High-strength hot-dip galvanized steel sheet reduced in burr formation and process for producing same

A technology of hot-dip galvanized steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, hot-dip galvanizing technology, chemical instruments and methods, etc., can solve the problems of corrosion resistance deterioration, processing accuracy deterioration, precision deterioration, etc., and achieve excellent burr resistance , The effect of low burr height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

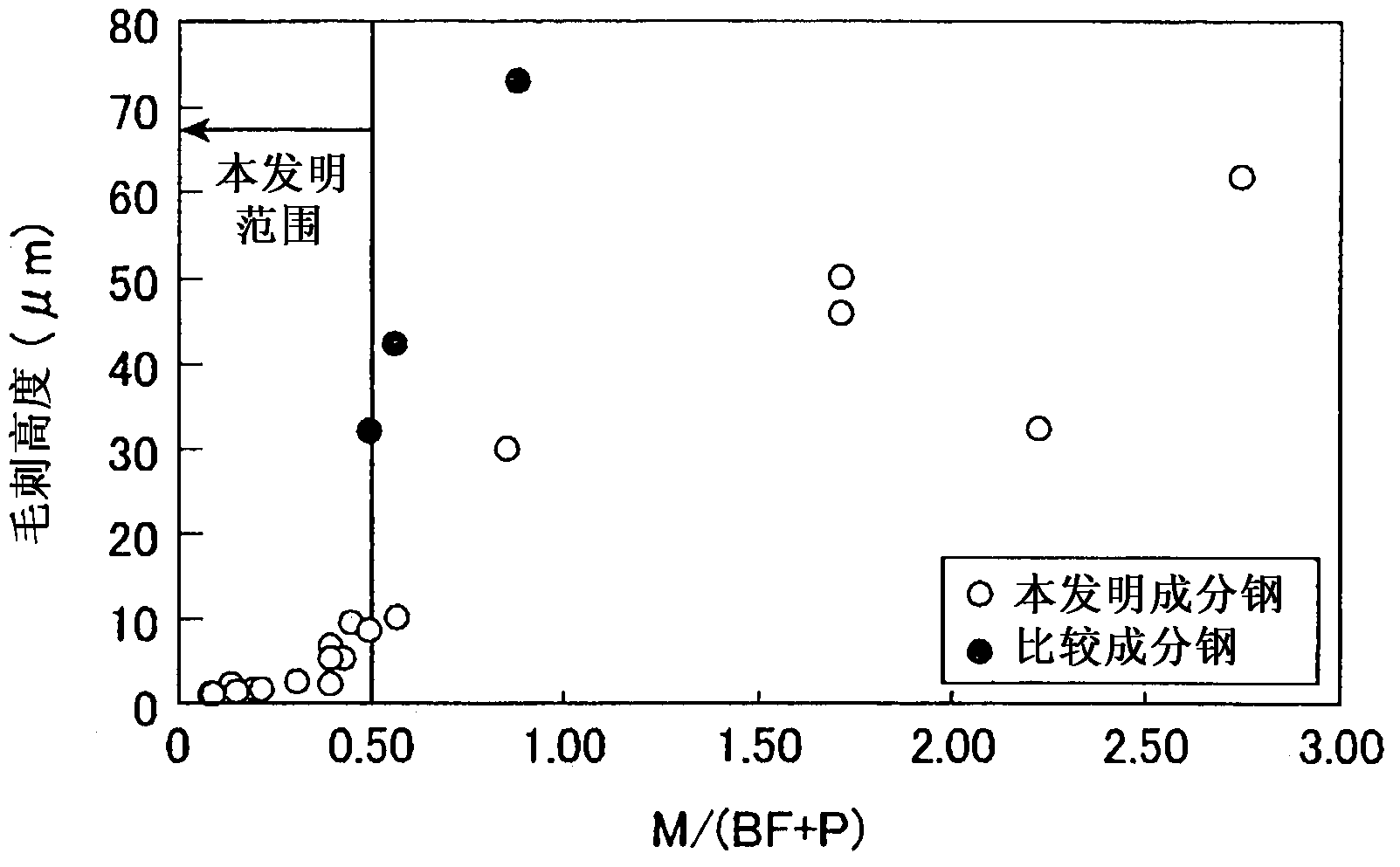

