Patents

Literature

36 results about "Burr formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous-oily low-viscosity environment-friendly two-component adhesive and preparation method thereof

PendingCN107488431ACritical volume reductionReduced flame retardancyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNano siliconOrganic solvent

The invention relates to an aqueous-oily low-viscosity environment-friendly two-component adhesive and a preparation method thereof. The objective of the invention is to provide the environment-friendly polyurethane two-component adhesive which is good in bonding strength, wettability, fire resistance and weatherability, stable in performance and easy to coat. The adhesive is characterized in that the adhesive comprises a component A including water glass and a component B including a mixture of a polyurethane prepolymer and polyisocyanate; the component A contains no or little filler; and in the component B, the content of NCO is 8.5 to 25%, and the content of an organic solvent is 8% to 19.9%. Because the component A contains no or little filler and the component B contains an appropriate amount of an organic solvent, hydroxylated nano-silicon in the water glass and a part of reactive groups wrapped and concealed in the prepolymer are fully activated, so a unique dense interpenetrating polymer network is formed, thereby overcoming the problem of burr formation caused by small amounts of filler and solvents and the problems of poor compatibility and difficult coating caused by multiple solvents and producing unexpected technical effects.

Owner:CHONGQING LIERDA SCI & TECH DEV

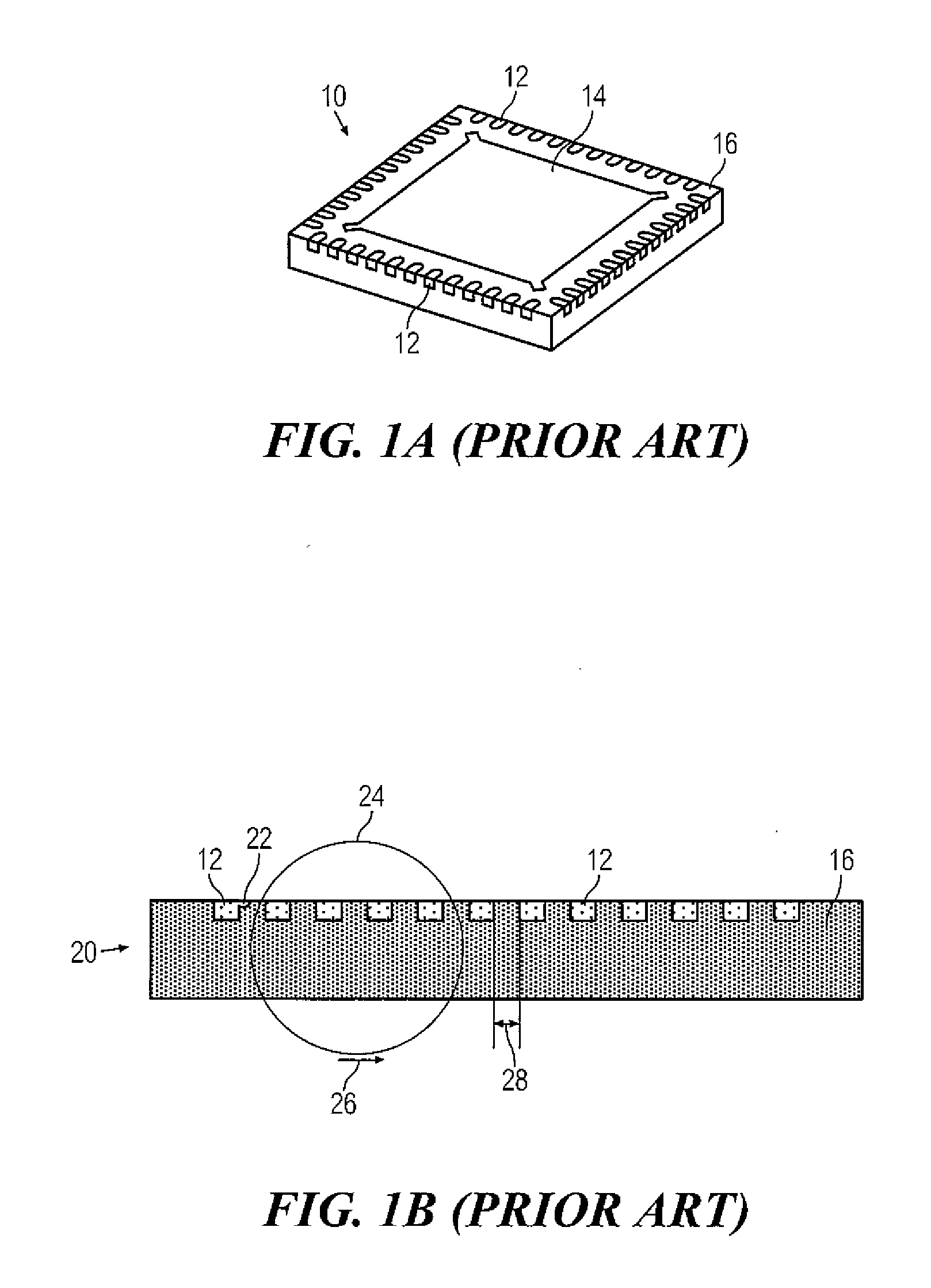

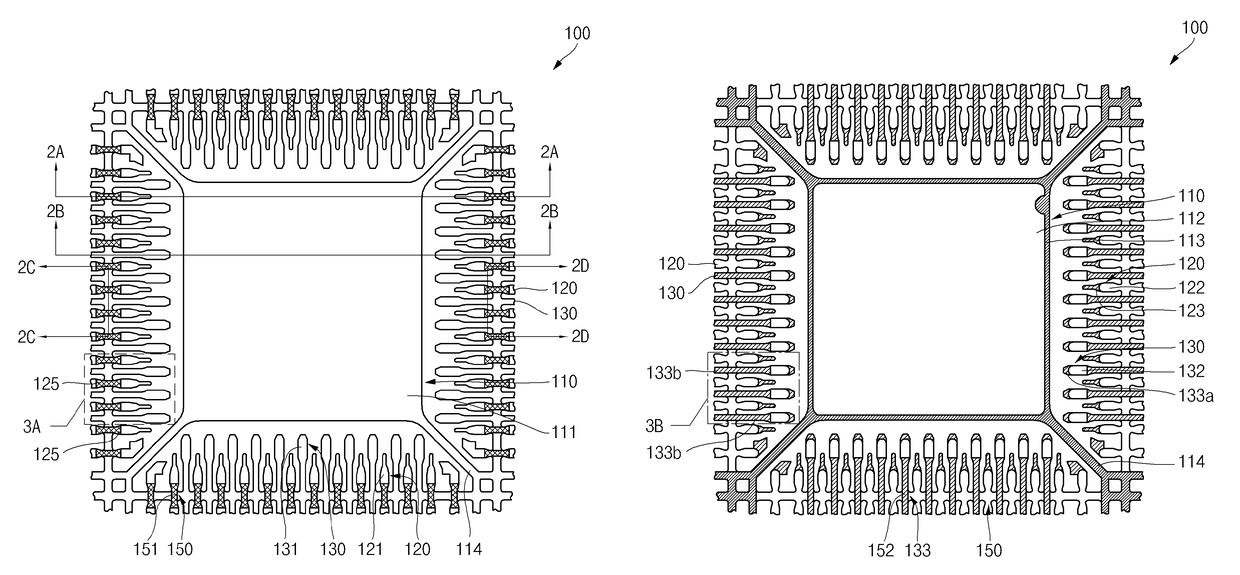

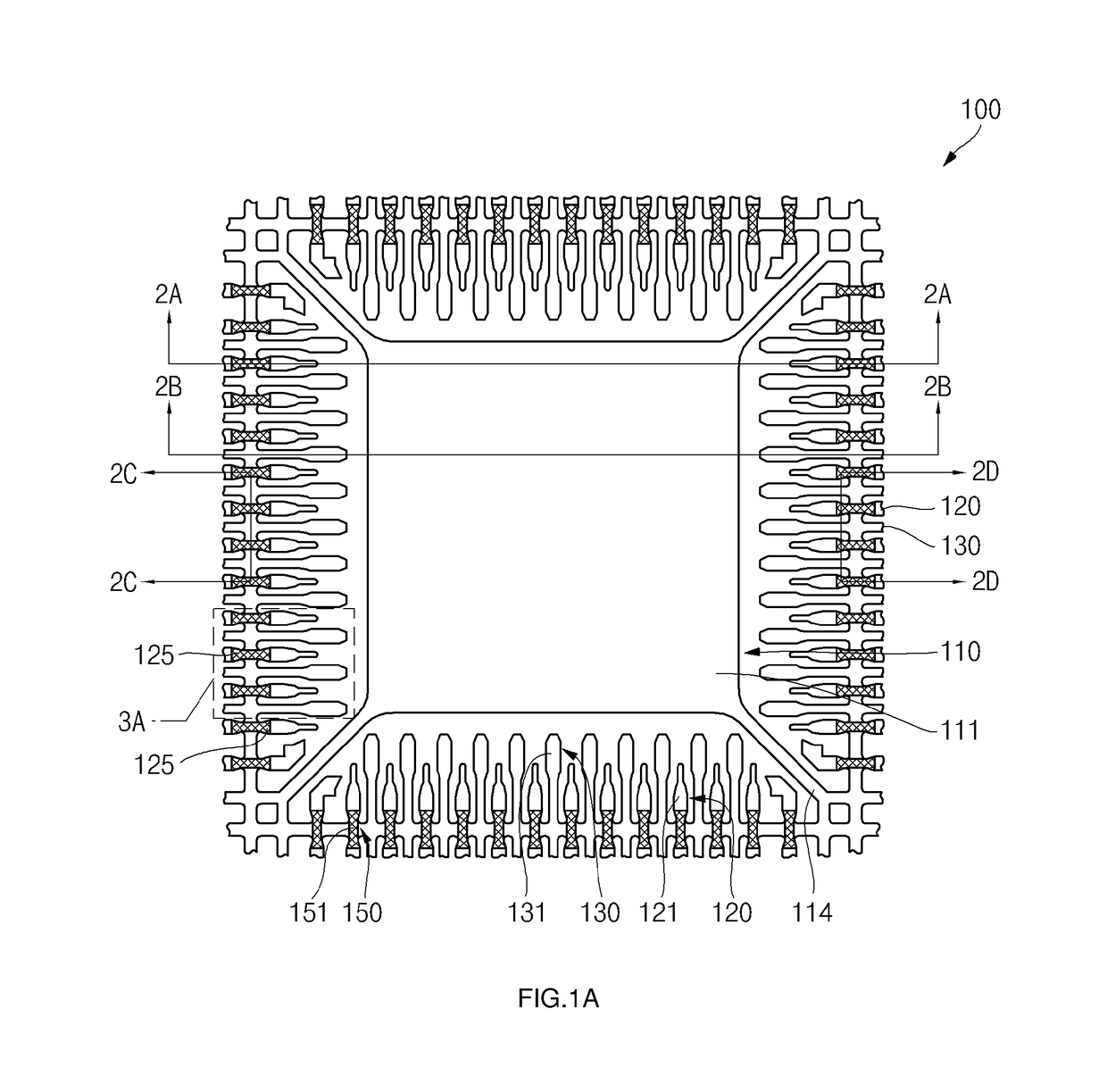

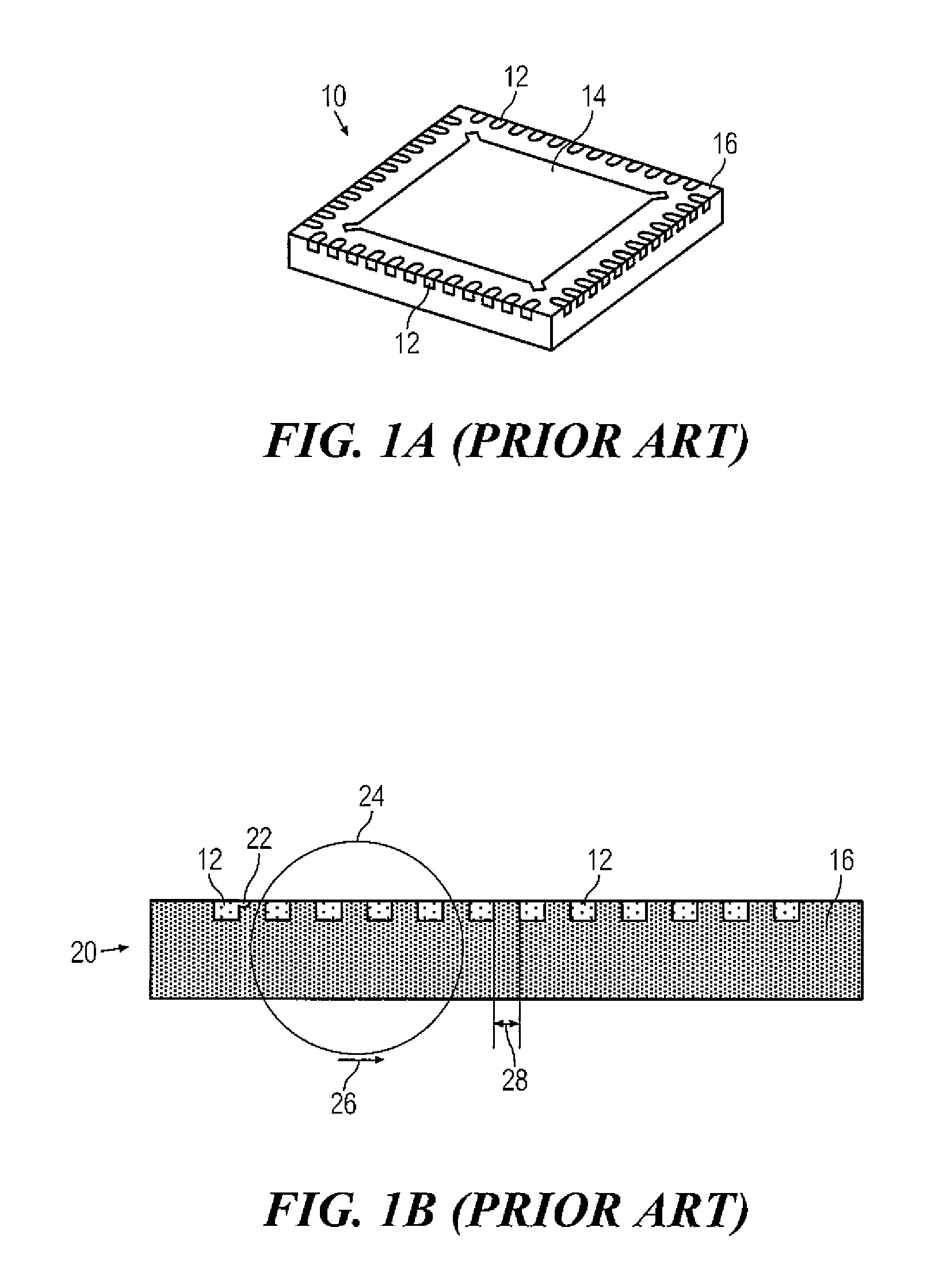

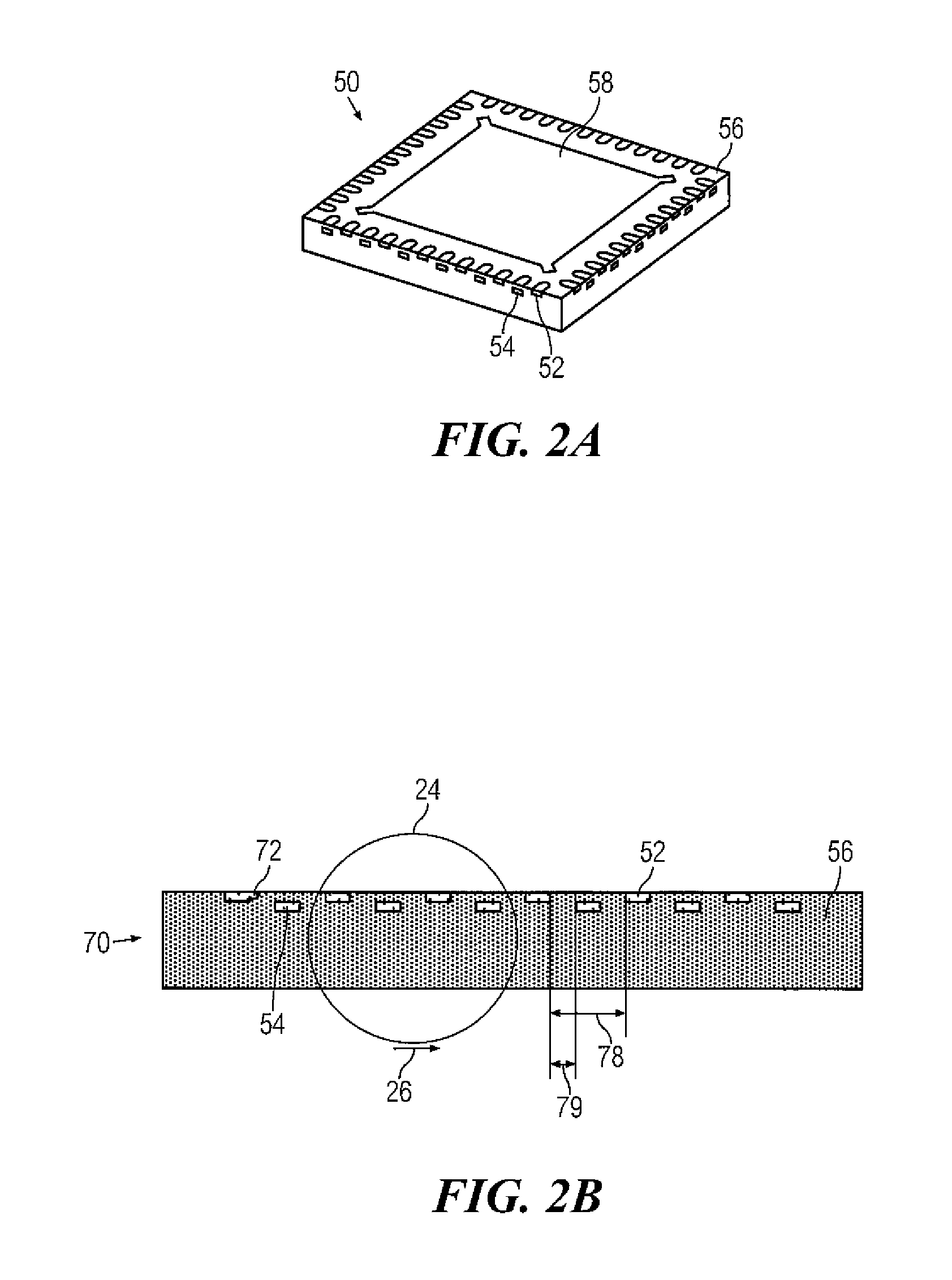

Lead frame for semiconductor device

ActiveUS20110248393A1Eliminate the effects ofSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A lead frame for reducing detrimental effects of burr formation includes a lead frame that has leads where a portion of a top surface is removed from a first lead and a portion of a bottom surface is removed from a second lead adjacent to the first lead to reduce spacing between leads while reducing the detrimental effects of burr formation, such as shorting and the like, caused during singulation of a semiconductor device manufactured with the lead frame.

