mass fraction is 45%, the pH value is 8.5, the viscosity is 6.5 centipoise, SiO 2 The silica sol with a particle size of 15 nanometers was added into the reactor in a spray form within 1 hour, and the stirring was continued for 1.5 hours after the addition, and then the temperature was raised to 150°C under stirring conditions, and dried to obtain the surface-modified corn of the silica sol. rod powder. Take 100 parts of recycled ABS, 120 parts of the above-mentioned silica sol surface-modified corn stalk powder, 5 parts of ABS-g-MA, 8 parts of plastic processing aids and 25 parts of activated calcium carbonate, add them to the high-speed mixer, close the mixer and feed Turn on the mixer, raise the temperature to 65°C, and mix for...

Embodiment 3

[0026] Put 100 parts of wheat straw powder with a size of 70 mesh and a water content of 7.5% into a 10-liter reactor, turn on the stirring equipment, and at the same time raise the temperature of the reactor to 65 °C, add 80 parts of SiO 2 The mass fraction is 35%, the pH value is 7.5, the viscosity is 4 centipoise, SiO 2The silica sol with a particle size of 10 nanometers was added to the reactor in a spray form within 1.2 hours, and the stirring was continued for 1 hour after the addition, and then the temperature was raised to 140°C under stirring conditions, and dried to obtain the surface-modified corn of the silica sol. rod powder. Take 100 parts of recovered PS, 100 parts of the above-mentioned silica sol surface-modified wheat straw powder, 8 parts of PS-g-MA, 10 parts of plastic processing aid and 30 parts of activated calcium carbonate, add them to the high-speed mixer, close the mixer and feed Open the mixer, raise the temperature to 70°C, and mix for 20 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com