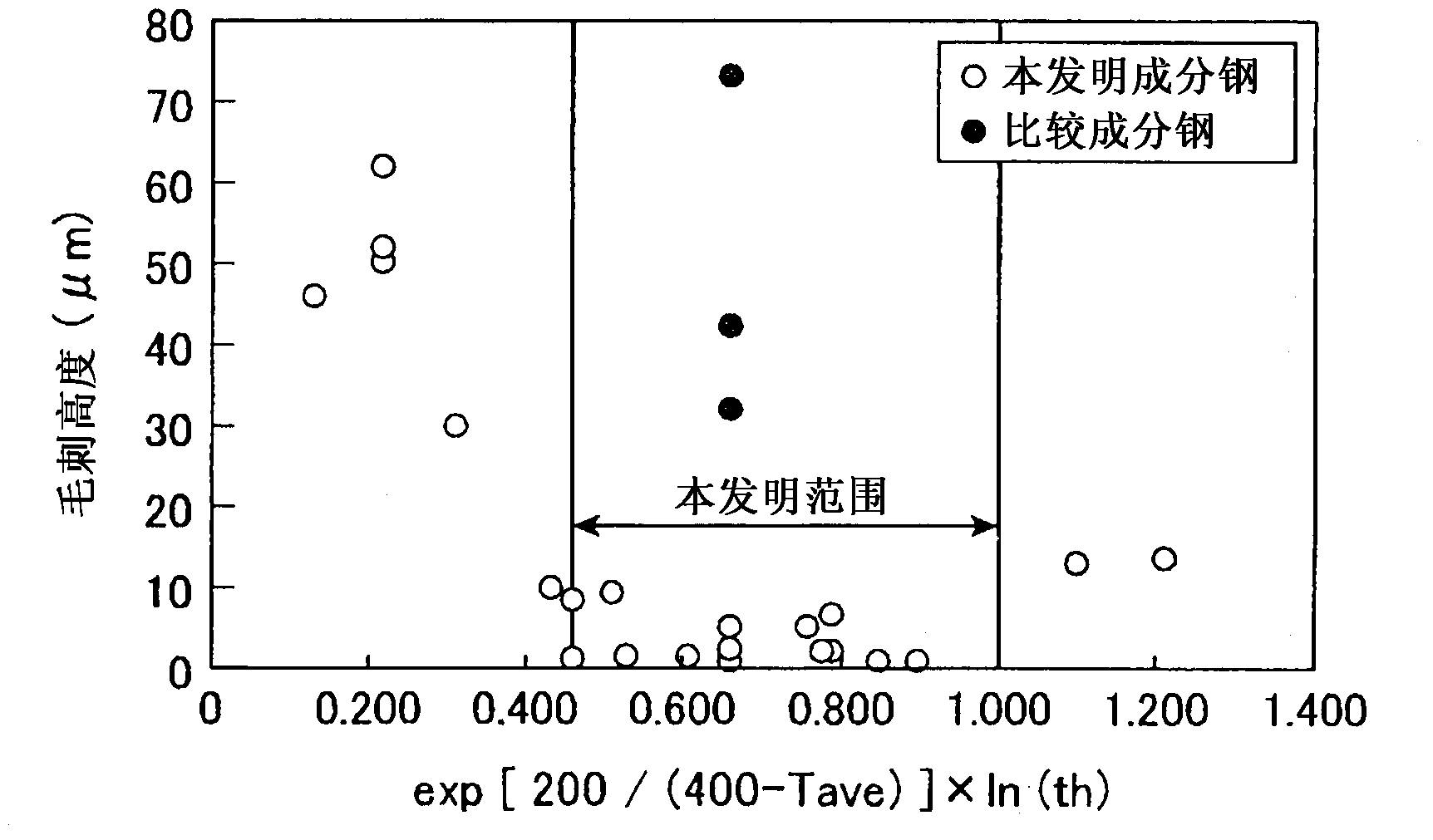

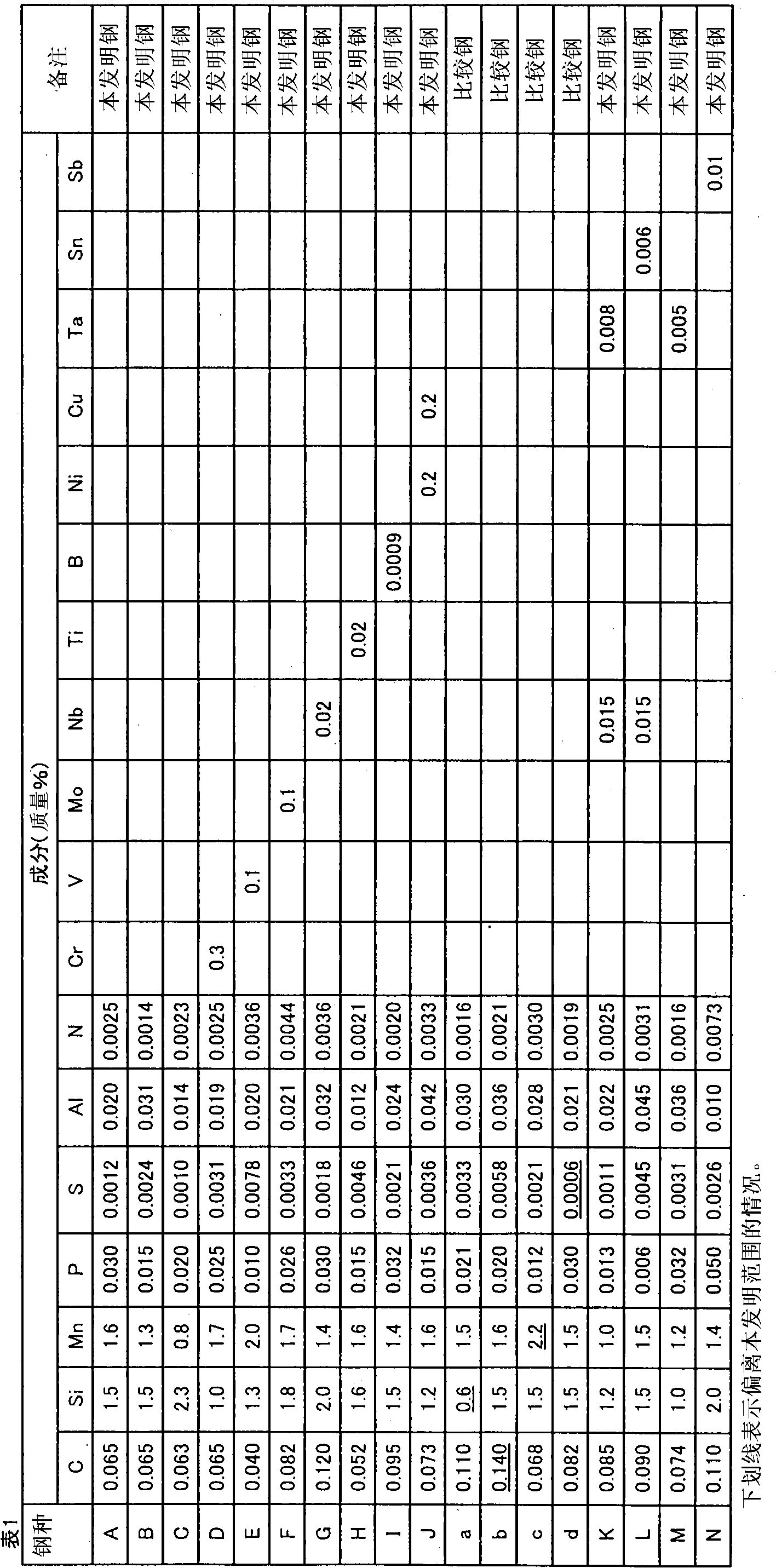

[0076] A total of 18 kinds of steels including the invention component steels A to N and comparative component steels a to d shown in Table 1 were adjusted in composition in a converter, followed by casting and hot rolling to produce hot-rolled sheets. The finishing temperature of hot rolling is set in the range of 890 to 960° C. and the coiling temperature is set in the range of 450 to 650° C. After the hot-rolled sheets were pickled, some were kept in the pickled state, some were cold-rolled, and then heat treatment and plating were performed under the conditions shown in Table 2 on a continuous galvanizing line (CGL). It should be noted that the amount of coating adhesion is adjusted to 35~45g / m per single side 2 .

[0077] The tensile strength of the obtained hot-dip galvanized steel sheets was measured, and the burr heights of n=10 end faces punched into a circular shape with a diameter of 50 mm were measured for each steel sheet, and the average burr height was obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com