Owner:NXP USA INC

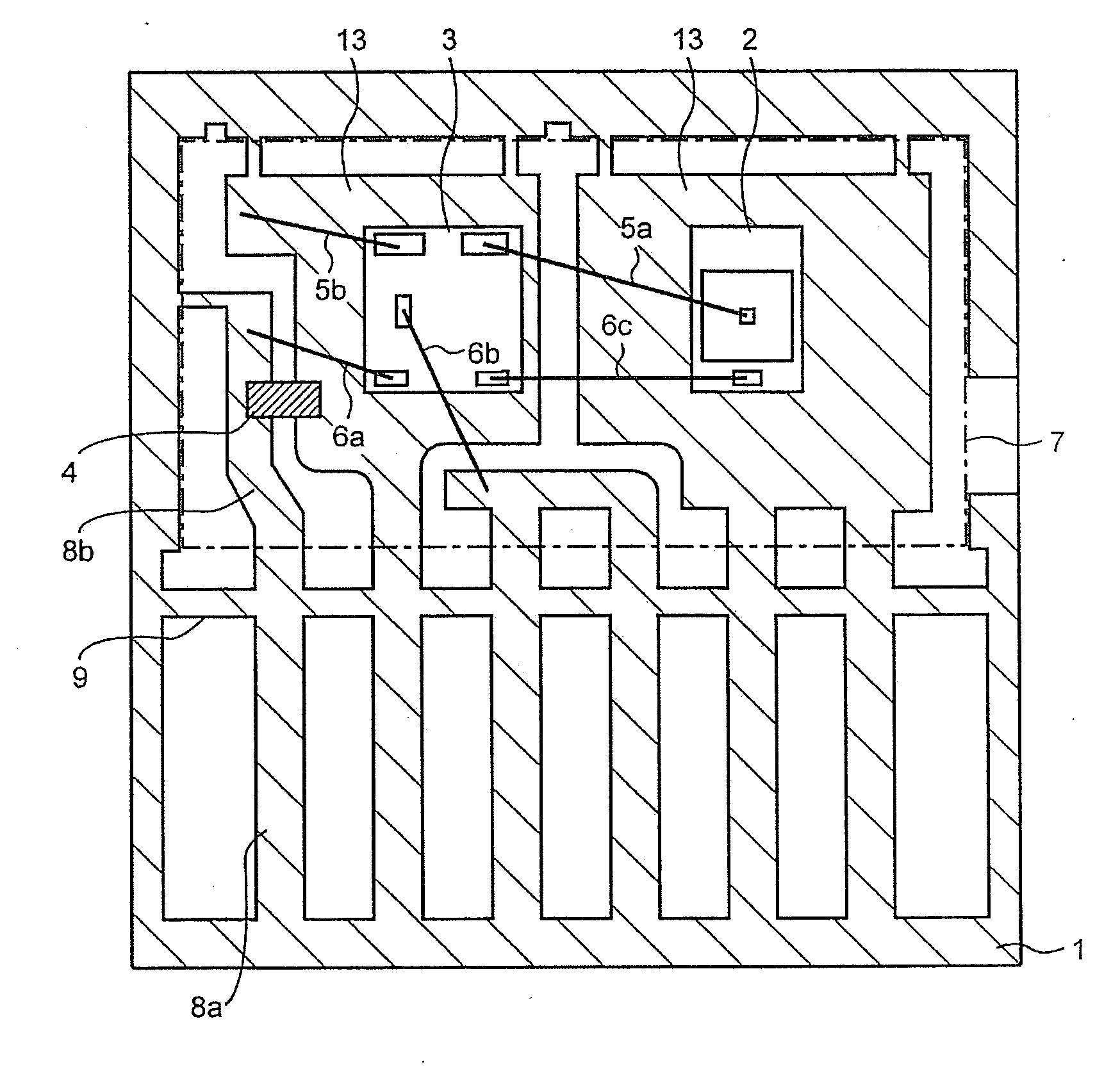

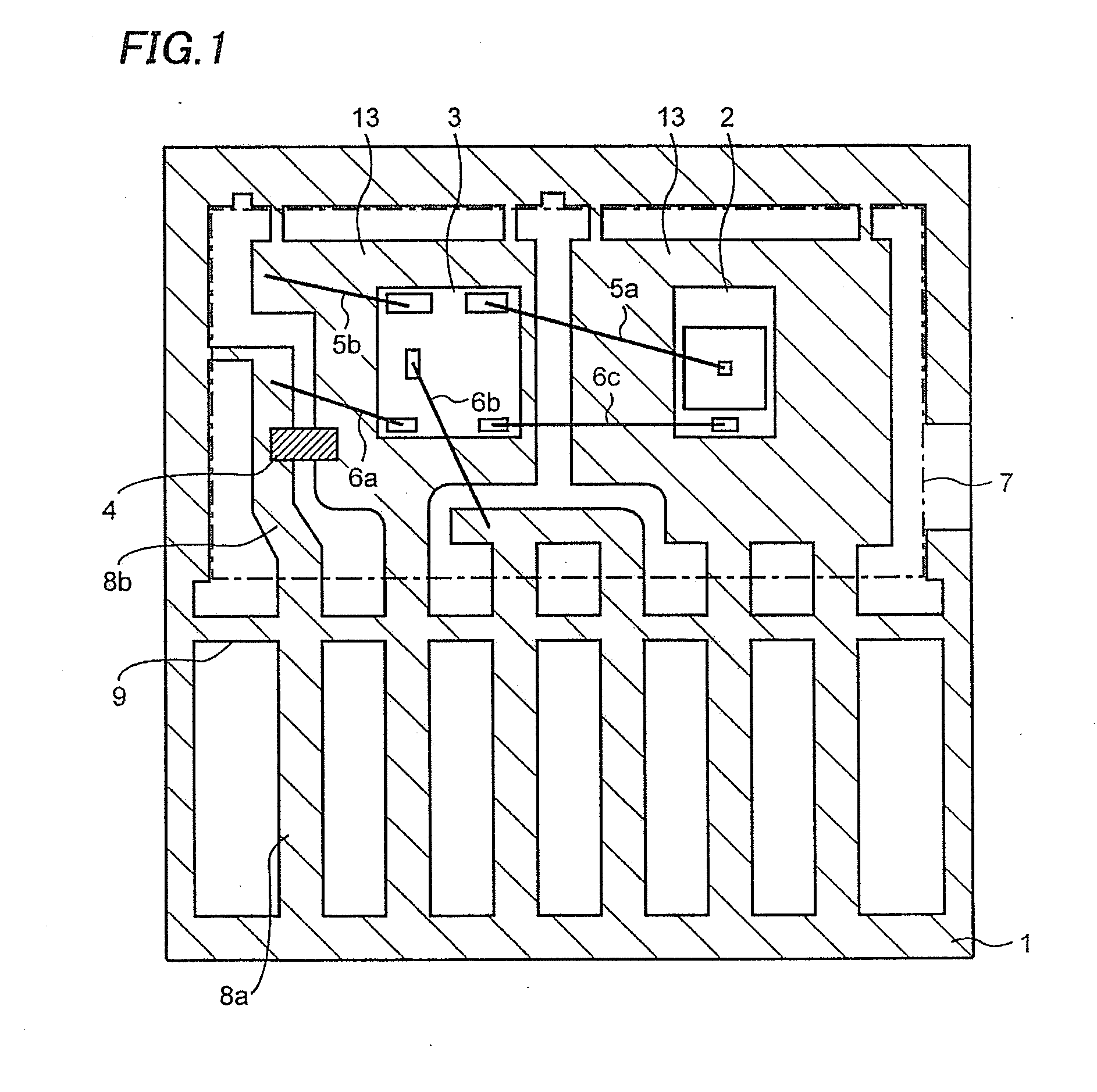

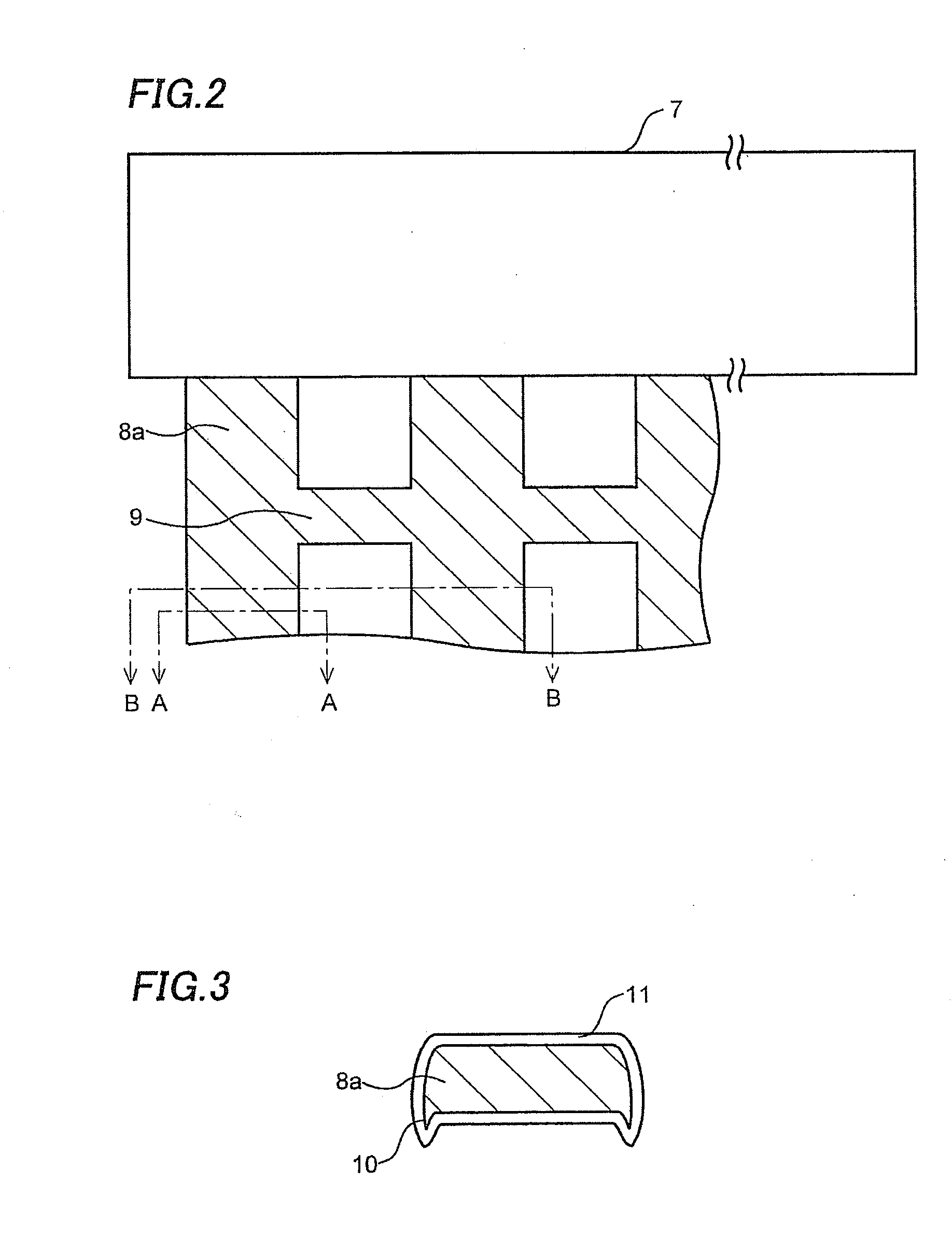

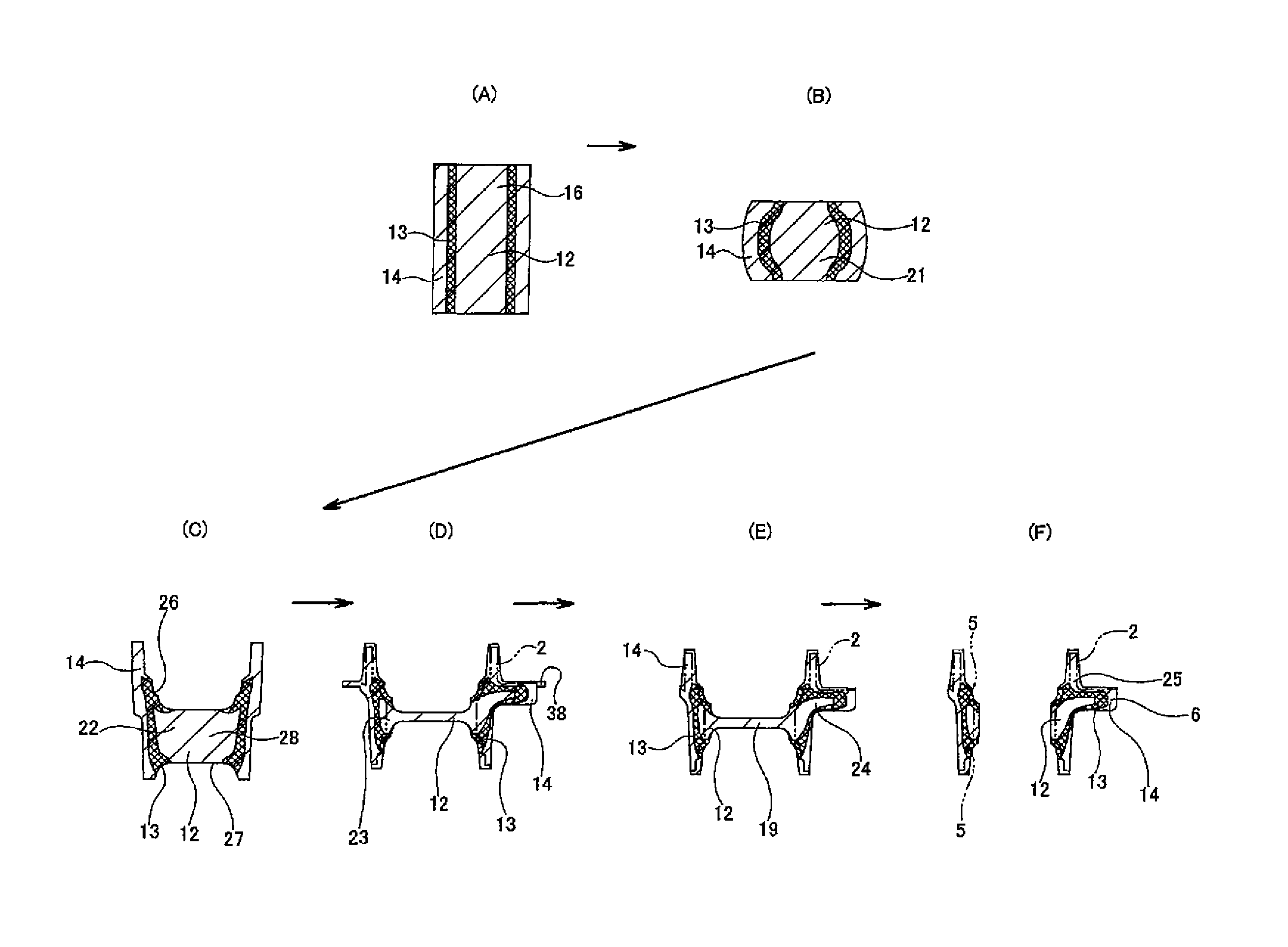

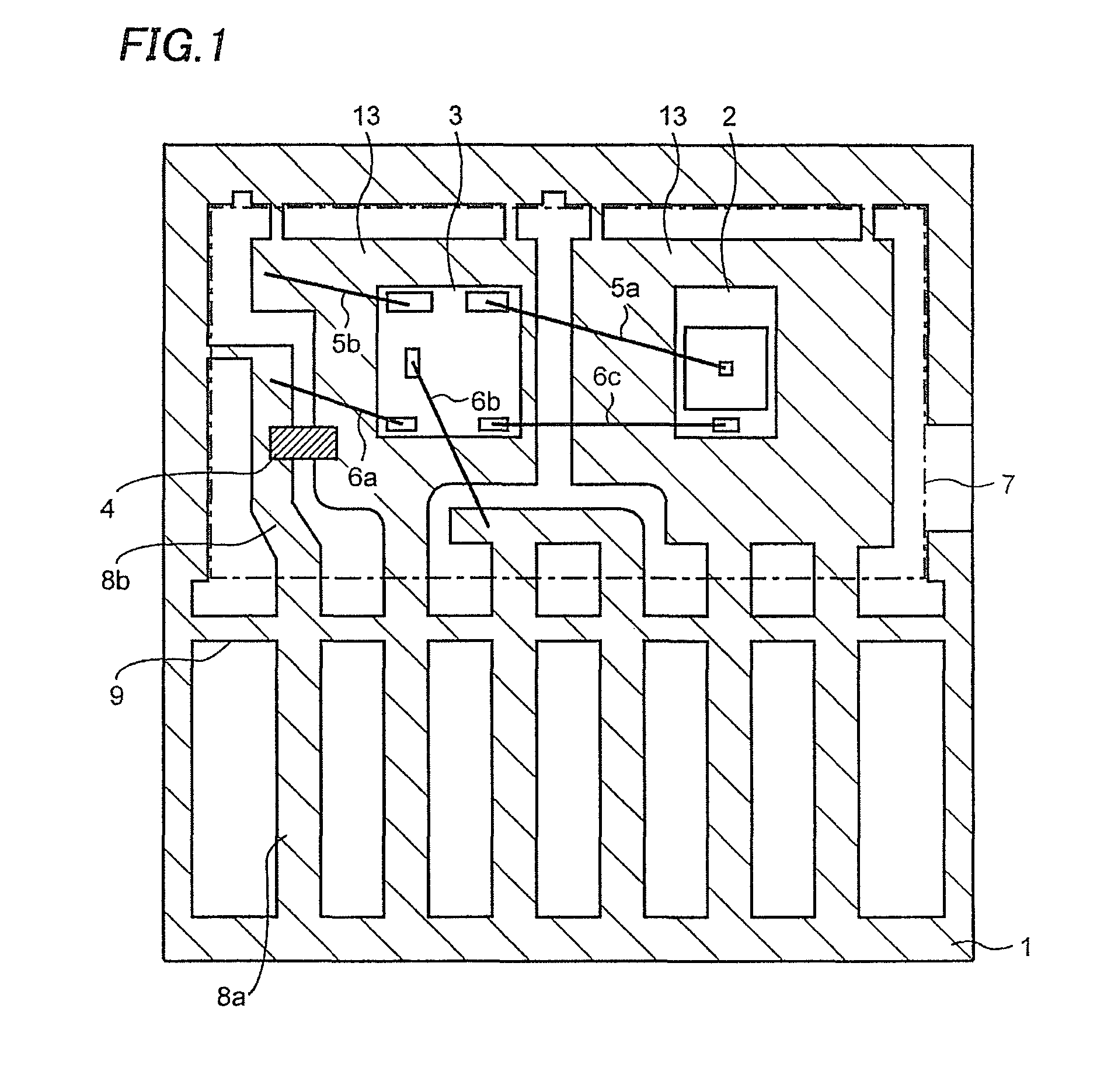

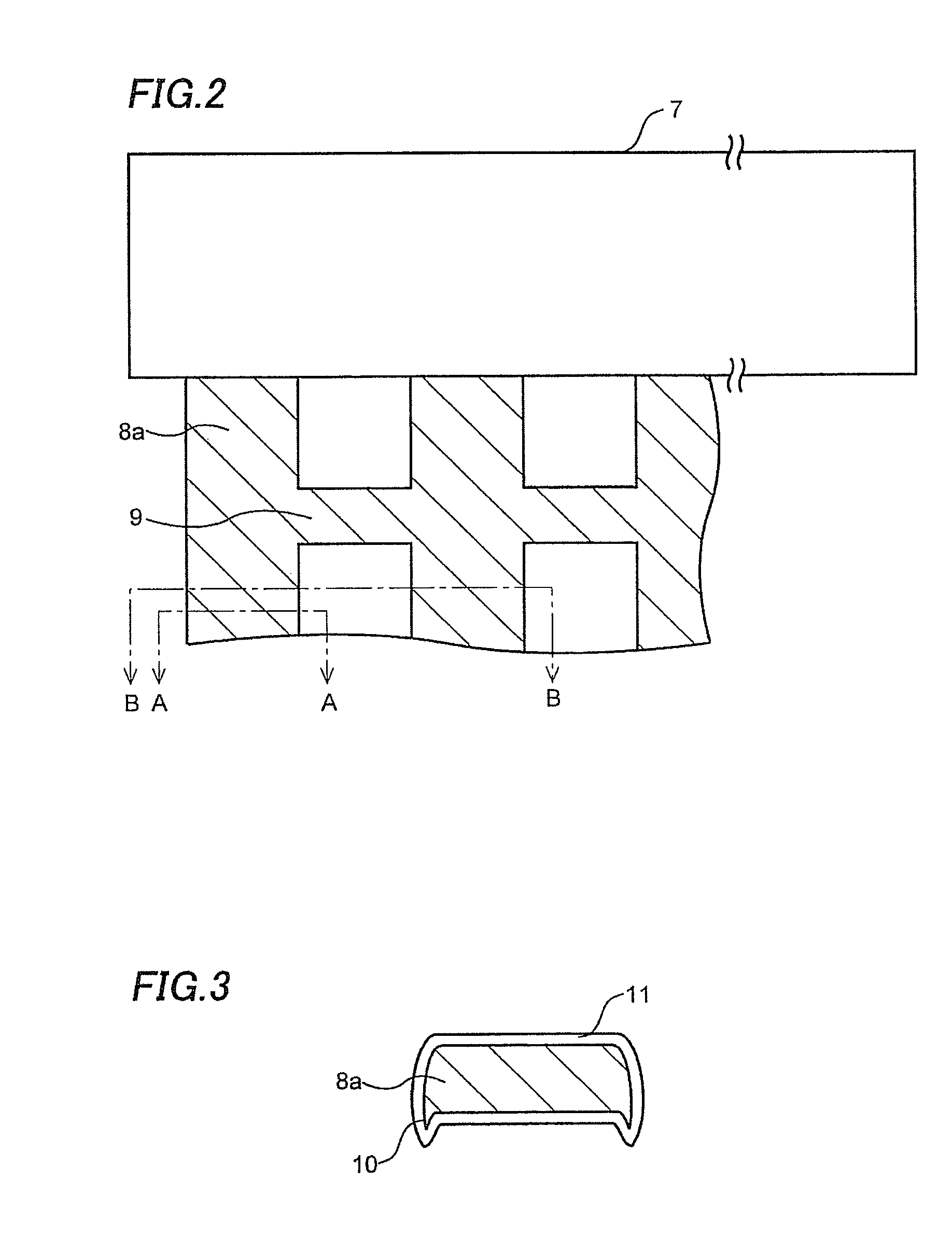

Resin sealing type semiconductor device and method of manufacturing the same, and resin sealing type electronic device

ActiveUS20100052124A1Improve reliabilitySemiconductor/solid-state device detailsSolid-state devicesConductive pasteEngineering

The invention provides a resin sealing type electronic device having high reliability by eliminating a solder burr formed when a tie bar is cut. The invention also prevents a welding failure between a lead of the resin sealing type electronic device and an external electrode, and provides a large area for bonding an electronic component to the lead to prevent a connection failure. In the method of manufacturing the resin sealing type semiconductor device of the invention, in a case that a tie bar is cut after a semiconductor die and so on are mounted on a lead frame and these are resin-sealed, the cutting of the tie bar is performed from the side of the lead frame where a lead burr is formed by presswork. Furthermore, in the resin sealing type electronic device of the invention, a die capacitor is bonded to burr formation surfaces of a lead and an island using conductive paste. Since the burr formation surface has a larger surface area than a rounded surface, a large bonding area is obtained. A welding surface of the lead to a control electrode is the rounded surface that is opposite to the burr formation surface.

Owner:SEMICON COMPONENTS IND LLC

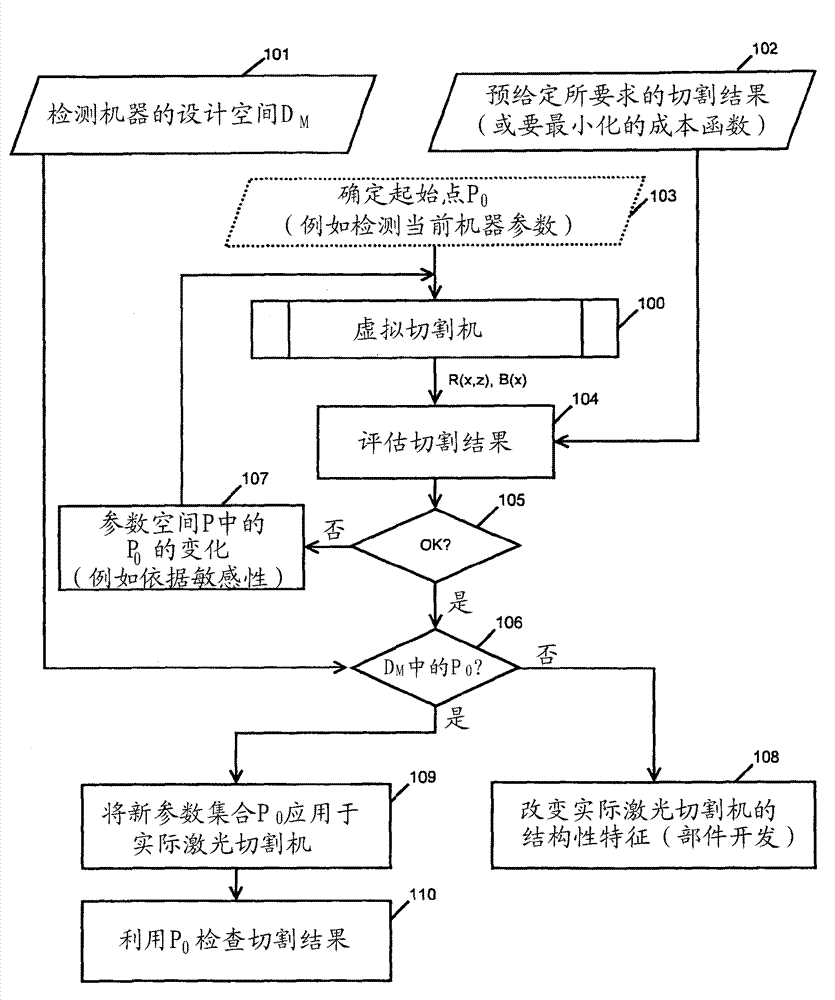

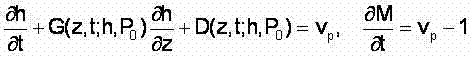

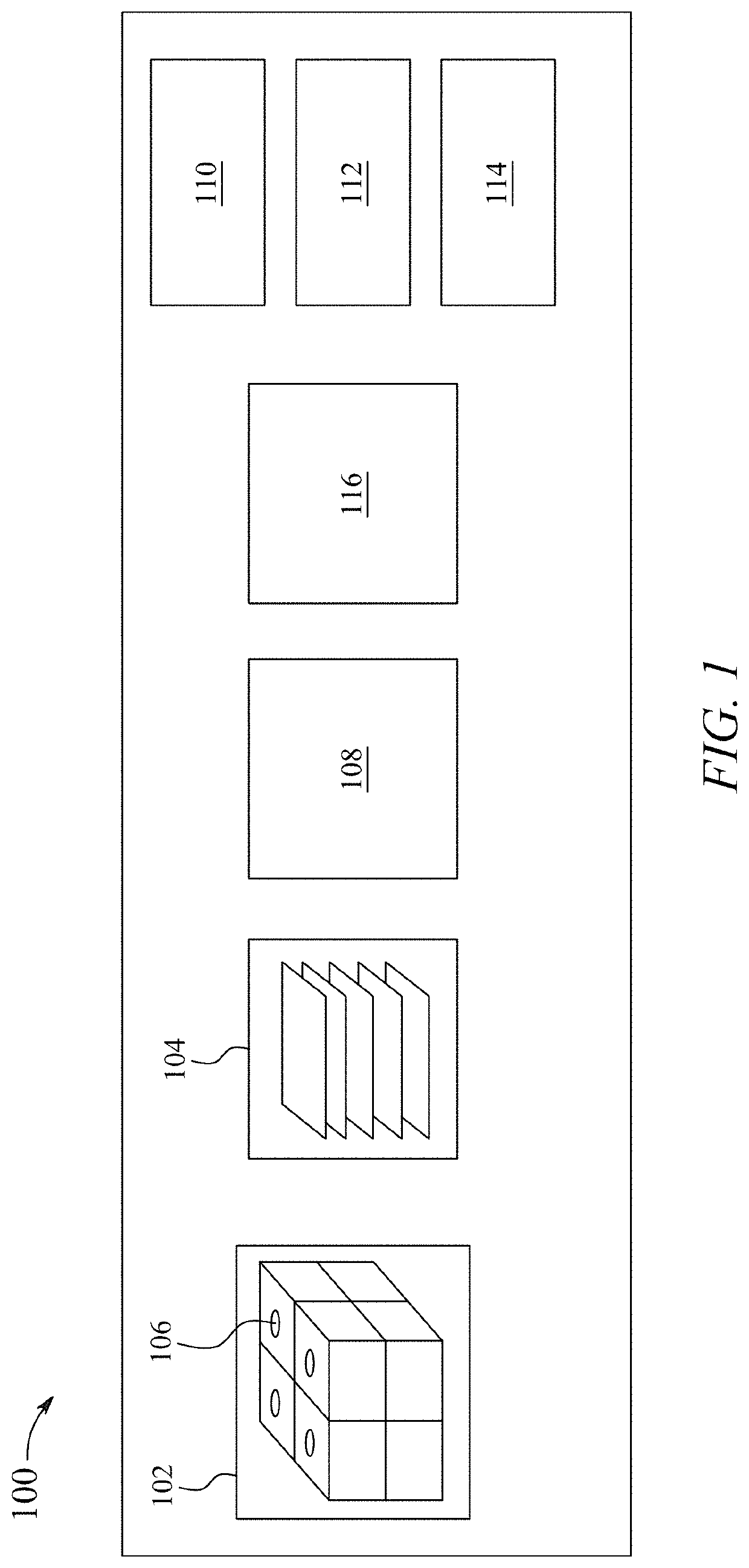

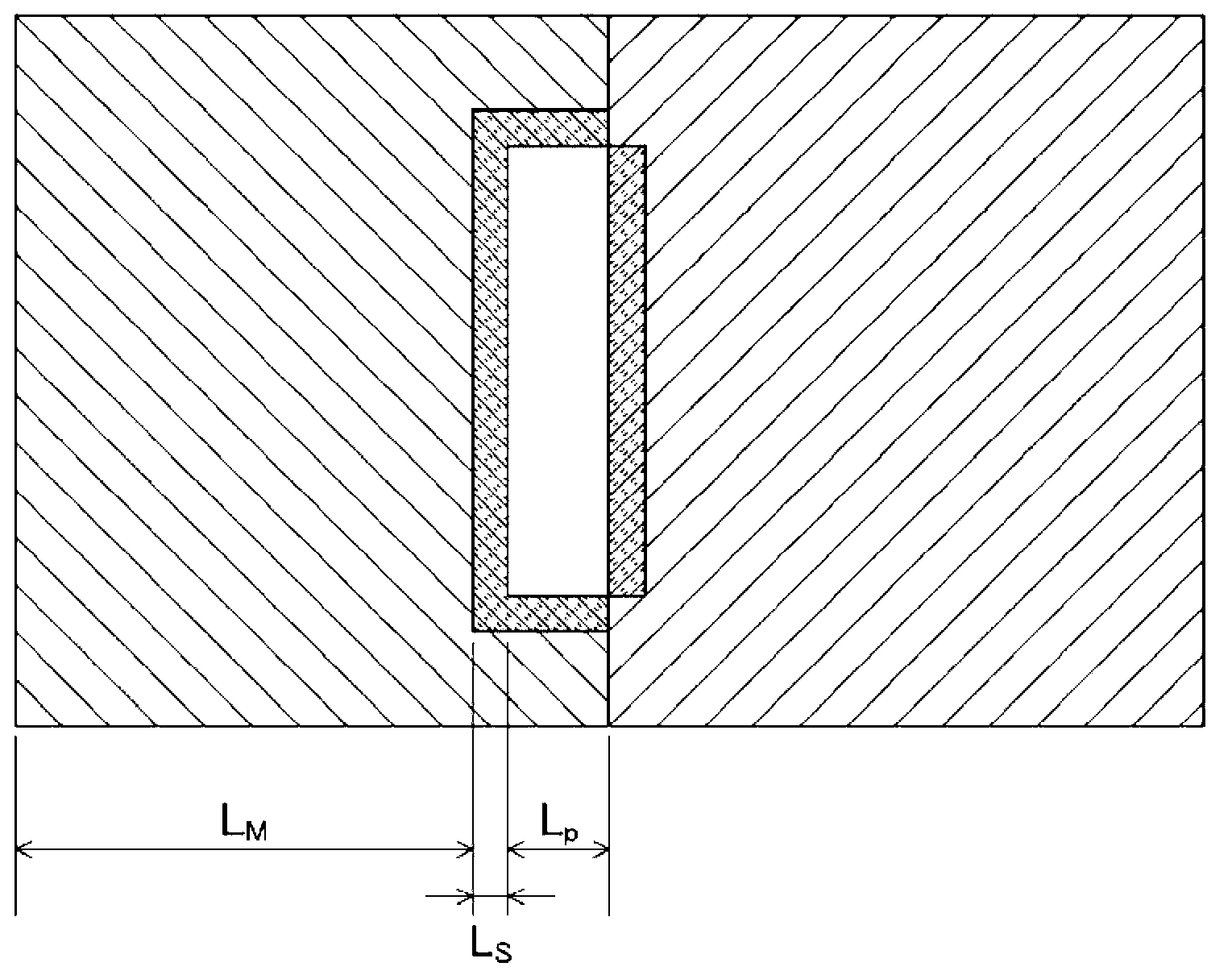

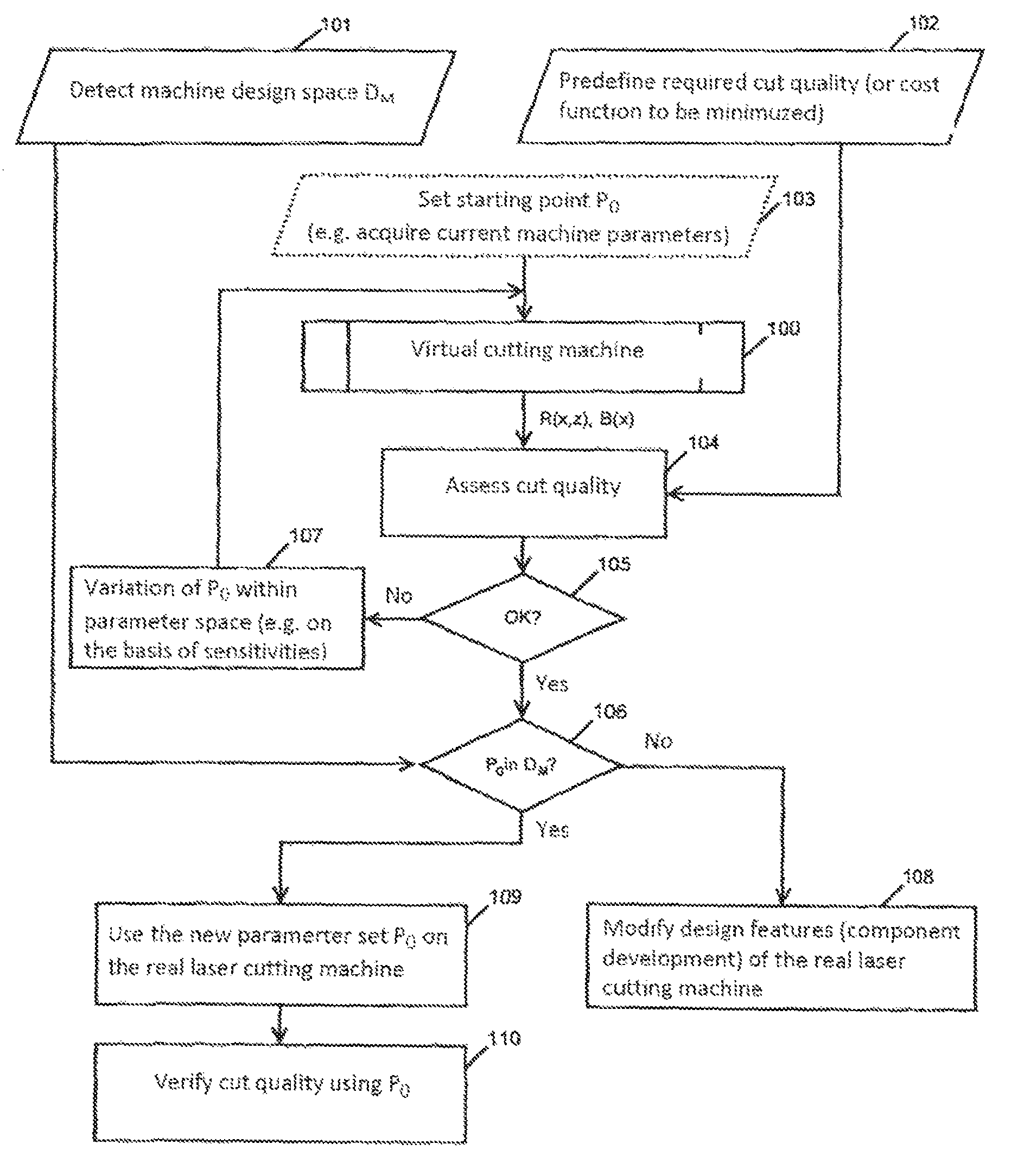

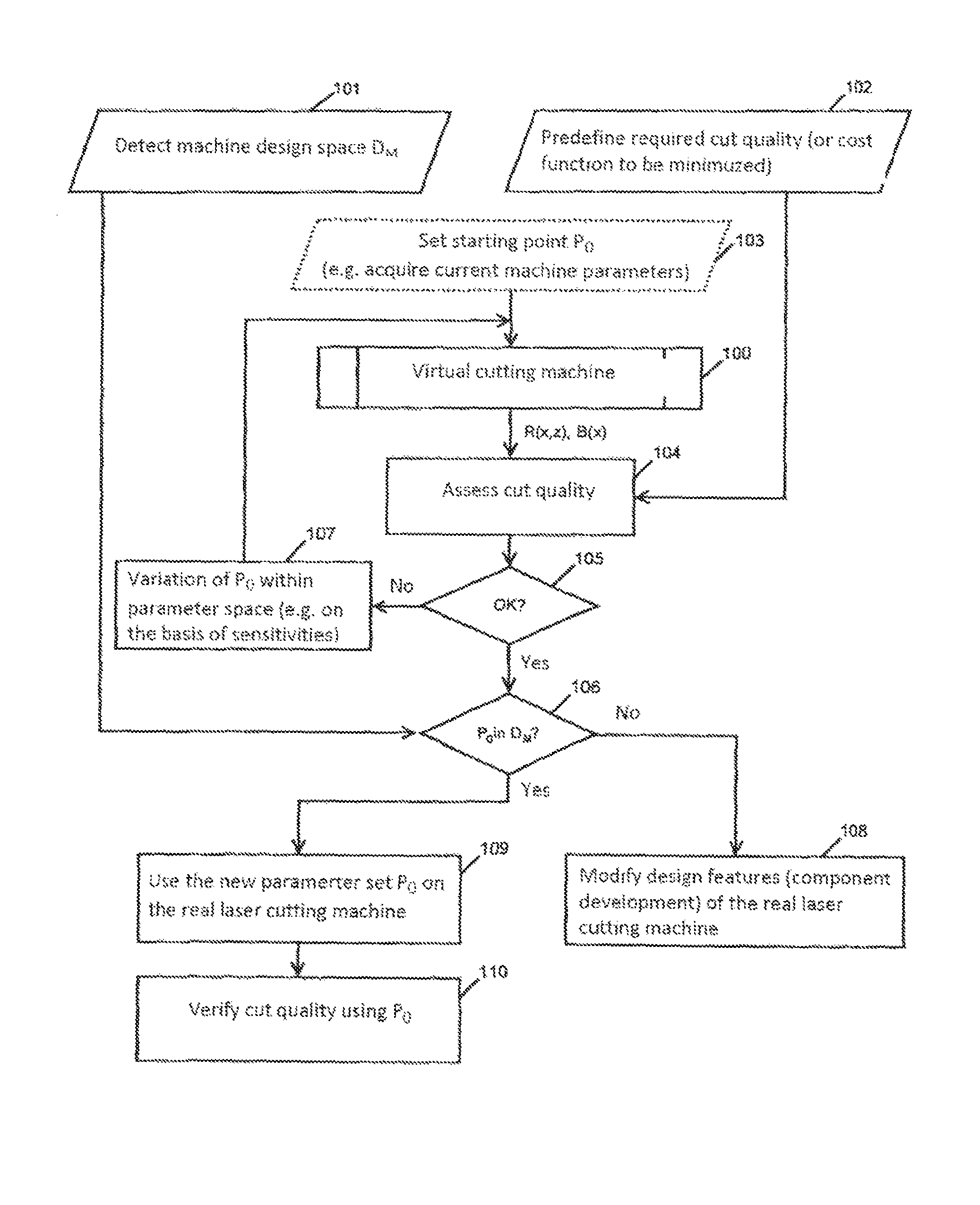

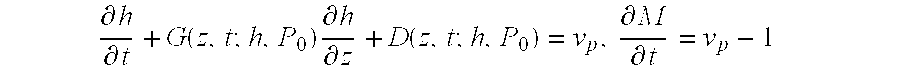

Method for determining the cut quality of a laser cutting process using a simulation program

InactiveCN102741009ADesign optimisation/simulationSpecial data processing applicationsBoundary valuesPartial differential equation

The application relates to a method for determining the cut quality of a laser cutting process, said quality being assessed on the basis of the formation of solidification ridges along the cut face and / or burr formation on the lower edge of the cut face. In said method, a virtual laser cutting machine in a simulation program can be virtually operated with a set of values P0 from a parameter space P.; In a step a), the parameter set P0 is entered in the virtual cutting machine (103), then in step b), a cut is made in the virtual workpiece by calculating, from partial differential equations with initial and boundary values, the progression of the melt film thickness over time and the position of the melt front at the apex of the cutting front according to the depth of the cut and the time, and then in step c), the spatial distribution of the ridge amplitude on the cut face is specified by projecting the progression of the absorption front onto the cut face and / or a spatial distribution of the burr is calculated from the progression of the melt film thickness over time and the discharge speed on the lower edge of the cut face, and in step d), a virtual cut quality is provided (104) for further analysis.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

