Hot-rolling anneal-free coil rod production method for 8.8 grade high-strength cold forging steel

A production method and high-strength technology, applied in the field of hot rolling of medium carbon cold heading steel wire rods, can solve the problems of large energy consumption, environmental pollution, metal loss, etc., and achieve the effects of improving quality, reducing environmental pollution and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

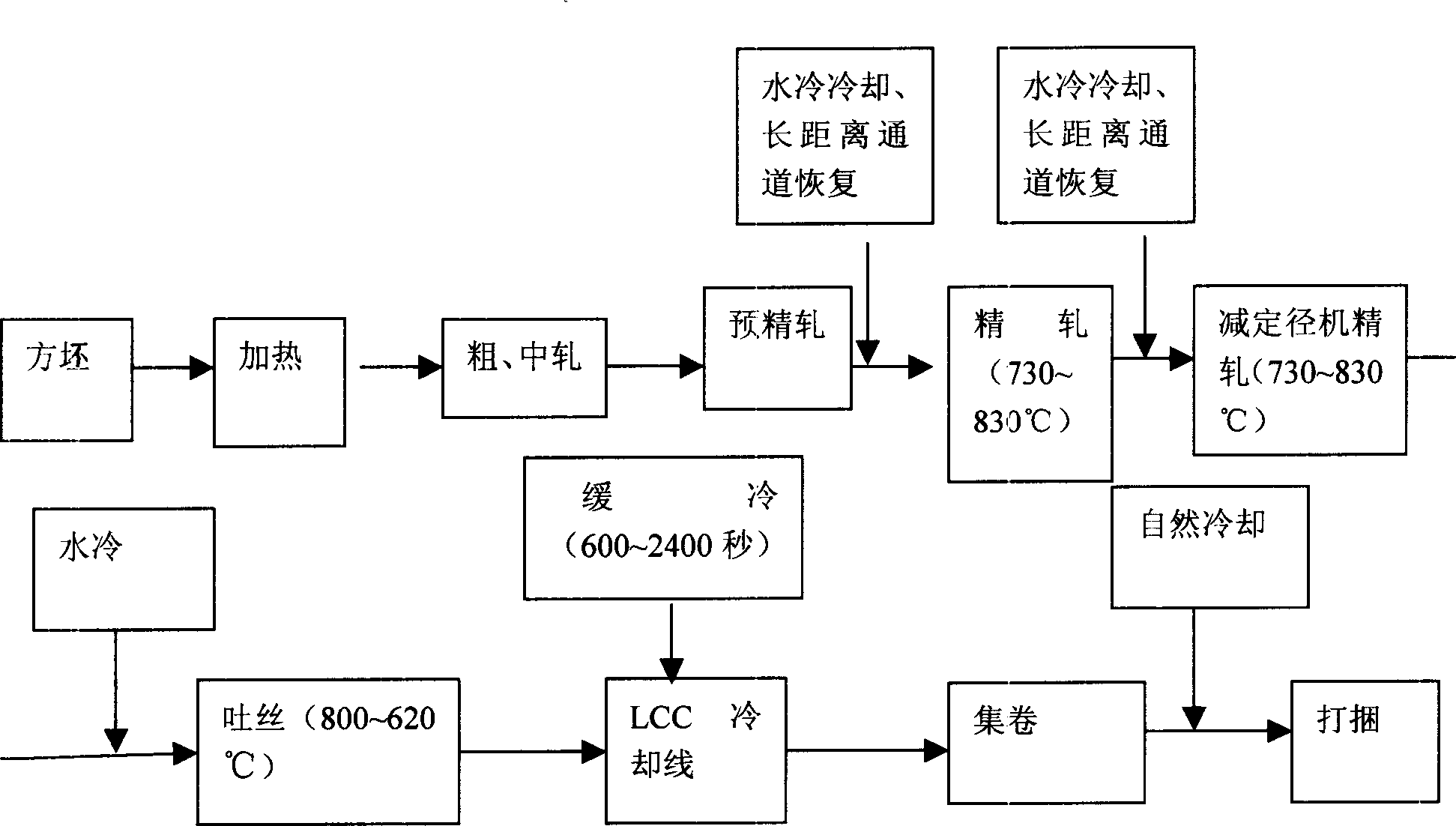

Method used

Image

Examples

Embodiment 1

[0009] Example 1: Carbon cold heading steel with a carbon equivalent of 0.49%, the chemical composition is C-0.37%, Si-0.15%, Mn-0.70%, P-0.016%, S-0.012%; steel mill refining and continuous casting 140 square billet; in the high-speed wire plant, the steel billet is reheated to 1100°C, first rolled at the conventional temperature of the roughing and intermediate rolling mill, and then cooled by controlled water, the rolled piece is finished rolled at 735°C in the finishing rolling unit and reducing sizing mill to Φ8mm Standard wire rod, the accumulative area reduction rate is 81%. After spinning, the coils are unrolled and cooled slowly for 20 minutes, cooled to below 580°C, collected and coiled, cooled naturally and bundled. 5 rolls of 10 tons of wire rod, in a fastener factory, pickled directly without annealing→drawing, and remade into 7.6mm process material, using 13B multi-position cold heading machine made in Taiwan, with 200 pieces / min Upsetting speed, made into M8×20 ...

Embodiment 2

[0010] Example 2: Carbon cold heading steel with a carbon equivalent of 0.44%, the chemical composition is C-0.34%, Si-0.14%, Mn-0.63%, P-0.016%, S-0.01%; steel mill refining and continuous casting 140 square billet; in the high-speed wire plant, the steel billet is reheated to 1100°C, firstly rolled at the conventional temperature of the roughing and intermediate rolling mill, and then cooled by controlled water, and the rolled piece is finished rolled at 770°C in the reducing and sizing mill to form a Φ10mm wire rod. The surface reduction rate is 56%. After silk spinning, the coils are loosened and cooled slowly for 35 minutes, cooled to below 580°C to collect the coils, cooled naturally and bundled. 30 rolls totaling 60 tons. In a fastener factory, direct pickling without annealing→drawing, remade into 9.5mm process material, cold heading into M10×45mm inner hexagonal bolts on general low-speed multi-position cold heading machine , the appearance quality is very good, there...

Embodiment 3

[0011] Example 3: Alloy cold heading steel with carbon equivalent of 0.47%, chemical composition is C-0.23%, Si-0.16%, Mn-1.47%, P-0.016%, S-0.009%, Ti-0.08%, B- 0.003%; refining and continuous casting in the steel mill into 140 billet; in the high-line factory, the billet is reheated to 1100 ° C, first rolled at the conventional temperature of the rough and medium rolling mill, and then cooled by controlled water, the rolled piece is in the reducing and sizing machine at 820 °C ℃ finish rolling into Φ14mm wire rod, the accumulative area reduction rate is 38%. After spinning, the coils are loosely cooled for 20 minutes, cooled to below 580 ℃ and collected into coils, cooled naturally and bundled. 32 volumes totaling 65 tons. In a fastener factory, direct pickling without annealing→drawing, and reworked into 13.5m process material. On general low-speed multi-position cold heading machine, cold heading into M14×60mm inner hexagonal bolts , the appearance quality is very good, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com