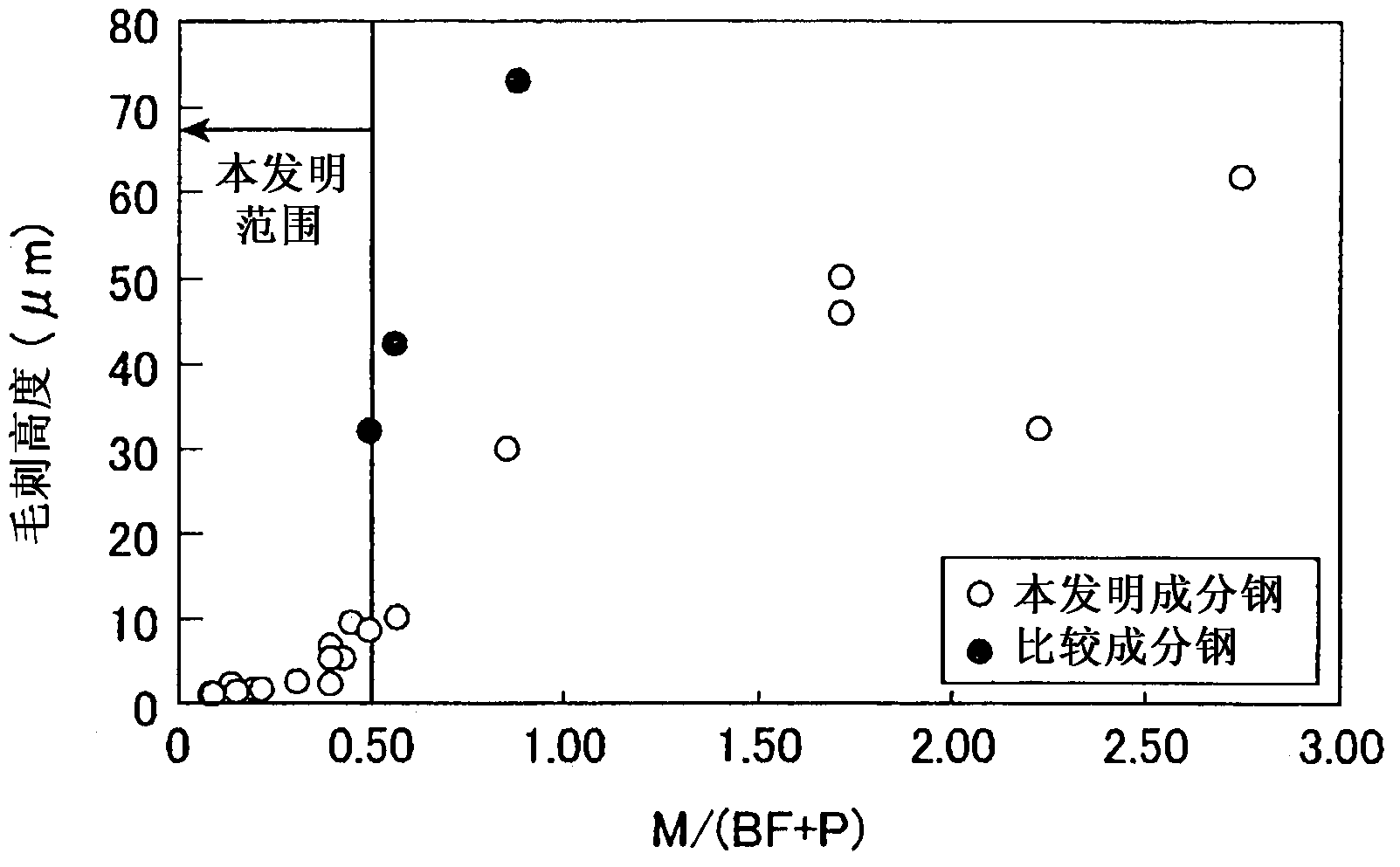

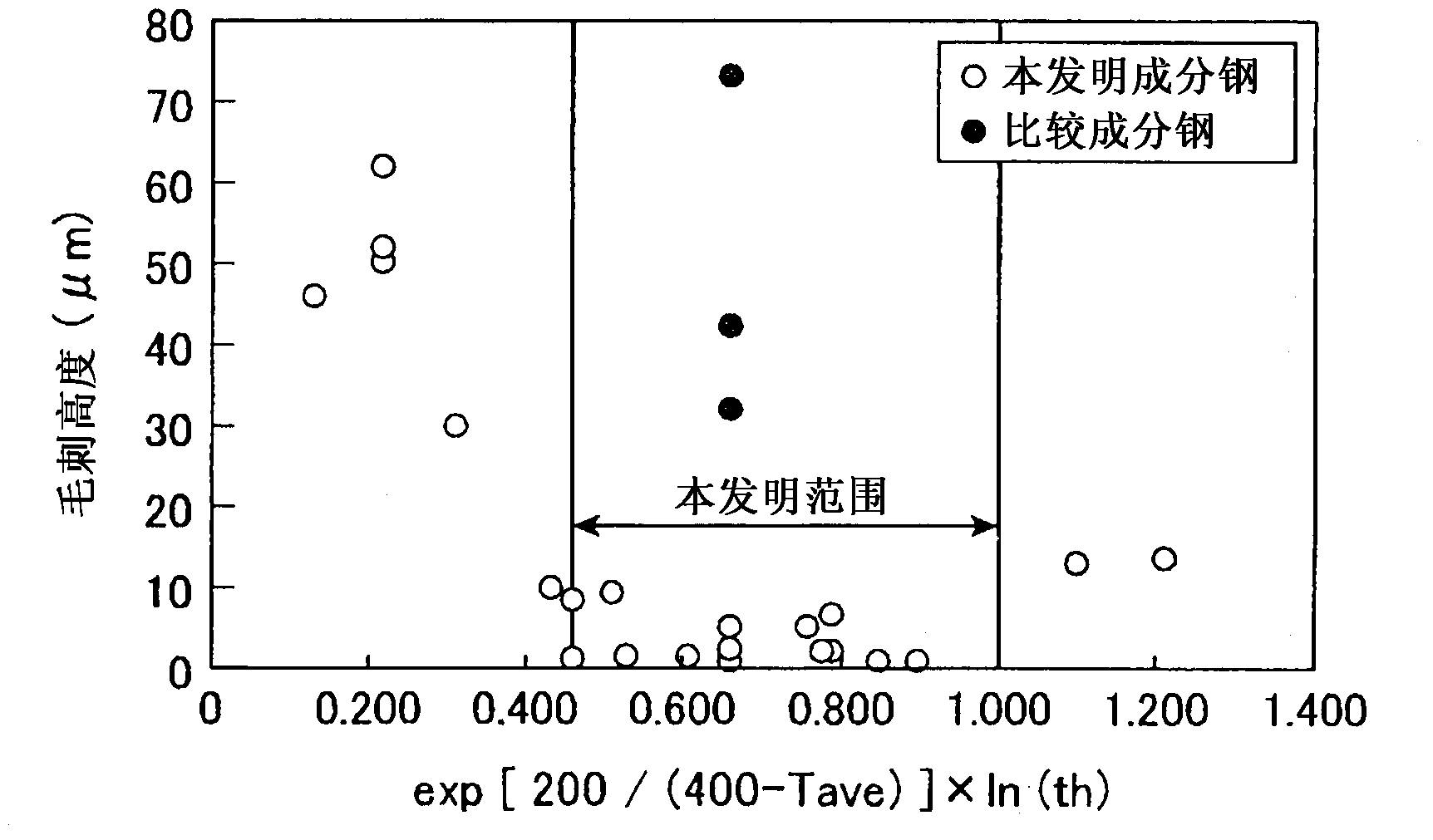

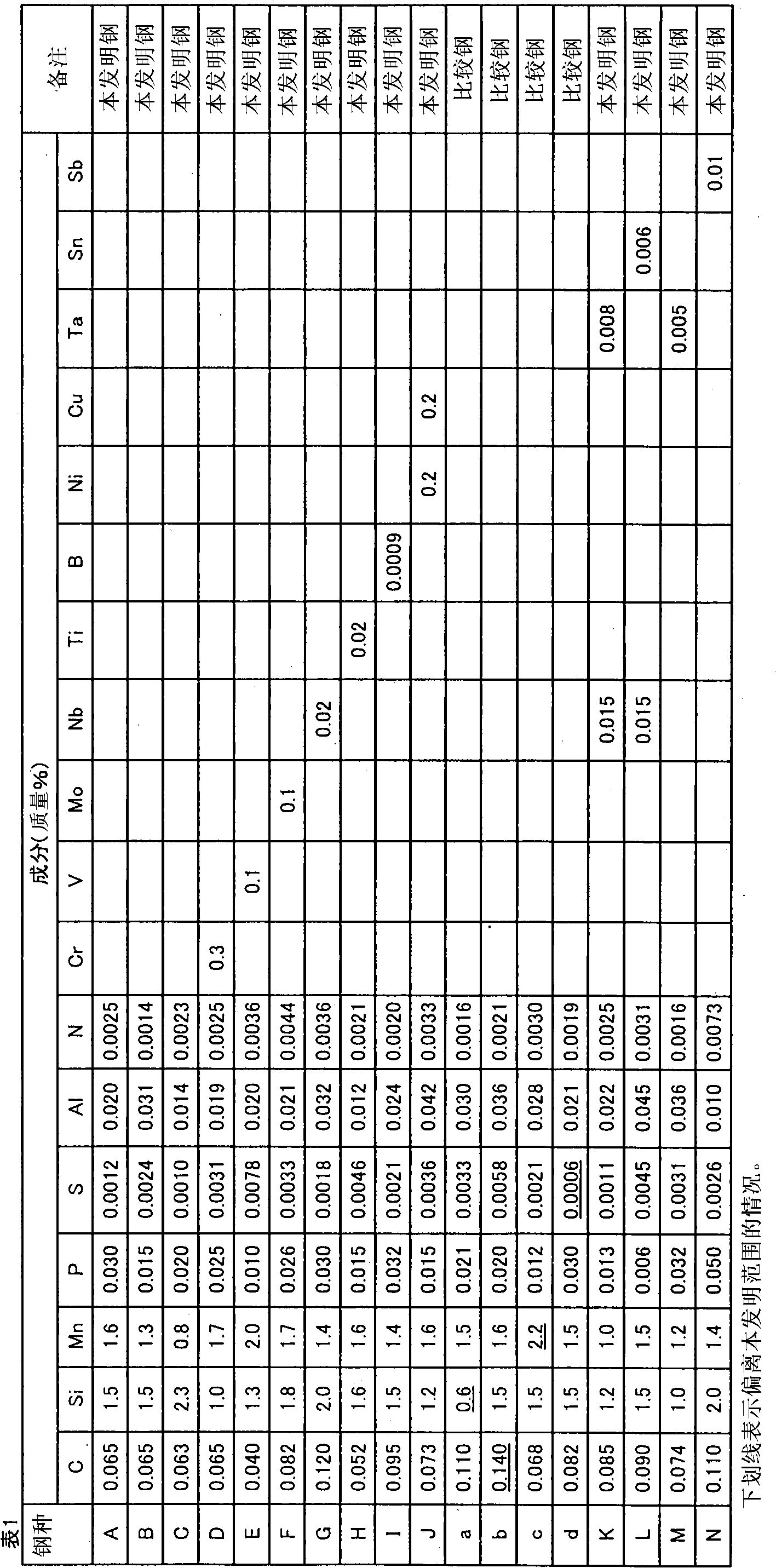

High-strength hot-dip galvanized steel sheet reduced in burr formation and process for producing same

ActiveCN102712979AExcellent burr resistanceHot-dipping/immersion processesFurnace typesPearliteMartensite

Provided are a high-strength hot-dip galvanized steel sheet which is reduced in burr formation, i.e., low in the height of burrs, and a process for producing the steel sheet. The high-strength hot-dip galvanized steel sheet reduced in burr formation is characterized by having a composition which contains, in terms of mass%, 0.04-0.13% C, 1.0-2.3% Si, 0.8-2.0% Mn, up to 0.05% P, 0.0010-0.01% S, up to 0.1% Al, and up to 0.008% N, with the remainder comprising Fe and incidental impurities, and by having a structure which comprises, in terms of areal proportion, at least 75% ferrite phase, at least 1% bainitic ferrite phase, and 1-10% pearlite phase, has a martensite phase content less than 5% in terms of areal proportion, and satisfies (areal proportion of martensite) / ((areal proportion of bainitic ferrite)+(areal proportion of pearlite))<=0.5.

Owner:JFE STEEL CORP

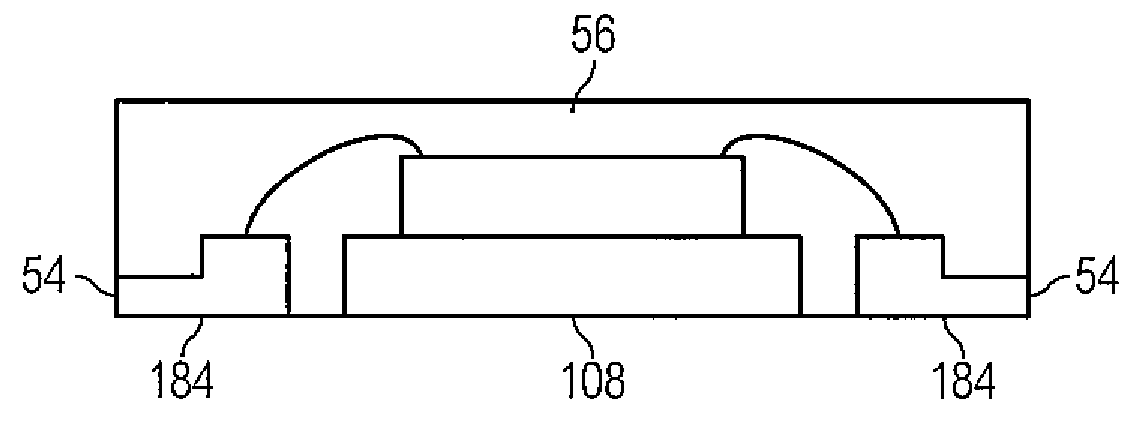

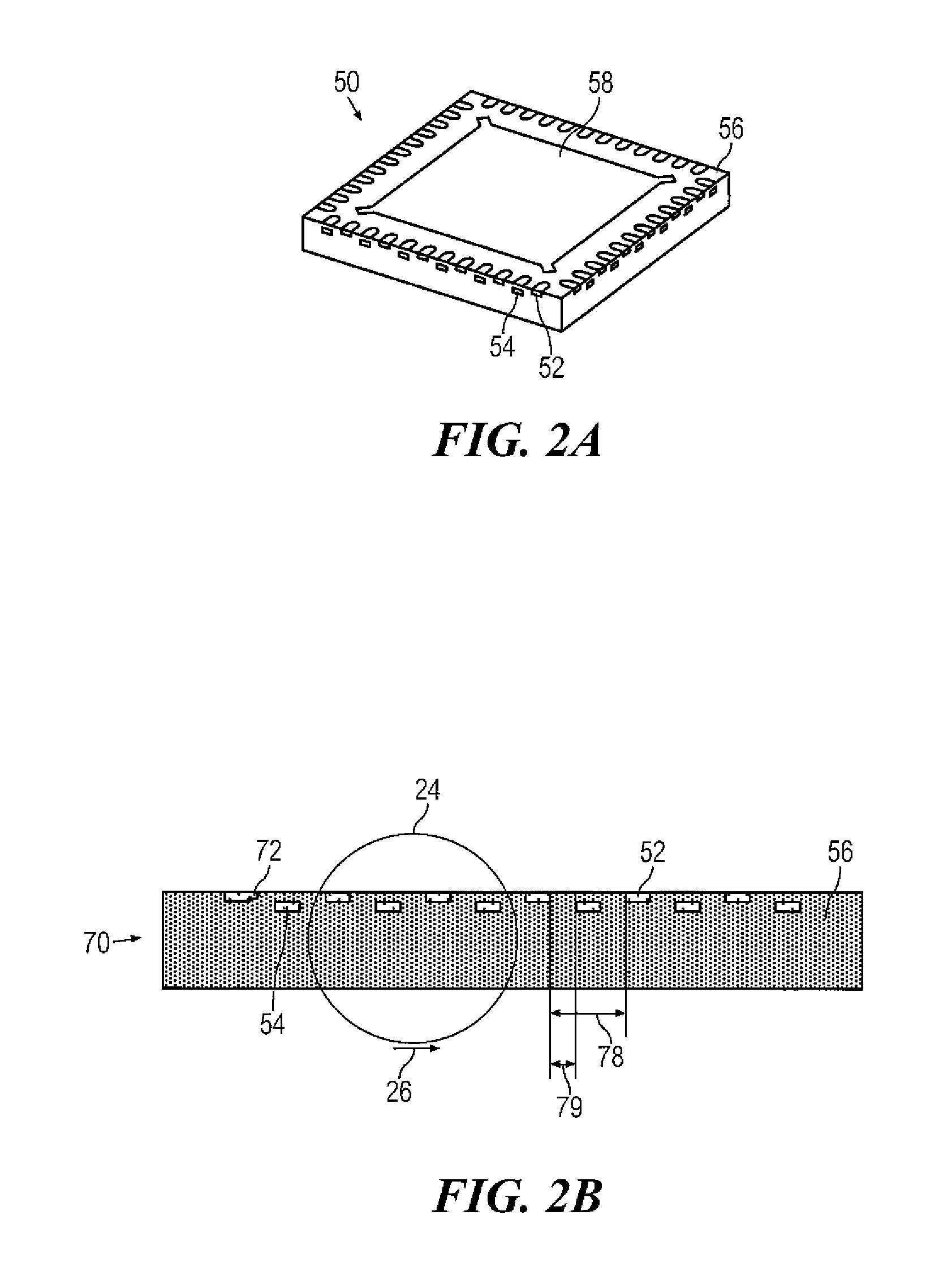

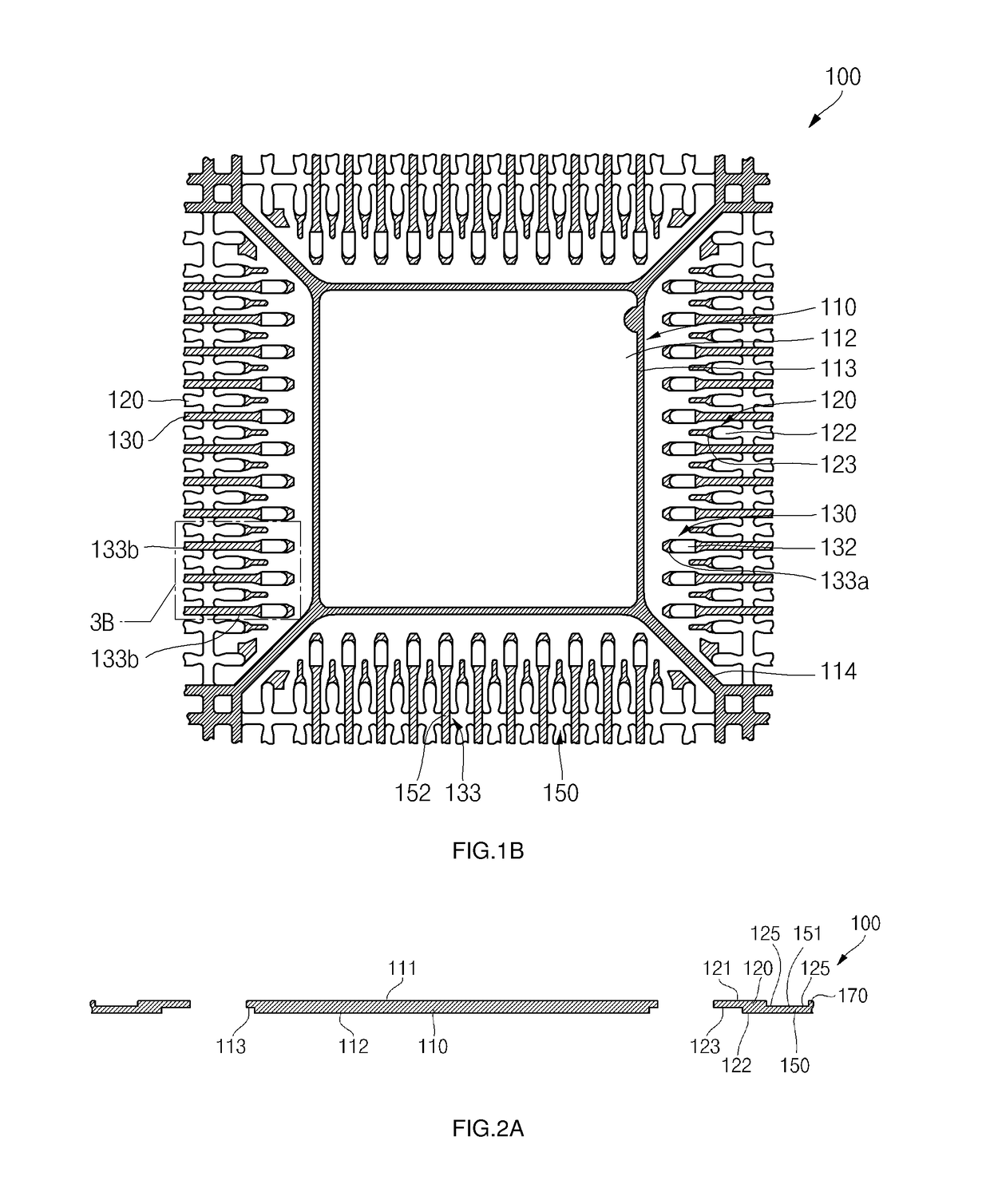

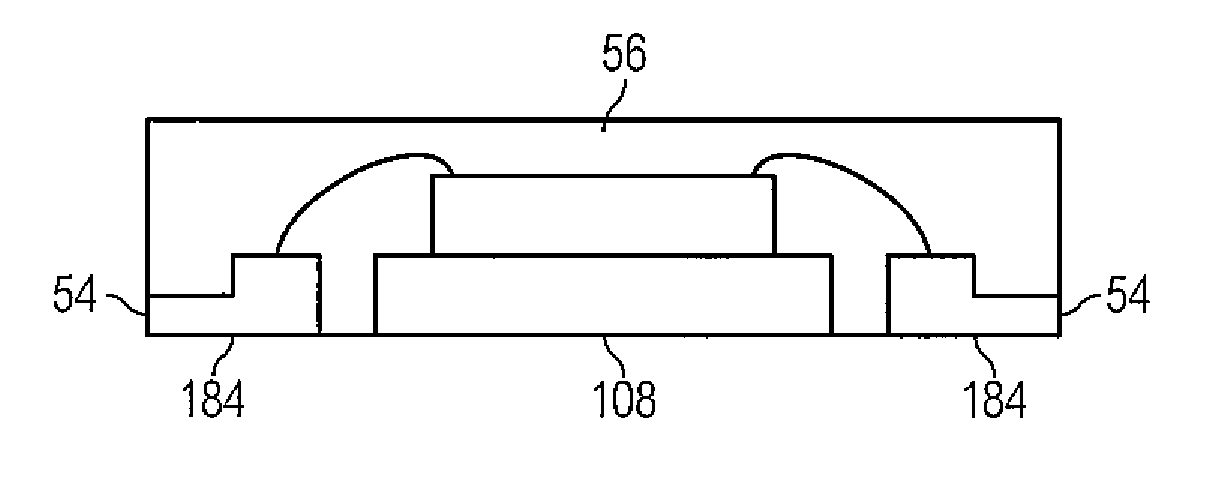

Semiconductor device with leadframe configured to facilitate reduced burr formation

ActiveUS9704725B1Semiconductor/solid-state device detailsSolid-state devicesEdge segmentSemiconductor package

A semiconductor package or device including a uniquely configured leadframe defining a plurality of leads which are arranged and partially etched in a manner facilitating a substantial reduction in burr formation resulting from a saw singulation process used to complete the fabrication of the semiconductor device. The semiconductor device includes a die pad defining multiple peripheral edge segments. In addition, the semiconductor device includes a plurality of leads which are provided in a prescribed arrangement. Connected to the top surface of the die pad is at least one semiconductor die which is electrically connected to at least some of the leads. At least portions of the die pad, the leads, the lands, and the semiconductor die are encapsulated by the package body, with at least portions of the bottom surfaces of the die pad and the leads being exposed in a common exterior surface of the package body.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

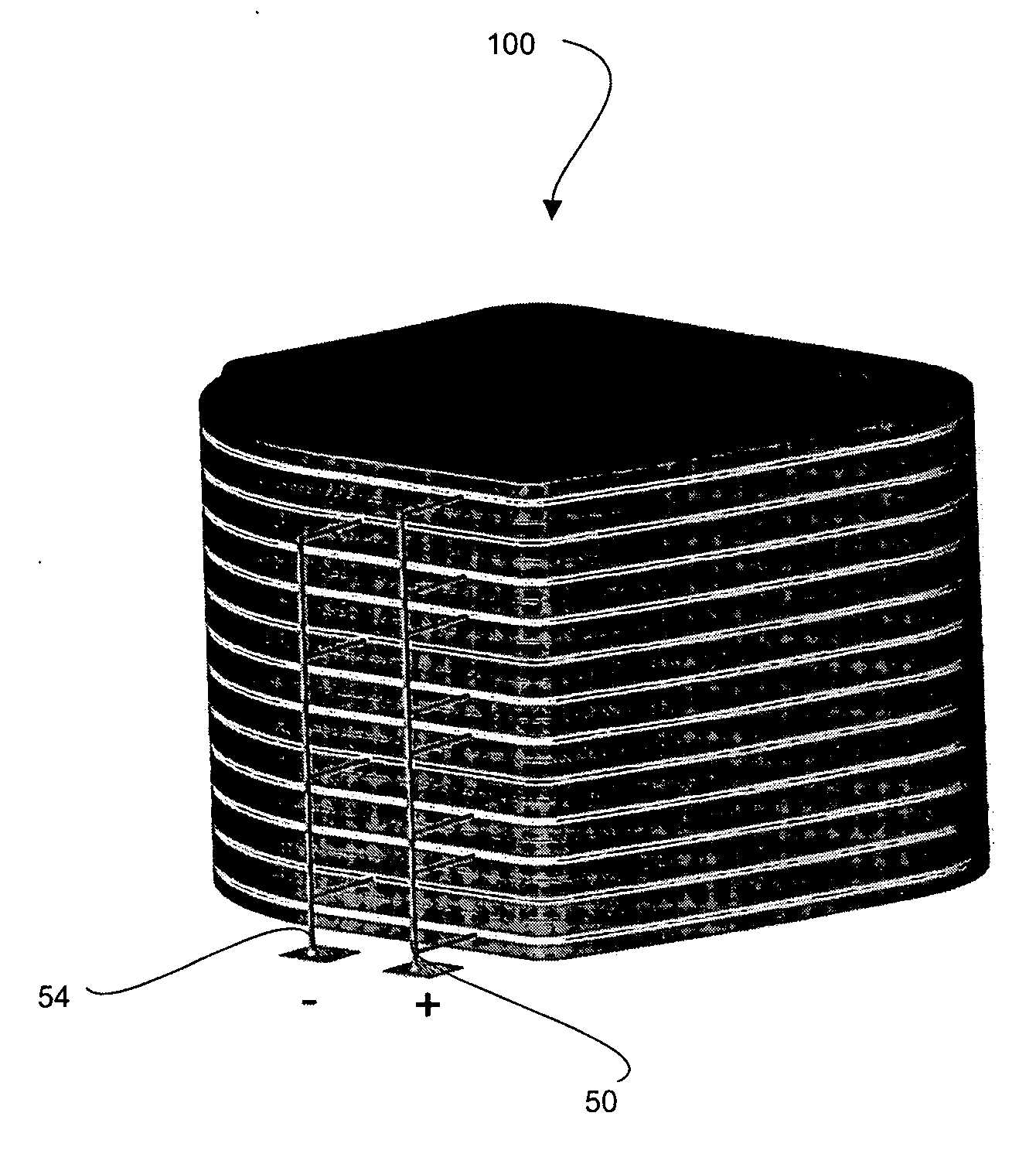

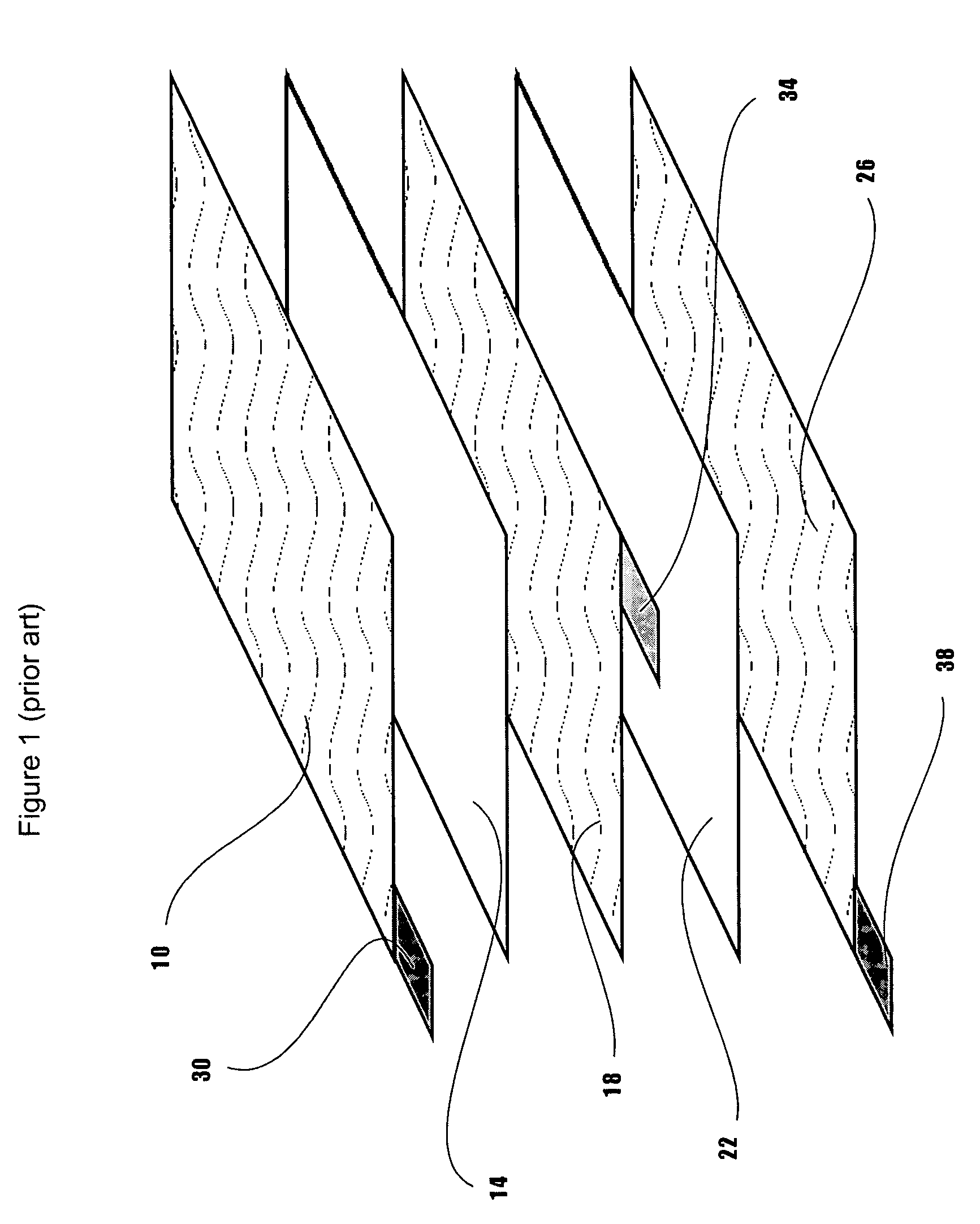

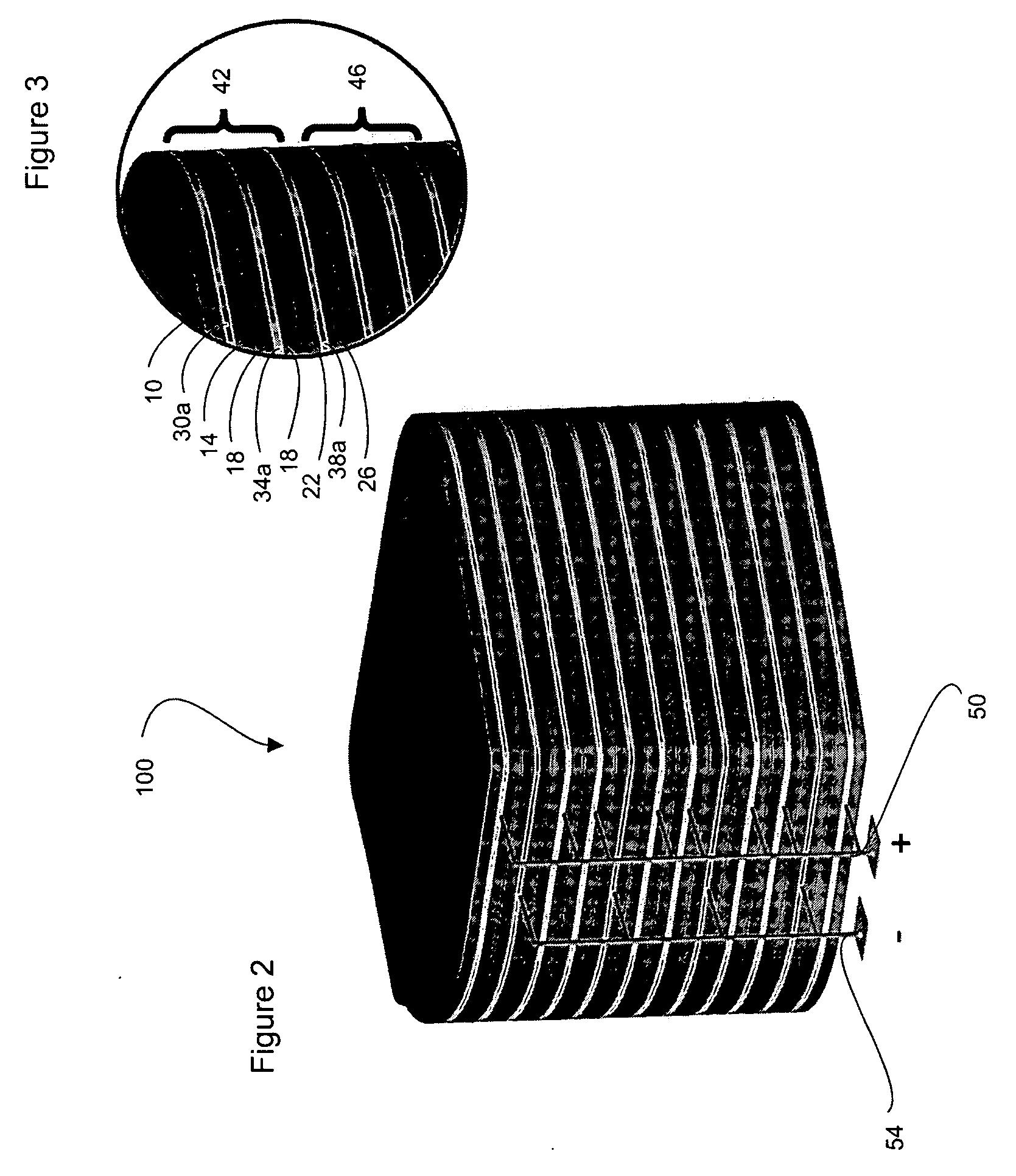

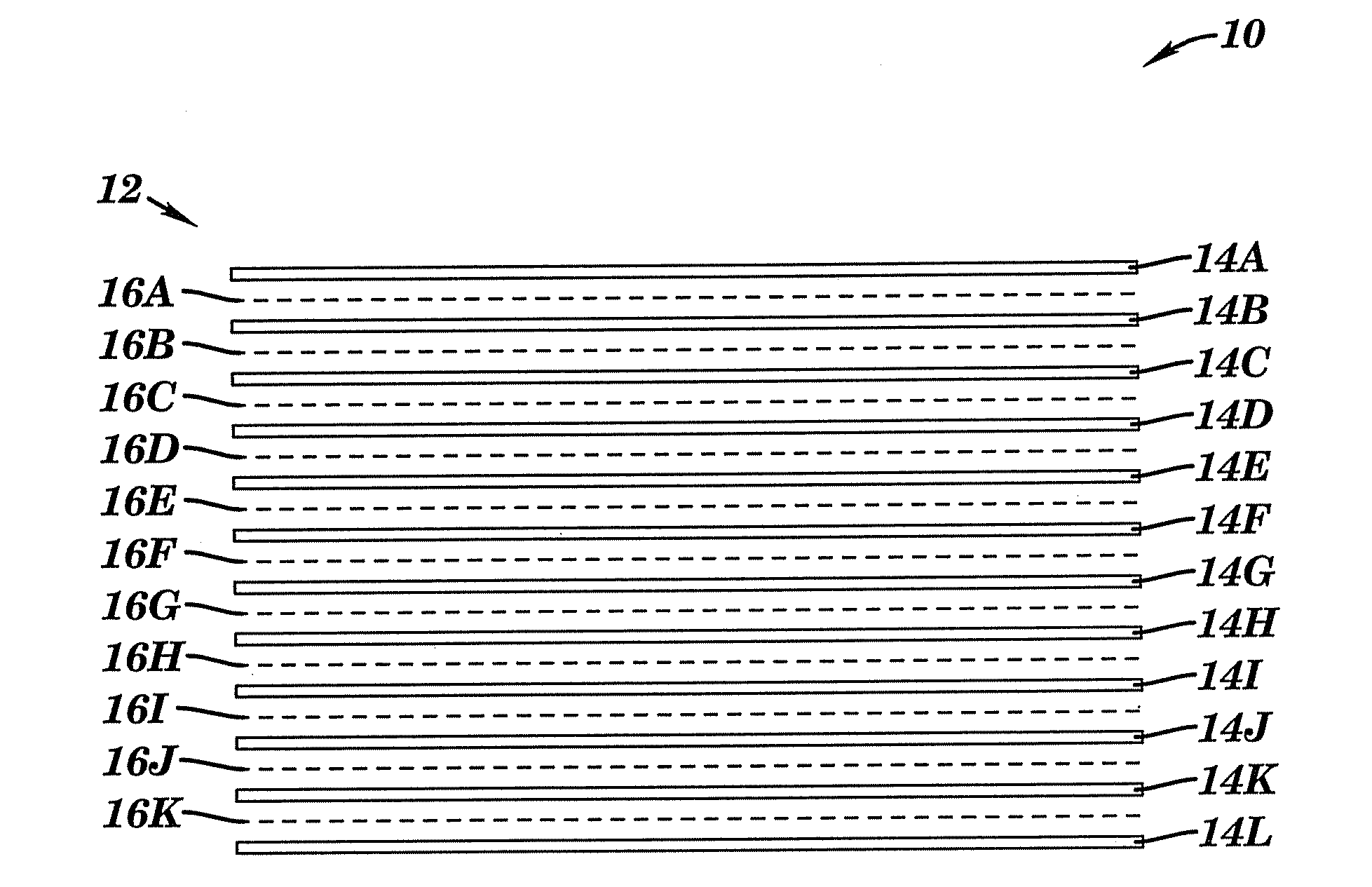

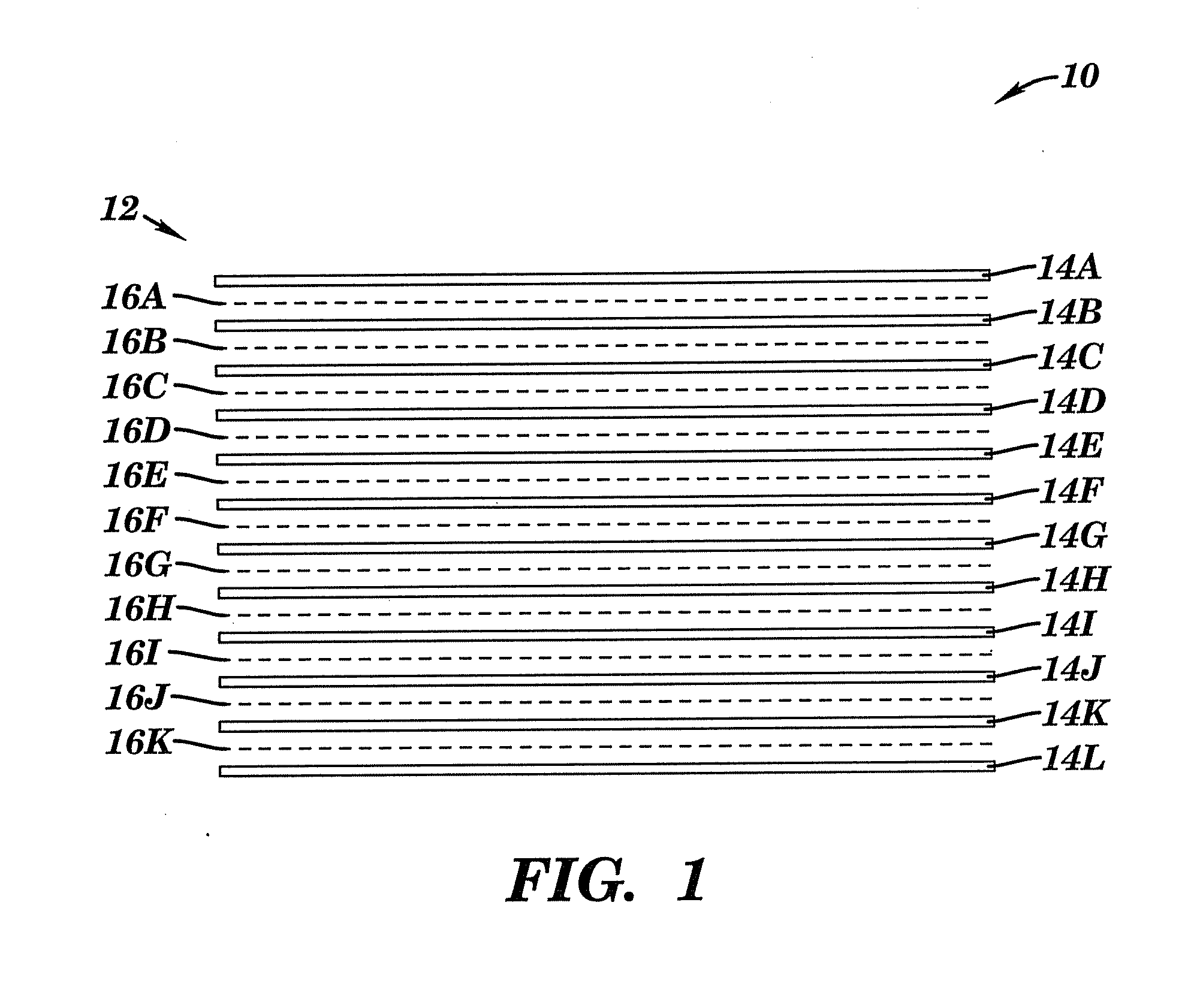

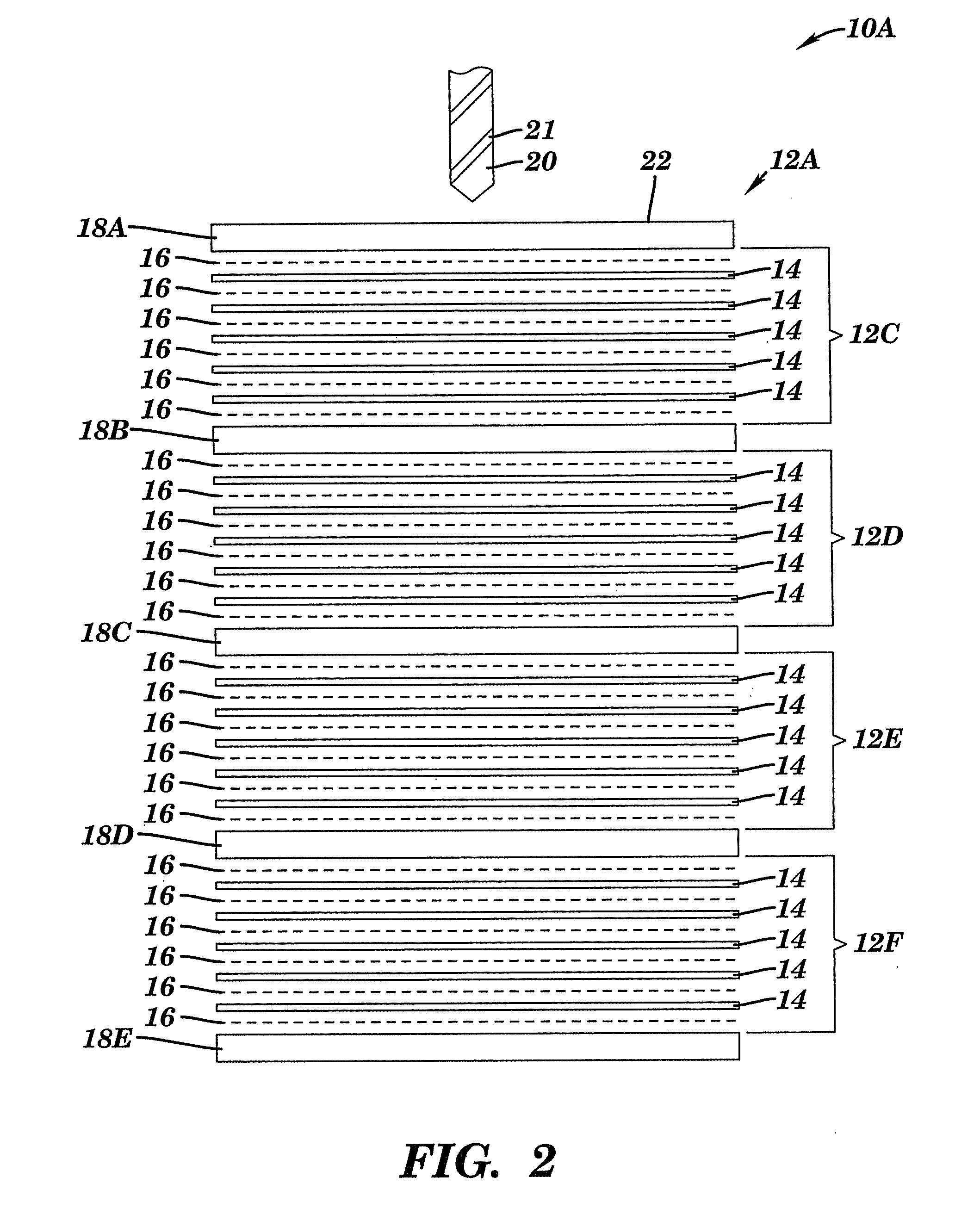

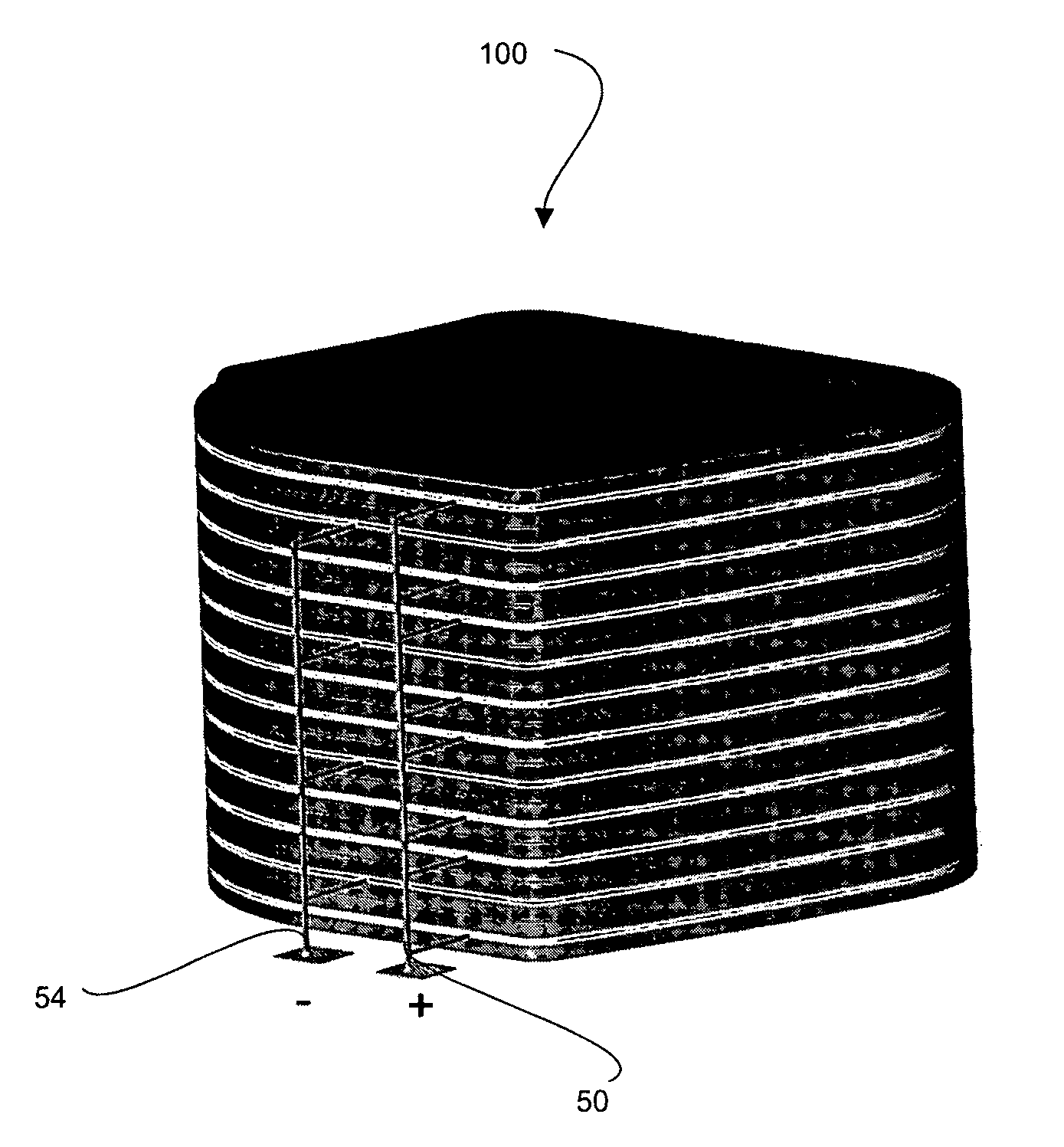

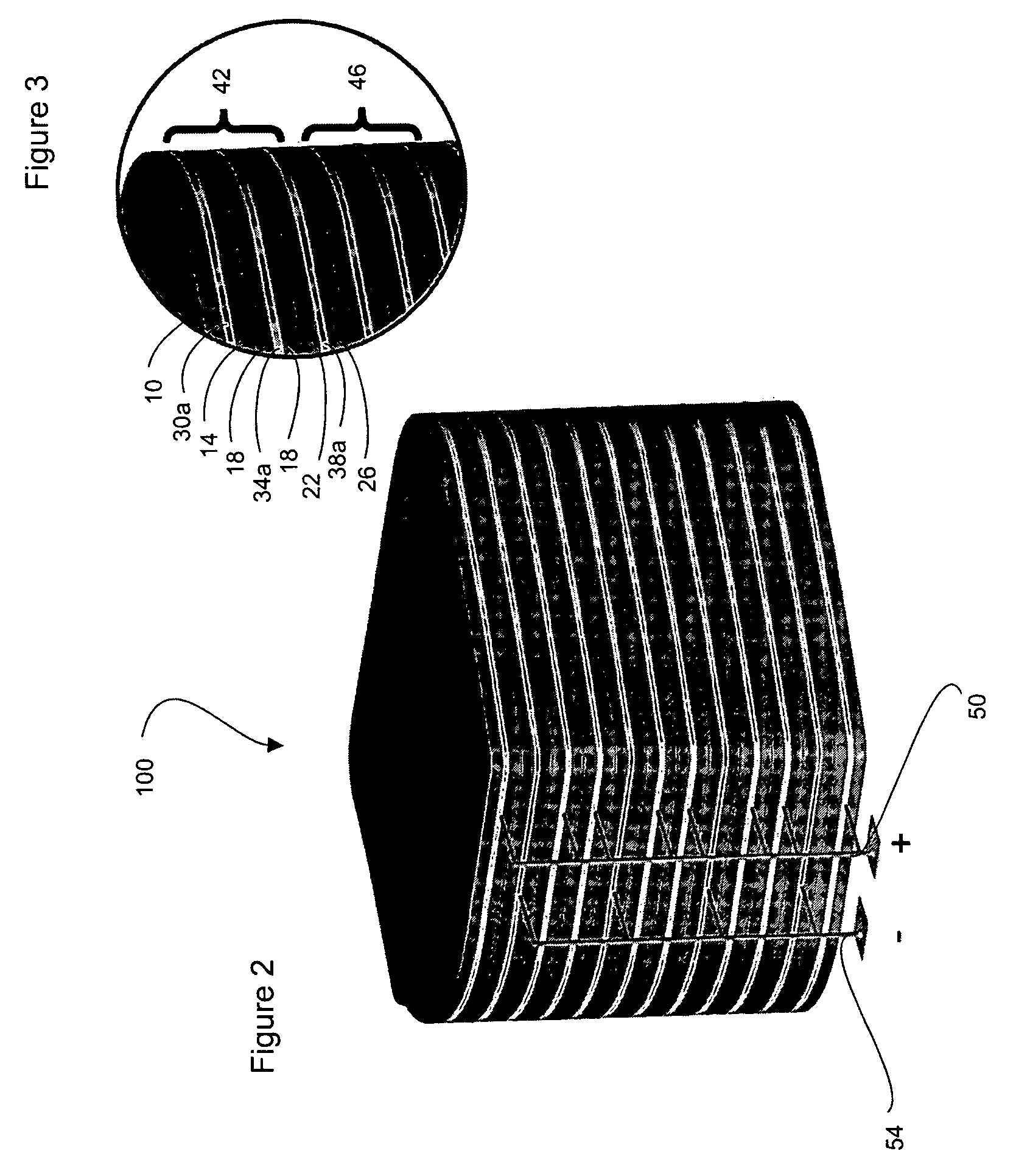

Conformal lithium polymer battery

InactiveUS20070079500A1Efficient constructionMinimized tensionFinal product manufacturePrimary cellsThermoplasticEpoxy

This invention is a method of fabricating a conformal lithium polymer battery comprising the steps of: selecting a slab of lithium polymer battery material of a desired height, containing a desired number of cells; freezing the slab; vertically cutting the slab to a desired shape; attaching a lead to each anode conductor; and attaching a lead to a each cathode conductor. The slab may contain one or many cells. The leads may be made of multistranded, metallic wire, metallic ribbon, low melting point alloy, self-healing metal, and litz wire. Attachment is accomplished so as to minimize tension on the leads. The cut slab may need to be deburred after cutting and before attaching leads. Preferably, burr formation is prevented by recessing the edge of the anodic or cathodic half cells. Lead attachment my be accomplished by: wire bonding; wedge bonding; adhesive bonding with conductive epoxy, anistotropic conductive adhesive or conductive thermoplastic; stapling; adhering the lead to the electrode by electropolymerization; welding; and growing a lead in place by electroless plating, electro-plating or a combination of electroless plating and electroplating. The distal ends of the leads may be connected together so that the cells are connected together in series, in parallel or some in series and the remainder in parallel. After the leads have been attached to the cut slab and connected together, the assembly will preferably be wrapped with standard packaging for lithium polymer batteries.

Owner:MB RES & DEV LLC A CA LTD LIABILITY

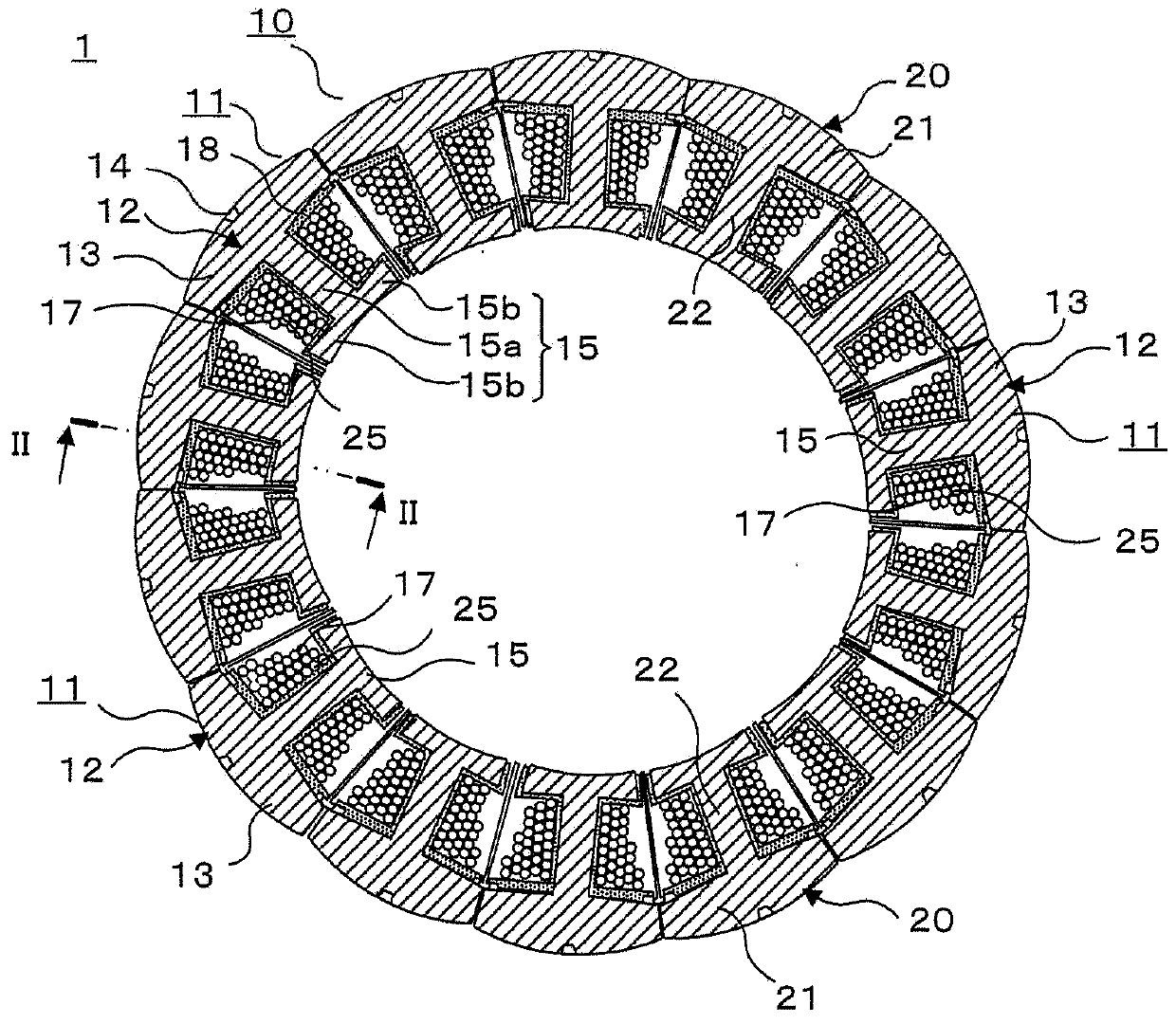

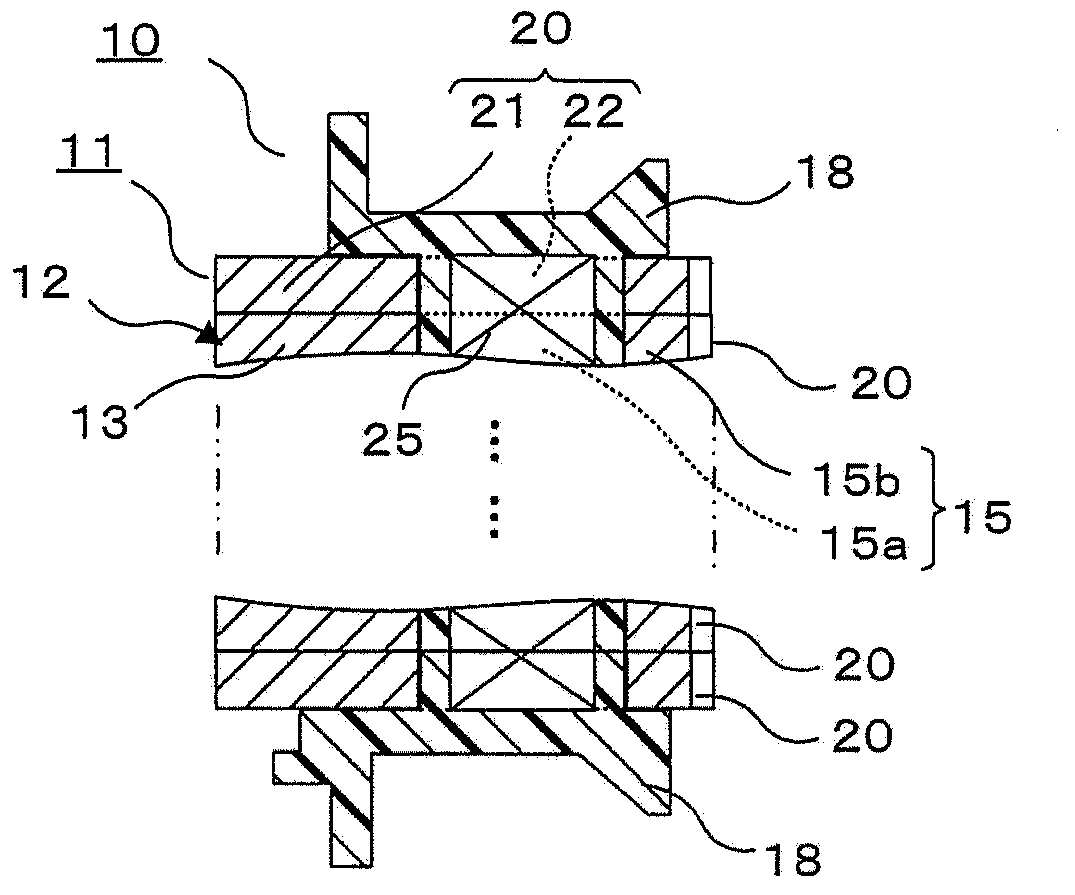

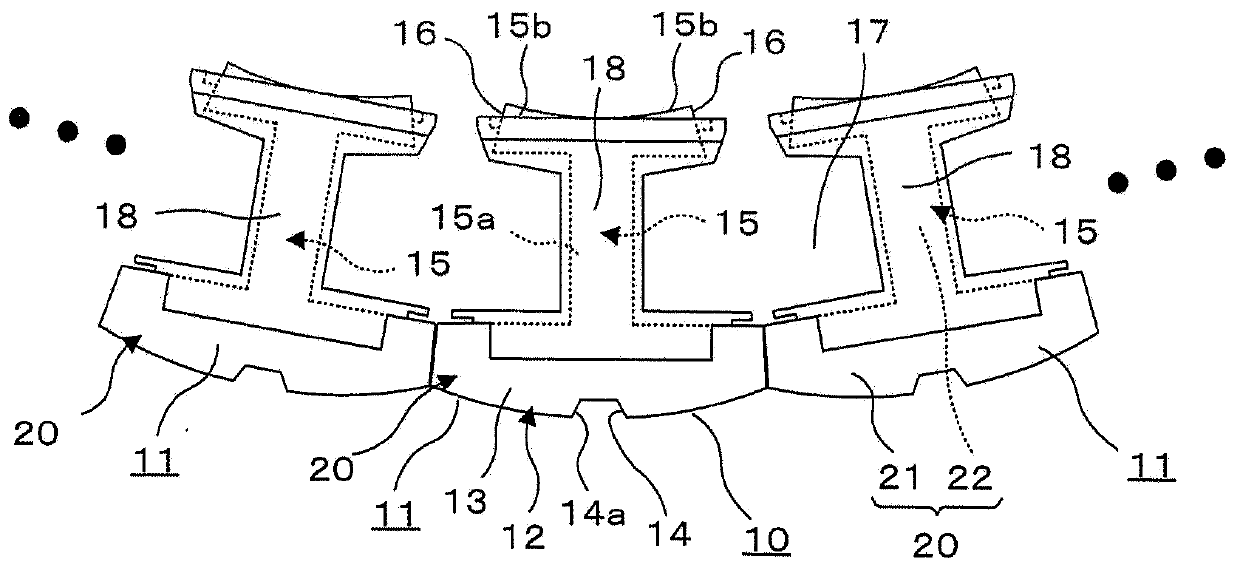

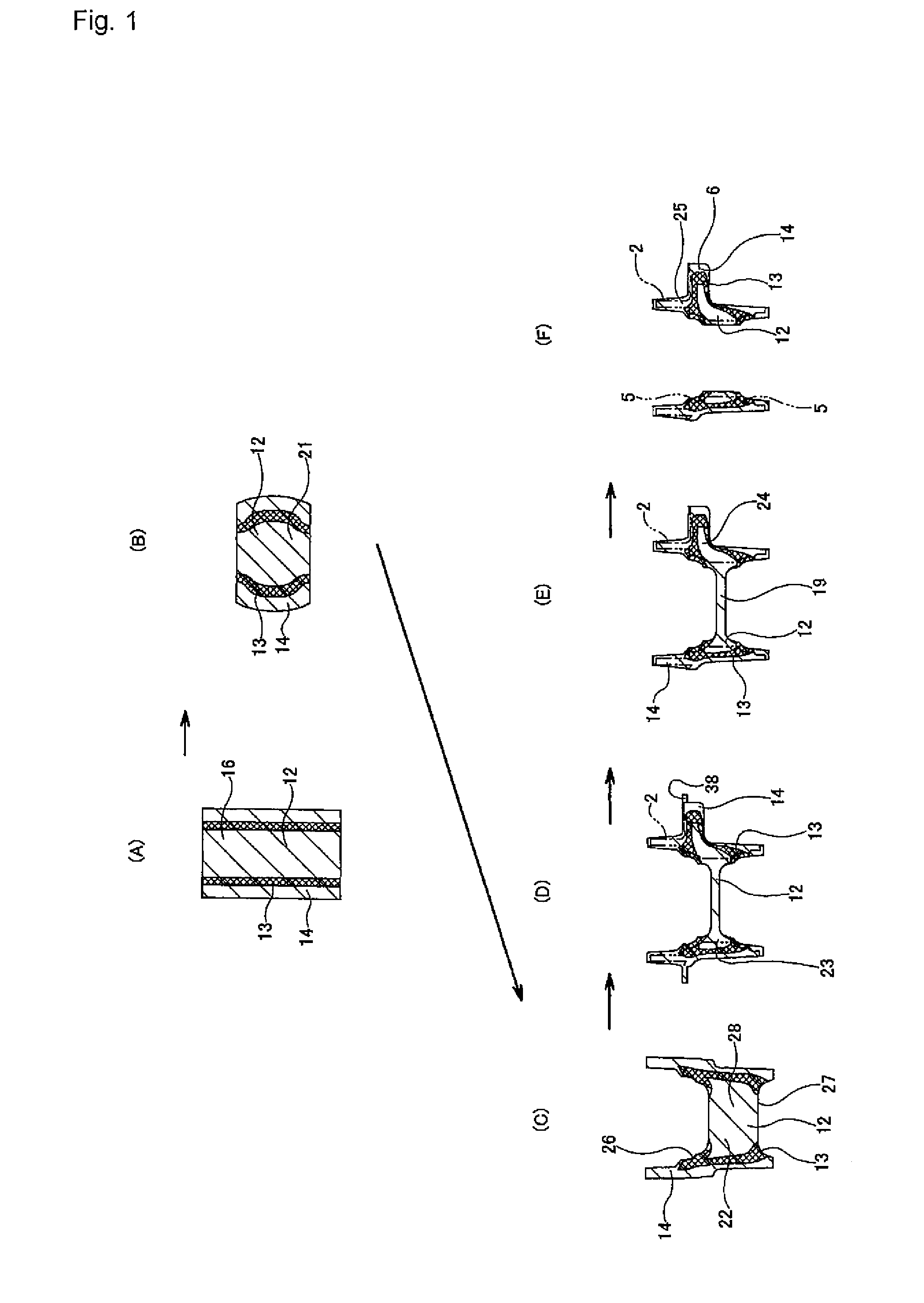

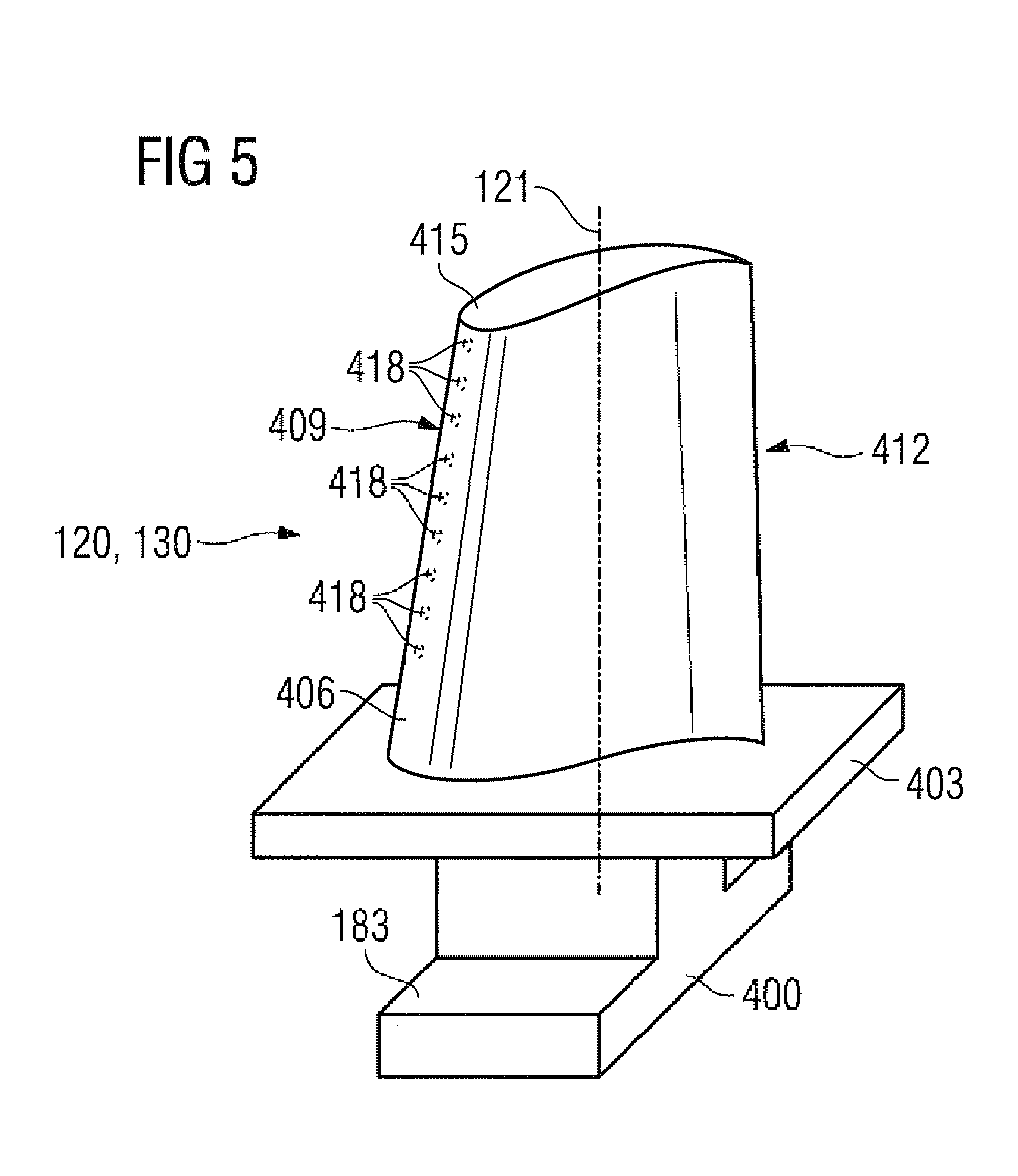

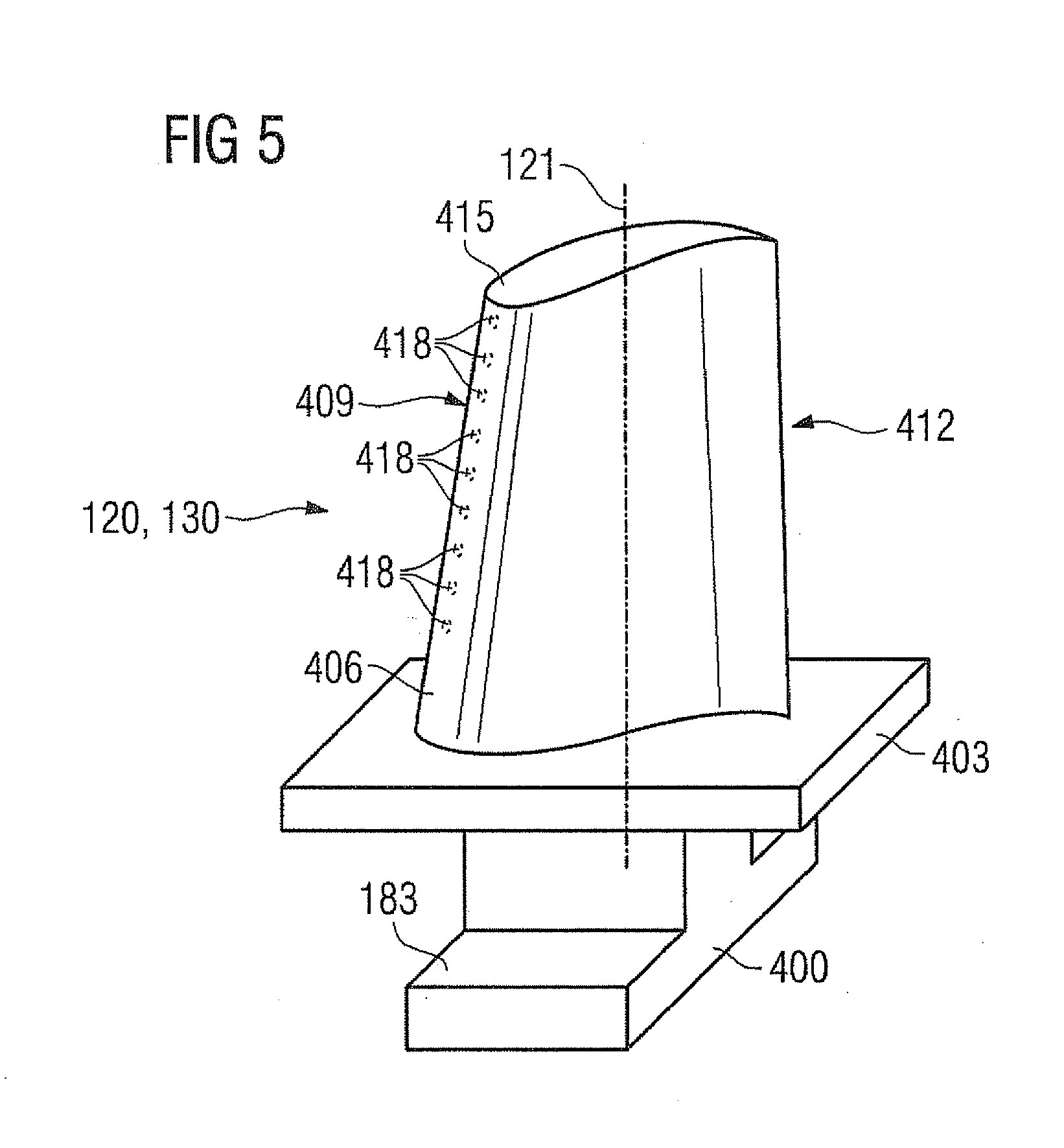

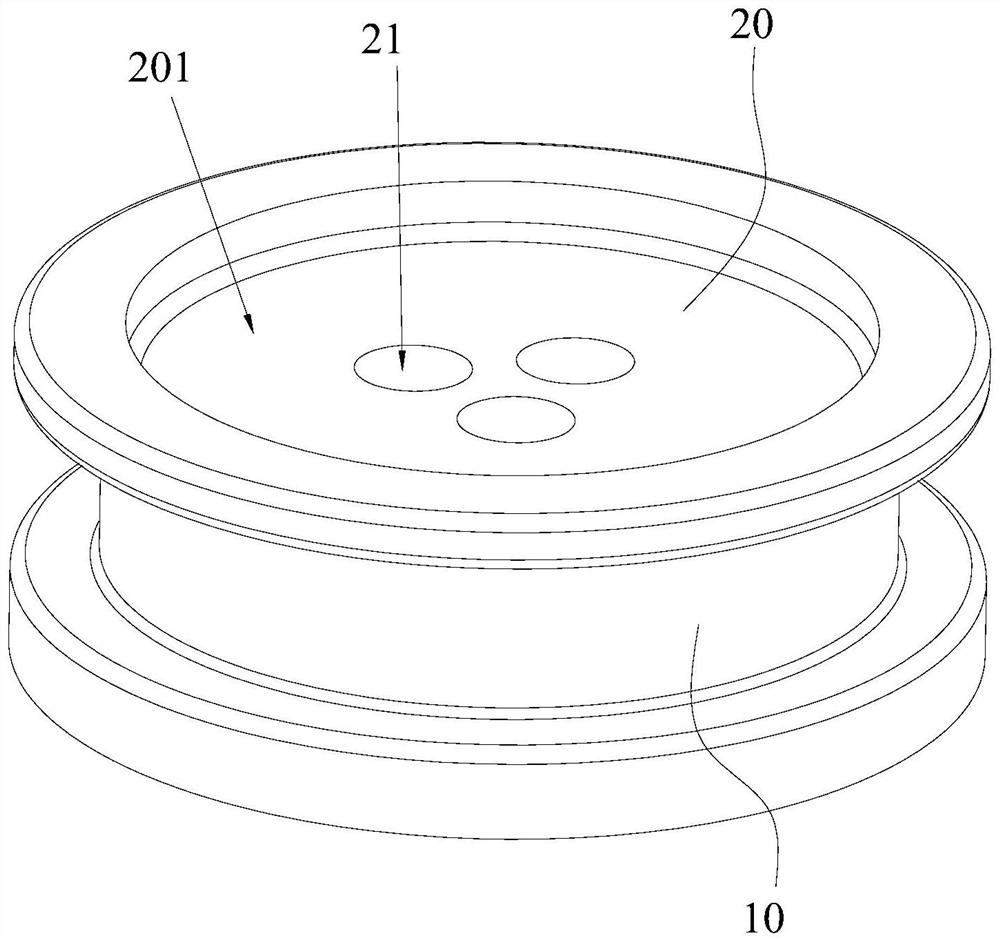

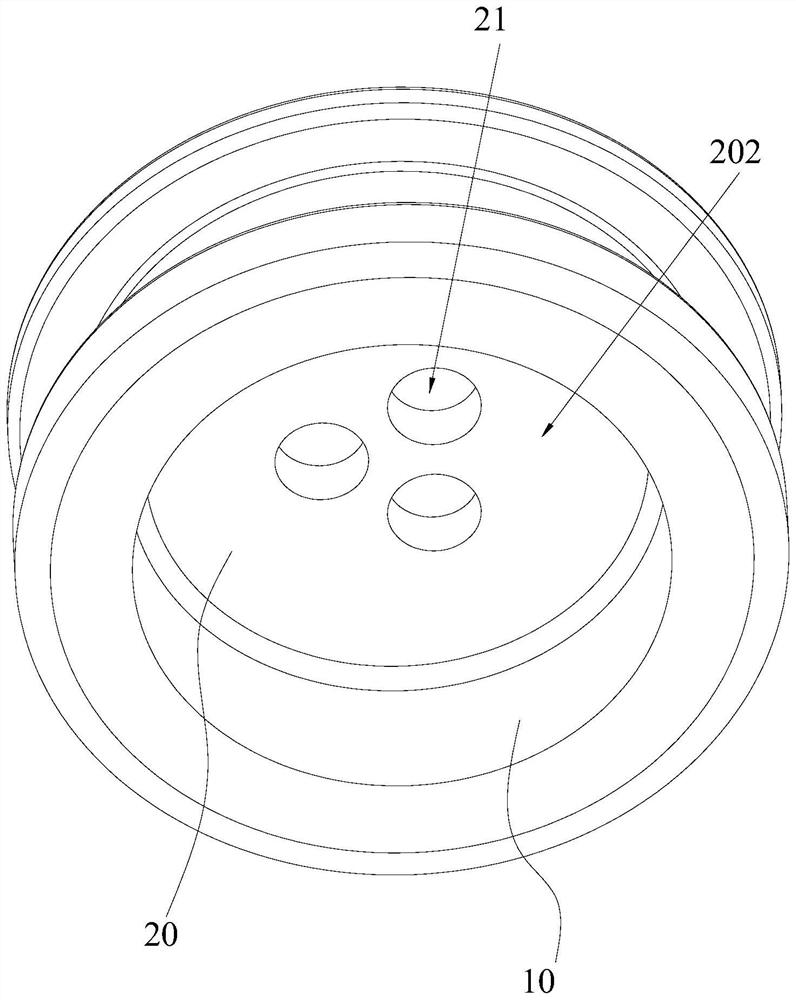

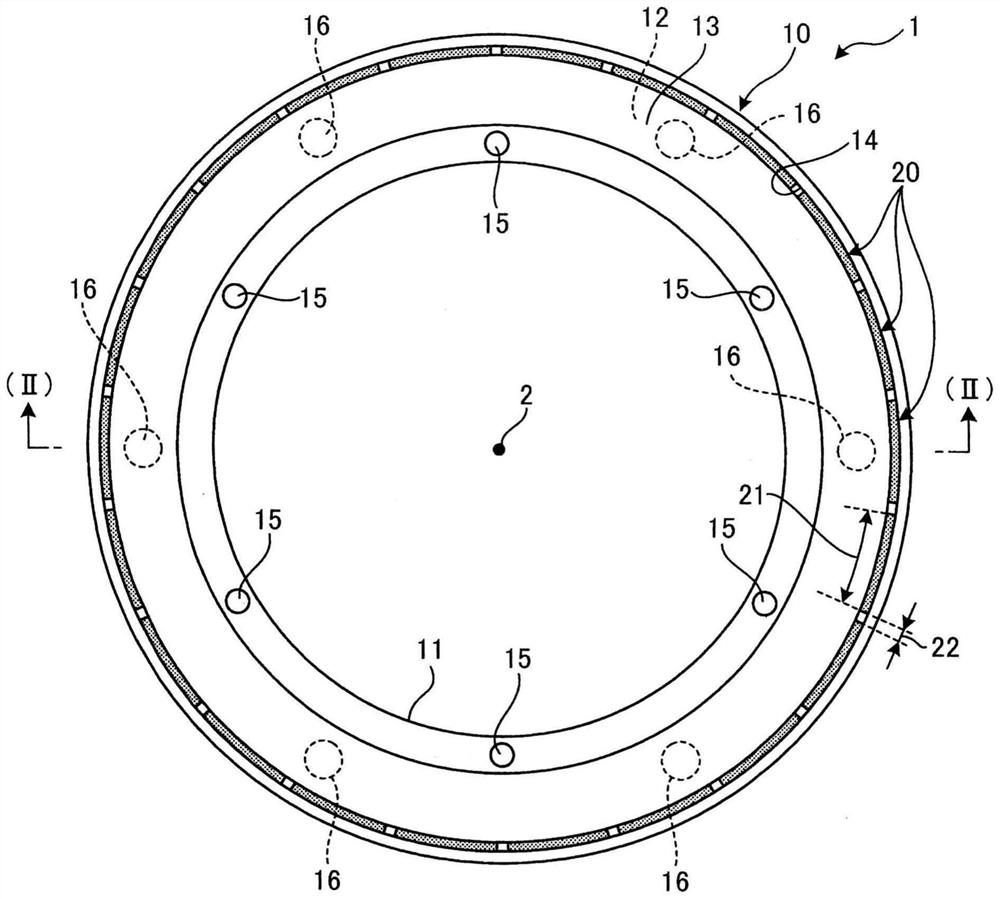

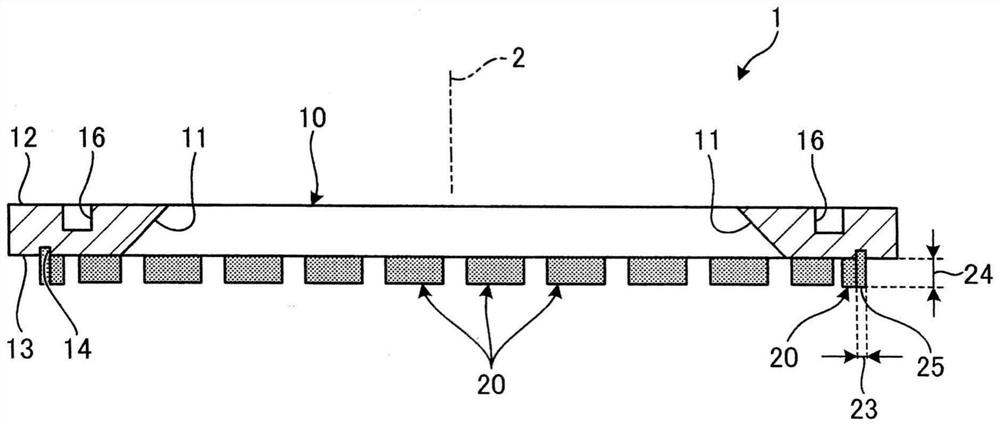

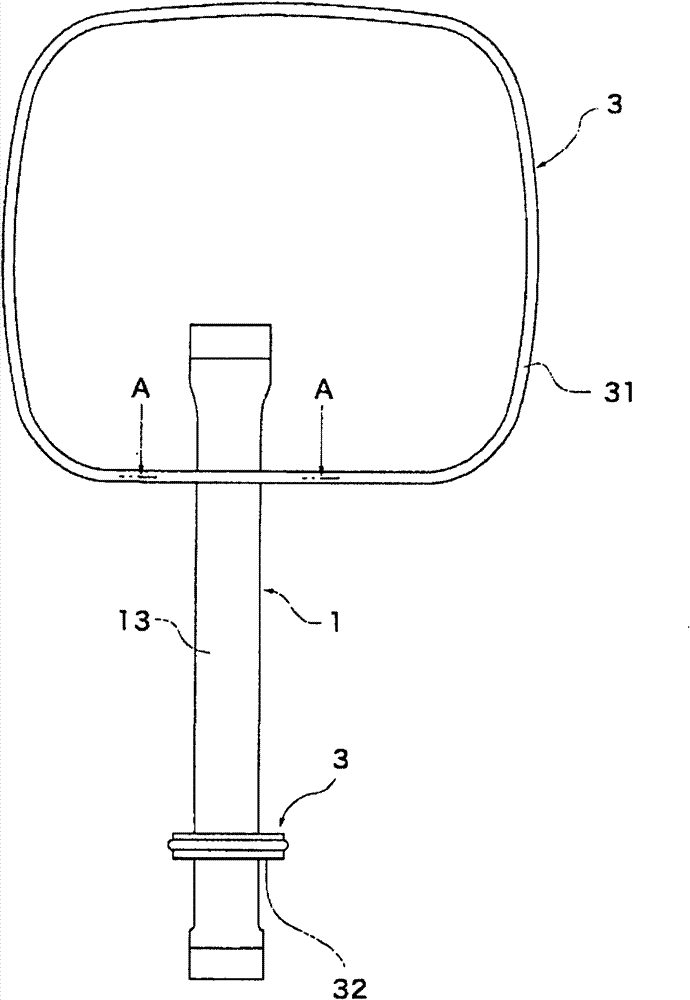

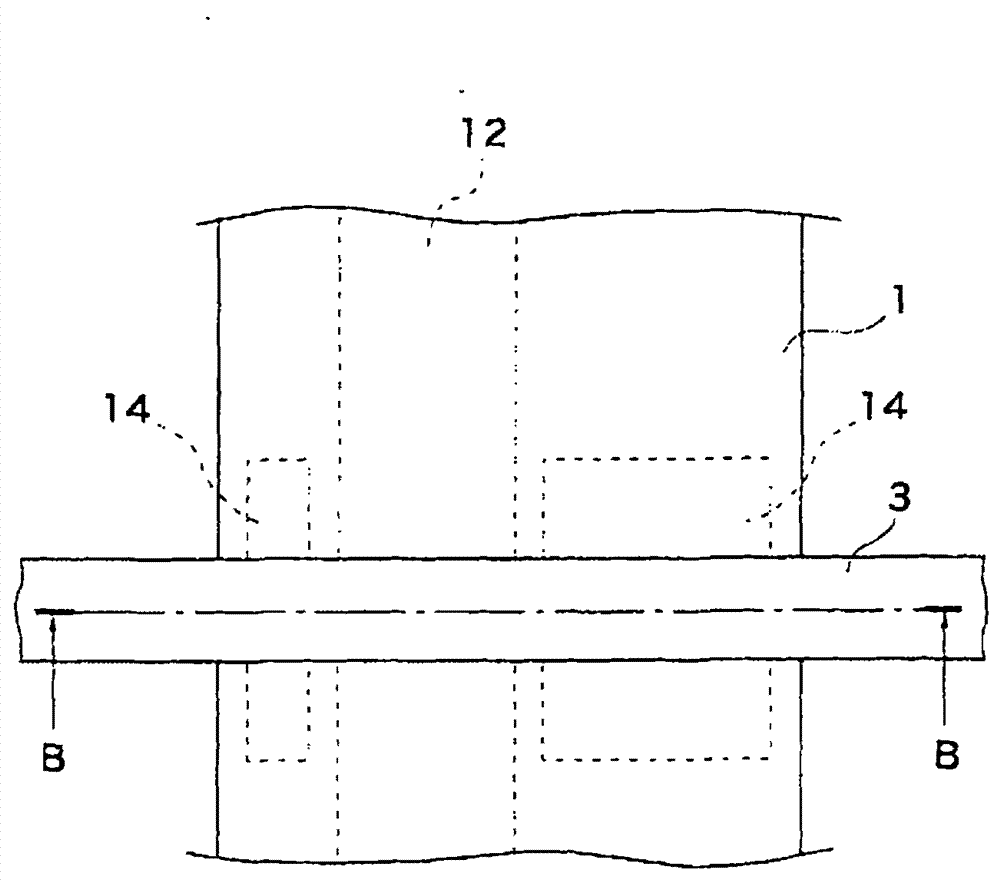

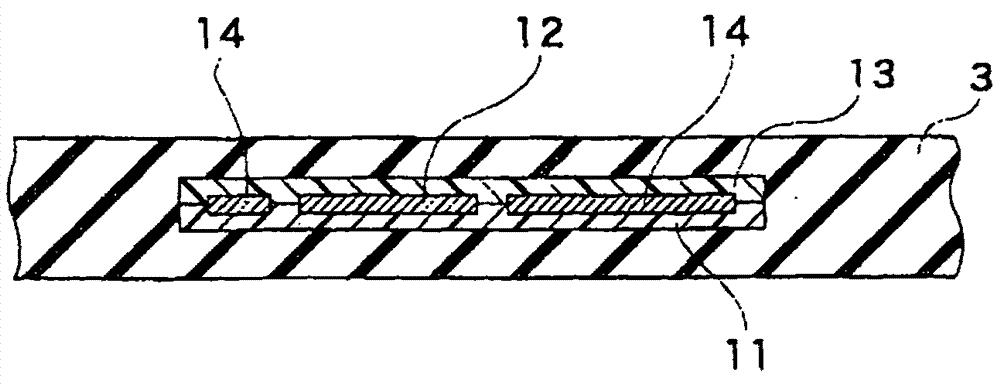

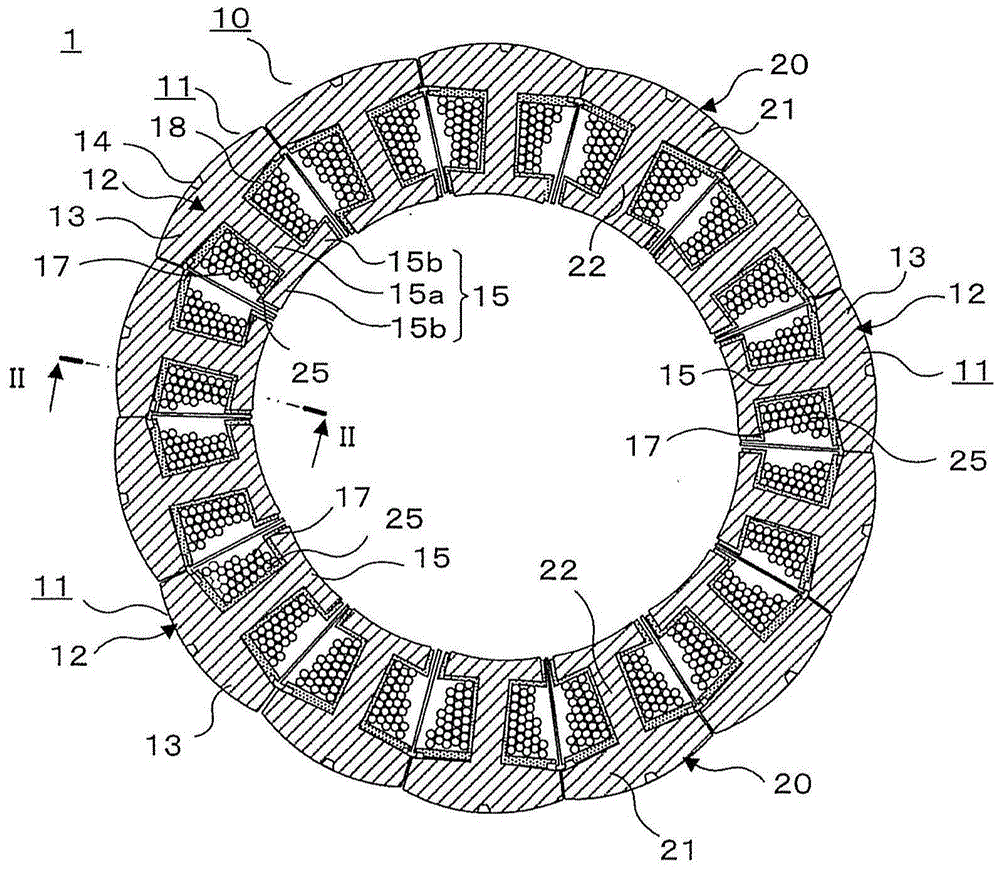

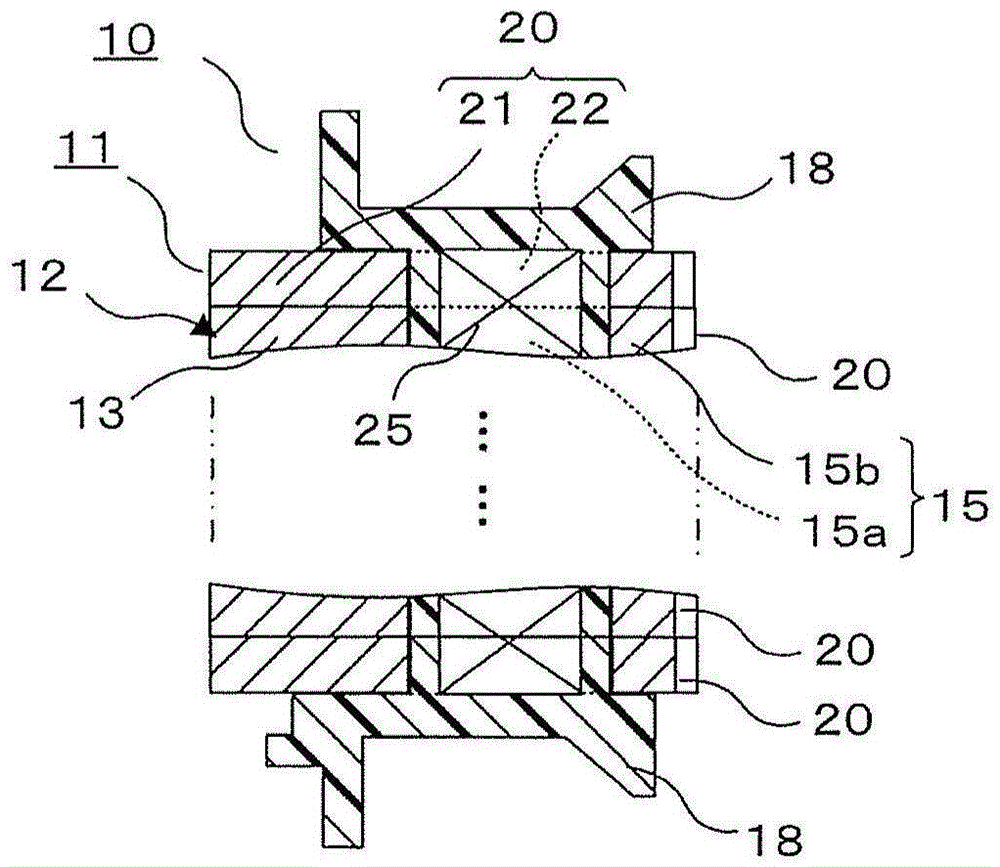

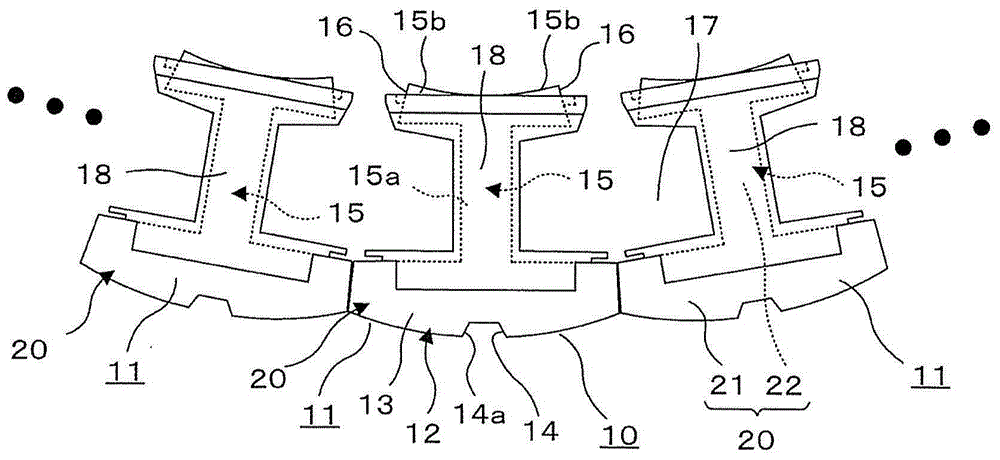

Stator core manufacturing method and stator core

ActiveCN104025432AWon't leakAvoid formingWindings insulation shape/form/constructionMagnetic circuit stationary partsMagnetic polesEngineering

In order to prevent unwanted burr formation on an insulating resin that is provided between a stator winding and a main core block body, the present invention provides a stator core manufacturing method for manufacturing a stator core that is constructed by connecting, into a circular shape, multiple core blocks (11), each being constructed by laminating multiple core pieces (20) together in the axial direction, wherein each core block (11) is equipped with a main core block body (12) that has a yoke section (13) and a magnetic pole tooth section (15), and an insulating resin layer (18) that is provided between a stator winding (25) and the main core block body (12) so as to cover a section that includes the surface of the magnetic pole tooth section (15) around which the stator winding (25) is wound. The stator core manufacturing method includes an injection molding step in which the insulating resin layer (18) is integrally formed with the main core block body (12) for each main core block body (12) by means of injection molding.

Owner:MITSUBISHI ELECTRIC CORP

Lead frame for semiconductor device

ActiveUS8115288B2Eliminate the effects ofSemiconductor/solid-state device detailsSolid-state devicesLead frameSemiconductor

A lead frame for reducing detrimental effects of burr formation includes a lead frame that has leads where a portion of a top surface is removed from a first lead and a portion of a bottom surface is removed from a second lead adjacent to the first lead to reduce spacing between leads while reducing the detrimental effects of burr formation, such as shorting and the like, caused during singulation of a semiconductor device manufactured with the lead frame.

Owner:NXP USA INC

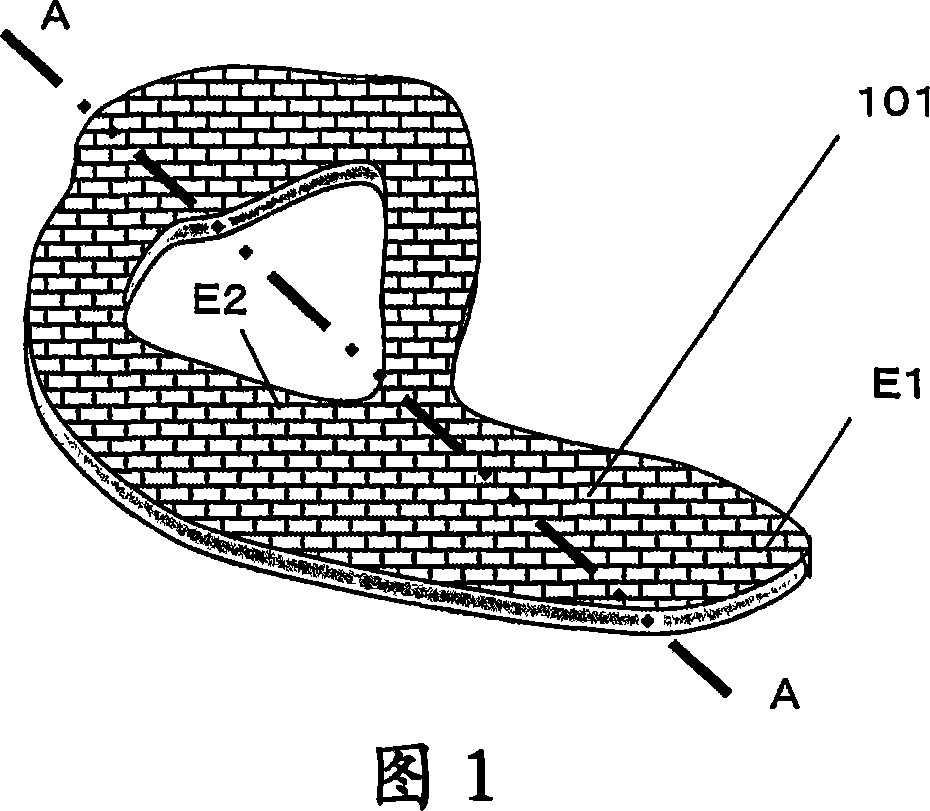

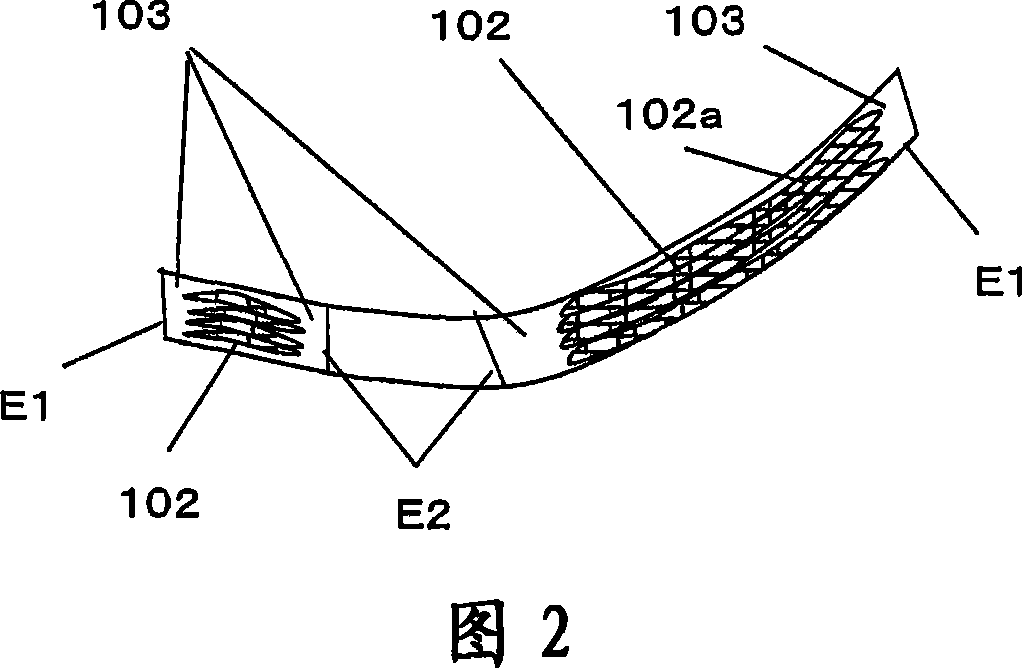

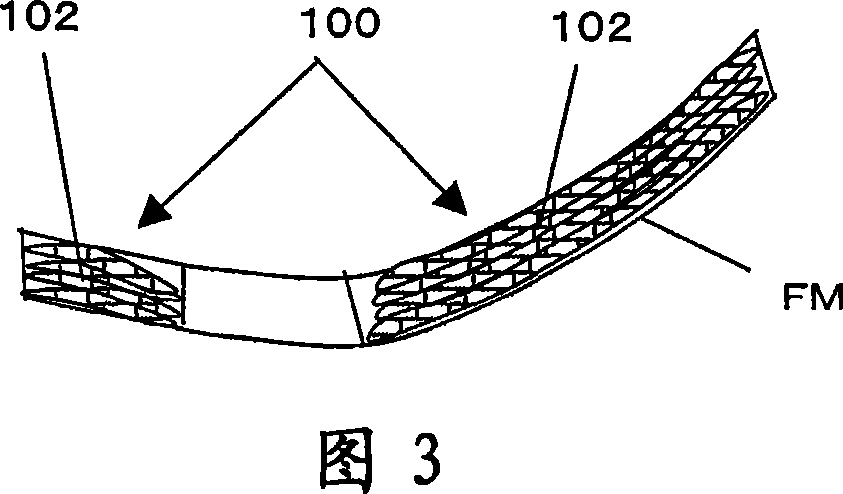

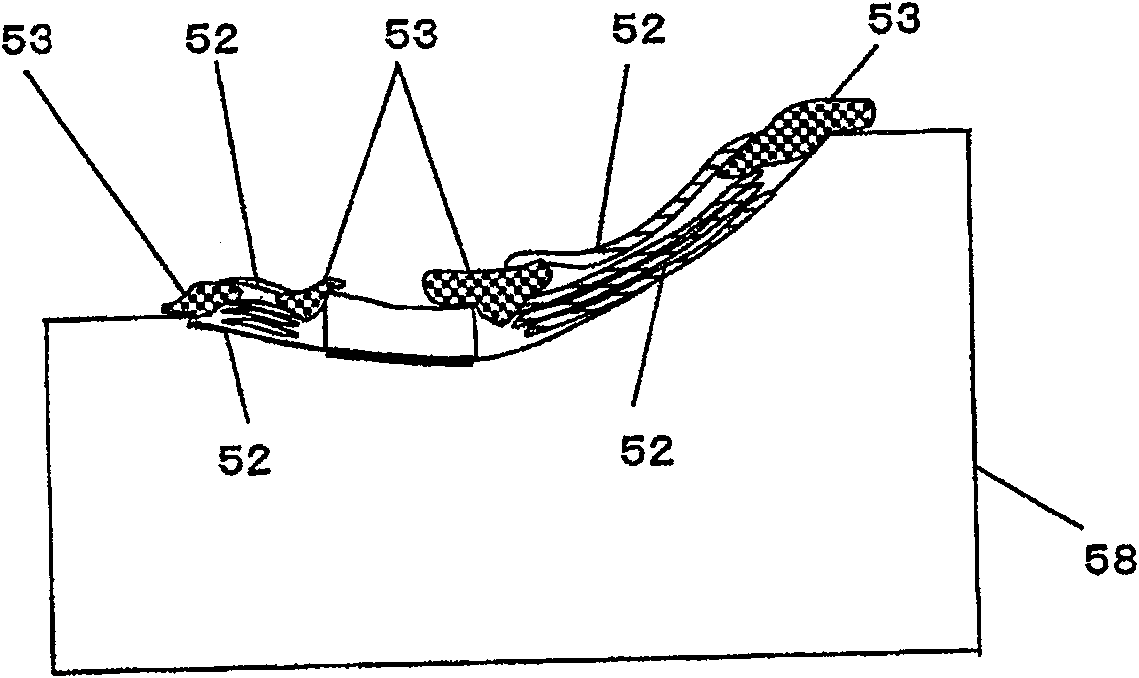

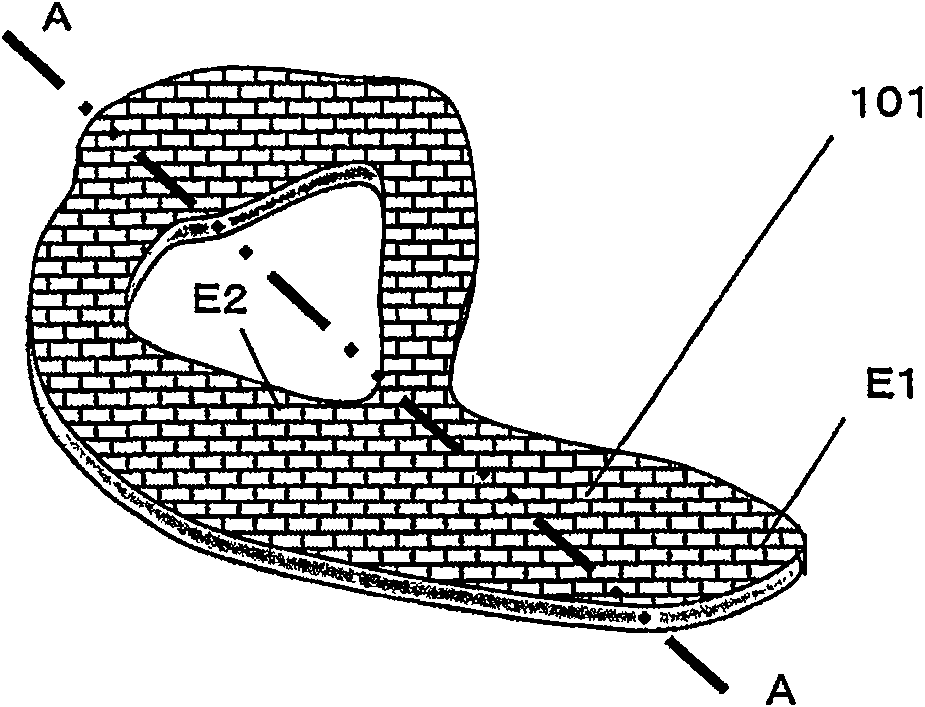

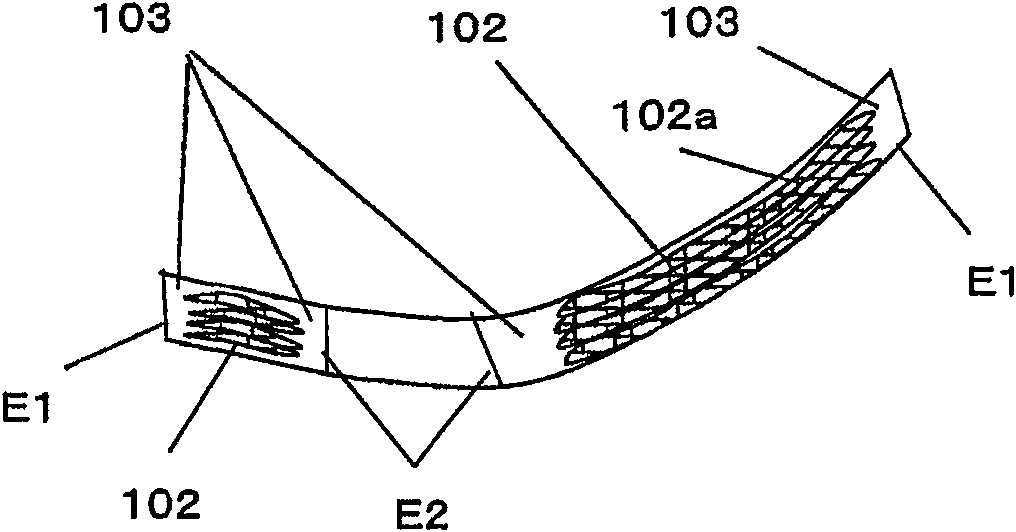

Molding precursor, process for manufacturing fiber-reinforced resin molding, and fiber-reinforced resin molding

InactiveCN101068668AEasy to manufacture and stableReduce manufacturing costWoven fabricsThin material handlingMaterials scienceFiber reinforcement

A molding precursor which comprises a main body part and a burr formation part protruding outward from the edge of the main body part and extending continuously along the edge, wherein the main body part comprises a first base comprising many reinforcing fibers and a second base which comprises many fibers and has been superposed on the first base in an outer peripheral part of the main body part, the burr formation part is constituted of that part of the second base which protrudes outward from the edge of the main body part, and spaces among the many fibers constitute passages for a molding resin.

Owner:TORAY IND INC

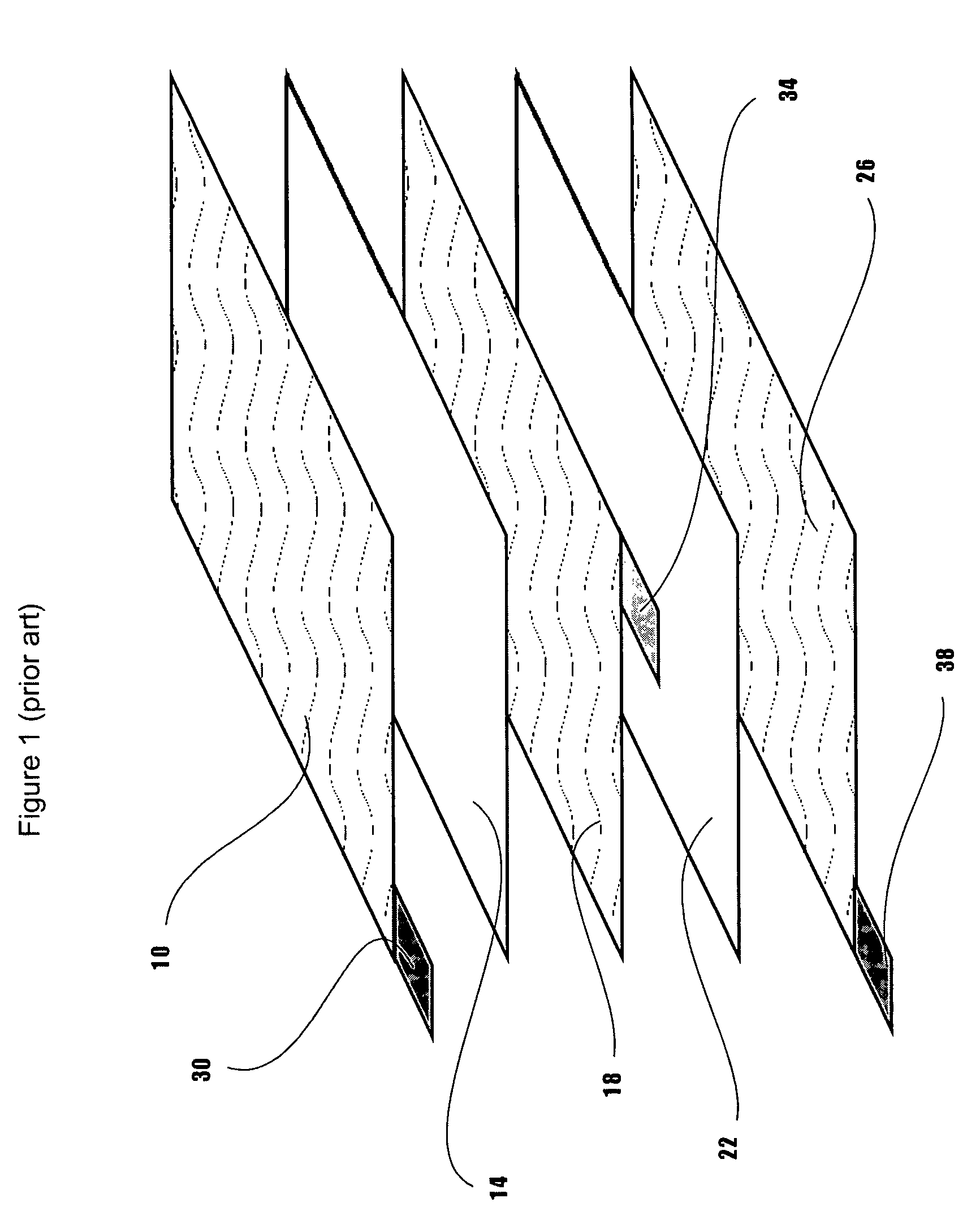

Drill stack formation

InactiveUS20080032155A1Avoiding burr formationTool workpiece connectionWorkpiecesAdhesiveBurr formation

A structure. The structure includes a stack of two or more sheets. Successive sheets in each pair of successive sheets of the stack are adhesively coupled to each other by an adhesive layer consisting of a removable adhesive that is removable if heated to an elevated temperature at which the removable adhesive melts. The removable adhesive is also disposed on top and bottom surfaces of the stack. The removable adhesive consists of a liquid while adhesively coupling the successive sheets to each other. A first surface of a first layer coupled with the removable adhesive to a first surface of the stack. A first surface of a second layer is coupled with the removable adhesive to a second surface of the stack. The first and second layers are adapted to prevent burr formation in a hole subsequently drilled through the stack.

Owner:GLOBALFOUNDRIES INC

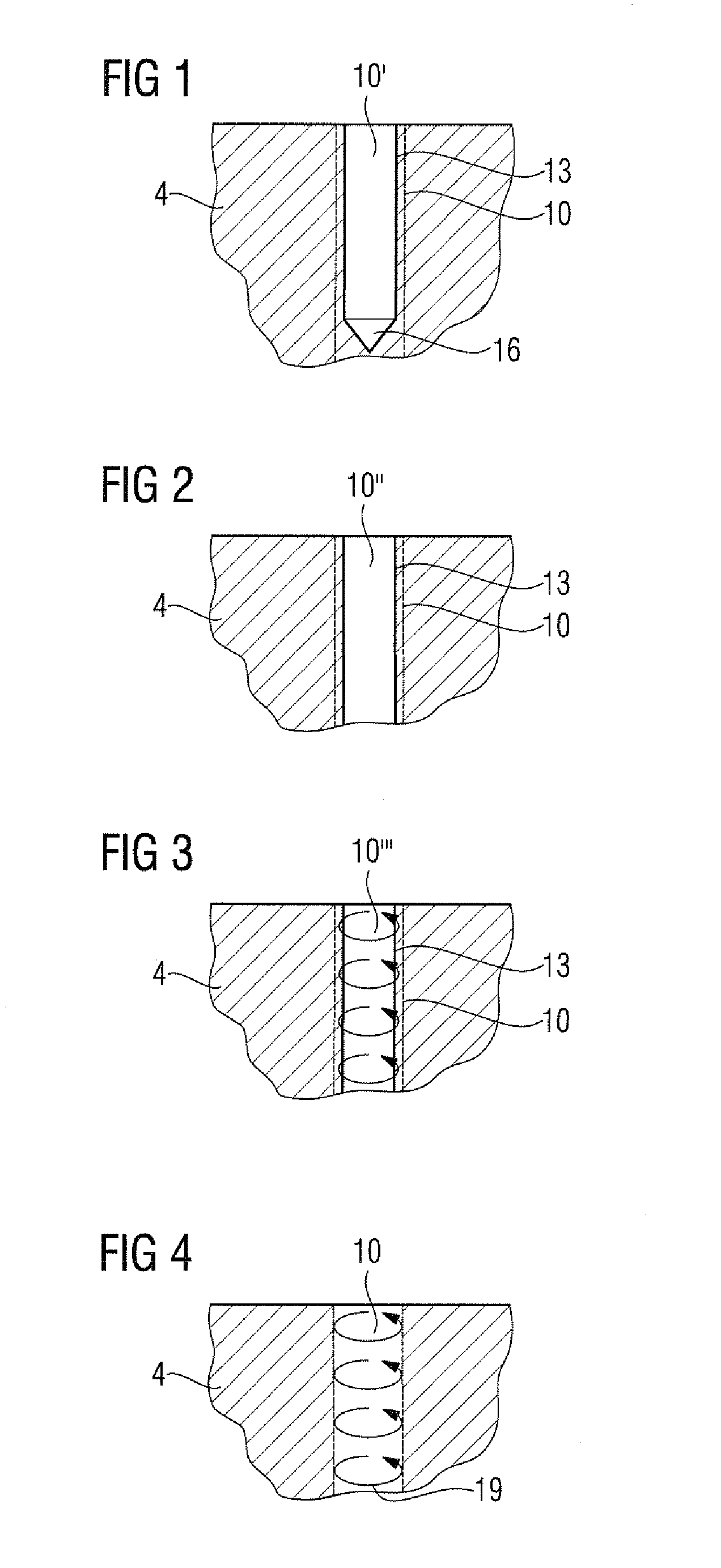

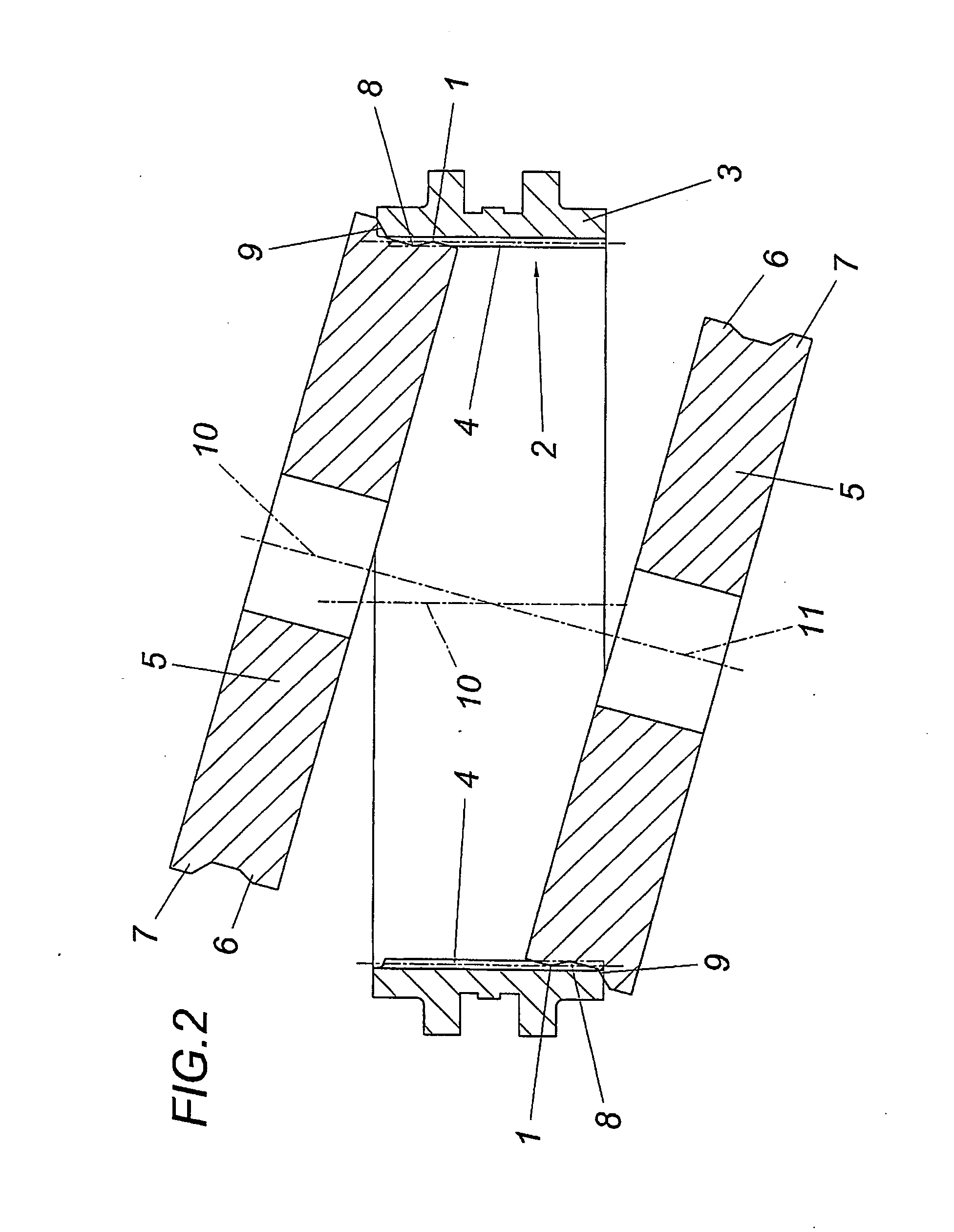

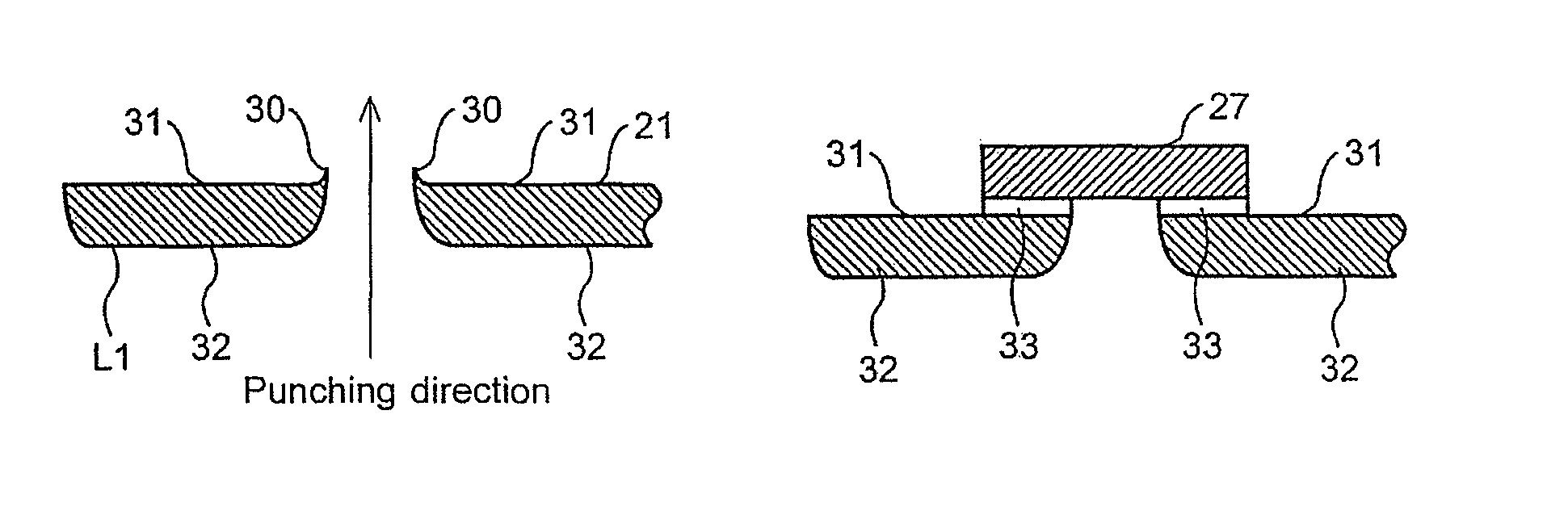

Method for manufacturing a bearing ring member

ActiveUS8424205B2Increase freedomSimplify workRolling contact bearingsMetal-working apparatusPunchingForward backward

The present invention provides a manufacturing method of a bearing ring member such as an outer ring comprising an installation portion on the outer peripheral surface and a double row of outer-ring raceways on the inner peripheral surface, in which a raw material is processed to obtain a final stage intermediate member through a first upsetting process, a forward-backward extrusion process, a second upsetting process, a burr removing process, and a punching process, wherein a movable die which leaves a stationary die in the final step is used in the second upsetting process, and the excess metal material is moved toward outside in the radial direction to a portion which become the installation section and a burr formation section, exposing a high pure metal material at least in a portion where the load of rolling bodies acts so as to ensure the rolling fatigue life of the both of outer-ring raceways.

Owner:NSK LTD

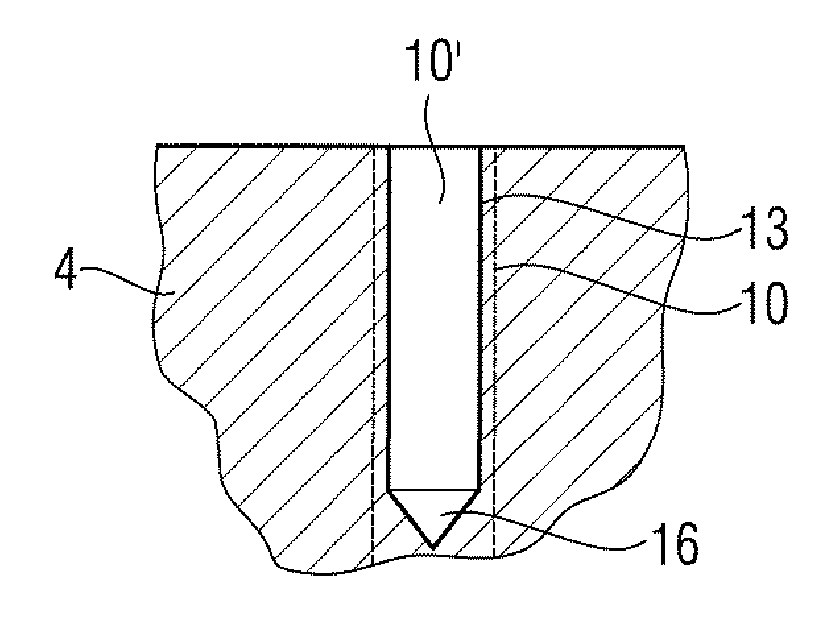

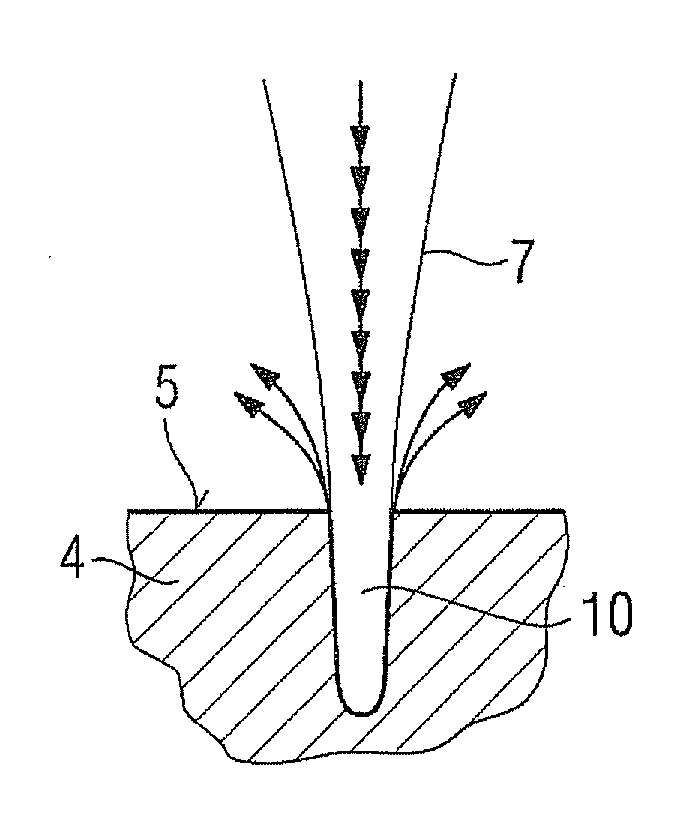

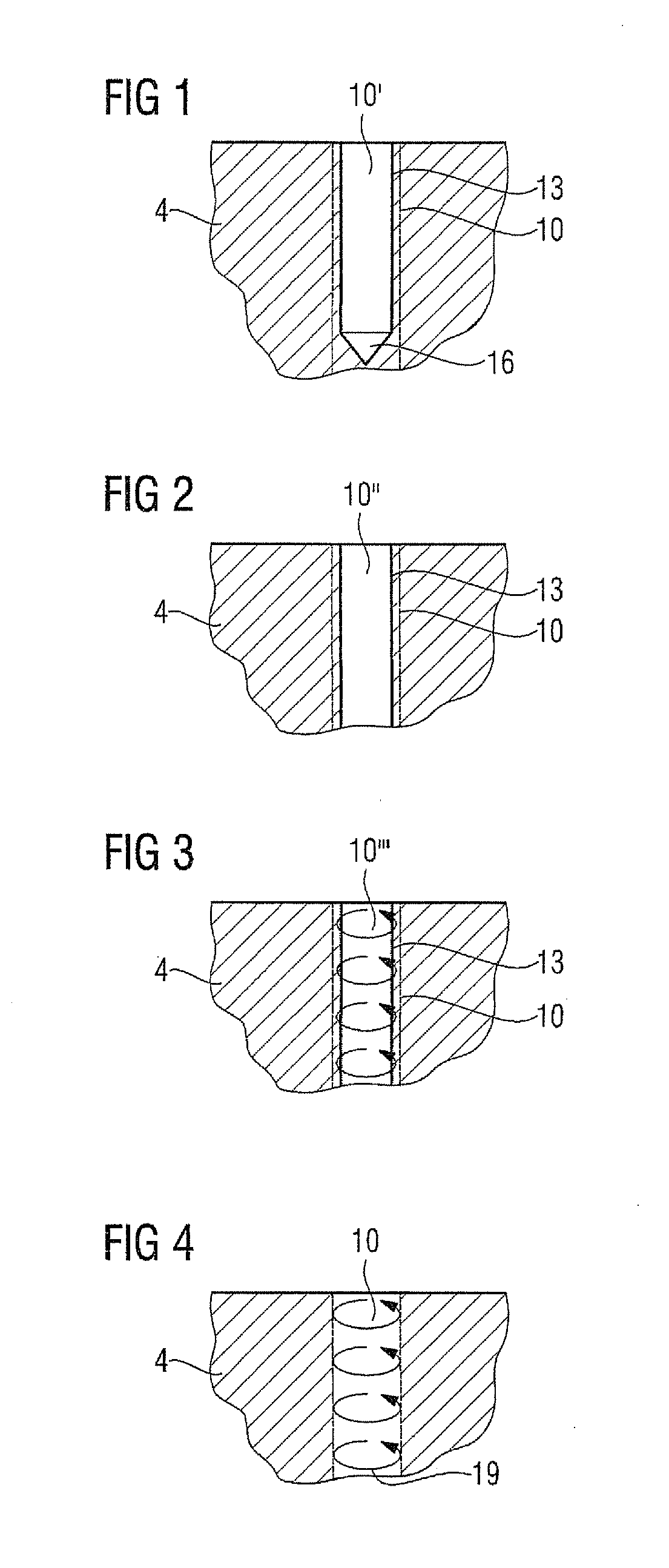

Laser drilling without burr formation

A process for making a hole into a substrate by at least one laser includes a first step which involves producing at least one intermediate hole with a diameter which is smaller than a final diameter of a final hole to be produced. The intermediate hole with the smaller diameter is a through-hole. The intermediate hole is produced by percussion process. The process further includes a second step which involves producing the final hole having the final diameter. The final hole is produced by machining the intermediate through-hole by a trepanning process so that the final diameter of the final hole is achieved.

Owner:SIEMENS AG

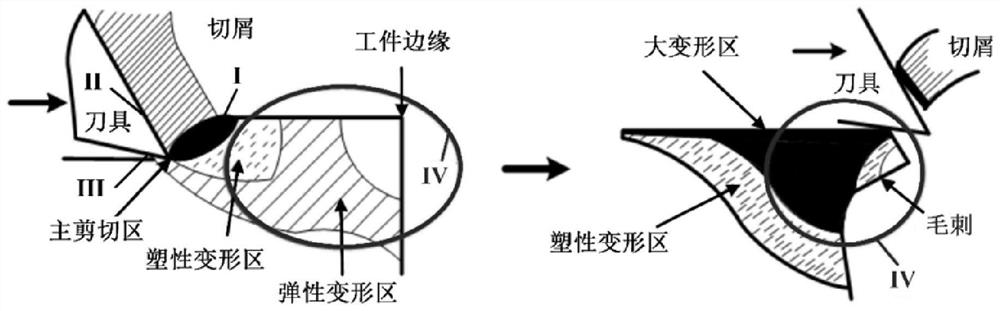

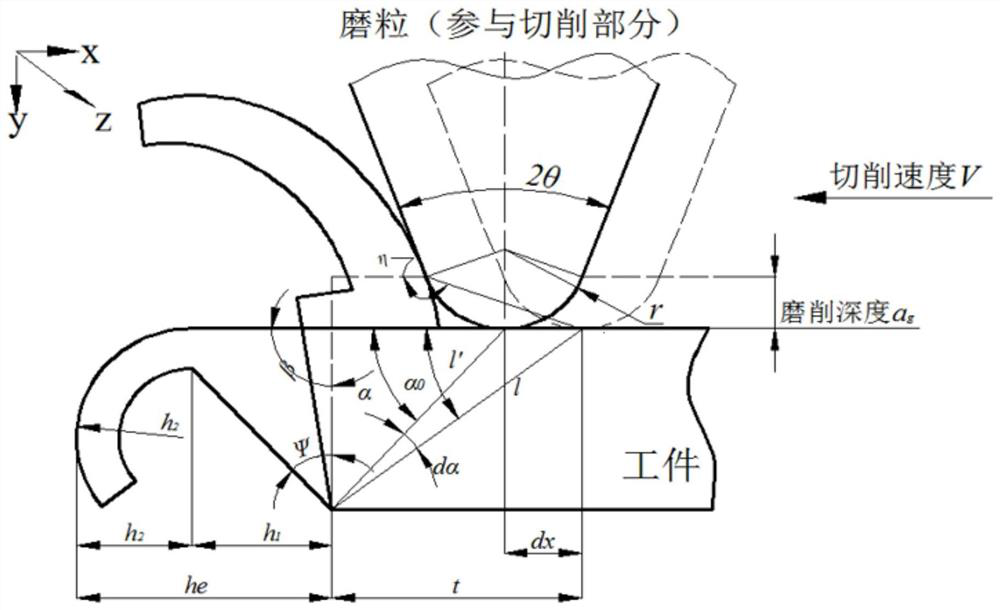

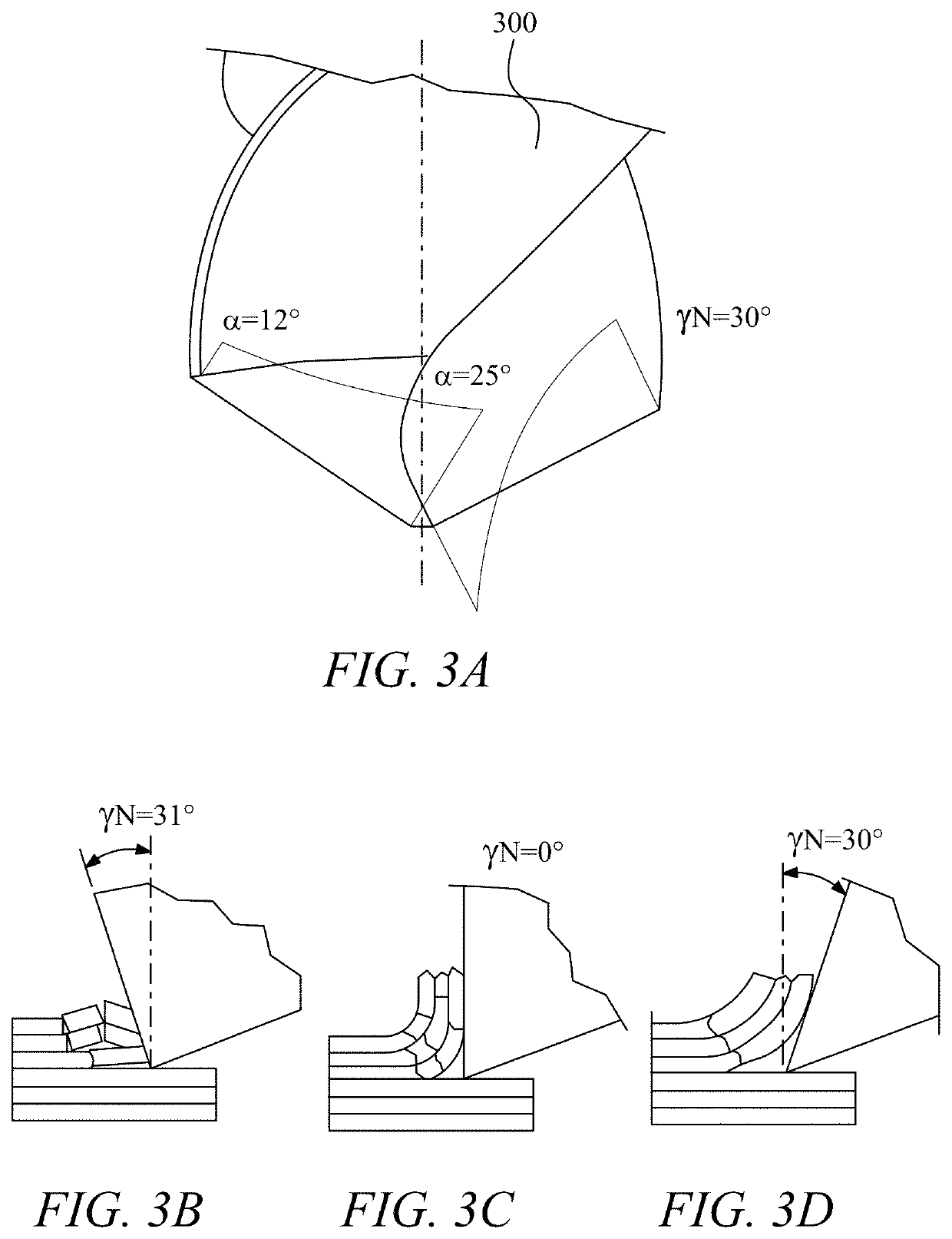

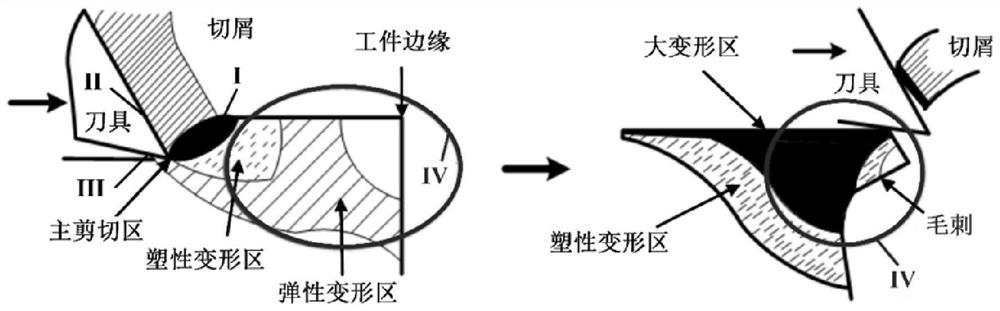

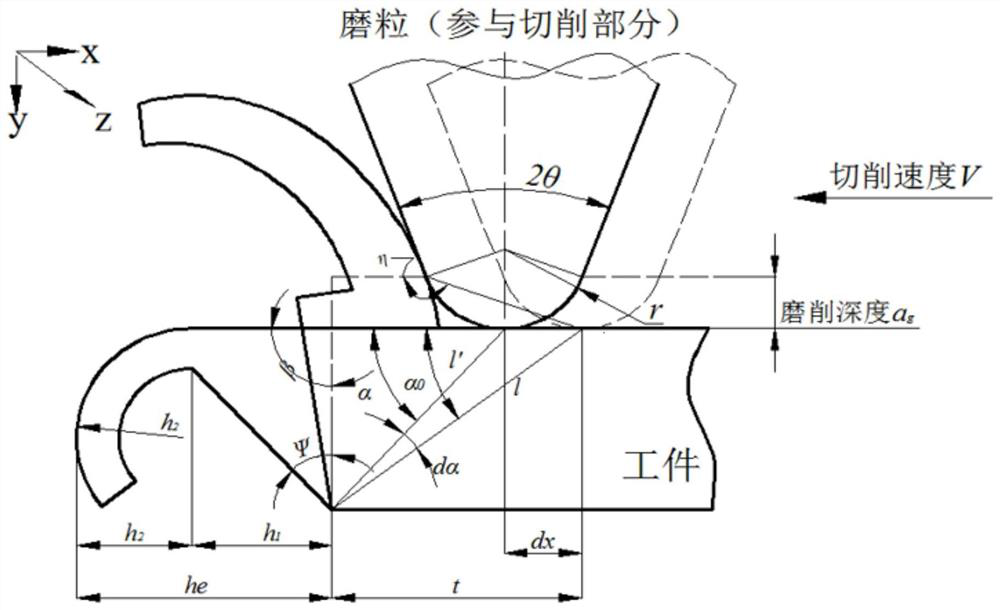

Valve element edge grinding burr form prediction method based on energy conservation

The invention discloses a valve element edge grinding burr form prediction method based on energy conservation. According to the method, a valve element working edge grinding tiny burr form predictionmodel is established based on the energy conservation law according to a rubbing-plowing-cutting removal mechanism of materials in the grinding process, a fourth deformation zone theory and a chip bending model, and optimization of a grinding process is realized according to the action relation of the grinding depth, the feeding speed and the grinding wheel speed on the burr form. The method hasthe advantages that the edge grinding tiny burr form prediction model based on energy conservation is established, a basis is provided for burr formation active control and accurate removal, and burrformation can be remarkably reduced or inhibited.

Owner:SHANGHAI JIAO TONG UNIV +1

Conformal lithium polymer battery

InactiveUS7780745B2Efficient constructionMinimized tensionFinal product manufacturePrimary cellsElectrical conductorAlloy

This invention is a method of fabricating a conformal lithium polymer battery comprising the steps of: selecting a slab of lithium polymer battery material of a desired height, containing a desired number of cells; freezing the slab; vertically cutting the slab to a desired shape; attaching a lead to each anode conductor; and attaching a lead to a each cathode conductor. The slab may contain one or many cells. The leads may be made of multistranded, metallic wire, metallic ribbon, low melting point alloy, self-healing metal, and litz wire. Attachment is accomplished so as to minimize tension on the leads. The cut slab may need to be deburred after cutting and before attaching leads. Preferably, burr formation is prevented by recessing the edge of the anodic or cathodic half cells.

Owner:MB RES & DEV LLC A CA LTD LIABILITY

Laser drilling without burr formation

A process for making a hole into a substrate by a laser is provided. According to the proposed process, in a first step, at least one intermediate hole is produced into the substrate by at least one laser, the intermediate hole having an intermediate diameter that is smaller than a final diameter of the hole to be made. In a second step, the hole having the final diameter is produced into the substrate by the at least one laser.

Owner:SIEMENS AG

Mould And Method For Producing A Panel That Is Embedded In Or Surrounded By Injection -Moulded Or Expanded Plastic

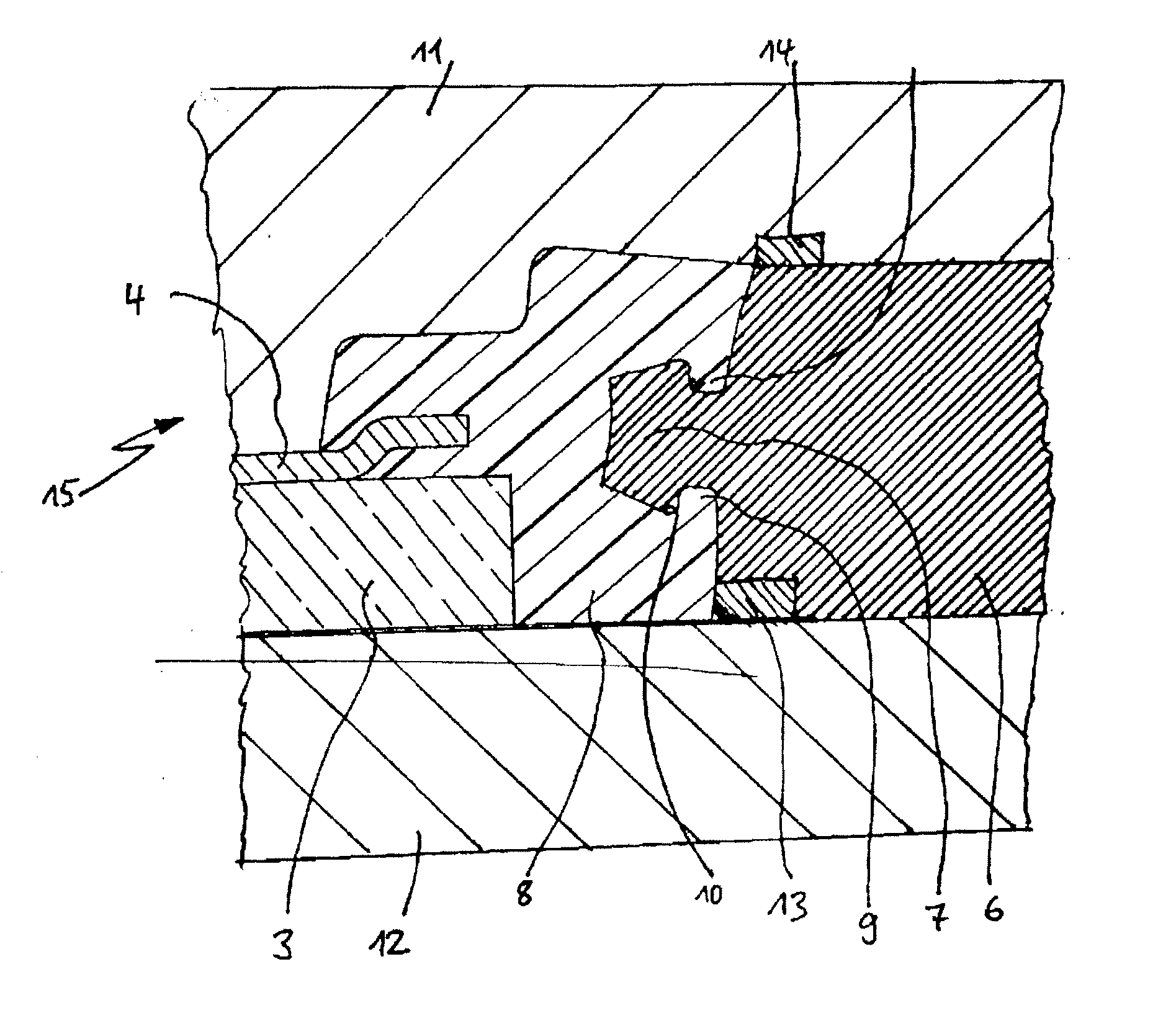

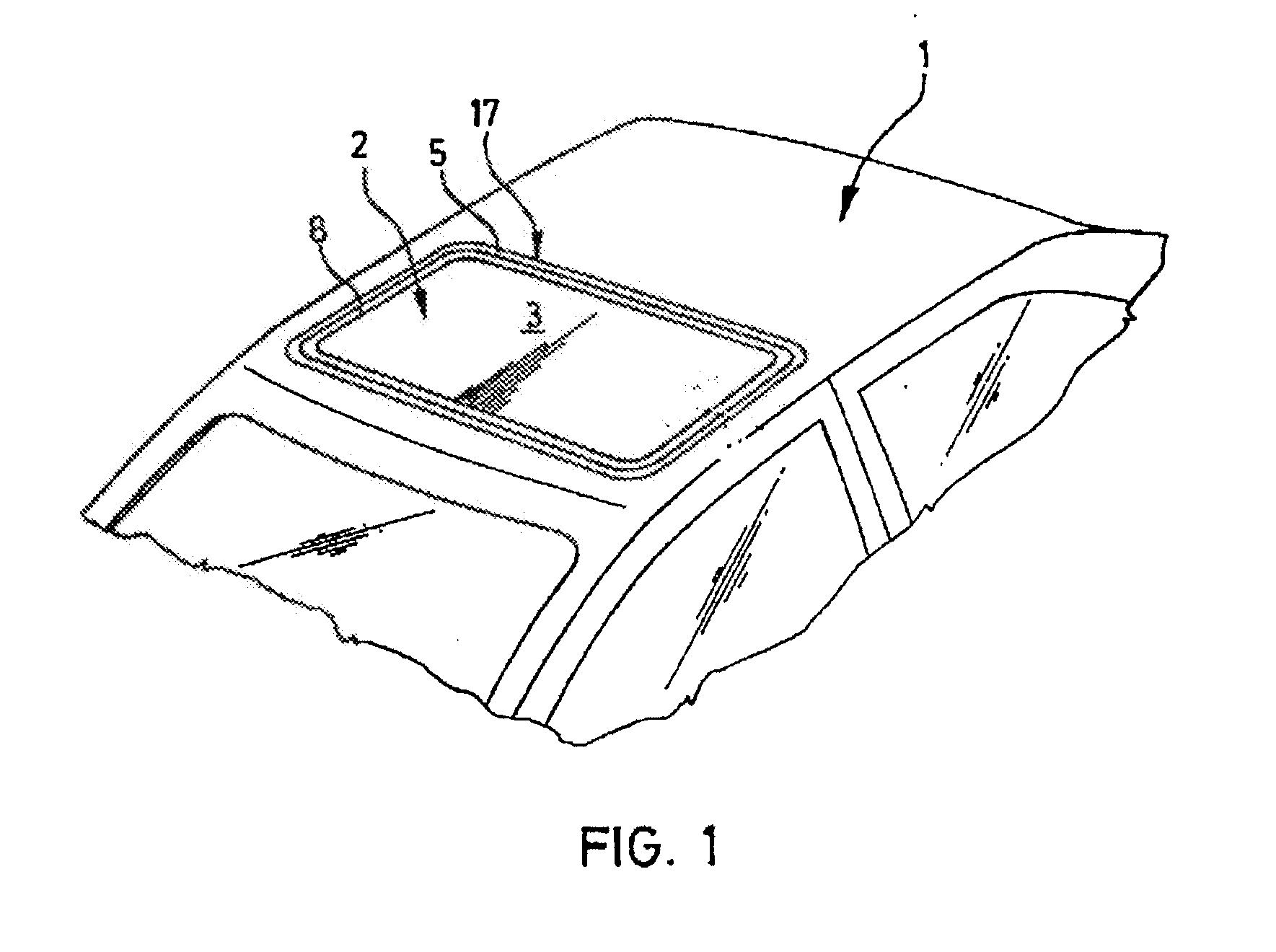

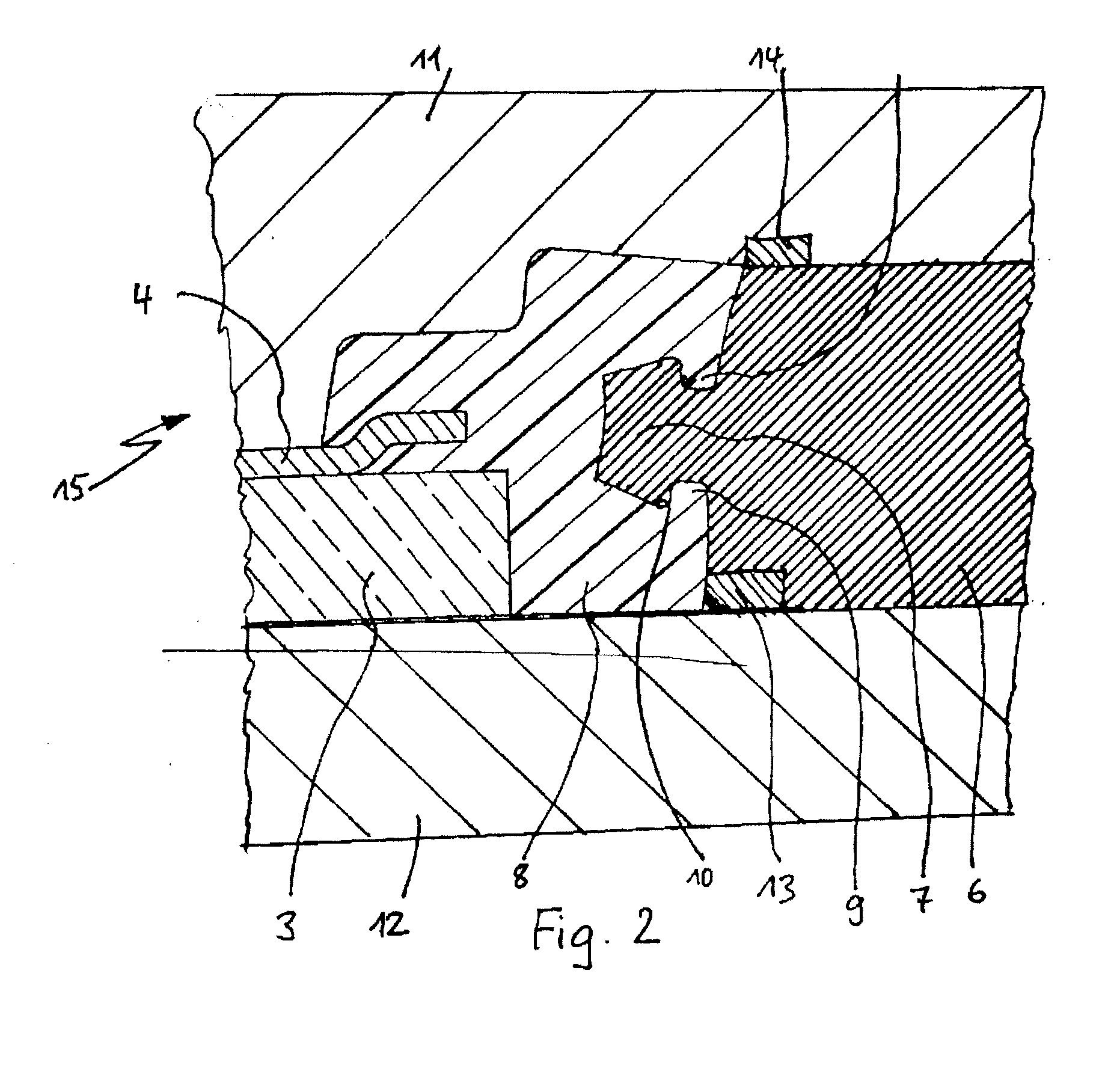

InactiveUS20080044512A1Reduce formation of burrReduce formationEngine sealsVehicle sealing arrangementsInjection mouldingBurr formation

A molding tool and process for producing a plate which has been foamed, injected or cast in situ with plastic, for example, a cover provided with a plastic frame for a motor vehicle roof. To prevent burr formation, at least one wire (13, 14) which can be heated is provided in the region of at least one parting line between adjacent tool parts (11, 12, 6) to eliminate excess plastic material of the plastic frame (8).

Owner:WEBASTO AG

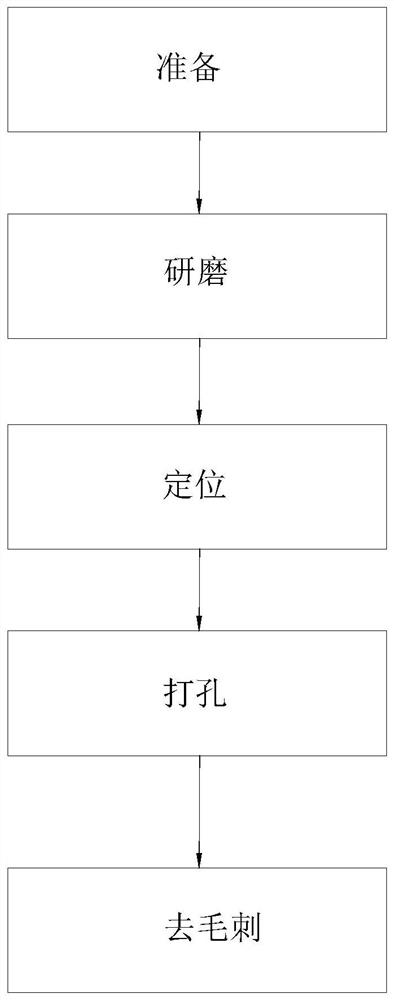

Machining method for micro-miniature part with open hole

PendingCN114799903APrecise positioningReduce opening errorEdge grinding machinesOther manufacturing equipments/toolsPunchingEngineering

The invention provides a processing method of a micro-miniature part with an open pore, which comprises the following steps: preparing, grinding, positioning, punching and deburring: in the preparation step, preparing a product to be punched; in the grinding step, a to-be-punched surface of the to-be-punched product is ground to form a grinding surface, and the light reflectivity of the grinding surface is smaller than that of the to-be-punched surface; in the positioning step, an optical image capturing device is adopted to position a position to be punched on a grinding surface; in the punching step, laser punching is conducted on the position to be punched, and a punched product is formed. In the deburring step, burrs on the periphery of the open hole are removed, and a deburring product is formed. According to the method, the grinding face with the light reflectivity smaller than that of the face to be punched is ground, so that the influence of reflected light on positioning is reduced, the punching error can be reduced through laser punching, meanwhile, burrs cannot appear on the hole wall of the punched hole, the burrs only appear on the back face, the deburring step is simplified, and operation is convenient.

Owner:国泰达鸣精密科技集团有限公司

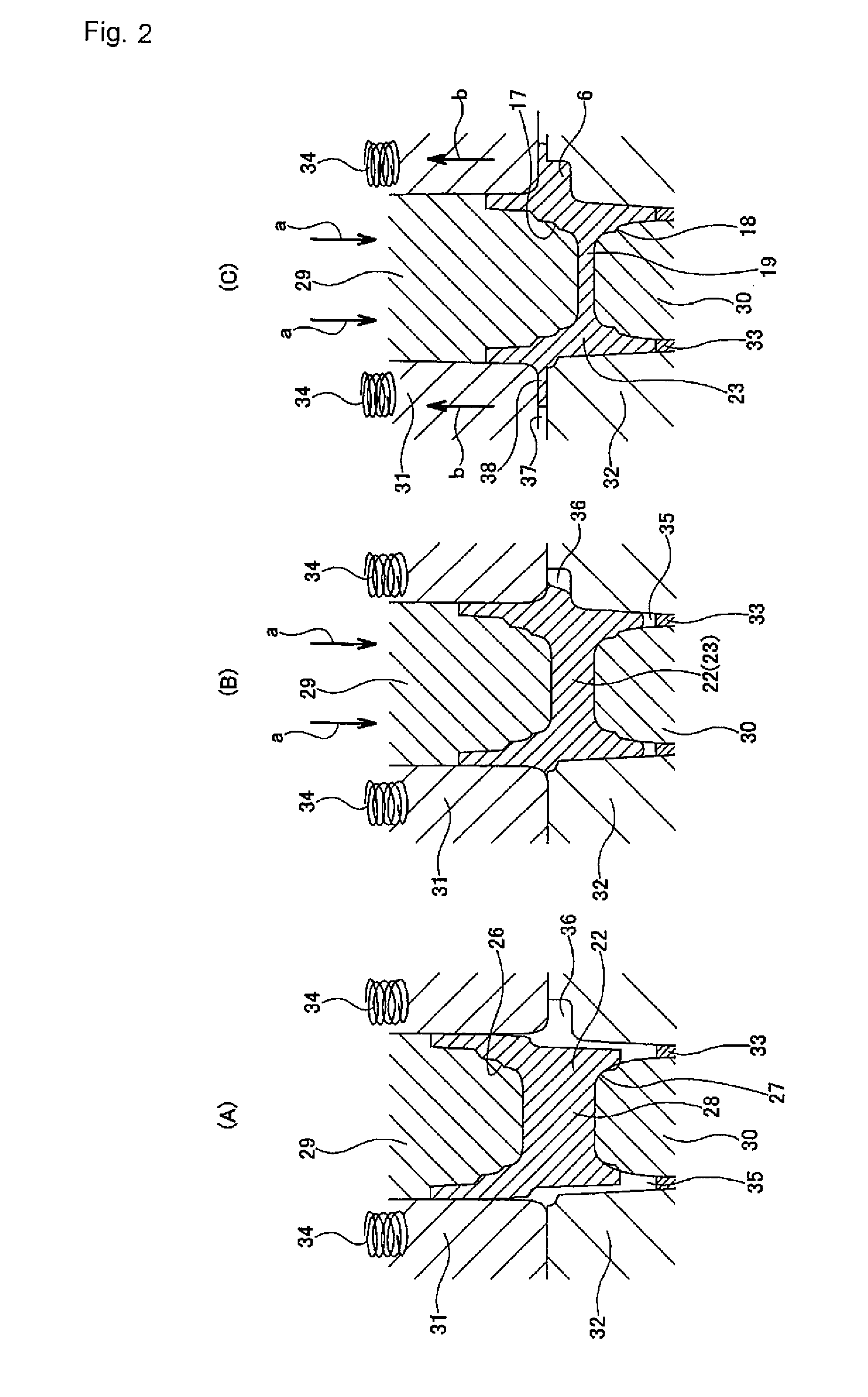

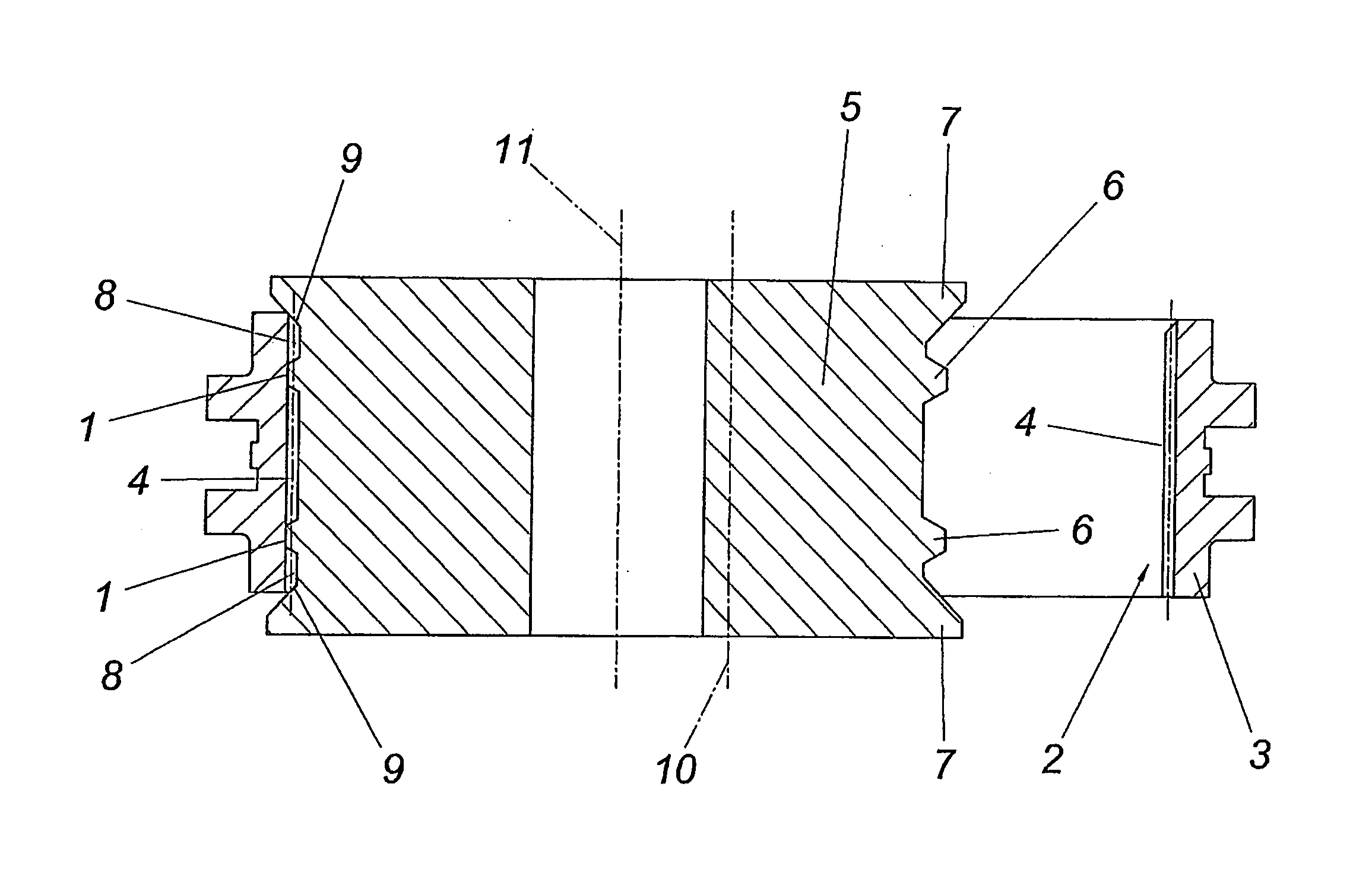

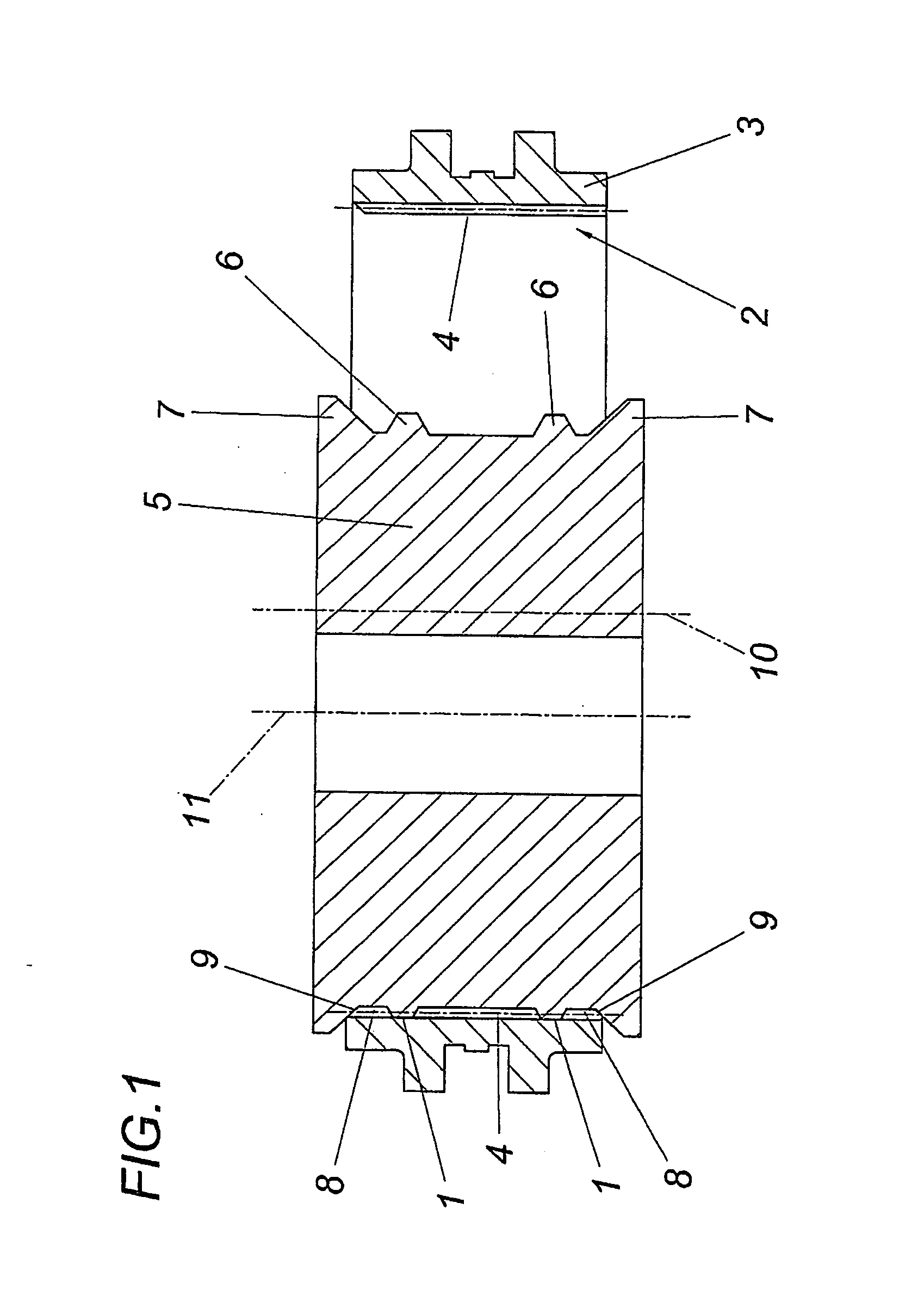

Method and apparatus for backing the insde teeth of a sliding sleeve produced by way of powder metallurgy for a manual transmission

InactiveUS20110232092A1Ensures required dimensional stabilityProlong total treatment processGear wheelsEngine componentsEngineeringSide Tooth

A method for backing the inside teeth (2) of a sliding sleeve (3) produced by way of powder metallurgy for a manual transmission is described where the backings (1) of the teeth (4) forming the front-side pitches (9) are formed with the aid of a rolling tool (5) by back rolling accompanied by plastic deformation of material from the backing region. In order to prevent burr formation, it is proposed that the front-side tooth sections (8) delimited by the backings (1) are simultaneously calibrated whilst forming and / or calibrating the relevant pitches (9) with the aid of the rolling tool (5) for forming the backings (1).

Owner:MIBA SINTER AUSTRIA

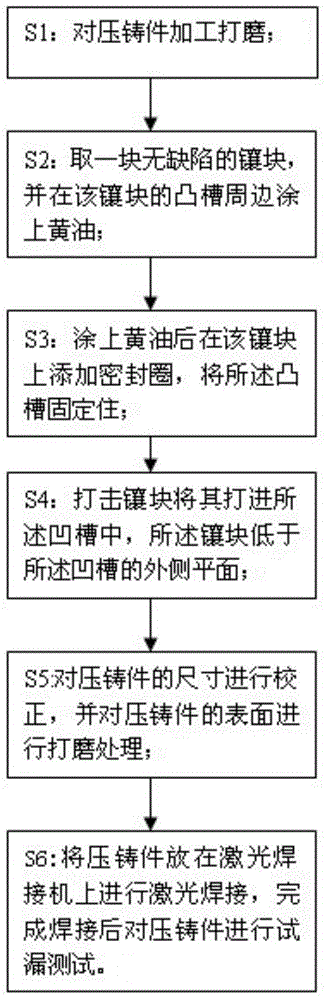

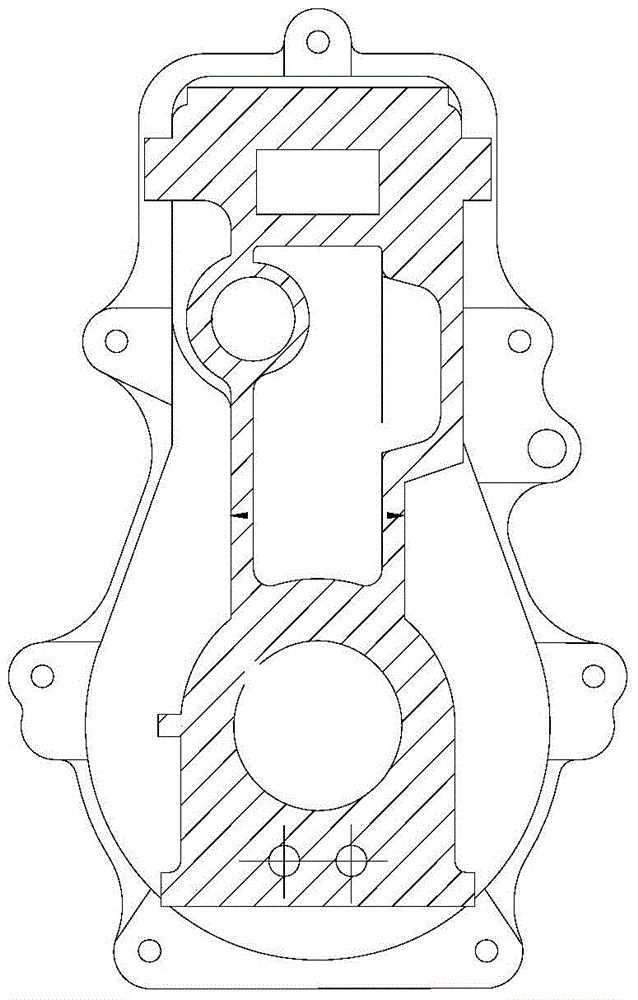

Pump body die casting welding method

InactiveCN104128748AComplete structureRemove blemishesPositive displacement pump componentsLiquid fuel engine componentsDie castingLaser soldering

Provided is a pump body die casting welding method. The pump body die casting welding method includes the following steps that 1 a die casting is machined and polished until the phenomena of burrs, die drawing, excessive materials and misrun do not exist in a concave groove of the die casting; 2 a flawless insert is taken, and the periphery of a convex groove of the insert is coated with grease; 3 a sealing ring is added to the insert after the insert is coated with the grease, and the convex groove is fixed; 4 the insert is struck to enter the concave groove, wherein the insert is lower than the outside plane of the concave groove; 5 the size of the die casting is corrected, and the surface of the die casting is polished; 6 the die casting is placed on a laser welding machine, laser welding is conducted on the die casting, and leakage testing is conducted on the die casting after welding is completed. According to the pump body die casting welding method, polishing, insert machining and welding are conducted on a pump body formed in a die-casting mode, the surface of the pump body formed in the die-casting mode is smooth and free of burrs, the formed pump body is more complete in structure, defects formed in the die pressing process are well overcome, and the qualified pump body is machined and obtained.

Owner:ANHUI HUOSHAN LONGXIN METAL TECH CO LTD

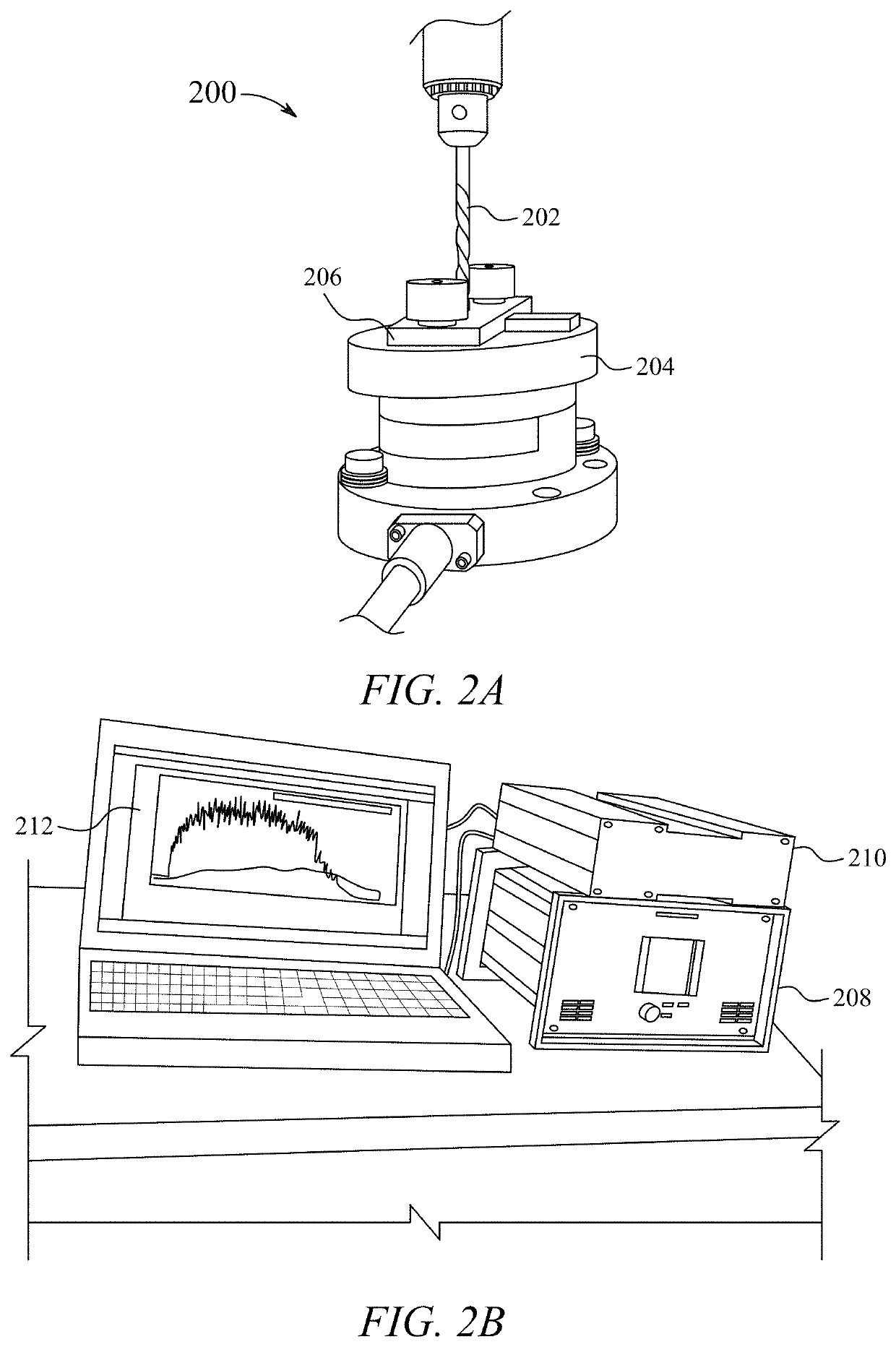

System and method for analysis of chip and burr formation in drilled fiber reinforced plastic composites using image processing

A system and a method for measuring drilling damage in fiber reinforced plastic (FRP) composites is described. Multiple holes are drilled in the FRP composite using a drill having nominal diameter, and the FRP composite is separated into multiple drilled blocks. Each block, covered with the black substrate, is scanned on a scanner to generate a scanned image depicting a hole region, a background, and delamination damage peaks. For each scanned image, a maximum delamination damage peak and a maximum diameter of a first circle concentric with the drilled hole and passing through tip of the maximum delamination peak, are measured. Further, a delamination size and a delamination factor are calculated based on the maximum diameter of the first circle and the nominal diameter of the drill.

Owner:KING ABDULAZIZ UNIV

Prediction Method of Grinding Burr Shape of Valve Core Based on Energy Conservation

A method for predicting the shape of grinding burrs on valve core edges based on energy conservation. According to the friction-plough-cutting removal mechanism of materials in the grinding process, the theory of the fourth deformation zone and the chip bending model, based on the law of energy conservation, a valve is established. The prediction model of tiny burr shape while grinding while the core is working, realizes the optimization of the grinding process according to the relationship between the grinding depth, feed speed, and grinding wheel speed on the burr shape. The invention establishes a shape prediction model of tiny burrs in edge grinding based on energy conservation, provides a basis for active control and precise removal of burrs, and can significantly reduce or inhibit the formation of burrs.

Owner:SHANGHAI JIAOTONG UNIV +1

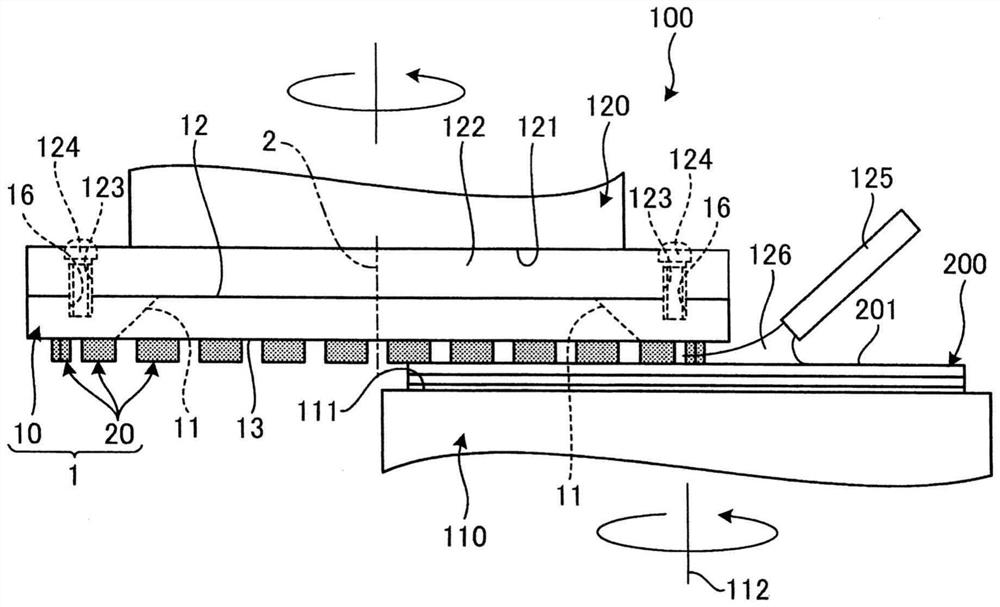

Grinding wheel

PendingCN114643541AInhibition of extensionBonded abrasive wheelsLapping toolsGrinding wheelMechanical engineering

The invention provides a grinding wheel which can inhibit extension and burr formation of a ductile material such as resin or metal compared with the prior art. A grinding wheel for grinding a ductile material includes: an annular grinding wheel base having a fixed end portion fixed to a lower end of a main shaft and a free end portion facing a ground workpiece; and a plurality of rectangular plate-shaped grindstones, wherein the long sides of the plurality of grindstones are arranged at the free end part at specified intervals along the circumferential direction of the grinding wheel base station. The grindstone is a rectangular plate-shaped electroformed grindstone in which abrasive grains are fixed by nickel plating, the grindstone has a thickness of 1 mm or less, and the value represented by the ratio of the height of the grindstone from the free end to the thickness of the grindstone is 5 or more and less than 35.

Owner:DISCO CORP

Molding precursor, process for manufacturing fiber-reinforced resin molding, and fiber-reinforced resin molding

InactiveCN101068668BEasy to manufacture and stableHigh strengthWoven fabricsThin material handlingMaterials scienceFiber reinforcement

A molding precursor which comprises a main body part and a burr formation part protruding outward from the edge of the main body part and extending continuously along the edge, wherein the main body part comprises a first base comprising many reinforcing fibers and a second base which comprises many fibers and has been superposed on the first base in an outer peripheral part of the main body part, the burr formation part is constituted of that part of the second base which protrudes outward from the edge of the main body part, and spaces among the many fibers constitute passages for a moldingresin.

Owner:TORAY IND INC

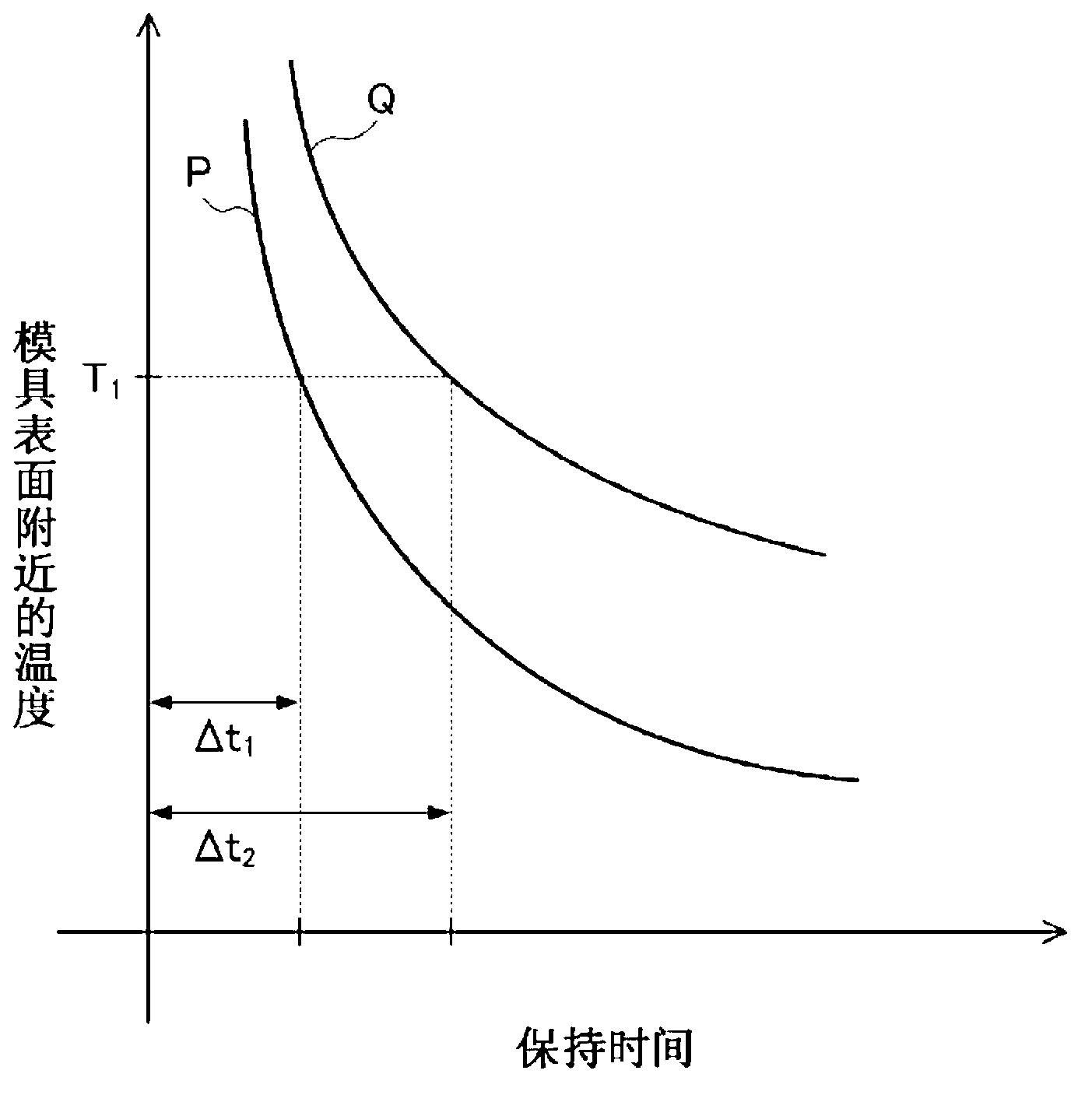

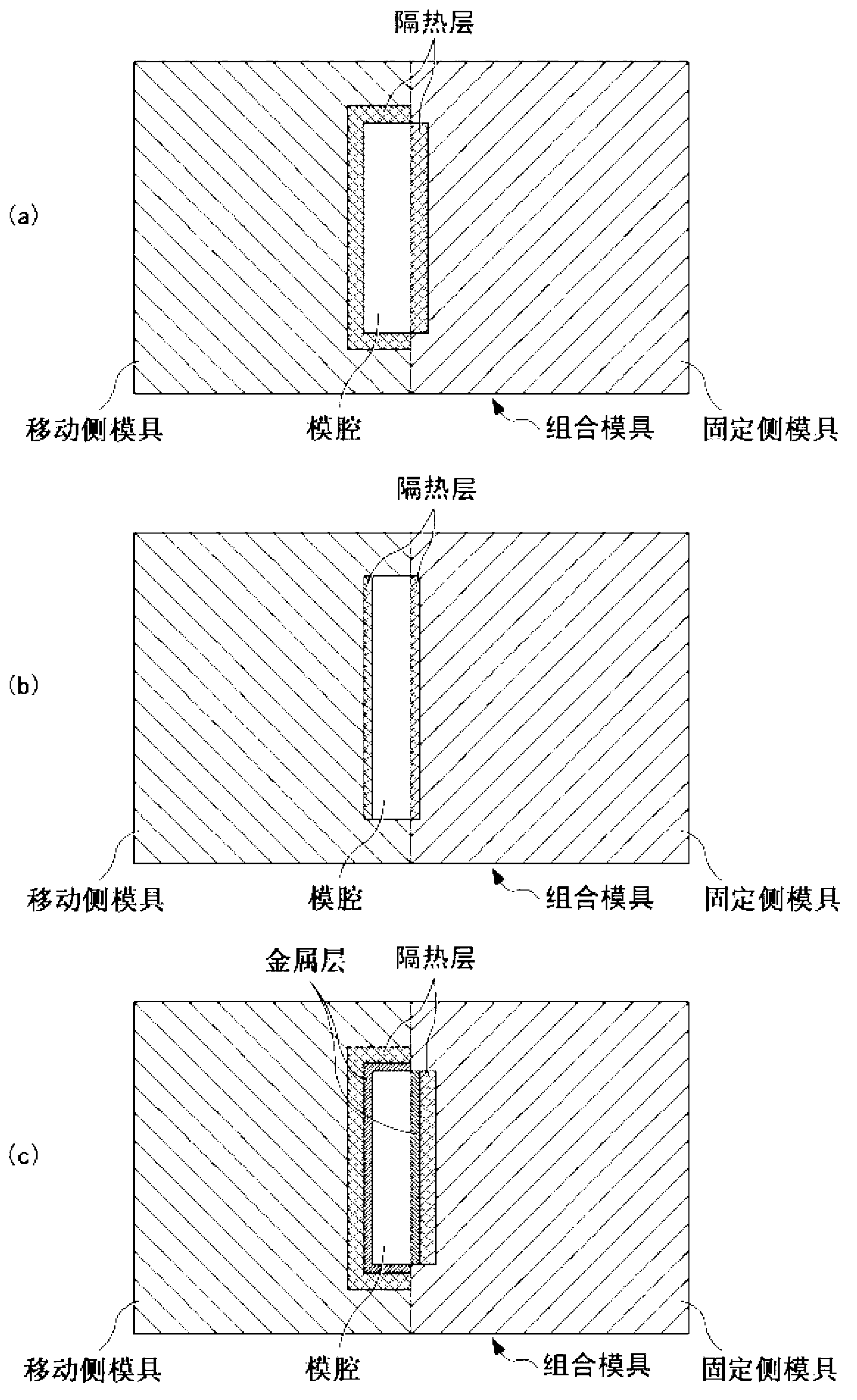

Manufacturing method for die

Provided is a method of manufacturing a die for the manufacture of molded products that prevents burr formation and sufficiently promotes surface crystallization, by setting die temperature at no more than Tc2-100 DEG C when molding a crystalline thermoplastic resin. The temperature at which the crystallization speed of the resin filled into the die will be sufficiently fast in the vicinity of the surface of the die so that the degree of crystallization at the surface of the molded article will fall within a determined range, and the sustain period during which the temperature is sustained at or above the temperature at which the crystallization speed of the crystalline thermoplastic resin in the die is sufficiently fast are determined on the basis of the relationship between the crystallization speed and resin temperature of the crystalline thermoplastic resin, and the die is provided with a heat insulating layer so that when the die temperature is Tc2-100 DEG C, the period during which the temperature in the vicinity of the surface of the die is not lower than the determined temperature conforms to the determined sustain period.

Owner:POLYPLASTICS CO LTD

Method for determining the cut quality of a laser cutting process using a simulation program

InactiveUS9002683B2Determination of the cut qualityLow costComputation using non-denominational number representationDesign optimisation/simulationPartial differential equationEngineering

The application relates to a method for determining the cut quality of a laser cutting process, said quality being assessed on the basis of the formation of solidification ridges along the cut face and / or burr formation on the lower edge of the cut face. In said method, a virtual laser cutting machine in a simulation program can be virtually operated with a set of values P0 from a parameter space P.; In a step a), the parameter set P0 is entered in the virtual cutting machine (103), then in step b), a cut is made in the virtual workpiece by calculating, from partial differential equations with initial and boundary values, the progression of the melt film thickness over time and the position of the melt front at the apex of the cutting front according to the depth of the cut and the time, and then in step c), the spatial distribution of the ridge amplitude on the cut face is specified by projecting the progression of the absorption front onto the cut face and / or a spatial distribution of the burr is calculated from the progression of the melt film thickness over time and the discharge speed on the lower edge of the cut face, and in step d), a virtual cut quality is provided (104) for further analysis.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

Sealing structure

ActiveCN101682984BReliable integrationNo leakageCircuit bendability/stretchabilityPrinted circuit manufactureThin membraneStructural engineering

To eliminate rubber burr formation at the time of molding and to make sealing members to be surely integrated with the flexible wiring board, a sealing structure consists of housings to which the flexible wiring board is inserted, and sealing members integrally formed on the flexible wiring board to seal gaps between the housings and the flexible wiring board, the flexible wiring board consists of a base board made of an elastic material, a conductive printed wiring layer formed on the surface of the base board, and a cover film covering the surface of the printed wiring layer, and dummy printed wiring layers are arranged in regions where the sealing members are integrated with the flexible wiring board, so as to make a shape as if the printed wiring layer exists substantially over the entire base board in the width direction.

Owner:NIPPON MEKTRON LTD

Resin sealing type semiconductor device and method of manufacturing the same, and resin sealing type electronic device

ActiveUS8502360B2Improve reliabilitySemiconductor/solid-state device detailsSolid-state devicesConductive pasteLead frame

The invention provides a resin sealing type electronic device having high reliability by eliminating a solder burr formed when a tie bar is cut. The invention also prevents a welding failure between a lead of the resin sealing type electronic device and an external electrode, and provides a large area for bonding an electronic component to the lead to prevent a connection failure. In the method of manufacturing the resin sealing type semiconductor device of the invention, in a case that a tie bar is cut after a semiconductor die and so on are mounted on a lead frame and these are resin-sealed, the cutting of the tie bar is performed from the side of the lead frame where a lead burr is formed by presswork. Furthermore, in the resin sealing type electronic device of the invention, a die capacitor is bonded to burr formation surfaces of a lead and an island using conductive paste. Since the burr formation surface has a larger surface area than a rounded surface, a large bonding area is obtained. A welding surface of the lead to a control electrode is the rounded surface that is opposite to the burr formation surface.

Owner:SEMICON COMPONENTS IND LLC

A method for deburring the edge of high-frequency Teflon circuit board

InactiveCN106304639BGood removal effectSolve the problem of glitchingInsulating layers/substrates workingConductive material chemical/electrolytical removalEtchingCopper foil

The invention discloses a board edge de-burring method for a high-frequency Teflon circuit board. Compared with the prior art, the method of the invention is characterized in that: a traditional negative film is replaced by a positive film in technique; primary edge milling is carried out before etching, so that burrs formed at a base material originally are transferred to a copper foil required to be etched, so that de-burring in subsequent etching can be facilitated; the problem of burr formation in traditional edge milling of the high-frequency Teflon circuit board can be solved in a copper foil etching process; after the etching is completed, secondary edge milling is adopted to process connection positions, so that the whole board will have no burrs; and in a whole process, the circuit board obtained finally has no burrs through technique change, and damage to the circuit board caused by a manual scraping method can be avoided, and manual work is not required, and therefore, a lot of labors can be saved, and production efficiency can be increased.

Owner:广东冠锋科技股份有限公司

Manufacturing method of stator core and stator core

ActiveCN104025432BWon't leakAvoid formingWindings insulation shape/form/constructionMagnetic circuit stationary partsMagnetic polesEngineering

In order to prevent unwanted burr formation on an insulating resin that is provided between a stator winding and a main core block body, the present invention provides a stator core manufacturing method for manufacturing a stator core that is constructed by connecting, into a circular shape, multiple core blocks (11), each being constructed by laminating multiple core pieces (20) together in the axial direction, wherein each core block (11) is equipped with a main core block body (12) that has a yoke section (13) and a magnetic pole tooth section (15), and an insulating resin layer (18) that is provided between a stator winding (25) and the main core block body (12) so as to cover a section that includes the surface of the magnetic pole tooth section (15) around which the stator winding (25) is wound. The stator core manufacturing method includes an injection molding step in which the insulating resin layer (18) is integrally formed with the main core block body (12) for each main core block body (12) by means of injection molding.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com